Page 1

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

INTRODUCTION

The BE3-76SH dc overcurrent relay provides overcurrent

protection in dc circuits found in applications such as the

excitation field of a synchronous machine, transit systems,

and dc substation systems. The BE3-76SH utilizes a usersupplied 50 mV or 100 mV shunt to quickly detect excessive

dc current. When the monitored current exceeds the useradjustable setpoint and the user-adjustable inverse time

delay expires, a set of DPDT output contacts changes state

and the red RELAY LED lights. A green POWER LED

indicates the presence of relay operating power.

SPECIFICATIONS

Operating Power

Voltage (Style xxxAx): 90 to 150 Vac

Voltage (Style xxxBx): 180 to 300 Vac

Frequency: 45 to 65 Hz

Burden: <2 VA

Sensing Input

Rated Value: 50 mVdc (style xFxxx)

100 mVdc (style xGxxx)

Input Impedance: 50 kΩ

Source Impedance: 100 Ω maximum

Overload: 10 times input continuously

Setpoint

Overcurrent Range: 40 to 120% (±3%) of nominal

shunt input

Differential: Fixed at 5%

Repeatability: <0.5% of full span

Time Dial: 0.1 to 20

Relay Output

Relay Type: D.P.D.T.

AC Rating: 250 V, 5 A, non-resistive,

1,200 VA

DC Rating: 125 V, 1 A, resistive, 120 W

Mechanical Life: 5 million operations

Environment

Temperature

Operating: 0°C (32°F) to 60°C (140°F)

Functional: –25°C (–13°F) to 70°C (158°F)

Storage: –40°C (–40°F) to 70°C (158°F)

Coefficient: 0.03% per °C (300 ppm/°C)

Humidity

Relative: 95% non-condensing

Enclosure

Complies with DIN-EN 50022, BS 5584, any position. Case

material complies with UL 94 VO.

Size: 55 mm (2.17 in)

Model

Weight: 400 g (14.1 oz)

Mounting: DIN rail, 35 by 7.5 mm

Enclosure Code

Case: IP 50

Terminals: IP 30

Applicable Standards

General

IEC 144, BS 5420, VDE/VDI 0435, IEC 947, EN 60947

Safety

BS EN 61010, DIN 57411, VDE 0411, ANSI C37

Surge Withstand

IEC 801, EN 55020, ANSI C37-90a

Radio Frequency Interference

RFI degree N, complies with VDE 0875

cULus

cULus listed to UL 508 and CSA C22.2 No. 14

CE Compliance

This product meets or exceeds the standards required for

distribution in the European Community.

GOST-R Certification

GOST-R certified per the relevant standards of Gosstandart

of Russia.

BE3-76SH

OPERATION

BE3-76SH relays have two user-adjustable controls: SET

and TIME DIAL.

The SET control defines the level of dc current that causes

the BE3-76SH to trip. The SET control has an adjustment

range of 40 to 120% (±3%) of the nominal shunt rating.

The TIME DIAL control defines the time delay from when the

monitored dc current reaches the trip point and the output

contacts change state. The TIME DIAL control has an

adjustment range of 0.1 to 20.

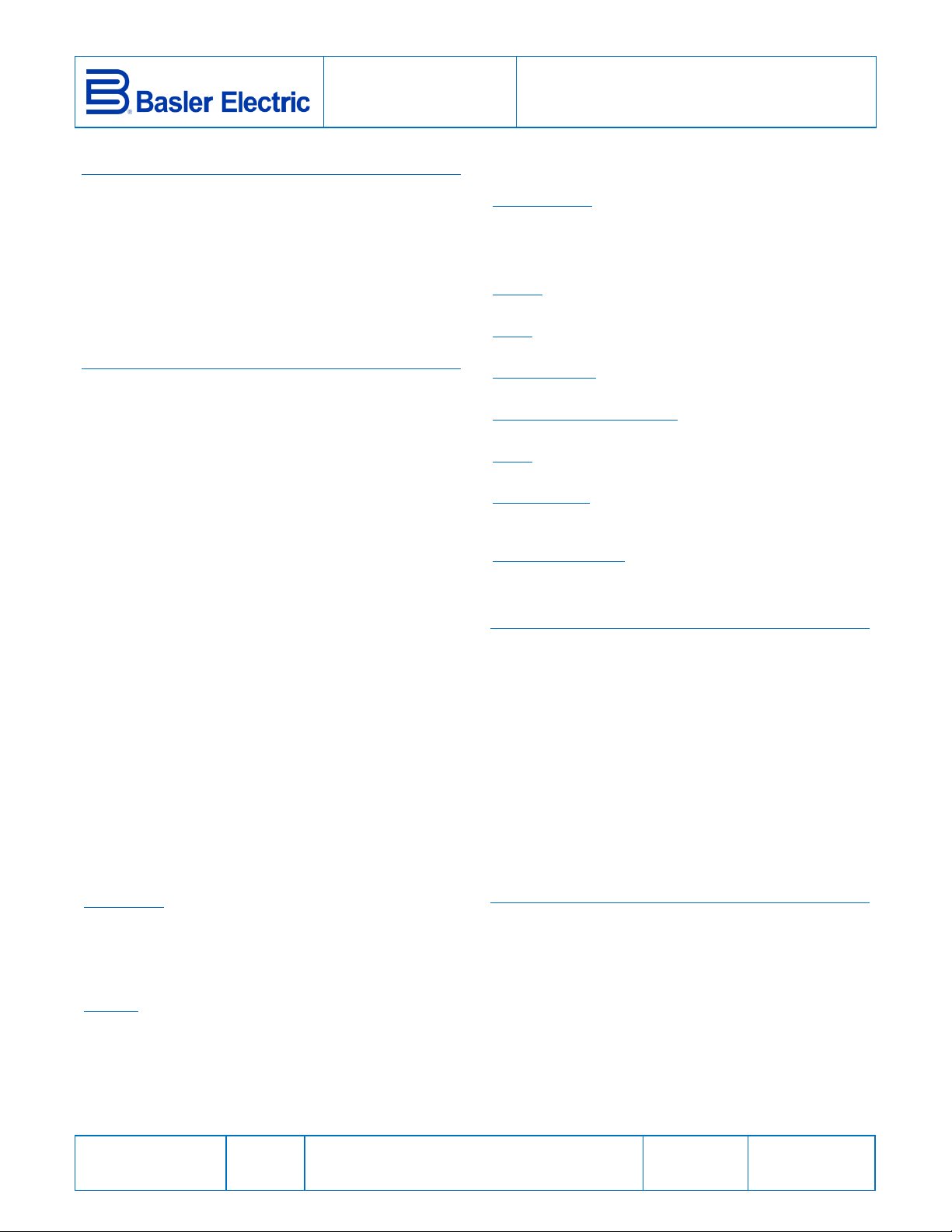

The settings of the SET and TIME DIAL controls are related

by an inverse function. See Figure 1. This means that the

higher the sensed current rises above the setting of the SET

control, the shorter the time to a relay trip. The TIME DIAL

setting is a linear multiplier for the time to a relay trip.

MOUNTING

BE3-76SH relays should be installed in a dry, vibration-free

location where the ambient temperature does not exceed

the operating temperature range.

BE3-76SH relays are designed for mounting on standard

DIN rails that comply with DIN-EN 50022. Mounting involves

hooking the top edge of the cutout on the base of the case

over one edge of the DIN rail. The opposite side of the

cutout containing the release clip is then pushed over the

opposite side of the DIN rail. To remove or reposition the

relay, lever the release clip and move the relay as required.

Publication

9409900990

Revision

D

Instructions

Date

04/14

Copyright

2014

Page 2

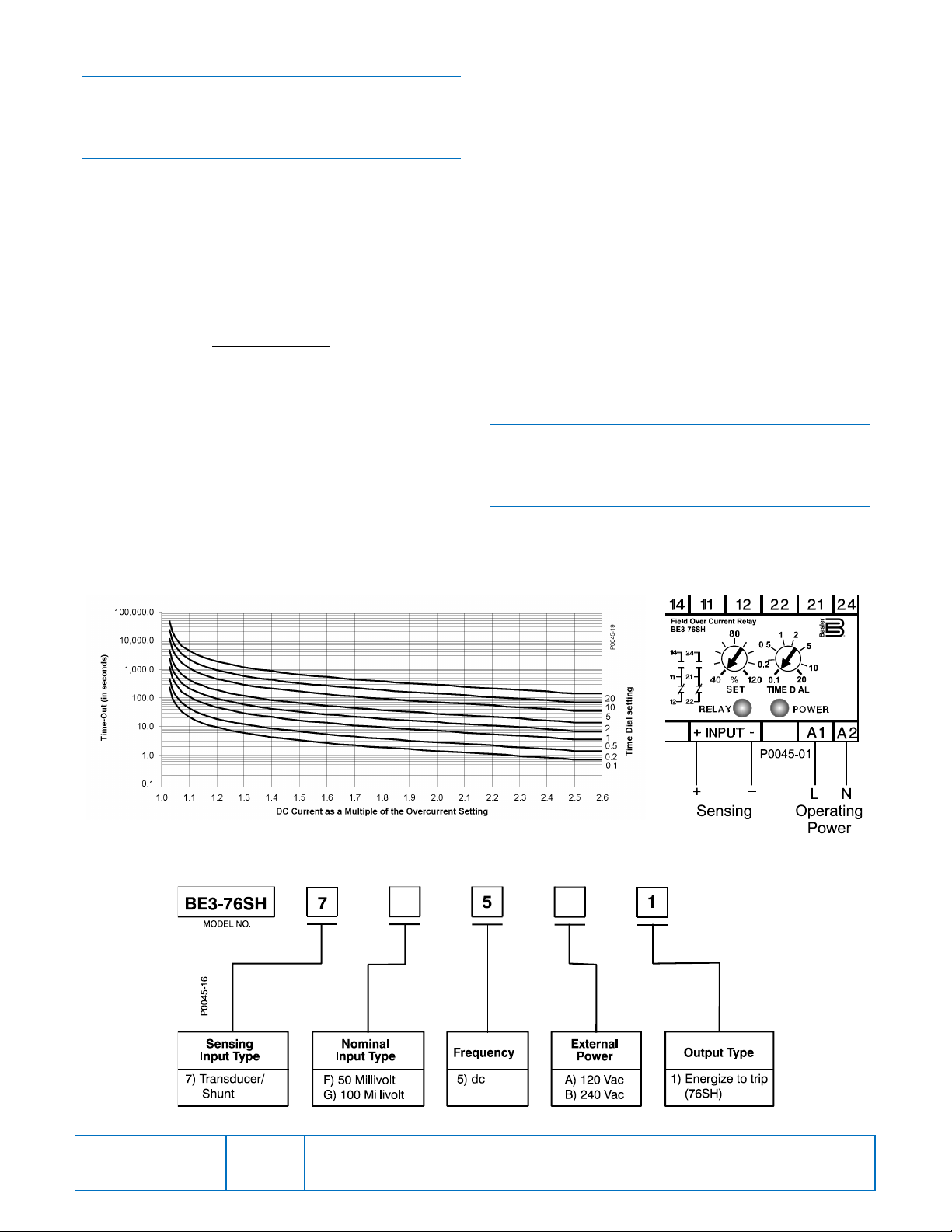

CONNECTIONS

and Connections

Relay connections should be made using wire that meets

applicable codes and is properly sized for the application.

Figure 2 shows the input connections for the BE3-76SH.

CALIBRATION

The calibration marks on the faceplate have a maximum

error of 10% and are provided only as guides. Proper

calibration requires using an accurate millivolt meter in

parallel with the input signal. When setting the relay, the

following performance conside r ation s shou ld be made to

determine the relay’s response to the various conditions

possible in a given application.

Multiple of Pickup (MoP)

The MoP ratio is determined by:

𝐴𝑐𝑡𝑢𝑎𝑙 𝑑𝑐 𝑐𝑢𝑟𝑟𝑒𝑛𝑡

𝑆𝑒𝑡 𝑐𝑜𝑛𝑡𝑟𝑜𝑙 𝑠𝑒𝑡𝑡𝑖𝑛𝑔

For example, if the relay SET control setting is the

equivalent of 100 Adc (the actual setting is expres sed as a

percentage of the rated, nominal sensing input) and the

actual current is 125 Adc, the MoP is 125/100 or 1.25.

Calibration Procedure

1. Rotate the SET control fully clockwise to the 120%

position and the TIME DIAL control fully

counterclockwise to the 0.1 position.

2. Apply the desired trip voltage to the relay, allowing for a

1.03 MoP factor.

FIGURES

3. Slowly rotate the SET control counterclockwise until the

RELAY LED starts flashing (allow for a 700 ms delay

before the LED lights). Then, slowly rotate the SET

control clockwise until the LED turns off.

4. Repeat Step 3 until the amount of rotation required

between LED turn-on and turn-off is minimal. The MoP

at this point will be 1.03.

Setting Example

The desired trip voltage in a 100 mV shunt application is

103 mVdc (103%).

When the SET control (expressed in %) is set above the

level of trip voltage, the MoP is below 1 and the relay is not

tripped.

When the setting value of the SET control equals the value

of trip voltage, the MoP is 1 and the relay is not tripped.

When the SET control setting is 100% (2.91% below the trip

voltage) the MoP is 1.03 so the relay time delay starts and

the RELAY LED starts flashing, but the relay is not tripped.

In this instance, the trip time delay is 244 seconds.

MAINTENANCE

BE3-76SH relays are solid-sta t e devi ces that require no

maintenance. In the event that your relay requires repair,

contact Basler Electric.

STYLE CHART

The BE3-76SH style identification chart is illustrated in

Figure 3.

Publication

9409900990

Figure 1. Inverse Time Characteristic Curves

Figure 3. BE3-76SH Style Chart

Revision

D

Instructions

Figure 2. Front Panel View

Date

04/14

Page

2 of 2

Loading...

Loading...