Avdel Genesis 7537, Genesis 07537 Instruction Manual

0

7

5

3

7

0

7

5

3

7

Genesis®7537

Hydro-Pneumatic Power Tool

Instruction Manual

3

Contents

Safety Rules 4

Specifications

Specification for 7537 Tool 5

Tool Dimensions 5

Intent of Use 6

Putting into Service

Air Supply 7

Mechanical Cursors 8

Cursor 9

Loading and Reloading the Tool 10

Operating Procedure 10

Mandrel Follower Springs Identification 11

and Orientation

Nose Assemblies

Nose Jaws 12

Selecting a Nose Jaw 13

Nose Jaw Selection - Imperial 14

Nose Jaw Selection - Metric 15

Mandrels and Mandrel Follower Springs 16

Chobert®and Grovit®- Imperial 16

Chobert®and Grovit®- Metric 17

Briv®- Imperial 18

Mandrel Head Types and ‘P’ Length 19

Briv®- Metric 19

Avlug®, Avsert®, Avtronic®and Rivscrew

®

Imperial and Metric 20

Servicing the Tool

Daily 21

Weekly 21

MolyLithium Grease EP 3735 Safety Data 21

Molykote®55m Safety Data 22

Molykote®111 Safety Data

Service Kits 23

Maintenance

Dismantling 07537-00200 24-25

General Assembly and Parts List 07537-00200 26-27

Priming

Oil Details 28

Hyspin®VG 32 and AWS 32 Oil Safety Data 28

Priming Kit 28

Priming Procedure 29

Fault Diagnosis

Symptom, Possible Cause and Remedy 30

LIMITED WARRANTY

Avdel makes the limited warranty that its products will be free of defects in workmanship and materials

which occur under normal operating conditions. This Limited Warranty is contingent upon: (1) the product

being installed, maintained and operated in accordance with product literature and instructions, and (2)

confirmation by Avdel of such defect, upon inspection and testing. Avdel makes the foregoing limited

warranty for a period of twelve (12) months following Avdel’s delivery of the product to the direct purchaser

from Avdel. In the event of any breach of the foregoing warranty, the sole remedy shall be to return the

defective Goods for replacement or refund for the purchase price at Avdel’s option. THE FOREGOING

EXPRESS LIMITED WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES

AND REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY

ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

4

Safety Rules

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

1 Do not use outside the design intent.

2 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel

UK Limited. or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited. will be pleased to advise upon any

proposed modification.

4 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and

function by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK

Limited procedures. Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact Avdel

UK Limited. with your training requirements.

5 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health and

Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety should

be directed to Avdel UK Limited.

6 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7 Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8 Do not operate a tool/machine that is directed towards any person(s) or the operator.

9 Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered and that hoses are always in good condition.

11 The operating pressure shall not exceed 7 bar (100 lbf/in

2

).

12 The combination of fastener, mandrel, hole size and sheet thickness shall be in accordance with Avdel UK Limited. Specifications.

13 Do not operate the tool if it is not fitted with a complete nose assembly unless specifically instructed otherwise.

14 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against

fastener ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the

application.

15 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be

kept dry and clean for best possible grip.

16 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent startup.

17 Excessive contact with hydraulic oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

IMPORTANT

While a small amount of wear and marking will naturally occur through normal and correct use of mandrels,

they must be regularly examined for excessive wear and marking, with particular attention to the head

diameter, the tail jaw gripping area of the shank or heavy pitting of the shank and any mandrel distortion.

Mandrels which fail during use could forcibly exit the tool. It is the customer's responsibility to ensure that

mandrels are replaced before any excessive levels or wear and always before the maximum recommended

number of placings. Contact your Avdel. representative who will let you know what that figure is by measuring

the broach load of your application with a calibrated test tool. These tools can also be purchased under Part

Number 07900-09080, supplied with all necessary information for testing in this manual.

5

Specification for 07537 Tool

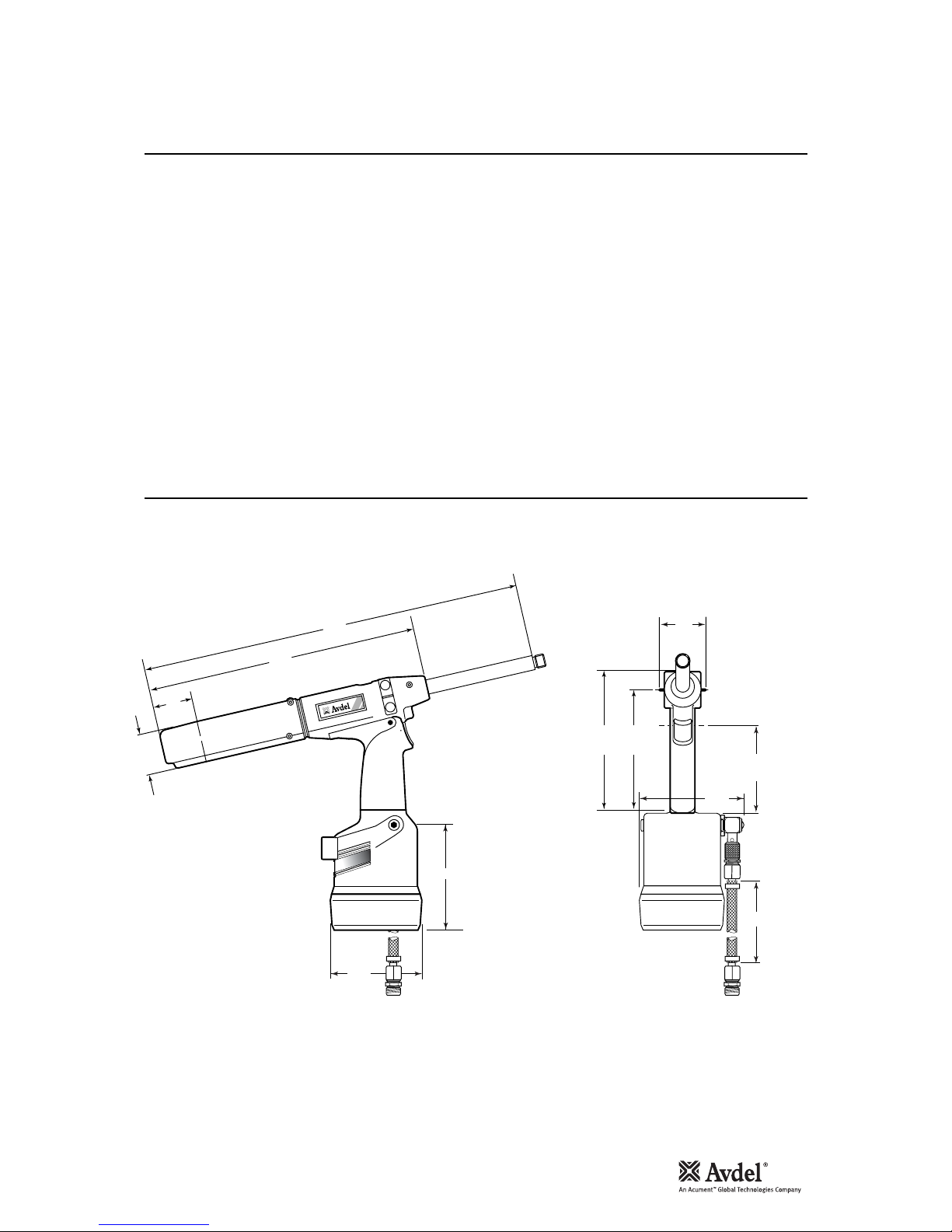

Tool Dimensions

Specifications

Air Pressure Minimum - Maximum 5-7 bar (70-100 lbf/in2)

Free Air Volume Required @ 5.1 bar /75 lbf/in

2

2.6 litres (0.09 ft3)

Stroke Minimum 28.0 mm (1.10 in)

Pull Force @ 5.5 bar /80 lbf/in

2

3.89 kN (875 lbf)

Cycle time Approximately 1 second

Noise Level Less than 70 dB(A)

Weight Tool 2.3 kg (5.06 lb)

Vibration Less than 2.5 m/s2(8 ft/s2)

0

7

5

3

7

475

18.70

338

13.30

51

2

110

120

121

150

60

2.36

98

3.85

163

6.41

140

5.51

50

1.96

0

7

5

3

7

Part Number 07537-00200

Intent of Use

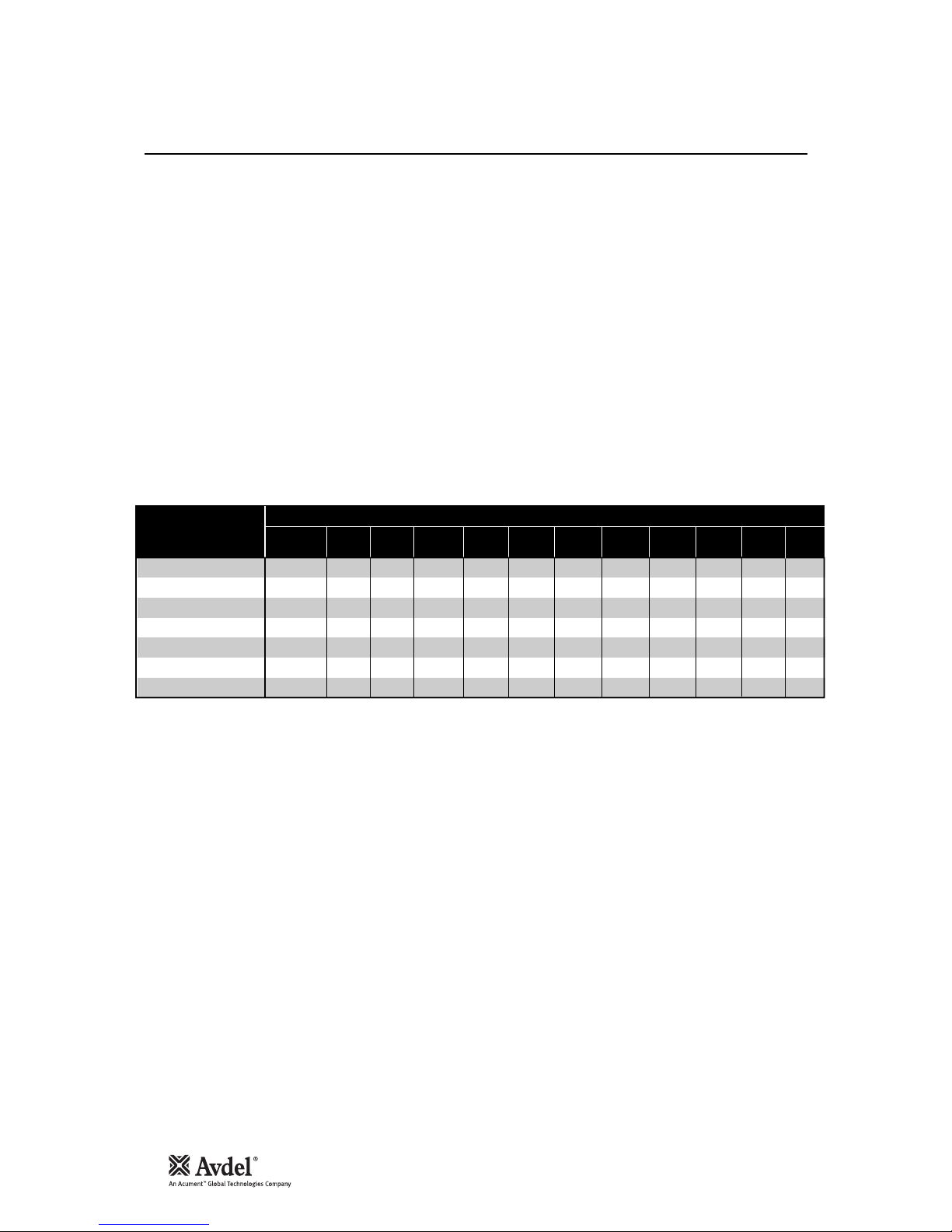

FASTENER NAME

2.5mm

2.8mm

●●● ●

●

● ●

FASTENER SIZE

CHOBERT

®

GROVIT

®

AVLUG

®

BRIV

®

RIVSCREW

®

AVTRONIC

®

AVSERT

®

●●●●●

●●●●

●●

●●●●

3

/32"

1

/4"

3

/16"

5

/32"

1

/8"

M3

6-32

UNC

M2.5

4-40

UNC

4mm3.5mm3mm

6mm

●

The pneumatic 07537 tool is a handheld lightweight tool designed to place Avdel®speed fasteners (except 1/16” Avlug®) making it

ideal for batch or flow-line assembly in a wide variety of applications throughout all industries.

Part numbers are shown to order a complete tool but no nose equipment.

The tool part number for the 07537 model is 07537-00200. See the general assemblies on pages 26-27.

The tool will place most repetition fasteners, as shown in the table below.

The tool is used with specific nose equipment. Reference must be made to the Nose Equipment section of the manual when selecting

compatible components for the type and size of fastener used in your application (see pages 12-20). Nose jaw dimensions are shown

on page 13.

6

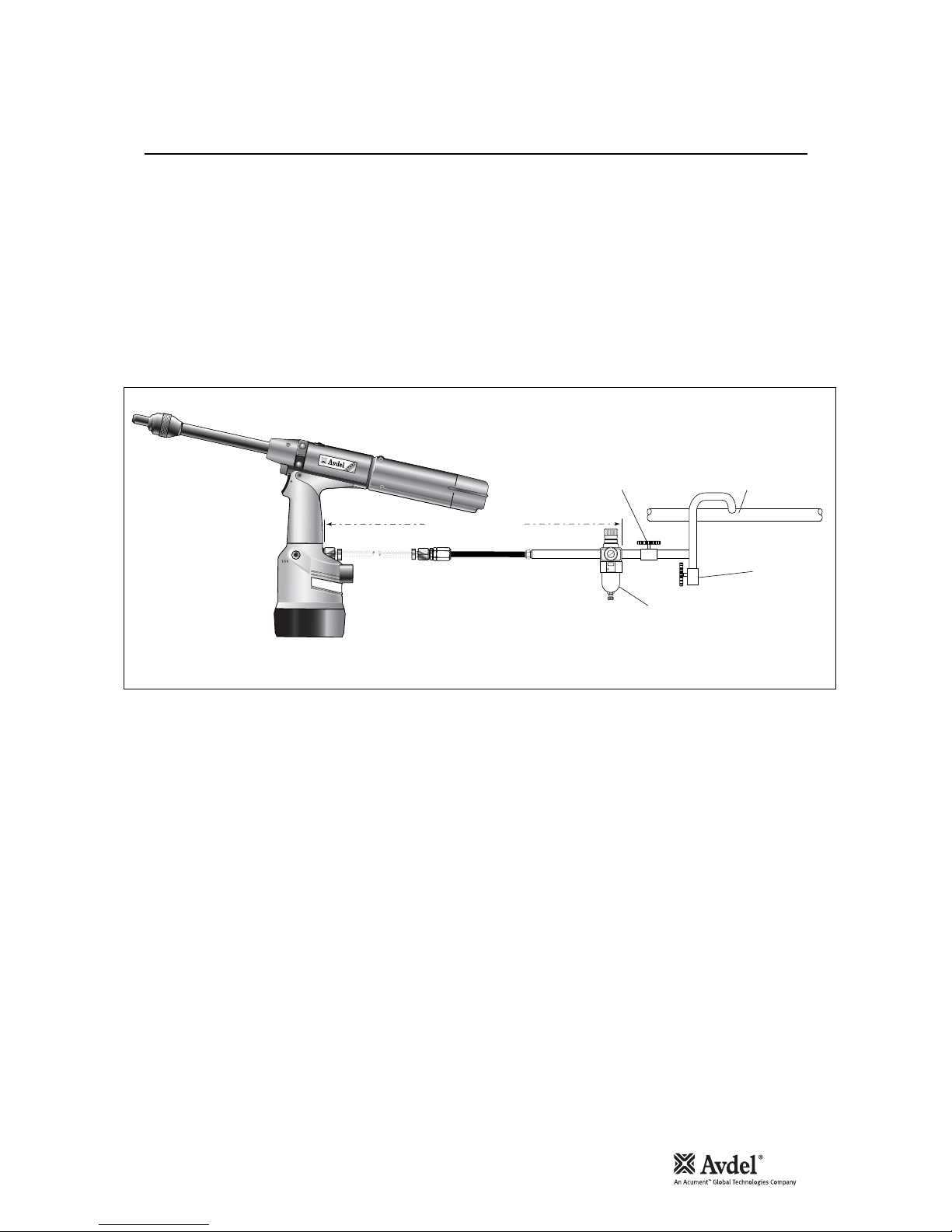

Air Supply

Putting into Service

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure maximum

tool life and minimum tool maintenance.

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system

or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured

where operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres

or

1

/4 inch.

Read servicing daily details page 21.

8

6

4

2

0

1

0

1

2

14

1

6

TAKE OFF POINT

FROM

MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR UNIT)

MAIN SUPPLY

DRAIN POINT

PRESSURE REGULATOR

AND FILTER (DRAIN DAILY)

3 METRES MAXIMUM

0

7

5

3

7

7

8

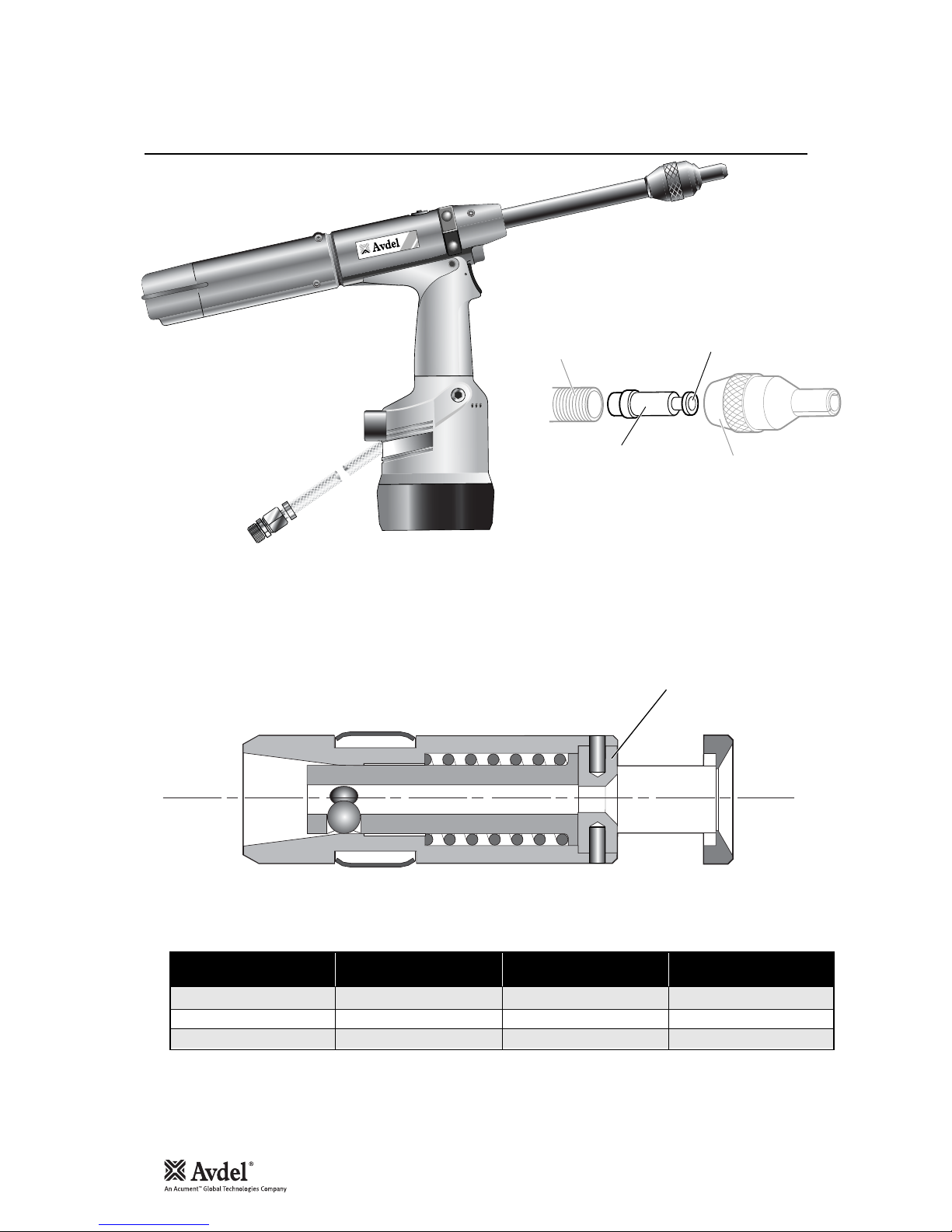

Mechanical Cursors

Putting into Service

MECHANICAL CURSOR

PART NO.

END PLUG

PART NO.

07271-01100

07279-05843

07279-05845

07150-00402

07159-05844

07159-05846

COLOUR

PLAIN STEEL

GOLD

SILVER

HOLE DIAMETER

(mm)

2.7

2.2

3.3

For reference there are three different mechanical cursor types:

• 07271-01100 Used for Standard mandrels and 5/32” Disposable mandrels

• 07279-05843 Used for 1/8” Disposable mandrels

• 07279-05845 Used for 3/16” Disposable mandrels

The difference in the above assemblies is the internal diameter of the End Plug.

These are colour coded see below:

END PLUG

0

7

5

3

7

0

7

5

3

7

NOSE

JAWS

TOOL

BARREL

CURSOR

SPRING

LOADED END

9

Cursor

Loading and Reloading the Tool

Putting into Service

While the cursor will be fitted the correct way round when the tool is supplied, we recommend that you check its orientation before

fitting the nose equipment. The sprung loaded, slightly concave, end of the cursor should point towards the front of the tool as shown

in the illustration.

When fitted the correct way round, the cursor will easily slide out of the barrel when a mandrel is pushed into its centre then pulled

back.

To reverse the orientation of the cursor, follow these steps:

Item numbers in bold refer to the general assembly and parts list for

the 07537-00200 on pages 26-27.

• Remove the clip 48 and slide off end cap 50.

• Using an Allen Key, remove one cap head screw 5 ensuring that

any trapped air is exhausted. remove the second cap head screw

5.

• Pull out rear plug 47.

• Pull out tail jaw piston assembly 51 together with jaws 34.

• Lift out spring 35 and jaw housing 41.

• Insert a mandrel into the hole in the rear end of barrel 44 until it protrudes through the front of the barrel, then pull out the

mandrel and cursor together through the front.

• Reassemble components in reverse order.

• Insert Mechanical Cursor Assembly 36 into the front of the barrel, correct way round.

When ordering a complete tool or system you will normally be supplied with all the nose equipment required for the fastener to be placed.

To identify nose equipment components or to select the correct elements, read the nose equipment section, on pages 12-20.

If you have been supplied with a nose jaw, mandrels and mandrel follower springs proceed with loading the tool and fitting the nose equipment

as shown overleaf.

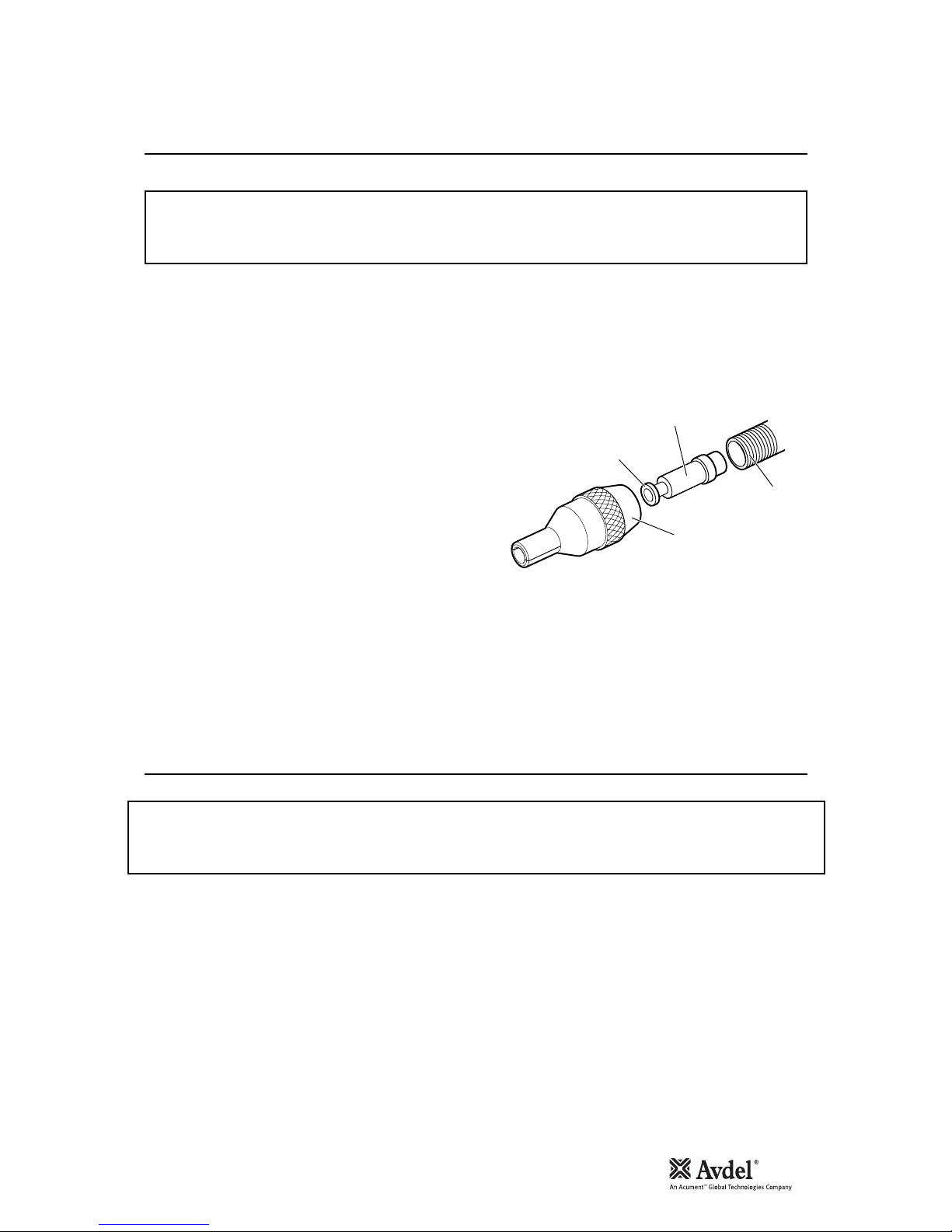

NOSE

JAWS

TOOL

BARREL

CURSOR

SPRING

LOADED END

IMPORTANT

If fitted incorrectly, the cursor will not allow feeding of the fasteners.

IMPORTANT

The procedure for loading the tool and for fitting the nose equipment to the tool is integral.

Item numbers in bold refer to the general assembly and parts list for the 07537-00200 on pages 26-27.

English

10

Loading the Tool

Reloading the Tool

Operating Procedure

Putting into Service

• Connect the air supply to the tool.

• Open tail jaws 34 which grip the mandrel, by switching off the tail jaw switch (items 22 and 23).

• Screw selected nose jaws onto barrel 44 of the tool.

•* Insert a mandrel into the tail end of the fasteners through the paper pod.

• Slide the mandrel follower spring onto the mandrel ensuring correct orientation, as shown in the table on page 11.

• Gripping the tail end of the mandrel, tear off the paper pod from around the fasteners.

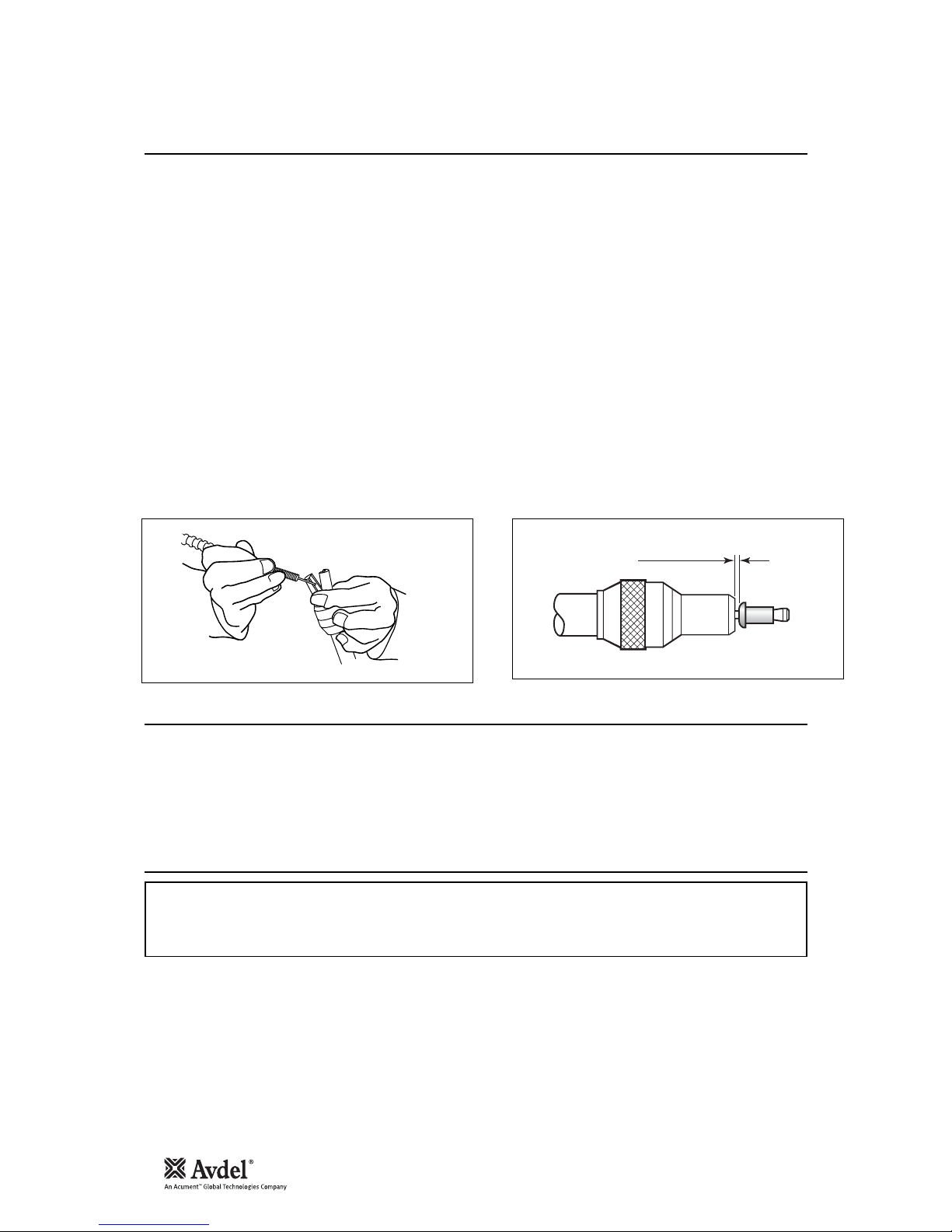

• Open the nose jaws either by rotating the outer ring on Cam operated jaws or by pushing outwards on the jaw ends, as illustrated

below left.

• Insert the previously assembled mandrel, mandrel follower spring and fasteners into the nose jaws until the first fastener to be

placed is protruding from the nose jaw.

• Close the nose jaws and adjust so that the first fastener protrudes by 1.5mm - 3mm (

1

/16” to 1/8”), as shown in the illustration

below right.

• Close the tail jaws to ensure the mandrel is gripped, by switching on the tail jaw switch (items 22 and 23).

• Push the fastener, protruding from the nose jaws, fully into the application holes ensuring that the tool is held square.

• Operate the trigger without releasing - the mandrel head is pulled through the fastener, forming the fastener into the application.

• Remove the tool.

• Release the trigger. The next fastener will be automatically presented through the nose jaws, ready for placing.

• Open tail jaws 34 of tool.

• Open the nose jaws and pull the empty mandrel and mandrel follower spring out of the tool.

• Reload the tool by following the above instructions, starting at stage •*.

IMPORTANT

You must check that the cursor orientation and the nose equipment are correct before attempting to operate the

tool.

Item numbers in bold refer to the general assembly and parts list for the 07537-00200 on pages 26-27.

1.5mm - 3mm

(

1

/16" - 1/8")

Loading...

Loading...