Page 1

Page 2

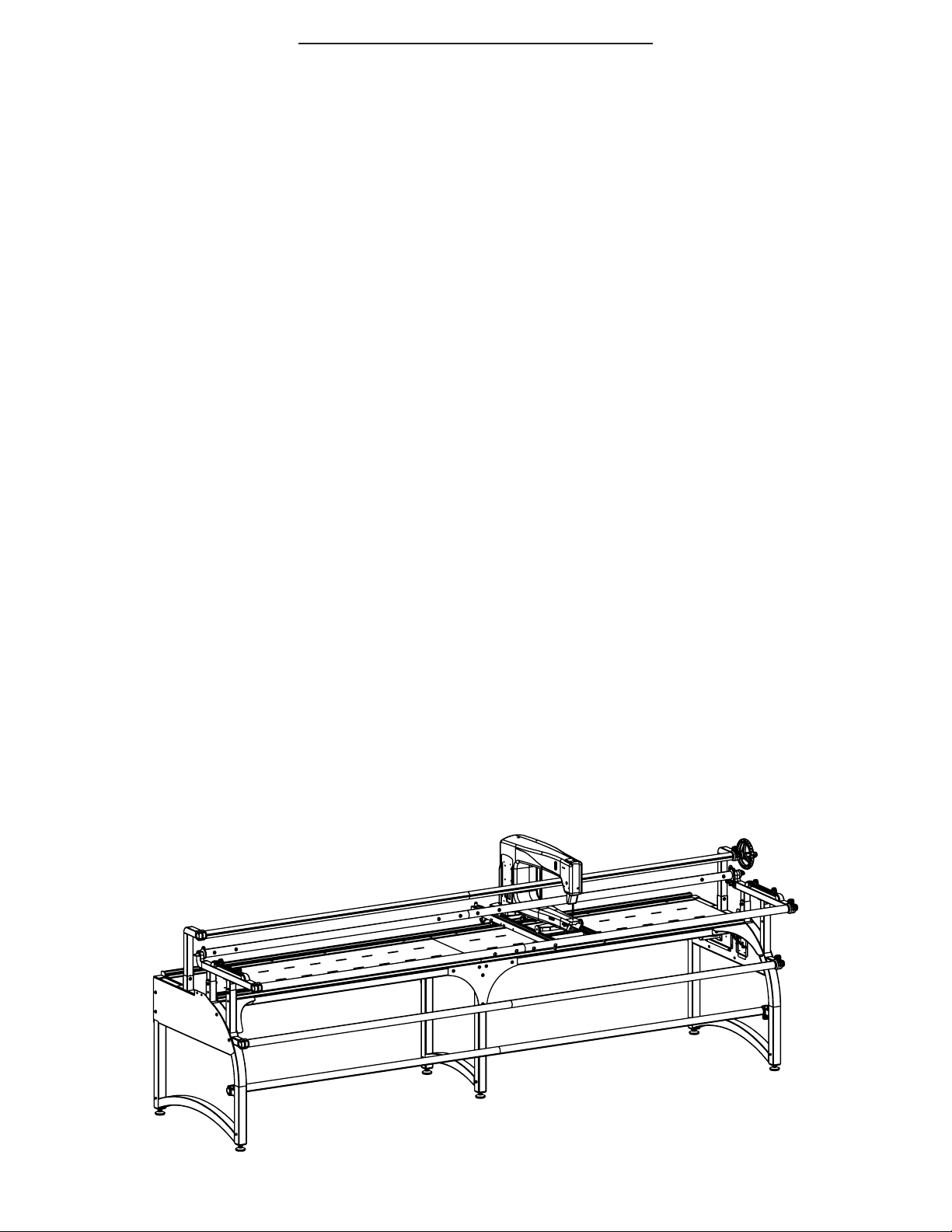

Assembly and Use Instruction Manual

Table of Contents

Assembly and Use Instruction Manual ...................................................................................................................... 1

Safety Instruction ..................................................................................................................................................... 2

Parts List ................................................................................................................................................................... 3

Corner Supports & Middle Leg Support Inner Box (Box 1) ....................................................................................... 3

Hardware Box (Box 1) ............................................................................................................................................... 3

Corner Supports & Middle Leg Support Inner Box (Box 1) ....................................................................................... 3

Hardware Box Continued (Box 1) ............................................................................................................................. 4

Box 2 Contents .......................................................................................................................................................... 4

Box 3 Contents .......................................................................................................................................................... 4

Step 1: Ratchet and Rail Holder Installation ............................................................................................................ 5

Step 2: Height Adjustable Leg Assembly .................................................................................................................. 5

Step 3: King Table to Frame Ends ............................................................................................................................. 6

Step 3-C: Crib Table to Frame Ends ........................................................................................................................... 6

Step 4: Corner Brace for King Assembly ................................................................................................................... 7

Step 4-C: Corner Brace for Crib Assembly ................................................................................................................. 7

Step 5: Track Assembly for King Size Frame ............................................................................................................. 8

Step 5-C: Track Assembly for Crib Size Frame .......................................................................................................... 9

Step 6: Front Rail Bracket Assembly ......................................................................................................................... 9

Step 7: Take Up Rail Bracket Assembly ................................................................................................................... 10

Step 8: Bottom Carriage Assembly .......................................................................................................................... 10

Step 9: Track Adjustment ........................................................................................................................................ 11

Step 10: Rail Assembly for King .............................................................................................................................. 12

Step: 10-C: Rail Assembly for Crib .......................................................................................................................... 13

Step 11: Machine Magnetic Bracket ........................................................................................................................ 13

Step 12: Idler Rail Clamp Attachment to Frame ..................................................................................................... 14

Step 13: Rail Attachment to Frame ......................................................................................................................... 15

Step 14: Handwheel Attachment to Rail End .......................................................................................................... 15

Step 15: Leveling Feet Adjustment ......................................................................................................................... 15

Step 16: Wire Connection ........................................................................................................................................ 16

Step 17: Speed Control ............................................................................................................................................ 17

Frame Center Diagram ............................................................................................................................................ 17

Frame Rail Diagram ................................................................................................................................................. 18

Section 1: Fabri-Fast System................................................................................................................................... 18

Section 2: Leader Cloth ........................................................................................................................................... 19

Section 3: Attaching Fabric on the Frame Rails ...................................................................................................... 20

Section 4: Bungee Clamps ....................................................................................................................................... 22

Getting Started ........................................................................................................................................................ 22

Trouble Shooting Guide ........................................................................................................................................... 23

Page. 1

Page 3

Safety Instruction

Read all instructions before using.

When using this machine, basic safety precautions should always be taken, including the following:

FCC Warning Statement

Changes or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help

WARNING -

Warning: Unplug both power cords from the power outlet when attaching the fabric to your

frame to protect your system from static discharge.

• Never operate this system if it has a damaged cord or plug, if it is not working properly, or if it has been

dropped or damaged. Return the system to the nearest authorized dealer for repair or adjustment.

• Keep ngers away from all moving parts.

• To disconnect, always turn the power button to the off position before unplugging any cables.

• Keep the machine and frame free from the accumulation of lint, dust, and loose cloth.

• Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

If you have any questions contact your authorized Baby Lock retailer.

Page. 2

Page 4

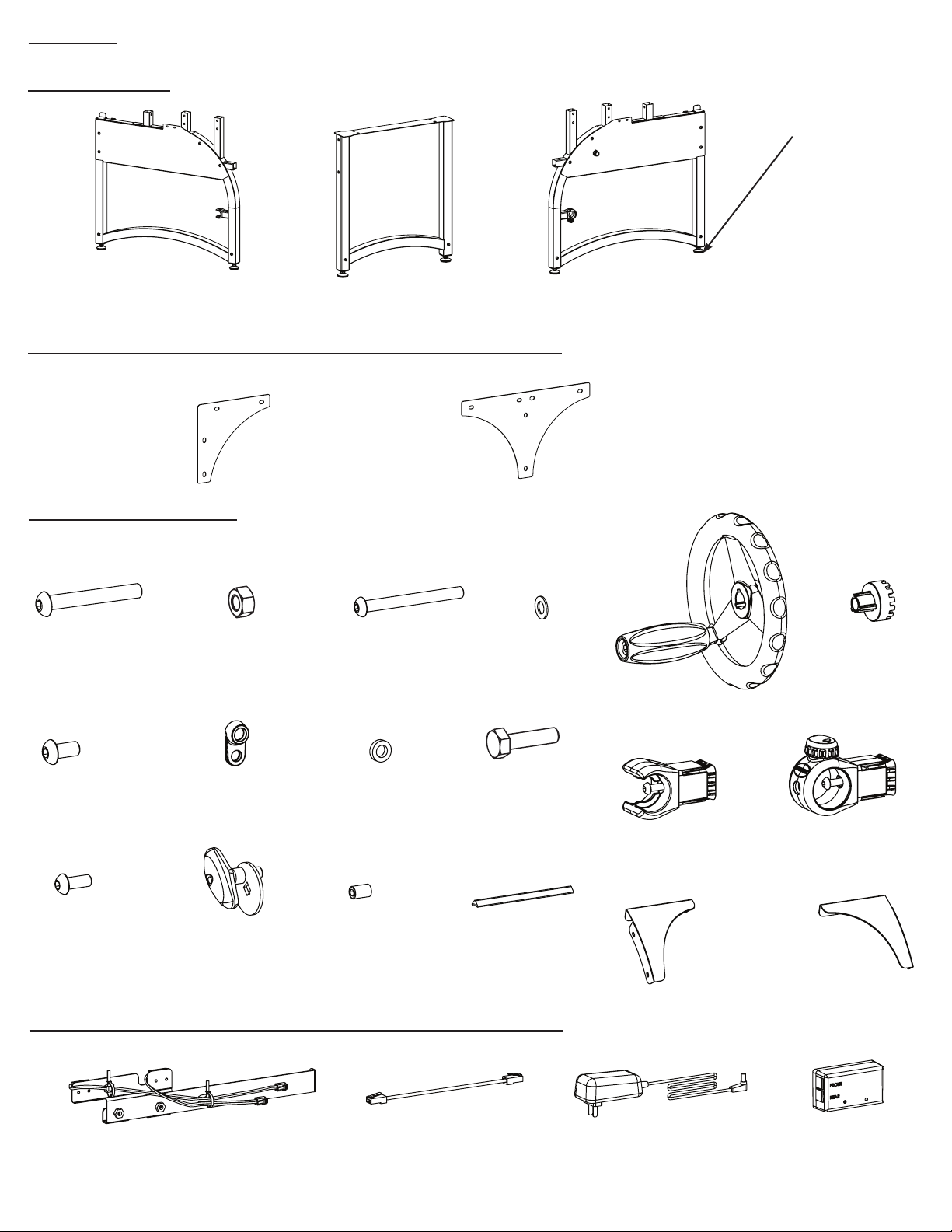

Parts List

Box 1 Contents

Leveling Foot (6)

(Pre-installed on

Frame Ends and

Middle Leg)

03-10943

Left Frame End (1)

A100091

Middle Leg (1)

A100092

Corner Supports & Middle Leg Support Inner Box (Box 1)

Corner Support (2)

04-10708

Middle Leg

Brace (2)

04-10709

Hardware Box (Box 1)

M8 x 50mm

SBHCS (6)

03-10726

M8 Nylock

Nut (6)

03-10730

M10 x 125mm

SBHCS (1)

03-10950

M10 Washer (1)

03-10952

Right Frame End (1)

A100093

Handwheel

Coupler (1)

05-10926

Handwheel Assembly (1)

A100095

M8 x 16mm

SBHCS (36)

03-10951

M6 x 16mm

SBHCS (1)

03-10003

Magnet

Bracket (1)

05-10928

Rail Clamp Lock

Pin Assembly (1)

A100096

Magnet Bracket

Spacer (1)

05-10933

M6 x 8mm Set

Screws (10)

03-10111

1/4 x 1 inch Hex

Bolt (1)

03-10964

Track Coupler (2)

04-10443

Corner Supports & Middle Leg Support Inner Box (Box 1)

Sensor Bracket (1)

A100094

Ethernet Cable

Short (1)

02-10941

Rail Holder

Assembly (1)

A100097

Front Leg

Brace Left (1)

04-10711

Power Supply (2)

02-10940

Top Rail Ratchet

Assembly (1)

A100098

Front Leg

Brace Right (1)

04-10712

Master Board

Box (1)

A100099

Page. 3

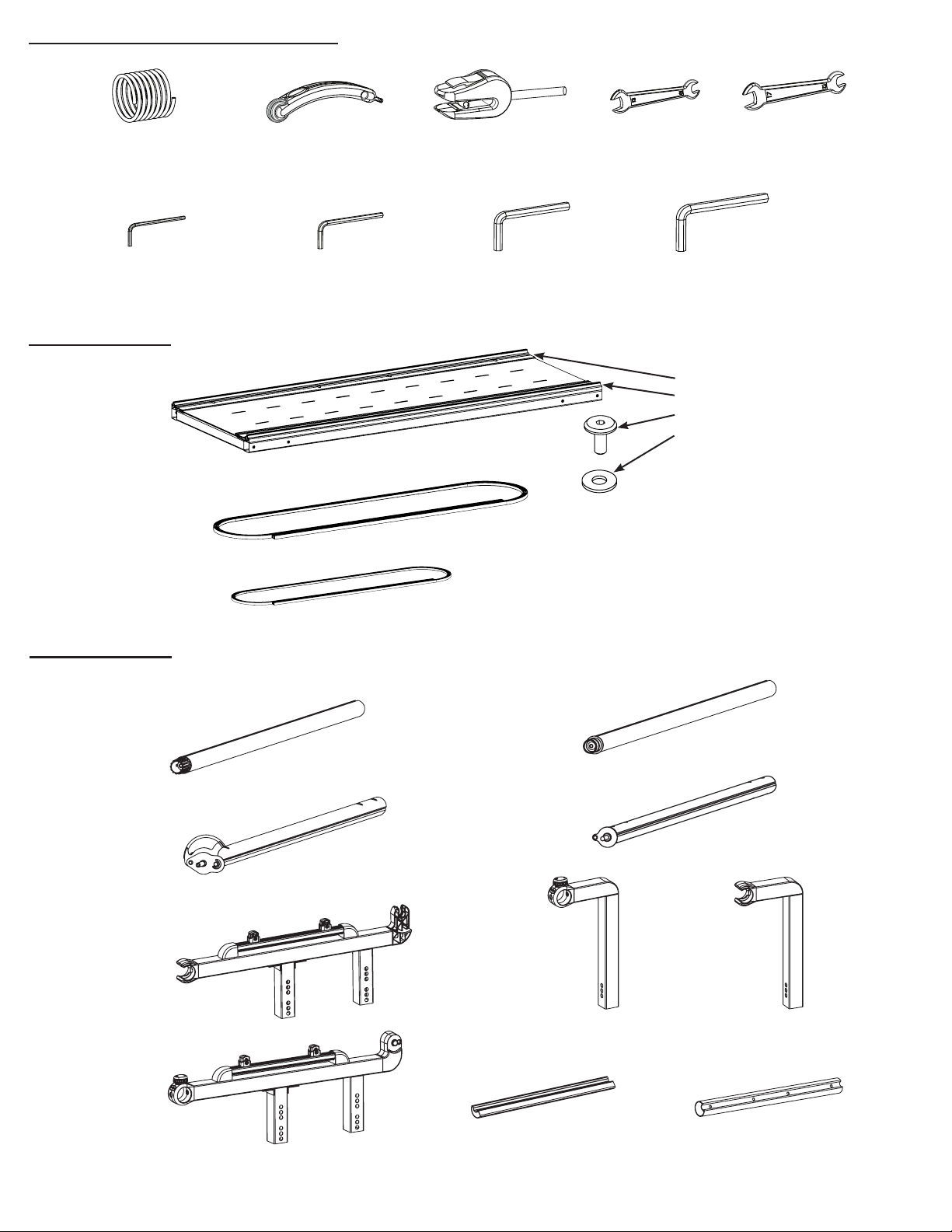

Page 5

Hardware Box Continued (Box 1)

Fabri-Fast Tubing (4)

05-10439

Box 2 Contents

Table Assembly (2)

A100100

10 ft Plastic Track (4)

05-10330

5 ft Plastic Track (4)

05-10329

3mm Allen

Wrench (1)

03-10166

Fabri-Fast Tool (1)

05-10417

Bungee Clamp (4)

4mm Allen

Wrench (1)

03-10167

08-10572

Open Wrench

13mm and 10mm

03-10743

5mm Allen

Wrench (1)

03-10741

Open Wrench 17mm

and 13mm

03-10948

6mm Allen

Wrench (1)

03-10742

(The following items are preinstalled in Table Assembly)

Rear Track 04-10880

Front Track 04-10878

M6 Connector Bolt 03-10953

M6 Plastic Washer 05-10949

Box 3 Contents

Rail Ratcheting End (4)

A100101

Idler Rail Clamp Locking

Assembly (1)

A100103

Front Rail Bracket Left

Rail Holder End (1)

A100105

Rail Non-Ratcheting End (4)

A100102

Idler Rail Clamp Floating

Assembly (1)

A100104

Take Up Rail Right Arm

Ratchet End (1)

A100108

Take Up Rail Left Arm

Rail Holder End (1)

A100107

Front Rail Bracket

Right Ratchet (1)

A100106

Clamp Rail Coupler (2)

04-10714

Rail Coupler (4)

04-10457

Page. 4

Page 6

Frame Assembly

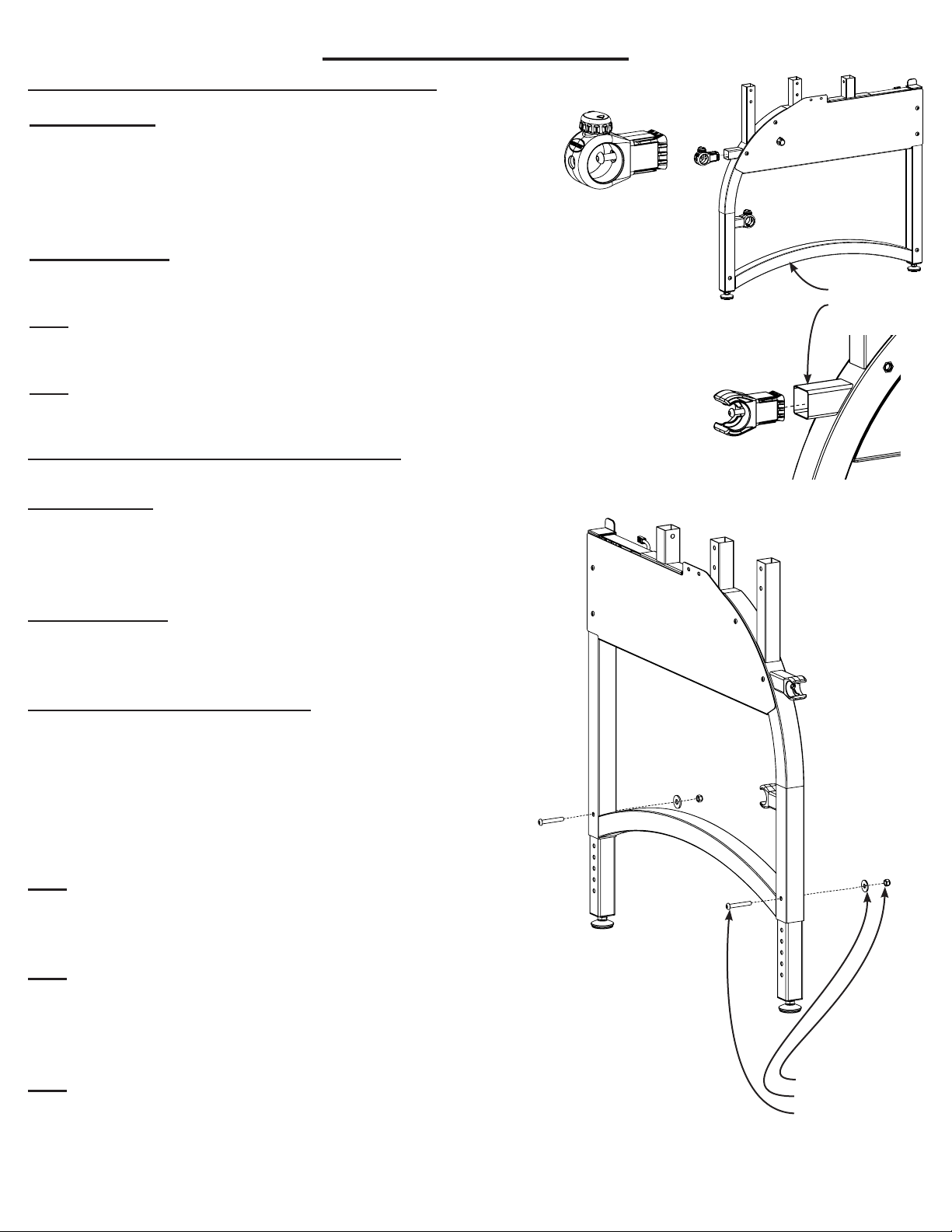

Step 1: Ratchet and Rail Holder Installation

Parts Needed

1- Right Frame End

1- Left Frame End

1- Top Rail Ratchet Assembly

1- Rail Holder Assembly

Tools Required

4mm Allen Wrench

1-1: Insert the Top Rail Ratchet Assembly into the Right Frame End tube end

and tighten the M6 x 25mm SBHCS. (Fig. 1-2)

1-2: Insert and fasten the Rail Holder Assembly into Left Frame End tube

end. (Fig. 1-3)

Top Rail Ratchet

Assembly (Right)

Fig. 1-1

Right Frame End

Left Frame End

Fig. 1-2

Step 2: Height Adjustable Leg Assembly

Parts Needed

1- Right Frame End

1- Left Frame End

1- Middle Leg

Tools Required

5mm Allen Wrench

Open Wrench 13mm and 10mm

Height of Fabric Surface Chart

(Height is determined by the quilting surface to the oor.)

Top Hole 44” 4th 39”

8th 43” 3rd 38”

7th 42” 2nd 37”

6th 41” Bottom Hole 36”

5th 40”

2-1: To adjust the legs, remove the pre-installed M8 x 55mm

SBHCS, M8 Flat Washer, and M8 Nylock Nut from the frame

ends and middle leg if assembling in King size. (Fig. 2-1)

Rail Holder Assembly

(Left)

Fig. 1-3

2-2: Adjust the leg height using the Height of Fabric Surface

Chart. The bottom of the machine handles typically start at

about 8” above the Quilting surface. Determine what setting

will be most comfortable for you based on your height.

2-3: Fasten the M8 x 55mm SBHCS, M8 Flat Washer, and M8

Hex Nut to the adjusted legs with the tools provided. (Fig.

2-1)

Fig. 2-1

M8 Hex Nut

M8 Flat Washer

M8 x 55mm SBHCS

Page. 5

Page 7

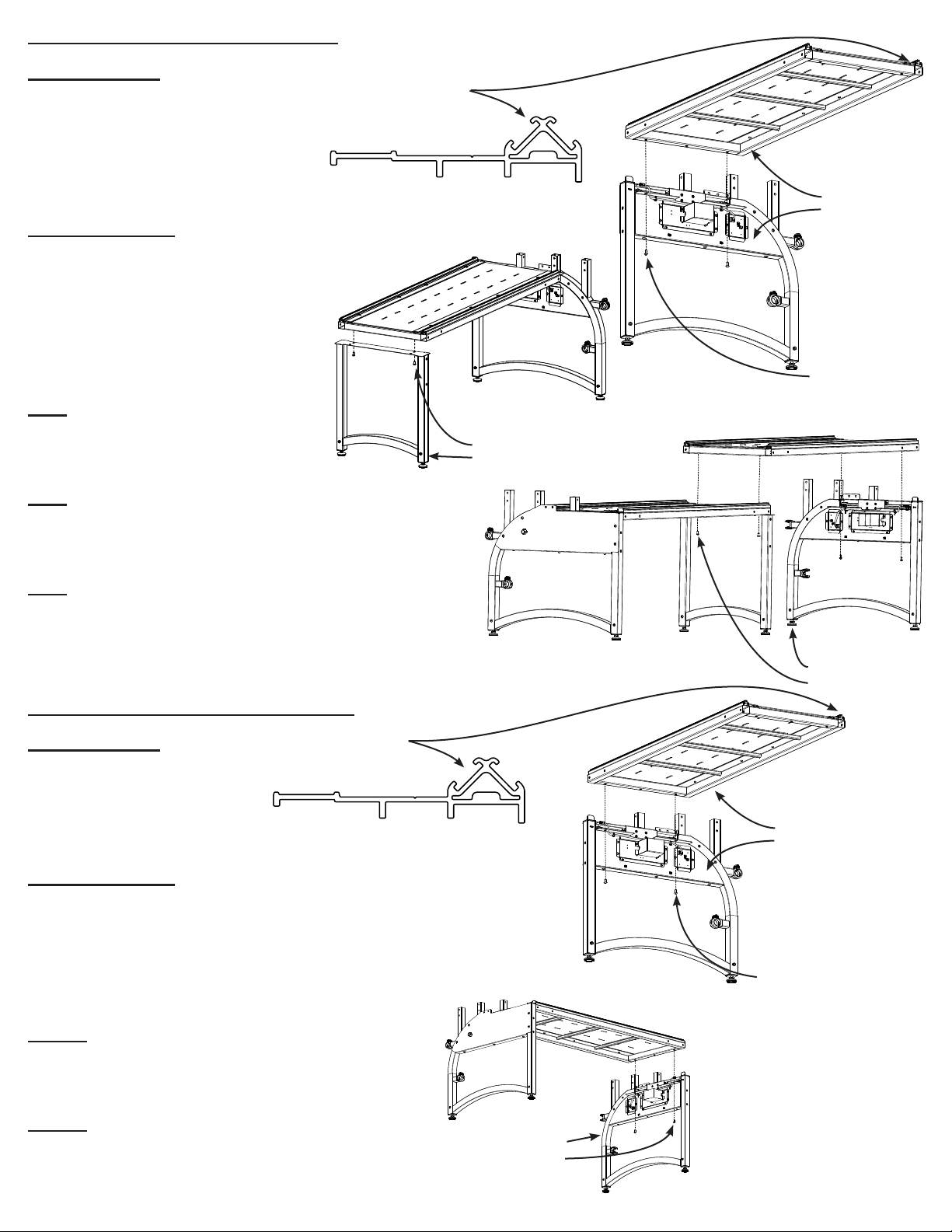

Step 3: King Table to Frame Ends

Parts Needed:

1- Right Frame End

1- Left Frame End

1- Middle Leg

2- Table Assembly

8- M8 x 16mm SBHCS

Tools Required:

5mm Allen Wrench

Note: Using two people is recommended for this step. Loosely fasten

the M8 x 16mm SBHCS to allow for

adjustment in step 4.

3-1: Attach the Table Assembly to

the frame ends using M8 x 16mm

SBHCS. (Fig. 3-1)

Table Assembly Front

Track Prole

Note: The Table Assemblies have

a Pro-Stitcher Compatible Track

which is wider than the rear track.

M8 x 16mm SBHCS

Middle Leg

Fig. 3-1

Table Assembly

Right Frame End

M8 x 16mm SBHCS

3-2: Fasten the Middle Leg to Table

Fig. 3-2

Structure using M8 x 16mm SBHCS.

(Fig. 3-2)

3-3: Bolt the second Table Assembly

to the Middle Leg and Right Frame

End. (Fig. 3-3)

Step 3-C: Crib Table to Frame Ends

Parts Needed:

1- Right Frame End

Table Assembly Front

Track Prole

1- Left Frame End

1- Table Assembly

4- M8 x 16mm SBHCS

Note: The Table Assemblies have

a Pro-Stitcher Compatible Track

which is wider than the rear track.

Tools Required:

5mm Allen Wrench

Fig. 3-3

Left Frame End

M8 x 16mm SBHCS

Table Assembly

Right Frame End

Note: Using two people is recommended for this

step. Loosely fasten the M8 x 16mm SBHCS to

allow for adjustment in step 4-C.

3-1-C: Attach the Table Assembly to the bracket

of the frame ends using M8 x 16mm SBHCS.

(Fig. 3-1-C)

3-2-C: Bolt the other end of the Table Assembly

to the remaining frame end to complete the crib

size frame assembly. (Fig. 3-2-C)

Left Frame End

M8 x 16mm SBHCS

Fig. 3-2-C

Fig. 3-1-C

M8 x 16mm SBHCS

Page. 6

Page 8

Step 4: Corner Brace for King Assembly

Parts Needed:

Corner Support Long Edge

1- Front Leg Brace Left

1- Front Leg Brace Right

2- Corner Support

2- Middle Leg Brace

26- M8 x 16mm SBHCS

Tools Required:

5mm Allen Wrench

Fig. 4-1

Middle Leg Brace

M8 x 16mm SBHCS

Corner Support

4-1: Align the Corner Supports so that the long edge follows the table surface and fasten with M8 x 16mm

SBHCS. The Corner Supports should lay ush with the Table Assembly and Frame End surfaces. (Fig. 4-1)

4-2: Fasten the Middle Leg Braces to the Table Assemblies and Middle Leg. The Middle Leg Braces should

lay ush with the surface of the Table Assemblies and Middle Leg. (Fig. 4-1)

4-3: Attach the Front Leg Braces to the Table Assemblies and Frame Ends. (Fig. 4-2)

4-4: Securely fasten all the M8 x 16mm SBHCS in this Step and from Step 3.

M8 x 16mm SBHCS

Front Leg Brace Left

Fig. 4-2

Step 4-C: Corner Brace for Crib Assembly

Parts Needed:

1- Front Leg Brace Left

1- Front Leg Brace Right

2- Corner Support

2- Middle Leg Brace

14- M8 x 16mm SBHCS

Tools Required:

5mm Allen Wrench

Corner Support Long Edge

M8 x 16mm SBHCS

Corner Support

4-1-C: Align the Corner Supports so that the

long edge follows the table surface and fasten

with M8 x 16mm SBHCS. The Corner Supports

should lay ush with the Table Assembly and

Frame End surfaces. (Fig. 4-1-C)

Fig. 4-1-C

Page. 7

Page 9

4-2-C: Attach the Front Leg Braces to the Table Assemblies and Frame Ends. (Fig. 4-2-C)

4-3-C: Securely fasten all the M8 x 16mm SBHCS in

this Step and from Step 3-C.

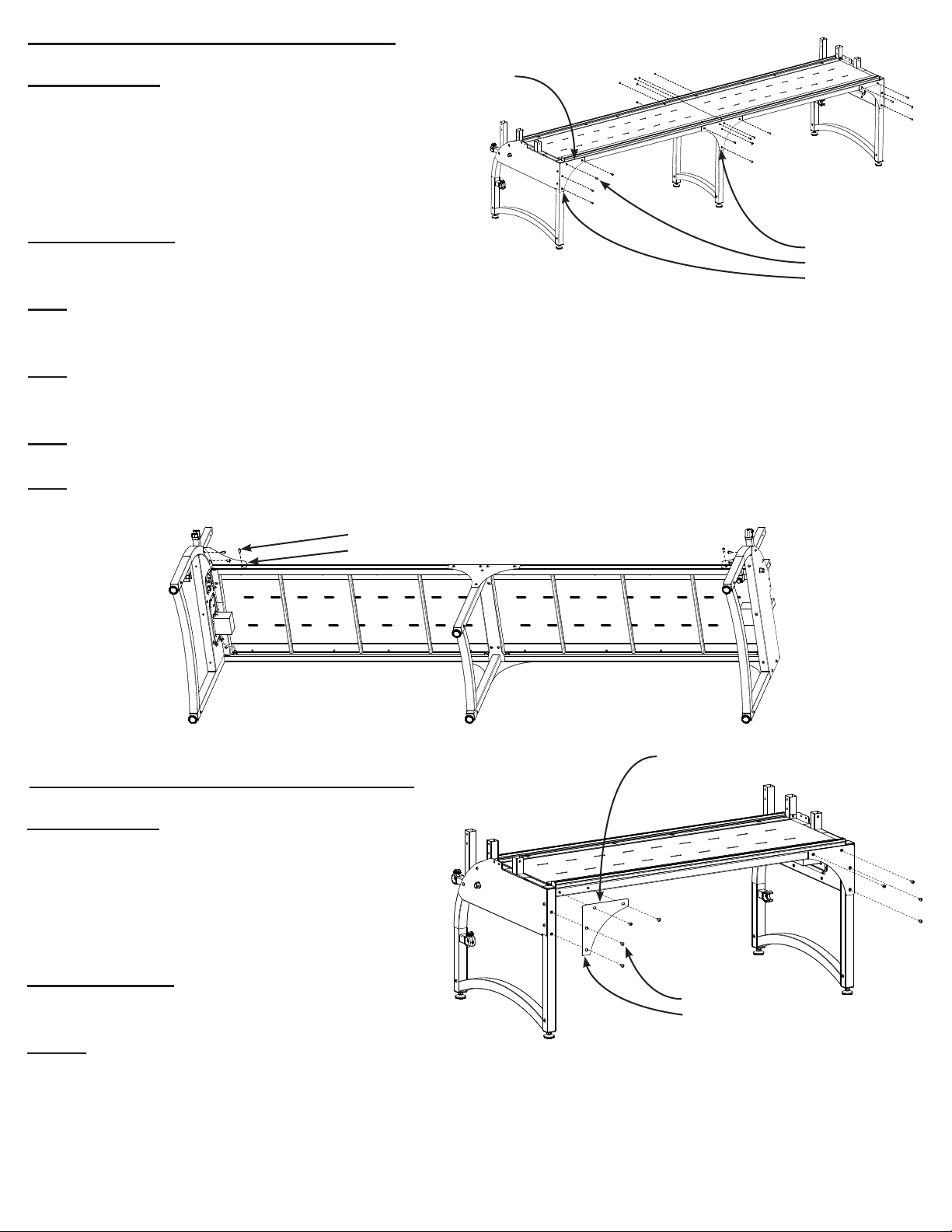

Step 5: Track Assembly for King Size Frame

Parts Needed:

2- Track Coupler

4- 10 ft Plastic Track

8- M6 x 8mm Set Screw

Tools Required:

3mm Allen Wrench

Back Track Support

Front Track Support

4mm Allen Wrench

5-1: Detach the pre-installed Track Support

from the Table Assembly by unfastening the

M6 Connector Bolts with a 4mm Allen Wrench.

(Fig. 5-1)

M8 x 16mm SBHCS

Front Leg Brace Left

Fig. 4-2-C

M6 Connector Bolt

M6 Plastic Washer

5-2: Insert the Track Coupler into the Track

Support end leaving approximately half of the

coupler exposed. (Fig. 5-2) Insert and fasten

M6 x 8mm Set Screws into the Track Support

end using a 3mm Allen Wrench. (Fig. 5-3)

5-3: Slide a Track Support end onto the

coupled back track assembly and fasten M6 x

8mm Set Screws with a 3mm Allen Wrench to

complete one 10 ft Track Support. (Fig. 5-3)

5-4: Slide the 10 ft Plastic Track down the

track groves of the Back Track Support Assembly. (Fig. 5-4)

5-5: Repeat step 5-2 to 5-4 to assemble the

10 ft Front Track Support Assembly.

5-6: Loosely fasten the Front Track Assembly

and securely fasten the Rear Track Assembly

onto the Table Assembly with Connector Bolts

and M6 Plastic Washers. The Rear Track As-

sembly side should be ush with the back edge

of the table. (Fig. 5-1)

Fig. 5-1

Fig. 5-2

Fig. 5-3

Back Track Support

Track Coupler

M6 x 8mm Set Screw

Note: The Front Track Assembly will be adjusted and tightened in step 9.

Fig. 5-4

Rear Track Assembly Side

Plastic Track

Page. 8

Page 10

Step 5-C: Track Assembly for Crib Size Frame

Parts Needed:

Back Track Support

Front Track Support

4- 5 ft Plastic Track

Tools Required:

4mm Allen Wrench

5-1-C: Detach the pre-installed Track Support

from the Table Assembly by unfastening the

M6 Connector Bolts with a 4mm Allen Wrench.

(Fig. 5-1-C)

5-2-C: Slide the 5 ft Plastic Track down the

track grooves of the Track Support Assembly.

(Fig. 5-2-C)

5-3-C: Repeat step 5-2 to assemble the 5 ft

Front Track Support Assembly.

5-4-C: Loosely fasten the Front Track Assembly and securely fasten the Back Track Assembly onto the Table Assembly with Connector

Bolts and M6 Plastic Washer. The Rear Track

Assembly side should be ush with the back

edge of the table. (Fig. 5-1)

Fig. 5-1-C

Fig. 5-2-C

M6 Connector Bolt

M6 Plastic Washer

Back Track Assembly Side

Plastic Track

Note: The Front Track Assembly will be adjusted and tightened in step 9.

Front Rail Bracket Left Rail Holder

End

Step 6: Front Rail Bracket Assembly

Parts Needed:

1- Front Rail Bracket Right Ratchet End

1- Front Rail Bracket Left Rail Holder End

Fig. 6-1

Note: Loosen the M8 x 16mm SBHCS on the Rail Brackets if the brackets are a tight t into frame ends.

4- M8 x 50mm SBHCS

4- M8 Nylock Nut

Tools Required:

5mm Allen Wrench

Open Wrench 13mm and 10mm

Note: The bolt height may need to be adjusted after the

sewing machine has been set on the frame so that fabric

lays at in the throat of the machine. This assembly step

is universal for both Crib and King size frames.

6-1: Insert the Rail Brackets into the corresponding tube

ends. (Fig. 6-2)

M8 x 16mm SBHCS

Front Rail Bracket Left Rail Holder End

Front Rail Bracket Right Ratchet End

Rail Holding End

M8 Nylock Nut

M8 x 50mm SBHCS

Ratchet End

Fig. 6-2

Page. 9

Page 11

6-2: Fasten a set of M8 x 50mm SBHCS and M8 Nylock

Nuts through the second hole from the bottom of the Rail

Brackets as a default. (Fig. 6-2 and Fig. 6-3)

M8 Nylock Nut

M8 x 50mm SBHCS

Step 7: Take Up Rail Bracket Assembly

Parts Needed:

1- Take Up Rail Right Arm Ratchet End

1- Take Up Rail Left Arm Rail Holder End

2- M8 x 50mm SBHCS

2- M8 Nylock Nut

Tools Required:

5mm Allen Wrench

Open Wrench 13mm and 10mm

Fig. 6-3

Take Up Rail Left Arm Rail Holder End

Take Up Rail Right Arm Ratchet End

Note: The height may need to be adjusted after

the sewing machine has been set on the frame.

This assembly step is universal for both Crib and

King size frames.

7-1: Insert the Rail Brackets into the corresponding

tube ends. (Fig. 7-1)

7-2: Fasten a set of M8 x 50mm SBHCS and M8

Nylock Nuts through the middle hole of the Rail Arm

Brackets. (Fig. 7-1)

Step 8: Bottom Carriage Assembly

Parts Needed:

2- M6 Set Screw

1- Sensor Bracket

1- Carriage Assembly (included

with sewing machine)

1- Master Board Box

1- Power Supply

Fig. 8-1

Non-Ratchet End

Fig. 7-1

Ratchet End

Backside of

the carriage

Sensor

Bracket tab

Tools Required:

3mm Allen Wrench

8-1: Attach and align the Sensor Bracket to the

backside of the carriage. The Sensor Bracket tab

should be ush against the rear of the carriage.

(Fig. 8-1)

8-2: Insert and fasten a set of M6 Set Screws

into the Sensor Bracket. (Fig. 8-2)

Fig. 8-2

M6 Set Screw

Page. 10

Page 12

8-3: Position the Master Board Box so that the

two ports are facing the front of the carriage.

Peel the tape from the back of the Master Board

Box and attach the box to the side of the Carriage Assembly. (Fig. 8-3)

8-4: Plug the Front Cable into the Front Port

and Rear Cable into the Rear Port on the Master

Board Box. (Fig. 8-4)

Step 9: Track Adjustment

Parts Needed:

1- Bottom Carriage Assembly

1- Frame Assembly

Tools Required:

4mm Allen Wrench

Fig. 8-3

Fig. 8-4

Front Cable

Rear Cable

Master Board Box

Front

Rear

Note: This assembly step is universal for both

Crib and King size frames.

9-1: Place and align the Bottom Carriage Assembly on the track assemblies. The Front Track

Assembly should be loosely fastened from a

previous step. (Fig. 9-1)

9-2: The Rear Track Support should be aligned

ush with the Table Frame Side from a previous

step. If not, align and securely fasten. (Fig. 9-1)

9-3: Press down on the Bottom Carriage As-

sembly and move the carriage from left to right,

fastening the Front Track M6 Connector Bolts

rmly. Continue this step for the remainder of

the Connector Bolts along the frame. (Fig. 9-2)

Fig. 9-1

Fig. 9-2

Rear Track Side

Rear Frame Side

M6 Connector Bolts

Page. 11

Page 13

Step 10: Rail Assembly for King

Parts Needed:

4- Rail Ratcheting End

4- Rail Non-Ratcheting End

4- Rail Coupler

2- Clamp Rail Coupler

1- Idler Rail Clamp Locking

Assembly

1- Idler Clamp Floating Assembly

24 - M6 x 10mm Set Screws (Pre-

installed in the Rail Couplers)

Tools Required:

3mm Allen Wrench

Note: Loosen M6 x 10mm Set Screws if the

Rail Couplers do not easily slide into the rail

ends. (Fig. 10-1)

10-1: Insert a Rail Coupler into a Rail Ratcheting End. Align the holes on the Rail Coupler

with the holes in the rail ends. (Fig. 10-2 and

Fig. 10-3.)

10-2: Tighten the pre-installed M6 x 10mm

Set Screws in the ratcheting and Non-Ratchet-

ing rail ends with an 3mm Allen Wrench. (Fig.

10-4)

Fig. 10-1

End

Fig. 10-2

Fig. 10-3

Fig. 10-4

Idler Rail Clamp

Locking Assembly

Fig. 10-5

3mm Allen Wrench

Rail Ratcheting EndRail Non-Ratcheting

Rail Coupler

Idler Clamp Floating

Assembly

Clamp Rail Coupler

10-3: Repeat step 10-1 and 10-2 for the

three remaining Rail Assemblies.

10-5: Insert the Clamp Rail Couplers into an

Idler Clamp Floating Assembly End. Align the

holes on the Clamp Rail Couplers with the

holes in the rail ends. (Fig. 10-5 and Fig. 10-

6.) Align the Clamp Rails so that the hinges

are on the same side. (Fig. 10-7)

10-6: Tighten the pre-installed M6 x 10mm

Set Screws into the Idler Rail Clamp Locking

Assembly and Idler Clamp Floating Assembly

with an 3mm Allen Wrench. (Fig. 10-7)

Fig. 10-6

Fig. 10-7

Hinges

Page. 12

Page 14

Step: 10-C: Rail Assembly for Crib

Parts Needed:

4- Rail Ratcheting End

4- Rail Non-Ratcheting End

Fig. 10-1-C

Rail Ratcheting End

Non-Ratcheting End Insert

1- Idler Rail Clamp Locking

Assembly

1- Idler Clamp Floating Assembly

Hinge

Hinge

8 - M6 x 10mm Set Screws (Pre-

installed in the Rail Couplers)

Tools Required:

3mm Allen Wrench

4mm Allen Wrench

6mm Allen Wrench

Fig. 10-2-C

Idler Rail Clamp Locking Assembly

Idler Clamp Floating Insert

M6 Set Screws

10-1-C: Unfasten the Non-Ratcheting End Insert from a Rail Non-Ratcheting End with a 6mm Allen Wrench.

Insert and fasten the Non-Ratcheting End Insert into the Rail Ratcheting End. (Fig. 10-1-C)

Note: If the rail end is difcult to remove, loosen the bolt half way out. Push in the bolt to release the compression cone, which will allow the rail end to be easily removed.

10-2-C: Repeat step 10-1-C for the remaining 3 rail ends.

10-3-C: Unfasten the Idler Clamp Floating Insert from the Idler Clamp Floating Assembly by removing four

M6 Set Screws with an M3 Allen Wrench. Insert and Fasten the Idler Clamp Floating Insert into the Idler Rail

Clamp Locking Assembly. Align the Clamp Rails so that the hinges are on the same side. (Fig. 10-2-C)

Step 11: Machine Magnetic Bracket

Parts Needed:

1- Magnet Bracket

1- Magnet Bracket Spacer

1- 1/4 x 1 inch Hex Bolt

Tools Required:

Fig. 11-1

1- 7/16 inch Wrench (Not provided with frame

contents.)

Magnet Bracket Spacer

Magnet Bracket

1/4 inch Hex Bolt

11-1: Remove the 1/4 x 1 inch hex bolt from the rear

right machine wheel. Align and fasten the Magnet

Bracket Spacer, Magnet Bracket, and 1/4 x 1 inch Hex

Bolt. (Fig. 11-1)

11-2: Place the Machine on the Bottom Carriage. (Fig.

9-3)

Note: Magnet Bracket Spacer is not used when using a

Pro-Stitcher system. This assembly step is universal for

both Crib and King size frames.

Fig. 11-2

Page. 13

Page 15

Step 12: Idler Rail Clamp Attachment to Frame

Parts Needed:

1- Idler Rail Assembly

1- Rail Clamp Lock Pin Assembly

1- M6 x 16mm SBHCS

Tools Required:

4mm Allen Wrench

Foward

Note: This assembly step is universal for

both Crib and King size frames.

Idler Rail Assembly clamp locking end

Front Rail Bracket Ratchet End rear hole

12-1: Insert the Idler Rail Assembly

through the throat of the machine and

clamp locking end into the Front Rail

Bracket Ratchet End rear hole. (Fig. 12-1)

Fig. 12-1

12-2: Rotate the Idler Rail Assembly so

that the Clamp Lock Rail End square Key is

facing forward. (Fig. 12-2)

12-3: Clip the Non-Ratcheting Floating

Clamp Lock Rail End Key

End into Front Rail Bracket Non-Ratchet

rear coupler. (Fig. 12-3)

Fig. 12-2

12-4: Align the keyed ends of the Idler Rail Assembly clamp locking end with the Rail Clamp Lock Pin end.

Attach the Rail Clamp Lock Pin Assembly to the Idler Rail Clamp Locking Assembly by fastening the M6 x

16mm SBHCS with a 4mm Allen Wrench. (Fig. 12-4)

Fig. 12-3

Front Rail Bracket Non-Ratchet rear coupler

Rail Clamp Lock Pin Assembly

M6 x 16mm SBHCS

Idler Rail Assembly clamp locking end key

Rail Clamp Lock Pin end key

Fig. 12-4

Page. 14

Page 16

Step 13: Rail Attachment to Frame

Parts Needed:

4- Rail Assembly

Note: This assembly step is universal for

both Crib and King size frames.

13-1: Insert the Rail Assembly through

the throat of the machine and Ratcheting

End into the Rail Ratchet End of the take

up rail ratchet assembly. (Fig. 13-1)

13-2: Clip the Non-Racheting End of the

rail into the Rail Holder of the take up rail

non-ratchet assembly. (Fig. 13-1)

13-3: Similar to Steps 13-1 and 13-2

install the remaining rails into their corresponding frame ends. (Fig. 13-1)

Fig. 13-1

Non-Ratcheting End

Rail Holder

Rail Ratchet End

Ratching End

Step 14: Handwheel Attachment to Rail End

Parts Needed:

1- Handwheel Assembly

1- Handwheel Coupler

1- M10 Washer

1- M10 x 125mm SBHCS

Tools Required:

6mm Allen Wrench

Note: This assembly step is universal for both

Crib and King size frames.

14-1: Remove the M10 x 80mm SBHCS from

the existing Take Up Rail Assembly with a 6mm

Allen Wrench. (Fig. 14-1)

14-2: Fasten Handwheel Coupler, Handwheel

Assembly, M10 Washer, and M10 x 125mm

SBHCS with a 6mm Allen Wrench to the end of

the Rail Assembly from Step: 14-1. (Fig. 14-2)

M10 x 80mm SBHCS

Fig. 14-1

M10 x 125mm SBHCS

M10 Washer

Handwheel Assembly

Handwheel Coupler

Fig. 14-2

Step 15: Leveling Feet Adjustment

Tools Required:

1- Open Wrench 17mm

Step 15-1: Adjust leveling feet with the 17mm Open Wrench so

that the machine remains stationary without interaction from the

user. To raise the leg of the machine simply turn the foot clock-wise

shown in Fig. 15-1 and reverse action to lower the foot.

Fig. 15-1

Page. 15

Page 17

Step 16: Wire Connection

Parts Needed:

1- Ethernet Cable Short

2- Ethernet Cable Long (Pre-installed on frame

ends)

1- Power Supply

2- Motor Cable (Pre-installed on frame ends)

16-1: Plug the Ethernet Cable Short into the Ethernet

ports on the underside of the Table Assemblies between

the Middle Leg. (Fig. 16-1)

Note: Step 16-1 is only required for King size frame as-

sembly.

16-2: Plug the Ethernet Cable Long, Power Supply Cable, and Motor Cable into the corresponding ports in the

Right Frame End. The Motor Cable Tab must be oriented

upward. (Fig. 16-2 and Fig. 16-3)

16-3: Plug the Ethernet Cable Long and Motor Cable into

the corresponding ports on the Left Frame End.

Note: The Left Frame End does not require a power supply.

16-4: Plug the Ethernet Cables that are near the rear of

the Frame Ends into the Table Assembly Ethernet Port.

(Fig. 16-4 and Fig. 16-5)

Fig. 16-1

Motor Cable

Tab

Fig. 16-2

Ethernet Cable Short

Middle Leg

Right Frame

End

Ethernet Cable Long

Power Supply Cable

Motor Cable

16-5: Plug the Power Supply into the Master Board Box.

(Fig. 16-6)

Fig. 16-3

Ethernet Port

Ethernet Cable

Fig. 16-4

Fig. 16-5

Right Frame

End

Master Board Box

Power Supply

Fig. 16-6

Page. 16

Page 18

16-6: Plug a 12V power supply into the sewing machine board on the carriage and into 110 – 220 VAC

power.

Step 17: Speed Control

Note: The Speed Control knob is located

on the side of the Right Frame End.

17-1: Switching the Speed Control Knob

setting away from STOP turns the sliding

rail on and controls the speed at which the

sliding rails move. (Fig. 16-1)

Frame Center Diagram

Crib Center 30 in

Fig. 17-1

King Center 60 in

King Total Length 120 in

Page. 17

Page 19

Frame Rail Diagram

Quilting Setup

Take up Rail

Idler Rail

Backing Rail

Top Rail

Batting Rail

Section 1: Fabri-Fast System

Tools Required:

1- Fabri-Fast Tool

4- Fabri-Fast Tube

Fig-S. 1-1

Fabri-Fast Tool

Fabri-Fast Tube

Note: This assembly step is universal for both Crib and King size frames.

Section 1-1: Lay the fabric over the Fabri-Fast Slot of a rail assembly and secure the fabric by pressing in

the Fabri-Fast Tubing with a Fabri-Fast Tool. (Fig. 1-1-S)

Note: Some fabrics maybe difcult to insert into the Fabri-Fast Slot, another option is to tape the fabric to

the rail.

Page. 18

Page 20

Section 2: Leader Cloth

Leader Cloth Diagram

Section 2-1: High thread count fabric such as Muslin is recommended for

18"

3/4" Casing

Top Leader

Leader Cloth material. Thick fabric may

be difcult to install in the rail Fabri-Fast

Slot.

18"

3/4" Casing

Backing Leader

Section 2-2: Cut your Leader Cloth

fabric to the match that of the Leader

Cloth Diagram with room for 1 inch for

a fabric casing and the width 6 inches

shorter than your rail length. Surge or

24"

3/4" Casing

Take-up Leader

Center Marks

hem all edges.

Fig-S. 2-1

Section 2-3: Fold over 1 inch for the fabric casing and sew a 3/4 inch casing with a conventional

sewing machine leaving both ends open.

Section 2-4: Slide the Fabri-Fast Tubing down the casing to ease the use of the Fabri-Fast system.

(Section 1)

Section 2-5: Pin the Leader Cloths to the appropriate sections of the quilt. (Fig-S. 2-2)

Leader Cloth Example

Casing

Take Up Leader

Insert Fabri-Fast Tube

Down the Length of

Casing

Fig-S. 2-2

Pins

Casing

Top Leader

Quilt Top

Batting

Quilt Backing

Backing Leader

Casing

Page. 19

Page 21

Section 3: Attaching Fabric on the Frame Rails

Tools Required:

1- Fabri-Fast Tool

4- Fabri-Fast Tube (Crib or King)

Note: This assembly step is universal for both Crib

and King size frames.

Section 3-1: Move the sewing machine back so that

the Take Up Rail moves to the rear position. (Fig-

S. 3-1) Unplug the power cords so the Take Up Rail

stays in the rear position.

Section 3-2: Pull the Rail Clamp Clip out and twist

the Idler Rail Clamp open. (Fig-S. 3-2)

Section 3-3: Attach the Take Up Leader into the

Take Up Rail using the Fabri-Fast System. (Fig-S. 3-3)

Section 3-4: Feed the Take Up Leader through the

Idler Rail hinged slot. (Fig-S. 3-3)

Take up Rail

Fig-S. 3-1

Take up Rail

Section 3-5: Pin the fabric and the batting to the

Take Up Leader. (Section 2: Leader Cloth and Fig-S.

3-3)

Section 3-6: Clamp the fabric by latching the Rail

Clamp Clip. (Fig-S. 3-3 and Fig-S. 3-4)

Take up Rail

Rail Clamp

Clip

Take Up Leader

Fig-S. 3-2

Take up Rail

Idler Rail

Rail Clamp

Clip

Idler Rail

Rail Clamp Clip

Fig-S. 3-3

Batting

Fabric

Idler Rail

Take Up Leader

Fig-S. 3-4

Page. 20

Page 22

Section 3-7: Disengage the Clamp Rail Lock Pin and

tighten the Idler Rail Assembly by turning the rail Counterclockwise a full rotation. Re-engage the Clamp Rail

Lock Pin ensuring the fabric is wrapped on the Idler Rail.

(Fig-S. 3-5)

Note: Section 3-7 will make the Quilting Surface at

and taut during quilting while the sliding rail operates.

Sections: 3-2, 3-6, and 3-7 will have to be repeated as

the quilt is rolled up on the Take Up Rail.

Section 3-6: Attach the Backing Leader to the Backing

Rail using the Fabri-Fast System and ratchet the remaining fabric onto the rail. (Section 1: Fabri-Fast System

and Fig-S. 3-7)

Section 3-7: Similarly, attach the Top Leader to the Top

Rail using the Fabri-Fast System and ratchet the remaining fabric onto the rail. (Section 1: Fabri-Fast System

and Fig-S. 3-8)

Take Up Leader

Fig-S. 3-5

Clamp Rail Lock

Pin

Section 3-8: The batting can be Fabri-Fasted onto the

Batting Rail if the batting is thin, otherwise tape and roll

it onto the rail to ease batting management. (Fig-S. 3-8)

Note: The Take Up Rail and Batting Rail have no par-

ticular direction of rotation and can rotate both ways

without effecting the frames performance.

Plug the power cords back in after the fabric installation

has been completed.

Top Leader

Quilt Top

Batting

Quilt Backing

Fig-S. 3-6

Quilt Top

Batting

Backing Rail

Fig-S. 3-7

Top Rail

Batting Rail

Fig-S. 3-8

Page. 21

Page 23

Section 4: Bungee Clamps

Tools Required:

4- Bungee Clamp

Note: This assembly step is universal for

both Crib and King size frames.

Section 4-1: Depress the bungee stop that

is built into the Bungee Track System and

pass the end of the bungee cord through the

bungee stop hole. (Fig-S. 4-1)

Section 4-2: Clamp the Bungee to the edge

of the fabric. Depress the bungee stop while

pulling on the cord end for tension and release when taut to lock. (Fig-S. 4-1)

Getting Started

Press to Unlock

Bungee Clamp

Fig-S. 4-1

The Momentum Frame is a unique patented system that allows the user to quilt the same size patterns all

the way through the quilt unlike traditional quilting frames. As a quilt is rolled onto the Take Up Rail through

the quilting process, the Momentum Frame automatically moves the completed portion of the quilt that is

rolled onto the Take Up Rail forward and back to permit the user take advantage of the entire length of the

throat of the machine. For the rst time ever, the maximum pattern size possible for the sewing machine

can be quilted from the beginning to end of a quilt without having to plan or compensate for the increasing

size of the fabric roll on the take up rail.

Upon completing the assembly of the frame, plug in the power supply from the Master Control Box and the

from the Right Frame End. The system is designed for use with 110-220 AVC power. Using a power strip or

surge protector will protect your system from power surges. The red LED light on the Master Control Board

and Right Frame Side indicates the system has power. The blue LED light indicates communication between

the circuit boards.

To use the system, set the control knob on the right side of the frame to Fast. Move the sewing machine forward and back on the carriage ve or six times to calibrate the system. The Take Up Rail Assembly will move

away from the needle as you move the machine back and away from the back of the throat of the machine

as you move the machine forward. During calibration the initial rst few movements of each side of the

frame may not be immediately even until calibration is complete. The system will gradually calibrate with

each movement causing the two sides to increasingly move more and more evenly. Each time the frame is

powered on or the speed setting is changed, it will begin the calibration process. After the initial ve or six

movements, the system will be calibrated and is ready for quilting.

Page. 22

Page 24

Trouble Shooting Guide

Sliding Rail not moving: Check if the Speed Control Knob is switched away from stop. The cables to the

Master Board Box, Frame Ends, and Table Structure must be attached correctly in their respective ports.

(Step 8: Bottom Carriage Assembly, Step 15: Wire Connection, and Step 16: Speed Control) There is also a

built-in sleep mode when the machine is not in operation. This may need to be reset, which would require

the user to unplug and plug the AC Power Supply.

Bungee Clamps: If it is necessary to use the bungee clamps over the batting on your quilt, turn the bun-

gee clamps upside down so the rubber grip in the clamp is gripping against the bottom fabric instead of the

batting. Having the rubber grip clamp against the batting is less effective than having it clamp against the

fabric.

Fabric Issues: Do not over-tighten the fabric on the quilting frame. Stretching the fabric will result in a

quilt that does lay at when it is nished.

Frame Cleaning: Regularly clean the wheels and track of your carriage and frame. Lint from the batting

will build up quickly, causing the carriage not to roll as smoothly if neglected.

Page. 23

Loading...

Loading...