Avdel Avbolt 07220, Avbolt T10, Avbolt T30 Assembly Instructions Manual

5

Intent of Use

Tool Specification

Tool Dimensions

Specifications

The T10 Installation Tool is basically a Piston and Cylinder Assembly. When coupled Hydraulically and Electrically to a compatible

Hydraulic Power Source and the relevant Nose Assembly is attached, it is then used to install

3

/8” Avdelok®, 5/16” to 3/8” Avbolt®and

16mm to 20mm Avseal

®

in Industrial Environments.

Refer to the table below for the list of applicable fasteners and associated nose equipment.

Refer to the datasheets listed in the table for the relevant nose assembly insructions.

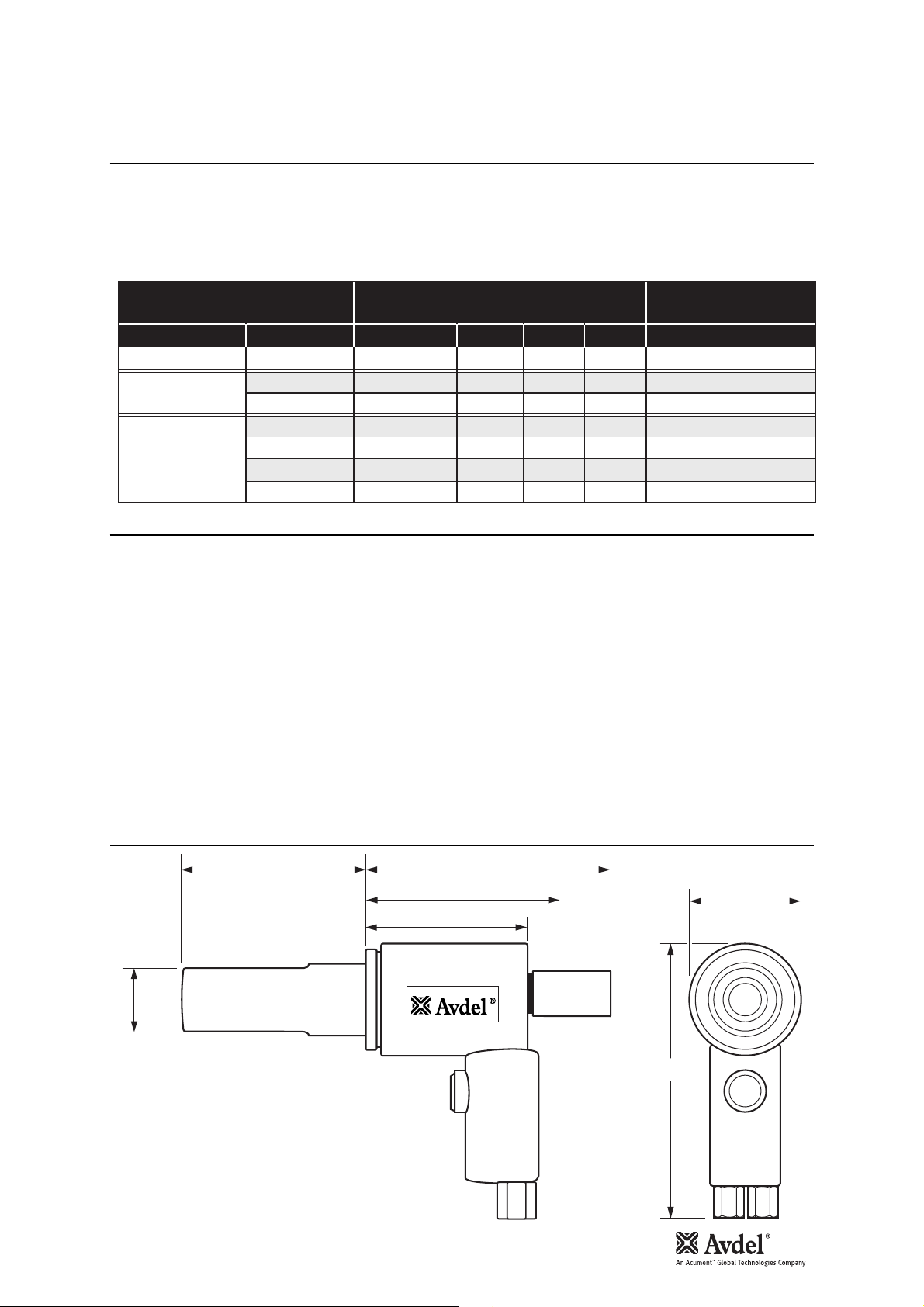

Length 158 mm 6.25 in

Body Diameter 60 mm 2.36 in

Height 176 mm 6.93 in

Weight 3.5 kg 7.7 lbs

Stroke 25 mm 1 in

Pull-Force 58kN 13040 lbf

Pull pressure 55.2 mPa 8000 PSI

Return Pressure 20.7 mPa 3000 PSI

Hydraulic Oil ISO VG 46 OR EQUIVALENT

Fastener Range 5 to 10 mm incl. M.G. & Blind Fasteners

Noise Level Below reportable levels

Sound Power Below reportable levels

Vibration Below reportable levels

TYPE SIZE

Avdelok

Avbolt

Avseal

FASTENER

®

®

®

3

/

î (10mm)

8

5

/

3

/

16mm

16mm flanged

18mm

20mm

NOSE ASSEMBLY

PART Nº HAT REF. DIM. ‘A’

73411-03100

”

16

”

8

73411-03300

73411-03200

73411-05000

73411-05000

73411-05200

73411-05400

N10

-

N11

-

-

-

-

NOSE ASSEMBLY

DIM. ‘B’ PART Nº

28mm89mm

27mm86mm

29mm86mm

27mm89mm

27mm89mm

27mm89mm

27mm89mm

DATASHEET

07900-00919

07900-00905

07900-00905

07900-00840

07900-00840

07900-00840

07900-00840

158 mmA

118 mm

60 mm

98 mm

B

176 mm

This technical datasheet must be read with particular attention to the safety rules and operating instructions

listed in the 07220 (07900-00648), T10 (07900-00820) and T30 (07900-00821) Instruction Manuals, by any

person fitting or operating the Avbolt

®

nose assemblies and hand tools.

The Avbolt

®

nose assemblies in combination with the 07220, T10 and T30 tools are designed for placing Avdel®Avbolt

®

structural fasteners only. The correct placing tool and nose assembly must be selected for each fastener size as shown in

Table 1 below.

I M P O R T A N T

The tools and nose assemblies must be used in accordance with the safety rules and fitting instructions

contained within this datasheet and the tool instruction manual. The placing of fasteners not included in this

datasheet could have a detrimental impact on the working life of the tool and nose assemblies and could

invalidate the warranty.

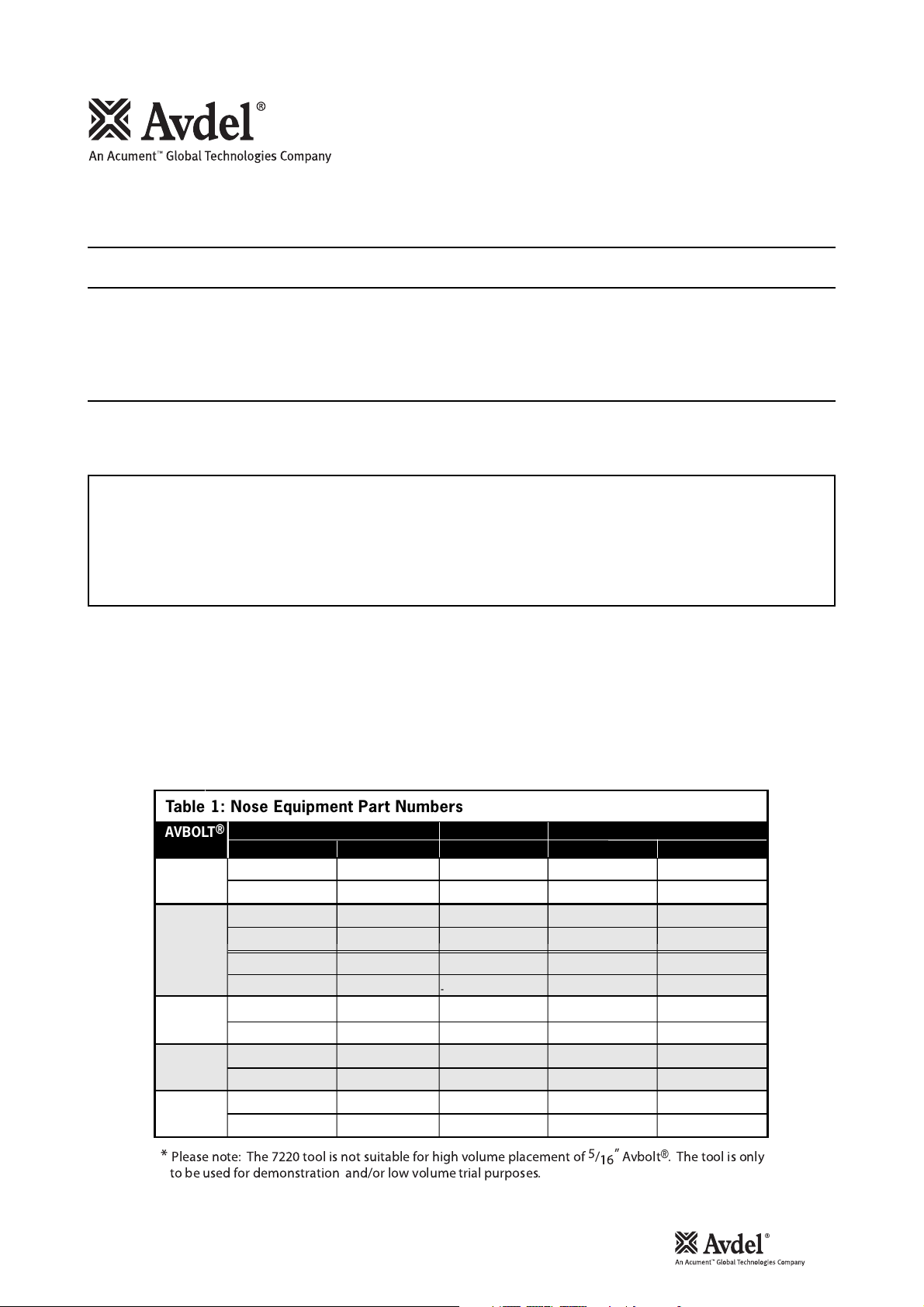

The Table 1 below provides a full list of part numbers, nose assemblies and base tools required to place each Avbolt®size.

This table should be used to select and order the correct placing equipment.

Please note that there are two variants of nose equipment available to fit either Avdel

®

or Huck®hand tools.

For the fitting and servicing instructions for each nose assembly refer to the page number provided in Table 1.

1

Avbolt®Nose Assembly Instructions

07220, T10 and T30 Tools

Safety Rules

Intent of Use

Table 1: Nose Equipment Part Numbers

AVBOLT

SIZE

”

1

/

4

”

5

/

16

”

3

/

8

”

1

/

2

”

5

/

8

®

NOSE ASSEMBLY

PART No REF. PAGE

07220-07500

07220-07600

07220-07700

07220-07800 73411-033034

73411-03300 73411-033036

73411-03400 73411-033036

73411-03200

73411-03500

73412-03400

73412-03500

*

-

-

2

2

4

8

8

10

10

JAWS

PART No

07220-07502

07220-07502

73411-03303

73411-03203

73411-03203

73412-03403

73412-03403

BASE TOOL

MODEL PART No

7220

®

HUCK

256

7220

*

®

HUCK

256

T10

®

2600

HUCK

T10

®

HUCK

2600

--

--

T30

HUCK

-

-

®

585

07220-00200

-

07220-00200

-

73411-02000

-

73411-02000

-

-

-

73412-02000

-

*

* Please note: The 7220 tool is not suitable for high volume placement of

to be used for demonstration and/or low volume trial purposes.

5

”

/

Avbolt®. The tool is only

16

2

1

/

4

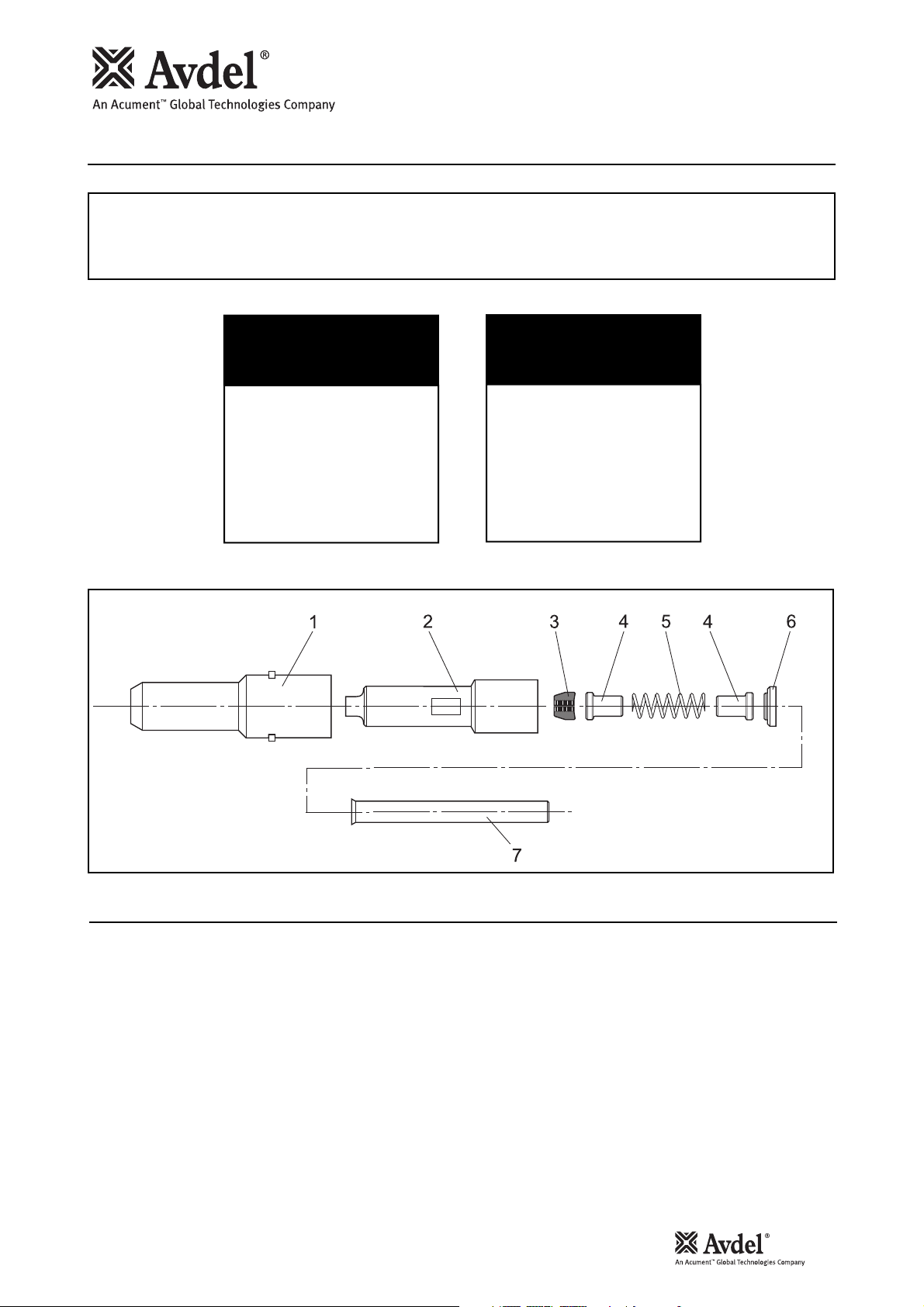

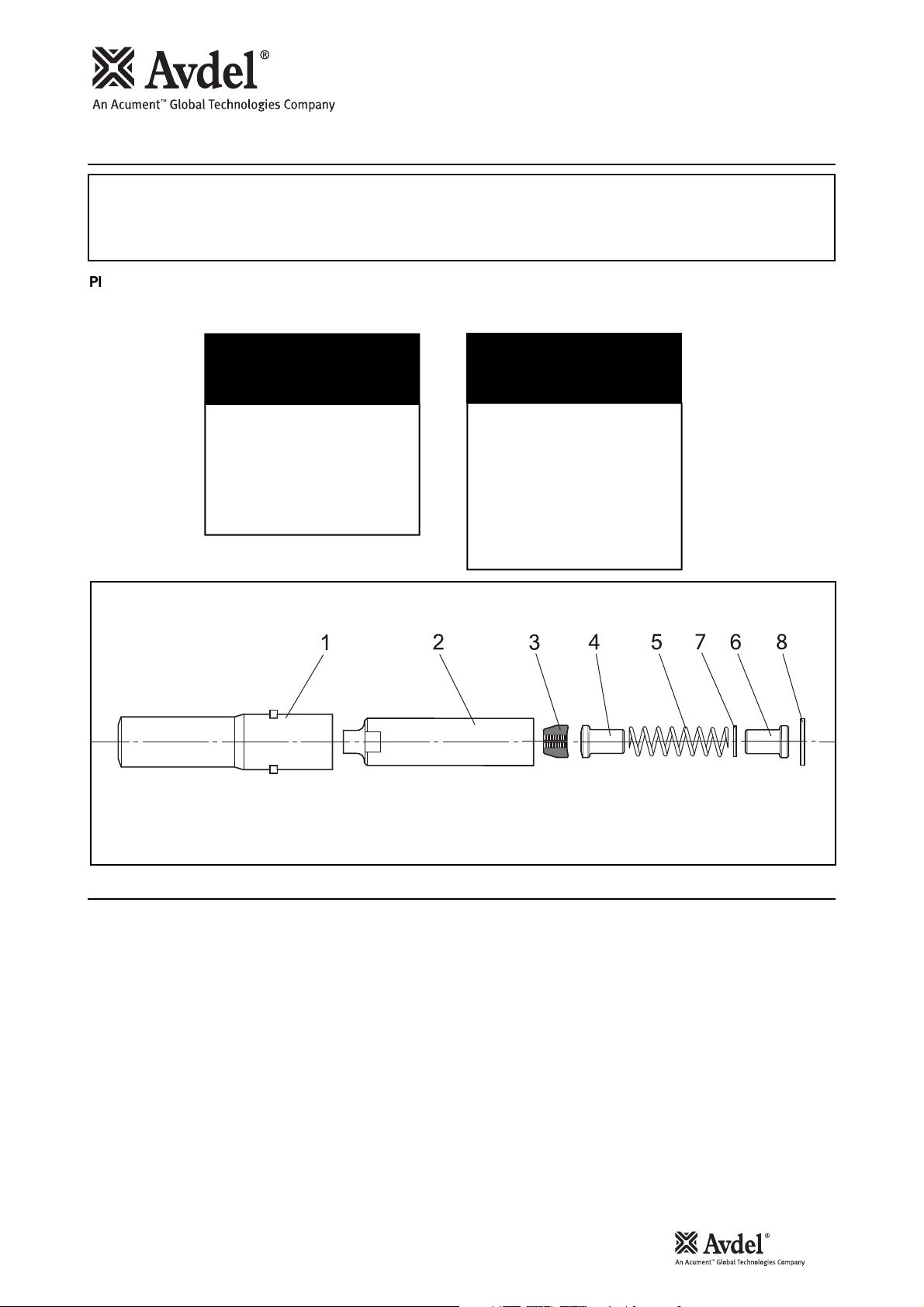

” Avbolt®Nose Assemblies - 07220-07500 and 07220-07600

I M P O R T A N T

The air supply must be disconnected when fitting or removing nose assemblies.

Item numbers in bold refer to nose assembly components in the tables and illustration above.

• Lightly coat Jaws 3 with Moly Lithium grease.

• Assemble Spring Guide 4 and Spring 5 and stand on end on a flat even surface.

• Balance the three Jaws 3 on the upper Spring Guide 4.

• Carefully lower Collet 2 over the assembled components.

• Holding the assembled collet pointing downwards insert Spacer 6 behind the rear Spring Guide 4.

• Insert Pintail Tube 7 into the tool head piston bore.

• Holding the tool pointing down, screw the assembled collet fully onto the tool head piston and tighten with a suitable

spanner.

Fitting Instructions

NOSE ASSEMBLY

for Avdel® 07220 tool

part nº 07220-07500

ITEM DESCRIPTION

1 ANVIL 07220-07501

2 COLLET 07220-07503

3 JAWS 07220-07502

4 SPRING GUIDE 07220-02104

5 SPRING 07220-02103

6 SPACER 07220-07504

7 PINTAIL TUBE 07220-07505

P

ART Nº

NOSE ASSEMBLY

for Huck® 256 tool

part nº 07220-07600

ITEM DESCRIPTION

1 ANVIL 07220-07501

2 COLLET 07220-07503

3 JAWS 07220-07502

4 SPRING GUIDE 07220-02104

5 SPRING 07220-02103

6 SPACER - HUCK

7 PINTAIL TUBE 07220-07505

P

ART Nº

®

07220-07601

3

1

/

4

” Avbolt®Nose Assemblies - 07220-07500 and 07220-07600

07220 Tool:

• Place Anvil 1 over Collet 2 and onto the tool, ensuring that the lugs on the body enter the slots in the

head extension of the tool.

• Turn the reducing adaptor body through 90° then turn the head extension ring until it springs into its position

in the slots of the head extension.

Huck

®

256 Tool:

• Place Anvil 1 over Collet 2 and into the tool. Slide the retainer nut over Anvil 1, screw fully onto the

tool and tighten by hand.

Servicing Instructions

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components

of the nose assembly as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws 3.

• Check that Spring 5 and Spring Guides 4 are not distorted.

• Clean and inspect components, renewing worn or damaged items.

• Assemble according to the ‘Fitting Instructions’.

Fitting Instructions

4

5

/

16

”

Avbolt

®

Nose Assemblies - 07220-07700 and 07220-07800

I M P O R T A N T

The air supply must be disconnected when fitting or removing nose assemblies.

Please note: The 7220 tool is not suitable for high volume placement of

5

/

16

”

Avbolt®. The tool is only to be used

for the demonstration and/or low volume trial purposes.

Item numbers in bold refer to nose assembly components in the tables and illustration above.

07220 Tool:

• Lightly coat Jaws 3 with Moly Lithium grease.

• Assemble Spring Guide 6, Spring 5 and Follower 4 and stand on end on a flat even surface.

• Balance the three Jaws 3 on Follower 4.

• Carefully lower Collet 2 over the assembled components.

• Holding the tool pointing down, screw the assembled collet fully onto the tool head piston and tighten with a suitable

spanner.

• Place Anvil 1 over Collet 2 and onto the tool, ensuring that the lugs on the body enter the slots in the head extension of

the tool.

• Turn the reducing adaptor body through 90° then turn the head extension ring until it springs into its position

in the slots of the head extension.

Fitting Instructions

NOSE ASSEMBLY

for Avdel® 07220 tool

part nº 07220-07700

ITEM DESCRIPTION

1 ANVIL 07220-07701

2 COLLET 07220-07702

3 JAWS 73411-03303

4 FOLLOWER 07220-07703

5 SPRING 07220-06305

6 SPRING GUIDE 07220-07704 SPRING GUIDE 07220-07704

P

ART Nº

NOSE ASSEMBLY

for Huck® 256 tool

part nº 07220-07800

ITEM DESCRIPTION

1 ANVIL 07220-07701

2 COLLET 07220-07702

3 JAWS 73411-03303

4 FOLLOWER 07220-07703

5 SPRING 07220-06305

6

8

SHIM 07220-078017

SHIM 07220-07802

P

ART Nº

78

5

5

/

16

”

Avbolt®Nose Assemblies - 07220-07700 and 07220-07800

Huck®256 Tool:

• Lightly coat Jaws 3 with Moly Lithium grease.

• Assemble Spring Guide 6, Shim 7, Sping 5 and Follower 4 and stand on end on a flat even surface.

• Balance the three Jaws 3 on Follower 4.

• Carefully lower Collet 2 over the assembled components.

• Holding the assembled collet pointing downwards, insert the Shim 8 behind the Spring Guide 6.

• Holding the tool pointing down, screw the assembled collet fully onto the tool head piston and tighten with a suitable

spanner.

• Place Anvil 1 over Collet 2 and into the tool. Slide the retainer nut over Anvil 1, screw fully onto the

tool and tighten by hand.

Servicing Instructions

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components

of the nose assembly as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws 3.

• Check that Spring 5, Follower 4 and Spring Guide 6 are not distorted.

• Clean and inspect components, renewing worn or damaged items.

• Assemble according to the ‘Fitting Instructions’.

Fitting Instructions

6

5

/

16

”

Avbolt

®

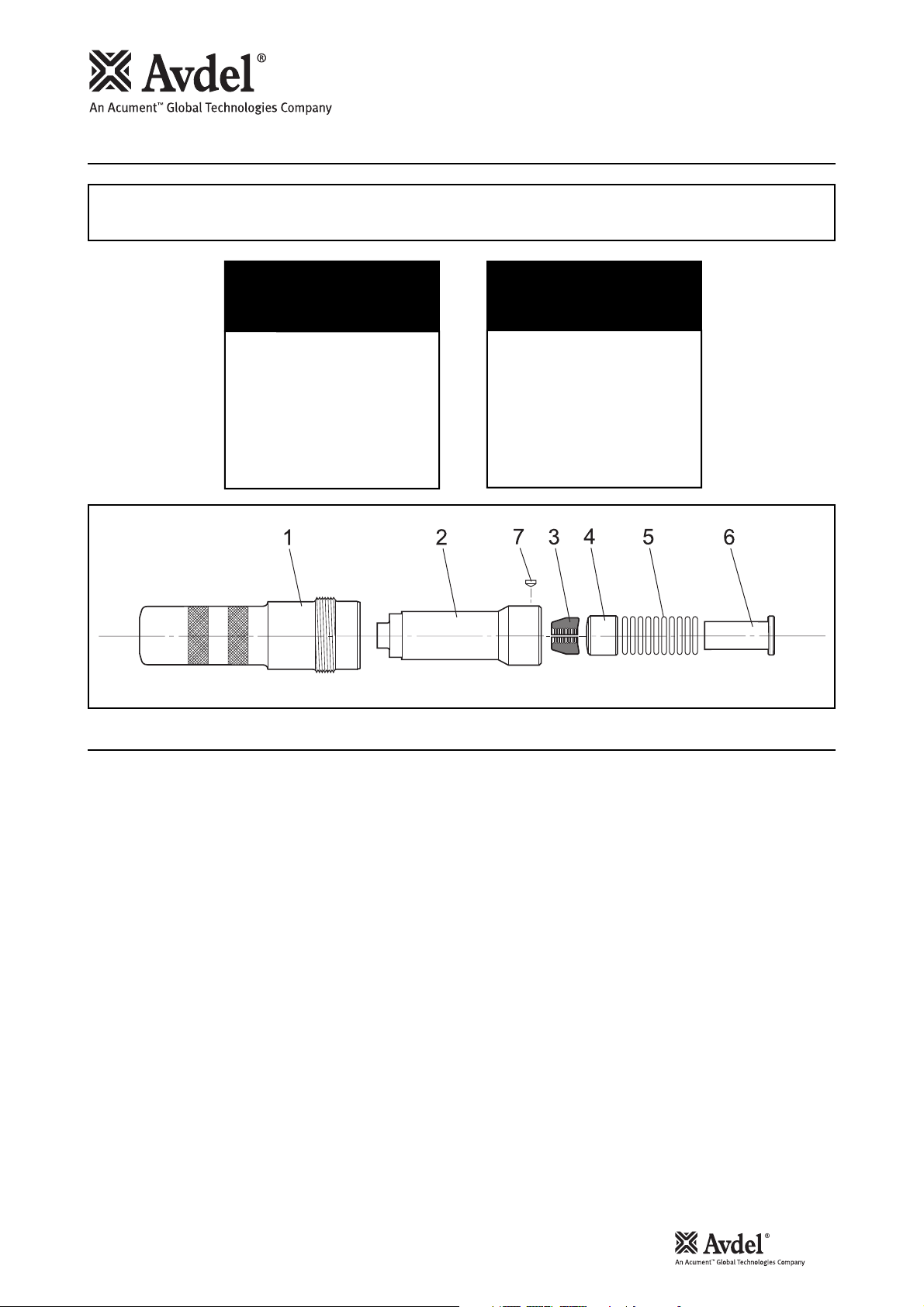

Nose Assemblies - 73411-03300 and 73411-03400

I M P O R T A N T

Be sure the tool power supply is turned off before fitting or removing the nose assembly.

Item numbers in bold refer to nose assembly components in the tables and illustration above.

• Lightly coat Jaws 3 with Moly Lithium grease.

• On a flat work surface, assemble the Sleeve 6, ‘O’ Rings 5, Follower 4 and Jaws 3 by stacking vertically in that order.

• Place the Collet 2 over the assembled stack, slide to the end of the work surface and with a finger, push the stack fully

inside the Collet.

T10 Tool:

• Holding the tool pointing down, screw the assembled collet fully onto the piston rod until it is flush with the end of the

collet adaptor.

• Insert Collet Lock 7 into Collet 2. Rotate Collet 2 on the piston rod in either direction until Collet Lock 7 slots into the

nearest groove in the collet adaptor. The Collet Lock 7 should be flush with the exterior of Collet 2.

• Slide Anvil 1 over the collet and screw into the anvil adaptor until it is firm.

• There is a locking ‘O’ Ring which will create a resistance to the final few turns of the nose casing. It is imperative that the

nose casing be hand tightened up against the rear locking face.

Huck

®

2600 Tool:

• Holding the tool pointing downwards, screw the assembled collet onto the piston rod until it bottoms out.

• Insert Collet Lock 7 into Collet 2. Rotate Collet 2 on the piston rod in either direction until Collet Lock 7 slots into the

nearest groove on the piston rod. The Collet Lock 7 should be flush with the exterior of Collet 2.

• Place Anvil 1 over Collet 2 and into the tool. Slide the retainer nut over Anvil 1, screw fully onto the tool and tighten by

hand.

Fitting Instructions

NOSE ASSEMBLY

ITEM DESCRIPTION

1 ANVIL 73411-03301

2 COLLET 73411-03302

3 JAWS 73411-03303

4 FOLLOWER 73411-03304

56 ‘O’ RINGS 07003-00426

7 COLLET LOCK 73411-05004

for Avdel T10 tool

part nº 73411-03300

P

ART Nº

SLEEVE 73411-03305

NOSE ASSEMBLY

for Huck 2600 tool

part nº 773411-03400

ITEM DESCRIPTION

1 ANVIL-HUCK 73411-03401

2 COLLET-HUCK 73411-03402

3 JAWS 73411-03303

4 FOLLOWER 73411-03304

5 ‘O’ RINGS 07003-00426

6 SLEEVE 73411-03305

7 COLLET LOCK 73411-05004

P

ART Nº

10 off

7

5

/

16

”

Avbolt®Nose Assemblies - 73411-03300 and 73411-03400

Servicing Instructions

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components

of the nose assembly as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws 3.

• Check that Follower 4, Sleeve 6 and ‘O’ Rings 5 are not distorted.

• Assemble according to the ‘Fitting Instructions’.

8

3

/

8

”

Avbolt®Nose Assemblies - 73411-03200 and 73411-03500

IMPORTANT

Be sure the tool power supply is turned off before fitting or removing the nose assembly.

Fitting Instructions

Item numbers in bold refer to nose assembly components in the tables and illustration above.

• Lightly coat Jaws 3 with Moly Lithium grease.

• On a flat work surface, assemble Sleeve 6, ‘O’ Rings 5, Follower 4 and Jaws 3 by stacking vertically in that order.

• Place Collet 2 over the assembly stack, slide to the end of the work surface and with a finger, push the stack fully into

Collet 2.

T10 Tool:

• Holding the tool pointing down, screw the assembled collet onto the piston rod until it is flush with the end of the

collet adaptor.

• Insert Collet Lock 7 into Collet 2. Rotate Collet 2 on the piston rod in either direction until Collet Lock 7 slots into the

nearest groove on the collet adapter. The Collet Lock 7 should be flush with the exterior of Collet 2.

• Slide Anvil 1 over Collet 2 and screw into the anvil adaptor until it is firm.

• There is a locking 'O' ring which will create a resistance to the final few turns of the nose casing. It is imperative that the

nose casing be hand tightened up against the rear locking face.

Huck

®

2600 Tool:

• Holding the tool pointing down, screw the assembled collet onto the piston rod until it bottoms out.

• Insert Collet Lock 7 into Collet 2. Rotate Collet 2 on the piston rod in either direction until Collet Lock 7 slots into the

nearest groove on the piston rod. The Collet Lock 7 should be flush with the exterior of Collet 2.

• Place Anvil 1 over Collet 2 and into the tool. Slide the retainer nut over the Anvil 1, screw fully onto the tool and tighten by

hand.

NOSE ASSEMBLY

for Avdel® T10 tool

part nº 73411-03200

ITEM DESCRIPTION

1 ANVIL 73411-03201

2 COLLET 73411-03202

3 JAWS 73411-03203

4 FOLLOWER 73411-03204

56 ‘O’ RINGS 07003-00426

7 COLLET LOCK 73411-05004

SLEEVE 73411-03205

P

ART Nº

NOSE ASSEMBLY

for Huck® 2600 tool

part nº 73411-03500

ITEM DESCRIPTION

1 ANVIL-HUCK

2 COLLET-HUCK® 73411-03502

3 JAWS 73411-03203

4 FOLLOWER 73411-03204

5 ‘O’ RINGS 07003-00426

6 SLEEVE 73411-03205

7 COLLET LOCK 73411-05004

P

ART Nº

®

73411-03501

10 off

9

3

/

8

”

Avbolt®Nose Assemblies - 73411-03200 and 73411-03500

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components of the nose

assembly as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws 3.

• Check that Follower 4, Sleeve 6 and ‘O’ Rings 5 are not distorted.

• Assemble according to the ‘Fitting Instructions’.

Servicing Instructions

10

5

/

8

”

Avbolt

®

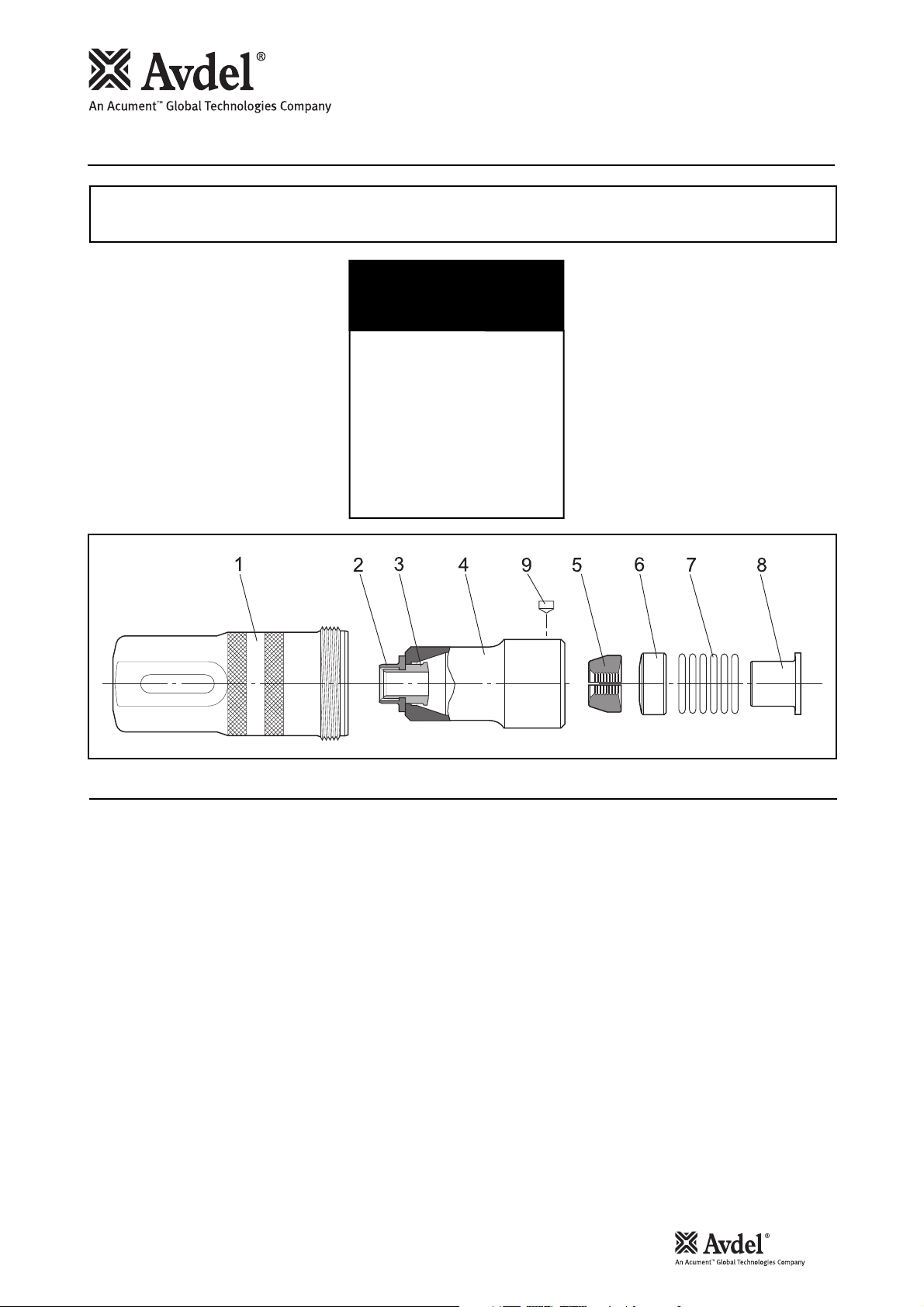

Nose Assembly - 73412-03400 for Avdel®T30

IMPORTANT

Be sure the tool power supply is turned off before fitting or removing the nose assembly.

Fitting Instructions

Item numbers in bold refer to nose assembly components in the table and illustration above.

• Lightly coat Jaws 5 with Moly Lithium grease.

• On a flat work surface, assemble Sleeve 8, ‘O’ Rings 7, Follower 6 and Jaws 5 by stacking vertically in that order.

• The Collet 4 will be supplied pre-assembled with Collar Ejector 2 and Jaw Release 3 as shown.

• Place Collet 4 over the assembled stack, slide to the end of the work surface and with a finger, push the stack fully

inside Collet 4.

• Holding the tool pointing down, screw the assembled collet onto the piston rod until it is flush with the end of the collet

adaptor.

• Insert Collet Lock 9 into Collet 4. Rotate Collet 4 on the piston rod in either direction until Collet Lock 9 slots into the

nearest groove on the collet adapter. The Collet Lock 9 should be flush with the exterior of Collet 4.

• Slide Anvil 1 over Collet 4 and screw into the anvil adaptor until it is firm.

• There is a locking 'O' ring which will create a resistance to the final few turns of the nose casing. It is imperative that the

nose casing be hand tightened up against the rear locking face.

• Correct installation of the nose assembly can be gauged by the free movement of the correct size pintail through the

assembled jaws in the nose.

NOSE ASSEMBLY

for Avdel® T30 tool

part nº 73412-03400

ITEM DESCRIPTION

1 ANVIL 73412-03401

2 COLLAR EJECTOR 73412-03408

3 JAW RELEASE 73412-03406

4 COLLET 73412-03402

5 JAWS 73412-03403

6 FOLLOWER 73412-03404

7

‘O’ RINGS 07003-00427

8 SLEEVE 73412-03405

9 COLLET LOCK 73412-03407

P

ART Nº

6 off

11

5

/

8

”

Avbolt®Nose Assembly - 73412-03400 for Avdel®T30

Nose assemblies should be serviced at weekly intervals. You should hold some stock of all internal components

of the nose assembly as they will need regular replacement.

• Remove the nose assembly using the reverse procedure to the ‘Fitting Instructions’.

• Any worn or damaged part should be replaced.

• Clean and check wear on Jaws 5.

• Check that Collar Ejector 2, Follower 6, Sleeve and ‘O’ Rings 7 are not distorted.

• To remove a damaged or worn Collar Ejector 2 cut at a point between the flange of the ejector and the end of Collet 4.

The Collar Ejector 2 and Jaw Release 3 can then be separated and removed from Collet 4.

• When assembling a new Collar Ejector 2 and Jaw Release 3 in Collet 4, first ensure that the threads are clean, before

applying Loctite

®

243 and screwing the two parts together within Collet 4.

• Assemble according to the ‘Fitting Instructions’.

Servicing Instructions

Loading...

Loading...