Page 1

INSTRUCTION MANUA L

FOR

DIGITAL EXCITATIO N CONTROL SYSTEM

DECS-100

Publication: 9287500991

Revision: M 02/15

Page 2

Page 3

INTRODUCTION

This instruction manual provides information about the operation and installation of the DECS-100 Digital

Excitation Control System. To accomplish this, the following informati on is provid ed:

• General Information and Specifications

• Controls and Indicators

• Functional Description

• Installation

• Maintenance and Troubleshooting

WARNING!

To avoid personal inj ury or equipment damage, only qualified personnel should

perform the procedures in this manual.

Lethal voltage is present at the rear pan el when t he u nit is ener gized. Rear pane l

connections should be made only when the unit is de-energized.

CAUTION

The Manual mode excitation level must be evaluated prior to enabling this

feature. If the level of excit ation current is inappr opriat e for the gener ator, sev ere

damage to the generator may occur.

Improper PID numbers will result in poor system performance or system damage.

When applying operating power for programming purposes, observe the pre-

cautions called out in Section 4, Installation, Preliminary Setup.

When programming the DECS-100 without the generator spinning, the

connections to DECS-100 terminals F+ and F– should be removed.

Before uploading a settings file, remove operating power from the DECS-100,

disconnect the field wiring from terminals F+ and F–, and re-apply operating

power to the DECS-100.

NOTE

Be sure that the DECS-100 is hard-wired to ear th gro und wit h no sma ller than 1 2

AWG copper wire attache d to the ground terminal on the rear of the unit case.

When the DECS-100 is configured in a system with other devices, it is

recommended to use a separate lead to the ground bus from each unit.

9287500991 Rev M DECS-100 Introduction i

Page 4

First Printing: March 2001

Printed in USA

© 2015 Basler Electric, Highland Illinois 62249 USA

All Rights Reserved

CONFIDENTIAL INFORMATION

of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject

to return on request, and with the mutual understanding that it will not be used in

any manner detrimental to the interest of Basler Electric.

It is not the intent ion of th is manual to cover a ll detai ls and variat ions in eq uipment, n or does this manu al

provide data for every pos s ible c ont ing enc y regar di ng i ns tal lat ion or o per at ion . Th e av ai lab ility and des ign

of all features and options are subject to modification without notice. Should further information be

required, contact Basler Electric.

For terms of service relati ng to this product and software, see the Commercial Ter ms of Products and

Services document available at www.basler.com/terms.

BASLER ELECTRIC

12570 STATE ROUTE 143

HIGHLAND IL 62249-1074 USA

http://www.basler.com, info@basler.com

PHONE +1 618.654.2341 FAX +1 618.654.2351

ii DECS-100 Introduction 9287500991 Rev M

Page 5

REVISION HISTORY

Hardware

Version and Date

Change

E, 01/01

• Initial release

F, 05/01

• Deepened potting shell

G, 10/01

• Began supplying mou nti ng s c rew s

H, 02/02

• SIL-PADS were added between power components and the heat sinks

Added manufactur i ng origin to the rear label

J, 07/02

• Revised EEPROM

K, 02/03

• Replaced transistor Q8B1 with an improved part

L, 03/03

• Incremental improv em ents to firmw are and B ESTCOMS™

M, 01/04

• Improved flash memory retention

N, 05/05

• Redesigned current transformer

• Enhanced EMI/RF I im mun it y

O

• Version letter O not used

P, 08/06

• Updated CD-ROM supplied with unit to include English and French

language instruction manuals

Q

• Version letter Q not used

R, 04/07

• Resolved UEL issue with firmware modification

S, 05/07

• Provided German language manual on CD-ROM supplied with DECS-100

T, 07/07

• Released firmware version 2.13.XX

U, 01/08

• Improved power amplifier circuitry with more robust components

V, 03/08

• Added Setpoint Auto Save feature

W, 03/09

• Released BESTCO M S vers ion 1.0 8.X X.

X, 02/10

• Added enhancement for production testing.

Firmware

Version and Date

Change

1.09.XX, 01/01

• Initial release

1.11.XX, 07/01

• Enabled the protection function during the first 5 seconds of operation

• Established minimum voltage regulation at 30% of nominal sensing voltage

1.12.XX, 03/02

• Added register to detect CT type

2.13.XX, 07/07

• Added underexcitation limiting

• Added bus voltage matching provisions

2.14.XX, 03/08

• Added Setpoint Auto Sav e sett ing

2.14.XX, 04/14

• Maintenance release

BESTCOMS for

Version and Date

Change

1.02.XX, 02/01

• Initial Release

1.03.XX, 08/01

• Changed OEL scale from 100 to 1,000 to match the change in firmware

• Changed the default for all protection functions to enabled

The following information provides a historical summary of the changes made to the DECS-100 hardware,

firmware, and software. Th e corresponding revisions made to this i nstruction manual (9287500991) ar e

also summarized. Revisions are listed in chronological order.

•

• Added front panel Underexcitation Limiting indicator

• Modified the OEL setpoint scale factor to be compatible with BESTCOMS

version 1.03.XX

• Added the scale factor for per-unit gain

• Added takeover-style excitation limiting

Windows® OS

version 1.11.01

• Changed OEL default setting from 1 to 15

9287500991 Rev M DECS-100 Introduction iii

Page 6

BESTCOMS for

Windows® OS

Version and Date

Change

• Add support for French regional settings

1.04.XX, 04/02

• Made BESTCOMS compatible with older firmware versions

• Changed minimum Ki setpoint from 0 to 0.01

1.05.XX, 05/05

• Added underexcitation limiting capability

• Added provisions for bus voltage matching

1.06.XX, 11/07

• Added compatibility with Microsoft® Vista to BESTCOMS

1.07.XX, 03/08

• Added Setpoint Auto Sav e sett ing.

1.08.XX, 03/09

• Improved comm un icati ons with DEC S-100.

1.09.XX, 01/11

• Added Windows® 7 compatibility and improved field overvoltage shutdown.

1.09.XX, 04/14

• Added Windows® 8 compatibility

BESTCOMS for

Version and Date

Change

1.01.XX, 01/01

• Initial Release

1.02.XX, 08/01

• Added a Check for New Ve r sion button to the Contac t Basler screen

• Added version checking

1.03.XX, 04/02

• Added password protection

• Improved version checking function

NOTE

• BESTCOMS for Palm OS is compatible only with firmware versions

1.12.XX and earlier

Manual

Revision and Date

Change

—, 03/01

• Initial release

A, 03/01

• In Section 5, BESTCOMS Software for the Windows® Operating System

utility for the DECS-100 CD-ROM

B, 08/01

• Added Embedded Software subsection to Section 5, BEST COMS Software

• Corrected various minor errors throughout manual

C, 05/02

• Revised the torque specification for the mounting screws supplied with unit

illustrations were revised to accommodate software enhancements

D, 01/03

• Revised Voltage Matching Time Adjustment Range from 0 to 300 seconds

• Corrected figure number references in Sections 5 and 6

E, 03/04

• Added Operating Power Considerations During DECS-100 Programm ing to

• Corrected CT ratio setting range stated in Section 5

Palm® OS

• Added support for all regional settings

• Enabled reading of secondary CT value for units with firmware version

1.12.01 and higher

• Simplified the Analy s is scr een

• Added feature to calculate and send voltage matching reference for

different generator and bus PT ratios

• Added ability to select either summing point or takeover style OEL

• Added a date/time stamp to the “Save to File” names

and Section 6, BESTCOMS Software for the Palm OS® Platform, Step 2 of

Installing BESTCOMS was revised to reflect the addition of an auto-start

for the Windows® Operating System

• In Section 5, BESTCOMS Software for the Windows® Operating System

and Section 6, BESTCOMS Software for the Palm® OS Platform, text and

to 1 to 300 seconds throughout manual

Section 4, Installation, Preliminary Setup

• Added caution box regarding application of operating power during DECS100 programming to Section 5, BESTCOMS for Windows® OS and

iv DECS-100 Introduction 9287500991 Rev M

Section 6, BESTCOMS for Palm OS®

Page 7

Manual

Revision and Date

Change

F, 05/05

• Added material covering added UEL capability

• Revised all drawings to show new front panel with UEL indicator

• Added troubleshooting procedure for a UEL annunciation

G, 03/07

• Corrected illustration and des c riptio ns of BESTCO M S Meter ing, Operation

• Removed expired patent information

H, 05/08

• Added DNV compliance statement to manual specifications

• Added description of BESTCO MS Set poi nt Aut o Save featur e

J, 10/08

• Revised the setting ranges of control gain settings OEL KI, OEL Kg,

BESTCOMS version 1.07.01.

K, 05/11

• Revised Introduction to reflect new epoxy-potted package.

• Corrected various minor errors throughout manual

L, 07/13

• Section 1: Added maritime agency recognition.

capacitors while in storage.

M, 02/15

• Added UL recognition for UL6200.

• Minor text edits.

• Updated all illustrations of rear panel to show revised CT

• Added discussion of summing point and takeover style OEL limiting

• Revised voltage matching description to cover Maintain and Revert modes

• Corrected the hole drilling diameter shown in Figure 4-2

• Added illustration/description for using the ICRM-7 with the DECS-100

• Removed Section 6, BESTCOMS Software for the Palm® OS Platform and

moved Maintenance and Troubleshooting to Section 6

and Alarms screen, Operation tab

UEL KI, and UEL Kg from 0–1,000 to 0–300 to reflect changes made in

• Removed “(optional feature)” from note 5 of Figures 4-7 to 4-10, due to the

setpoint option now being standard.

• Added storage / electrolytic capacitors procedure to Section 6.

• Section 1: Added Power Dissipation to specifications.

• Section 4: Added maritime agency conditions of acceptability.

• Section 4: Added note box r egardi ng 24 Vdc operat ing power bei ng us ed

for programming the DECS-100.

• Section 5: Added caution box regarding PID calculations and instruction to

allow 5 seconds after sending settings or firmware to the DECS-100.

• Section 5: Added description for Derivative Gain TD.

• Section 6: Added energizing procedure for maintaining electrolytic

• Added EAC certification.

• Added ferrite clamp recommendations for CE compliant installation.

9287500991 Rev M DECS-100 Introduction v

Page 8

This page intentionally left blank .

vi DECS-100 Introduction 9287500991 Rev M

Page 9

CONTENTS

A detailed table of contents is provided at the start of each manual section. The manual sections are

ordered as follows.

SECTION 1 • GENERAL INFORMATION ................................................................................................. 1-1

SECTION 2 • HUMAN-MACHINE INTERFACE ........................................................................................ 2-1

SECTION 3 • FUNCTIONAL DESCRIPTION ............................................................................................ 3-1

SECTION 4 • INSTALLATION ................................................................................................................... 4-1

SECTION 5 • BESTCOMS™ SOFTWARE ............................................................................................... 5-1

SECTION 6 • MAINTENANCE AND TROUBLESHOOTING .................................................................... 6-1

9287500991 Rev M DECS-100 Introduction vii

Page 10

This page intentionally left blank.

viii DECS-100 Introduction 9287500991 Rev M

Page 11

SECTION 1 • GENERAL INFO RMATION

TABLE OF CONTENTS

SECTION 1 • GENERAL INFORMATION ................................................................................................ 1-1

INTRODUCTION.................................................................................................................................... 1-1

FEATURES ............................................................................................................................................ 1-1

Model and STYLE NUMBERs ............................................................................................................... 1-1

Style Number ...................................................................................................................................... 1-1

SPECIFICATIONS ................................................................................................................................. 1-2

Operating Power ................................................................................................................................ 1-2

Generator Voltage Sensing ................................................................................................................ 1-2

Generator Current Sensing ................................................................................................................ 1-2

Bus Voltage Sensing (Optional) ......................................................................................................... 1-2

Accessory Input .................................................................................................................................. 1-3

Communication Port ........................................................................................................................... 1-3

Contact Input Circuits ......................................................................................................................... 1-3

Common Alarm Output ....................................................................................................................... 1-3

Field Output ........................................................................................................................................ 1-3

AVR Operating Mode ......................................................................................................................... 1-3

FCR (Manual) Operating Mode .......................................................................................................... 1-4

Var Operating Mode (Optional) .......................................................................................................... 1-4

PF Operating Mode (Optional) ........................................................................................................... 1-4

Parallel Compensation ....................................................................................................................... 1-4

Field Overvoltage Protection .............................................................................................................. 1-4

Generator Overvoltage Protection ..................................................................................................... 1-4

Overexcitation Limiter ......................................................................................................................... 1-5

Underexcitation Limiter ....................................................................................................................... 1-5

Soft Start Function (AVR Mode Only) ................................................................................................ 1-5

Voltage Matching ................................................................................................................................ 1-5

Metering (BESTCOMS™) .................................................................................................................. 1-5

Environment ....................................................................................................................................... 1-6

Type Tests .......................................................................................................................................... 1-6

Physical .............................................................................................................................................. 1-6

Maritime Recognition .......................................................................................................................... 1-6

EAC Mark (Eurasian Conformity) ....................................................................................................... 1-6

UL Recognized Component ............................................................................................................... 1-6

CE Compliance .................................................................................................................................. 1-6

Figures

Figure 1-1. DECS-100 Style Chart ................................

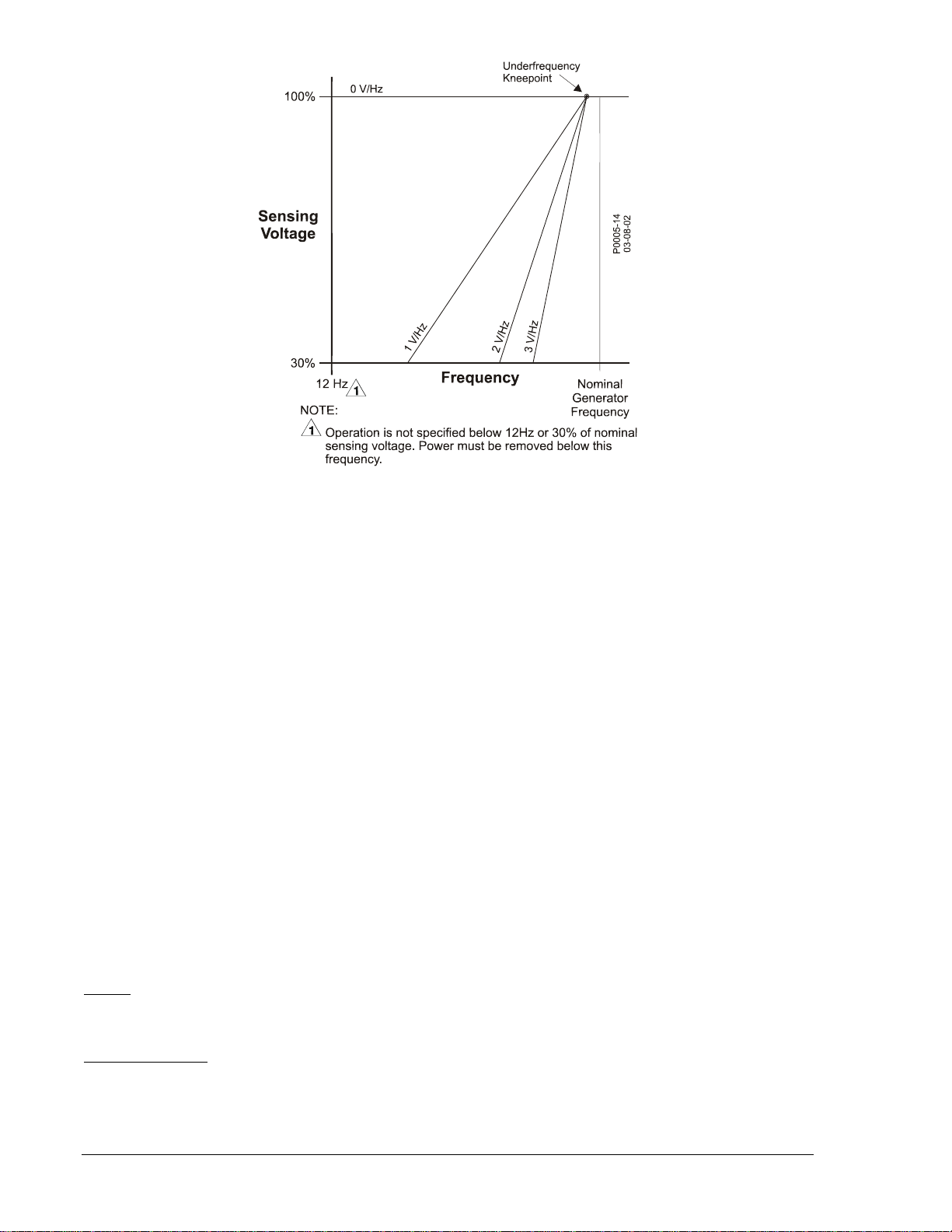

Figure 1-2. Typical V/Hz Curves ................................................................................................................ 1-4

9287500991 Rev M DECS-100 General Information i

............................................................................ 1-1

Page 12

This page intentionally left blank .

ii DECS-100 General Information 9287500991 Rev M

Page 13

SECTION 1 • GENERAL INFOR MATION

INTRODUCTION

The Basler Digital Excitation Control System (DECS-100) is an electronic, solid-state, microprocessor

based control device. The DECS-100 regulates the output voltage of a brushless, ac generator by

controlling the current int o the generator ex citer field. Input power to the DECS-100 can be from a mul tipole, high-frequency , permanent magnet ge nerator (PMG) or from t he generator outp ut when used as a

conventional, shunt-excited, excitation system.

The DECS-100 is supplied in an epoxy-potted package designed for behind-the-panel mounting. The

DECS-100 is held in place by thread-forming screws that thread into its plastic shell. Front panel

indicators (LEDs) annunc iate DEC S-100 status and system c onditions. D ECS-100 c onnections ar e made

through quarter-inch, q uick-connect terminals on the r ear panel. A 9-p in DB-9 type conn ector on the rear

panel provides communication between the DECS-100 and an IBM compatible PC.

FEATURES

DECS-100 units have the following features and capabilities:

• Four control modes: automatic voltage regulation (AVR), manual or field current regulation (FCR),

power factor (PF) regulation, and reactive power (var) regulation.

• Programmable stability settings.

• Soft start and voltage buildup control with an adjustable ramp in AVR control mode.

• Overexcitation limiting (OEL) and underexcitation limiting (UEL) in AVR, Var, and PF control modes.

• Underfrequency (volts/hertz) regulation.

• Three-phase or single-phase generator voltage (rms) sensing/regulation in AVR mode.

• Single-phase bus voltage (rms) sensing.

• Single-phase generator current sensing for metering and regulation purposes.

• Field current and field voltage sensing.

• One analog input for proportional remote control of the setpoint.

• Five contact sensing inputs for system interface.

• One common output relay for alarm indication and trip functions.

• Three protection functions: field overvoltage, generator overvoltage, and loss of sensing.

• Generator paralleling with reactive droop compensation and reactive differential compensation.

• Rear RS-232 communication port for personal computer communication using BESTCOMS™

Windows® based software for fast, user-friendly, setup and control.

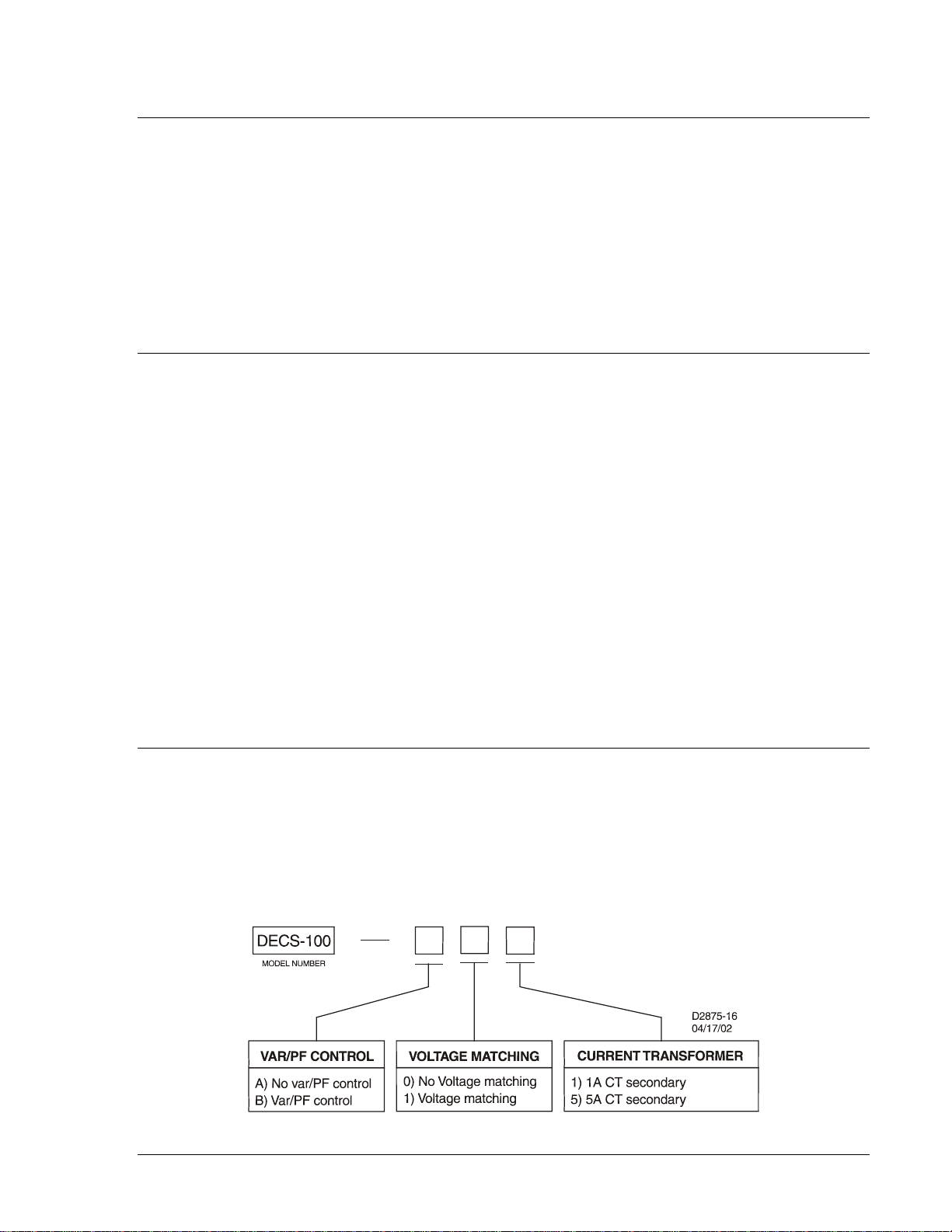

MODEL AND STYLE NUMBERS

The model number, together w ith the style number, describes the options included in a specific device,

and appear on a label affixed to the r ear panel. Upon receipt of a DEC S-100, be sur e to check the style

number against the requisition and the packing list to ensure that they agree.

Style Number

DECS-100 electrical c haracteristics and oper ational features are defi ned by a combination of let ters and

numbers that make up the style number. The DECS-100 style number chart is shown in Figure 1-1.

Figure 1-1. DECS-100 Style Chart

9287500991 Rev M DECS-100 General Information 1-1

Page 14

Style Number Example

For example, a DECS-100 with a style number of A15 would have the following characteristics and

operating features.

A ------- No var or power factor control

1 -------- Voltage matching

5 -------- 5 ampere current sensing

SPECIFICATIONS

DECS-100 specifications and qualifications are listed in the following paragraphs.

Operating Power

Refer to Section 4, Installation for special requirements concerning the application of operating power

during DECS-100 programming and the application of station power.

Voltage: 88 to 250 Vac, single-phase or three-phase (L-L)

Frequency: 50 to 400 Hz

Power Dissipation: 40 W (maximum continuous)

Burden: 650 VA

Voltage Buildup: ≥6 Vac

Terminals: 3, 4, 5

Generator Voltage Sensing

Type: 1-Phase/3-Phase, 4 ranges

Burden: <1 VA per phase

Terminals: E1, E2, E3

50 Hertz Sensing

Range 1: 100 Vac (85 to 132 Vac)

Range 2: 200 Vac (190 to 220 Vac)

Range 3: 400 Vac (380 to 440 Vac)

Range 4: N/A

60 Hertz Sensing

Range 1: 120 Vac (85 to 132 Vac)

Range 2: 240 Vac (170 to 264 Vac)

Range 3: 480 Vac (340 to 528 Vac)

Range 4: 600 Vac (540 to 660 Vac)

Generator Current Sensing

Type: 1-phase (B-phase), 50/60 Hz

Style XX1: 1 Aac maximum continuous

Style XX5: 5 Aac maximum continuous

Burden: <0.1 VA

Terminals: CT1, CT2

Bus Voltage Sensing (Optional)

Type: 1-phase, 4 ranges

Burden: <1 VA per phase

Terminals: B1, B3

50 Hertz Sensing

Range 1: 100 Vac (85 to 132 Vac)

Range 2: 200 Vac (190 to 220 Vac)

Range 3: 400 Vac (380 to 440 Vac)

Range 4: N/A

60 Hertz Sensing

Range 1: 120 Vac (85 to 132 Vac)

Range 2: 240 Vac (170 to 264 Vac)

Range 3: 480 Vac (340 to 528 Vac)

Range 4: 600 Vac (540 to 660 Vac)

1-2 DECS-100 General Information 9287500991 Rev M

Page 15

Accessory Input

Voltage Range: –3 Vdc to +3 Vdc

Setpoint Range: –30% to +30% shift

Burden: 1 kΩ

Terminals: A, B

Communication Port

Interface: Full duplex RS-232

Connection: Rear panel DB-9 connector

Baud: 4800

Data Bits: 8

Parity: None

Stop Bit: 1

Contact Input Circuits

Type: Dry contacts

Interrogation Voltage: 13 Vdc (supplied by DECS-100)

Terminal Assignments for Standard Functions

Raise: 6U, 7

Lower: 6D, 7

Var/PF Enable: 52J, 52K

Parallel Control: 52L, 52M

Voltage Matching: VM, VMC

Common Alarm Output

Type: Form A

Rated Load: 7 Aac/Adc continuous

Make: 30 Aac/Adc, carry for 0.2 sec

Break: 7 Aac/0.1 Adc

Operating Voltage: 240 Vac/250 Vdc maximum

Terminals: AL1, AL2

Field Output

Continuous Rating: 63 Vdc, 7 Adc

Field Resistance: 9 Ω minimum

Terminals: F+, F–

10 Second Forcing Rating

200 Vac Power Input: 135 Vdc, 15 Adc

110 Vac Power Input: 90 Vdc, 10 Adc (9Ω field)

75 Vdc, 15 Adc (5Ω field)

AVR Operating Mode

Adjustment Range: See Generator Voltage Sensing

Voltage Regulation: ±0.25% over load range at rated power factor and constant generator

frequency.

±0.5% with 3-phase sensing and shunt power at 40% THD of the voltage

waveform (due to a six SCR load).

Temperature Drift: ±0.5% for a 40°C change

V/Hz Characteri stic: Slope from 0 to 3PU is adjustable in 0.01PU increments. Transition

(Corner) frequency is adjustable from 40 to 65 Hz. See Figure 1-2 for the

V/Hz curves.

Response Time: Within 1 cycle

9287500991 Rev M DECS-100 General Information 1-3

Page 16

Figure 1-2. Typical V/Hz Curves

FCR (Manual) Operating Mode

Adjustment Range: 0 to 7 Adc

Increment: 0.01 Adc

Var Operating Mode (Optional)

Adjustment Range: –100 to 100%

Increment: 0.1%

PF Operating Mode (Optional)

Adjustment Range: 0.6 lag to 0.6 lead

Increment: 0.001

Parallel Compensation

Modes: Reactive Droop and Reactive Differential (cross-current)∗

Droop Adjust Range: 0 to 10%

Increment: 1%

∗ Burden can exceed 1 VA if external resistors are added to the CT circuit.

Field Overvoltage Protection

Pickup Range: 0 to 250 Vdc

Time Delay: 10 s (fixed)

Generator Overvoltage Protection

Pickup

Range: 100 to 120% of system voltage setting

Increment: 1.0%

Alarm Time Delay

Range: 0 to 10 s

Increment: 1 s

1-4 DECS-100 General Information 9287500991 Rev M

Page 17

Overexcitation Limiter

Pickup

Range: 0 to 15 Adc

Increment: 0.001 Adc

Alarm Time Delay

Range: 0 to 10 s

Increment: 1 s

Underexcitation Limiter

Pickup

Range: 0 to 100% of rated vars

Increment: 1%

Alarm Time Delay

Range: 0 to 10 s

Increment: 1 s

Soft Start Function (AVR Mode Only)

Time Adjust Range: 1 to 7,200 s

Increment: 1 s

Voltage Matching

Accuracy: Generator rms voltage is matched with the bus rms voltage to within

±0.5% of the generator voltage.

Time Adjustment

Range: 1 to 300 s

Increment: 0.01 s

Metering (BESTCOMS™)

Generator Voltage

Range: 10 V to 79 kV

Accuracy: ±0.5% (at 25°C)

Generator Current

Range: 0.04 to 3,000 Aac for 1 A CT (Not to exceed nominal CT rating)

0.2 to 15,000 Aac for5 A CT (Not to exceed nominal CT rating)

Accuracy: ±0.5% (at 25°C)

Frequency

Range: 40 to 65 Hz

Accuracy: ±0.2 Hz (at 25°C)

Field Voltage

Range: 0 to 200 Vdc

Accuracy: ±5.0% (at 25°C)

Field Current

Range: 0 to 20 A

Accuracy: ±0.5% (at 25°C)

Bus Voltage

Range: 10 V to 79 kV

Accuracy: ±0.5% (at 25°C)

Auxiliary DC Input

Range: –3 V to +3 V

Accuracy: ±0.5% (at 25°C)

9287500991 Rev M DECS-100 General Information 1-5

Page 18

Power (Apparent, Real, and Reactive)

Range: 0 to 99 MVA, MW, Mvar

Accuracy: ±3.0% (at 25°C)

Power Factor

Range: –1.0 to –0.6, +0.6 to +1.0

Accuracy: ±0.02 at rated current (25°C), CT input ≥10% nominal rating

Phase Angle

Range: 0 to 360 degrees

Accuracy: ±2.0 degrees (at 25°C), CT input ≥10% nominal rating

Environment

Operating Temperature

DECS-100: –40 to 70°C (–40 to 158°F)

Storage Temperature

DECS-100: –40 to 85°C (–40 to 185°F)

CD-ROM: 0 to 50°C (32 to 122°F)

Type Tests

Shock: Withstands 20 G in three perpendicular planes

Vibration: Withstands 1.2 G at 5 to 26 Hz

Withstands 0.914 mm (0.036 in) double amplitude at 27 to 52 Hz

Withstands 5 G at 53 to 500 Hz

Salt Fog: Qualified per MIL-STD-810E

Physical

Weight

Unit: 1.10 kg (2.42 lb)

Shipping: 1.31 kg (2.88 lb)

Shipping Carton Dimensions (W x H x D)

Single Unit: 299 x 79 x 146 mm (11.75 x 3.125 x 5.75 in)

48 Units: 841 x 653 x 352 mm (33.13 x 25.69 x 13.88 in)

Maritime Recognition

Recognized per standard IACS UR (sections E10 and E22) by the following:

• Bureau Veritas (BV) – BV Rules Pt. C, Ch. 3

• Det Norske Veritas (DNV) – No. 2.4

• Germanischer Lloyd (GL) – VI-7-2

IEC 60092-504 is the base standard for IACS UR sec tion E10. I ACS UR is the ba se standar d for the B V,

DNV, and GL rules listed above.

Additional conditions must be met in order to comply with maritime agency standards, see Section 4,

Installation for further instructions.

EAC Mark (Eurasian Conformity)

• TP TC 004/2011

• TP TC 020/2011

UL Recognized Component

The DECS-100 is recognized to applicable Canadian and US safety standards and requirements by UL.

Standards used for evaluation: UL6200

CE Compliance

LVD 2006/95/EC

BS EN 50178 – Electronic Equipment for use in Power Installations

EMC 2004/108/IEC

IEC 61000-6-2 – Electromagnetic Compatibility (EMC) Immunity for Industrial Environments

IEC 61000-6-4 – Electromagnetic Compatibility (EMC) Emissions Standard for Industrial Environments

1-6 DECS-100 General Information 9287500991 Rev M

Page 19

SECTION 2 • HUMAN-MACHINE INTERFACE

TABLE OF CONTENTS

SECTION 2 • HUMAN-M ACHINE INTERF ACE ....................................................................................... 2-1

INTRODUCTION.................................................................................................................................... 2-1

FRONT PANEL INDICATORS ............................................................................................................... 2-1

Overexcitation Shutdown ................................................................................................................... 2-1

Generator Overvoltage ....................................................................................................................... 2-1

Loss of Generator Sensing ................................................................................................................. 2-1

Overexcitation Limiting ....................................................................................................................... 2-2

Underexcitation Limiting ..................................................................................................................... 2-2

Var/P.F. Mode Active ......................................................................................................................... 2-2

Manual Mode Active ........................................................................................................................... 2-2

Underfrequency Active ....................................................................................................................... 2-2

COMMUNICATION PORT ..................................................................................................................... 2-2

Figures

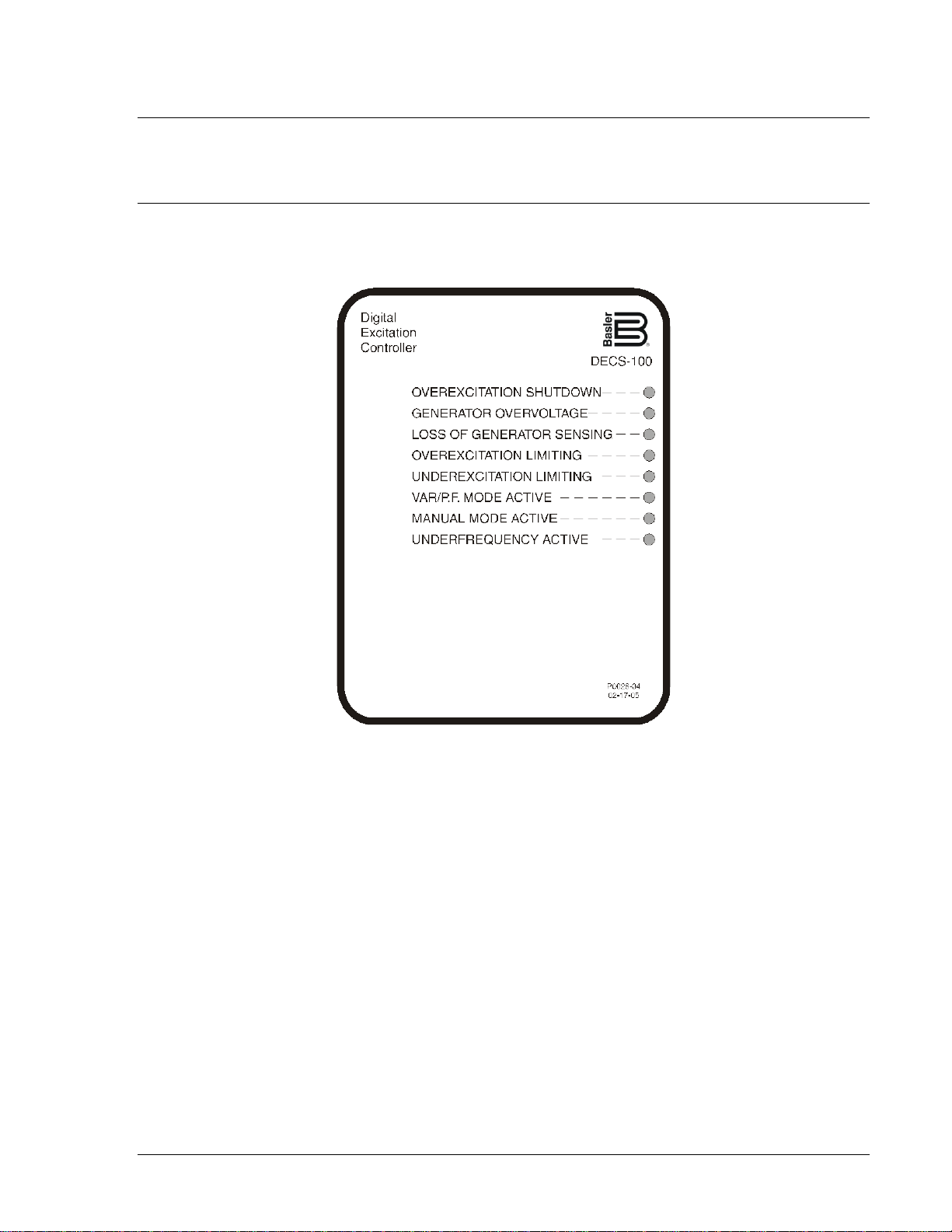

Figure 2-1. DECS-100 Front Panel Indicators ........................................................................................... 2-1

Figure 2-2. DECS-100 Communication Port Location ............................................................................... 2-2

9287500991 Rev M DECS-100 Human-Machine Interface i

Page 20

This page intentionally left blank .

ii DECS-100 Human-Machine Interface 9287500991 Rev M

Page 21

SECTION 2 • HUMAN-MACHINE INTERFACE

INTRODUCTION

The DECS-100 human-machine interface (HMI) consists of front panel indicators and a rear-panel

communication port.

FRONT PANEL INDICATORS

DECS-100 front pane l indicators consist of eight r ed LEDs. The indicators are s hown in Figure 2-1 and

described in the following paragrap hs .

Figure 2-1. DECS-100 Front Panel Indicators

Overexcitation Shutdown

This LED lights when the Over excitation Protection feature is en abled and the field voltage exceeds the

adjustable setpoint for 10 seconds. The DECS-100 will shutdown when an overexcitation condition is

detected. The Overex citation Shutdown L ED will light for 5 seconds when the D ECS-100 is powere d up

following an overexcitation shutdown.

Generator Overvoltage

This LED lights when gen er ator out put vo ltage exc eeds the adjusta ble se tpoint f or 0.75 secon ds. Wh en a

generator overvoltage condition exists, the DECS-100 output contacts close and the DECS-100 shuts

down (if hardware shut down is enabled). The G enerator Overvoltage LED wil l light for 5 seconds when

the DECS-100 is powered up following a generator overvoltage shutdown.

Loss of Generator Sensing

This LED lights when a los s of generator sensing voltage is det ected. When a loss of s ensing condition

occurs, the DECS-100 out put contacts close. D epe nd i ng o n the protective actio n s elected , t h e D ECS -100

will either shutdown or transfer to Manual mode. The Loss of Generator Sensing LED will flash for 5

seconds when the DECS-100 is powered up following a loss of generator sensing shutdown.

9287500991 Rev M DECS-100 Human-Machine Interface 2-1

Page 22

Overexcitation Limiting

This LED lights when the field cur rent exceeds the programmed overexcit ation limit. It stays lit until the

overexcitation condit ion ceases or the overexcitation t ime delay expires and the DEC S-100 shuts down.

The Overexcitation Limit ing LED will flash for 5 seconds when the D ECS-100 is power ed up following an

overexcitation limiting shutdown.

Underexcitation Limiting

This LED lights when the sensed, reactive power (leading vars) decreases below the programmed

underexcitation limit. It stays lit until the underexcitation condition ceases or the underexcitation time

delay expires and th e DECS-100 shuts down. The Underexc itation Limiting LED will flash for 5 s econds

when the DECS-100 is powered up following an underexcitation limiting shutdown.

Var/P.F. Mode Active

This LED lights to ind icate that the DECS-100 is op erating in the optiona l Var or Power Factor mo de of

control. Var/Power Fact or c ontrol is ena bl ed thro ugh B ESTC O MS ™ software and when t he 52J / K contact

input is open.

Manual Mode Active

This LED lights when the DECS-100 is operating in Manual mode. Manual mode is enabled through

BESTCOMS software.

Underfrequency Active

This LED lights when the generator frequency decreases below the underfrequency setpoint and the

DECS-100 is regulating on the selected volts per hertz curve.

COMMUNICATION PORT

The communication port is located on the rear panel and

consists of a female, RS-232 (DB-9) connector. The

communication port serves as an interface for progra mming

(setup) of the DECS-10 0. Figure 2-2 illustrates the loc ation of

the communication port.

Programming requires a standard, nine-pin, serial

communication cable c onnected between th e DECS-100 and

an IBM-compatible PC operating wit h BESTCOMS software.

BESTCOMS software is a Microsoft Windows®-based

communication software package that is supplied with the

DECS-100. A detai led descriptio n of BESTCO MS is prov ided

in Section 5, BESTCOMS Software.

WARNING!

Lethal voltage is present at the rear panel when the unit is

energized. Rear pa nel connections should be made only

when the unit is de-energized.

Figure 2-2. DECS-100

Communication Port Location

2-2 DECS-100 Human-Machine Interface 9287500991 Rev M

Page 23

SECTION 3 • FUNCTIONAL DESCRIPTION

TABLE OF CONTENTS

SECTION 3 • FUNCTIONAL DESCRIPTION ........................................................................................... 3-1

INTRODUCTION.................................................................................................................................... 3-1

DECS-100 FUNCTION BLOCKS ........................................................................................................... 3-1

Analog Input Circuits .......................................................................................................................... 3-1

Bus Voltage..................................................................................................................................... 3-1

Generator Voltage .......................................................................................................................... 3-1

B-Phase Line Current ..................................................................................................................... 3-2

Accessory Input (Auxiliary Adjust) .................................................................................................. 3-2

Field Voltage ................................................................................................................................... 3-2

Field Current ................................................................................................................................... 3-2

Contact Input Circuits ......................................................................................................................... 3-2

Raise ............................................................................................................................................... 3-2

Lower .............................................................................................................................................. 3-2

Var/Power Factor Control (52J/K) Option ....................................................................................... 3-2

Parallel Generator Compensation (52L/M) ..................................................................................... 3-2

Voltage Matching Control Option .................................................................................................... 3-3

RS-232 Communication Port.............................................................................................................. 3-3

Microprocessor ................................................................................................................................... 3-3

Power Input Stage .............................................................................................................................. 3-3

Power Supply ..................................................................................................................................... 3-3

Power Amplifier Stage ........................................................................................................................ 3-3

Front Panel Indicators ........................................................................................................................ 3-3

Relay Output....................................................................................................................................... 3-3

DECS-100 OPERATING FEATURES ................................................................................................... 3-3

Operating Modes ................................................................................................................................ 3-3

Automatic Voltage Regulation Mode .............................................................................................. 3-3

Manual Mode .................................................................................................................................. 3-4

Var Control Mode (Optional) ........................................................................................................... 3-4

Power Factor Control Mode (Optional) ........................................................................................... 3-4

Reactive Droop Compensation .......................................................................................................... 3-4

Underfrequency .................................................................................................................................. 3-4

Protection ........................................................................................................................................... 3-4

Generator Overvoltage ................................................................................................................... 3-5

Loss of Sensing Voltage ................................................................................................................. 3-5

Field Overvoltage (Overexcitation Shutdown) ................................................................................ 3-5

Limiters ............................................................................................................................................... 3-6

Overexcitation Limiting ................................................................................................................... 3-6

Underexcitation Limiting ................................................................................................................. 3-6

Soft Start ............................................................................................................................................. 3-7

Voltage Matching (Optional) ............................................................................................................... 3-7

Figures

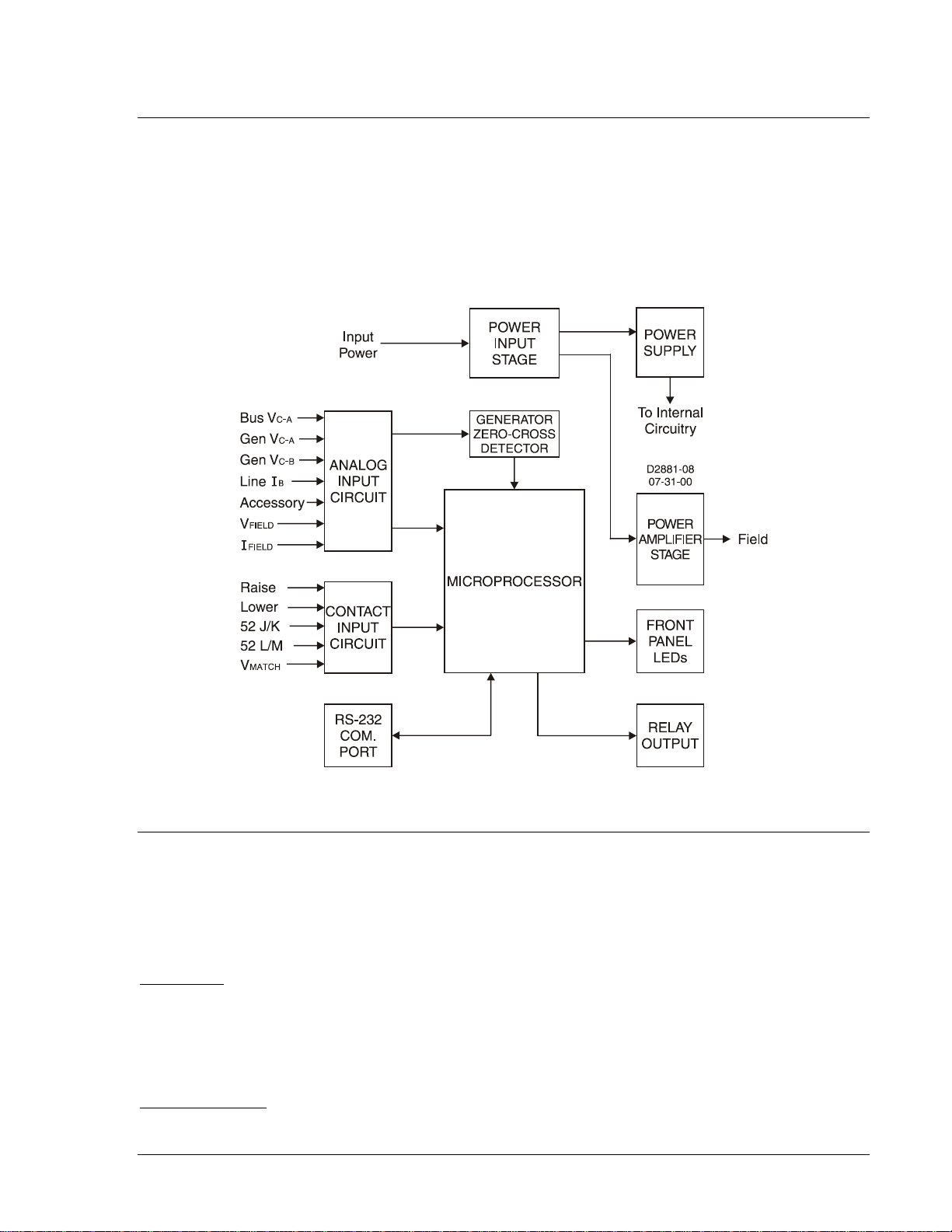

Figure 3-1. Simplified DECS-100 Block Diagram ...................................................................................... 3-1

Figure 3-2. Time Characteristic Curve for Takeover OEL ......................................................................... 3-6

9287500991 Rev M DECS-100 Functional Description i

Page 24

This page intentionally left blank .

ii DECS-100 Functional Description 9287500991 Rev M

Page 25

SECTION 3 • FUNCTIONAL DESC RIPTION

INTRODUCTION

This section describes how the DECS-100 functions and explains its operating features. To ease

understanding, DECS-100 functions are illustrated in the block diagram of Figure 3-1. A detailed

description of each function bl oc k is prov i ded i n t he paragraphs under th e hea din g of DECS-100 Func tio n

Blocks.

DECS-100 operating f eatures include four operating modes, four protect ive functions, st artup provisions,

reactive droop comp ensation, underfrequency c ompensation, and optiona l voltage matching. A detaile d

description of each operating feature is provided in the paragraphs under the heading of DECS-100

Operating Features.

Figure 3-1. Simplified DEC S-100 Block Diagram

DECS-100 FUNCTION BLOCKS

The following paragrap hs describe each of the function block s illustrated in Figure 3-1. The func tion of

each block is explained along with the operation of all function block inputs and outputs.

Analog Input Circuits

Seven analog voltages and current may be sensed and applied to the DECS-100.

Bus Voltage

C-phase and A-phase bus voltages are monitored at terminals B3 an d B1 on units that include voltage

matching. Nominal volta ge s of up to 600 Vac may be s ens ed at thes e t ermi na ls . Vol tag e mon itore d at t h is

input is scaled and conditioned bef ore being applied t o the input of the analog-to-digital converter (ADC) .

This bus voltage signal ap plied to the ADC is used to calcula te the rms value of the bus voltag e across

phases C and A (Bus V

Generator Voltage

Generator voltage is monitored at terminals E1 (A-phase), E2 (B-phase), and E3 (C-phase). Nominal

voltages of up to 600 Vac may be sensed at these terminals. Volt age applied to these inputs is scaled

9287500991 Rev M DECS-100 Functional Description 3-1

C-A

).

Page 26

and conditioned befor e being applied to the input of the A DC. The voltage signal from phas e C and A

(VC-A) of the generator is used by the ADC to calculate the rms value of generator voltage across phases

C and A. Likewise, the voltage signal from p hase C and B (V

) of the generator is used by the ADC t o

C-B

calculate the rms v al ue of g ener at or v olt age ac r oss p h as es C a nd B. T he rms v a l ue o f g enerator phase B

to phase A voltage (V

the phase C to phase B (V

) is calculated by the micr o proc es sor fr om the ph as e C to phas e A si gna l ( V

B-A

) signal.

C-B

Additionally, the generator phas e C to phase A (V

) signal is applied t o a filtered, zero-cross detector

C-A

C-A

)and

circuit. This signal is applied to the microprocessor and is used to calculate generator frequency.

B-Phase Line Current

The phase B line curr ent (IB) signal is d eveloped through a cus tomer supplied current tr ansformer (CT)

and monitored through terminals CT1 and CT2. Depending on the option selected, current up to 1 ampere

(style number xx1) or 5 amperes (style number xx5) rms may be monitored at these terminals. The

current monitored at these terminals is scaled and conditioned by an internal current transformer and

active circuitry for us e by the ADC. The s ignal applied to the A DC is used to calcula te the rms value of

phase B line current.

Additionally, the phas e angle between phase B line current and ph ase C to phase A gener ator voltage is

calculated for use during droop and var/power factor operation.

Accessory Input (Auxiliary Adjust)

This input allows adjustment of the DECS-100 regulation setpoint by the application of a positive or

negative dc voltage across terminals A and B. Positive voltage applied to terminal A with respect to

terminal B will cause th e active mode setpoint to increase. Volt age from –3 to +3 Vdc m ay be applied to

this input. The circ uit induces a 1,000-oh m burden on the dc sour ce. The Application of a ±3 Vdc signa l

corresponds to a ±30 perc e nt chan ge in setpoint.

Field Voltage

Voltage (V

) across the regulator field output terminals, F+ and F–, is monitored, scaled, and

FIELD

conditioned before b eing applied to the ADC. This signal is used to c alculate t he dc valu e of fiel d voltage

for use in system protection.

Field Current

Current (I

) through the main power output switch is converted to a proportional voltage level. This

FIELD

voltage signal is scaled an d conditioned before being applied to the inp ut of the ADC. The resu lt is used

to calculate the dc value of field cur rent for use in the Manual mode of o peration as well as protecti on of

the system.

Contact Input Circuits

Five contact input c ircuits p owered fr om an intern al 13 Vdc po wer supp ly provide input contr ol from us ersupplied, isolated, dry-type contacts.

Raise

Closing a contact across terminals 6U and 7 causes the active operating setpoint to increase. This

function is active as long as the contact is closed.

Lower

Closing a contact across terminals 6D and 7 causes the active operating setpoint to decrease. This

function is active as long as the contact is closed.

Var/Power Factor Control (52J/K) Option

Closing a contact across terminals 52J and 52K disables var/power factor control. An open contact

enables the DECS-100 to c ontrol the g enerat or reac tive pow er in ei ther th e var or t he power fac tor mo de.

The contact has no effect when this function is not enabled in th e software. For more information, see

Parallel Generator Compensation (52L/M) and Voltage Matching Control Option.

Parallel Generator Compensation (52L/M)

Closing a contact across terminals 52L and 52M disables parallel operation. An open contact enables

parallel operation and the DECS-100 operates in reactive droop compensation mode.

3-2 DECS-100 Functional Description 9287500991 Rev M

Page 27

If the Var/Power Factor Control option is present and is enabled in the software, the 52J/K input has

priority. Therefore, if the 5 2J/K and the 52L/M inputs are both open, the system operat es in var/power

factor mode. For more information, see Voltage Matching Control Option.

Voltage Matching Control Option

If the Voltage Matching option is enabled in the s oft w ar e, c los ing a c o ntac t ac ros s ter minals VM a nd VMC

causes the DECS-100 to operate in the voltage matching mode. An open contact disables voltage

matching. Voltage matching is also disabled when either the 52J/K or 52L/M inputs are open.

RS-232 Communication Port

The communication port provides the interface for user programming (setup) of the DECS-100.

Connection is made to the female RS-232 (DB-9) connector wi th a user-supplied, standard 9-pin cable.

The communication port is optically isolated and is powered from a transformer-isolated supply.

Microprocessor

The microprocessor is the heart of the DECS-10 0 and performs measurement, c omputation, cont rol, and

communication funct ions by the use of its embedded program ming and the nonv olatile settings st ored in

its memory.

Power Input Stage

Input power applied to terminals 3, 4, and 5 is rectified and filtered before being app lied to the power

amplifier and the power supply. Input power may be single-phase or three-phase in the range of 88 to 250

Vac at a frequency of 50 to 400 hertz.

The input power source should be properly fused for the application.

Power Supply

The internal switch-mod e p ower supp ly rec eives p ower from the power input sta ge and s upp lies pow er at

the required dc voltage levels to the internal circuitry of the DECS-100.

Power Amplifier Stage

The power amplifier receives power from the power input stage and supplies a controlled amount of

power to the exciter f ield via terminals F+ and F –. The amount of power sup plied to the exciter field is

based on gating pulses r eceived from the m icroprocessor. The pow er amplifier us es a solid state power

switch to provide the r equired power t o the exciter f ield. Power amplifier output to the field is rated up to

63 Vdc at 7 Adc continuous and 135 Vdc at 15 Adc for 10 seconds.

Front Panel Indicators

Eight front-panel LED indicators light to indicate various protective functions and operating modes.

Section 2, Human-Machine Interface provides more information about the front panel indicators.

Relay Output

A common alarm out put contact is provided through terminals AL 1 and AL2. Thi s normally open, form A

contact annunciates alarm or trip conditions. The relay output is latching.

DECS-100 OPERATING FEATURES

The following paragraphs describe the characteristics of each DECS-100 operating feature.

Operating Modes

The DECS-100 provides up to four modes of operation selectable through BESTCOMS™ software.

Automatic voltage regulation mode and Manual mode are standard features. Var and Power Factor

modes are an option.

Automatic Voltage Regulation Mode

In Automatic Voltage Regulation (AVR) mode, the DECS-100 regulates rms generator output voltage.

This is accomplish ed by sensing generator output v oltage and adjusting dc output excitation current to

maintain voltage at the reg ulation setpoint. The regulation setpoint is adjusted by the Raise and Lower

9287500991 Rev M DECS-100 Functional Description 3-3

Page 28

contact inputs, the Accessory input, or t hrough BESTCOMS so ftware. The regulation p oint may also be

modified by the Droop function or the Underfrequency function under certain conditions.

Manual Mode

In Manual mode, also known as Field Current Regulation (FCR) mode, the DECS-100 maintains dc

excitation current at a set level. The current-level setpoint is adjustable from 0 to 7 Adc in 0.01 Adc

increments by the Raise and Lower contact inputs, the Accessory input, or through BESTCOMS software.

CAUTION

The Manual mode excitation level must be evaluated prior to enabling this

feature. If the level of excit ation current is inappr opriat e for the gener ator, sev ere

damage to the generator may occur.

Var Control Mode (Optional)

In Var Control mode, the DECS-1 00 ma int ains generator vars (v olt-am per es , r eac tiv e) at a set level wh en

paralleling with an infinite bus. The DEC S-100 calculates gener ator vars by using t he sensed generator

output voltage and current quantities. It then adjusts the dc excitation current to maintain vars at the

setpoint. Var control is ena bled and dis abled throu gh BESTC OMS softw are. Wh en the softw are is tur ned

on, var control is enabled or disa bled through t he Var/Power Factor Control (5 2J/K) contact input circuit.

The var setpoint is adjustable from 1 00 percent absorb to 100 percent generat e through the Raise and

Lower contact inputs, the Accessory input, or through BESTCOMS software.

Power Factor Control Mode (Optional)

In Power Factor Control mode, the DECS-100 maintains generator power factor at a set level when

paralleling with an infinite bus. The DECS-100 calculates generator power factor using the sensed

generator output voltage and current quantities and then adjusts the dc excitation current to maintain

power factor at the setpoint. Power factor c ontrol is enabled or disabled through BESTCO MS software.

When the software is turn ed on, it is enabled or disab led through the Var/Power Factor Control (52J/K)

contact input circuit. The power factor setpoint is adjus table between 0.6 lag and 0.6 lead throu gh the

Raise and Lower contact inputs, the Accessory input, or through BESTCOMS software.

Reactive Droop Compensation

The DECS-100 provides a r eactive droop compensation feature to as sist in the sharing of reactive load

during parallel generat or operation. When th is feature is enabled, the DECS-100 calculates the reactive

portion of the generator load using the sensed gener ator output voltage and current quantities and then

modifies the voltage re gulation setpoint accordingly . A uni ty power factor gener ator load resu lts in almost

no change in generator output voltage. A lagging power factor generator load (inductive) results in a

reduction of generator output voltage. A leading power factor generator load (capacitive) results in an

increase of generator outp ut voltage. Droop is adjustable up to 10 percent with rated, nominal B-phase

line current (1 amp ere or 5 amperes applied throug h terminals CT1 a nd CT2) and 0. 8 power factor. The

droop feature is enable d and disabled thr ough the Paralle l Generator Com pensation contact input circuit

(terminals 52L and 52M). Droop is also disabled when operating in var or power factor control modes.

Underfrequency

When generator frequency drops below the selected knee frequency setpoint, the voltage setpoint is

automatically adjusted by t he DECS-100 so that gene rator v oltag e fo llow s t he sel ec ted PU ( p er uni t) V/Hz

curve. When operating on the s elected PU V/Hz curve, the Underf requency Active ind icator lights on the

front panel and in BESTCOMS. Under freq uenc y control is disabled below 12 hertz. The knee frequency is

adjustable from 40 to 65 hertz in 0.1 hertz increments and the PU V/Hz curv e may be set at a s lope of 0

to 3 in 0.01 steps through BESTCOMS software. A slope of 0 eff ectively disables the underfrequency

function. The DECS-100 has a minimum regulation point of approximately 30 percent of the nominal

setpoint.

Protection

The DECS-100 includes three protective functions: gener ator overvoltage, loss of sensi ng voltage, and

field overvoltage. Eac h protective function h as a corresponding fr ont panel indicat or that lights when the

function is active. An active protective function is also annunciated through BESTCOMS.

3-4 DECS-100 Functional Description 9287500991 Rev M

Page 29

Generator Overvoltage

A generator overvoltage condition can be configured (in BESTCOMS) to close the DECS-100 relay

output, disable the D ECS-100, init iate both actio ns, or initiat e neither act ion. When the se nsed generator

voltage increases above th e adjustab le vo ltage lev el s etpoint f or the dur ation of the ad justa ble alar m time

delay, the DECS-100 initiates the selected action.

If the DECS-100 is configured to c lose the relay output, a generator overvol tage condition will light the

front panel and BESTC OMS Gen erator Over voltage in dicator and c lose the r elay output at ter minals A L1

and AL2.

If the DECS-100 is config ured for hardware shutd own, a generator overvolt age condition will disab le the

DECS-100 after the alarm time delay expires. When t he DECS-100 is powered up fol lowing a generator

overvoltage shutdown, the Generator Overvoltage indicator will light for five seconds.

The voltage level setpoint i s adjustable from 10 0 to 120 % of the system v oltage setting. The alarm t ime

delay is adjustable from 0 to 10 seconds.

Loss of Sensing Voltage

The DECS-100 monitors the sensed generator output voltage and takes protective action if a loss of

sensing voltage is detected. A loss of sensing voltage is detected during the following conditions.

• The sensed voltage is less than 50 percent of the rated voltage (one-phase or three-phase sensing).

• A total loss of any phase occurs (three-phase sensing).

• The voltage difference between any phase (line-to-line) and the three-phase average exceeds 20

percent of nominal (three-phase sensing).

A time delay of 0 to 25 se conds is adjustable through B ESTCOMS software. This delays the protectiv e

action in order to allow field forcing in applications that do not sense B-phase generator current. The

default time delay setting is 10 seconds.

BESTCOMS software al lows the selection of one o f two protective ac tions for a loss of sens ing. Either a

complete shutdown or a transfer to Manual mode may be selected.

If shutdown is selec t ed and a los s of sensing occurs , t he Loss of Generator Sens i ng ind ic ator on t he fro nt

panel and in BESTCOMS lights, the relay output closes, and the DECS-100 shuts down after the

adjustable time delay ex pires. When the DECS-100 is powered up follow ing a loss of genera tor sensing

shutdown, the Loss of Generator Sensing indicator will light for five seconds. However, if the loss of

sensing conditions st ill exists, the DECS-100 will n ot shut down due to loss of sensing until the soft -start

time delay and the loss of sensing time delay expires.

If transfer to Manu al is s ele cted a nd a loss of sens ing occ urs, the r elay out put clo ses , and th e DEC S-100

transfers to the Manual mode of operation after the adjustable time delay expires. The DECS-100 will

remain in this mode of oper ation until switched via BE STCOMS. Prior to selectin g transfer to Manual on

loss of sensing, it is necessary to determine an appropriate Manual (FCR) mode setpoint level to be

transferred to. An inappropriate excitation level could result in severe damage to equipment.

This function is disabled when the fr equency decreas es below 12 hertz or when a generat or short circuit

condition is detected. A generator short-circuit is determined wh en the B-phase CT current ex ceeds thr ee

times the per unit value. Loss of sensing shutdown or transfer is not active during the soft-start time.

Field Overvoltage (Overexcitation Shutdown)

A field overvoltage condition can be configured (in BESTCOMS) to close the DECS-100 relay output,

disable the DECS-1 00, initiate both actions, or initiat e neither action. When the field voltage increases

above the adjustable vo ltage level setpoint for the fixed dur ation of 10 seconds, the DECS-100 initiates

the selected action.

If the DECS-100 is configu red to close the relay output, a field overv oltage condition will light the front

panel and BESTCOMS Ov erexcitation Shutdown indicator and close the relay output at terminals AL1

and AL2.

If the DECS-100 is configured for hardware shutdown, a field overvoltage condition will disable the DECS100 after the 10 second time delay expires. When the DECS-100 is powered up following a field

overvoltage shutdown, the Overexcitation Shutdown indicator will light for five seconds.

The voltage level setp oint is adjustabl e from 0 to 250 Vdc . The field ov ervoltage time de lay is fixed a t 10

seconds.

9287500991 Rev M DECS-100 Functional Description 3-5

Page 30

Limiters

3level var rated ××=

BAVG

IV

DECS-100 limiters c onsist of an overexcit ation limiter (OEL) triggered by an increas e in field current and

an underexcitation limiter (UEL) triggered by excessive leading vars.

Overexcitation Limiting

The DECS-100 provides two types of overexcitation limiting: summing point and takeover.

Summing Point OEL. When the level of field cur rent increases above the ad justab l e c urr ent lev e l setpo int,

the front panel and BESTCOMS Overexcitation Limiting indicators light. If the overexcitation condition

persists for the dur ation of the user-adjustable alar m time delay, the relay output at terminals AL1 and

AL2 closes.

The advantage of a summi ng-point type of OEL is tha t it can provide a smooth trans ition into and out of

the limit. Its drawbac k is that it does not c ontrol field cur rent directly, but has to work throug h the normal

voltage regulator, and may be influenced by changes in terminal voltage.

Takeover OEL. When takeover-style overexcitation limiting is used, the level of field current at which

limiting occurs is de termined by an adjustab le current level set point. If the field cur rent increases above

the adjustable curr ent level setpoint, the front p anel and BESTCOMS Overex citation Limiting indicators

light and the field current is limited and forced to follow the characteristic time curve. See Figure 3-2.

The advantage of a takeover type of OEL is that it provides direct control of the exciter field current

without relying on the normal voltage regu lator’s control act ion. Its drawback is that it may not provide a

smooth transition into and out of the limit.

If hardware shutdown is enabled, the D ECS-100 will be disab led when the time delay expires. W hen the

DECS-100 is powered up following a shutdown triggered by overexcitation limiting, the Overexcitation

Limiting indicator will light for five seconds.

The current level s etpoint i s adjustab le from 0 to 15 Adc. The alarm tim e delay is adjus table from 0 to 10

seconds.

Figure 3-2. Time Characteristic Curve for Takeover OEL

Underexcitation Limiting

When the level of leading vars increases above the adjustable var level setpoint, the front panel and

BESTCOMS Underexcitation Limiting indicators light. If the underexcitation condition persists for the

duration of the adjustable alarm time delay, the relay output at terminals AL1 and AL2 closes.

If hardware shutdown is enabled, t he DECS-100 will be disab led when the time delay expires . When the

DECS-100 is powered up foll owing a shutdown triggered by underexcitation limiting, th e Underexcitation

Limiting indicator will light for five seconds.

The var level setpoint is adj ustable fr om 0 to 100% of the rate d var s. The r ated va r level is det ermined by

the following equation:

Where IB is the DECS-100 nominal current sensing rating (1 Aac or 5 Aac)

3-6 DECS-100 Functional Description 9287500991 Rev M

Page 31

The alarm time delay is adjustable from 0 to 10 seconds.

NOTE

The UEL function is active only during parallel operation when the 52J/K

contact input or 52L/M contact input is open.

Soft Start

The DECS-100 also incorporates an adjustable soft start feature that controls the time for generator

voltage or field current to r amp to the regulation setpoint. The ra mp rate is adjustable from 1 to 7,200

seconds in 1 second increments through BESTCOMS. The under frequency feature is also active dur ing

soft start and takes priority in control of the generator voltage in an effort to minimize voltage overshoot.

Voltage Matching (Optional)

Voltage matching is useful when the PT ratios in an application are not matched exactly. Using

BESTCOMS to enter the gener ator PT ratio and bus PT ratio will automat ical ly compe nsate for t he offset .

The DECS-100 voltage matc hing optio n automat ically matches the r ms gen erator output with the r ms bus

voltage prior to synchr onizing. The D ECS-100 co mpares and ma tches the g enera tor voltage wit h the bus

voltage by adjusting th e dc excitat ion current. Voltage match ing is enabled when the bus voltage input is

within 10% of the n ominal generator secondary input sensing range selected . As long as the values o f

generator and bus voltage (applies secondary voltage to the D ECS-1 00 v ol tag e s ensing inp uts ) ar e with in

the acceptable range, voltage matching can be achieved.

The rate at which the DECS-100 matches the generator input level with the bus input level is controlled by

a voltage matching speed setting. this setting is adjustable from 1 to 300 seconds in 0.01 second

increments.

Voltage matching can be disabled by the state of the DECS-100 contact inputs. In BESTCOMS, the

52J/K contact input, 52L/ M contact input, or bo th contact inputs can be c onfigured to enabl e and disable

voltage matching. To enab le bus voltage matching, select 5 2J/K. This will allow droop to re main active.

When the utility tie break er closes, voltag e matching wil l be disabled aut omatically (via th e 52J/K contact

input) and var/power factor control will be enabled.

Two voltage matching modes are available: Maintain and Revert. When Maintai n mode is implemented,

the DECS-100 setpoint is maint a ined at t he b us volta ge l ev el eve n w h en th e ge n er ator or ut il ity br eak er is

open. When Revert mode is implemented, the DECS-100 setpoint rever ts to its original level when the

generator or utility breaker opens. Revert is the default voltage matching mode.

9287500991 Rev M DECS-100 Functional Description 3-7

Page 32

This page intentionally left blank .

3-8 DECS-100 Functional Description 9287500991 Rev M

Page 33

SECTION 4 • INSTALLATION

TABLE OF CONTENTS

SECTION 4 INSTALLATION ..................................................................................................................... 4-1

INTRODUCTION.................................................................................................................................... 4-1

MOUNTING ............................................................................................................................................ 4-1

CONNECTIONS..................................................................................................................................... 4-4

DECS-100 Terminations .................................................................................................................... 4-4

Bus Voltage Sensing Inputs (Optional) .............................................................................................. 4-5

Generator Voltage Sensing Inputs ..................................................................................................... 4-5

Phase B Line Current Sensing Input .................................................................................................. 4-5

Accessory Input .................................................................................................................................. 4-5

Raise and Lower Contact Inputs ........................................................................................................ 4-5

Var/Power Factor Control Contact Input (Optional) ........................................................................... 4-5

Parallel Generator Com pen s ation ...................................................................................................... 4-6

Parallel Control and Var/PF Control Inputs ........................................................................................ 4-6

Voltage Matching (Optional) ............................................................................................................... 4-6

Power Supply Inputs .......................................................................................................................... 4-6

Chassis Ground .................................................................................................................................. 4-6

Power (Field) Output .......................................................................................................................... 4-6

Relay Output (Alarm) .......................................................................................................................... 4-7

Communication Port ........................................................................................................................... 4-7

DECS-100 Connections for Typical Applications ............................................................................... 4-7

INSTALLATION FOR CE COMPLIANCE ............................................................................................ 4-13

Mounting ........................................................................................................................................... 4-13

Wiring ............................................................................................................................................... 4-13

Installation for EMC Compliance.......................................................................................................... 4-14

Protection ......................................................................................................................................... 4-14

Mounting ........................................................................................................................................... 4-14

Wiring ............................................................................................................................................... 4-14

Ferrite Beads .................................................................................................................................... 4-14

PRELIMINARY SET U P ........................................................................................................................ 4-15

Operating Power Considerations During DECS-100 Programming................................................. 4-15

ADJUSTMENTS................................................................................................................................... 4-16

Figures

Figure 4-1. DECS-100 Dimensions ........................................................................................................... 4-2

Figure 4-2. Cutout and Drilling Dimensions ............................................................................................... 4-3

Figure 4-3. DECS-100 Terminals .............................................................................................................. 4-4

Figure 4-4. RS-232 Port Pin Assignments ................................................................................................ 4-7

Figure 4-5. Personal Computer to DECS-100 Connections ...................................................................... 4-7

Figure 4-6. Typical Connections for PMG Application with ABC Rotation and Three-Phase Sensing ..... 4-8

Figure 4-7. Typical Connections for PMG Application with ABC Rotation and Single-Phase Se ns ing .... 4-9

Figure 4-8. Typical Connections for Shunt Application with ABC Rotation and Three-Phase Sensing .. 4-10

Figure 4-9. Typical Connections for Shunt Application with ABC Rotation and Single-Phase Sensing . 4-11

Figure 4-10. Typical Connections for Station Power Application and Three-Phase Sensing ................. 4-12

Figure 4-11. Cross-Current (Reactive Differential) Connections ............................................................. 4-13

Figure 4-12. Operating Power Connections for DECS-100 Programming (Inpu t Voltage >1 20 Vac ) ..... 4-16

Tables

Table 4-1. Bus Voltage Sensing Terminals ............................................................................................... 4-5

Table 4-2. Generator Voltage Sensing Terminals ..................................................................................... 4-5

Table 4-3. 52L/M and 52J/K Control Modes .............................................................................................. 4-6

Table 4-4. Communicat ion Por t Pin Functions .......................................................................................... 4-7

Table 4-5. Ferrite Bead Specifications and Corresponding Wire Terminals ........................................... 4-14

9287500991 Rev M DECS-100 Installation i

Page 34

This page intentionally left blank .

ii DECS-100 Inst all ati on 9287500991 Rev M

Page 35

SECTION 4 • INSTALLATION

INTRODUCTION

DECS-100 Digital Exc itat io n Con tr ol Sys tems are d el iv ered in s tur dy c ar t ons t o pr ev ent s h ipp ing da mag e.

Upon receipt of a system, c hec k the p ar t nu mber a gainst the requisitio n an d pack a gin g l ist for agr e em ent.

Inspect for damage, and if there is evidenc e of such, immedia tely file a claim wit h the carrier and notify

the Basler Electric Regiona l Sales Office, your Sal es Representative or a Sales Representativ e at Basler

Electric, Highland, Illinois.

If the unit is not install ed im mediate ly, store it i n the ori ginal sh ippin g pack age in a mo isture and dus t fr ee

environment.

MOUNTING

The DECS-100 is normally located in the generator conduit box. It is designed for behind the panel

mounting and requires a c utout for front panel view ing. Supplied mount ing hardware consists of six #12

thread-forming screws that pass through mounting holes in the conduit box and thread int o the plastic

shell of the DEC S-100. The recommen ded torque range for the stee l mounting screws is 4.07 to 4.5 2

newton-meters (36 to 40 in ch-pounds). The unit must be mo unted where the ambient tem perature does

not exceed the allowable environmental conditions called out in Section 1, General Information,

Specifications. DECS-1 00 package dimensions are s hown in Figure 4-1. Cutou t and drilling dimensions

are shown in Figure 4-2. Drawing dimensions are shown in inches and millimeters (in parenthesis).

9287500991 Rev M DECS-100 Installation 4-1

Page 36

Figure 4-1. DECS-100 Dimensions

4-2 DECS-100 Installation 9287500991 Rev M

Page 37

Figure 4-2. Cutout and Drilling Dimensions

9287500991 Rev M DECS-100 Installation 4-3

Page 38

CONNECTIONS

DECS-100 connections are dependent on the application and excitation scheme. Incorrect wiring may

result in damage to the unit. Check the part number to ensure that you have the correct unit before

connecting and applying pow er.

NOTE

Be sure that the DECS-100 is hard-w ired to ear th grou nd with no s maller th an 12

AWG copper wire attache d to the ground terminal on the rear of the unit case.

When the unit is configure d in a system with other devices, connect a separate

lead from the ground bus to each DECS-100 un it.

DECS-100 Terminations

DECS-100 units have two types of interface terminals (Figure 4-3). One type is quarter-inch, quickconnect terminals an d t he other is a 9-pin D B9 c onn e c tor . A ll ter m ina ls ar e l oc at ed o n t he r e ar of the unit.

The quarter-inch, quick-connect terminal labels are located on the rear of the case. Wires performing

common functions, such as voltage sensing leads, should be grouped together. The 9-pin DB-9 type

connector is used for temporary interface with both IBM compatible PCs and hand-held computers.

Figure 4-3 shows the term inal connections loc ated on the rear panel of t he DECS-100. Except as noted

above, connections should be made with minimum wire size of 14 AWG.

Figure 4-3. DECS-100 Terminals

4-4 DECS-100 Installation 9287500991 Rev M

Page 39

Bus Voltage Sensing Inputs (Optional)

Bus Voltage Phase

Terminal

A

B1 C B3

Sensing

Generator

Phase

Terminal

A

E1

B

E2 C E3

A

E1

C

E2, E3