Page 1

INSTRUCTION MANUA L

FOR

DECS-250N

Digital Excitation Control System

Publication: 9440500990

Revision: D May-15

Page 2

Page 3

9440500990 Rev D i

Caution

Note

Note

Be sure that the device is hard-wired to earth groun d with no smaller

with local codes and conventions.

Preface

This instruction manual provides information about the installation and operation of the DECS-250N

Digital Excitation Control System. To accomplish this, the following information is provided:

• General Information

• Human-machine interface

• Functional description

• Installation

• BESTCOMSPlus

• Setup

• Communication protocols

• Maintenance

• Specifications

• Expansion modules

Conventions Used in this Ma nua l

Important safety and procedural information is emphasized and presented in this manual through

warning, caution, and note boxes. Each type is illustrated and defined as follows.

®

software

Warning!

Warning boxes call attention to conditions or actions that may cause

personal injury or death.

Caution boxes call attention to operating conditions that may lead to

equipment or property damage.

Note boxes emphasize important information pertaining to installation

or operation.

than 12 AWG (3.3 mm2) copper wire attached to the case ground

terminal. When the device is configured in a system with other

devices, a separate lead should be connected from the ground bus to

each device.

Current transformer (CT) grounding should be applied in accordance

DECS-250N Preface

Page 4

ii 9440500990 Rev D

Basler Electric does not assume any responsibility to compliance or noncompliance with national code, local code,

For terms of service relating to this product and software, see the Commercial Terms of Products and Services

document available at www.basler.com/terms.

This publication contains confidential information of Basler Electric Company, an Illinois corporation. It is loaned for

and options are subject to modification without notice. Over time, improvements and revisions may be made to this

manual.

The English-language version of this manual serves as the only approved manual version.

12570 State Route 143

Highland IL 62249-1074 USA

www.basler.com

info@basler.com

Tel: +1 618.654.2341

Fax: +1 618.654.2351

© 2015 by Basler Electric

All rights reserved

First printing: October 2012

Warning!

READ THIS MANUAL. Read this manual before installing, operating, or maintaining the DECS-250N.

Note all warnings, cautions, and notes in this manual as well as on the product. Keep this manual with

the product for reference. Only qualified personnel should install, operate, or service this system.

Failure to follow warning and cautionary labels may result in personal injury or property damage.

Exercise caution at all times.

or any other applicable code. This manual serves as reference material that must be well understood prior to

installation, operation, or maintenance.

confidential use, subject to return on request, and with the mutual understanding that it will not be used in any

manner detrimental to the interests of Basler Electric Company and used strictly for the purpose intended.

It is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide

data for every possible contingency regarding installation or operation. The availability and design of all features

publication. Before performing any of the following procedures, contact Basler Electric for the latest revision of this

Preface DECS-250N

Page 5

9440500990 Rev D iii

This product contains, in part, open source softw are (software licensed in a way that ensures freedom to run,

copy, distribute, study, change, and improve the software) and you are granted a license to that software under the

formation is provided above). A fee of no more than our cost of physically performing the source code distribution

Portions of this software are copyright © 2014 The Free Type Project (www.freetype.org). All rights reserved.

terms of either the GNU General Public License or GNU Lesser General Public License. The licenses, at the time

of sale of the product, allow you to freely copy, modify, and redistribute that software and no other statement or

documentation from us, including our End User License Agreement, places any additional restrictions on what you

may do with that software.

For at least three (3) years from the date of distribution of this product, a machine-readable copy of the complete

corresponding source code for the version of the programs distributed to you will be sent upon request (contact

in

is charged.

The source code is distributed in the hope that it will be useful, but WITHOUT ANY REPRESENTATION or

WARRANTY or even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

Refer to the source code distribution for additional restrictions regarding warranty and copyrights.

For a complete copy of GNU GENERAL PUBLIC LICENSE Version 2, June 1991 or GNU LESSER GENERAL

PUBLIC LICENSE Version 2.1, February 1999 refer to www.gnu.org or contact Basler Electric. You, as a Basler

Electric Company customer, agree to abide by the terms and conditions of GNU GENERAL PUBLIC LICENSE

Version 2, June 1991 or GNU LESSER GENERAL PUBLIC LICENSE Version 2.1, February 1999, and as such

hold Basler Electric Company harmless related to any open source software incorporated in this product. Basler

Electric Company disclaims any and all liability associated with the open source software an d the user agr ees to

defend and indemnify Basler Electric Company, its directors, officers, and employees from and against any and all

losses, claims, attorneys' fees, and expenses arising from the use, sharing, or redistribution of the software.

Review the software website for the latest version of the software documentation.

DECS-250N Preface

Page 6

iv 9440500990 Rev D

Revision History DECS-250N

Page 7

9440500990 Rev D v

Contents

Introduction ................................................................................................................................................. 1

Features and Functions ............................................................................................................................. 1

Applications ............................................................................................................................................... 2

Package ..................................................................................................................................................... 2

Optional Features and Capabilities ........................................................................................................... 2

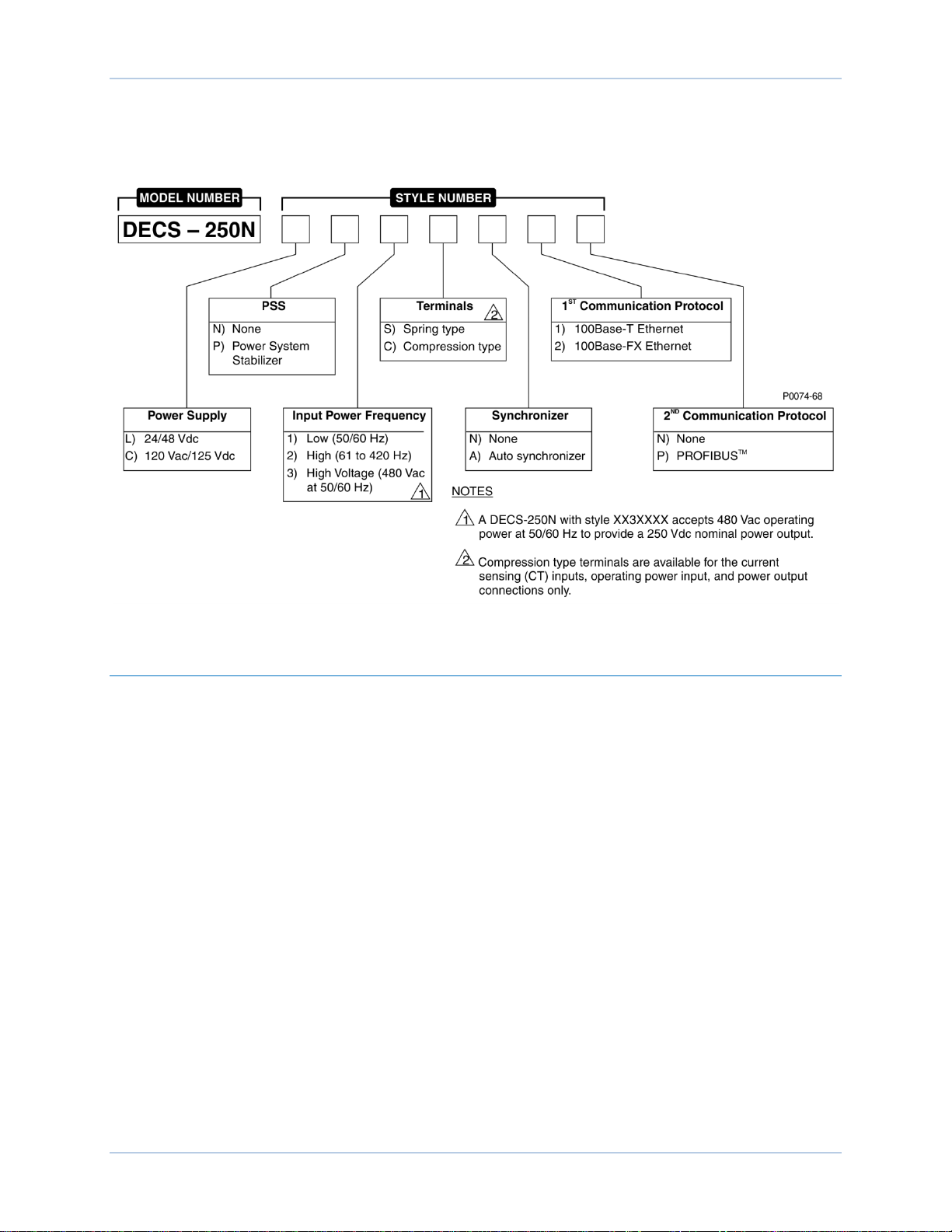

Style Number ......................................................................................................................................... 3

Storage ...................................................................................................................................................... 3

Electrolytic Capacitor Considerations .................................................................................................... 3

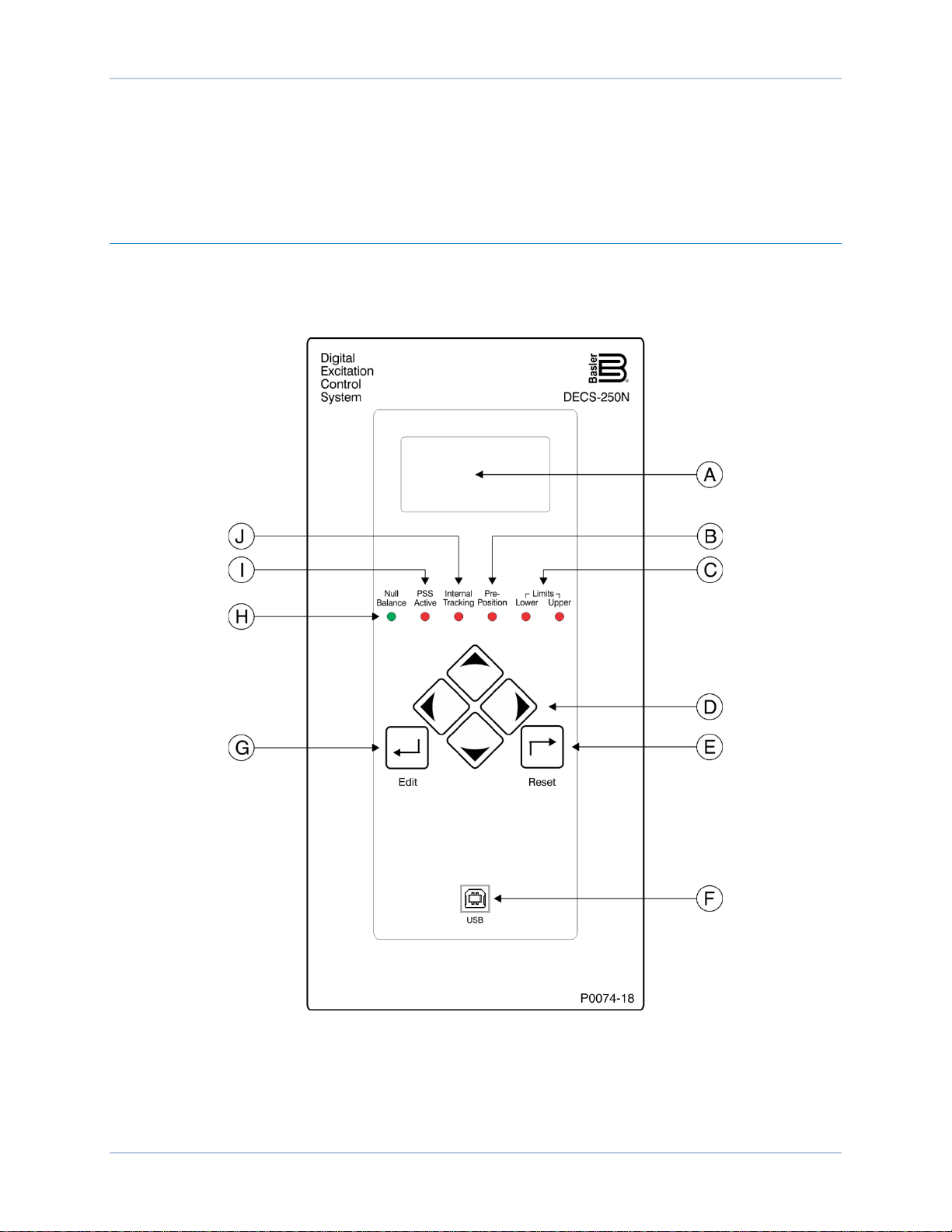

Controls and Indicators .............................................................................................................................. 5

Front Panel Illustration and Description .................................................................................................... 5

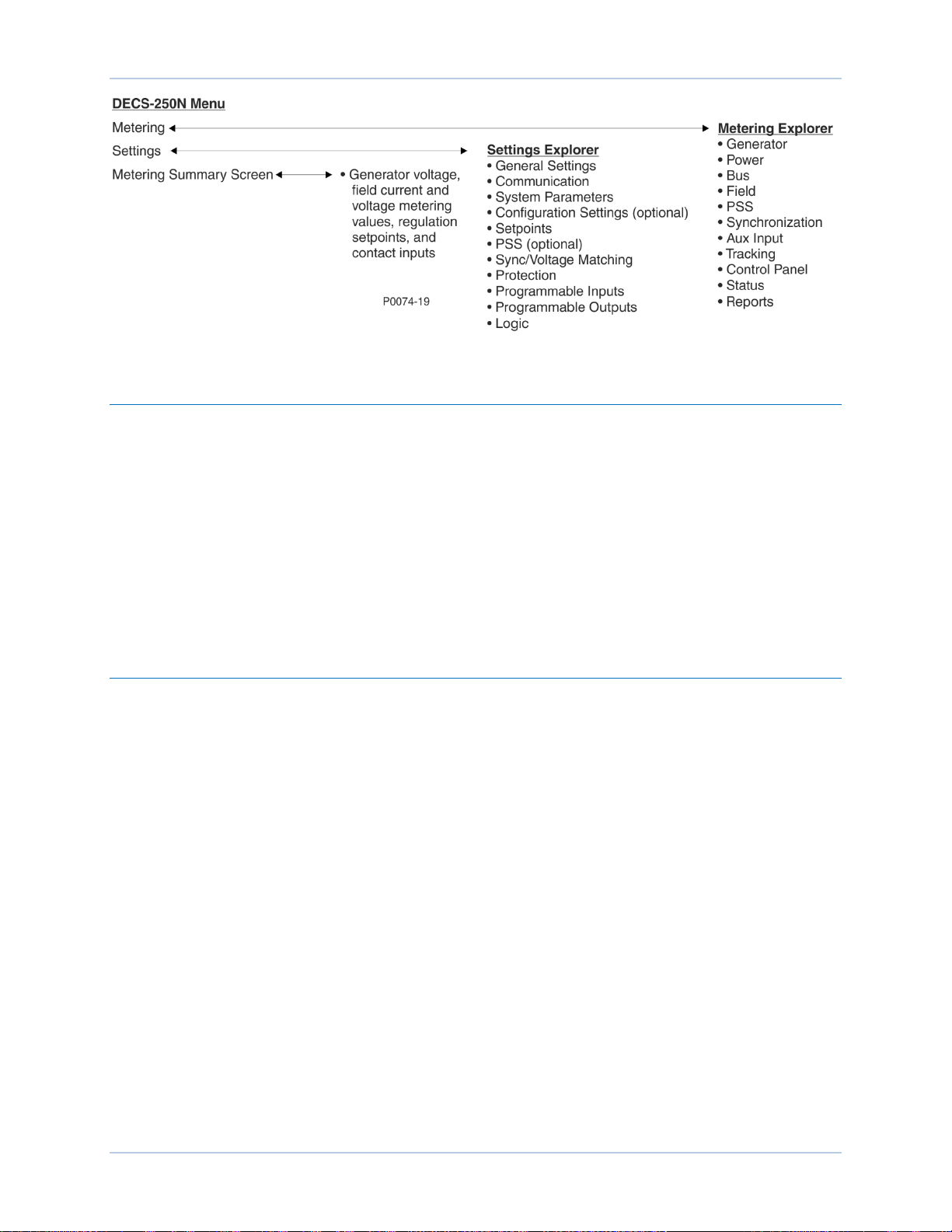

Menu Navigation ........................................................................................................................................ 6

Adjusting Settings ...................................................................................................................................... 7

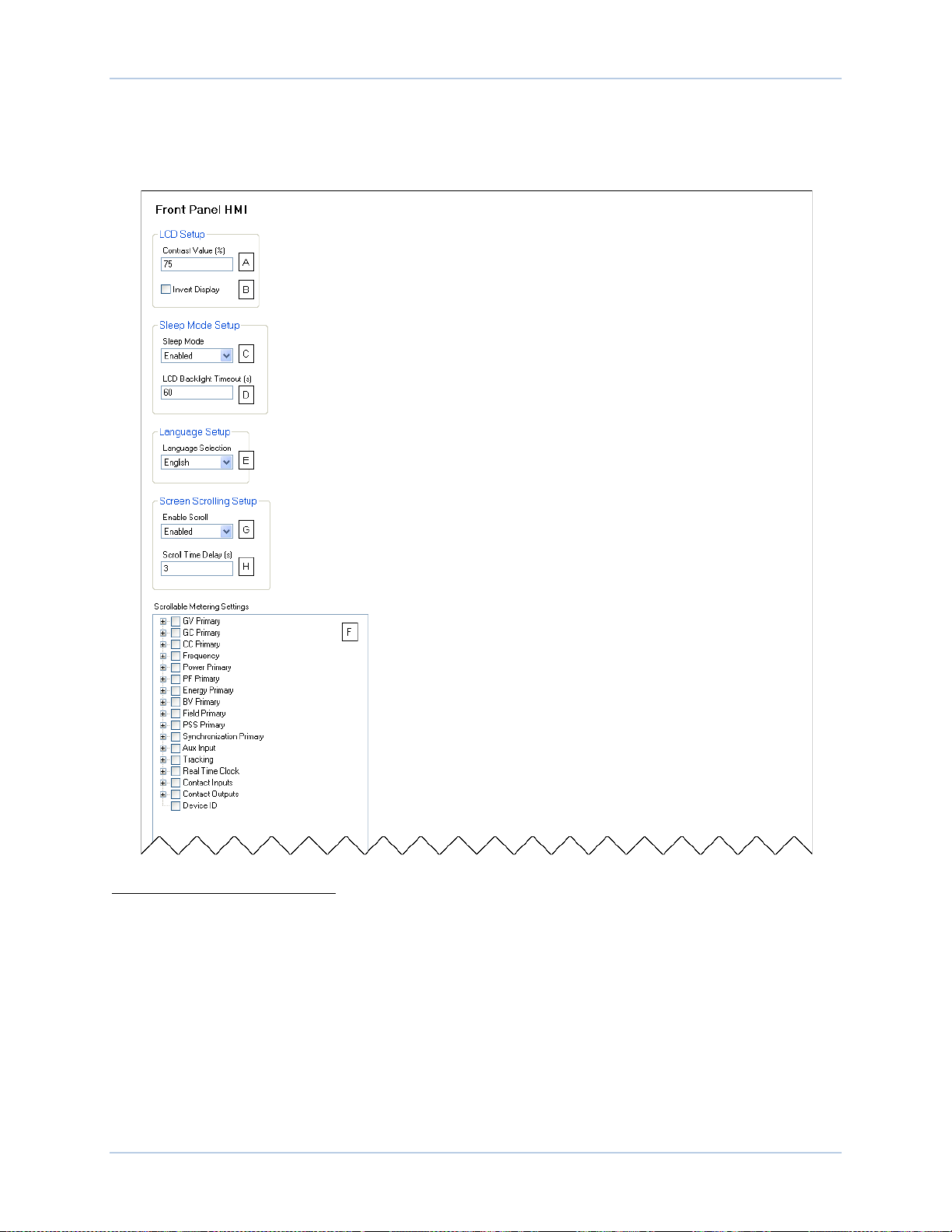

Display Setup ............................................................................................................................................ 7

LCD ........................................................................................................................................................ 7

Sleep Mode ............................................................................................................................................ 7

Language ............................................................................................................................................... 7

Screen Scrolling ..................................................................................................................................... 8

Power Inputs ................................................................................................................................................ 9

Control Power ............................................................................................................................................ 9

Operating Power ........................................................................................................................................ 9

Power Stage ............................................................................................................................................... 11

Field Transient Protection........................................................................................................................ 11

Inverting Style Excitation System Compatibility ...................................................................................... 11

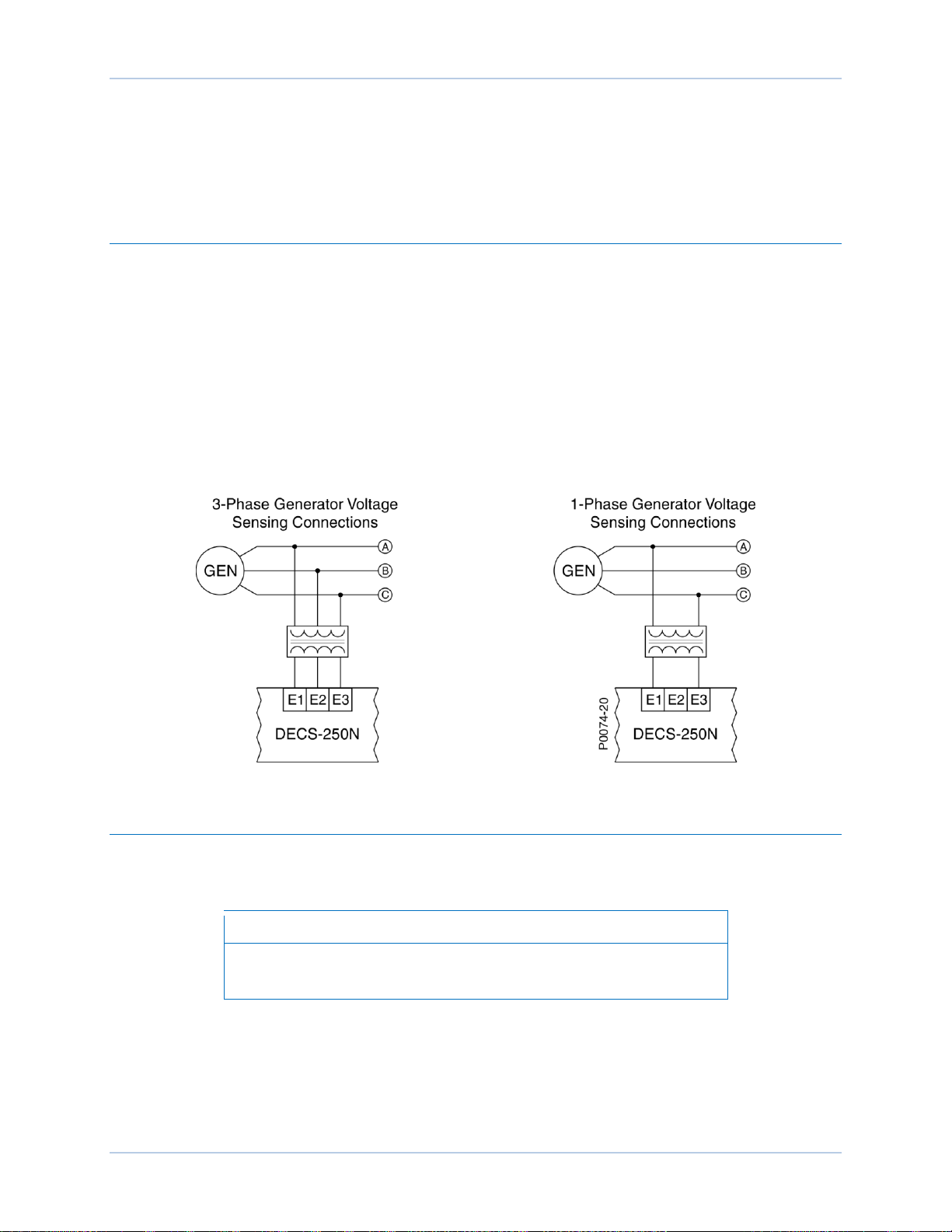

Voltage and Current Sensing ................................................................................................................... 13

Generator Voltage ................................................................................................................................... 13

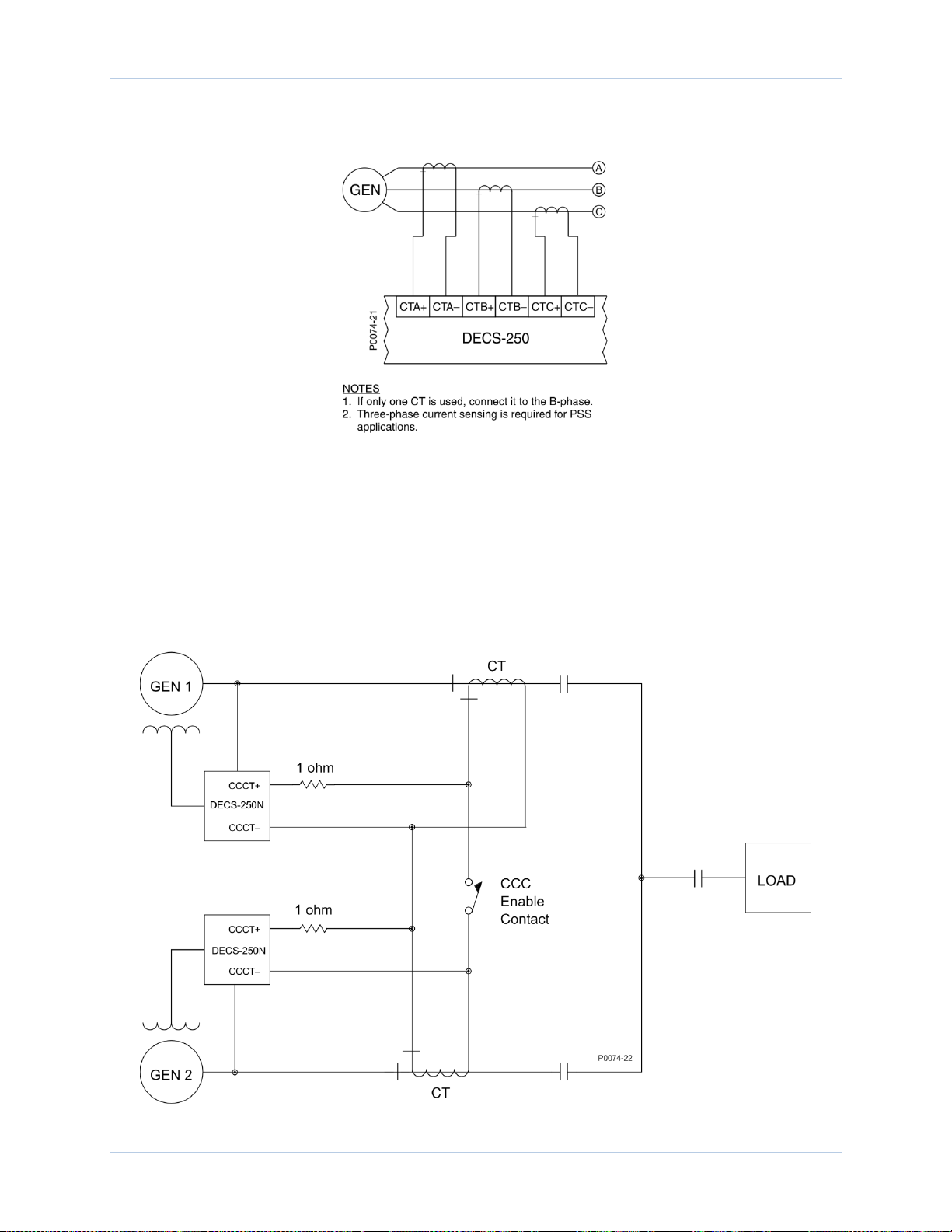

Generator Current ................................................................................................................................... 13

Phase Sensing ..................................................................................................................................... 13

Cross-Current Compensation .............................................................................................................. 14

Bus Voltage ............................................................................................................................................. 15

Synchronizer ............................................................................................................................................. 17

Generator Synchronizat ion ...................................................................................................................... 17

Frequency Correction .......................................................................................................................... 17

Voltage Correction ............................................................................................................................... 17

Angle Compensation ........................................................................................................................... 18

Failure of Synchronization ................................................................................................................... 18

Voltage Matching ..................................................................................................................................... 19

Breaker Hardware Configuration ............................................................................................................. 19

Breaker Failure .................................................................................................................................... 19

Generator Breaker ............................................................................................................................... 19

Generator and Bus Condition Detection.................................................................................................. 20

Generator Condition............................................................................................................................. 21

Generator Stability ............................................................................................................................... 21

Bus Condition ....................................................................................................................................... 21

Bus Stability ......................................................................................................................................... 21

Generator Governor Control .................................................................................................................... 23

Regulation .................................................................................................................................................. 25

Regulation Modes .................................................................................................................................... 25

AVR ...................................................................................................................................................... 25

FCR ...................................................................................................................................................... 25

FVR ...................................................................................................................................................... 25

Var ....................................................................................................................................................... 26

DECS-250N Contents

Page 8

vi 9440500990 Rev D

Power Factor ........................................................................................................................................ 27

Pre-Position Setpoints ............................................................................................................................. 27

Transient Boost ....................................................................................................................................... 28

Operation with Paralleled Generators ..................................................................................................... 29

Reactive Droop Compensation ............................................................................................................ 29

Cross-Current Compensation .............................................................................................................. 29

Network Load Sharing ......................................................................................................................... 29

Line Drop Compensation ..................................................................................................................... 30

Autotracking ............................................................................................................................................. 31

Internal Setpoint Tracking .................................................................................................................... 31

External Setpoint Tracking ................................................................................................................... 32

Setpoint Configure ................................................................................................................................... 32

Auxiliary Control ....................................................................................................................................... 33

Auxiliary Control Input Type .................................................................................................................... 33

Auxiliary Control Input Function .............................................................................................................. 33

PSS Test Input ..................................................................................................................................... 33

Limiter Scaling ..................................................................................................................................... 33

Setpoint Limits ..................................................................................................................................... 33

Auxiliary Control Gains ............................................................................................................................ 33

AVR Mode ............................................................................................................................................ 34

FCR Mode ............................................................................................................................................ 34

FVR Mode ............................................................................................................................................ 34

Var Mode ............................................................................................................................................. 34

Power Factor Mode.............................................................................................................................. 34

Summing Type ........................................................................................................................................ 34

Contact Inputs and Outputs ..................................................................................................................... 37

Contact Inputs ......................................................................................................................................... 37

Start and Stop Inputs ........................................................................................................................... 37

Programmable Inputs .......................................................................................................................... 37

Contact Outputs ....................................................................................................................................... 38

Watchdog Output ................................................................................................................................. 38

Programmable Outputs ........................................................................................................................ 38

Protection................................................................................................................................................... 41

Voltage Protection ................................................................................................................................... 41

Overexcitation (Volts per Hertz) ........................................................................................................... 41

Generator Undervoltage ...................................................................................................................... 43

Generator Overvoltage ........................................................................................................................ 44

Loss of Sensing ................................................................................................................................... 44

Frequency Protection .............................................................................................................................. 45

Overfrequency ..................................................................................................................................... 45

Underfrequency ................................................................................................................................... 45

Power Protection ..................................................................................................................................... 46

Reverse Power .................................................................................................................................... 46

Loss of Excitation ................................................................................................................................. 46

Field Protection ........................................................................................................................................ 48

Field Overvoltage ................................................................................................................................. 48

Field Overcurrent ................................................................................................................................. 48

Exciter Diode Monitor .......................................................................................................................... 50

Power Input Failure .............................................................................................................................. 52

Sync-Check Protection ............................................................................................................................ 53

Generator Frequency Less Than 10 Hertz .............................................................................................. 54

Configurable Protection ........................................................................................................................... 54

Limiters ...................................................................................................................................................... 57

Overexcitation Limiter .............................................................................................................................. 57

Summing Point OEL ............................................................................................................................ 57

Takeover OEL ...................................................................................................................................... 58

Contents DECS-250N

Page 9

9440500990 Rev D vii

Underexcitation Limiter ............................................................................................................................ 61

Stator Current Limiter .............................................................................................................................. 63

Low-Level Limiting ............................................................................................................................... 64

High-Level Limiting .............................................................................................................................. 64

Initial Delay .......................................................................................................................................... 64

Var Limiter ............................................................................................................................................... 65

Limiter Scaling ......................................................................................................................................... 65

Underfrequency Limiter ........................................................................................................................... 66

Volts per Hertz ..................................................................................................................................... 67

Metering ..................................................................................................................................................... 69

Metering Explorer .................................................................................................................................... 69

HMI ...................................................................................................................................................... 69

BESTCOMSPlus® ................................................................................................................................ 69

Metered Parameters ................................................................................................................................ 70

Generator ............................................................................................................................................. 70

Power ................................................................................................................................................... 70

Bus ....................................................................................................................................................... 71

Field ..................................................................................................................................................... 72

PSS ...................................................................................................................................................... 72

Synchronization ................................................................................................................................... 73

Auxiliary Control Input .......................................................................................................................... 73

Tracking ............................................................................................................................................... 73

Control Panel ....................................................................................................................................... 74

Metering Summary............................................................................................................................... 75

Status Indication ...................................................................................................................................... 76

System Status ...................................................................................................................................... 76

Inputs ................................................................................................................................................... 77

Outputs ................................................................................................................................................ 78

Network Load Share ............................................................................................................................ 79

Configurable Protection ....................................................................................................................... 79

Alarms .................................................................................................................................................. 80

Real-Time Clock .................................................................................................................................. 83

Auto Export Metering ............................................................................................................................... 84

Event Recorder .......................................................................................................................................... 85

Sequence-of-Events Recording .............................................................................................................. 85

Data Logging ........................................................................................................................................... 85

Setup .................................................................................................................................................... 86

Triggers ................................................................................................................................................ 86

Trending .................................................................................................................................................. 89

Power System Stabilizer ........................................................................................................................... 91

Supervisory Function and Setting Groups............................................................................................... 91

Supervisory Function ........................................................................................................................... 91

Setting Groups ..................................................................................................................................... 91

Theory of Operation ................................................................................................................................. 91

Speed Signal ........................................................................................................................................ 93

Rotor Frequency Calculation ............................................................................................................... 93

Generator Electrical Power Sig na l ....................................................................................................... 93

Derived Mechanical Power Signa l ....................................................................................................... 94

Stabilizing Signal Selection .................................................................................................................. 94

Torsional Filters ................................................................................................................................... 95

Phase Compensation .......................................................................................................................... 95

Washout Filter and Logic Limiter ......................................................................................................... 95

Output Stage ........................................................................................................................................ 96

Terminal Voltage Limiter ...................................................................................................................... 96

Stability Tuning ....................................................................................................................................... 101

AVR Mode ............................................................................................................................................. 101

DECS-250N Contents

Page 10

viii 9440500990 Rev D

Predefined Stability Settin g s .............................................................................................................. 101

Custom Stability Settings ................................................................................................................... 101

Auto Tuning ........................................................................................................................................ 103

FCR and FVR Modes ............................................................................................................................ 104

FCR Mode Stability Settings .............................................................................................................. 104

FVR Mode Stability Settings .............................................................................................................. 105

Other Modes and Functions .................................................................................................................. 106

Var Mode ........................................................................................................................................... 106

Power Factor Mode............................................................................................................................ 106

Overexcitation Limiter (OEL) ............................................................................................................. 106

Underexcitation Limiter (UEL) ............................................................................................................ 106

Stator Current Limiter (SCL) .............................................................................................................. 106

Var Limiter .......................................................................................................................................... 106

Voltage Matching ............................................................................................................................... 106

Mounting .................................................................................................................................................. 109

Mounting Considerations ....................................................................................................................... 109

Projection Mounting ............................................................................................................................... 109

Behind-the-Panel Mounting ................................................................................................................... 109

Terminals and Connectors ..................................................................................................................... 115

Overview ................................................................................................................................................ 115

Terminal Types ...................................................................................................................................... 119

Typical Connections ............................................................................................................................... 121

BESTCOMSPlus® Software ..................................................................................................................... 125

General Description ............................................................................................................................... 125

Installation ............................................................................................................................................. 126

Install BESTCOMSPlus® .................................................................................................................... 126

Activation of the DECS-250N Plugin for BESTCOMSPlus® .................................................................. 126

Connect a USB Cable ........................................................................................................................ 127

Start BESTCOMSPlus® and Activate DECS-250N Plugin Automatically .......................................... 127

Manual Activation of the DECS-250N Plug in .................................................................................... 129

Establishing Communicat io n ............................................................................................................. 130

Menu Bars ............................................................................................................................................. 130

Upper Menu Bar (BESTCOMSPlus® Shell) ....................................................................................... 130

Lower Menu Bar (DECS-250N Plugin) .............................................................................................. 132

Settings Explorer ................................................................................................................................... 132

Metering Explorer .................................................................................................................................. 132

Settings File Management ..................................................................................................................... 133

Opening a Settings File ..................................................................................................................... 133

Saving a Settings File ........................................................................................................................ 133

Upload Settings and/or Logic to Device ............................................................................................ 133

Download Settings and Logic from Device ........................................................................................ 133

Printing a Settings File ....................................................................................................................... 133

Comparing Settings Files ................................................................................................................... 133

Automatic Metering Export .................................................................................................................... 135

Firmware Updates ................................................................................................................................. 135

Upgrading Firmware in Expansion Modules ...................................................................................... 136

Upgrading Firmware in the DECS-250N............................................................................................ 137

BESTCOMSPlus® Updates .................................................................................................................... 138

BESTlogic™Plus ...................................................................................................................................... 139

Introduction ............................................................................................................................................ 139

Overview of BESTlogic™Plus ............................................................................................................... 139

BESTlogic™Plus Composition .......................................................................................................... 140

Logic Schemes ...................................................................................................................................... 154

The Active Logic Scheme .................................................................................................................. 154

Sending and Retrieving Logic Schemes ............................................................................................ 154

Default Logic Schemes ...................................................................................................................... 155

Contents DECS-250N

Page 11

9440500990 Rev D ix

Programming BESTlogic ™Plus.............................................................................................................. 158

Pickup and Dropout Timers ............................................................................................................... 159

Offline Logic Simulator .......................................................................................................................... 160

BESTlogic™Plus File Management ...................................................................................................... 160

Saving a BESTlogicPlus File ............................................................................................................. 161

Opening a BESTlogicPlus File ........................................................................................................... 161

Protecting a BESTlogicPlus File ........................................................................................................ 161

Uploading a BESTlogicPlus File ........................................................................................................ 161

Downloading a BESTlogicPlus File ................................................................................................... 161

Copying and Renaming Preprogrammed Logic Sche mes ................................................................ 161

Printing a BESTlogicPlus File ............................................................................................................ 162

Clearing the On-Screen Logic Diagram ............................................................................................. 162

BESTlogic™Plus Examples .................................................................................................................. 162

Example 1 - GOVR Logic Block Connections ................................................................................... 162

Example 2 - AND Gate Connections ................................................................................................. 162

Communication ....................................................................................................................................... 163

Local Communication ............................................................................................................................ 163

Communication with a Second DECS ................................................................................................... 163

Modbus™ Communication ..................................................................................................................... 164

RS-485 Port ....................................................................................................................................... 164

Ethernet Port ...................................................................................................................................... 165

CAN Communication ............................................................................................................................. 166

Connections ....................................................................................................................................... 166

Port Configuration .............................................................................................................................. 166

Remote Module Setup ....................................................................................................................... 166

Ethernet Communication ....................................................................................................................... 167

Ethernet Connection .......................................................................................................................... 167

PROFIBUS Communication .................................................................................................................. 170

Configuration ........................................................................................................................................... 171

Generator, Field, and Bus Ratings ........................................................................................................ 171

Sensing Transformer Ratings and Configuration .................................................................................. 172

Generator PT ..................................................................................................................................... 172

Generator CTs ................................................................................................................................... 172

Bus PT ............................................................................................................................................... 172

Bridge Operating Power Configuration .................................................................................................. 173

Operating Power Input ....................................................................................................................... 173

Modes of Operation ........................................................................................................................... 173

Rated Frequency ............................................................................................................................... 174

Maximum Over-Speed ....................................................................................................................... 174

Startup Functions .................................................................................................................................. 174

Soft Start ............................................................................................................................................ 174

Field Flashing ..................................................................................................................................... 174

Device Information ................................................................................................................................. 175

Firmware and Product Information .................................................................................................... 175

Device Identification ........................................................................................................................... 175

Display Units .......................................................................................................................................... 176

Security .................................................................................................................................................... 179

Password Access .................................................................................................................................. 179

Password Creation and Configuration ............................................................................................... 179

Port Security .......................................................................................................................................... 180

Port Access Configuration ................................................................................................................. 181

Login and Access Controls .................................................................................................................... 181

Access Timeout ................................................................................................................................. 181

Login Failure ...................................................................................................................................... 182

Timekeeping ............................................................................................................................................ 183

Time and Date Format........................................................................................................................... 183

DECS-250N Contents

Page 12

x 9440500990 Rev D

Daylight Saving Time Adjustments ........................................................................................................ 183

Network Time Protocol (NTP) ............................................................................................................... 183

NTP Settings ...................................................................................................................................... 183

IRIG ....................................................................................................................................................... 183

Testing ...................................................................................................................................................... 187

Real-Time Metering Analysis ................................................................................................................ 187

Graph Parameters ............................................................................................................................. 188

Frequency Response ............................................................................................................................ 188

Test Mode .......................................................................................................................................... 188

Bode Plotting ...................................................................................................................................... 189

Transfer Function ............................................................................................................................... 189

Frequency Response ......................................................................................................................... 190

Time Response ..................................................................................................................................... 190

Signal Input ........................................................................................................................................ 191

Test Signal Characteristics ................................................................................................................ 191

Step Response Analys is ........................................................................................................................ 192

AVR, FCR, and FVR Tabs ................................................................................................................. 192

Var and PF Tabs ................................................................................................................................ 193

Analysis Options .................................................................................................................................... 193

Layout Tab ......................................................................................................................................... 193

Graph Display Tab ............................................................................................................................. 194

CAN Communication .............................................................................................................................. 195

Introduction ............................................................................................................................................ 195

CAN Parameters ................................................................................................................................... 195

Diagnostic Trouble Codes (DTCs) ..................................................................................................... 197

Modbus™ Communication ...................................................................................................................... 199

Introduction ............................................................................................................................................ 199

Message Structure ............................................................................................................................. 199

Modbus Modes of Operation ................................................................................................................. 200

Modbus™ Over Serial Line ................................................................................................................. 200

Modbus on TCP/IP............................................................................................................................. 201

Error Handling and Exception Responses ......................................................................................... 202

DECS-250N Modbus™ via Ethernet .................................................................................................. 203

Detailed Message Query and Response for RTU Transmission Mode ................................................ 203

Read Holding Registers ..................................................................................................................... 203

Return Query Data ............................................................................................................................. 203

Restart Communications Option ........................................................................................................ 204

Listen Only Mode ............................................................................................................................... 204

Preset Multiple Registers ................................................................................................................... 204

Preset Single Register ....................................................................................................................... 205

Data Formats ......................................................................................................................................... 206

Floating Point Data Format (Float) .................................................................................................... 206

Long Integer Data Format (Uint32) .................................................................................................... 207

Integer Data Format (Uint16) or Bit-Mapped Variables in Uint16 Format ......................................... 207

Short Integer Data Format/Byte Character Data Format (Uint8) ....................................................... 207

String Data Format (String) ................................................................................................................ 207

CRC Error Check ............................................................................................................................... 208

Secure DECS-250N Login via Modbus ................................................................................................. 208

Modbus Parameters .............................................................................................................................. 208

General .............................................................................................................................................. 208

Security .............................................................................................................................................. 209

Binary Points ...................................................................................................................................... 209

Metering ............................................................................................................................................. 218

Limiters .............................................................................................................................................. 223

Setpoints ............................................................................................................................................ 225

Global Settings ................................................................................................................................... 227

Relay Settings .................................................................................................................................... 228

Contents DECS-250N

Page 13

9440500990 Rev D xi

Protection Settings ............................................................................................................................. 230

Gains Settings .................................................................................................................................... 232

Legacy Modbus .................................................................................................................................. 233

PROFIBUS Communication ................................................................................................................... 243

Data Types ............................................................................................................................................ 243

Float/UINT32 ...................................................................................................................................... 243

UINT8 ................................................................................................................................................. 243

Setup ..................................................................................................................................................... 245

PROFIBUS Param eter s......................................................................................................................... 246

Maintenance ............................................................................................................................................ 303

Storage .................................................................................................................................................. 303

Preventive Maintenance ........................................................................................................................ 303

Connections ....................................................................................................................................... 303

Electrolytic Capacitors ....................................................................................................................... 303

Cleaning the Front Panel ....................................................................................................................... 303

Troubleshooting ..................................................................................................................................... 304

DECS-250N Appears Inoperative ...................................................................................................... 304

Display Blank or Frozen ..................................................................................................................... 304

Generator Voltage Does Not Build .................................................................................................... 304

Low Generator Voltage in AVR Mode ................................................................................................ 304

High Generator Voltage in AVR Mode ............................................................................................... 304

Generator Voltage Unstable (Hunting) .............................................................................................. 305

Protection or Limit Annunciation ........................................................................................................ 305

HMI Meter Readings Incorrect ........................................................................................................... 305

No Communication ............................................................................................................................ 305

DECS-250N Reboots Frequently ....................................................................................................... 305

Support .................................................................................................................................................. 305

Specifications .......................................................................................................................................... 307

Operating Power .................................................................................................................................... 307

Voltage Range ................................................................................................................................... 307

Frequency Range (Style Dependent) ................................................................................................ 307

Control Power ........................................................................................................................................ 307

Style LXXXXXX .................................................................................................................................. 307

Style CXXXXXX ................................................................................................................................. 307

Terminals ........................................................................................................................................... 308

Generator and Bus Voltage Sensing ..................................................................................................... 308

Terminals ........................................................................................................................................... 308

50 Hz Sensing Voltage Nominal Input, Range .................................................................................. 308

60 Hz Sensing Voltage Nominal Input, Range .................................................................................. 308

Generator Current Sensing ................................................................................................................... 308

Burden ............................................................................................................................................... 308

Terminals ........................................................................................................................................... 308

Accessory Inputs ................................................................................................................................... 309

Current Input ...................................................................................................................................... 309

Voltage Input ...................................................................................................................................... 309

Contact Inputs ....................................................................................................................................... 309

Terminals ........................................................................................................................................... 309

Communication Ports ............................................................................................................................ 309

Universal Serial Bus (USB) ................................................................................................................ 309

RS-232 ............................................................................................................................................... 309

RS-485 ............................................................................................................................................... 310

Ethernet ............................................................................................................................................. 310

Controller Area Network (CAN) ......................................................................................................... 310

IRIG Time Synchronization Input .......................................................................................................... 310

Contact Outputs ..................................................................................................................................... 310

Field Power Output ................................................................................................................................ 311

Maximum Positive Forcing Voltag e ................................................................................................... 311

DECS-250N Contents

Page 14

xii 9440500990 Rev D

Maximum Negative Forcing Voltage .................................................................................................. 311

Minimum Field Resistance ................................................................................................................. 311

Regulation ............................................................................................................................................. 311

FCR Operating Mode ......................................................................................................................... 311

FVR Operating Mode ......................................................................................................................... 311

AVR Operating Mode ......................................................................................................................... 311

Var Operating Mode........................................................................................................................... 312

Power Factor Operating Mode ........................................................................................................... 312

Parallel Compensation .......................................................................................................................... 312

Setpoint Range .................................................................................................................................. 312

Generator Protection Functions ............................................................................................................ 312

Overvoltage (59) and Undervoltage (27) ........................................................................................... 312

Loss of Sensing ................................................................................................................................. 312

Overfrequency (81O) and Underfrequency (81U) ............................................................................. 313

Reverse Power (32R) ........................................................................................................................ 313

Loss of Excitation (40Q) .................................................................................................................... 313

Field Protection Functions ..................................................................................................................... 313

Field Overvoltage ............................................................................................................................... 313

Field Overcurrent ............................................................................................................................... 313

Loss of PMG ...................................................................................................................................... 314

Exciter Diode Monitor (EDM) ............................................................................................................. 314

Synchronism Check (25) Protection ...................................................................................................... 314

Voltage Difference ............................................................................................................................. 314

Slip Angle ........................................................................................................................................... 314

Slip Frequency ................................................................................................................................... 314

Startup ................................................................................................................................................... 314

Soft Start Level .................................................................................................................................. 314

Soft Start Time ................................................................................................................................... 314

Field Flash Dropout Level .................................................................................................................. 314

Maximum Field Flash Time ................................................................................................................ 315

Voltage Matching ................................................................................................................................... 315

On-Line Overexcitation Limiting ............................................................................................................ 315

High Current Level ............................................................................................................................. 315

Medium Current Level ....................................................................................................................... 315

Low Current Level .............................................................................................................................. 315

Off-Line Overexcitation Limiting ............................................................................................................ 315

High Current Level ............................................................................................................................. 315

Low Current Level .............................................................................................................................. 315

Sequence of Events Recording (SER)2 ................................................................................................ 315

Data Logging (Oscillography) ................................................................................................................ 316

Environment .......................................................................................................................................... 316

Temperature ...................................................................................................................................... 316

Humidity ............................................................................................................................................. 316

Salt Fog .............................................................................................................................................. 316

Type Tests ............................................................................................................................................. 316

Shock ................................................................................................................................................. 316

Vibration ............................................................................................................................................. 316

Impulse .............................................................................................................................................. 316

Transients .......................................................................................................................................... 316

Static Discharge ................................................................................................................................. 316

Radio Interference ............................................................................................................................. 316

HALT (Highly Accelerated Life Testing) ............................................................................................ 316

Patent .................................................................................................................................................... 317

Physical ................................................................................................................................................. 317

Regulatory Standards ............................................................................................................................ 317

Maritime Recognition ......................................................................................................................... 317

UL Approval ....................................................................................................................................... 317

CSA Certification ................................................................................................................................ 317

Contents DECS-250N

Page 15

9440500990 Rev D xiii

CE Compliance .................................................................................................................................. 317

EAC Mark (Eurasian Conformity) ...................................................................................................... 318

Analog Expansion Module ..................................................................................................................... 319

General Information ............................................................................................................................... 319

Features ................................................................................................................................................ 319

Specifications ........................................................................................................................................ 319

Operating Power ................................................................................................................................ 319

Analog Inputs ..................................................................................................................................... 319

RTD Inputs ......................................................................................................................................... 319

Thermocouple Inputs ......................................................................................................................... 319

Analog Outputs .................................................................................................................................. 319

Communication Interface ................................................................................................................... 320

Type Tests ......................................................................................................................................... 320

Environment ....................................................................................................................................... 320

UL Approval ....................................................................................................................................... 320

CSA Certification ................................................................................................................................ 320

CE Compliance .................................................................................................................................. 321

Physical .............................................................................................................................................. 321

Installation ............................................................................................................................................. 321

Mounting ............................................................................................................................................ 321

Connections ....................................................................................................................................... 322

Communications .................................................................................................................................... 328

Functional Description ........................................................................................................................... 328

Analog Inputs ..................................................................................................................................... 328