Page 1

August, 2005

RS2 1

®

by:

MODEL CPX-RS2

REMOTE ENGINE STARTER

INSTALLATION MANUAL

Page 2

August, 2005

RS2 2

TABLE OF CONTENTS

This device complies with part 15 of the FCC rules.

Operation is subject to the following two conditions.

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Installer Warning ……………………………………….

3

H3 - 8 Pin Mini Connector Diagram ………………….

3

System Wiring Diagram ……………………………….

4

H1 - Main 6 Pin Heavy Gauge Harness ……………..

5

H2 – 6 Pin Harness ……………………………………

6

H3 – 8 White Connector Harness ……………………

6

Installation Factory Immobilizer Systems……………

8

H4 – 2 Pin Blue connector ……………………….……

8

H5 – 3 Pin Red Antenna/Receiver Connector ………

9

H6 – 3 Pin Door Lock Harness… ……………………

9

Remote Transmitter Programming …………………

10

Alarm Feature “I” Programming ……………………...

10

Alarm Feature “II” Programming ……………………..

11

Alarm Feature “III” Programming …………………….

11

RPM Learning ………………………………………….

12

Return To Factory Default Settings …………………..

12

To Remote Start The Vehicle ………………………….

12

Shutdown Diagnostics …………………………………

12

Trouble Shooting ……………………………………….

13

Testing Your Installation (Neutral Safety Switch)

13

Notes …………………………………………………….

16

Page 3

August, 2005

RS2 3

INTRODUCTION

INSTALLER WARNINGS

This Remote Starter System is designed to be installed on fuel-injected vehicles with an automatic transmission ONLY.

n Never install this remote starter on a manual transmission vehicle.

n This system must be installed and wired through a safety switch it will not start in any forward or reverse gear.

n Some automatic transmission vehicles [mainly older GM vehicles with a purple starter wire] have a mechanical-type

park safety switch instead of electrical safety switch. The mechanical type does not interrupt the starter circuit when the

transmission is any gear and does not offer the 100% level of safety required for remote starting purposes. Therefore,

our system should never be installed on any vehicle that uses a mechanical type park safety switch.

n Once you install this system, you must verify that the vehicle will not start any forward or reverse gear. Regardless of

the type of vehicle.

n Read operation manual for operating and programming routine.

n Do not install any component near the brake, gas pedal or steering linkage.

n Some vehicles have a factory installed transponder immobilizer system that can severely complicate the installation.

There is possibility that this system cannot be installed on some immobilizer-equipped vehicles.

n Most vehicles have an SRS air bag system. Use extreme care and do not probe any wires of the SRS system.

n Disconnect the car battery before connecting work on the vehicle.

n Check behind panels before drilling any holes. Ensure that no wiring harness or other components are located behind

the panels that would otherwise be damaged.

n Use conventional crimp lock, bullet on any wiring. Poor wiring, i.e. taped joints will possibly introduce unreliability into

the alarm system and may result in false alarms or incorrect operation.

n Install wiring neatly under carpets or behind trim to prevent possible damage to wires.

n For the wire operates the current more than 10A. We suggest soldering all connection point. Do not use crimp lock

type connectors or wire nuts.

INSTALLATION DIAGRAM

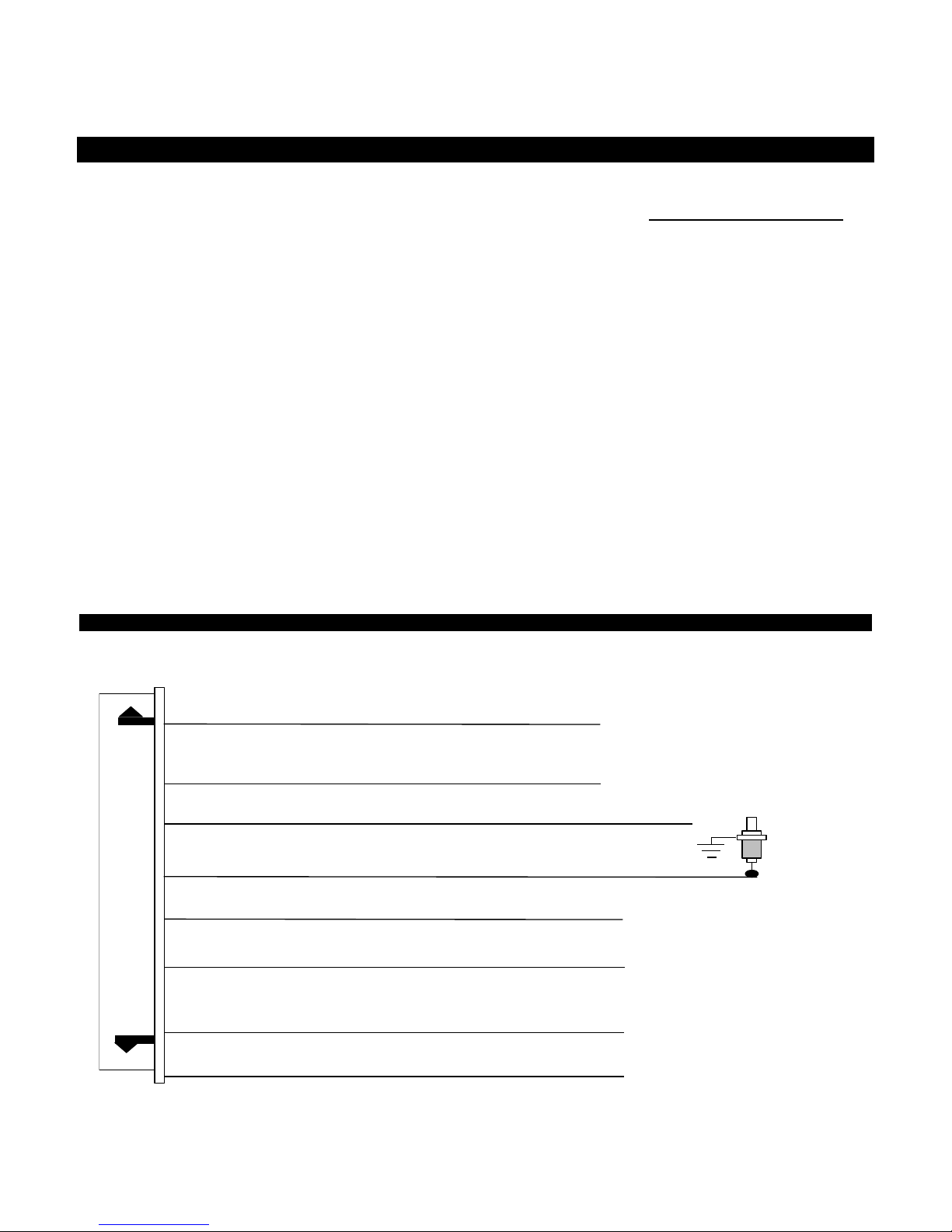

#H3 8 PIN WHITE CONNECTOR CONNECTION

6. White

Wire: (-) 200 mA Key Sensor By-Pass output

8. Yellow

Wire: (-) 200 mA Ignition 3 Control Output

7. Pink

Wire: (-) 200 mA Programmable output

Factory Security Disarm Signal Output (Factory Default setting)

Or Start Status (Shock Sensor Bypass Control) Output

5. Green

Wire: (-) Instant Start & Turn Off Input

4. White/Black

Wire: (-) Negative Safety Shut Down Input for Hood pin switch

3. White/Violet Wire: (+) Positive Safety Shut Down Input for Brake switch.

2. Black/White

Wire: (-) Neutral Safety Switch Input &

(-) Remote Start Toggle Switch Input

1. White/Red

Wire: Tachometer Signal Input

Page 4

August, 2005

RS2 4

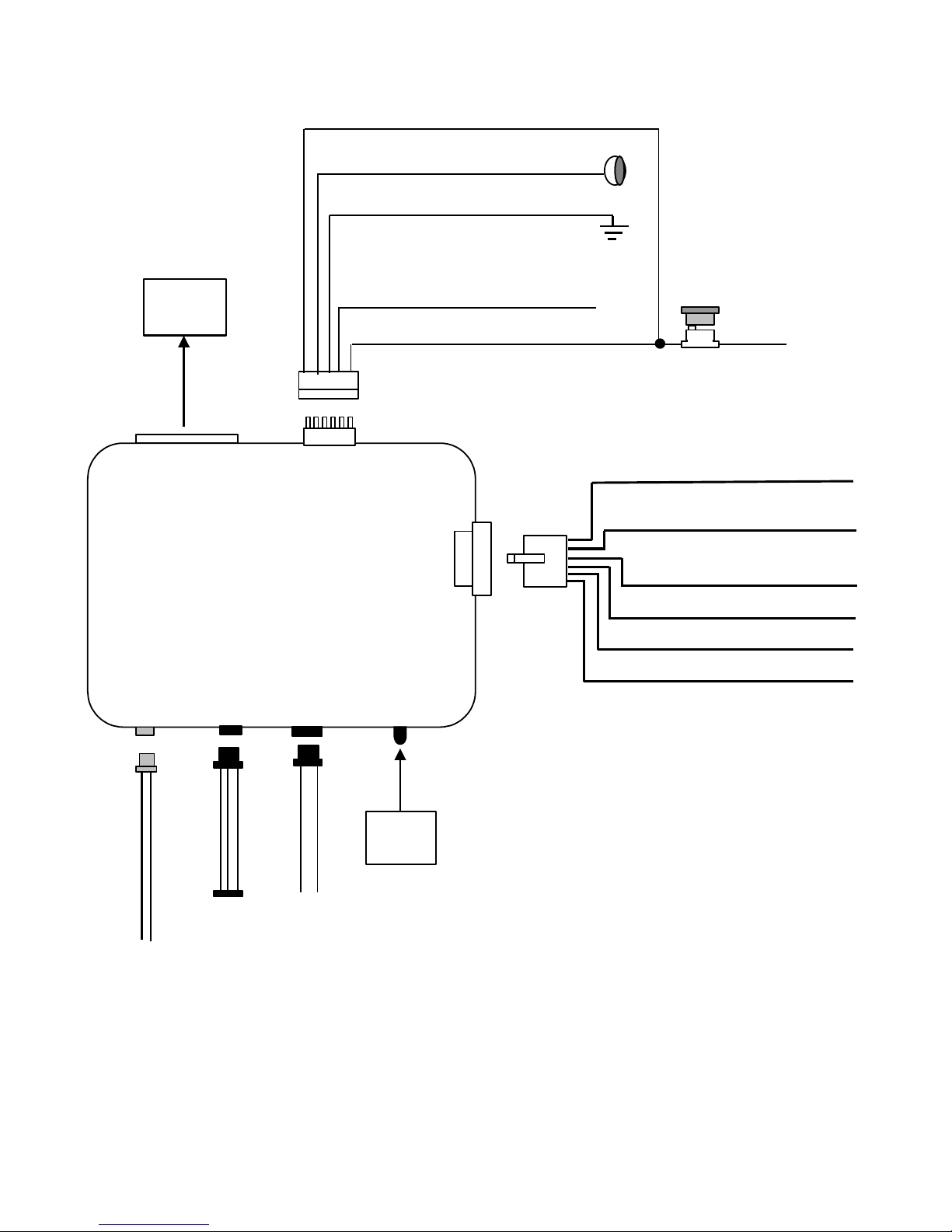

H 1

6 Pin

White

H 2

5 Pin

White

H 5

3 Pin

Red

H3

8 Pin

White

PROGRAM

SWITCH

H 4

2 Pin

Blue

1. Red/White: Parking Light Relay Power input

2. White: Parking Light Relay Output

3. Black: Ground to Vehicle Frame

4. Brown: (-) 200ma programmable Output

1. Horn Output (Factory Default Setting)

2. Factory Security Rearm Signal Output

5. Red: +12V Input

15A

Fuse

H3

8 Pin White

Connector

One Way

Transceiver

Antenna

Program

LED

Indicator

2. Red: +12V Input

3. Red: +12V Input

4. Yellow: Ignition 1 output

1. Violet:

Starter Output

20A

Fuse

20A

Fuse

5. Pink: Ignition 2 Output

6. Brown: ACC/Heater Output

H6

3-Pin

White

Page 5

August, 2005

RS2 5

WIRING

Keep wiring away from moving engine parts, exhaust pipes and high-tension cable. Tape wires that pass through holes on

the firewall to prevent fraying. Watches out sharp edges that may damage wires and causes short circuit.

CAUTION: Do not connect the wire harness to the control module until all wiring to vehicle is complete.

H1: 6 PIN HEAVY GAUGE WIRING CONNECTIONS:

Remember that the system does to start a vehicle is duplicate the functions of the ignition key switch! Below, we will

explain the three basic functions of the ignition switch. Since this installation will require analysis of the ignition switch

functions, we recommend making the three connections below at the ignition switch harness directly.

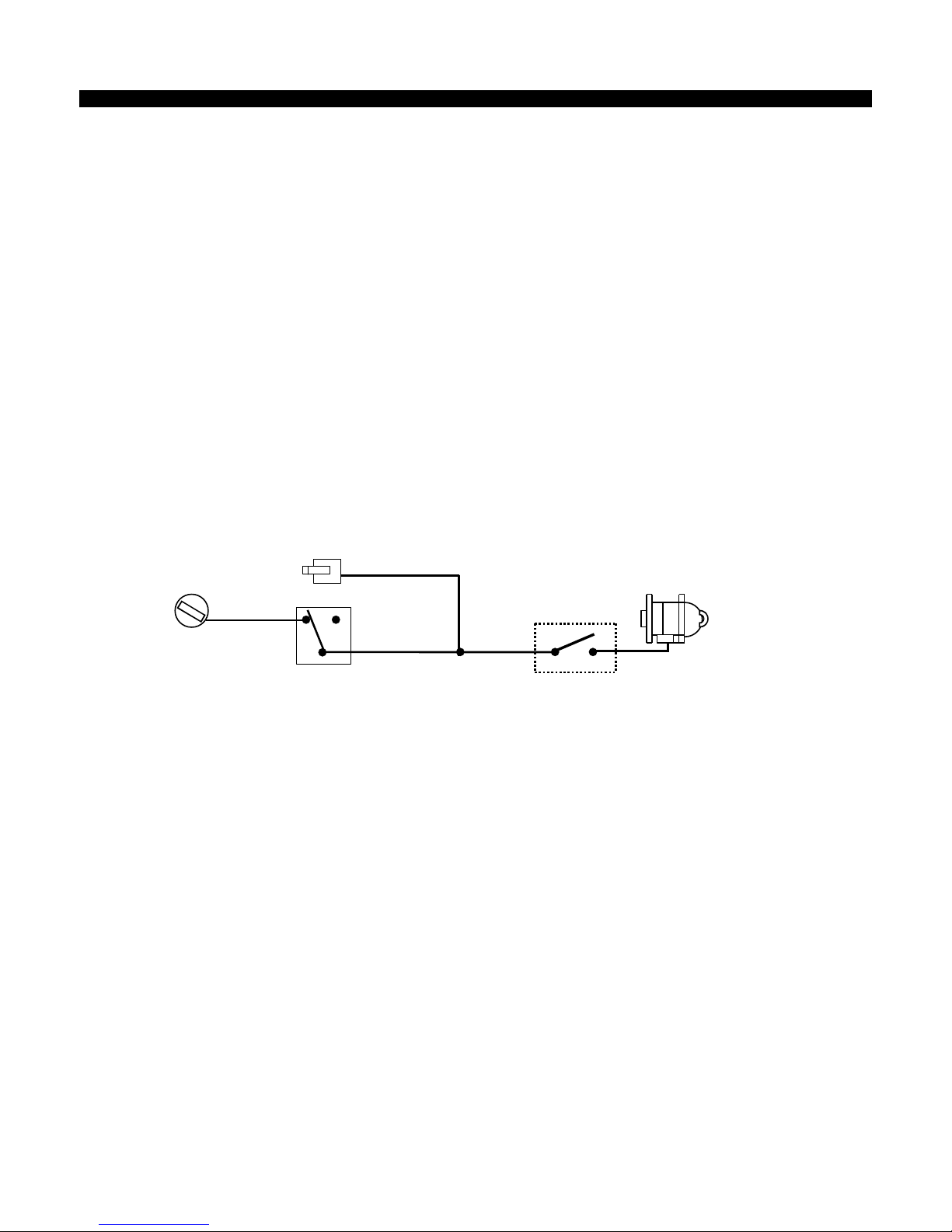

H1/1. Violet Wire—Starter Output

Careful consideration for the connection of this wire must be made to prevent the vehicle from starting while in gear.

Understanding the difference between a mechanical and an electrical Neutral Start Switch will allow you to properly

identify the circuit and select the correct installation method. In addition you will realize why the connection of the safety

wire is required for all mechanical switch configurations.

Failure to make this connection properly can result in personal injury and property damage.

In all installations it is the responsibility of the installing technician to test the remote start unit and assure that the vehicle

can not start via RF control in any gear selection other than park or neutral.

In both mechanical and electrical neutral start switch configurations; the connection of the VIOLET wire will be made to

the low current start solenoid wire of the ignition switch harness. This wire has +12 volts when the ignition switch is

turned to the “START” (CRANK) position only. This wire will have 0 volts in all other ignition switch positions.

NOTE: This wire must be connected to the vehicle side of the starter cut relay (when used). For the electrical neutral

switch configuration, this connection must be made between the starter inhibit relay (when used) and the neutral safety

switch as shown in the following diagram.

Failure to connect this wire to the ignition switch side of the neutral safety switch can result in personal injury and

property damage. SEE NEUTRAL START SAFETY TEST FOR FURTHER DETAILS.

Start Cut Relay

(When Used)

VIOLET

Wire

Closed in Park or

Neutral Only

Ignition

Switch

“Start”

“On”

Neutral Safety

Switch

“Acc”

“Off”

Starter

H1/2 & H1/3. Red Wire (2)-- +12V Power Input

Remove the two 20A fuses prior to connecting these wires and do not replace them until the satellite has been plugged

into the control module. These wires are the source of current for all the circuits the relay satellite will energize. They

must be connected to a high current source. Since the factory supplies (+) 12V to the key switch that is used to operate

the motor, it is recommended that these wires be connected there.

Note: If the factory supplies two separate (+) 12V feeds to the ignition switch, connect one RED wire of the satellite to

each feed at the switch.

H1/4. Yellow Wire – Ignition 1 Output

Connect the YELLOW wire to the ignition 1 wire from the ignition switch. The ignition wire should receive "12 volts" when

the ignition key is in the "ON" or “RUN” and "START" or “CRANK” position. When the ignition is turned "OFF", the

ignition wire should receive "0" voltage. The YELLOW wire must be connected.

H1/5 Pink wire – Ignition 2 Output

Some vehicles have [2] ignition wires that must be power. Connect the PINK wire to the ignition 2 wire from the ignition

switch. The ignition wire should receive "12 volts" when the ignition key is in the "ON" or “RUN” and "START" or

“CRANK” position. When the ignition is turned "OFF", the ignition wire should receive "0" voltage. If the PINK wire is not

used, cap the end of the wire.

H1/6 Brown wire – Accessory Output (Heater /ACC Output) –

Connect the BROWN wire to the accessory wire in the vehicle that powers the climate control system.

An accessory wire will show + 12 volts when the ignition switch is turned to the “ACCESSORY” or “ON” and “RUN”

positions, and will show 0 Volts when the key is turned to the “OFF” and “START” or “CRANK” position. There will often

be more than one accessory wire in the ignition harness. If selected, the correct accessory wire will power-up the

vehicle’s climate control system. Some vehicles may have separate wires for the blower motor and the air conditioning

compressor. In such cases, it will be necessary to add a relay to power the second accessory wire.

Page 6

August, 2005

RS2 6

H2: 5 PIN WIRE HARNESS:

H2/1. RED / WHITE WIRE –PARKING LIGHT RELAY INPUT --

The RED/WHITE wire is the input to the flashing parking light relay. The connection of the RED/WHITE wire will

determine the output polarity of the flashing parking light relay.

If the vehicle you are working on has +12volt switched parking lights, you don’t need connect this wire. This wire already

connected to +12volt. If the vehicle’s parking lights are ground switched, cut the RED/WHITE wire, connect the

RED/WHITE wire to chassis ground.

H2/2. WHITE WIRE -- PARKING LIGHT RELAY OUTPUT (+12 V 10A OUTPUT) --

Connect the WHITE wire to the parking light wire coming from the headlight switch. Do not connect the WHITE wire to

the dashboard lighting dimmer switch. (Damage to the dimmer will result). The limitation of the WHITE wire is 10 AMP

max. Do not exceed this limit or damage to the alarm and parking relay will result.

H2/3. BLACK WIRE -- SYSTEM GROUND –

This is main ground connection of the alarm module. Make this connection to a solid section of the vehicle frame. Do

not connect this wire to any existing ground wires supplied by the factory wire loom; make the connection to the

vehicle's frame directly.

H2/4. BROWN WIRE – (-) 200mA PROGRAMMABLE OUTPUT (See Feature I - 3 Programming)

HORN OUTPUT – (Factory Default Setting)

This wire is provided to use the existing vehicle's horn as the alarm system's optional's warning audible device. It's a

transistorized low current output, and should only be connected to the low current ground output from the vehicle's

horn switch.

FACTORY SECURITY RE-ARM SIGNAL OUTPUT– (See Alarm Feature I - 3 Programming)

This wire is designed to rearm a factory installed security system. This wire will sup

ply a pulse whenever the remote

start times out or is shut dowm using the transmitter and remote door locking..

H2/5. RED WIRE -- SYSTEM POWER (+12V CONSTANT) --

The RED wire supplies power to the system. Connect this wire to a constant +12 volt source.

H3: 8-PIN MINI WHITE CONNECTOR WIRE HARNESS:

H3/1. WHITE/RED wire—Tachometer Signal connection—

This input provides the remote start system with information about the engine’s revolutions per minute (RPM). It can be

connected to the negative side of the coil in vehicle with conventional coils. In multi-coil and high energy ignition system

locating a proper signal may be more difficult. Once connected, you must Program the Feature III – 1 to “Tachometer

checking type” and teach the system the RPM signal.

To test for a tachometer wire, a multi-meter capable of test AC voltage must be used. The tachometer wire will show

between 1V and 6V AC at idle, and will increase as engine RPM increases. In multi-coil ignition system, the system can

learn individual coil wire. Individual coil wires in a multi-coil ignition system will register lower amounts of AC voltage.

Also, if necessary, the system can use a fuel injector control wire for engine speed sensing. Common locations for a

tachometer wire are the ignitions coil itself, the back of the gauges, engine computers, and automatic transmission

computers.

IMPORTANT! Do not test tachometer wires with a test light or logic probe. The vehicle will be damaged.

How to find a tachometer wire with your multi-meter

1. Set the ACV or AC voltage (12V or 20V is fine.)

2. Attach the (-) probe of the meter to chassis ground.

3. Start and run the vehicle.

4. Probe the wire you suspect of being the tachometer wire with the red probe of the meter.

5. If this is the correct wire the meter will read between 1V and 6V.

NOTE: No connection of this wire is required, if you use the voltage or timer checking type mode.

H3/2. BLACK/WHITE wire — (-)Neutral Safety Switch Input —

—(-)Remote Start Enable Toggle Switch Input —

When the BLACK/WHITE wire is grounded, the remote start unit is operable. When this wire is open from ground, the

remote start is disabled.

1. The optional “remote start toggle switch” can be added on to temporarily disable the Remote Start Device, it can

prevent the vehicle from being remote started accidentally. This feature is useful if the vehicle is being serviced or

stored in an enclosed area. To disable the remote start, move the optional remote start enable toggle switch to the

OFF position. To enable the remote start, move the optional remote start enable toggle switch to the ON position.

2. If needed, this wire can be connected to the PARK/NEUTRAL switch in the vehicle. (See the TESTING YOUR

INSTALLATION GUIDE)

IMPORTANT NOTE: Directly connect the BLACK/WHITE wire to the “GROUND” when this wire is not used.

Page 7

August, 2005

RS2 7

H3/3. WHITE/VIOLET WIRE:– POSITIVE SAFETY SHUT DOWN INPUT

This wire provides an instant shutdown for the remote start, whenever it gets +12volts. If the brake lights switch in the

vehicle switches +12 volts to the brake light circuit, connect this wire to the output side of the brake switch. This will

allow the remote start to shut down if an attempt is made to operate the vehicle without the key while running under the

control of the remote start. In most vehicles, in order to shift gear, the brake pedal must be depressed. The brake input

will in turn cause the remote start unit to shut off. See below diagram.

+12 volts from fuse box

To White/ Violet wire

Brake light bulbs

Switch closes when

brake is depress

H3/4. WHITE/BLACK WIRE – NEGATIVE SAFETY SHUT DOWN INPUT --

The WHITE/BLACK wire provides an instant shutdown for the remote start, whenever it is grounded. Connect the wire

to the hood pin switch previously installed. This wire must be routed though a grommet in the firewall and connected to

the hood pin switch.

Important! This connection is a safety wire and must be connected as shown and tested as specifiled. Failure to do

so may result in personal injury or property damage. See detail of wiring in the following diagram. This wire may also be

used if the vehicle brake light circuit switches ground to the brake lights. An isolation diode must be used for ground

switched brake light circuits and must be connected to the output of the brake switch.

To:

White/Black

Wire /

Negative safety

To Vehicle Brake Switch

Hood Pin Switch

Diode

H3/5. GREEN WIRE – (-) INSTANT START & TURN OFF INPUT –(See Feature I - 1 Programming)

This wires activates and turns off the remote starter each time it sees a momentary ground signal. It is normally only

used for testing during installation or when activating the module from an after-market system.

H3/6. WHITE WIRE – (-) 200ma KEY SENSOR BY-PASS OUTPUT

This output is for a Key sense wire by-pass that some Chrysler and Toyota vehicles us to activate the remote start.

This wire comes on when the start is activated and stays on for 20 seconds.

H3/7. PINK WIRE – (-) 200ma PROGRAMMABLE OUTPUT(See Alarm Feature I - 2 Programming)

FACTORY SECURITY DISARM SIGNAL OUTPUT –(Factory Default Setting) --

This wire is designed to disarm a factory installed security system. This wire sends a negative (-) 1 seconds pulse

upon a remote start and remote door unlocking. Some factory systems must be disarmed to allow remote starting.

In most cases, this wire may be connected directly to the factory alarm disarm wire. The correct wire will show

nagative ground when the key is used to unlock the doors or trunk. This wire is usually found in the kick panel area

in the wiring harness coming into the car body from the door.

START STATUS (Shock Sensor Bypass Control) OUTPUT–

This wire is designed to by-pass shock sensor module. This wire will supply an output at all times the remote start

is operating plus an additional 3 seconds after the remote start unit turn off.

H3/8. YELLOW WIRE:- (-) 200ma IGNITION 3 OUTPUT–

This wire provides a 200mA (-) ground output that becomes active 4 seconds before the remote start unit initialize,

and remains grounded while running.

Page 8

August, 2005

RS2 8

Ignition 3 output:

Some newer vehicles use a second ignition

wire which is required to start and keep the

vehicle’s engine running. If this is the case,

wire an IGN 3 relay (not supplied) as shown

below:

Do not connect any vehicle circuits together,

they are isolated for a resaon.

Yellow Wire

87a

Ignition 3 Wire From

Ignition Key Switch

+ 12 V Constant

Fused 25A Capable

30 85 86 87

INSTALLATION WITH FACTORY IMMOBILIZER SYSTEMS

Vehicles using a Transponder-type immobilizer:

If the vehicle has transponder system installed, you will need to by-pass the system while the vehicle is

operating under the control of the Remote Start Unit. To do this:

1. You will need a transponder key that's already programmed to the vehicle.

2. Remove the trim around the ignition switch.

3. Wrap a thin (28 - 30awg) wire tightly around ignition switch 6 to 8 times and secure it.

4. About 6"down line make another loop of approximately 2"diameter.

5. Place the key inside this loop and secure it to the loop.

6. Connect on end of the (28 - 30awg) wire to pin (87) of the relay module.

7. Connect the other end of the loop wire to Pin (30) of relay module.

8. Connect the pin (86) of the relay module to the ignition wire from the ignition switch.

9. connect the pin (85) of the relay module to the H5/2 Yellow wire of 5-pin mini white connector.

GM VATS KEY OVERRIDE:

If the vehicle has the General Motor VATS system installed, you will need to by-pass the system while the vehicle is

operating under the control of the Remote Start Unit. To do this:

1. Measure the resistance of the resistor pellet on the ignition key then select a resistor within 5% of the key’s

value.

2. Locate the pair of VATS wires in the vehicle, usually a pair of thin gauge wires running from the ignition switch to

the VATS control module.

3. Connect the YELLOW wire from Remote Start Unit to TERMINAL #85 of an external relay. Connect terminal #86

of the relay to a fused +12 volt.

4. Cut (#1) wire (as shown), and connect the ignition switch side of the cut wire to terminal #87a of the relay.

Connect the other side of the (#1) wire to terminal #30.

5. Connect the previously selseced resistor from terminal #87 to the second(#2) wire (as shown).

To + 12 V

Ignition

Switch

YELLOW wire

Matching Resistor

VATS control Module

87a 86

30

87

85

VAT wire (#1)

VAT wire

(#2)

H4. 2 PIN BLUE CONNECTOR FOR THE PROGRAM SWITCH:

Select a mounting location for the switch that is easily accessible to the driver of the vehicle. Mount the valet switch in a

hidden but accessible location. Route the valet switch wires to the control module.

Page 9

August, 2005

RS2 9

H5. Red 3-PIN CONNECTOR. – Windshield Receiver /Antenna

The windshield receiver/antenna mounts on the windshield (Inside). We suggest you mount it on the lower left or upper

left-hand side of windshield.

Warning! Do not mount in such a manner that it obstructs the driver’s view.

- For Optimum Performance the receiver/antenna whip must be vertical facing up.

- Remove the protective tape backing.

- Carefully align the receiver/antenna and apply to windshield.

- Route the black connector wire behind the trim and connect to receiver/antenna.

- Connect the other end to the control module.

- Special considerations must be made for windshield glass as some newer vehicles utilize a metallic

shielded window glass that will inhibit or restrict RF reception. In these vehicles, route the windshield

receiver/antenna module away from metallic shielded window glass as far as possible.

H6. White 3-PIN DOOR LOCK CONNECTOR

1.

Wire

2.

Wire

( - ) Lock

Green

( - ) Unlock

Blue

NEGATIVE TRIGGER DOOR LOCK SYSTEM

Blue Wire Door Unlock

Green Wire Door Lock

Locking

Master

Switch

To Exiting

Door Lock Relay

+12V

Master Door

Lock Switch

To Door

Lock Motors

Unlock Wire

3 Pin Plug

To Alarm

3-WIRE POSITIVE DOOR LOCK

30 86

87a

85 87 30 86

87a

85 87

+12V

Green Wire

Blue Wire

+12V

Master Door

Lock Switch

X X

Splice

Splice

Cut the Existing

Lock Wire

To Door

Lock Motors

Cut the Existing

Unlock Wire

3 Pin Plug

To Alarm

5-WIRE ALTERNATING DOOR LOCK

30 86

87a

85 87 30 86

87a

85 87

+12V

Green Wire

Blue Wire

Page 10

August, 2005

RS2 10

PROGRAMMING

A. PROGRAMMING TRANSMITTER:

Note: This remote start system will only retain the last 4 remote transmitters programmed. If the transmitter memory is

exceeded, the security system will start deleting transmitters from memory in chronological order.

PROGRAMMING THE REMOTE TRANSMITTER

1. Turn the Ignition 'switch ‘OFF/ON’ 3 TIMES and stay in the ‘ON’ position. Within 15 seconds.

2. Push the Programming switch 3 times holding in on the 3rd push, until a long chirp from the horn (optional) and the LED

starts to flash then release the valet switch. You are now in the Transmitter programming mode.

3. Press the ‘Lock’ button on the transmitter until a chirp from the horn / a flash from the parking light / the LED turns on

for 2 seconds to confirming the first transmitter is now programmed.

4. Apply the same procedure (step 3) to program 2nd, 3rd and 4th.

Exit: Turn Ignition to 'OFF' position, or leave it for 15 seconds. 3 long chirps & 3 parking light flashes will confirm exit.

B. FEATURES PROGRAMMING:

FEATURE “I” PROGRAMMING:

1. Turn the Ignition 'switch ‘ON/OFF’ 3 TIMES and stay in the ‘OFF’ position.

2. Push the Programming switch 1 time and hold it until the LED turns on and (*) one chirp with a long chirp is heard ;

then release the Programming switch. You are now in the feature ‘I’ programming mode.

3. Press and release the transmitter button with the Icon corresponding to the feature with the icon you want to program.

The (optional) horn chirps and the LED will flash then pause indicating a previous setting.

The factory default settings are always [1] LED flash, [1] horn chirp.

4 Depress the transmitter button icon again to change the feature. Simply keep re-depressing the transmitter button icon

again until the module advances to your desired setting.

5. Depress the next desired transmitter icon button corresponding to the feature you want to program.

(*) The Horn must be connected to hear the programming chirps.

Exit: Turn Ignition to the 'ON' position, or leave it for 15 seconds. 3 long chirps & 3 parking light flashes will confirm exit.

Press

Transmitter

Button

One Chirp /

LED one pulse

Factory Default Setting

Two Chirps /

LED two pulse

1.

H3/5 Green Wire = 1 Pulse Remote Start H3/5 Green Wire = 3 Pulse Remote Start

2.

H3/7 Pink Wire = Factory Security Disarm

Signal Output

H3/7 Pink Wire = Start Status (Shock Sensor

Bypass Control) Output

3.

+

H2/4 Brown Wire = Horn Output

H2/4 Brown Wire = Rearm Signal Output

4.

+

Button Two Push Remote

Button One push Remote Start

5.

Without ignition controlled door locks &

unlocks

Ignition controlled door locks & unlocks

Page 11

August, 2005

RS2 11

FEATURE “II” PROGRAMMING:

1 Turn the Ignition 'switch ‘ON/OFF’ 3 TIMES and stay in the ‘OFF’ position.

2 Push the Programming switch 2 times and hold it until the LED turns on and (*) two chirps with a long chirp is heard;

then release the Programming switch. You are now in the feature ‘II’ programming mode.

3 Press and release the desired transmitter button icon corresponding to the feature you want to program.

(*) The Horn must be connected to hear the programming chirps.

Press

Transmitter

Button

One Chirp /

LED one pulse

Factory Default

Setting

Two Chirps /

LED two pulse

Three Chirps /

LED three pulse

Four Chirps /

LED four pulse

1.

Gasoline Engine Diesel Engine and 10

seconds warn-up

timer

Diesel Engine and 15

seconds warn-up

timer

Diesel Engine and 20

seconds warn-up

timer

2.

20 minutes run time 10 minutes run time 30 minutes run time 5 minutes run time

3.

+

H2/2 White wire =

Constant Parking

Light Output

H2/2 White wire =

Flash Parking Light

Output

4.

+

Door Lock before

start

Door Lock after start Door Lock before &

after start

Without this

feature

5.

0.8-second Door lock

pulses.

3.0-second Door

Lock pulse.

Double pulse unlock

Exit: Turn Ignition to the 'ON' position, or leave it for 15 seconds. 3 long chirps & 3 parking light flashes will confirm exit.

FEATURE “III” PROGRAMMING:

1. Turn the Ignition switch ‘ON/OFF’ 3 TIMES and stay in the ‘OFF’ position.

2. Push the Programming switch 3 times and hold it until the LED turns on and (*) three chirps with a long chirp is

heard; then release the Programming switch. You are now in the feature ‘III’ programming mode.

4. Press and release the desired transmitter button icon corresponding to the feature you want to program.

(*) The Horn must be connected to hear the programming chirps.

Press

Transmitter

Button

One Chirp /

LED one pulse

Factory Default

Setting

Two Chirps /

LED two pulse

Three Chirps /

LED three pulse

1.

Tachometer checking

type.

Voltage checking type Timer checking type

RPM learning

2.

Start Timer:

0.6-second

0.8-second (2 chirps), 1.0-second (3 chirps), 1.2-second (4 chirps),

1.4-second (5 chirps), 1.6-second (6 chirps), 1.8-second (7 chirps),

2.0-second (8 chirps), 3.0-second (9 chirps), 4.0-second (10 chirps),

3.

Low check level Hi check level

Exit: Turn Ignition to the 'ON' position, or leave it for 15 seconds. 3 long chirps & 3 parking light flashes will confirm exit.

Page 12

August, 2005

RS2 12

RPM LEARNING

1. Turn the Ignition 'switch ‘ON/OFF’ 3 TIMES and stay in the ‘OFF’ position.

2. Push the Programming switch 3 times and hold it until the LED turns on and three chirps with a long chirp is heard;

then release the Programming switch. You are now in the feature ‘III’ programming mode.

3. Press and release the transmitter button once to set the “Tachometer Checking Type”. [1] LED flash, [1] chirp to

confirm this setting.

4. Press and release the transmitter button once; [1] chirp to indicate your are in features “RPM Learning mode”.

5. Start the vehicle with the key. (While the engine is running, the parking & LED will flash, If don’t, please check

tachometer White/Red wire connection. (H3/1)

6. Press and hold the program switch for 2 seconds until a long chirp and the LED light constant for two seconds. The

RPM signal is learned.

7. Turn the ignition switch off to exit the program mode. 3 long chirps & 3 parking light flashes will confirm exit.

RETURN TO FACTORY DEFAULT SETTING:

1. Turn the ignition ‘ON’ then ‘OFF’ 3 TIMES and stay in the ‘OFF’ position.

2. Push the Programming switch 10 times and hold it on the 10th push. When ten chirps with a long chirp is heard*and the

LED turns on; then release the Programming switch. You are now in the “Return To Factory Default Setting”

programming mode. *Optional horn output must be installed to hear the chirps.

3. Press the + buttons on the transmitter together for 6 seconds, there will be a confirmation of six chirps with 3

long chirp to confirm the system “Feature Programming” have all returned to the factory default setting.

Exit: Turn the ignition switch “on” or leave it for 15 seconds. 3 long chirps & 3 parking light flashes will confirm exit.

TO REMOTE START THE VEHICLE:

1. Press the transmitter button twice to start the vehicle.

2. The parking light will activate to indicate the remote start received the signal.

3. It will take approximately 5 seconds for the engine to start.

4. Once the engine is running, after couple seconds the parking light will turn on again and climate controls will

activate and adjust the vehicles interior temperature to your preset setting.

5. The vehicle will run for 5 to 30 minute cycle and automatically shut down.

SHUTDOWN DIAGNOSTICS

The unit has the ability to report the cause of the last shutdown of the remote start system.

Enter:

1. Turn the Ignition 'switch to ‘ON position.

2. Press the button on the transmitter.

3. The LED will now report the last system shutdown by flashing for one minute in the following grouped patterns:

LED

Flashes

Shutdown Mode

1

(-) Safety Shutdown input (Hood)

1. Close the hood.

2. Check H3/4 White/ Black wire connection.

1

(+) Safety Shutdown input (Brake) or 3. Check H3/3 White/ Violet wire connection.

1

Neutral Safety Switch input fail. 4. Move the Enable Toggle Switch to “ON”

position. (If installed.)

5. Move the gear selector to “Park”/ “NEUTRAL”

position.

6. Check H3/2 Black/White wire connection.

Page 13

August, 2005

RS2 13

3

No RPM or

Low Voltage.

TACHOMETER CHECKING TYPE:

Check H3/1 White/Red wire connection

VOLTAGE CHECKING TYPE:

Program the “CHECK LEVEL” from

“Hi Check Level” to “Low Check Level”

5

Over-rev

6 System timed out

7 Transmitter

8 Tach. Signal has not been learned

Re-learning the RPM (Feature

III – 2

)

TROUBLE SHOOTING

There are 5 reasons why the remote start button will not respond from the transmitter.

1. The Black/White Neutral Safety wire is not grounded. Must be grounded to start.

2. Hood Pin switch White/Black wire has a ground present. Must not show ground to start.

3. Brake pedal switch White/Violet has 12 volt present. Must not show 12 volt to start.

4. The system is in Valet mode.

5. The remote start feature programming has not been programmed to start the vehicle. The remote start must be

programmed how to start the vehicle.

TESTING YOUR INSTALLATION:

Caution!! The following procedure must be performed after the installation of the Remote Start Device. It is the

responsibility of the installing technician to complete these tests. Failure to test the unit in the following manner may result

in personal injury, property damage, or both.

1. Test the BRAKE shutdown circuit: With the vehicle in park (P), start the vehicle using the remote transmitter, Once the

engine is running, press the brake pedal. The vehicle should shut down immediately. If the vehicle continues to run,

check the brake circuit WHITE/ VIOLET wire (H3/3) connection.

2. Test the HOOD PIN shutdown circuit: Start the vehicle using the remote transmitter, Once the engine is running, pull the

hood release and raise the hood. The vehicle should shut down immediately. If the vehicle continues to run, check the

hood pin WHITE/ BLACK wire (H3/4) connection.

3. NEUTRAL START SAFETY TEST:

1. Set the vehicle parking brake.

2. Block the drive wheels to prevent vehicle movement.

3. Sitting in the vehicle, turn the ignition switch to “ON” or “RUN” position. But do not start the engine.

4. Step on the brake pedal and shift the gear selector into “DRIVE” (D).

5. Put your foot over the brake pedal but do not press down on it. Be ready to step on the brake to shut down the

Remote Start Device.

6. Start the vehicle using remote transmitter.

If the starter does not engage, the test is complete.

If the starter engages, immediately step on the brake pedal to shut down the system, recheck your VIOLET wire

(H1/1 starter output wire) connection. The heavy gauge VIOLET wire must be connected to the ignition switch side

of the Neutral Start Switch. If the vehicle you are working on does not have an Electrical Neutral Safety Switch, it

will be necessary to reconfigure the Remote Starts Wiring to accommodate this vehicle. The information

concerning the Mechanical Neutral Safety Switch provided below will help you to determine if the vehicle you are

working on has this type of safety switch and will provide alternate wiring methods to accommodate this situation.

MECHANICAL NEUTRAL SAFETY SWITCH CONSIDERATIONS:

Mechanical neutral safety switch configurations differ slightly in that they do not offer the same level of safety when

installing a remote start device. Often when the ignition switch is turned off while the gear selector is in any position other

than park or neutral, the mechanical function will not allow the key to be turned to the start position or be removed from the

ignition cylinder. This configuration prevents mechanical operation while the vehicle is in gear but offers no consideration

for electrical operation. Because of this potential problem, this installation requires the additional connection of a safety

wire from the remote start device to the vehicle PARK/NEUTRAL ECM input or the vehicle key in sensor. This connection

will prevent remote start operation if the key is left in the ignition switch regardless of the gear selector position.

PARK/NEUTRAL ECM INPUT:

The Park/Neutral ECM input is the preferred method of installation. This not only maintains the integrity of the factory

circuit, it is also the easiest to install, providing the vehicle you are working on has this ECM input.

The installation required for this application (shown below), indicates in the slight reconfiguration of the control switch

Page 14

August, 2005

RS2 14

wiring. Shown is a typical GM Park/Neutral ECM input circuit. To connect the Remote Start unit to the GM Park/Neutral

ECM input:

1. Locate the Orange/Black reference wire in the “C2” connector found at the ECM in GM B Body vehicles or, locate the

equivalent reference wire in the vehicle you are installing the Remote Start Unit in.

2. Connect the BLACK/WHITE Neutral Safety Switch wire (H3/2) to this reference wire.

NOTE: If the optional remote starts enable toggle switch is installed, connect the one side the enable switch to this

reference wire and connect the other side of the enable switch to the BLACK/WHITE Neutral Safety Switch wire (H3/2) of

the Remote Start unit.

The reference diagram below shows a typical GM B Body ECM reference wire and how it is to be connected to the

Remote Start Unit.

Ignition

P 1

2DN

R

Electronic Control Module (ECM)

Solid State, Do Not Measure

Resistance

To Neutral Safety

Switch Input wire

Black/White (H3/2)

Optional Enable Switch

KEY-IN SENSOR CIRCUITS:

If the vehicle you are working on does not have or you cannot locate the ECM reference wire, there are two alternatives

available. Although not preferred, the vehicle Key In Sensor may be reconfigured to allow a margin of safety and will

prevent the vehicle with a Mechanical Neutral Start Switch from starting in gear.

WE ADVISE THAT YOU MAINTAIN THE FACTORY CIRCUIT WHENEVER POSSIBLE. The following two circuits

may be used only if the above circuit is not available.

NOTE: When completing an installation using either of the following key in sensor circuits, if the operator inserts the

ignition key while the vehicle is running under the control of the Remote Start, the vehicle will shut down. This must be

explained to the operator as it is in contrast to the normal operation of a vehicle utilizing an electrical neutral start switch

and is inconsistent with the operators’ manual.

Additional information concerning Key in Sensor methods 1&2 are listed below and should be reviewed before considering

either alternative.

Method 1 will allow the safety required for the remote start unit and prevent the vehicle from starting while in any gear

other than Park or Neutral while the key is in the ignition cylinder however, if the key is left in the ignition switch and the

door is left opened, the added relay will be energized causing a 150mA drain on the battery.

Method 2 will allow the safety required for the remote start unit and prevent the vehicle from starting while in any gear

other than Park or Neutral while the key is in the ignition cylinder however, the original factory key in chime module will not

alert the owner that the key has been left in the ignition switch. In addition, this may also affect other warning tones such

as the light ‘on’ reminder.

These situations should be carefully considered before altering the vehicle’s wiring and must be fully explained to the

consumer.

METHOD 1

+ 12 V

Ignition Key In Sensor

Switch Closes with Key In

Ignition Cylinder

Drivers Door Pin Switch

87a 86 30 87

85

Key In

Chime Module

Connected to (-) Negative

Safety Input Wire

White/ Black (H3/4

)

To Hood Pin Switch Safety

Shut Down (H3/4)

1N4003

+ 12V

To connect to the key in sensor as shown in method 1:

A. Locate the control wire that connects the driver’s door pin switch to the key in sensor switch.

B. Cut this wire and connect the ignition cylinder side to chassis ground.

C. Locate the key in sensor switch wire that connects the chime module to the ignition cylinder.

D. Cut this wire and connect the ignition cylinder side to terminal 30 of a P&B VF45F11 or equivalent relay.

E. Connect the cathode (striped) side of a 4003 series diode to this same wire, and connect the (non striped) side to the

negative safely input wire (WHITE/ BLACK) (H3/4) of the Remote Start Unit.

F. Connect terminal 86 of the relay to a fused + 12 volt constant battery source.

G. Connect terminal 87 of the relay to the Chime Module side of the previously cut wire in step D.

Page 15

August, 2005

RS2 15

H. Connect terminal 85 of the relay to the Drivers Door side of the pin switch wire previously cut in step B.

Note: A second 4003 series diode may be required to maintain the integrity of the hood open, shut down circuit. If this is

the case, it must be installed as shown in the diagram above. The anode (Non Stripped) side must be connected to the

WHITE/ BLACK wire (H3/4) of the Remote Start Unit. The cathode (Striped) side must be connected to the hood pin

switch.

METHOD 2

Ignition Key In Sensor

Switch Closes with Key

In Ignition Cylinder

Connected to (-

) Negative

Safety Input Wire

White/ Black (H3/4)

To Hood Pin Switch

Safety Shut Down (H3/4)

1N4003

To connect to the key in sensor circuit as shown for method 2:

A. Locate the control wire that connects the drivers door pin switch to the key in sensor switch.

B. Cut this wire and connect the ignition cylinder side to chassis ground.

C. Locate the key in sensor switch wire that connects the chime module to the ignition cylinder.

D. Cut this wire and connect the ignition cylinder side to the Remote Start Negative Safety Shut down wire WHITE/

BLACK (H3/4), using a 4003 series diode as shown above.

Note: A second 4003 series diode may be required to maintain the integrity of the hood open, shut down circuit. If this is

the case, it must be installed as shown in the diagram above. The anode (Non Striped) side must be connected to the

WHITE/ BLACK wire (H6/4) of the Remote Start Unit. The cathode (Striped) side must be connected to the hood pin

switch.

AFTER THE CONNECTION OF THE NEUTRAL START SAFETY WIRE AS INDICATED IN ANY OF THE PREVIOUS

ALTERNATE CONFIGURATIONS, THIS CIRCUIT MUST BE TESTED FOR OPERATION.

Retest by following the steps outlined in the NEUTRAL START SAFETY TEST shown in this manual.

Page 16

August, 2005

RS2 16

NOTES

Page 17

August, 2005

RS2 17

Auto Page, Inc.

960 Knox Unit #B

Torrance, CA 90502

Toll Free Tech Support Hotline: 800-262-2527 ext. 461 /463 / 460

(For certified installation technicians only)

Loading...

Loading...