Page 1

INSTRUCTION MANUA L

FOR

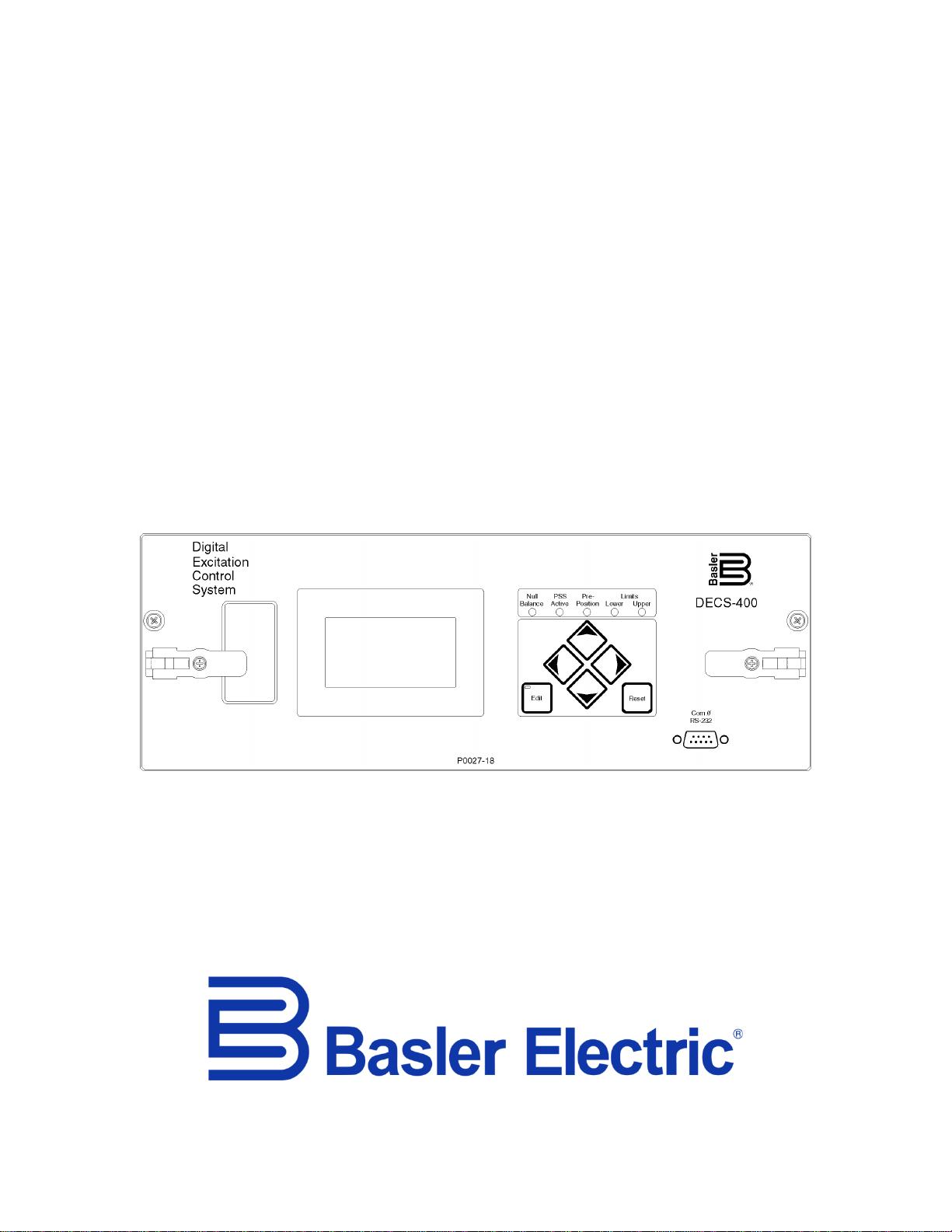

DECS-400

Digital Excitation Control System

Publication: 9369700990

Revision: R Jan-15

Page 2

Page 3

9369700990 Rev R i

Caution

Note

Preface

This instruction manual provides information about the installation and operatio n of the DECS-400 Digital

Excitation Control System. To accomplish this, the following inform ati on is provid ed:

• General Information

• Controls and Indicators

• Functional Description

• BESTCOMS Software

• Installation

• Commissioning

• Maintenance and Troubleshooting

• Specifications

• Modbus™ Protocol

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to installation

or operation.

DECS-400 Preface

Page 4

ii 9369700990 Rev R

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

(software licensed in a way that ensures freedom to run,

copy, distribute, study, change, and improve the software)and you are granted a license to that software under the

of sale of the product, allow you to freely copy, modify, and redistribute that software and no other statement or

documentation from us, including our End User License Agreement, places any additional restrictions on what you

corresponding source code for the version of the programs distributed to you will be sent upon request (contact

ormation is provided above). A fee of no more than our cost of physically performing the source code distribution

The source code is distributed in the hope that it will be useful, but WITHOUT ANY REPRESENTATION or

Review the software website for the latest version of the software documentation.

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2015 by Basler Electric

All rights reserved

First printing: January 2005

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the DECS-400.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

This product contains, in part, open source software

terms of either the GNU General Public License or GNU Lesser General Public License. The licenses , at the time

may do with that software.

For at least three (3) years from the date of distribution of this product, a machine-readable copy of the complete

inf

is charged.

WARRANTY or even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

Refer to the source code distribution for additional restrictions regarding warranty and copyrights.

For a complete copy of GNU GENERAL PUBLIC LICENSE Version 2, June 1991 or GNU LESSER GENERAL

PUBLIC LICENSE Version 2.1, February 1999 refer to www.gnu.org or contact Basler Electric. You, as a Basler

Electric Company customer, agree to abide by the terms and conditions of GNU GENERAL PUBLIC LICENSE

Version 2, June 1991 or GNU LESSER GENERAL PUBLIC LICENSE Version 2.1, February 1999, and as such

hold Basler Electric Company harmless related to any open source software incorporated in this product. Basler

Electric Company disclaims any and all liability associated with the open source software and the user agrees to

defend and indemnify Basler Electric Company, its directors, officers, and employees from and against any and all

losses, claims, attorneys' fees, and expenses arising from the use, sharing, or redistribution of the software.

Preface DECS-400

Page 5

9369700990 Rev R iii

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

DECS-400 Preface

Page 6

iv 9369700990 Rev R

Preface DECS-400

Page 7

9369700990 Rev R v

Contents

General Information .................................................................................................................................... 1

Features .................................................................................................................................................... 1

Generator Voltage Regulation ............................................................................................................... 2

Control Output ........................................................................................................................................ 2

Stability .................................................................................................................................................. 2

Power System Stabilizer (Style 1XXX) .................................................................................................. 3

Underfrequency Limiter or Volts per Hertz Limiter ................................................................................ 3

Soft-Start Voltage Buildup ..................................................................................................................... 3

Reactive Droop and Line Drop Compensation ...................................................................................... 3

Setpoint Control ..................................................................................................................................... 3

Dual Pre-Position Inputs ........................................................................................................................ 3

Manual Operating Modes ...................................................................................................................... 3

Var/Power Factor Operating Mode ........................................................................................................ 4

Overexcitation Limiters .......................................................................................................................... 4

Minimum Excitation Limiter .................................................................................................................... 4

Stator Current Limiter ............................................................................................................................ 4

Reactive Power Limiter .......................................................................................................................... 5

Autotracking Between DECS-400 Operating Modes ............................................................................. 5

Autotracking Between DECS-400 Units ................................................................................................ 5

Protective Functions .............................................................................................................................. 5

Programmable Logic .............................................................................................................................. 5

Metering ................................................................................................................................................. 6

Sequence of Events Recording ............................................................................................................. 6

Oscillography ......................................................................................................................................... 6

Real-Time Monitoring............................................................................................................................. 6

Internal Testing Provisions .................................................................................................................... 6

Communication ...................................................................................................................................... 6

Password Protection .............................................................................................................................. 7

Upgrading from DECS-300 to DECS-400 ................................................................................................. 7

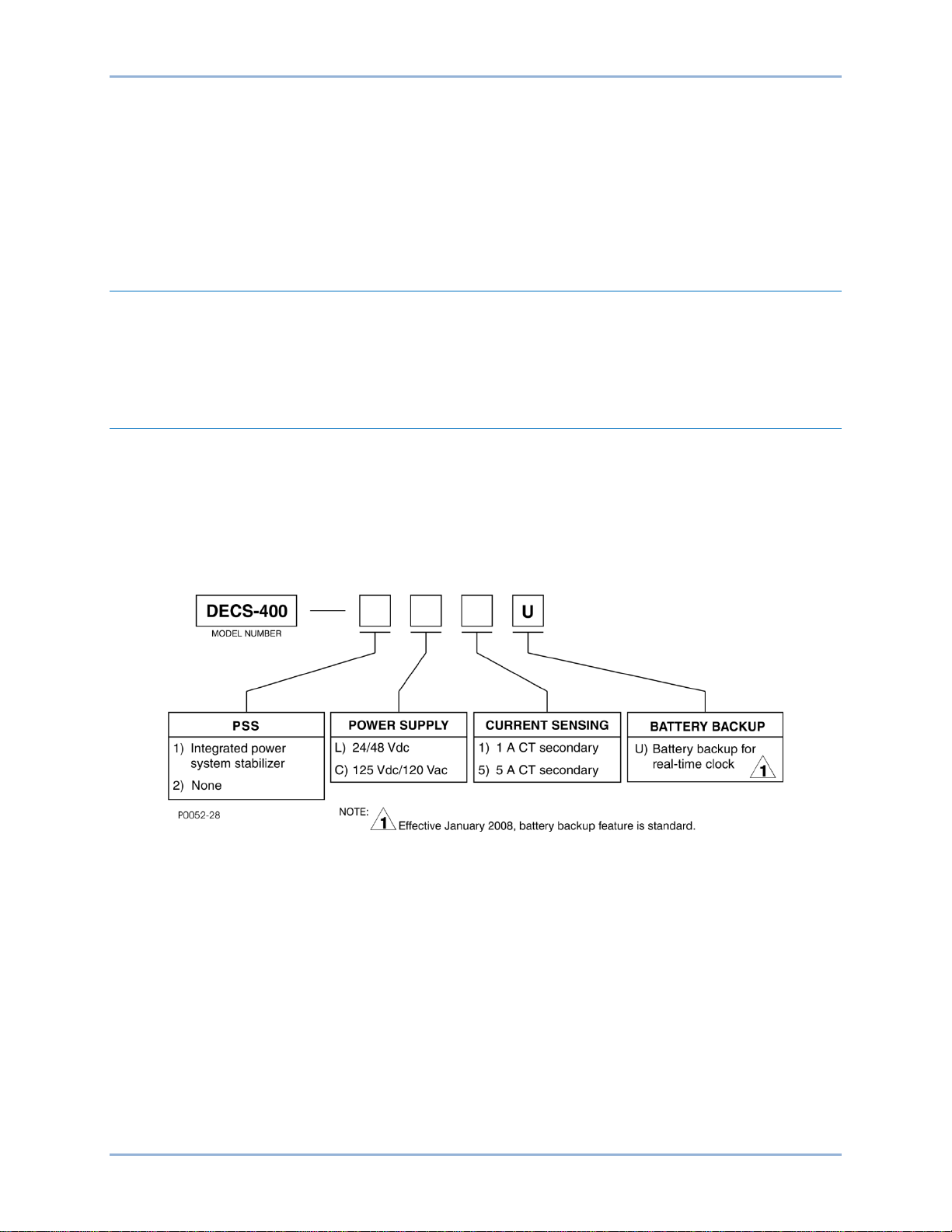

Model and Style Number ........................................................................................................................... 7

Style Number ......................................................................................................................................... 7

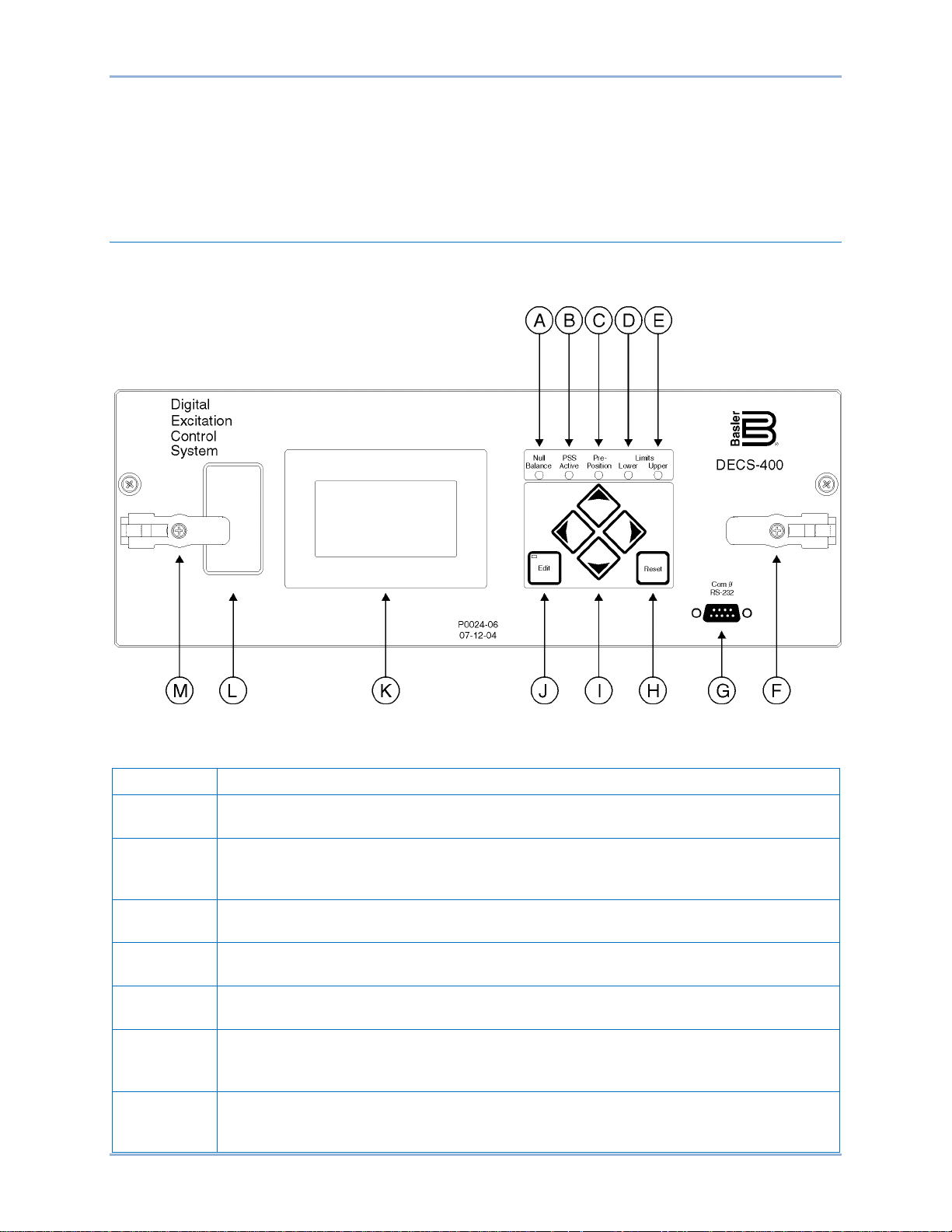

Human-Machine Interface .......................................................................................................................... 9

Controls and Indicators.............................................................................................................................. 9

Menu System ........................................................................................................................................... 10

Menu Navigation .................................................................................................................................. 10

Menu Structure .................................................................................................................................... 10

Editing Settings ........................................................................................................................................ 20

Screens with Special Editing Modes.................................................................................................... 20

Password Protection ................................................................................................................................ 21

Metering Screen ...................................................................................................................................... 22

Metering Values ................................................................................................................................... 22

Setpoint ................................................................................................................................................ 23

Percent of Range ................................................................................................................................. 23

Alarms Message .................................................................................................................................. 24

Operating Mode ................................................................................................................................... 25

Functional Description ............................................................................................................................. 27

DECS-400 Function Blocks ..................................................................................................................... 27

Analog Input Circuits ............................................................................................................................ 27

Front Panel Keyboard .......................................................................................................................... 29

Contact Input Circuits .......................................................................................................................... 29

Digital Signal Processor ....................................................................................................................... 30

Microprocessor .................................................................................................................................... 30

IRIG Port .............................................................................................................................................. 30

Memory Circuits ................................................................................................................................... 31

DECS-400 Contents

Page 8

vi 9369700990 Rev R

Digital to Analog Converter .................................................................................................................. 31

Control Output Circuits ........................................................................................................................ 31

Meter Driver Circuits ............................................................................................................................ 31

Relay Output Contacts ......................................................................................................................... 31

Front Panel LEDs................................................................................................................................. 32

Front Panel LCD .................................................................................................................................. 32

RS-232 Communication Port ............................................................................................................... 32

RS-485 Communication Ports ............................................................................................................. 32

Ethernet Port ........................................................................................................................................ 33

Modem ................................................................................................................................................. 33

Power Supply ....................................................................................................................................... 33

Startup Functions .................................................................................................................................... 33

Soft Start Function ............................................................................................................................... 33

Field Flash/Buildup .............................................................................................................................. 33

Failure to Build Up ............................................................................................................................... 34

Voltage Matching ................................................................................................................................. 34

Control Modes ......................................................................................................................................... 34

AVR ...................................................................................................................................................... 35

Manual ................................................................................................................................................. 35

Var ....................................................................................................................................................... 35

PF ........................................................................................................................................................ 36

Control Mode Pre-Pos it ion Setp oints ................................................................................................... 36

Transient Boost .................................................................................................................................... 37

Protection Functions ................................................................................................................................ 37

Field Overcurrent ................................................................................................................................. 37

Field Overvoltage ................................................................................................................................. 38

Generator Undervoltage ...................................................................................................................... 38

Generator Overvoltage ........................................................................................................................ 38

Loss of Sensing Voltage ...................................................................................................................... 38

Loss of Field Isolation Transducer ....................................................................................................... 39

Generator Frequency Less Than 10 Hertz .......................................................................................... 39

Power Supply Low ............................................................................................................................... 39

Loss of Field (40Q) .............................................................................................................................. 39

Field Overtemperature ......................................................................................................................... 40

Volts per Hertz (24) .............................................................................................................................. 40

Exciter Diode Monitor (EDM) ............................................................................................................... 42

Voltage / Current Unbalance Detection ............................................................................................... 43

Limiter Functions ..................................................................................................................................... 43

Stator Current Limiter .......................................................................................................................... 44

Overexcitation Limiter .......................................................................................................................... 44

Underexcitation Limiter ........................................................................................................................ 46

Underfrequency Limiter ....................................................................................................................... 47

Volts per Hertz Limiter ......................................................................................................................... 48

Var Limiter ............................................................................................................................................ 49

Limiter Scaling ..................................................................................................................................... 49

Operation with Paralleled Generators ..................................................................................................... 49

Droop Compensation ........................................................................................................................... 49

Reactive Differential ............................................................................................................................. 49

Line Drop Compensation ..................................................................................................................... 49

Autotracking ............................................................................................................................................. 50

Between DECS-400 Operating Modes ................................................................................................ 50

Between DECS-400 Units ................................................................................................................... 50

Data Recording and Reporting ................................................................................................................ 50

Sequence of Events ............................................................................................................................. 50

Data Logging ........................................................................................................................................ 51

Trending ............................................................................................................................................... 52

Power System Stabilizer.......................................................................................................................... 52

PSS Theory of Operation ..................................................................................................................... 53

Contents DECS-400

Page 9

9369700990 Rev R vii

Rate of Frequency Change Blocking ................................................................................................... 58

Field Isolation Module.............................................................................................................................. 58

BESTCOMS™ Software ............................................................................................................................. 59

Installation ............................................................................................................................................... 59

Installing BESTCOMS ......................................................................................................................... 59

Starting BESTCOMS ............................................................................................................................... 59

The BESTCOMS Interface .................................................................................................................. 59

Communication ........................................................................................................................................ 61

RS-232 Port Communication ............................................................................................................... 61

Ethernet Port Communication .............................................................................................................. 61

Modem Communication ....................................................................................................................... 63

Settings, Metering Values, and Data R ecor ds ........................................................................................ 63

System Configuration .......................................................................................................................... 63

Settings ................................................................................................................................................ 71

Gain Settings ....................................................................................................................................... 77

Limiters ................................................................................................................................................ 81

Protection ............................................................................................................................................. 88

PSS ...................................................................................................................................................... 93

Metering ............................................................................................................................................... 98

Data Log ............................................................................................................................................ 102

Analysis .............................................................................................................................................. 111

Logic .................................................................................................................................................. 120

DECS-300 Settings File Converter ........................................................................................................ 120

Installation ............................................................................................................................................... 121

Mounting ................................................................................................................................................ 121

DECS-400 .......................................................................................................................................... 121

Field Isolation Module ........................................................................................................................ 121

Isolation Power Transformer .............................................................................................................. 121

Connections ........................................................................................................................................... 125

DECS-400 Terminations .................................................................................................................... 125

Field Isolation Module Terminations .................................................................................................. 127

DECS-400 Terminal Functions and Assignments ............................................................................. 127

Field Isolation Module Terminal Functions and Assignments ........................................................... 131

Cross-Current Compensation ............................................................................................................ 132

Typical Interconnections .................................................................................................................... 133

Communication Connections ............................................................................................................. 136

Commissioning ....................................................................................................................................... 139

Preparation ............................................................................................................................................ 139

Record System Parameters ............................................................................................................... 139

Testing and Evaluation .......................................................................................................................... 139

Off-Line Tests—Turbine Not Spin ning ............................................................................................... 139

Off-Line Tests—Turb ine Spinn ing ..................................................................................................... 142

Excitation Performance Evaluation .................................................................................................... 145

Recommended PSS Testing ............................................................................................................. 147

Maintenance ............................................................................................................................................ 149

Storage .................................................................................................................................................. 149

Warranty and Repair Service ................................................................................................................ 149

Troubleshooting ..................................................................................................................................... 149

DECS-400 Appears Inoperative ........................................................................................................ 149

Display Blank or Frozen ..................................................................................................................... 149

Generator Voltage Does Not Build .................................................................................................... 149

Generator Voltage Builds but DEC S-400 Fails To Flash................................................................... 150

Field Voltage or Current Reading on LCD Does Not Change ........................................................... 150

Low Generator Voltage (In AVR Mode) ............................................................................................. 150

High Generator Voltage (In AVR Mode) ............................................................................................ 151

Generator Voltage Unstable (Hunting) .............................................................................................. 151

DECS-400 Contents

Page 10

viii 9369700990 Rev R

Poor Voltage Regulation .................................................................................................................... 151

No Buildup in FCR Mode ................................................................................................................... 151

No Control Signal at Firing Circuit Input ............................................................................................ 151

Limiters Do Not Limit at the Desired Level ........................................................................................ 151

Poor Reactive Control ........................................................................................................................ 151

Protection or Limit Annunciation ........................................................................................................ 151

Metering Readings Incorrect .............................................................................................................. 151

No Communication ............................................................................................................................ 151

Real-Time Clock Information Lost After Loss of Control Power ........................................................ 151

DECS-400 Reboots Frequently ......................................................................................................... 152

Backup Battery Replacement ................................................................................................................ 152

Upgrading DECS-400 Firmware ............................................................................................................ 152

Firmware Installation Procedure ........................................................................................................ 153

Specifications .......................................................................................................................................... 157

Operating Power .................................................................................................................................... 157

AC Input (Style XCXX Only) .............................................................................................................. 157

DC Input (Style XCXX, XLXX) ........................................................................................................... 157

Generator Voltage Sensing ................................................................................................................... 157

50 Hertz Sensing ............................................................................................................................... 157

60 Hertz Sensing ............................................................................................................................... 157

Bus Voltage Sensing ............................................................................................................................. 157

50 Hertz Sensing ............................................................................................................................... 157

60 Hertz Sensing ............................................................................................................................... 157

Generator Current Sensing ................................................................................................................... 158

Terminals ........................................................................................................................................... 158

Field Voltage and Current ..................................................................................................................... 158

Field Isolation Module............................................................................................................................ 158

Electrical Specification s ..................................................................................................................... 158

Physical Specifications ...................................................................................................................... 158

Contact Inputs ....................................................................................................................................... 158

Fixed Function Inputs ........................................................................................................................ 158

Programmable Inputs ........................................................................................................................ 159

Terminals ........................................................................................................................................... 159

Accessory Input (Remote Setpoint Control) .......................................................................................... 159

Voltage Input ...................................................................................................................................... 159

Current Input ...................................................................................................................................... 159

Control Outputs ..................................................................................................................................... 159

Voltage Control Output ...................................................................................................................... 159

Current Control Output ...................................................................................................................... 160

Metering Outputs ................................................................................................................................... 160

Contact Outputs ..................................................................................................................................... 160

Dedicated Outputs ............................................................................................................................. 160

Programmable Outputs ...................................................................................................................... 160

Contact Ratings ................................................................................................................................. 160

Terminal Assignments ....................................................................................................................... 160

Communication Ports ............................................................................................................................ 160

Com 0 ................................................................................................................................................ 160

Com 1 ................................................................................................................................................ 161

Com 2 ................................................................................................................................................ 161

Com 3 ................................................................................................................................................ 161

J1 ....................................................................................................................................................... 161

IRIG ....................................................................................................................................................... 161

Regulation Accuracy .............................................................................................................................. 161

AVR Mode .......................................................................................................................................... 161

FCR and FVR Mode .......................................................................................................................... 162

Var Control Mode ............................................................................................................................... 162

Power Factor Control Mode ............................................................................................................... 162

Metering Accuracy ................................................................................................................................. 162

Contents DECS-400

Page 11

9369700990 Rev R ix

Power System Stabilizer (PSS) ............................................................................................................. 162

Traverse Rates ...................................................................................................................................... 162

Setpoint .............................................................................................................................................. 162

Pre-Position Setpoint ......................................................................................................................... 162

Setpoint Tracking ................................................................................................................................... 162

Delay .................................................................................................................................................. 162

Traverse Rate .................................................................................................................................... 163

Soft Start ................................................................................................................................................ 163

Soft Start Bias Level .......................................................................................................................... 163

Soft Start Time Delay ......................................................................................................................... 163

Sequence of Events Recording ............................................................................................................. 163

Data Logging (Oscillography) ................................................................................................................ 163

Trending ................................................................................................................................................ 163

Limiters .................................................................................................................................................. 163

Underfrequency Compensation ......................................................................................................... 163

Volts per Hertz ................................................................................................................................... 163

Summing Point Overexcitat ion Li mit er ............................................................................................... 164

Takeover Overexcitation Limiter ........................................................................................................ 164

Underexcitation .................................................................................................................................. 164

Stator Current .................................................................................................................................... 165

Reactive Power .................................................................................................................................. 165

Protection Functions .............................................................................................................................. 165

Field Overvoltage ............................................................................................................................... 165

Field Overcurrent ............................................................................................................................... 165

Generator Undervoltage .................................................................................................................... 165

Generator Overvoltage ...................................................................................................................... 165

Loss of Sensing Voltage .................................................................................................................... 165

Generator Underfrequenc y ................................................................................................................ 165

Loss of Field (40Q) ............................................................................................................................ 165

Field Overtemperature ....................................................................................................................... 165

Volts per Hertz (24) ............................................................................................................................ 166

Exciter Diode Failure.......................................................................................................................... 166

Type Tests ............................................................................................................................................. 166

Agency Certifications ............................................................................................................................. 166

UL ...................................................................................................................................................... 166

CE ...................................................................................................................................................... 166

GOST-R ............................................................................................................................................. 166

NIIPT .................................................................................................................................................. 166

Real-Time Clock Battery........................................................................................................................ 166

Environment .......................................................................................................................................... 167

Physical ................................................................................................................................................. 167

Programmable Logic .............................................................................................................................. 169

Logic Timer Configuration .................................................................................................................. 169

Logic Schemes ...................................................................................................................................... 170

Default Logic Scheme ........................................................................................................................ 170

Predefined Logic Schemes ................................................................................................................ 170

Logic Scheme Modification ................................................................................................................... 184

Open “Single DECS-400 Without PSS” Logic Scheme for Editing .................................................... 185

Delete Unneeded Logic Associations ................................................................................................ 187

Create New Logic Associations ......................................................................................................... 189

Verify and Finalize Modified Logic Scheme ....................................................................................... 192

Logic for Compound Machine Paralleling.............................................................................................. 192

Logic Definitions .................................................................................................................................... 195

Logic Inputs ........................................................................................................................................ 195

Outputs .............................................................................................................................................. 198

Modbus™ Communication ...................................................................................................................... 203

DECS-400 Modbus™ Protocol ............................................................................................................... 203

DECS-400 Contents

Page 12

x 9369700990 Rev R

Message Structure ................................................................................................................................ 203

Device Address Field ......................................................................................................................... 203

Function Code Field ........................................................................................................................... 204

Data Block Field ................................................................................................................................. 204

Error Check Field ............................................................................................................................... 204

Modbus Modes of Operation ................................................................................................................. 204

Serial Transmission Details ................................................................................................................... 204

Message Framing and Timing Considerations .................................................................................. 205

Error Handling and Exception Responses ......................................................................................... 205

Communication Hardware Requirements ............................................................................................. 206

RTU Communication Requirements .................................................................................................. 206

TCP Communication Requirements .................................................................................................. 206

Modbus™/TCP ....................................................................................................................................... 206

Detailed Message Query and Response............................................................................................... 206

Read Holding Registers ..................................................................................................................... 206

Preset Multiple Registers ................................................................................................................... 207

Preset Single Register (Write Single Holding Register) .................................................................... 208

Response ........................................................................................................................................... 208

Loop Back Diagnostic Test (FC=8) with Diagnostic Sub Function, Return Query Data ................... 209

Loop Back Diagnostic Test with Diagnostic Sub-Function, Restart Communications Option ........... 209

Loop Back Diagnostic Test with Diagnostic Sub-Function, Force Slave to Listen-Only Mode ......... 209

Data Formats ......................................................................................................................................... 209

Generic Types UI8 and I8 .................................................................................................................. 210

Generic Types UI16 and I16 .............................................................................................................. 210

Generic Types UI32 and I3 2 .............................................................................................................. 210

Floating Point (R23_32) Data Format ................................................................................................ 211

CRC Error Check ................................................................................................................................... 211

DECS-400 Modbus™ Register Space ................................................................................................... 212

DECS-400 Register Tables ................................................................................................................... 213

Holding Registers for Version Data ................................................................................................... 213

Holding Registers for Metering, Group 1 ........................................................................................... 214

Holding Registers for System Configuration ...................................................................................... 216

Holding Registers for Operating Mode Parameters ........................................................................... 217

Holding Registers for Setpoint Parameters ....................................................................................... 218

Holding Registers for Startup Parameters ......................................................................................... 220

Holding Registers for Limiter Parameters .......................................................................................... 221

Holding Registers for Gain Parameters ............................................................................................. 223

Holding Registers for Protection Function Parameters ..................................................................... 224

Holding Registers for Exciter Diode Monitor Parameters .................................................................. 225

Holding Registers for Relay Parameters ........................................................................................... 225

Holding Registers for General ASCII and Modbus Communication Parameters .............................. 226

Holding Registers for Metering Parameters, Group 2 ....................................................................... 227

Holding Registers for Power System Stabilizer Parameters ............................................................. 227

Revision History ...................................................................................................................................... 231

Contents DECS-400

Page 13

9369700990 Rev R 1

General Information

The DECS-400 Digital Excitation Control System is a microprocessor-based controller that offers

excitation control, logic control, and optional power system stabilization in an integrated package. The

DECS-400 controls field excitation by providing an analog signal used to control the firing (output) of an

external power bridge. The DECS-400 monitors generator or motor parameters and acts to control, limit,

and protect the machine from operating outside its capability.

The optional, onboard power system stabilizer is an IEEE-d efi ned P SS 2A, dua l-input, “integral of

accelerating power” stabilizer that provides supplementary damping for low-frequency, local mode and

power system oscillations.

Integral programmable logic provides excitation system control and annunciation based on DECS-400

contact inputs, operating mode status, excitation system parameters, and user-defined programming.

Setup and initial operation are facilitated by Basler Electric’s user-friendly BESTCOMS™ PC software that

incorporates a test mode, flexible oscillography, and a graphic display of PSS test results.

The DECS-400 is designed for use with Basler Electric’s Interface Firing Module (IFM) and SSE or SSE-N

power bridges. However, it will work equally well with any power bridge with a firing circuit that is

compatible with the control signal output of the DECS-400.

Features

DECS-400 features and capabilities are listed below. The paragraphs following the list describe major

DECS-400 features and functions in more deta il .

• Five excitation control modes:

o Automatic Voltage Regulation (AVR)

o Field Current Regulation (FCR)

o Field Voltage Regulation (FVR)

o Power Factor (PF)

o Var

• Two pre-position setpoints (with adjustable traverse rate) for each excitation control mode

• Two PID groups

• Programmable analog control output selectable for 4 to 20 mAdc, –10 to +10 Vdc, or 0 to

+10 Vdc

• Remote setpoint control input accepts analog voltage or current control signal

• Real-time metering

• Integrated power system stabilizer (PSS):

o Generator or motor control modes, accommodates phase rotation changes between

modes

o Speed and power sensing or speed-only sensing

o Two-wattmeter or three-wattmeter methods of power measurement

• Soft start and voltage buildup control

• Five limiting functions:

o Stator current

o Overexcitation

o Underexcitation

o Underfrequency compensation

o Reactive power

• Ten protection functions:

o Field overvoltage

o Field overcurrent

DECS-400 General Information

Page 14

2 9369700990 Rev R

o Generator undervoltage

o Generator overvoltage

o Loss of sensing voltage

o Generator frequency less than 10 hertz

o Loss of field (40Q)

o Field overtemperature

o Volts per hertz (24)

o Exciter diode failure

• IRIG time synchronization

• Sixteen contact inputs:

o Six fixed-function inputs: AVR, Manual, Lower, Rais e, Start, and Stop

o Ten user-programmable inputs

• Eight contact outputs:

o Two fixed-funct ion out puts : Watc h dog, On/O ff

o Six user-programmable outputs, configurable for maintained, latched, or momentary

operation

• Five communication ports:

o Front RS-232 port for interface with PC running BESTCOMS software

o Rear RS-485 port for dedicated communication with secondary, redundant DECS-400

o Rear RS-485 port using Modbus™ protocol for communication with remote terminal

o Rear RJ-11 jack connects to onboard modem that provides dial-in and dial-out capability

o Rear RJ-45 jack provides Ethernet network communication

• Data logging, sequence of events recording, and trending

Generator Voltage Regulation

By utilizing digital signal processing and precise regulation algorithms, the DECS-400 regulates the

generator rms voltage to within 0.2% of the setpoint from no-load to full-load.

Control Output

The DECS-400 supplies an isolated control output signal of 4 to 20 mAdc, 0 to 10 Vdc, or ±10 Vdc to the

firing or control circuits of external power stages. The dc current produced by the power stages provides

excitation to the field of the generator, motor, or exciter. The DECS-400 can control virtually any bridge

that is capable of accepting these signals and is suitable for use on synchronous generators or motors.

Stability

PID (proportional + integral + derivative) stability control is utilized by the DECS-400. Preprogrammed

stability (PID) settings are provided for both main field and exciter field applications. A suitable, standard

stability set is available for most machines and applications. An additional, customizable setting group

provides optimum generator transient performance. A PID selection/calculation program supplied with the

DECS-400 assists in selecting the correct PID settings. Additional stability adjustments are provided for

customizing the stability and transient performance of the minimum and maximum excitation limiters and

the var/power factor controllers.

PID Setting Groups

The DECS-400 provides for two sets of PID settings to optimize performance under two distinct operating

conditions, such as with a power system stabilizer (PSS) in or out of service. A fast controller provides

optimum transient performance with the PSS in service, while a slower controller can provide improv ed

damping of first swing oscillations with the PSS offline.

General Information DECS-400

Page 15

9369700990 Rev R 3

Power System Stabilizer (Style 1XXX)

An optional, integrated PSS duplicates the excellent performance of the Basler PSS-100 power system

stabilizer without the complications of an additional control device. The PSS provides damping for local

mode, inter-area, and inter-unit oscillations in the 0.1 to 5.0 hertz range. The PSS incorporated in the

DECS-400 is a dual-input, IEEE type PSS2A stabilizer that utilizes the “integral of accelerating power”

algorithm. The PSS can also be set up to respond only to frequency if required for unusual applications.

Inputs required for PSS operation include three phase voltages and two or three phase line currents.

Underfrequency Limiter or Volts per Hertz Limiter

An underfrequency limiter or a V/Hz ratio limiter can be selected to avoid overfluxing the generator or

other connected magnetic devices.

The underfrequency limiter slope can be set from 0 to 3 PU V/Hz in 0.1 hertz increments . The frequ enc y

roll-off knee-point can be set across a range of 15 to 90 hertz in 0.1 hertz increments.

The V/Hz ratio limiter regulates voltage based on a user-defined V/Hz slope that is adjustable between

zero and 3.0 PU. The V/Hz ratio limiter includes two lim iting lev els to permit operation above the primary

V/Hz range for a user-adjustable time limit to inhibit limiter response during transient frequency or voltage

excursions.

Soft-Start Voltage Buildup

A user-adjustable voltage soft-start feature controls the rate of generator voltage buildup and prevents

voltage overshoot during generator system startup. The soft-start feature is active in both AVR and

Manual operating modes.

Reactive Droop and Line Drop Compensation

The DECS-400 has provisions for paralleling two or more generators by using reactive droop. Reactive

differential compensation can be used with the addition of an external current transformer (CT) with a

nominal secondary rating of 1 Aac or 5 Aac. The current input burden is less than 1 VA, so existing

metering CTs can be used. A Line Drop Compensation setting allows the DECS-400 to compensate for

line drop between parallel generators.

Setpoint Control

External adjustment of the active DECS-400 setpoint is possible through:

• Raise and lower contact inputs

• An auxiliary analog control input of 4 to 20 mAdc or ±10 Vdc

• A PC operating BESTCOMS software (provided with the DECS-400) and connected to the RS-

232 communication port

• A controller using Modbus™ protocol and connected to the RS-485 port

The traverse rates of all operating modes are independently adjustable, so the operator can customize

the rate of adjustment and “feel” to meet his or her needs.

Dual Pre-Position Inputs

Two user-adjustable sets of predetermined operating points are provided for each mode of operation. At

startup, and with the appropriate contact inputs applied to the DECS-400, the operating mode is driven to

one of two preset operating or regulation levels (depending on the configuration of the system). An

adjustable traverse rate setting can be used to control the rate at which the setpoint is driven toward the

pre-position operating point. This feature allows the DECS-400 to be configured for multiple system and

application needs.

Manual Operating Modes

The DECS-400 has two manual modes of operation: Field Current Regulation (FCR) and Field Voltage

Regulation (FVR).

DECS-400 General Information

Page 16

4 9369700990 Rev R

Field Current Regulation Mode

When operating in FCR mode, the DECS-400 regulates the dc output current of the power bridge.

Because regulation of the field current is not dependent upon a generator voltage sensing input to the

DECS-400, FCR mode can provide backup excitation control when a loss of sensing is detected. In FCR

mode, as the generator load varies, the operator must manually vary the field current to maintain nominal

generator voltage.

Field Voltage Regulation Mode

When operating in FVR mode, the DECS-400 regulates the dc output voltage of the power bridge. FVR

enables the user to perform generator modeling and validation testing in accordance with WECC testing

requirements for bus-fed (shunt type) excitation systems. FVR mode can also be used to smooth the

transfer from the active exciter to a backup exciter.

Var/Power Factor Operating Mode

Var and Power Factor control modes are available when the generator is operating in parallel with the

utility power grid. In Var control mode, the DECS-400 regulates the generator’s var output at a useradjustable setting. In Power Factor control mode, the DECS-400 regulates the generator’s var output to

maintain a specific power factor as the kW load varies on the generator.

Overexcitation Limiters

Overexcitation limiters monitor the field current output of the voltage regulator or static exciter and act to

limit the field current to prevent field overheating. The Overexcitation Limiter (OEL) function includes a

cool-down feature to avoid damage to the rotor caused by repeated high forcing. The OEL is active in all

modes except FCR mode. In FCR mode, limiter action is optional. The DECS-400 provides a choice of

two types of overexcitation limiters: Summing Po int and Tak eover . Th e outpu t of the Sum min g Point

limiter is applied to the summing junction of the AVR control loop in addition to the AVR controller output.

The output of the Takeover limiter overrides the normal AVR output.

Summing Point OEL

Three OEL current levels are defined for on-line operation: high, medium, and low. The generator can

operate continuously at the low OEL current level and for programmed times at the medium and high OEL

current levels. Two OEL current levels are defined for off-line (main breaker open) operation: high and

low. The generator can operate continuously at the low OEL current level and for a programmed time at

the high OEL current level.

Takeover OEL

The Takeover OEL determines the field current level at which limiting occurs by using an inverse time

characteristic. Two current levels and a time dial setting are defined for the Takeover OEL. Separate

curves may be selected for on-line and off-line operation. If the system enters an overexcitation condition,

the field current is limited and made to follow the selected curve. Selection of on-line or off-line OEL levels

and curves is determined by an OEL option selection.

Minimum Excitatio n Limite r

The Minimum Excitation Limiter prevents the excitation, being supplied to the generator field, from

decreasing below safe operating levels. This prevents pole slip and possible machine damage. This

action also limits the amount of vars being absorbed by the machine, based on user-defined settings. An

internally-generated Underexcitation Limiting (UEL) curve based on a permissible var level at 0 kW can

be utilized. Alternately, a five point UEL curve can be created to match specific generator characteristics.

UEL action is optional in FCR mode.

Stator Current Limiter

The stator current limiter (SCL) senses the level of stator current and limits it to prevent stator

overheating. The SCL operates in all modes except FCR and when the DECS-400 is off-line (52 J/K and

General Information DECS-400

Page 17

9369700990 Rev R 5

52 L/M contact inputs are closed). In FCR mode, the DECS-400 provides indication that a stator

overcurrent condition exists, but limiter action is inhibited.

Two SCL current levels are provided: high and low. The generator can operate continuously at the low

SCL level, but only for a programmed time at the high SCL level.

Reactive Power Limiter

The var limiter accommodates applications where the prime mover (turbine) has been uprated but the

generator ratings are unchanged. In this case, the generator power factor is increased and the generator

is var limited. The var limiter is available for these applications to limit reactive power flow out of the

generator to a safe level.

Autotracking Between DECS-400 Operating Modes

The DECS-400 can provide autotracking (automatic following) of the controlling mode by the noncontrolling modes. This allows the operator to initiate a controlled, bumpless transfer of the DECS-400

between operating modes with minimal disturbance to the power system. This feature can be used in

conjunction with a set of protective relays to initiate a transfer to a backup mode of operation (such as

FCR mode) upon the detection of a system failure or fault (such as loss of sensing).

Autotracking Between DECS-400 Units

The DECS-400 is also designed to automatically track a second DECS-400 unit using dedicated

communication ports on the two units. A backup DECS-400 controller can be placed in service and

programmed to track the control output of the primary DECS-400. In the unlikely event of a failure of the

first DECS-400, protective relays can initiate a transfer of control from the first to the second DECS-400

with minimal system disturbance.

Protective Functions

Protective functions built into the DECS-400 may be used as a backup to the primary protection relays

and can be assigned to as many as six programmable output contacts via BESTCOMS software. The

protective functions offer fully adjustable tripping levels and time delays. DECS-400 protective functions

are listed below. Functions marked with an asterisk (∗) have dual setting groups.

• Field overcurrent ∗

• Field overtemperature ∗

• Field overvoltage ∗

• Generator overvoltage ∗

• Generator undervoltage ∗

• Loss of field ∗

• Loss of Field Isolation Module

• Loss of sensing voltage

• Microprocessor watchdog

• Open exciter diode (brushless application)

• Shorted exciter diode (brushless application)

• Volts per hertz protection

Programmable Logic

The DECS-400 utilizes programmable logic functionality in the form of multiplexors, AND gates, OR

gates, NOT gates, and timer gates. Inputs to the logic are in the form of discrete information including

switching inputs, system status data, protection status data, limiter status data, alarm status data, and

PSS status data. The outputs of the programmable logic module can be used to control the relay outputs

as well as various other functions inside the DECS-400 such as control functions (start/stop, mode select,

etc.), protection functions (Field Overvoltage Enable, Field Overcurrent Enable, etc.), limiter functions

(OEL enable, UEL enable, etc.), and PSS functions. BESTCOMS provides a tool for customizing the

system control logic for specific applications.

DECS-400 General Information

Page 18

6 9369700990 Rev R

Metering

Two programmable, 4 to 20 mAdc, analog meter drivers are provided. The meter side is isolated from

DECS-400 circuitry. Either driver can be programmed to meter a broad range of generator and system

parameters.

Sequence of Events Recording

An integrated sequence of events recorder (SER) can be used to reconstruct the exact time of an event

or disturbance. The DECS-400 monitors its contact inputs and outputs for changes of state, system

operating changes, and alarm conditions. If any of these events occurs, the DECS-400 logs that event

with a date and time stamp. The resulting event record allows the user to analyze a chain of events with

accurate information regarding the sequence in which they occurred. Up to 127 events can be stored in

DECS-400 volatile memory and those events are retrievable through BESTCOMS software.

Oscillography

The data recording feature can record up to six oscillographic records and store them in volatile memory.

Up to six variables can be selected for monitoring. These variables include generator voltage, generator

current (single-phase), frequency, kW, power factor, field voltage, and field current. Oscillographic records

can be triggered through BESTCOMS or by a logic trigger or level trigger.

During commissioning, BESTCOMS can be used to trigger and save a record of a voltage step response.

At the completion of commissioning, a logic trigger or level trigger can be used to activate the data

recorder to capture the occurrence for review at a later time. DECS-400 alarms can also be used to start

the data recorder. When an alarm condition occurs, an oscillographic record can be stored. A level trigger

will initiate a record to be saved when a variable (such as field current) exceeds a predetermined setting.

Oscillographic records are recorded in accordance with the IEEE Standard Common Format for Transient

Data Exchange (COMTRADE) or log file format. Basler Electric provides BESTwave™, a COMTRADE

viewer that enables viewing of oscillography records saved by the DECS-400.

Real-Time Monitoring

Real-time monitoring is possible for any of the parameters available for oscillography. The HMI real-time

monitoring screen will display up to two parameters simultaneously. This data can be stored in a file for

later reference.

Internal Testing Provisions

Using BESTCOMS, the user can configure and run both frequency and step response tests to facilitate

commissioning or demonstrate system performance. The frequency response test has a frequency range

of 0.1 to 10 hertz, and gain/phase informat ion is gener ated in the form of a Bode plot . The DEC S -400

also allows injection of test signals at various points in the PSS/voltage regulation loop for a high level of

testing flexibility.

Communication

The DECS-400 is supplied with BESTC OM S sof twar e whic h makes DECS -400 programming and

customization fast and easy. BESTCOMS includes a PID selection utility that provides a user-friendly

format for selecting stability settings. BESTCOMS has monitoring screens for viewing all settings,

metering screens for viewing all machine parameters, and control screens for remote control of the

excitation system. A file converter within BESTCOMS enables conversion of DECS-300 settings files for

use with the DECS-400.

An RS-485 port on the rear panel supports Modbus™ (floating point) communication protocol. Modbus™ is

an open protocol, with all registers and operating instructions available in this instruction manual. This

makes it simple for the user to develop custom communication software.

An Ethernet port on the rear panel enables communication with the DECS-400 over a TCP/IP network.

Ethernet support in the DECS-400 enables remote access to DECS-400 settings and data through

Modbus TCP or BESTCOMS. DECS-400 time synchronization with a network time server is also

possible.

General Information DECS-400

Page 19

9369700990 Rev R 7

An internal modem is also provided to remotely access DECS-400 settings and alarms.

Password Protection

All DECS-400 parameters can be viewed at the front pane l display, throu gh BE ST C OMS, or through

Modbus™ without the need of a password. If the user wishes to change a setting, the proper password

must be entered to allow access to the parameter. Two levels of password protection exist. One level

provides global access to all parameters. The other level provides limited access to parameters normally

associated with operator control.

Upgrading from DECS-300 to DECS-400

The upgrading process was designed to be easy, but some additional wiring may be necessary. An

escutcheon plate for easy installation is recommended (see the Installation chapter). To make the

upgrade process easier, BESTCOMS software for the DECS-400 provides a tool to convert a DECS-300

settings file to a DECS-400 settings file (see the BESTCOMS Software chapter).

Model and Style Number

DECS-400 electrical characteristics and operational features are defined by a combination of letters and

numbers that make up the style number. The model number, together with the style number, describe the

options included in a specific device and appear on a label affixed to the rear panel.

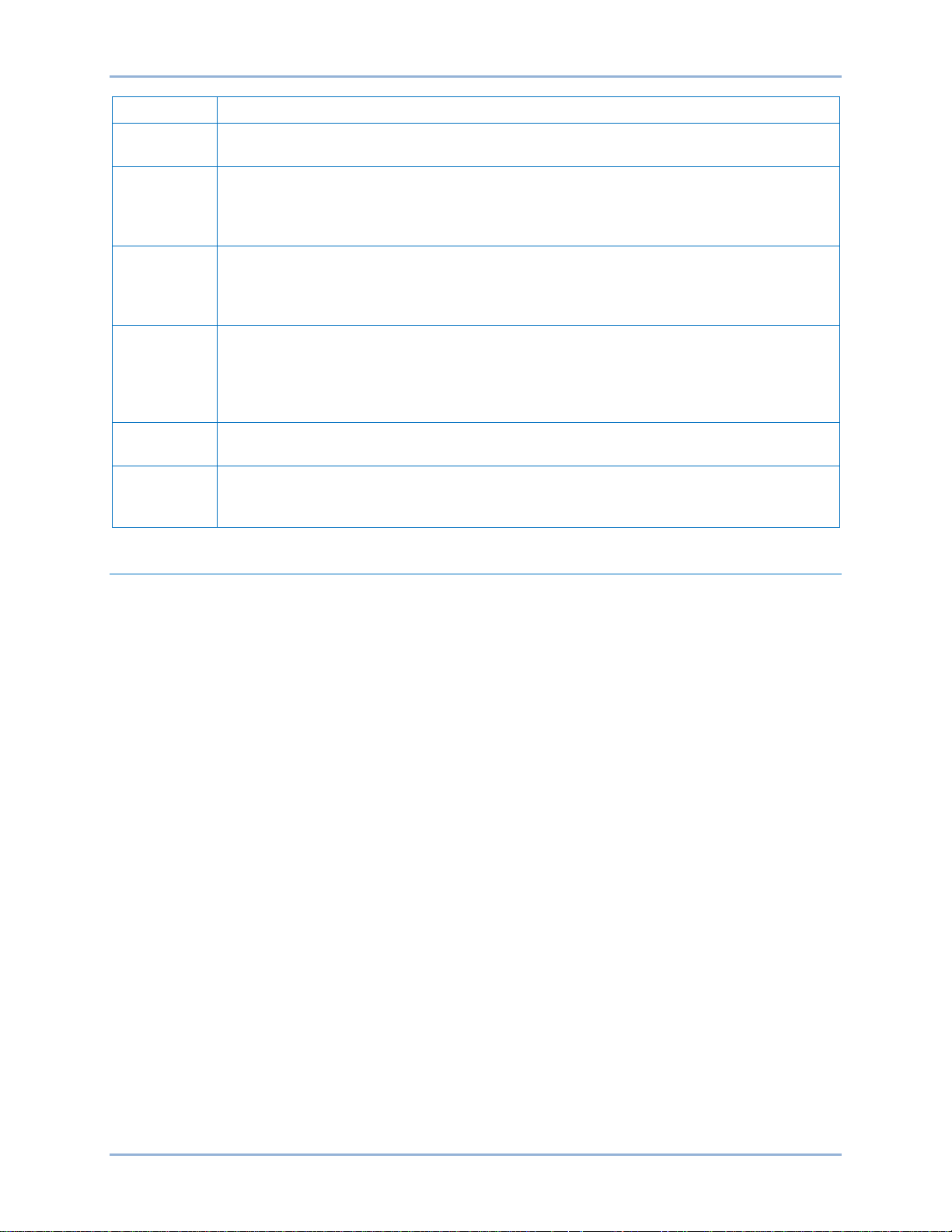

Style Number

The style number identification chart in Figure 1 defines the electrical characteristics and operational

features available in the DECS-400.

Figure 1. DECS-400 Style Chart

DECS-400 General Information

Page 20

8 9369700990 Rev R

General Information DECS-400

Page 21

9369700990 Rev R 9

Locator

Description

A

Null Balance Indicator. This LED lights when the setpoint of the inactive operating

modes (AVR, FCR, Var, or Power Factor) match the setpoint of the active mode.

B

PSS Active Indicator. This LED lights when the integrated power system stabilizer is

disturbance.

C

Pre-Position Indicator. This LED lights when the setpoi nt of the active oper at in g mode is

at either of the two pre-position setting levels.

D

Lower Limit Indicator. This LED lights when the setpoi nt of the activ e operat in g mode is

decreased to the lower setpoint limit.

E

Upper Limit Indicator. This LED lights when the set po i nt of the activ e operat in g mode is