Page 1

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

INTRODUCTION

BE3 frequency relays provide frequency monitoring and

protection in both single- and three-phase systems. They

are used in applications such as utility mains failure,

regulation of power supplies, and to protect generators

against over or underspeed. Underfrequency,

overfrequency, and combined under/ overfrequency units are

available. BE3 frequency relays operate when the

adjustable trip point is reached. A reset control is provided

with an adjustment of 0.3 to 3.0% on 50 or 60 hertz units

and 3 to 30% on 400 hertz units. Reset ensures that the

measured parameter return s to the percent set above or

below the trip point before the relay returns to the original

state. On overfrequency units, the output relay energizes

when the input signal exceeds the trip point. On

underfrequency units, the output relay de-energizes when

the input signal goes below the trip point. A red LED

indicates the state of the relay. A green LED indicates the

condition of the power supply.

SPECIFICATIONS

Operating Power

All units are self powered.

Nominal Voltage: 120 Vac, 240 Vac, 380 Vac,

or 480 Vac

Frequency: 50 Hz, 60 Hz, or 400 Hz

Burden: <2.5 VA per phase

Overload: 1.25 times nominal continuously.

2 times nominal for 3 s.

Setpoint

Over/Underfrequency Set Range

50 Hz Nominal: Adjustable 40 to 60 Hz

60 Hz Nominal: Adjustable 50 to 70 Hz

400 Hz Nominal: Adjustable 360 to 440 Hz

Over/Underfrequency Reset Range

50 Hz Nominal: Adjustable 0.3 to 3.0 Hz

60 Hz Nominal: Adjustable 0.3 to 3.0 Hz

400 Hz Nominal: Adjustable 3.0 to 30 Hz

Setpoint range accuracy is ±3%.

Repeatability

Greater than 0.5% of full span

Operating Time

200 ms typical

Output

Relay Type: D.P.D.T.

AC Rating: 250 V, 5 A, non-resistive,

1,200 VA

DC Rating: 125 V, 1 A, resistive, 120 W

Mechanical Life: 5 million operations

Model

BE3-81O, BE3-81U,

and BE3-81O/U

Temperature

Operating Temperature: 0°C (32°F) to 60°C (140°F)

Functional Temperature: –25°C (–13°F) to 70°C (158°F)

Storage Temperature: –40°C (–40°F) to 70°C (158°F)

Temperature Coefficient: 0.03% per °C (300 ppm/°C)

Humidity

Relative Humidity: 95% non-condensing

Physical

Mounting: DIN rail 1.38” by 0.29” (35 mm by

7.5 mm)

Case: Complies with IEC 529, DIN

40050, BS 5490

Case Material: Complies with UL 94VO

Weight

Single Function: 0.88 lb (0.4 kg)

Multiple Function: 1.32 lb (0.6 kg)

Size

Single Function: 2.17” wide (55 mm)

Multiple Function: 3.93” wide (100 mm)

Agency

cULus listed to UL 508 and CSA C22.2 No. 14

CE compliant

GOST-R certified per the relevant standards of Gosstandart

of Russia

OPERATION

BE3-81O and BE3-81U frequency relays have two useradjustable controls marked SET and RESET. The BE381O/U has four controls: UNDER SET, OVER SET, UNDER

RESET, and OVER RESET. Each SET control adjusts a

relay trip point. An overfrequency trip causes the relay

output to energize when the frequency rises above the SET

threshold. An underfrequency trip causes the relay output to

de-energize when the frequency decreases below the SET

threshold. Refer to the setpoint specifications for

overfrequency and underfrequency adjustment ranges. The

RESET control adjusts the difference between the nominal

input frequency and the reset frequency. An overfrequency

reset occurs when the frequency decreases below the

RESET setting. The overfrequency RESET setting is set as

the percentage above F

underfrequency reset occurs when the frequency increases

above the RESET setting. The underfrequency RESET

setting is set as the percentage below F

will reset. Refer to the setpoint specifications for the

underfrequency and overfrequency RESET setting ranges.

Setting Example

A BE3-81O relay with a nominal input rating of 60 Hz has

the following settings:

• SET - 65 Hz

• RESET - 2 Hz

where the relay will reset. An

nom

where the relay

nom

Publication

9321500990

Revision

C

Instructions

Date

04/14

Copyright

2014

Page 2

A trip occurs when the sensed frequency rises above 65 Hz.

The relay resets when the frequency decreases below

63 Hz.

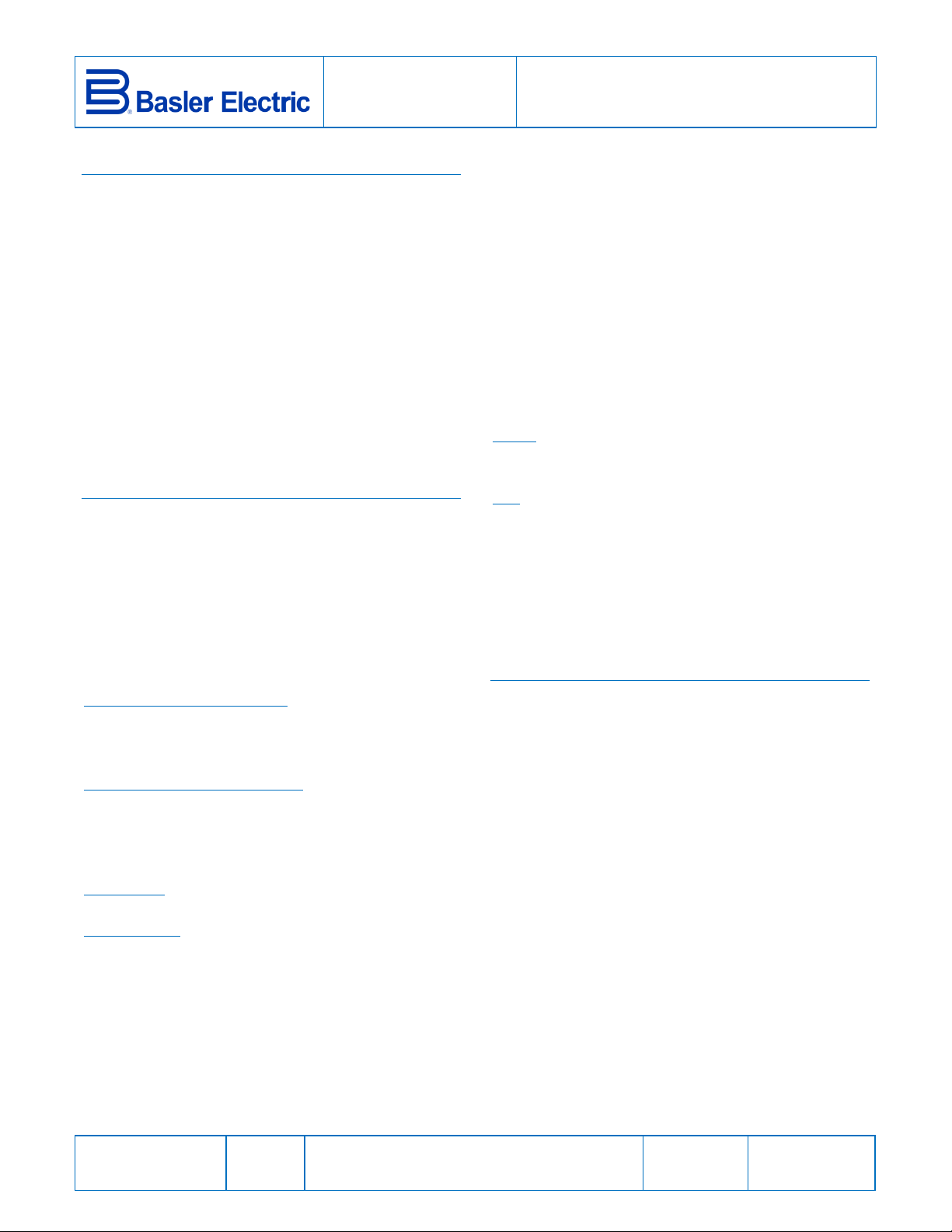

INSTALLATION

BE3 frequency relays are designed for mounting on

standard DIN rails that comply to DIN-EN 50022. Mounting

involves hooking the top edge of the cutout on the base of

the case over one edge of the DIN rail. The opposite side of

the cutout containing the release clip is then pushed over

the opposite side of the DIN rail. To remove or reposition the

relay, lever the release clip and move the relay as required.

BE3 relays should be installed in a dry, vibration-free

location where the ambient temperature does not exceed

the operating temperature range. Connections to the relay

should be made using wire that meets applicable codes and

is properly sized for the application. Figure 1 shows the

terminal connections for the BE3-81O, BE3-81U, and BE381O/U relays.

CALIBRATION

The calibration marks on the faceplate have a maximum

error of 10% and are provided only as guides. Proper

calibration requires using an a ccur ate fr equ enc y meter in

parallel with the input signal. Use the following procedure to

calibrate your relay.

Overfrequency

1. Adjust the SET and RESET controls fully clockwise.

2. Apply the desired trip frequency to the relay.

FIGURES

3. Slowly adjust the SET control counterclockwise until the

relay trips.

4. Reduce the applied frequency to the desired reset level.

5. Slowly adjust the RESET control counterclockwise until

the relay resets.

Underfrequency

1. Adjust the SET control fully counterclockwise and the

RESET control fully clockwise.

2. Decrease the applied frequency from the nominal value

until the desired tripping frequency is reached.

3. Slowly adjust the SET control clockwise until the relay

trips.

4. Increase the applied frequency to the desired reset

level.

5. Slowly adjust the RESET control counterclockwise until

the relay resets.

MAINTENANCE

BE3 relays are solid-state devices that require no

maintenance. In the event that your relay requires repair,

contact Basler Electric, Highland, IL, USA for return

authorization.

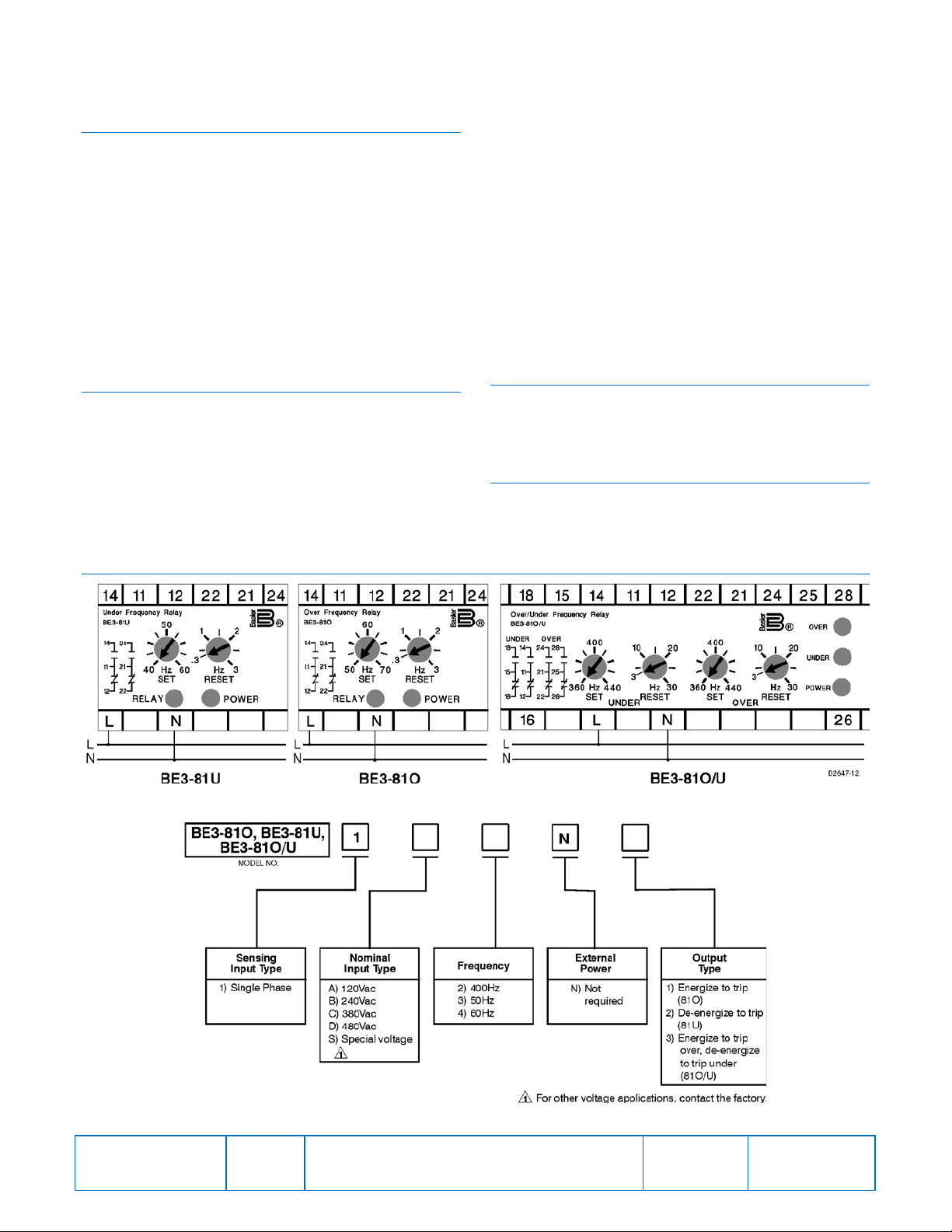

ORDERING INFORMATION

Figure 2 shows the BE3 frequency relay style number

identification chart.

Publication

9321500990

Figure 1. BE3-81O, BE3-81U, and BE3-81O/U Input Connections

Figure 2. BE3-81O, BE3-81U, and BE3-81O/U Style Number Identification Chart

Revision

B

Instructions

Date

04/14

Page

2 of 2

Loading...

Loading...