AZEK Trim Moulding User Manual

TRIM MOULDING DECK PORCH RAIL PAVERS

AZEK Trim & Moulding

Install Guide

Storage & Handling, Cutting, Drilling, Routing ............................................................................ 2

Fastening, Expansion & Contraction .............................................................................................. 3

Painting, Gluing .................................................................................................................................. 4

Spanning, Water Table ..................................................................................................................... 5

Garage Door Thermostop, Rabbeted Cornerboard .................................................................... 6

Universal Skirt Board, Integrated Drip Edge ................................................................................ 7

Installing Finish Grade Trim ............................................................................................................. 8

Notes ....................................................................................................................................................10

• These guidelines cover the general installation recommendations for AZEK Trim and AZEK Moulding. See

specic installation information for Universal Skirt Board, Integrated Drip Edge, Rabbeted Cornerboard,

Column Wrap, Finish Grade Trim, Water Table, and Garage Door Thermostop.

• AZEK Trim and AZEK Mouldings should be installed using the same good building principles used to install

wood trim and mouldings and in accordance with the local building codes and the installation guidelines included below. AZEK Building Products Inc. accepts no liability or responsibility for the improper installation

of this product.

• AZEK Trim and AZEK Moulding may not be suitable for every application and it is the sole responsibility of

the installer to be sure that AZEK Trim and Mouldings are t for the intended use. Since all installations are

unique, it is also the installer’s responsibility to determine specic requirements in regards to each trim and

moulding application.

• AZEK Building Products recommends that all applications be reviewed by a licensed architect, engineer or

local building ofcial before installation. If you have any questions or need further assistance, please call

AZEK Customer Service at 877-ASK-AZEK (877-275-2935) or visit our website at www.azek.com.

Installation Guidelines for AZEK Trim and AZEK Moulding

STORAGE &

HANDLING

• Store AZEK Trim and Moulding products on a at and level surface.

• Since AZEK Trim and Moulding products are more exible than wood, they may conform

to uneven surfaces. Ensure that storage areas, as well as all framing and substructures,

are at and level to minimize uneven surfaces.

• AZEK Trim and Moulding products have a density comparable to pine and should be

handled in a fashion as pine would be handled to avoid damage.

• Units of AZEK Trim and Moulding products are shipped from the manufacturer in a

protective covering. If covering has been removed, take care to keep product free of

dirt and debris at jobsite. If product gets dirty, clean after installation.

CUTTING

• AZEK Trim and Moulding products can be cut using the same tools used

to cut lumber.

• Carbide tipped blades designed to cut wood work well. Avoid using ne

tooth metal cutting blades.

• Rough edges from cutting may be caused by excessive friction, poor

board support, or worn or improper tooling.

DRILLING

• AZEK Trim and Moulding products can be drilled using the same tools

used to drill lumber.

• Drilling AZEK Trim and Moulding products is similar to drilling a hardwood.

Care should be taken to avoid frictional heat build-up.

• Periodic removal of AZEK shavings from the drill hole may be necessary.

ROUTING

• AZEK Trim and Moulding products can be routed using standard router

bits and the same tools used to rout lumber.

• Carbide tipped router bits are recommended.

• Routing AZEK Trim and Moulding products provides a crisp, clean edge.

Page 2

Installation Guidelines for AZEK Trim and AZEK Moulding

FASTENING

• For best results, use fasteners designed for wood trim and wood siding. These fasteners

have a thinner shank, blunt point, and full round head.

• A #8 trim screw may be used and works well with AZEK Trim and Moulding products.

• To take advantage of the performance of AZEK Trim and Moulding products, use a

highly durable fastener such as stainless steel or hot dipped galvanized.

• Staples, small brads, and wire nails must not be used.

• The fasteners should be long enough to penetrate the solid wood substrate a minimum

of 1 1/2".

• Standard nail guns work well with AZEK Trim and Moulding products. If using pneumatic

tools, the air pressure should be regulated so fasteners slightly penetrate the surface.

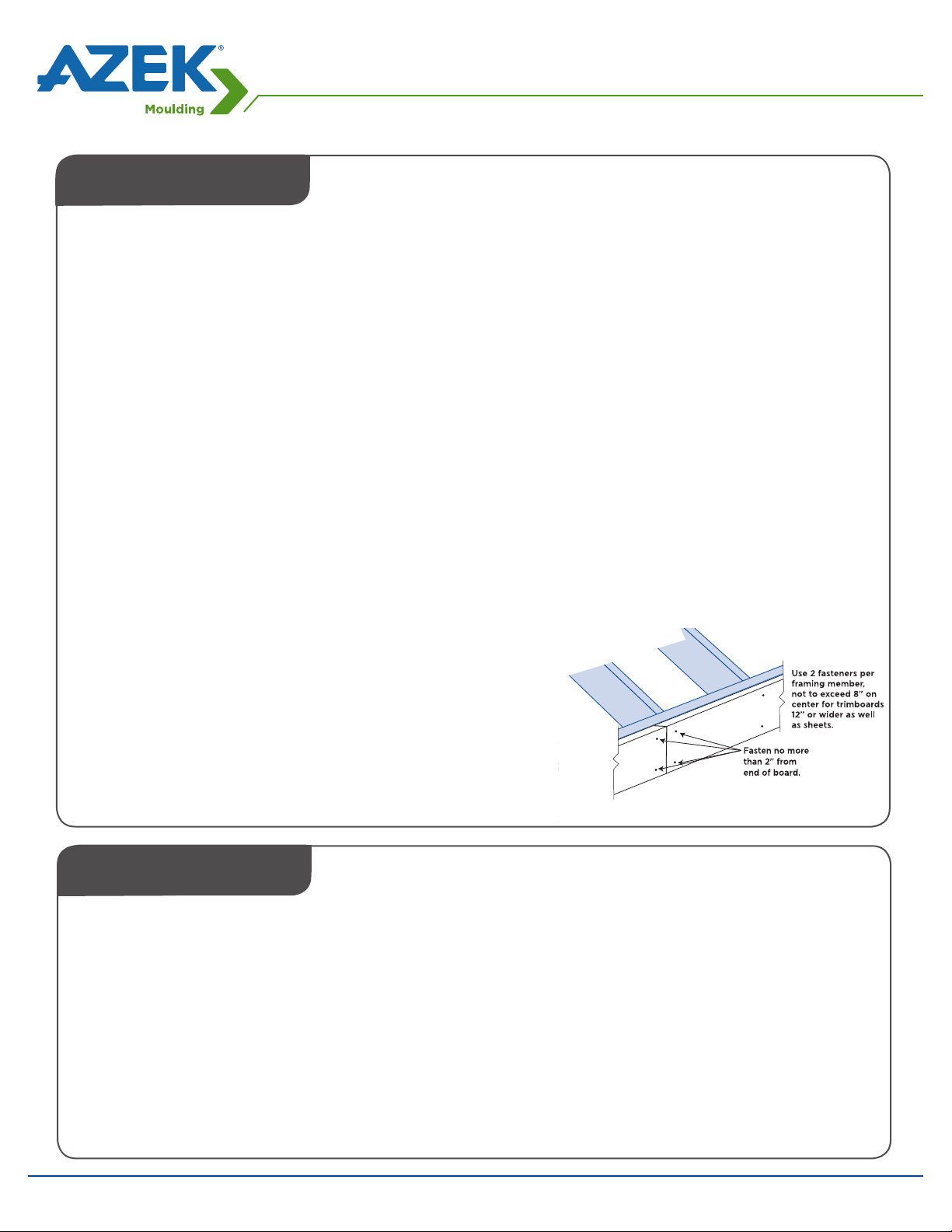

• Like wood, use 2 fasteners per every framing member for trimboard applications.

Trimboards 12” or wider, as well as sheets, will require additional fasteners, not to

exceed 8” on center. See illustration below.

• Fasteners must be installed within 2” of the end of each board. See illustration below.

• There must be 2 fasteners on each side of a board joint (scarf, miter, etc.).

• All fasteners must hit a solid framing member.

• AZEK Trim and Moulding products should be fastened into a at, solid substrate.

Fastening AZEK material into hollow or uneven areas must be avoided.

• Pre-drilling is typically not required unless a large fastener is used or product is installed

in low temperatures.

• 3/8” and 1/2” AZEK Sheet product is not intended

to be ripped into trim pieces. These proles must be

glued to a substrate and mechanically fastened.

• AZEK BEADBOARD FASTENING CONSIDERATIONS

(Use one of the following):

• #7 trim screw

• 16 gauge T-nail

• 15 gauge round head (for 1/2” Beadboard only)

• Fasteners should be a minimum of 1 1/2” in length

USE TWO FASTENERS ON

EACH SIDE OF JOINT

EXPANSION &

CONTRACTION

• AZEK Trim and Moulding products expand and contract with changes in temperature.

• Properly fastening AZEK Trim and Moulding material along it’s entire length will

minimize expansion and contraction.

• When properly fastened, allow 1/8” per 18 feet of AZEK Trim and Moulding products for

expansion and contraction. Joints between pieces of AZEK Trim and Moulding material

should be glued to eliminate joint separation. See “Gluing”.

• When gaps are glued on a long run of AZEK Trim and Moulding material, allow

expansion and contraction space at ends of the run.

• AZEK Trim and Moulding should be glued to a substrate and mechanically fastened to

help minimize expansion and contraction.

• WARNING: Dark colors may increase movement and expansion and contraction of PVC

Trim and Moulding.

Page 3

Installation Guidelines for AZEK Trim and AZEK Moulding

PAINTING

• AZEK Trim and Moulding does not require paint for protection, but accepts and holds

paint very well.

• If you choose to paint, use a 100% acrylic latex paint with colors

having a Light Reective Value (LRV) of 55 or higher.

• For darker colors (LRV of 54 or lower) use paints with heat

reective characteristics specically formulated for use on vinyl/

PVC products. These paints/coatings are designed to reduce

excessive heat gain.

• WARNING: It is recommended that should you choose to paint a

darker color (LRV of 54 or lower) all aforementioned installation

steps should be followed.

• Follow the paint manufacturer’s recommendations for use and

compatibility with AZEK Trim and Mouldings.

• AZEK Trim and Moulding surfaces must be clean, dry, and void of

any foreign material such as dirt, oil, grease or other contaminates

that may come from normal handling, storage and/or installation

prior to painting.

• Moisture cycling is a main reason for paint failure on wood. Since

AZEK Trim and Moulding material absorbs almost no moisture,

paints last longer on AZEK Trim and Moulding products than it

does on wood.

• Since AZEK Trim and Moulding products have almost no moisture absorption, paints

may take longer to cure than on wood. Generally paints used on AZEK Trim and

Moulding products will be dry to the touch quickly, but may take up to 30 days to

fully cure depending on the humidity and temperature.

100% Acrylic Latex

with LRV 55 or

higher.

Use specically

formulated paints

for darker colors

(LRV 54 or lower).

GLUING

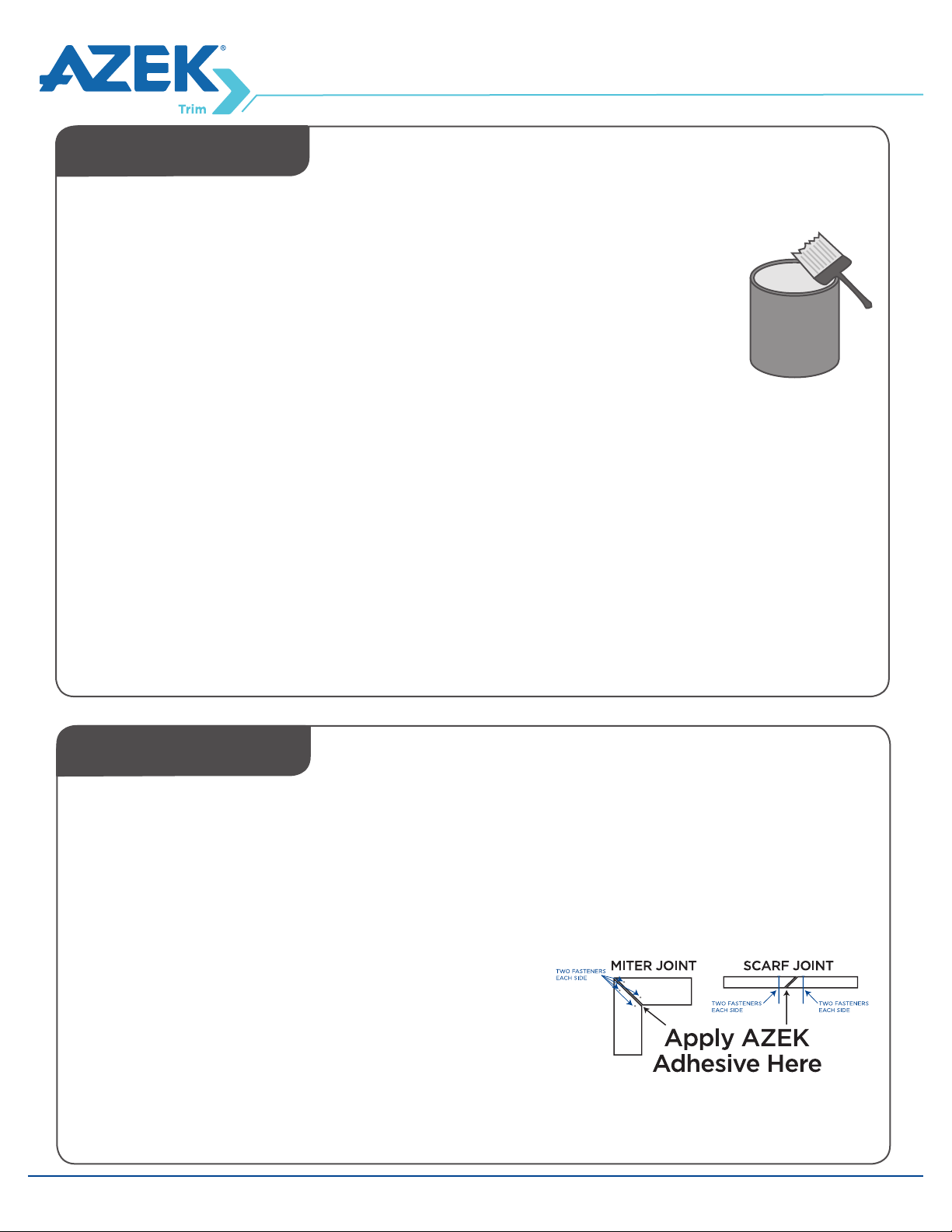

• For best results, glue all AZEK-to-AZEK joints such as window surrounds, long fascia

runs, etc., with AZEK Adhesive to prevent joint separation.

• The glue joint should be fastened on each side of the joint to allow adequate

bonding time.

• AZEK Adhesive has a working time of 10 minutes and will be fully cured in 24 hours.

• If standard pvc cements are used, these products typically cure quickly which will

result in limited working time and may reduce

adhesive strength.

• For best results, surfaces to be glued should

be smooth, clean and in complete contact

with each other.

• For best results, always use a scarf joint with

two fasteners on each side instead of butt

joints.

• To bond AZEK Trim and Mouldings to other

substrates, various adhesive may be used. Consult adhesive manufacturer to

determine suitability.

Page 4

Loading...

Loading...