AZEK Rail User Manual

TRIM MOULDING DECK PORCH RAIL PAVERS

AZEK Rail

Install Guide

Installing AZEK Rail with CableRail by Feeney® .......................................................................... 1

Installing CableRail by Feeney® for AZEK Rail ........................................................................... 7

Installing AZEK Rail Stairs with CableRail by Feeney® ............................................................10

Installing CableRail by Feeney® Stairs for AZEK Rail ...............................................................14

Notes .................................................................................................................................................... 18

• Please read all instructions completely before starting any part of the installation.

• AZEK Rail should be installed using the same good building principles used to install wood or composite

railing and in accordance with the local building codes and the installation guidelines included below.

AZEK Building Products Inc. accepts no liability or responsibility for the improper installation of this product.

• AZEK Rail may not be suitable for every application and it is the sole responsibility of the installer to be sure

that AZEK Rail is t for the intended use. Since all installations are unique, it is also the installer’s

responsibility to determine specic requirements in regards to each Rail application.

• AZEK Building Products Inc. recommends that all applications be reviewed by a licensed architect, engineer

or local building ofcial before installation. If you have any questions or need further assistance, please call

AZEK Customer Service at 877-ASK-AZEK (877-275-2935) or visit our website at www.azek.com.

• AZEK Railing is tested as a whole system and should be used that way. It is not intended to be used in

conjunction with other railing systems or fasteners.

• The following Installation Guidelines are applicable for installation of AZEK Premier, AZEK Trademark, and

AZEK Reserve Rail Systems (except AZEK Reserve over post applications).

• IMPORTANT: Make sure the DRIVE TOOL/DRILL is congured or set to use the SCREW setting when driving

and/or tightening all FASTENERS.

• SAFETY: Always wear goggles when handling, cutting, drilling and fastening materials.

• Failure to install this product in accordance with applicable building codes and AZEK’s written Rail Install

Guide may lead to personal injury, affect rail system performance and void the product warranty.

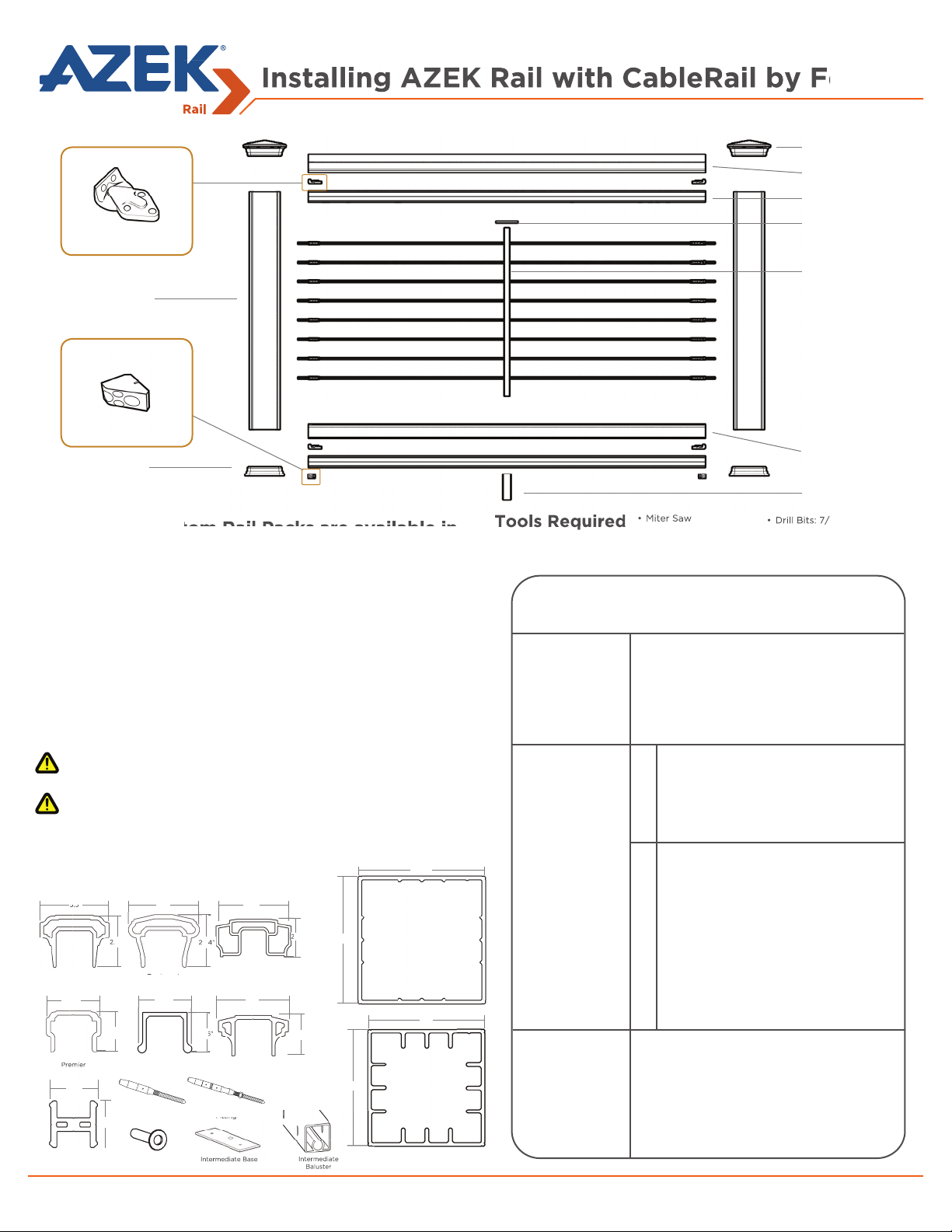

Installing AZEK Rail with CableRail by Feeney

•

Miter Saw

•

Drill Bits: 7/64”,1/4”, 3/16”,

2.64”

2.72”

3.5”

2.63”

Premier

Plate

Fitting

Intermediate Base

Intermediate

Baluster

®

Mounting Bracket (4

)

Post Sleeve (2)

Support Block (2)

Post Skirt (2)

AZEK Rail Custom Rail Packs are available in

10’, 8’ and 6’ lengths.

Visit www.azek.com/installation to view AZEK installation videos.

Consult your local building codes for guard and handrail requirements.

Measuring Your Railing Area

• Measurements are from center to center of the posts. Kits

are produced in 10’, 8’ and 6’ to allow for fi nished end cuts

and angles.

•Determine how many 10’, 8’ and 6’ AZEK Rail Custom Rail

Packs you need and check to be sure you have all the

components (and quantities) listed in the chart shown

to the right.

Important Information

•AZEK Rail 10’, 8’ and 6’ Rails are designed not to

exceed 10’, 8’ and 6’ from center of post to center of post,

respectively.

•For stair applications maximum rail length must not exceed 91”.

•4x4 lumber posts should be installed plumb.

•Cut slowly, using a fi ne tooth saw blade to avoid chipping.

•Cannot be installed using Secure Mount Post.

•For 42” railing, use 54” Post Sleeve.

Component Dimensions

2.63”

Quick-Connect

3.5”

Trademark

Top Rail

2.73”

Trademark

Bottom Rail

Fitting

5.38”

2.64”

Reserve Top

Rail

3.5”

2.05”

Reserve

Bottom Rail

Quick-Connect Swivel

Fitting

3.5”

Premier Top

Rail

2.72”

Premier

Bottom Rail

1.8”

2.05”

1.8”

2.72”

6.32”

2.05”

5.5”

6.32”

6” x 6” Post Sleeve

5.5”

Tools Required

Components Needed For Installing

The AZEK Rail Section

Hardware

included in

Hardware Kits:

Components

available

separately for

mix-and-match

rail

systems

Additional

Components

Needed for Each

System

Post Cap (2)

Top Rail (1)

Support Rail (2)

Intermediate

Base Plate

Intermediate

Baluster

Bottom Rail (1)

Foot Block (2)

• Miter Saw

• Tape Measure

• Drill

• Cable Cutters

• #2 Square Drive

Hardware Mounting Kit

4 - Mounting Brackets

2 - Support Blocks

16 - #8 x 3/4” screws

6 - #8 x 1 3/4” screws

6 - #8 x 2 5/8” screws (Stairs Only)

6 - #8 x 3” Screws

12 - #8 x 3” Green Screws

T20 Driver Bit

1 - Top Rail (Reserve Top Rail sold separately)

1 - Bottom Rail

2 - Support Rails (1-Aluminum Top Support Rail for 10')

Hardware Mounting Kit

Support Block Mounting Templates

Foot Blocks

Rail Pack

- 1 in 6’ Packs, - 2 in 8’ Packs, - 3 in 10' Packs

AZEK Rail Custom

36” Intermediate Baluster

-1 for 6’, 2 for 8’, 3 for 10'

42” Intermediate baluster

-1 for 6’, 2 for 8’, 3 for 10'

Stair Intermediate

baluster

-1 for 6’, 2 for 8’, 3 for 10'

Cable

-100’ spool or 500’

spool

CableRail Components

2 - Post Sleeves

2- Post Caps

2- Post Skirts

Protector Sleeves

- 42” System: 22 per Thru Post

- 36” System: 18 per Thru Post

• Drill Bits: 7/64”,1/4”, 3/16”,

1/8” 9/64”

• Extended 1/4” Drill Bit

• 2 3/8” Open-End

Wrenches

36” Hardware Kit

- 9 Quick-Connect

Fittings

- 9 Quick-Connect

Swivel Fittings

- 18 Hanger Bolts

- 9 lock nuts

42” Hardware Kit

- 11 Quick-Connect

Fittings

- 11 Quick-Connect

Swivel

Fittings

- 22 Hanger Bolts

- 11 lock nuts

CableRail Accessory

Pack Includes:

- Quick-Connect release

tool

- Lacing Needle

- Hanger Bolt

Installation Tool

Support Rail

Protector Sleeve

Intermediate

Baluster

5 1/2” x 5 1/2” Post Sleeve

Page 2

Installing AZEK Rail with CableRail by Feeney

skirt.

For angled rail installations

- align angled face of Support

Block parallel to rail section.

®

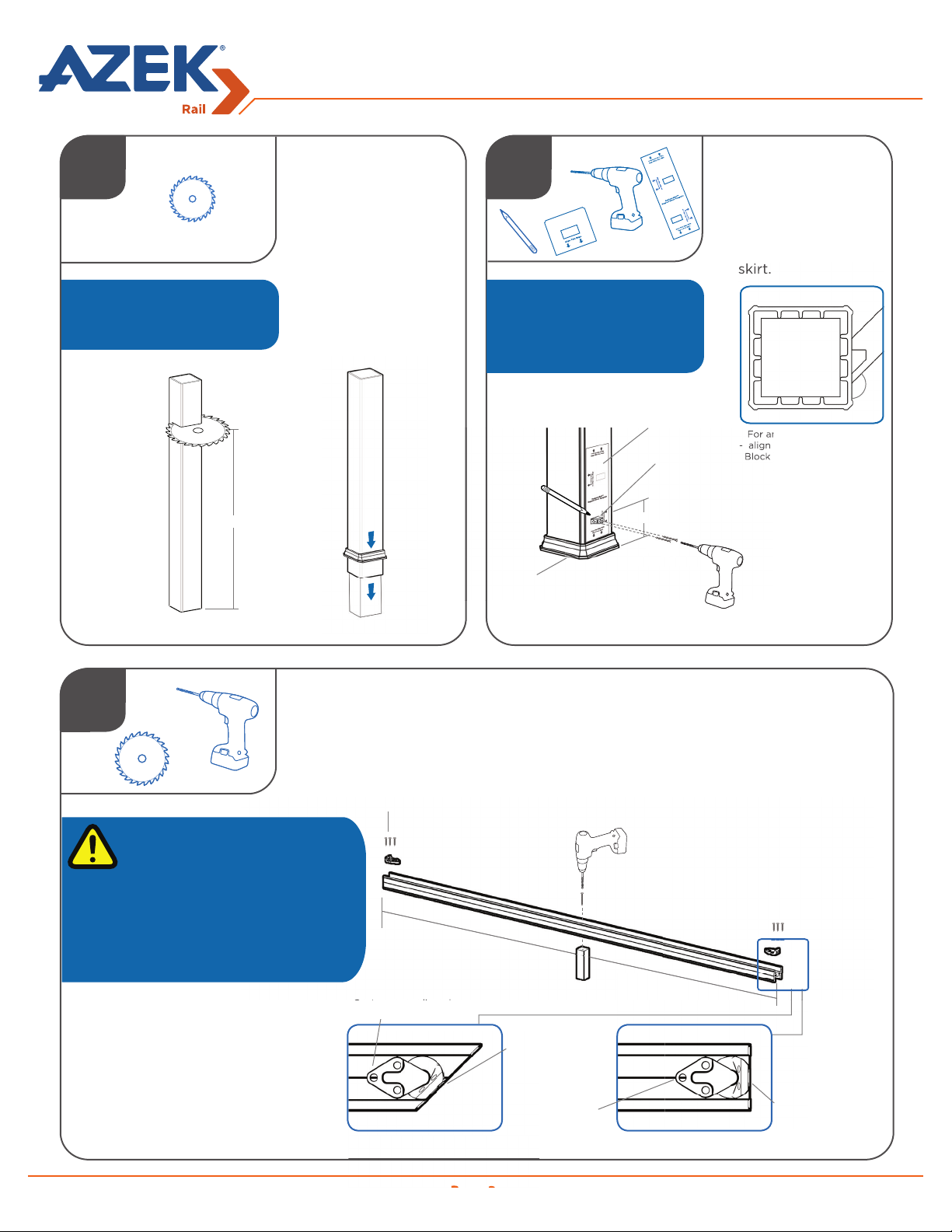

1

40” above deck surface is

optimal for 36” railing heights.

Optimal 40”

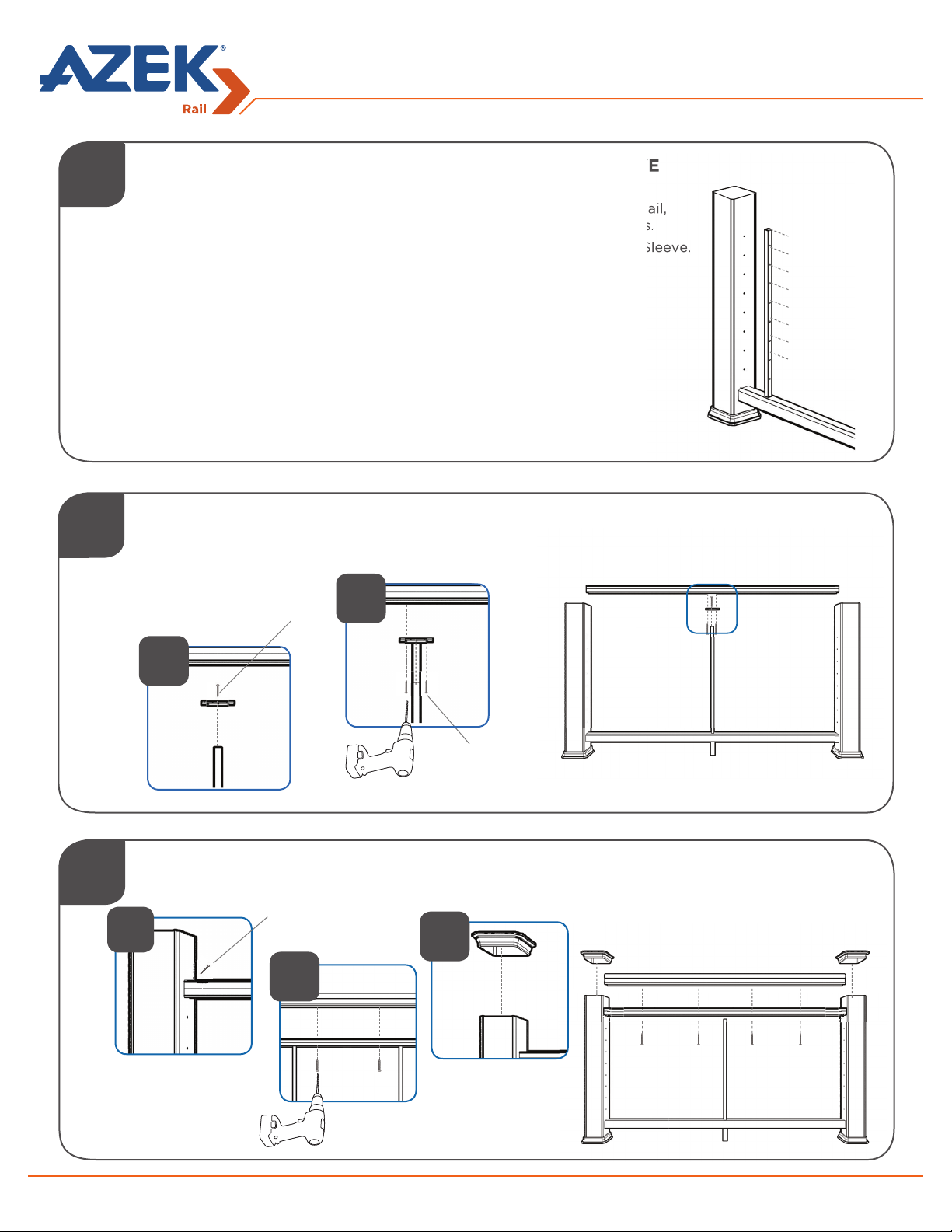

INSTALL POST

SLEEVE

• Trim Post Sleeve to

desired length.

• Slide Post Sleeve and

Post Skirt over post

(do not force).

• Ensure posts are

square and plumb.

2

If you do not have a the

template, position

the top of the Support Block 4”

above the deck.

Template

Support

4”

7/64” Pre-drill

Post

Skirt

#8 x 3” Green

Coated Screws

Block

INSTALL LOWER

SUPPORT BLOCK

• Position template at

bottom of post

sleeve above post

skirt.

For angled rail installations

- align angled face of Support

Block parallel to rail section.

45°

3

CUT AND ASSEMBLE BOTTOM SUPPORT RAIL

•Cut the Bottom Support Rail to length.

For sections up to 6’: Place one Foot

Block in the center of the rail.

For sections 6’ to 8’: Space two Foot

Blocks approximately at 1/3 intervals on

the rail.

For sections 8’ to 10’: Space three Foot

Blocks approximately at 1/4 intervals on

the rail.

7/64” Pre-drill

#8 x 3/4” Coated Screws

1/2

Center screw aligned

to rail centerline

Angled Section

7/64” Pre-drill

#8 x 3” Coated

Screws

Bracket set

fl ush to rail

face

Foot Block

Center screw

aligned to rail

centerline

Straight Section

1/2

Bracket set

fl ush to rail

face

Page 3

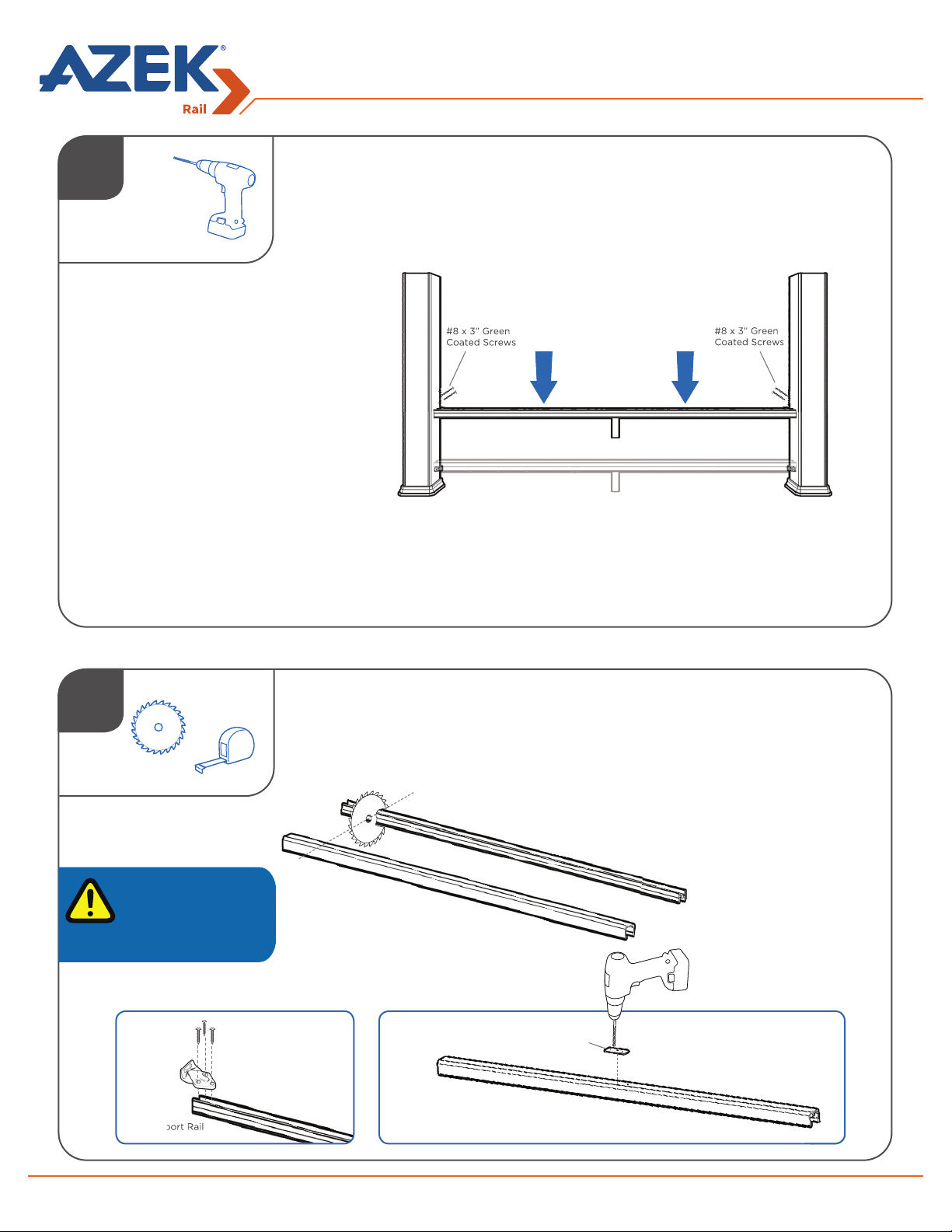

4

#8 x 3” Green

Coated Screws

#8 x 3” Green

Coated Screws

Installing AZEK Rail with CableRail by Feeney

INSTALL BOTTOM SUPPORT RAIL

• Position rail assembly onto Support Blocks.

®

5

#8 x 3” Green

Coated Screws

#8 x 3” Green

Coated Screws

CUT AND PREP BOTTOM RAIL AND TOP SUPPORT RAIL

• Measure distance between the posts at the Bottom Rail and Top Support Rail.

• Cut to length.

• Attach Brackets to the Top Support Rail.

6’ sections require 1

Intermediate Baluster;

8’ sections require 2

Intermediate Balusters.

10’ sections require 3

Intermediate Balusters.

8 x 3/4” Coated

Screws

Top Support Rail

Top Support Rail

Bottom Rail

Page 4

Use

Intermediate

Base Plate as

template

Bottom Rail

Pre-drill 3/16”

6

Installing AZEK Rail with CableRail by Feeney

ATTACH INTERMEDIATE BALUSTERS

®

Intermediate

Baluster

Pre-drill

3/16”

#10 x 2” Coated

Screws

For ease of installation, pre-drill

screw chase with a 3/16” drill bit.

Ensure the screw fi nds the screw

chase.

Screw Chase

Bottom Rail

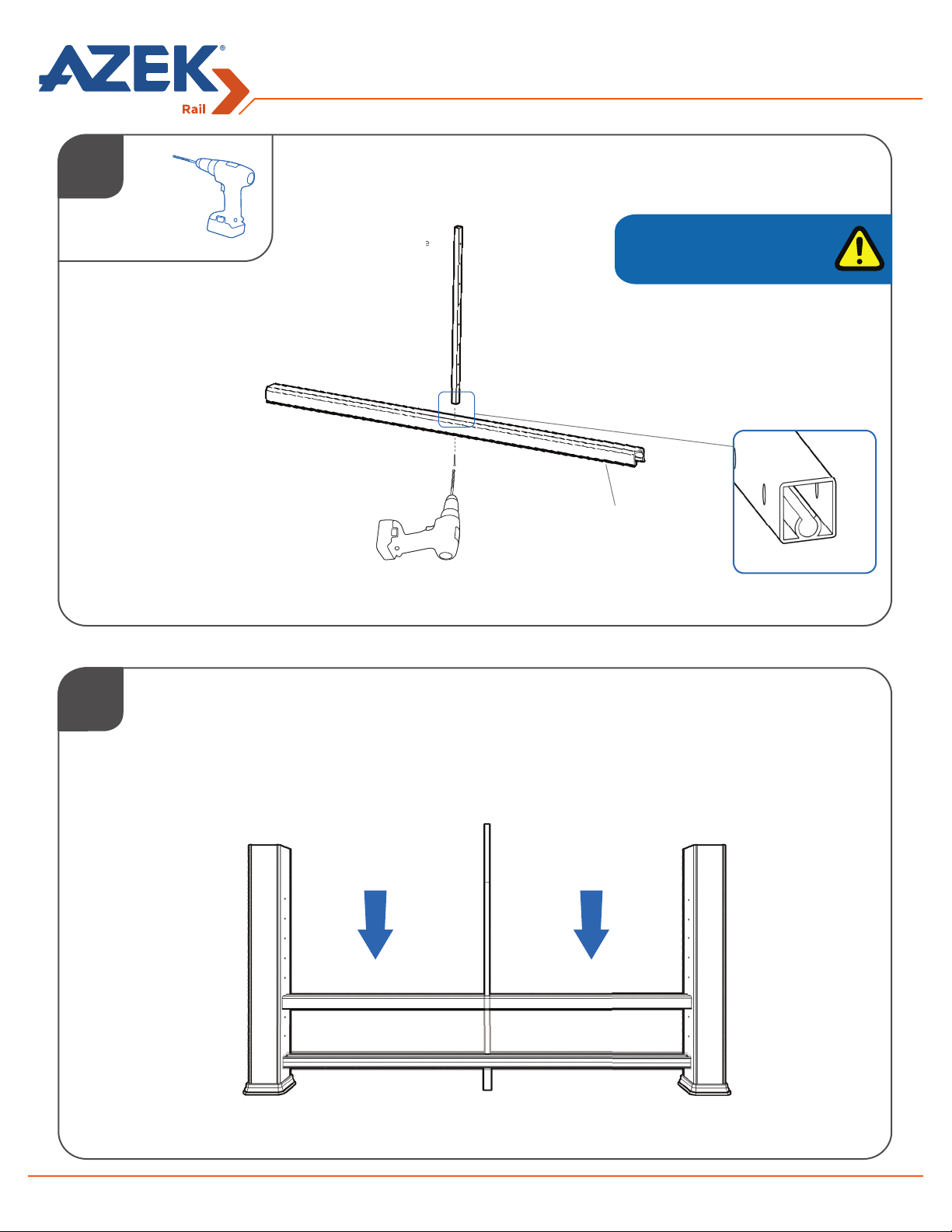

7

INSTALL BOTTOM RAIL

• Place the Bottom Rail between the posts and allow the rail to

rest on the Bottom Support Rail.

Bottom Rail

Bottom

Support Rail

Page 5

8

9

Installing AZEK Rail with CableRail by Feeney

TRANSFER HOLE LOCATION ONTO POST SLEEVE

• Use an extra Intermediate Baluster, rested on the Bottom Rail,

as a template for the CableRail Hardware and through holes.

• Using a 3/16” drill bit to transfer your marks onto the Post Sleeve.

ATTACH TOP SUPPORT RAIL

Support

Rail

®

10

a

a

#10 x 1”

Coated

Screws

b

Pre-drill

9/64”

#10 x 1”

Coated

Screws

INSTALL TOP RAIL AND POST CAPS

Pre-drill 7/64”

#8 x 3” Green

Coated Screws

c

b

Secure Post

Caps with

exterior

grade caulk.

Intermediate

Base Plate

Intermediate

Baluster

Pre-drill 3/16”

#8 x 1 3/4” Coated

Screws

Page 6

Loading...

Loading...