Avision @V6600 Service Manual

Network Scanner

Service Manual

(P/N: 253-0115-E)

Avision Inc.

ii

Contents

1. INTRODUCTION ....................................................................................... 1-1

1.1 GENERAL NOTES FOR SERVICING ................................................................. 1-1

2. SPECIFICATION ....................................................................................... 2-1

3. PRECAUTIONS OF INSTALLATION/TRANSPORTATION ................................. 3-1

3.1 PRECAUTIONS OF INSTALLATION ................................................................. 3-1

3.2 TRANSPORTATION.................................................................................. 3-1

4. THEORY OF OPERATION ............................................................................ 4-1

4.1 INTRODUCTION ..................................................................................... 4-1

4.2 MAIN CONTROL UNIT .............................................................................. 4-2

4.2.1 System Diagram ...................................................................... 4-2

4.2.2 SENSOR INPUT ........................................................................ 4-3

4.2.3 SUB POWER SUPPLY CIRCUIT ..................................................... 4-3

4.2.4 POWER SUPPLY ....................................................................... 4-4

5. PROBLEM SOLVING .................................................................................. 5-1

5.1 TROUBLESHOOTING FLOWCHART ................................................................. 5-2

5.1.1 POWER ON TO @V6600 READY ................................................... 5-2

5.1.2 E-MAIL OPERATION .................................................................. 5-3

5.1.3 FILING OPERATION .................................................................. 5-4

5.1.4 SCAN TO USB FLASH DRIVE OR PUBLIC FOLDER. ........................... 5-5

5.2 TABLES ............................................................................................. 5-6

5.2.1 LCD does not display ................................................................ 5-7

5.2.2 SCANNING IS NOT PERFORMED .................................................. 5-7

5.2.3 IMAGE UNCLEAR ...................................................................... 5-8

5.2.4 NOISE GENERATED .................................................................. 5-8

5.2.5 LCD DOES NOT SHOW MESSAGE AFTER COMMAND ........................ 5-9

5.2.6 THE PRODUCT IS NOT CONNECTED TO THE NETWORK.................... 5-9

5.2.7 INFORMATION MESSAGES DURING INITIATION OR SCANNING.........5-10

5.2.8 INFORMATION MESSAGES DURING NETWORKING .........................5-11

5.2.9 INFORMATION MESSAGES DURING E-MAILING .............................5-12

5.2.10 INFORMATION MESSAGES DURING FILING ...................................5-14

5.2.11 INFORMATION MESSAGES DURING SCAN TO USB DRIVE OR PUBLIC

FOLDER ................................................................................5-16

iii

6. DISASSEMBLY .......................................................................................... 6-1

6.1 SERVICE TOOL ..................................................................................... 6-1

6.2 PROCEDURE FOR DISASSEMBLY AND REASSEMBLY .............................................. 6-2

6.2.1 Notes on disassembly ............................................................... 6-2

6.2.2 Removing the ADF pad .............................................................. 6-3

6.2.3 Removing the ADF Roller ........................................................... 6-5

6.2.4 Removing the Output Tray ......................................................... 6-6

6.2.5 Removing the ADF Front Cover ................................................... 6-8

6.2.6 Removing the 2 Sensor Units on the front case .............................6-10

6.2.7 Removing the Sensor Board ......................................................6-14

6.2.8 Removing the ADF Board ..........................................................6-16

6.2.9 Removing ADF Chassis .............................................................6-17

6.2.10 Removing ADF Inverter ............................................................6-20

6.2.11 Removing ADF Motor ...............................................................6-22

6.2.12 Removing the Hinge ................................................................6-24

6.2.13 Removing the Metal Cover ........................................................6-26

6.2.14 Removing the Main Board .........................................................6-28

6.2.15 Removing the CF Card Board .....................................................6-30

6.2.16 Removing the Name Plate.........................................................6-31

6.2.17 Removing the Panel Main Board .................................................6-33

6.2.18 Removing the Panel Screen.......................................................6-36

6.2.19 Removing the Back Cover of the Panel ........................................6-38

6.2.20 Removing the Rubber Cap ........................................................6-40

6.2.21 Removing the Upper Housing ....................................................6-41

6.2.22 Removing the Metal Plate .........................................................6-43

6.2.23 Removing the Sliding Rod .........................................................6-44

6.2.24 Removing the Flatbed Chassis ...................................................6-45

6.2.25 Removing the Chassis Cover .....................................................6-46

6.2.26 Removing the Motor ................................................................6-47

6.2.27 Removing the Inverter .............................................................6-50

6.2.28 Removing the Lamp Assembly ...................................................6-53

Service Manual

1-1

1. INTRODUCTION

General Notes for Servicing

General Description

The manual describes areas to be maintained, the detailed installation, the disassembly,

and the component replacement procedures as well as the main trouble shooting guides.

Please take your time to read this manual thoroughly to obtain comprehensive knowledge

about the scanner before serving the unit.

1.1 General notes for servicing

(1) Before trying to disassemble the scanner, make sure the power supply cord of the

scanner is disconnected from the power outlet. Under any circumstance, do not

remove or install the connectors on the scanner with the power supply turned ON.

(2) Use caution not to drop small parts or screws inside the unit when disassembling and

reassembling. If left inside, they might cause the malfunction of the unit.

(3) Do not pull the connector cable when disconnecting it. Hold the connector.

(4) When carrying the scanning head unit, put it in an anti-static bag.

(5) Keep the document table glass surface always clean. If contaminated, use a dry

clean cloth for cleaning.

(6) Use caution not to injure your fingers or hands when disassembling or reassembling

the unit.

2-1

2. SPECIFICATION

Model Name

@V6600

Product Type

Legal size Flatbed + DADF (Dual Reading Head

Duplex ADF)

Optical Resolution

600 x 600 dpi

Adaptor Input Voltage

AC 100~240V

Adaptor Output

24V DC, 3.2A

CPU

400 MHz, Toshiba x4939 (MIPS64)

Scanner ASIC / Image

Processor

124 MHz, visionMax 800 * 2

DSP Co-Processor

500 MHz, SPI SP-16

Memory Size

896 Mbytes DRAM in total

System: 128MB

Scanner/Image Buffer: 256MB

DSP: 512MB

Flash Memory Size

40.5 Mbytes in total

System: 8.5Mbytes

DSP: 32 Mbytes

Built-in CF Card Storage

8/16Gbytes

LCD display

7” color TFT LCD

800*480 dots

Effective Area: 152.4 * 91.44 mm

With Touch Panel

Specifications

Service Manual

2-2

Connectivity (External Ports)

USB 2.0 Device * 1

USB 2.0 Host * 2 (on Rear Panel)

USB 2.0 Host * 1 (on Front Panel)

RJ-45 Network Connector * 1

Dimensions (W x D x H)

531 x 484 x 401 mm3 (with ADF)

Weight

12.92 Kgs (With ADF)

Maximum Scanning Area

(Flatbed)

8.5” x 14”

Document Set Reference

Left upper corner

Life

Scanner life(Flatbed)

Lamp life

50,000 scans or 5 years

More than 10,000 hours

Acoustic Noise

46 dB

MTBF

5,000 hours

Type

U-shape, Dual-Head Duplex

Capacity

50 sheets

Document Size

4.5” x 5.5” ~ 8.5” x 14”

Paper Feed

Face Up

Paper Weight

16 lb ~ 28 lb (60g/m2 ~ 105 g/m2)

0.002”~0.006”

Multi-Feed Detect

Yes

ADF life

600,000 scans or 5 years, whichever comes first

Recommended Pad

Replacement

30,000 scans

Customer Replaceable

Recommended Roller

Replacement

200,000 scans

MTBF

5,000 hours

Network Topology

10/100/Gigabit Ethernet

Connectivity

RJ-45 UTP connector

Service Manual

2-3

Protocol

TCP/IP, DHCP

802.1x, SSL/TLS

DNS, DDNS, SNTP

LDAP, LDAP-SSL, SLP,

SMTP, HTTP, HTTPS, MIME, FTP, FTPS, CIFS(SMB)

HTTP Server

, Port9100

Connection Configuration

1. Enable DHCP or

2. assign physical IP address:

IP address

IP subnet mask

IP Gateway

Device URL

Same as Information/Device Name

Security

IEEE802.1x, SSL/TLS

Service Manual

3-1

3. PRECAUTIONS OF

INSTALLATION/TRANSPORTATION

Precautions of Installation

Transportation

3.1 Precautions of Installation

Pay attention to the following matters before unpacking and installation.

Do not install in a place where vibration may occur.

Keep the scanner out of direct sunlight. Do not install near a heat source.

Do not place the scanner around materials which shut off the circulation of air.

Do not install in a humid or dusty place.

Use care not to scratch the glass surface of the scanner or the document holding

pad with a clip or staple.

Do not use the wall socket with connecting devices which may generate noise, for

example, air-conditioner, etc.

Use a suitable AC power source.

Place the scanner on a level surface.

3.2 Transportation

To move the scanner from where it is installed, for repair or any other reason, make

sure to observe the following conditions:

(1) Turn off the power of the scanner.

(2) Remove the power cable and lock the scanner.

(3) Put the scanner in the packing case with the packing material.

4-1

Main

Board

1 0 0 1 0

Cold Cathode

Lens

CCD

Analogue

Signal

Digital

Signal

Fluorescent Lamp

Image

Processor

CPU

Reflected

Rays

TouchScreen

CPU

ASIC

Ethernet

SMTP

/Filing

Server

PC Scan

Ethernet

USB

Host

USB flash

drive

RJ-45

USB Device

Email

Filing

NetworkPrint

4. THEORY OF OPERATION

Introduction

Main Control Unit

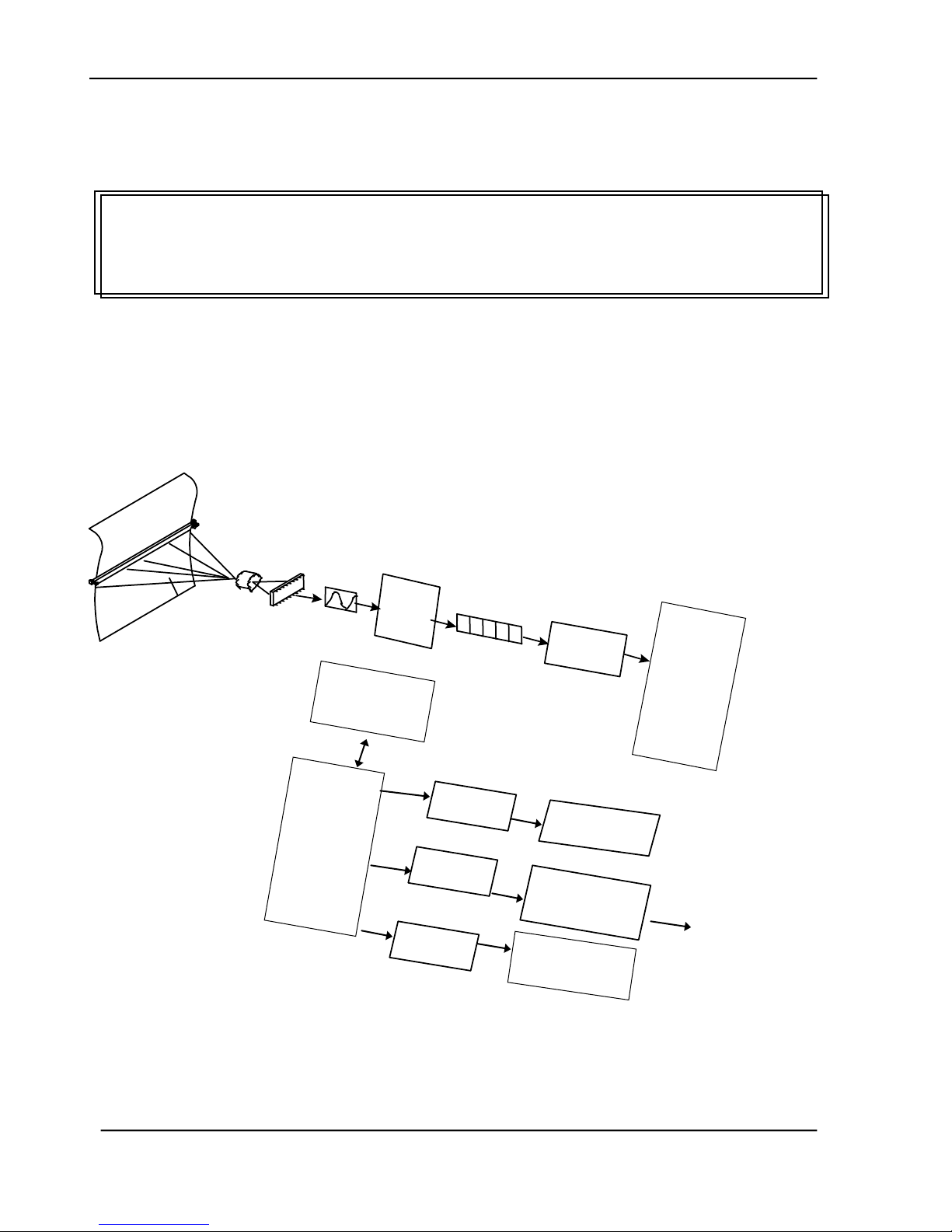

4.1 Introduction

Figure 4.1 Theory of formation of image.

Service Manual

4-2

The reflected rays of your original as shown in the above figure pass through the lens and

create an image on the CCD (Charged Coupled Device). Then, according to the different

light intensity perceived by the CCD, the CCD will transfer these data into a series of

analog signals to the main board, where the signals are turned into digital signals. The

digital signals flow to the image processor and store into the CPU (Central Processing

Unit). Through the commands from the Panel, the digital signals may goes to 4939

Controller to RJ-45 to the SMTP or filing server to send an email or store an image via

entherne , or to remote printer to make digital copy via enthernet, as well as allow to usb

flash drive or CF card ( removable storage) through usb host.

4.2 Main Control Unit

4.2.1 System Diagram

The following shows the system block diagram.

Figure 4.2 Product System Block Diagram

Service Manual

4-3

Switching

Regulator

+24V

+1.5V

+2.5V

+1.25V

+1.8V

+ 3.3 V

+ 32V

+ 16V

Linear

Regulator

+24V

+12V

4.2.2 SENSOR INPUT

The sensor input includes home position sensor.

Home position sensor

The home position of the carrier motor is detected by photo sensor. The photo transistor

transmission to the photo sensor receiver circuit is shown below.

Figure 4.3 Home Sensor

The home position is detected when the carrier passes between the LED and the photo transistor.

4.2.3 SUB POWER SUPPLY CIRCUIT

The sub power supply circuit is provided for the internal analog circuit. Input is 24V and

output is Vcc and +5Va. The circuit configuration is shown below:

Figure 4.4 Power Aupply Circuit Configuration

The sub power supply is used for: A/D, and logic circuits.

4-4

Type

Characteristic

Wall-mount

Input voltage range

100-240V

Input current(max.)

1.0~1.7A

Input frequency

50-60Hz

Output voltage

+24Vdc

Max. load current

3.2A

Output Wattage

76.8W

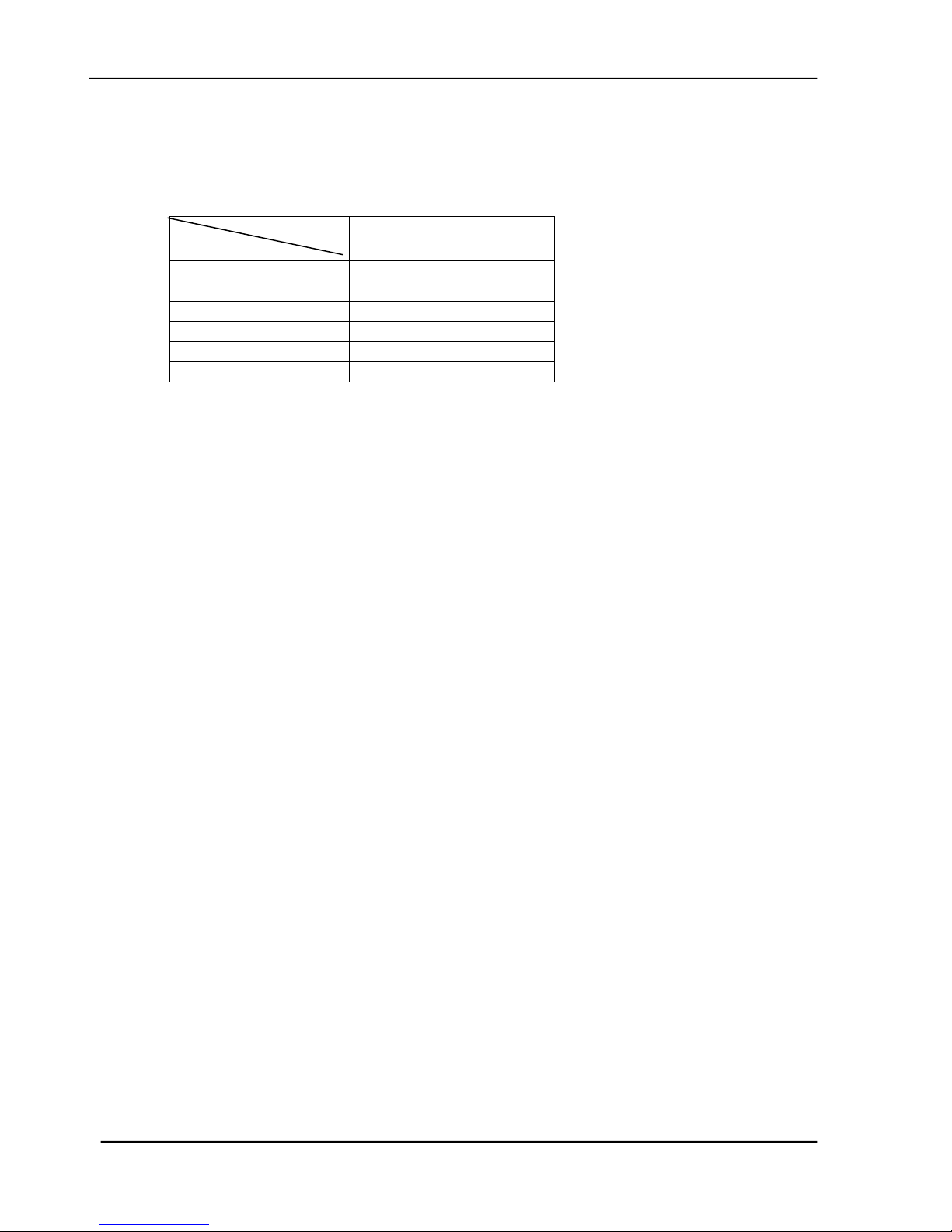

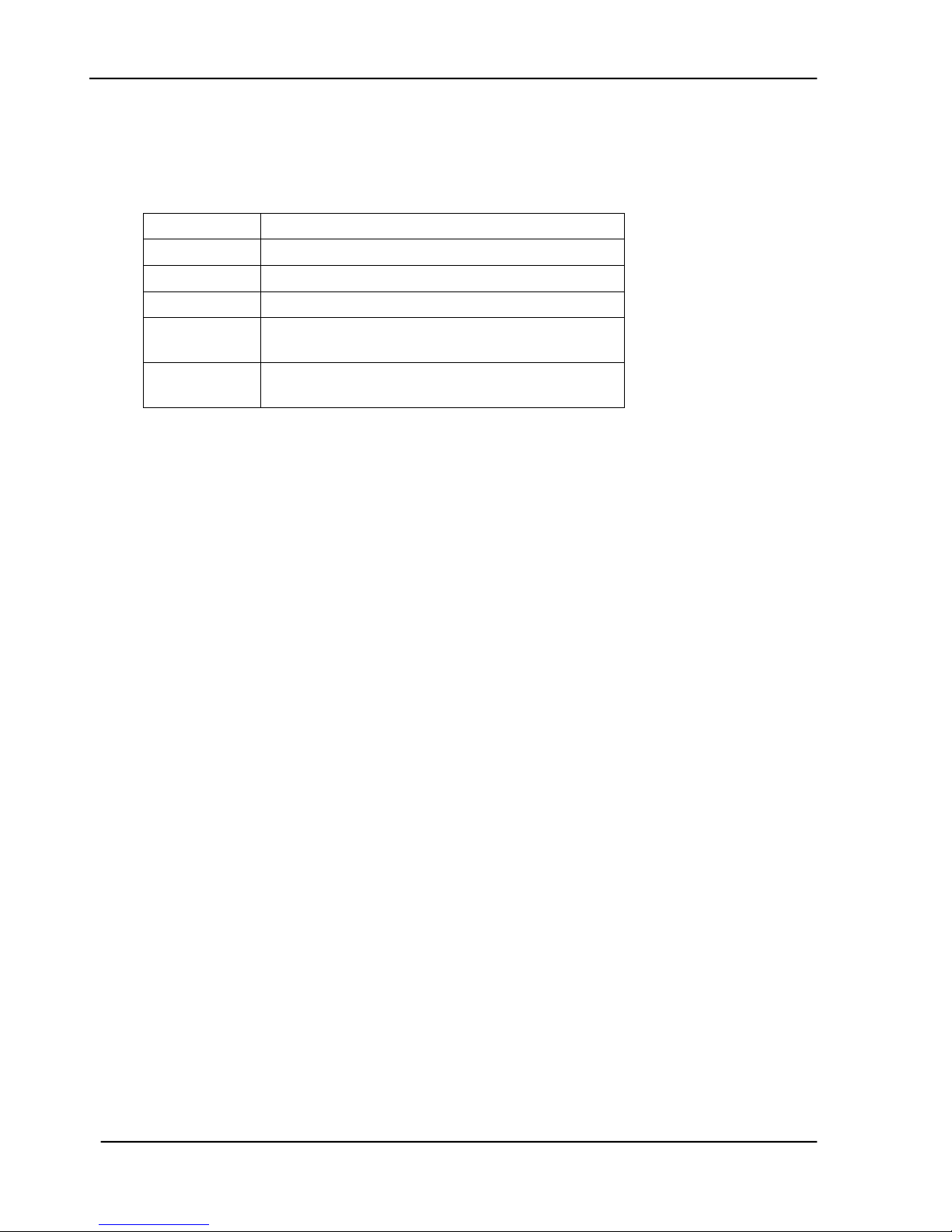

4.2.4 POWER SUPPLY

In this system, there is only one type of power supply. Please see the following table for

details.

Table 4.5 Power Adapter

Service Manual

5-1

5. PROBLEM SOLVING

Diagnostics

Troubleshooting

This section is given to locate and resolve the causes of troubles so as the product is always

in good working condition. The trouble modes, relevant units and maintenance methods are

described below.

When a problem occurs, troubleshoot the problem according to the symptoms it shows.

Check the following first:

1. Is anything being operated improperly?

2. Does the problem recur, or is it regular?

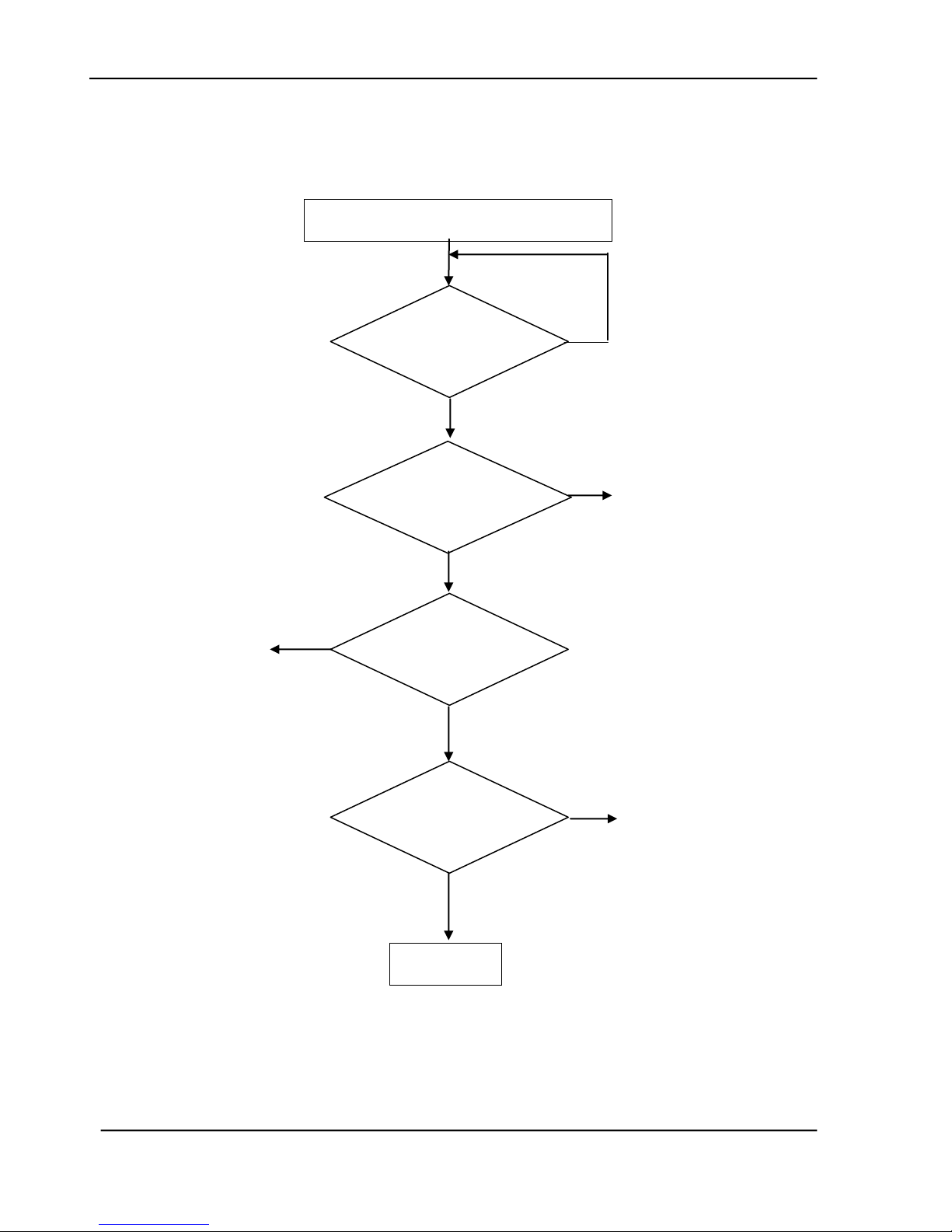

The sections, 5.1.1 to 5.1.4, show the troubleshooting flowcharts.

The causes and maintenance methods for each failure mode are described in Table 5.1

through 5.11

5-2

Power on

Screen shows

Warming up

Message

No

Yes

See Table 5.1 or

Table 5.7

Screen shows

Default working mode

Yes

5.1 Troubleshooting Flowchart

5.1.1 POWER ON TO @V6600 READY

5-3

Email Online Troubleshooting

Yes

Yes

Yes

See Table 5.3

No

No

Yes

Press the

Mono/Color

button?

Connect SMTP

server and start

scanning?

Send the

scanned image?

Transferring

completed ?

END

No

No

See Table 5.8

Or

5.2.10 Info. Message During Networking

5.2.11 Info. Message During E-Mailing

See Table 5.8

Or 5.2.10 Info. Message During Networking

5.2.11 Info. Message During E-Mailing

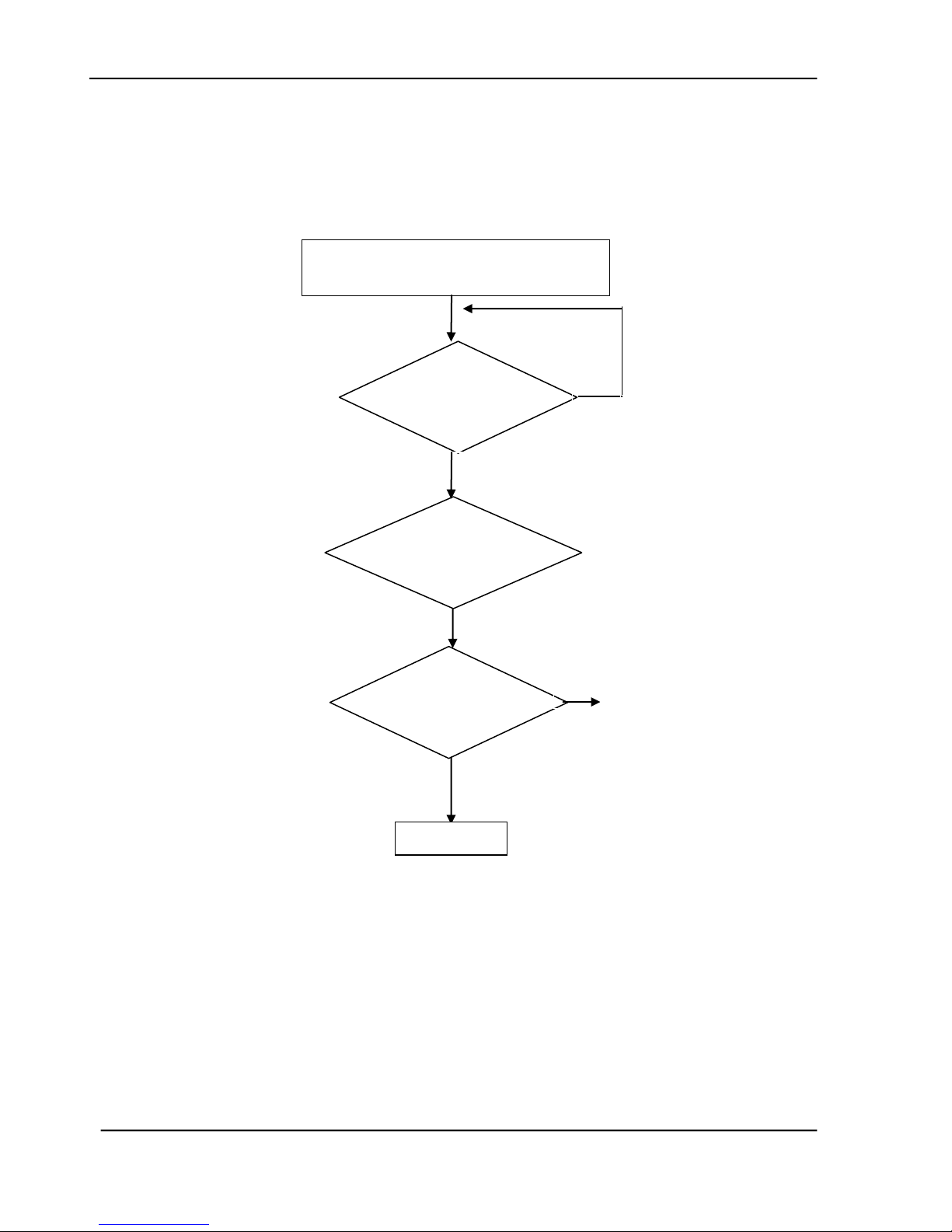

5.1.2 E-MAIL OPERATION

Service Manual

5-4

See Table 5.8

Or 5.2.10 Info. Message During Networking

5.2.12 Info. Message During Filing

Yes

Yes

See Table 5.3

See Table 5.8

Or 5.2.10 Info. Message During Networking

5.2.12 Info. Message During Filing

Yes

Filing Online Troubleshooting

Press the

Mono/Color

button?

Send the

scanned image?

Transferring

completed ?

END

No

No

Yes

Connect FTP/HTTP/HTTPS/CIFS

server and start scanning?

No

5.1.3 FILING OPERATION

5-5

Scan to USB flash drive or Public folder

Online Troubleshooting

Press the

Mono/Color

button?

Yes

Start scanning?

Save the

scanned image?

END

No

See Table 5.2.13

INFORMATION MESSAGES

DURING SCAN TO USB

DRIVE OR PUBLIC FOLDER

No

5.1.4 SCAN TO USB FLASH DRIVE OR PUBLIC FOLDER.

Service Manual

5-6

Table 5.1

The LCD does not display

Table 5.2

Scanning Is not Performed

Table 5.3

Image not clear

Table 5.4

Noise generated

Table 5.5

LCD does not show message after

command

Table 5.6

The product is not connected to the

network

5.2 Tables

The following tables provide detailed troubleshooting information.

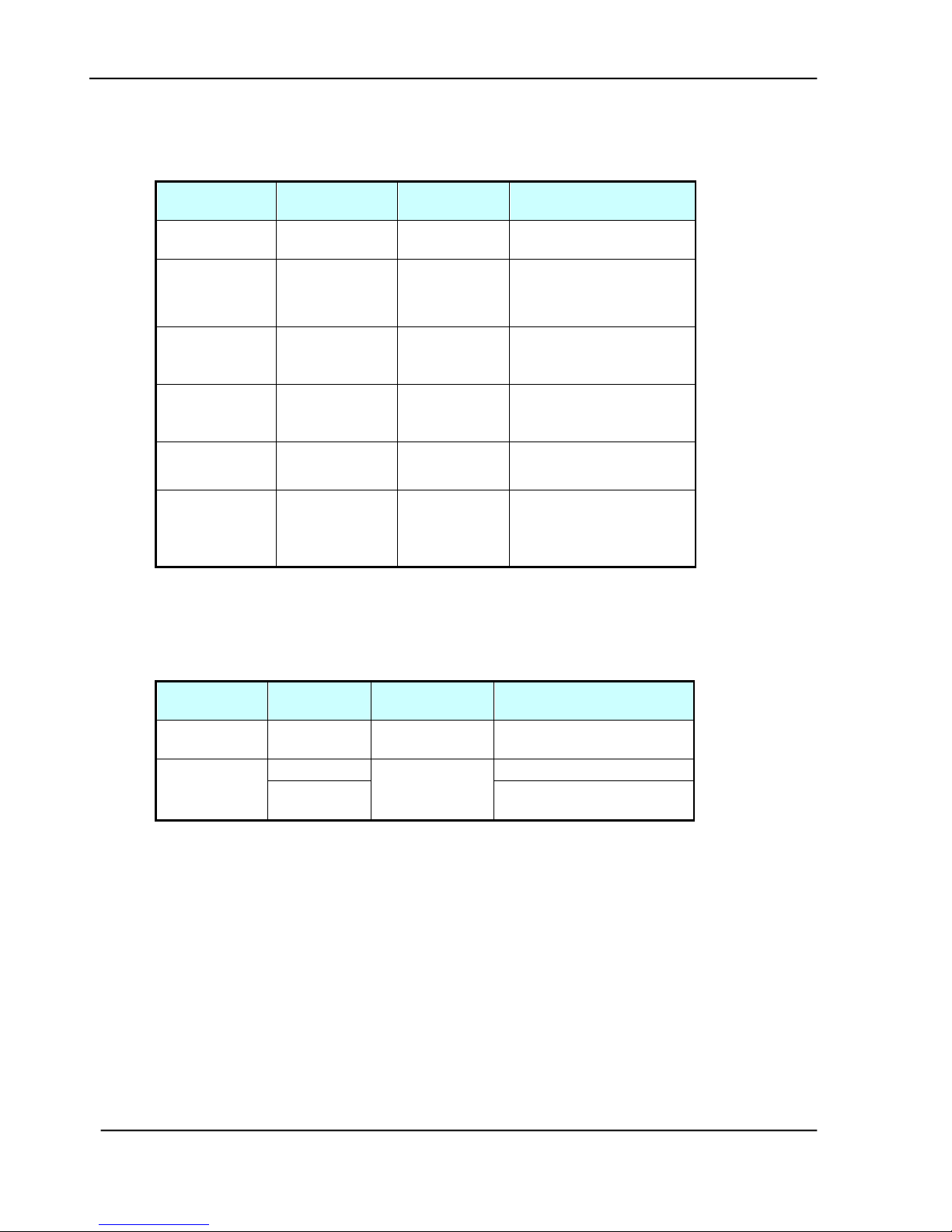

5-7

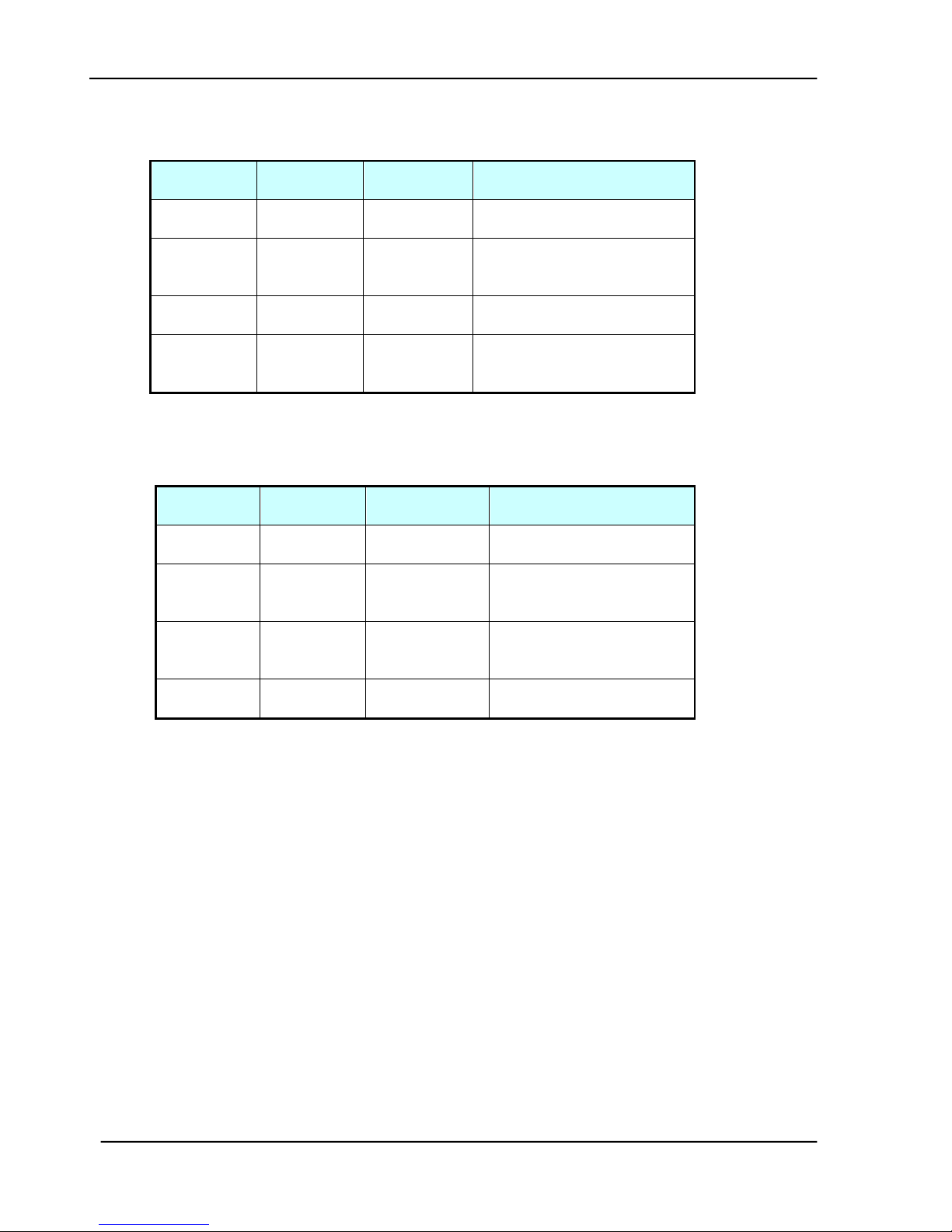

Cause

Relevant

Unit

Check

Method

Maintenance

Method

Unplugged

from outlet

None

Visual check

Insert the AC plug into

the outlet

DC power

unplugged

from unit

None

Visual check

Insert the DC power

adapter cable into the

unit

AC voltage

failure

None

AC outlet

voltage

check

None

Power adapter

output voltage

failure

Power unit

Output

voltage

(+24v) check

Replace the power

unit

PCB failure

Main control

PCB

Tester check

(+24V, GND)

Remove the cause or

replace the PCB

LCD module

main board

connection

failure

LCD module

main board

Visual check

Plug the connector and

secure it firmly

Cause

Relevant

Unit

Check

Method

Maintenance Method

Scanner USB

cable failure

Scanner

USB cable

Visual check

Attach the scanner USB

cable

Scanner link

failure

Main PCB

Visual check

Replace the PCB

Optical

Chassis

Replace the Optical

Chassis

5.2.1 LCD does not display

Service Manual

Table 5.1

5.2.2 SCANNING IS NOT PERFORMED

Table 5.2

5-8

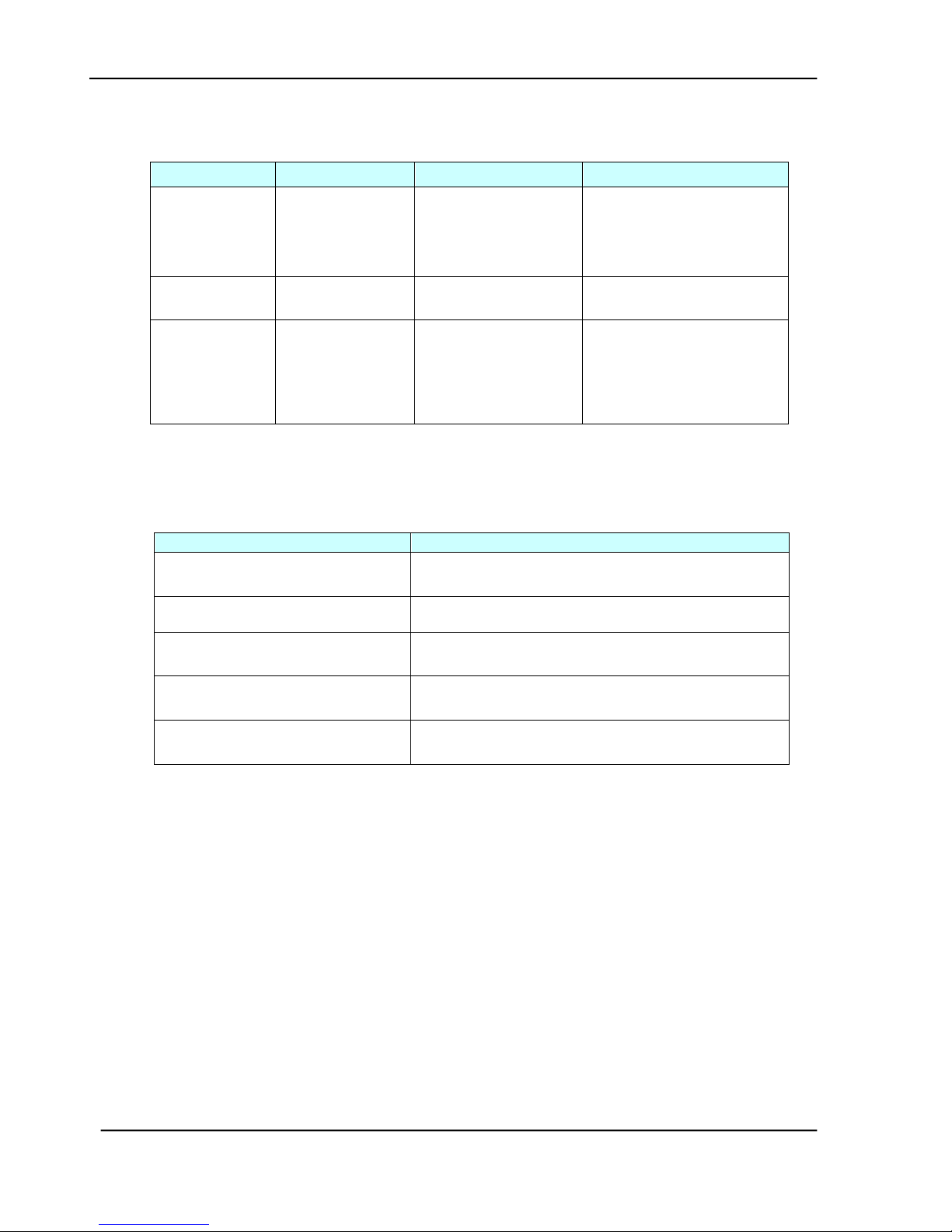

Cause

Relevant

Unit

Check

Method

Maintenance Method

Lamp too

dark

Lamp

Visual check

Replace the lamp

Dirt on

flatbed glass

Flatbed

glass

Visual check

Clean the

flatbed glass with isopropyl

alcohol

Printer toner

low

Printer toner

Visual check

Check printer toner or

replace the toner

Printer

memory not

enough

Printer

Visual check

Add printer memory

Cause

Relevant

Unit

Check

Method

Maintenance Method

Motor unit

failure

Motor unit

Replace the

motor unit

Replace the motor

Main control

PCB failure

Main control

PCB

Replace the

main control

PCB

Replace the main control

PCB

Optical

chassis

failure

Optical

chassis

Check optical

chassis

shakiness

Replace the optical

chassis

Dirt on rail

None

Visual check

Clean the rail

with oil

5.2.3 IMAGE UNCLEAR

5.2.4 NOISE GENERATED

Table 5.3

Table 5.4

5-9

Cause

Relevant unit

Check method

Maintenance method

LCD module

cable failure

Panel cable

Visual check

Attach the LCD module

cable and

secure it firmly

LCD problem

LCD PCB

Replace the LCD

PCB

Replace the LCD PCB

Push button

failure

Panel PCB

Replace the panel

PCB

1. Check the panel

cable and secure it

firmly.

2. Replace the panel

PCB.

Cause

Maintenance Method

RJ-45 connector is not plugged

in

Plug the connector in.

Network cable is damaged

Replace a good one

IP address is invalid

Ask your network administrator for a valid

address.

Subnet Mask is invalid

Ask your network administrator for a valid

value.

Gateway IP is invalid

Ask your network administrator for a valid

address.

5.2.5 LCD DOES NOT SHOW MESSAGE AFTER COMMAND

Table 5.5

5.2.6 THE PRODUCT IS NOT CONNECTED TO THE NETWORK

Service Manual

Table 5.6

5-10

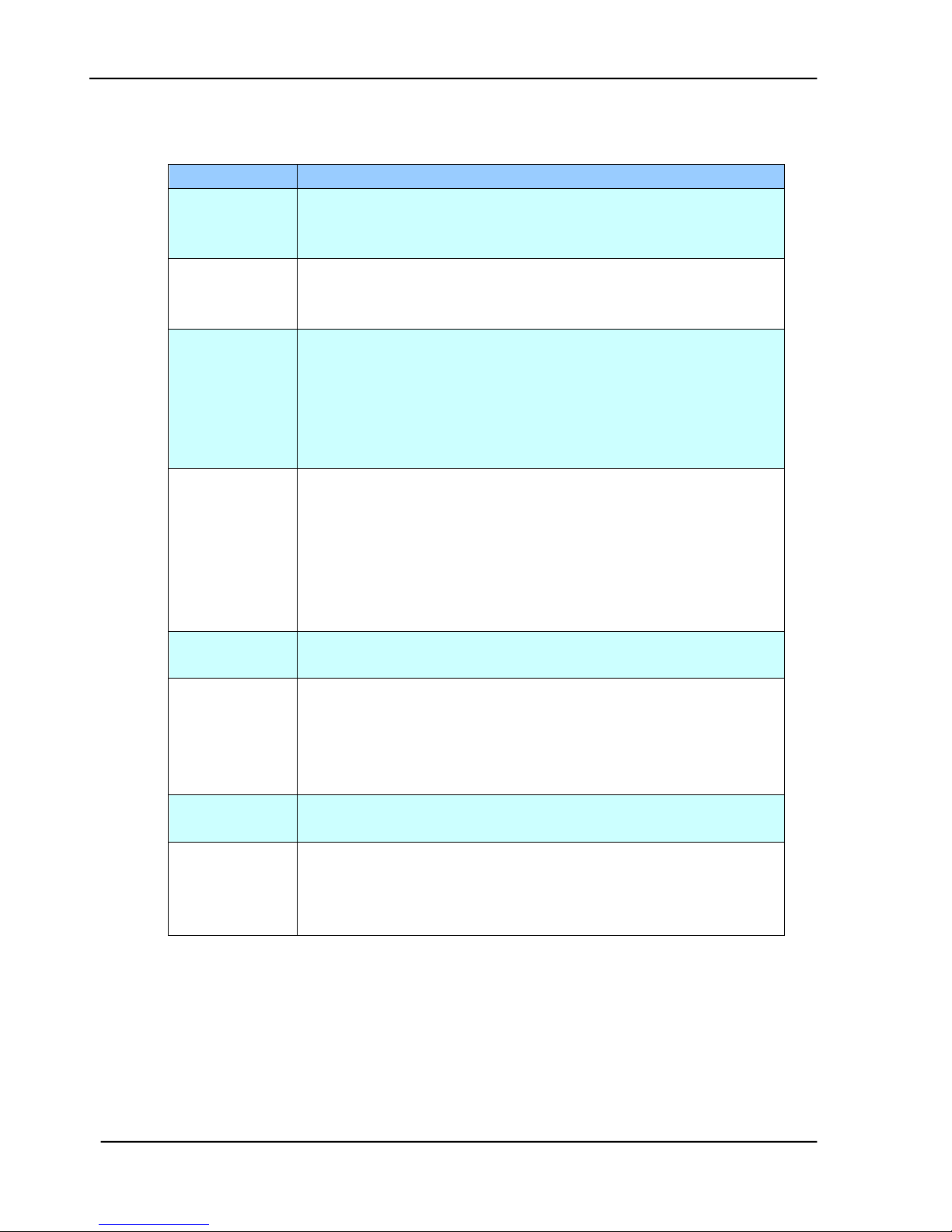

Message

Action

FB/ADF Home

sensor error

Restart your product.

If the code still appears, check optical chassis. If optical

chassis is malfunction, replace it.

FB/ADF Lamp

error

Restart your product.

If the code still appears, check lamp, inverter or main board.

If one of them is malfunction, replace it.

ADF paper jam

ADF paper jam.

Open the ADF cover and remove the paper from the ADF

then restart your product.

If the code still appears, check if paper-in sensor, paper-out

sensor, main board, or the AV board is malfunction. If one

of them is malfunction, replace it.

Release The

Sensor Lock

Optical Chassis is locked.

1. Turn off your product.

2. Find the lock switch underneath the machine and unlock

the machine.

3. Restart your product.

If the code still appears, check main board. If main board

is malfunction, replace it.

ADF Cover

Open

1. Close ADF Cover.

2. Follow instruction on screen.

ADF MultiFeed

Open the ADF cover and remove the paper from the ADF

then restart your product.

If the code still appears, check if ultrasonic, paper-in sensor,

paper-out sensor, main board, or the AV board is

malfunction. If one of them is malfunction, replace it.

FB Cover Open

1. Close FB Cover.

2. Follow instruction on screen to restart your product.

Scanner

Synchronization

Error

1. Check if ADF cable is tightly attached.

2. Follow instruction on screen to restart your product.

3. If the code still appears, check main board. If main

board is malfunction, replace it.

5.2.7 INFORMATION MESSAGES DURING INITIATION OR SCANNING

Table 5.7

Loading...

Loading...