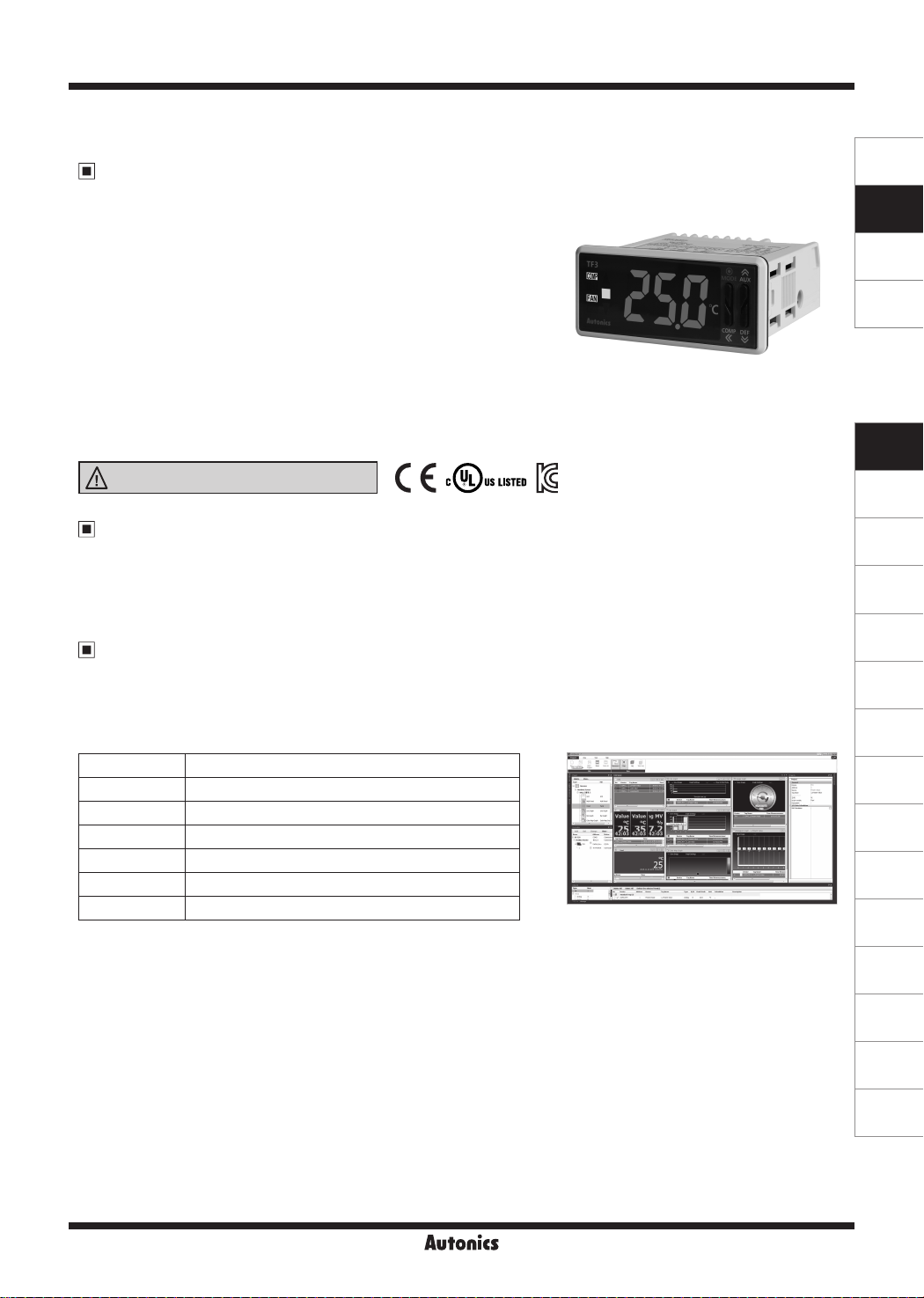

Refrigeration Temperature Controller

Features

Standard installation size for refrigeration and air-cooling panels

●●●

(W70.3×H28.2mm)

● Various compressor load current capacity: 5A, 16A, 20A

● Various user-friendly functions:

- Defrost sync function:

simultaneous defrost operation of multiple controllers (up to 6 units)

- RTC (Real Time Clock) function:

night mode operation and real-time defrost control

- Built-in alarm function

● Remote monitoring of real-time temperature and output control

(using TFD series remote display unit, sold separately)

● Communication output models available: RS485 (Modbus RTU)

● Parameter conguration via PC (RS485 communication)

- DAQMaster software included (comprehensive device management software)

● IP65 protection structure (IEC standard): front panel only

Please read “Safety Considerations”

in the instruction manual before using.

TF3 Series

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

Manual

● Visit our website (www.autonics.com) to download user manual and communication manual.

● User manual describes for specications and function, and communication manual describes for RS485 communication

(Modbus RTU protocol) and parameter address map data.

Comprehensive Device Management Program (DAQMaster)

● DAQMaster is comprehensive device management program. It is available for parameter setting, monitoring, and user

parameter group setting, parameter mask setting for only TF3 Series.

● Visit our website (www.autonics.com) to download user manual and comprehensive device management program.

< DAQMaster screen >< Computer specication for using software >

Item Minimum requirements

System IBM PC compatible computer with Intel Pentium Ⅲ or above

Operating system Microsoft Windows 98/NT/XP/Vista/7/8/10

Memory 256MB or more

Hard disk More than 1GB of free hard disk space

VGA 1024×768 or higher resolution display

Others RS-232 serial port (9-pin), USB port

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

J-171

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

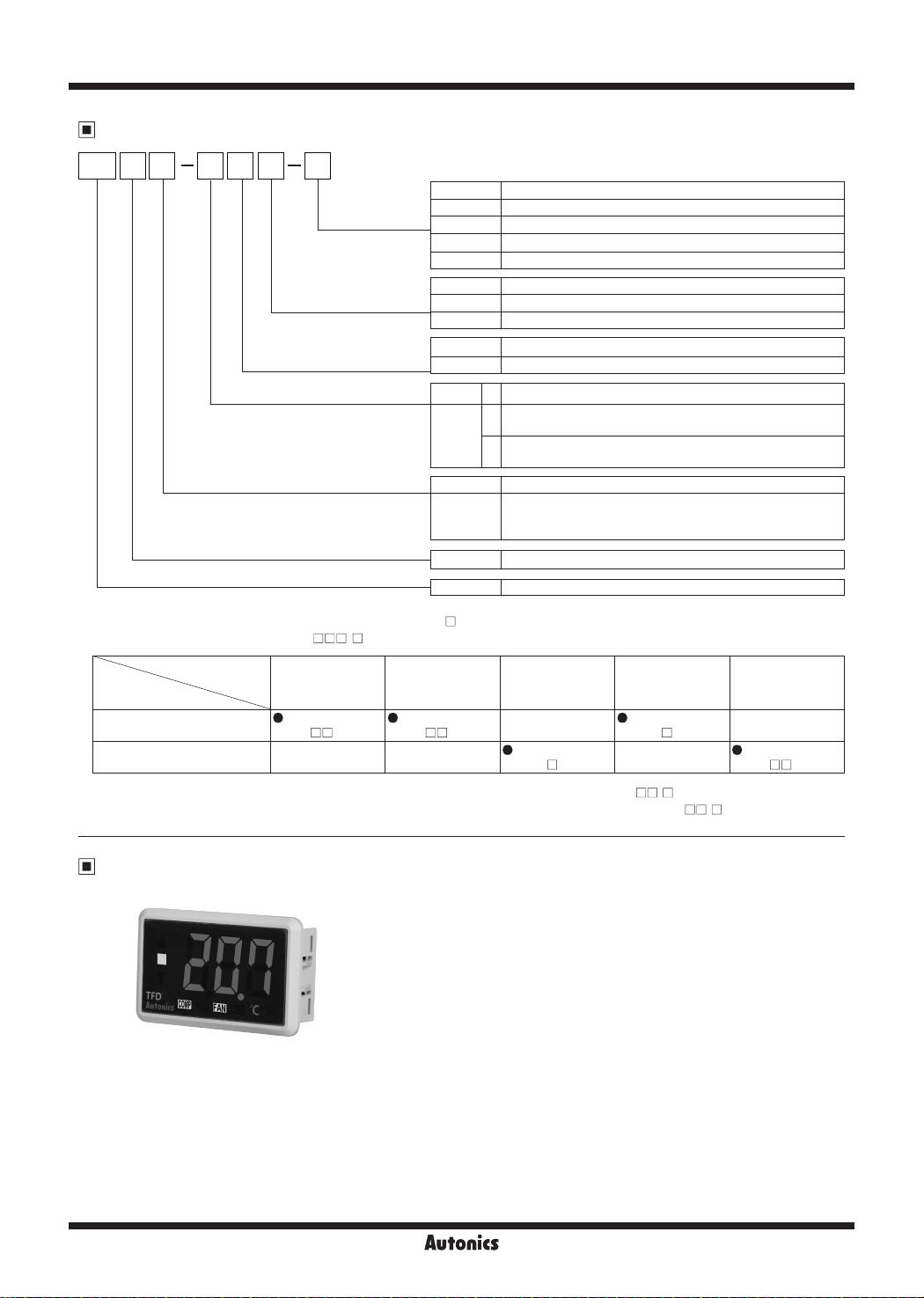

Ordering Information

TF

3 3 3 4 H T

Output

Number of input channels

Digits

Item

Option function

Compressor load capacity

Power supply

No-mark No option

S Synchronize defrost

※

2

T RS485 communication

※

3

R

※

3

A

※

1

G

A

H

1 24VAC 50/60Hz, 12-24VDC

4 100-240VAC 50/60Hz

1CH 1 Compressor output

1CH,

3CH

1

3

3 999 (3-digit)

TF Refrigeration Temperature Controller

RTC (real time clock)

RS485 communication+RTC (real time clock)

Compressor 20A 1a contact

Compressor 5A 1a contact

Compressor 16A 1c contact

Compressor+Defrost or Auxiliary

2

(alarm/evaporator-fan) output

Compressor+Defrost+Auxiliary

3

(alarm/evaporator-fan) output

1CH input (NTC or RTD) [temperature+digital input (DI)]

3CH input (NTC)

[inlet temperature+defrost temperature+

outlet temperature or digital input (DI)]

※

1: Only for 1CH input, compressor output model (TF31-1 G).

※

2: Only for 3CH input model (TF33- - ). Option function is varied by compressor load capacity and contact.

Compressor

load capacity & contact

Compressor 5A 1a contact

Compressor 16A 1c contact

※

3: Except compressor+defrost or auxiliary (alarm/evaporator-fan) output model (TF33-2

※

Only for 3CH input, compressor+defrost+auxiliary (alarm/evaporator-fan) output model (TF33-3

Remote Display Unit (TFD Series, Sold Separately)

Option function

Synchronize defrost

function

(TF33- A-S) (TF33- A-T)

- -

RS485

communication

RTC function

-

(TF33-3 H-R)

RS485

communication+

RTC function

(TF33-3 A-A)

-

- )

No option

-

(TF33- H)

- )

supports buzzer.

Remote display unit (TFD) displays current temperature or output

status of TF3 at remote place.

TFD cable is TFD-3: 3m, TFD-5: 5m.

Connect the phone-jack of remote display unit (TFD) to the data

loader port of TF3.

This unit is dedicated for TF3 Series and it does not directly

communicate with upper devices (PC, PLC, etc.)

If TFD communication with TF3 error occurs, TFD ashes display

component for 1 sec. Check the connection with TF3.

※

When connecting TFD to the data loader port of TF3, you cannot connect Autonics SCM-US (USB to Serial converter,

sold separately). for communication. Use SCM-US48I(USB to RS485 converter, sold separately), SCM-38I(RS232C to

RS485 converter, sold separately).

J-172

Refrigeration Temperature Controller

Specifications

TF3 Series

Model TF31- TF33- Number of channels 1CH 3CH

Power supply

Allowable voltage range 90 to 110% of rated voltage

Power

consumption

Display method 7 Segment LED method (red)

Character size (W×H) 9.4×19.3mm

Input type

Sampling period 500ms

Display accuracy

Control

output

Communication output

Digital input

Control method ON/OFF control

Hysteresis 0.5 to 5.0℃, 2 to 10℉ variable

Relay life

cycle

Memory retention Approx. 10 years (non-volatile memory method)

Insulation resistance Min. 100MΩ (at 500VDC megger)

Dielectric

strength

Noise resistance Square-wave noise by the noise simulator (pulse width: 1㎲) ±2kV R-phase and S-phase

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Environ

ment

Accessories Bracket: 2, NTC sensor (5kΩ): 1

Protection structure IP65 (front case)

Approval

Weight

Remote display unit [TFD]

Model

Power supply 3.3VDC

Power consumption Max. 1W

Display method 7 Segment LED method (red)

Communication method Serial (TTL Level), Half duplex

Communication cycle 100ms

Cable Ø2.5mm, 3m Ø2.5mm, 5m

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Enviornment

Protection structure IP67

Approval

Weight

※

1: The weight includes packaging. The weight in parentheses is for unit only.

※

Environment resistance is rated at no freezing or condensation.

AC power 100-240VACᜠ 50/60Hz

AC/DC power 24VACᜠ 50/60Hz, 12-24VDC

ᜡ

AC power Max. 8VA (100-240VACᜠ 50/60Hz)

AC/DC power Max. 5VA (24VACᜠ 50/60Hz), Max. 3W (12-24VDCᜡ)

NTC 5kΩ/10kΩ

RTD DPt100Ω

At room temp. (23℃±5℃): ±1℃±1 digit Out of room temp. range: ±2℃±1 digit

-

Compressor (COMP) 250VACᜠ 5A , 30VDCᜡ 5A, 1a / 250VACᜠ 16A, 24VDCᜡ 16A, 1c / 250VACᜠ 20A 1a

Defrost (DEF) 250VACᜠ 10A, 24VDCᜡ 10A, 1a

Auxiliary (AUX) 250VACᜠ 5A, 30VDCᜡ 5A, 1a

-

Contact input: ON max. 1㏀, OFF min. 100

㏀

RS485 communication output (Modbus RTU)

No contact input: ON residual voltage: max. 1V, OFF leakage current: max. 1mA, outow current: 4

Compressor

(COMP)

5A 1a Mechanical: 5,000,000 operations, Electrical: 50,000 operations (250VAC 5A)

16A 1c Mechanical: 20,000,000 operations, Electrical: 30,000 operations (250VAC 16A)

20A 1a Mechanical: 10,000,000 operations, Electrical: 100,000 operations (250VAC 20A)

Defrost (DEF) Mechanical: 20,000,000 operations, Electrical: 100,000 operations (250VAC 10A)

Auxiliary (AUX) Mechanical: 5,000,000 operations, Electrical: 50,000 operations (250VAC 5A)

AC power 3000VAC 50/60Hz for 1 min (between all terminals and case, power and input circuit)

AC/DC power 1000VAC 50/60Hz for 1 min (between all terminals and case, power and input circuit)

Ambient temperature -10 to 50℃, storage: -20 to 60

℃

Ambient humidity 35 to 85%RH, storage: 35 to 85%RH

※

1

● ● ●

Approx. 207g (approx. 105g)

TFD-3 TFD-5

ᜡ

Ambient temp. -10 to 50℃, storage: -20 to 60

℃

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

※

1

Approx. 77g (approx. 48g)

The weight is varied by model option.

㎂

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-173

TF3 Series

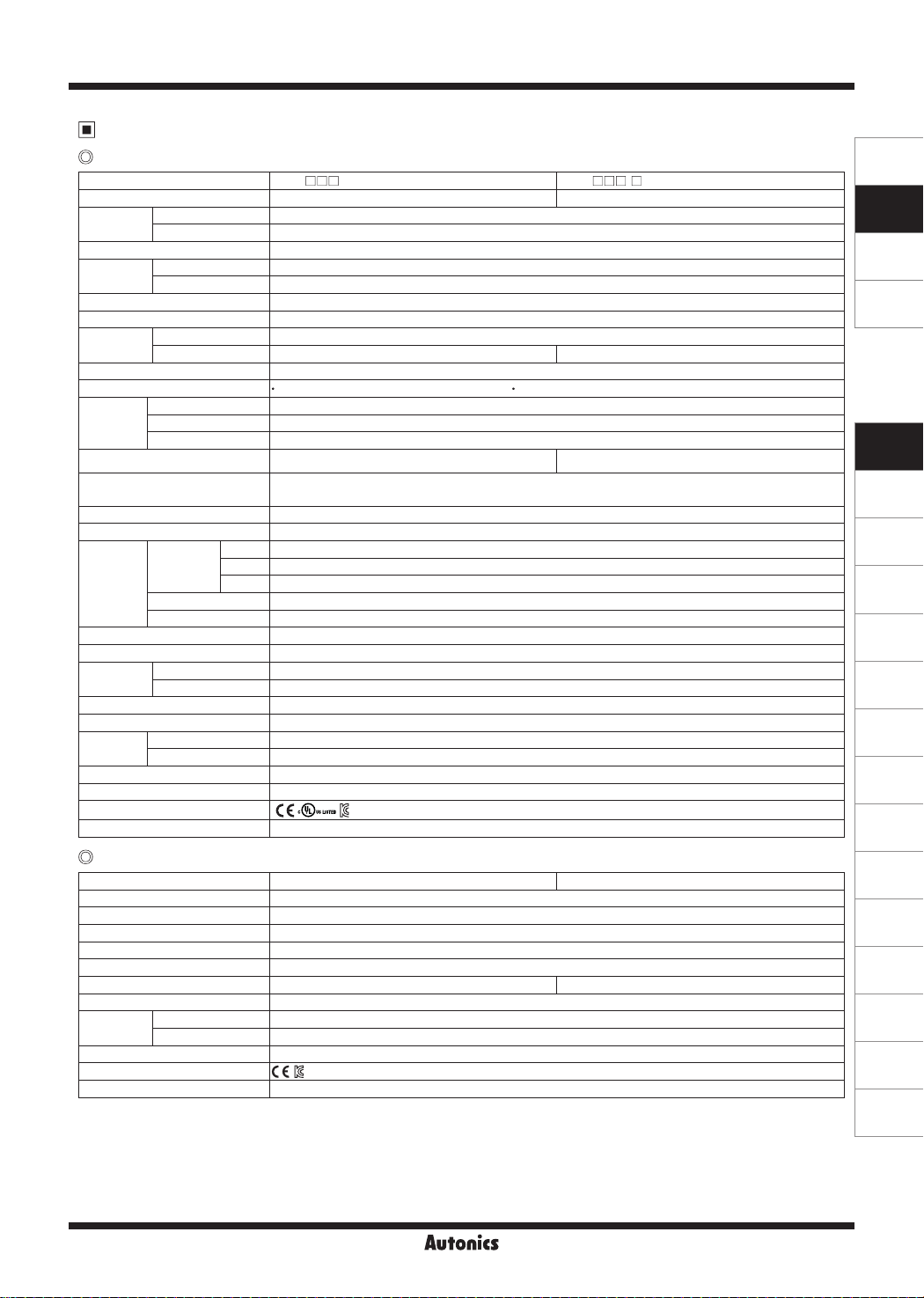

Connections

※

Use crimp terminals of size specied below.

a

c

<Crimp terminal>

Terminal number a b c

General 1 to 4 4 to 6mm Max. 1.7mm Max. 3.7mm

TF3 - H 5 to 10 6 to 8mm Max. 2.3mm Max. 4.5mm

TF3 - A

5 to 6 6mm Max. 1.9mm Max. 4.0mm

7 to 10 6 to 8mm Max. 2.3mm Max. 4.5mm

TF3 - G 6 to 7 6 to 8mm Max. 2.3mm Max. 4.5mm

General 11 to 12 6mm Max. 1.9mm Max. 4.0mm

TF31-1 G TF31- A

COMP OUT

250VAC 20A

RESISTIVE LOAD

b

COMP OUT

250VAC 5A

30VDC 5A

RESISTIVE LOAD

DEF OUT

250VAC 10A

24VDC 10A

RESISTIVE

※1

LOAD

AUX OUT

250VAC 5A

30VDC 5A

RESISTIVE

※2

LOAD

NTC 5K/10K

DPt100

SENSOR

DIGITAL INPUT

TF31- H

NTC 5K/10K

DPt100

SENSOR

DIGITAL INPUT

TF33- A-

S1 S2 S3 COM

COMP OUT

250VAC 16A

24VDC 16A

RESISTIVE LOAD

COMP OUT

250VAC 5A

30VDC 5A

RESISTIVE LOAD

DEF OUT

250VAC 10A

24VDC 10A

RESISTIVE

※1

LOAD

DEF OUT

250VAC 10A

24VDC 10A

RESISTIVE

※1

LOAD

SOURCE

100-240VAC 50/60Hz,

24VAC 50/60Hz,

12-24VDC

AUX OUT

250VAC 5A

30VDC 5A

RESISTIVE

※2

LOAD

SOURCE

100-240VAC 50/60Hz,

24VAC 50/60Hz,

12-24VDC

AUX OUT

250VAC 5A

30VDC 5A

RESISTIVE

※2

LOAD

NTC 5K/10K

DPt100

SENSOR

DIGITAL INPUT

TF33- H-

S2 S3 COM

S1

COMP OUT

250VAC 16A

24VDC 16A

RESISTIVE LOAD

DEF OUT

250VAC 10A

24VDC 10A

RESISTIVE

※1

LOAD

SOURCE

100-240VAC 50/60Hz,

24VAC 50/60Hz,

12-24VDC

AUX OUT

250VAC 5A

30VDC 5A

RESISTIVE

※2

LOAD

A+ B-

NTC 5K/10K

SENSOR

DIGITAL INPUT

※

1: Only for compressor+defrost or auxiliary (alarm/evaporator-fan) output model (TF3 -2 - ),

SYNCHRONIZE

※

3

/RS485

SOURCE

100-240VAC 50/60Hz,

24VAC 50/60Hz,

12-24VDC

NTC 5K/10K

SENSOR

DIGITAL INPUT

compressor+defrost+auxiliary (alarm/evaporator-fan) output model (TF3 -3 - ).

※

2: Only for compressor+defrost+auxiliary (alarm/evaporator-fan) output model (TF3 -3 - ).

※

3: Only for synchronize defrost function model (TF33- A-S), or RS485 communication model (TF33- A-T/A).

J-174

SOURCE

100-240VAC 50/60Hz,

24VAC 50/60Hz,

12-24VDC

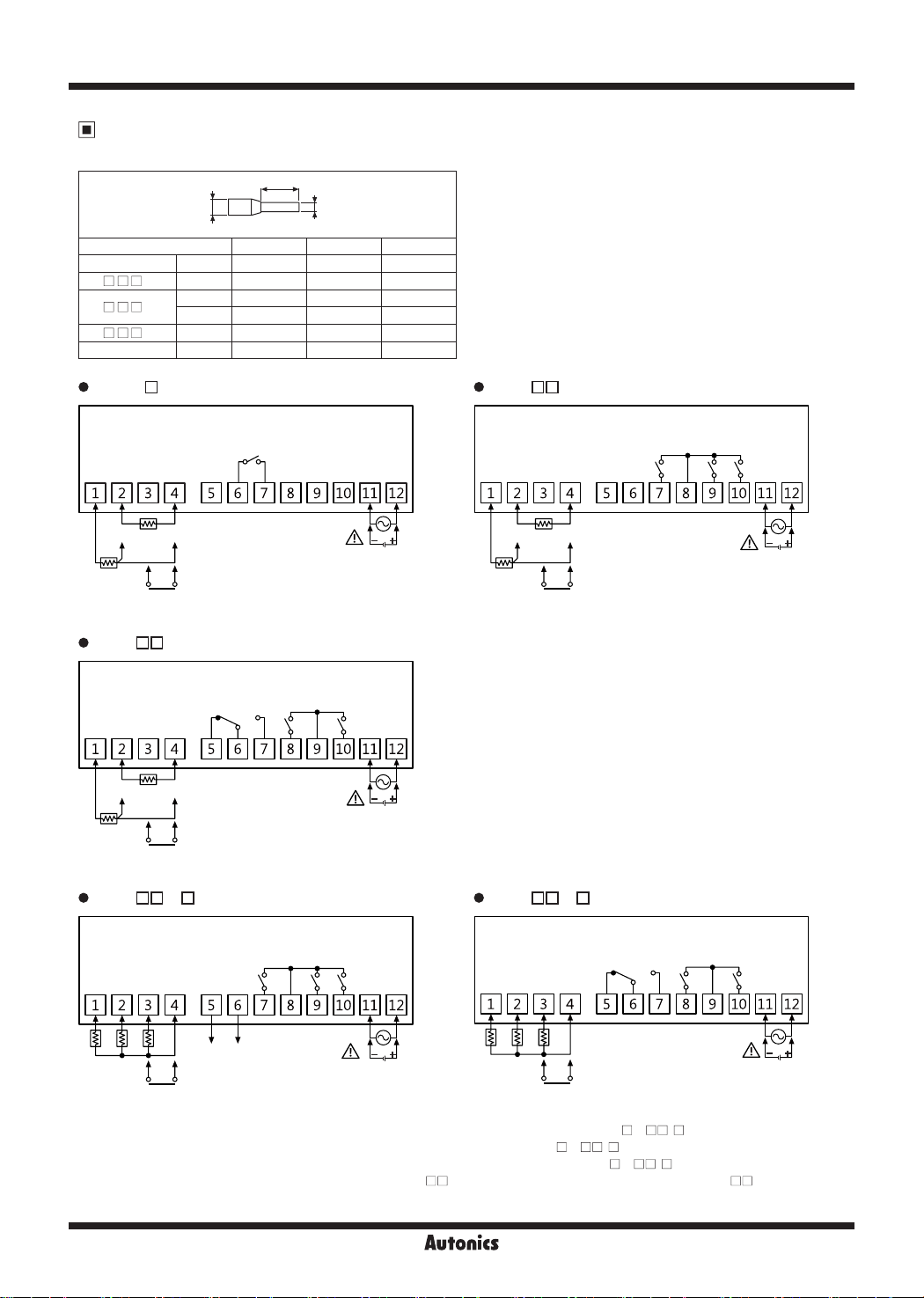

Dimensions

TF3 Series

Refrigeration Temperature Controller

(unit: mm)

77

5.5

74.3

SENSORS

CONTROLLERS

NTC sensor (5kΩ)

Max. 5

6±0.2

Max. 15

Panel cut-out

B

A

2000±50

C

AWG22

TPE lead wire

Soldering

D

35

28

Bracket

3.3

4

46

37.5

40.5

5±1

Size

Series

A B C D

TF3 Min. 100

TFD Min. 65 Min. 40 45.7

※

1. When connecting remote display unit (TFD), or SCM-US, Min. 120

12

23.9

※

1

Min. 55 70.3

+ 0.7

0

+ 0.6

0

(unit: mm)

+ 0.5

28.2

0

+ 0.3

25.4

0

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

Sold Separately

TFD

52

Communication converter

SCM-WF48

( Wi-Fi to RS485·USB wireless

communication converter)

3

12

31.5

SCM-US48I

(USB to RS485 converter)

25

Ø2.5,

3m or 5m

SCM-38I

(RS232C to RS485 converter)

SCM-US

(USB to Serial converter)

J-175

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

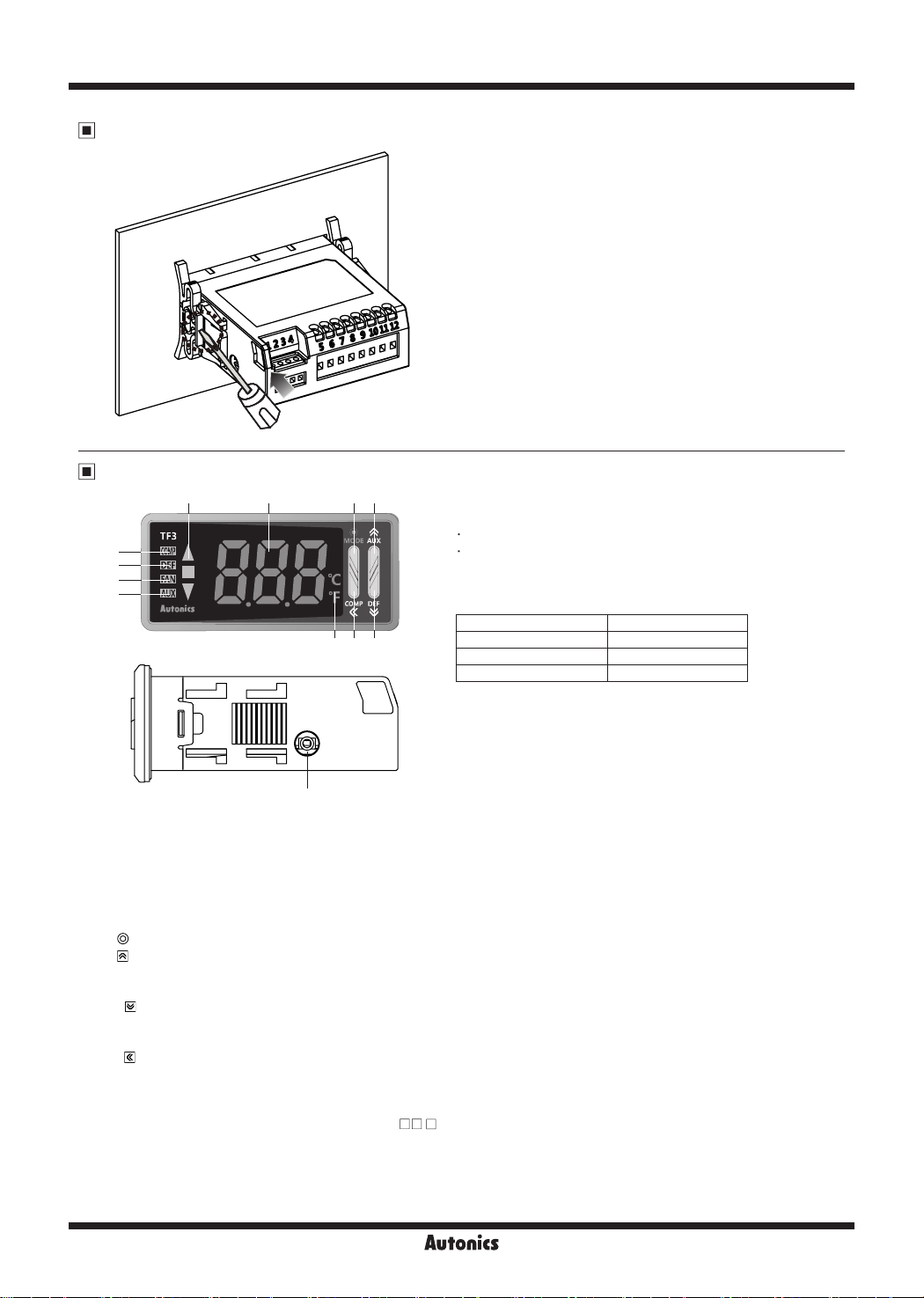

Product Mounting

Insert the unit into a panel, fasten the bracket by

(-) driver

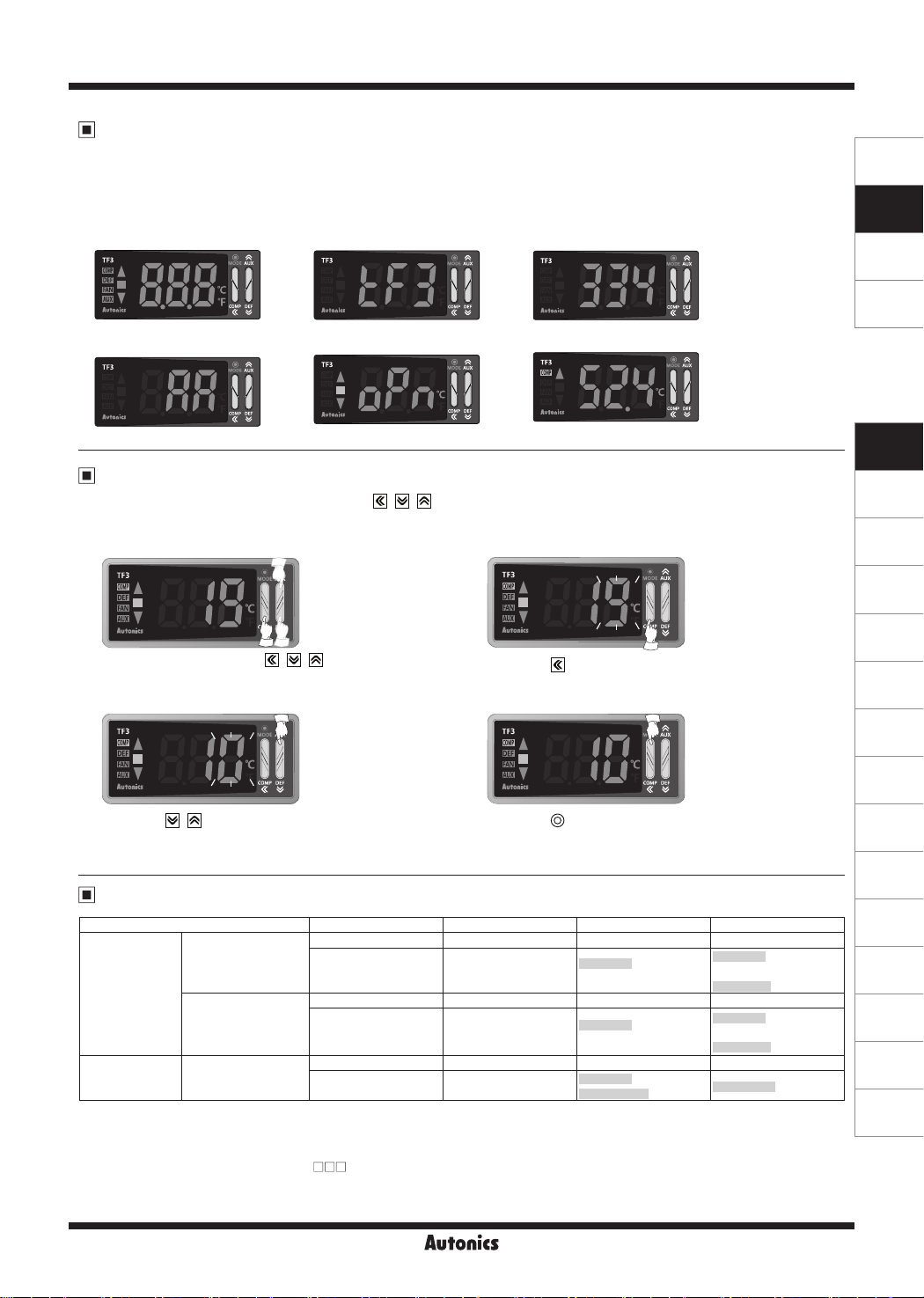

Unit Description

1 8 92

3

4

5

6

7 11 10

12

4. Defrost (DEF) output indicator (green):

Turns ON for defrost output. Flashes for defrost delay operation.

Turns ON for 2 sec and OFF for 1 sec for manual defrost or Power ON defrost.

5. Evaporator-fan (FAN) output indicator (green):

Turns ON for evaporator-fan output. Flashes for delay operation of evaporator-fan output.

6. Auxiliary (AUX) output indicator (green):

7. Unit indicator (red):

8. (MODE) key:

9. (AUX) key:

Used for entering SV setting group or changing setting value.

Hold the key over 3 sec to select active/inactive auxiliary output in RUN mode.

10. (DEF) key:

Used for entering SV setting group or changing setting value.

Hold the key over 3 sec to execute/stop manual defrost in RUN mode.

11. (COMP) key:

Used for entering SV setting group, changing setting value, moving digits.

Hold the key over 3 sec to active/inactive compressor output in RUN mode.

When buzzer alarm occurs, press the key once to stop the sound. (Only for 3CH input, compressor+defrost+auxiliary

(alarm/evaporator-fan) output model (TF33-3 - ) supports buzzer.

Buzzer [

12. Data loader port:

BUZ

It is for displaying TF3 data at remote display unit (TFD) by connecting phone-jack.

In other case, for connecting Autonics SCM-US (USB/Serial converter, sold separately),

it is a PC loader port of serial communication for parameter setting or monitoring by PC.

Displays temperature unit set at temperature unit [

Used for entering parameter setting group, returning RUN mode, moving parameter or saving SV.

] of parameter 1 group is set as [ON])

pushing with tools with a (-) driver.

1. Present value (PV) display component (red):

RUN mode: Displays present value (PV).

Setting mode: Displays parameter and setting value.

2. Deviation indicator (■: green, ▼/▲: red):

Displays deviation of present value (PV) based on setting

value (SV).

PV deviation temperature Deviation display

More than 1.8℃

Within ±1.8

Less than -1.8

3. Compressor (COMP) output indicator (green):

Turns ON for compressor output. In case of compressor

protection operation and output does not turn ON,

it ashes. When operating compressor continuously, it turns ON

for 2 sec, and turns OFF for 1 sec.

Turns ON for alarm output. Flashes for delay operation of alarm output.

℃

℃

▲

indicator turns ON

■

indicator turns ON

▼

indicator turns ON

] of parameter 1 group.

UNT

J-176

Refrigeration Temperature Controller

Front Panel Display When Power Is On

When power supplies to the unit, whole display part flashes approx. 1 sec. The display part displays model specification (no.

of input CHs, output, power supply, compressor load capacity, option function), flashes input type twice and the unit returns

to RUN mode to operate.

Model specification display is same as the unit model name. (E.g.: TF33-34A-A model)

SENSORS

CONTROLLERS

1. Whole display part

4. Compressor load capacity/

Option function

2. Series 3. No. of input CHs/Output/Power supply

5. Run mode

Sensor input error Normal operation

SV Setting

You can set the temperature to control with the , , keys.

Set range is within SV low-limit value [

] to SV high-limit value [

LSV

E.g.) In case of changing SV from 19℃ to 10℃

1 2

Press any key among the , , in RUN mode

to enter into SV setting mode. Last digit (100 digit)

on SV display part ashes.

3 4

].

HSV

Press the key to move digit.

(100→ 10¹→ 10²→10³→ 100)

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

Press the , key to raise

or lower the set value. (9 → 0)

Press the (MODE) key to save the set value.

(If there is no additional key operations in 3 sec,

the changed SV is automatically saved.)

Input Type and Range

Input type Decimal point Display method Temperature range (℃) Temperature range (℉)

1

NTC 5kΩ

Thermistor

(NTC)

NTC 10kΩ

※

1

RTD

※

TF3 Series displays only 3 digits. If PV decimal number of shaded temperature range is out of 3 digit, TF3 does

DPt 100Ω

0.1

1

0.1

1

0.1

N%H

N%L

N!H

N!L

DpH

DpL

-40 to 99 -40 to 212

-40 to -20

-19.9 to 99.9

-40 to -20

-19.9 to 99.9

100 to 212

-40 to 99 -40 to 212

-40 to -20

-19.9 to 99.9

-40 to -20

-19.9 to 99.9

100 to 212

-99 to 99 -148 to 212

-99 to -20

-19.9 to 99.9

※

2

-148 to 212

not display the numbers below decimal point. You can check it at the comprehensive device management program

(DAQMaster) by communicating via PC.

※

1: Only for 1CH input model (TF31- ).

※

2: If PV with "-" sign is over 3 digits (e.g.: -99.9), the numbers below decimal point does not display.

You can check it at the comprehensive device management program (DAQMaster) by communicating via PC.

J-177

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

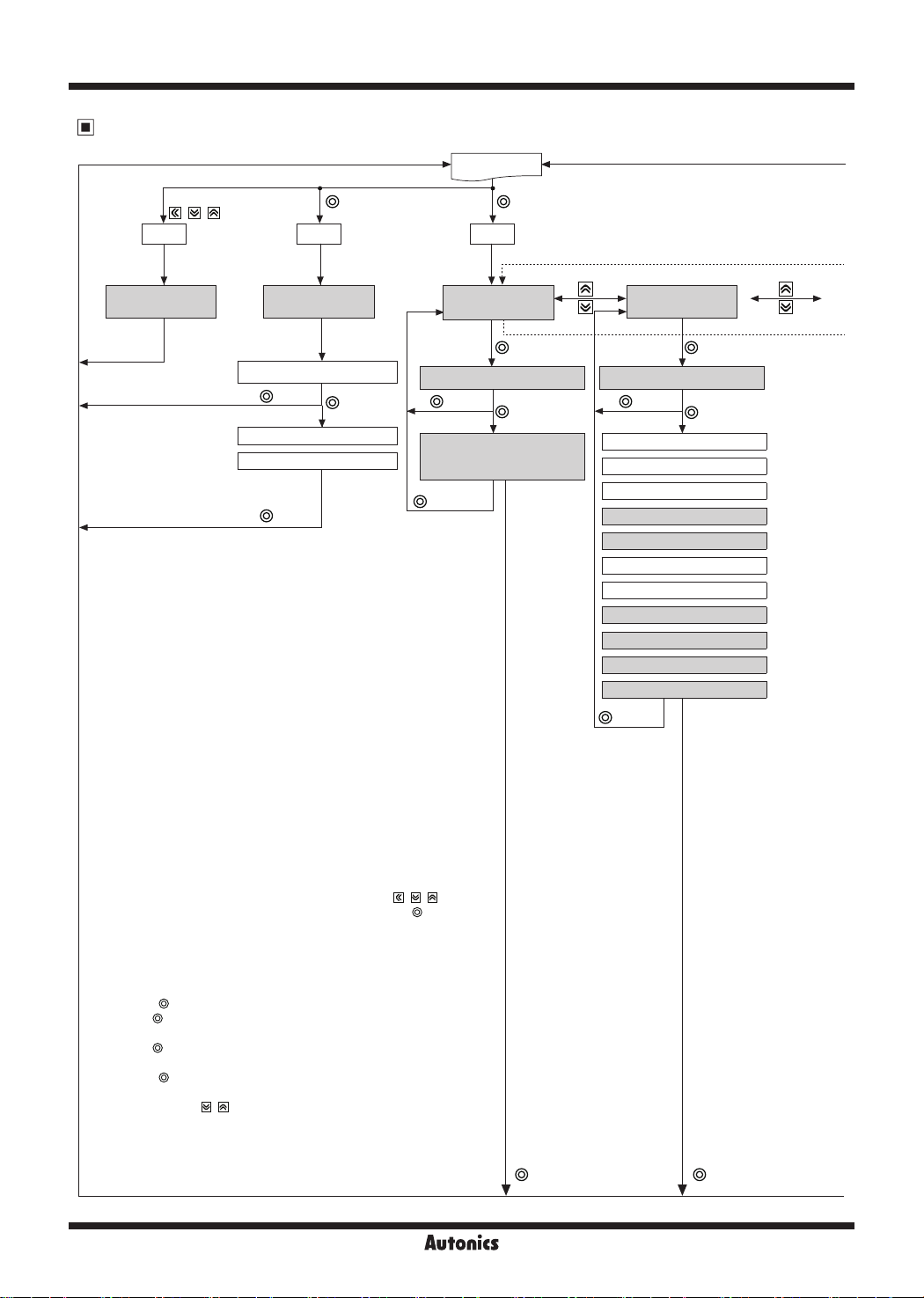

Parameter Group

RUN mode

Press any key among

, , once

※

1

PS PSPS

SV setting

[SV]

Saved automatically

after 3 sec

Monitoring time [

Max. value [

Min. value [

※

Display selection

[

]

DpT

MoT

1.5 sec

]

hPK

]

lPK

1.5 sec

2 sec

[

PAU

※

1

When PW is validWhen PW is validWhen PW is valid

Parameter 1 group

[

BUZ

PA1

ㅑINT

]

]

]

VtR

]

UNT

]

Ib1

]

Ib2

]

Ib3

]

DsT

]

sDA

]

AUX

]

※

2

]

Input type [

Input sensor 2 ON/OFF [S2]

Input sensor 3 selection [S3]

Virtual temperature rate [

Temperature unit [

Input correction 1 [

Input correction 2 [

Input correction 3 [

Delay display period [

Defrost/auxiliary output [

Auxiliary output [

Buzzer [

1

Parameter user group

]

User parameter 0

1.5 sec 1.5 sec

User parameter 1 to 29

※

1. [PS] parameter appears only when password is set.

The default password is [

password code appears. Press any key among the , ,

keys to return to password entering window. Press the

(MODE) key to return to RUN mode.

If you forget password, contact Autonics after checking

password code.

※

2. It appears when setting user parameter group in the

comprehensive device management program (DAQMaster).

※Press the

※

Hold the (MODE) key for 1.5 sec while in setting mode to move to

the parameter group.

※

Hold the (MODE) key for 3 sec while in setting mode to return

RUN mode.

※

Press the (MODE)key at the last parameter of each parameter

group, it moves to that parameter group name. You can move to

other groups with , keys.

※

If there is no additional key operation within 30 sec after entering

into setting mode, it will be automatically returned to RUN mode and

previous setting value will be remained.

※

The shaded parameters are displayed when user level [

parameter 5 group is set as standard level [

(MODE) key after changing the setting to save the SV.

000

]. If password is not valid, the

STD

].

J-178

USR

] of

3 sec 3 sec

Refrigeration Temperature Controller

3sec

SENSORS

CONTROLLERS

MOTION DEVICES

Parameter 2 group

[

]

PA2

Comp. output mode [

OFT

]

Parameter 3 group

[

]

PA3

Defrost method & operation [

Parameter 4 group

]

Alarm operation mode [AL]

DEF

[

PA4

]

1.5sec 1.5sec 1.5sec 1.5sec

Hysteresis [

Oset [

SV high-limit [

SV low-limit [

Night mode [

Night mode SV correction [

Night mode hysteresis [

Night mode oset [

Night mode start hour [

Night mode start min [

Night mode end hour [

Night mode end min [

Temperature monitoring [

Comp. start-up delay time [

Comp. min. operation cycle [

Comp. restart delay time [

Comp. min. operation time [

OFS

HYS

]

HSV

LSV

nMD

]

]

]

]

nSV

nHY

]

nOF

nSH

]

nSM

]

nEH

]

nEM

eMO

SDL

CYC

RDL

ONT

Comp. continuous operation [CC]

Alarm delay time after

continuous operation [

AdC

]

Comp. operation cycle when

sensor break [

CLE

]

Comp. duty rate when

sensor break [

DUT

]

Defrost cycle [

Real-time defrost cycle [

Real-time defrost cycle 1: hour [

Real-time defrost cycle 1: min [

]

Real-time defrost cycle 8: hour [

]

Real-time defrost cycle 8: min [

Defrost time [

]

Pump down delay time [

Defrost end delay time [

Defrost end temperature [

Defrost hysteresis [

]

Defrost when power ON [

]

Defrost delay when power ON/

manual defrost [

]

Defrost group [

]

Parameter copy [

]

Prior defrost selection [

Defrost time unit [

Alarm delay after defrost/

door open [

Temperature display during

defrosting [

AdD

tDE

DIN

...

ㅑDET

dDE

dGR

]

]

]

]

pDC

uDE

dHY

]

]

rDI

DH1

DM1

DH8

DM8

Alarm option [

]

Alarm high-limit deviation [

]

Alarm low-limit deviation [

Alarm hysteresis [

]

Alarm ON delay time [

Alarm OFF delay time [

]

External alarm delay time [

]

AlT

]

aHY

]

aON

aOF

AlH

AlL

eAD

]

]

]

]

]

Alarm output method [aN]

PdD

DrT

EDT

]

pDE

Evaporator-fan operation [

]

Evaporator-fan control

]

temperature [fT]

]

Evaporator-fan hysteresis [

Evaporator-fan mode [

]

Evaporator-fan start-up

delay time [

pDR

]

FAN

fTY

fHY

]

]

]

]

]

dPR

]

Parameter 5 group

[

]

PA5

Current hour [

Current minute [

CUH

CUM

]

]

Digital input [DI]

Loop break alarm

monitoring time [

Comm. address [

Comm. speed [

Comm. parity bit [

Comm. stop bit [

LBA

BPS

STP

ADR

PRT

]

]

]

]

]

Comm. response wait time [

Comm. write [

User level [

SV setting group lock [

Front key lock [

PA 0 group lock [

PA user group lock [

PA 1 group lock [

PA 2 group lock [

PA 3 group lock [

PA 4 group lock [

PA 5 group lock [

Password [

USR

PWD

COW

lDK

]

]

]

lP0

lP1

lP2

lP3

lP4

lP5

lSV

]

]

lPU

]

]

]

]

]

RwT

]

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

]

(O)

Digital

Panel Meters

]

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

3 sec 3 sec 3 sec 3 sec

J-179

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

Parameter 1 Group

3 sec

'PS

PW code appears

at SV display part

for wrong PW

RUN mode

1

※

S

Password input

'PS

When

PW

is wrong

Parameter 1 group

PA1

Input type

Input sensor 2 ON/OFF

2 sec

When PW is correct

+ 1 time

S

S

S2

1. S: Press any key among , , keys.

※

After entering setting mode, hold the (MODE) key anytime for 3 sec to return to RUN mode.

※

After entering setting mode, hold the (MODE) key anytime for 1.5 sec to go to the concerned

※

group name.

If you press the (MODE) key after changing the set value of the parameter the set value will

※

be stored.

Shaded parameters are for standard-level users, the others are for high-level users.

※

(You can set the user level [

This parameter might not be displayed depending on other parameter settings or model

※

specications.

S

000

NsH NsL DpLINT

OFF

ON

] in parameter 5 group).)

USR

Setting range: Refer to '▣ input type and

When changing input type, SV,

※

lPK, Ib1

LSV, nSV, nHY, EDT, dHY, AlH, AlL,

aHY, fT, fHY

reset.

range'.

,

,

Ib2

Ib3

parameter values are

,

HYS, OFS

hPK

,

HSV,

,

Input sensor 3 selection

S3

Virtual temperature rate

VtR

Temperature unit

UNT

Input correction 1

Ib1

Input correction 2

Ib2

Input correction 3

Ib3

Delay display period

DsT

Defrost/

auxiliary output

sDA

S

DI TS

S

S

S

S

S

S

S

0

?C ?F

0

0

0

)5

DEF AUX

Setting range: 0 to 100%

Appears only when input sensor 3

※

selection [

] is set as [TS].

INT

When changing temperature unit,

※

lPK, Ib1

LSV, nSV, nHY, EDT, dHY, AlH, AlL,

aHY, fT, fHY

Setting range: -40 to 40℃/

Setting range: -40 to 40℃/

Appears only for 3CH input model.

※

Setting range: 0.5 to 10.0 sec

Appears only for compressor+defrost or auxiliary

※

(alarm/evaporator-fan) output model.

Appears only for 3CH input model.

※

,

,

Ib2

,

Ib3

HYS, OFS, HSV,

parameter values are reset.

℉

℉

hPK

,

J-180

Auxiliary output

AUX

Buzzer

BUZ

Appears only for compressor+defrost or

S

OFF

S

ON

FAN ALM

Only for 3CH input, compressor+defrost+auxiliary

OFF

※

(alarm/evaporator-fan) output model supports buzzer.

※

auxiliary (alarm/evaporator-fan)

output model, compressor+defrost+auxiliary

(alarm/evaporator-fan).

Parameter 2 Group

3 sec

'PS

PW code appears

at SV display part

for wrong PW

RUN mode

1

※

S

Password input

When

PW

is wrong

Parameter 2 group

2 sec

'PS

When PW is correct

+ 2 times

PA2

Comp. output

mode

S

Refrigeration Temperature Controller

1. S: Press any key among , , keys.

※

After entering setting mode, hold the (MODE) key anytime for 3 sec to return to RUN mode.

※

After entering setting mode, hold the (MODE) key anytime for 1.5 sec to go to the concerned

※

group name.

If you press the (MODE) key after changing the set value of the parameter the set value will

※

be stored.

Shaded parameters are for standard-level users, the others are for high-level users.

※

(You can set the user level [

This parameter might not be displayed depending on other parameter settings or model

※

specications.

S

000

C HOFT

] in parameter 5 group).)

USR

When changing compressor output mode,

※

CLE, DUT

parameter values are reset.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

Hysteresis

HYS

Oset

OFS

SV high-limit

HSV

SV low-limit

LSV

Night mode

nMD

Night mode

SV correction

nSV

Night mode

hysteresis

nHY

Night mode

oset

nOF

(K)

]in

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

S

S

S

99

S

-40

S

S

S

S

Setting range: 1 to 5℃ (0.5 to 5.0℃), 2 to 10℉ (2.0 to 10.0℉)

1

Setting range: 0 to 5℃ (0.0 to 5.0℃), 0 to 10℉ (0.0 to 10.0℉)

0

Setting range: (

When changing SV high-limit value and SV >

※

+1digit) to high-limit value of input type

LSV

Setting range: low-limit value of input type to (

When changing SV low-limit value and SV <

※

TIN DIOFF

Setting range: -20 to 20℃ (-20 to 20.0℃)/

1

Setting range: 1 to 5℃ (0.5 to 5.0℃),

1

Setting range: 0 to 5℃ (0.0 to 5.0℃),

0

-50 to 50℉ (-50 to 50.0℉)

2 to 10℉ (2.0 to 10.0℉)

0 to 10℉ (0.0 to 10.0℉)

HSV, SV

HSV

LSV, SV

is reset as

HSV

-1digit)

is reset as

Appears for RTC function

※

LSV

model or when digital

input [DI] is set as [

parameter 5 group.

Does not appear when night

※

mode [

[

OFF

].

nMD

] is set as

.

.

nMD

Night mode

start hour

nSH

Night mode

start min.

nSM

(W)

Panel PC

Appears for RTC function

S

S

Setting range: 0 to 23 hour

0

Setting range: 0 to 59 min

0

※

model.

Does not appear when night

※

mode [

[

OFF, DI

nMD

].

] is set as

(X)

Field Network

Devices

J-181

TF3 Series

Night mode

end hour

nEH

Night mode

end min.

nEM

Temperature

monitoring

eMO

Comp. start-up

delay time

SDL

Comp. min.

operation cycle

CYC

S

S

S

S

S

8

0

OFF S1 VS

0

0

Setting range: 0 to 23 hour

Setting range: 0 to 59 min

Appears for RTC function

※

model.

Does not appear when night

※

mode [

nMD

[

].

OFF, DI

Setting range:

OFF, S1, S2, S3, VS

] is set as

Comp. restart

delay time

RDL

Comp. min.

operation time

ONT

Comp. continuous

operation

CC

Alarm delay time after

continuous operation

AdC

Comp. operation cycle

when sensor break

CLE

Comp. duty rate when

sensor break

DUT

Setting range: 0 to 60 min

S

S

S

S

S

S

50

0

0

0

Setting range: 0 (OFF) to 24 hour

2

0

Setting range: 0 to 100 min

Setting range: 0 to 100%

J-182

Parameter 3 Group

3 sec

'PS

PW code appears

at SV display part

for wrong PW

RUN mode

1

※

S

Password input

When

PW

is wrong

Parameter 3 group

Defrost method

& operation

Defrost cycle

Real-time

defrost cycle

Real-time defrost

cycle : hour

Real-time defrost

cycle : min

Defrost time

2 sec

'PS

When PW is correct

+ 3 times

PA3

DEF

DIN

rDI

DH

DM

DET

Setting range: In case of compressor output model, below parameters of parameter 3

S

S

S

S

S

S

Refrigeration Temperature Controller

1. S: Press any key among , , keys.

※

After entering setting mode, hold the (MODE) key anytime for 3 sec to return to RUN mode.

※

After entering setting mode, hold the (MODE) key anytime for 1.5 sec to go to the concerned

※

group name.

If you press the (MODE) key after changing the set value of the parameter the set value will

※

be stored.

Shaded parameters are for standard-level users, the others are for high-level users.

※

(You can set the user level [

This parameter might not be displayed depending on other parameter settings or model

※

specications.

S

000

group do not appear.

hTM gTM hTT gTT

4

Setting range: 0 to 24 hour/0 to 100 min

OFF ON

OFF

OFF

30

Setting range: 0 to 23 hour, OFF

Setting range: 0 to 59 min, OFF

Setting range: 1 to 100 min/1 to 100 sec

] in parameter 5 group).)

USR

You can set up to 8 real-time defrost cycles:

hour, min.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

Pump down

delay time

PdD

Defrost end

delay time

DrT

Defrost end

temperature

EDT

Defrost

hysteresis

dHY

(S)

Sensor

Controllers

S

)00

Setting range: 0 min 00 sec to 9 min 59 sec

S

!00

S

S

Setting range: -40 to 99℃, -40 to 212

4

Setting range: 1 to 5℃ (0.5 to 5.0℃), 2 to 10℉ (2.0 to 10.0℉)

1

℉

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-183

TF3 Series

Defrost when

power ON

Defrost delay when

power ON/manual defrost

dDE

S

OFF ONpDE

S

0

Setting range: 0 to 60 min

Defrost group

dGR

Parameter copy

pDC

Prior defrost selection

dPR

Defrost time unit

uDE

Alarm delay after

defrost/door open

AdD

Temperature display

during defrosting

tDE

Parameter 4 Group

3 sec

'PS

PW code appears

at SV display part

for wrong PW

RUN mode

※

1

S

Password input

When

PW

is wrong

Parameter 4 group

'PS

PA4

S

S

S

S

S

S

2 sec

When PW is correct

+ 4 times

Setting range: In case of compressor output model, below parameters of

OFF

MAS SLV

OFF ON

OFF ON

HGH LOW

1

Setting range: 0 to 24 hour

OFF ON

1. S: Press any key among , , keys.

※

After entering setting mode, hold the (MODE) key anytime for 3 sec to return to RUN mode.

※

After entering setting mode, hold the (MODE) key anytime for 1.5 sec to go to the concerned

※

group name.

If you press the (MODE) key after changing the set value of the parameter the set value will

※

be stored.

Shaded parameters are for standard-level users, the others are for high-level users.

※

(You can set the user level [

This parameter might not be displayed depending on other parameter settings or model

※

specications.

S

000

parameter 4 group do not appear.

] in parameter 5 group).)

USR

J-184

Alarm operation mode

AL

Alarm option

AlT

S

AlD OFF

S

AlA AlB AlF

Setting range:

※

When changing alarm option,

AlL, AhY

AlA, AlB, AlC, AlD

AlE, AlF

parameter values are reset.

AlH

,

,

Refrigeration Temperature Controller

Alarm high-limit deviation

AlH

Alarm low-limit deviation

AlL

Alarm hysteresis

aHY

Alarm ON delay time

aON

Alarm OFF delay time

aOF

External alarm delay time

eAD

Alarm output method

aN

Evaporator-fan operation

fTY

Evaporator-fan control

temperature

fT

Evaporator-fan

hysteresis

fHY

S

139

S

139

S

S

S

S

S

S

S

S

1

0

0

0

NO NC

FAN DEF

4

1

Setting range: -F.S. to F.S

Setting range: 1 to 5℃ (0.5 to 5.0℃), 2 to 10℉ (2.0 to 10.0℉)

Setting range: 0 to 60 min

Setting range: -40 to 99℃, -40 to 212

℉

Setting range: 1 to 5℃ (0.5 to 5.0℃), 2 to 10℉ (2.0 to 10.0℉)

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

Evaporator-fan mode

FAN

Evaporator-fan start-up

delay time

pDR

S

EF1 EF2 EF5

S

!00

Setting range: 0 min 00 sec to 9 min 59 sec

Setting range:

EF1, EF2, EF3, EF4, EF5

J-185

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

Parameter 5 Group

3 sec

'PS

PW code appears

at SV display part

for wrong PW

RUN mode

※

1

S

Password input

When

PW

is wrong

Parameter 5 group

'PS

PA5

2 sec

S

When PW is correct

+ 5 times

1. S: Press any key among , , keys.

※

After entering setting mode, hold the (MODE) key anytime for 3 sec to return to RUN mode.

※

After entering setting mode, hold the (MODE) key anytime for 1.5 sec to go to the concerned

※

group name.

If you press the (MODE) key after changing the set value of the parameter the set value will

※

be stored.

Shaded parameters are for standard-level users, the others are for high-level users.

※

(You can set the user level [

This parameter might not be displayed depending on other parameter settings or model

※

specications.

] in parameter 5 group).)

USR

000

Current hour

CUH

Current minute

CUM

Digital input

DI

Loop break alarm

monitoring time

LBA

Comm. address

ADR

Comm. speed

BPS

Comm. parity bit

PRT

S

Random

hour

S

Random

min

S

ㅑOFF sTP mDF

S

S

S

S

0

01

ㅑ96 192 48

Setting range: 24, 48, 96,

Multiply SV ×100 to read.

NON EVN ODD

Setting range: 0 to 23 hour

Setting range: 0 to 59 min

Setting range: 0 to 100 min

Setting range: 01 to 99

192,384

※

Appears only for RTC function

model.

Setting range:

OFF, sTP, dSW, nMD

eAL, eDF, mDF

,

J-186

Comm. stop bit

STP

Comm. response

wait time

RwT

Comm. write

COW

S

S

S

2 1

20

EnA DsA

Setting range: 0 to 99ms

※

Appears only for RS485

communication model.

Refrigeration Temperature Controller

User level

USR

SV setting

group lock

lSV

Front key lock

lDK

Parameter

group lock

lP

Password

PWD

Parameter Reset

S

STD HGH

S

OFF ON

S

OFF ON

S

OFF ON

S

000

Hold + + keys for 5 sec to reset all parameters in memory to default value.

Set [

] parameter to [

INI

] to reset all parameters.

YES

In case password function is ON, it is required to enter valid password to reset parameters.

Password is also reset.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-187

TF3 Series

Factory Default

SV setting [SV]

Parameter Factory default

SV 0

Parameter 1 group [

Parameter Factory default Parameter Factory default Parameter Factory default

INT NsH UNT ?C AUX OFF

S2 OFF Ib 0 BUZ ON

S3 DI DsT )5

VtR 0 sDA DEF

Parameter 2 group [

Parameter Factory default Parameter Factory default Parameter Factory default Parameter Factory default

OFT C nSV 1 nEM 0 CC 0

HYS 1 nHY 1 eMO OFF AdC 2

OFS 0 nOF 0 SDL 0 CLE 0

HSV 99 nSH 0 CYC 0 DUT 50

LSV -40 nTM 0 RDL 0

nMD OFF nEH 8 ONT 0

Parameter 3 group [

Parameter Factory default Parameter Factory default Parameter Factory default Parameter Factory default

DEF hTM DET 30 pDE OFF uDE ㅑHGH

DIN 4 PdD )00 dDE 0 AdD 1

rDI OFF DrT !00 dGR OFF tDE OFF

DH OFF EDT 4 pDC OFF

DM OFF dHY 1 dPR OFF

PAR1

PAR2

PAR3

]

]

]

Parameter 0 group

Parameter Factory default

DpT S1

MoT

-

Parameter 4 group [

Parameter Factory default Parameter Factory default Parameter Factory default Parameter Factory default

AL AlD aHY 1 aN NO FAN EF1

AlT AlA aON 0 fTY FAN pDR !00

AlH 139 aOF 0 fT 4

AlL 139 eAD 0 fHY 1

Parameter 5 group [

Parameter Factory default Parameter Factory default Parameter Factory default Parameter Factory default

CUH

CUM

LBA 0 STP 2 lSV OFF

J-188

Random hour

Random min

DI OFF PRT NON USR STD PWD 000

PAR4

PAR5

]

]

ADR 01 RwT 20 lDK OFF

BPS 96 COW EnA lP OFF

Refrigeration Temperature Controller

Alarm (Except 1CH, Compressor Output Model: TF31-1 )

Set both alarm operation and alarm option by combining. Alarm function is available for compressor+defrost or auxiliary

(alarm/evaporator-fan) output model (TF3 -2 - ). Also defrost/auxiliary output [

set as auxiliary [

], and auxiliary output [

AUX

] should be set as alarm [

AUX

ALM

].

In case of compressor+defrost+auxiliary (alarm/evaporator-fan) output model (TF3 -3 - ), auxiliary output [

parameter 1 group should be set as alarm [

ALM

].

Alarm operation [AL]

Mode Name Alarm operation Description

OFF

- -

Deviation

AlD

※

high, low-limit

alarm

H: alarm output hysteresis [

H H

ON ON

PV

-10℃

High-limit deviation [

Low-limit deviation [

]

aHY

OFF

SV

0℃

]: Set as 20,

AlH

]: Set as 10

AlL

20℃

PV

No alarm output.

If deviation between present value (PV) and setting

value (SV) is higher than high-limit or low-limit

deviation SV, alarm output turns ON.

] of parameter 1 group should be

sDA

AUX

] of

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

Alarm option [

AlT

]

Mode Name Description

Standard alarm If it is an alarm condition, alarm output is ON. If it is a clear alarm condition, alarm output is OFF.

AlA

AlB

Alarm latch

※1

If it is an alarm condition, alarm output is ON and maintains ON status.

First alarm condition is ignored and from second alarm condition, standard alarm operates.

Standby sequence 1

AlC

Alarm latch and

AlD

standby sequence 1

Standby sequence 2

AlE

When power is supplied and it is an alarm condition, this rst alarm condition is ignored and from the

second alarm condition, standard alarm operates.

If it is an alarm condition, it operates both alarm latch and standby sequence. When power is supplied

and it is an alarm condition, this rst alarm condition is ignored and from the second alarm condition,

alarm latch operates.

First alarm condition is ignored and from second alarm condition, standard alarm operates.

When re-applied standby sequence

※

2

and if it is alarm condition, alarm output does not turn ON.

After clearing alarm condition, standard alarm operates.

Basic operation is same as alarm latch and standby sequence 1. It operates not only by power ON/OFF,

Alarm latch and

AlF

standby sequence 2

but also alarm set value, or alarm option changing. When re-applied standby sequence

condition, alarm output does not turn ON.

After clearing alarm condition, alarm latch operates.

※

1: To clear alarm, turn OFF the power (also digital input [DI] is set as RUN/STOP [

] and input is ON for

STP

pausing compressor output) or press the front key once. (press twice when buzzer is set)

※

2: Condition of re-applied standby sequence for standby sequence: Power ON, changing temperature,

alarm settings, switching STOP mode to RUN mode (also digital input [DI] is set as RUN/STOP [

OFF from ON for operation mode by releasing pause compressor output)

※

2

and if it is alarm

] and input turns

STP

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

J-189

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TF3 Series

Functions

Compressor protection

This function is for preventing compressor from life cycle shortening or malfunction by overload and frequent ON/OFF

of compressor. As compressor protection settings, when compressor output does not ON, the front compressor (COMP)

output indicator (green) is ashing.

● Compressor start-up delay time [

If power turns ON instantly from break-down or power OFF, it delays start-up during the set time of compressor.

Setting range: 0 to 60 (min)

● Compressor restart delay time [

To prevent frequent compressor ON/OFF, set compressor ON time after compressor turns OFF.

Setting range: 0 to 60 (min)

● Compressor min. operation time [

To prevent frequent compressor ON/OFF, set min. operation time and min. operation cycle.

Setting range of compressor min. operation time: 0 to 60 (min),

Setting range of compressor min. operation cycle: 0 to 60 (min)

Compressor

Temp.

Compressor

start-up

delay time

min. operation cycle

Compressor

delay time

]

SDL

]

RDL

], compressor min. operation cycle [

ONT

Compressor

min. operation cycle

restart

Compressor

※

restart

delay time

min. operation cycle

2

]

CYC

Compressor

Compressor

restart delay

time

Compressor

min. operation

time

SV

※

ON

Comp.

OFF

output

※

1: When starting compressor, if present value (PV) is out of hysteresis range, compressor output does

1

※

2

※

3

※

4

Hysteresis

Time

not turn ON and the compressor (COMP) output indicator is ashing during compressor start-up delay time.

※

2: When compressor delay is completed and it is within compressor min. operation cycle, compressor output

does not turn ON and the compressor (COMP) output indicator is ashing. (The latest one has priority

between compressor restart delay time and compressor min. operation cycle.)

※

3: When present value (PV) is out of hysteresis, compressor output does not turn ON and the

compressor (COMP) output indicator is ashing during compressor restart delay time.

※

4: If present value (PV) is below the SV, compressor output maintains ON status during compressor

min. operation time. After compressor min. operation time, it turns OFF.

※

If compressor output does not turn ON due to compressor output condition or parameter settings for compressor

protection, the compressor (COMP) output indicator is ashing.

For more information about parameters for compressor prevention, refer to user manual.

★

Compressor control when sensor break

If normal temperature control is impossible due to sensor break, it controls compressor output by the set operation cycle

and duty ratio to protect control object. Until error is cleared, operation cycle and duty ratio are applied repeatedly. When

error is cleared, the compressor operates after completing the currently applied operation cycle and compressor restart

delay time.

● Compressor operation cycle when sensor break [

Set compressor operation cycle when sensor break.

Set as [0] and compressor output turns OFF when sensor break.

Setting range: 0 to 100 (min)

● Compressor duty ratio when sensor break [

DUT

Set compressor ON duty ratio when sensor break.

Setting range: 0 to 100 (%)

E.g.) When compressor operation cycle when sensor break [

is set as 60 min and compressor duty ratio when sensor break

[

] is set as 50%, compressor output has 60 min cycle and

DUT

turns ON for 30 min and turns OFF for 30 min.

]

CLE

]

Operation cycle

(60 min)

]

CLE

Compressor

output

ON rate (50%)

ON

OFF

J-190

Refrigeration Temperature Controller

Defrost control (except 1CH, compressor output model: TF31-1 )

When operating a compressor for a long time, an evaporator and a freezer are freezing and thermal eciency of

compressor is decreased. For increasing thermal eciency, defrost operation helps to remove frost or ice around of

evaporator.

Set defrost cycle, time, and end temperature, etc to operate defrost (heater/hot-gas defrost).

The front defrost (DEF) output indicator (green) turns ON during defrost output and it ashes during defrost delay operation.

In case of compressor+defrost or auxiliary (alarm/evaporator-fan) output model (TF3 -2 - ), defrost operation is

available when defrost/auxiliary output [

Defrost method and operation [

Parameter Defrost method Defrost operation

hTM

gTM

hTT

gTT

Heater defrost

Hot-gas defrost

heater defrost

Hot-gas defrost

DEF

Operates during the set defrost cycle/time

Operates when PV is lower than defrost end temperature during the set defrost cycle/time

(only for 3CH input model (TF33- - ))

] of parameter 1 group is set as defrost [

sDA

]

DEF

].

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

● Defrost cycle [

], defrost time [

DIN

DET

]

Set defrost cycle and time to operate defrost at every set cycle and during the set time.

Defrost cycle setting range: 0 to 24 (hour)/0 to 100 (min)

Defrost time setting range: 1 to 100 (min/sec)

※

Compressor operation during defrost is varied by defrost method. In case of heater defrost, compressor output turns

OFF, and in case of hot-gas defrost, compressor output turns ON. Evaporator-fan operation is varied by evaporator-fan

operation mode setting.

※

In case of RTC function model (TF33-3 -R/A), defrost operates at every specic time. Set real-time defrost cycle [

rDI

of parameter 3 group as [ON] and 8 real-time defrost times are available to set.

● Defrost end temperature [

], Defrost hysteresis [

EDT

] (only for 3CH input model: TF33- - )

dHY

Set defrost end temperature and defrost hysteresis from input sensor 2 (defrost temperature). When the measured

temperature of defrost sensor is same as the set defrost end temperature, defrost operation is stopped. It is available when

input sensor 2 ON/OFF [S2] is set as [ON] and defrost method and operation [

DEF

] is set as [

hTT

] or [

gTT

].

Defrost end temperature setting range: -40 to 99 (℃) / -40 to 212 (℉)

Defrost hysteresis setting range: 1 to 5 (1.0 to 5.0) (℃) / 2 to 10 (℉)

● Manual defrost

Execute defrost manually regardless of the set defrost cycle which consists of defrost method and operation setting. Hold

the front key over 3 sec or, turn ON the digital input when digital input [DI] of parameter 5 group is set as [

mDF

] to

operate defrost during the set defrost time.

The front defrost (DEF) output indicator turns ON for 2 sec and turns OFF for 1 sec during manual defrost. Hold the front

key over 3 sec or turn OFF the digital input during manual defrost, and the set defrost cycle re-starts.

Defrost synchronization

●

(only for synchronize defrost function model: TF33- A-S, RS485 communication model: TF33- A-T/A)

When connecting over 2 units of TF3, defrost and compressor operation is able to synchronize via synchronize terminal/

RS485 communication.

It is available for synchronize defrost function model (TF33- A-S), or RS485 communication model (TF33- A-T/A).

[Setting Order]

1. Connect each other synchronize terminals or RS485 communication terminals of the units which are synchronized for

defrost.

2. Set defrost cycle [

3. Set defrost group [

] same as among the units. (if error occurs, defrost cycle is the setting of each unit)

DIN

] as 1 master unit [

dGR

] and slave unit (s) (up to 5 units) [

MAS

SLA

].

4. According to defrost operation of Master, the defrost operation of slave (s) executes. (when changing the defrost

parameters of master, defrost operations of slave (s) are also changed forcibly as same as the defrost operation of

master via connected terminals. The defrost parameters of slave (s) are not changed.)

※

Defrost operation by real-time defrost cycle is not able to synchronize.

※

Defrost operation of master is prior to the compressor operation of slave.

For more information about parameters for defrost operations, refer to user manual.

★

(J)

Temperature

Controllers

(K)

SSRs

]

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-191

TF3 Series

Evaporator-fan control (except 1CH, compressor output model: TF31-1 )

To improve the eciency of cooling, install and control evaporator-fan at evaporator.

It is available for compressor+defrost or auxiliary (alarm/evaporator-fan) output model (TF3 -2 - ). Also defrost/

auxiliary output [

evaporator-fan [

It is available for compressor+defrost+auxiliary (alarm/evaporator-fan) output model (TF3 -3 - ). Also, auxiliary output

[

] of parameter 1 group should be set as evaporator-fan [

AUX

●Evaporator-fan operation [

Evaporator-fan operates by two control methods; [

sensor or [

FAN

●Evaporator-fan control temperature [fT] and hysteresis [

When evaporator-fan operation [

defrost sensor), and the temperature of defrost sensor is same as evaporator-fan control temperature [fT], evaporator-fan

output turns OFF. Set evaporator-fan control temperature [fT] and evaporator-fan control hysteresis [

Evaporator-fan control temperature setting range: -40 to 99 (℃), -40 to 212 (℉)

Evaporator-fan control hysteresis setting range: 1 to 5 (0.5 to 5.0) (℃), 2 to 10 (℉)

●Evaporator-fan operation mode [

When evaporator-fan operation [

for evaporator-fan operation mode for compressor/defrost operation.

Parameter Operation method

EF1

EF2

EF3

EF4

EF5

If evaporator temperature is increased by defrost operation, warm air may ow into cooling system by evaporator-fan

operation. Set evaporator-fan start-up delay time [

Evaporator-fan start-up delay time setting range: 0.00 to 9.59 (0 min 00 sec to 9 min 59 sec)

Start-up

delay

Compressor

] of parameter 1 group should be set as auxiliary [

sDA

].

FAN

]

fTY

] controls evaporator-fan by measured temperature from defrost

DEF

FAN

].

], and auxiliary output [

AUX

] should be set

AUX

] controls evaporator-fan by compressor/defrost operation.

]

] is set as [

fTY

] and evaporator-fan start-up delay time [

FAN

] is set as [

fTY

When compressor operates, evaporator-fan also operates.

When compressor operation is nished, evaporator-fan also operation turns OFF.

(except compressor operation for hot gas defrost)

When compressor operates, evaporator-fan operates after the set evaporator-fan start-up delay time.

When compressor operation is nished, evaporator-fan operation turns OFF. (regardless of defroster operation)

When power turns ON, evaporator-fan operates. When defroster operates, evaporator-fan stops.

(regardless of compressor operation)

Evaporator-fan operates only when operating compressor or defrost. Evaporator-fan stops when compressor and

defroster stops. (for above zero temperature control)

Evaporator-fan operates from power ON to power OFF. (regardless of defroster operation of freezer. When door is open

(digital input [DI] is set as RUN/STOP [

] controls (evaporator-fan is controlled by measured temperature from

DEF

] for control by compressor/defrost operation, it is available to set [

FAN

] or door switch [

STP

pDR

Compressor

operation

Defrost

cycle

Defroster operation period Defroster operation period

Defroster

operation

Defrost

time

end

delay

Defrost

Compressor

fHY

].

fHY

]

pDR

]), evaporator-fan stops.

dSW

] to prevent warm air inow, and it may increase cooling eciency.

operation

Defrost

cycle

Defroster

operation

Defrost

time

Defrost

end

delay

Compressor

operation

Defrost cycle

Defrost time

FAN

]

Defrost

EF1

Evaporator-fan

delay

EF2

EF3

EF4

EF5

Power ON

※

: Output does not turn ON but the dedicated indicator ashes at the delay period (compressor, defrost, evaporator-fan).

For more information about parameters for evaporator-fan control, refer to user manual.

★

Evaporator-fan

delay

Evaporator-fan

delay

J-192

Refrigeration Temperature Controller

Digital input [DI]

※

Digital input is available only for 3CH input model (TF33- - ). Also input sensor 3 selection [S3] should be set as

digital input [DI].

Parameter Function

OFF

RUN/STOP

Door switch

Night mode ON/OFF

※

External alarm

Defrost ON/OFF

Manual defrost

※

1: Except 1CH, compressor output model (TF31-1 ).

1

※

1

※

1

Virtual temperature rate [

In case of 3CH input model (TF33- - ), input sensor 3 selection [S3] of parameter 1 group is set as outlet temperature

[TS]. You can set virtual temperature rate.

If the temperature of inlet and outlet is signicantly dierent at freezer, virtual temperature helps to control temperature

eciently.

Virtual temperature is designated by the rate of input sensor 1 (inlet temperature) and input sensor 3 (outlet temperature).

There is virtual temperature calculation formula.

Virtual temperature (PV)=

If virtual temperature rate [

If virtual temperature rate [

E.g.) If inlet temperature of input sensor 1 is 0℃, and outlet temperature of input sensor 3 is 10℃,

set virtual temperature rate [

[{100-50}×0]+ [50×10]

5=

100

Setting range of virtual temperature rate: 0 to 100 (%)

Display selection [

You can select input sensor to display at present value (PV) display component in RUN mode.

Parameter Description

S1

S2

S3

VS

Displays PV of input sensor 1 (inlet temperature).

Displays PV of input sensor 2 (defrost temperature).

Displays PV of input sensor 3 (outlet temperature).

Displays virtual temperature.

Parameter mask

This function is able to hide unnecessary parameters to user environment or less frequently used parameters in parameter

group. You can set this in the comprehensive device management program (DAQmaster).

Masked parameters are only not displayed. The setting value of masked parameters are applied.

For more information, refer to DAQMaster user manual.

Visit our web site (www.autonics.com) to download DAQmaster program and the user manual.

Before applying mask

After applying mask

The above is masking input sensor 3 selection [S3], temperature unit [

(TF33- - ).

No digital input

OFF

Pauses compressor output. All output indicators turn OFF.

STP

When digital input is OFF, it controls normally after compressor restart delay time.

By connecting freezer door switch and digital input contact, it controls compressor/defrost/evaporator-fan

according the door status.

- Digital input ON (door open): Compressor, defrost, evaporator-fan output turns OFF

- Digital input OFF (door close): After 1 min, it returns the previous status of door open.

dSW

(not applied compressor protection operations)

Alarm occurs after the time of alarm delay after defrost/door open [

operating compressor continuously, compressor start-up time is extended as long as the door open time.

When digital input turns ON, night mode is active.

nMD

When digital input turns ON, alarm output turns ON forcibly. (except alarm is ON) When external alarm

eAL

delay time [

When digital input turns ON and it is defrost operation condition, defrost output turns ON.

eDF

Even though it is defrost operation condition, if digital input turns OFF, defrost output turns OFF also.

When digital input turns ON, it executes manual defrost.

mDF

] of parameter 4 group is set, alarm turns ON after the set time.

eAD

] (only for 3CH input model: TF33- - )

VtR

] of parameter 3 group. When

AdD

[{100-virtual temperature rate} × input sensor 1 temperature]

+ [virtual temperature rate × input sensor 2 temperature]

100

] is set as [0], virtual temperature (PV)= input sensor 1.

VtR

] is set as [

VtR

VtR

] (only for 3CH input model: TF33- - )

DpT

PA1 INT S2 S3 VtR UNT

PA1 INT S2 VtR

], virtual temperature (PV)= input sensor 3

100

] as [50] and virtual temperature is 5℃ to control temperature.

] of parameter 1 group for 3CH input model

UNT

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-193

TF3 Series

Parameter user group [

PAU

]

This function is able to set the frequently used parameters to the user parameter group. You can quickly and easily set

parameter settings. User parameter group can have up to 30 parameters in the comprehensive device management

program (DAQMaster).

For more information, refer to the DAQMaster user manual.

Visit our web site (www.autonics.com) to download the DAQMaster program and the user manual.

RUN mode

PAU PA1 PA5

DsT HYS nHY DEF DET aHY

The above is setting user parameter group in the DAQMaster with delay display period [

hysteresis [

parameter 3 group, alarm output hysteresis [

], night mode hysteresis [

HYS

] of parameter 2 group, defrost method [

nHY

] of parameter 4 group.

aHY

] of parameter 1 group,

DsT

], defrost time [

DEF

DET

] of

Communication output

It is for parameter setting and monitoring via external devices (PC, PLC, etc.).

Interface

●

Comm. protocol Modbus RTU Comm. speed 2400, 4800, 9600, 19200, 38400 bps

Connection type RS485 Comm. response wait time 5 to 99 ms

Application standard Compliance with EIA RS485 Start bit 1-bit (xed)

Max. connection 31 units (address: 01 to 99) Data bit 8-bit (xed)

Synchronous method Asynchronous Parity bit None, Odd, Even

Comm. method Two-wire half duplex Stop bit 1-bit, 2-bit

Comm. distance Max. 800m

※

It is not allowed to set overlapping communication address at the same communication line.

Use twisted pair wire for RS485 communication.

Application of system organization

●

Computer

RS232C/

USB/Wi-Fi

Comm.

converter

ON

RS485

B (-)

OFF

Terminating resistance

A (+) B (-) A (+) B (-) A (+) B (-)

RS485

DEVICE

#1

※

Only for RS485 communication output model.

(100 to 120Ω)

RS485

DEVICE

#2

RS485

DEVICE

#30

B (-)

A (+)

RS485

DEVICE

#31

A (+)

※

It is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485·USB wireless communication

converter, sold separately), SCM-US48I (USB to RS485 converter, sold separately), SCM-38I (RS232C to RS485

converter, sold separately).

Please use twisted pair wire, which is suitable for RS485 communication, for SCM-WF48, SCM-US48I and SCM-38I.

Error Display

Flashing in turn Description Troubleshooting

※1※

2

↔

ER

※

1

↔

ER

※

1

↔

ER

ERR↔LBA

※

1: indicates input sensor number of error display priority which occurs error.

Error display priority:

※

2:

ERV

When input sensor is break or sensor is disconnected. Check input sensor status.

OPN

If the measured temperature of the dedicated sensor is

lower than low-limit temperature among temperature setting

LLL

range.

If the measured temperature of the dedicated sensor is

higher than high-limit temperature among temperature

HHH

setting range.

Even though input sensor is normal, freezer temperature

does not change over 1.0℃ (1.8℉) during loop break alarm

monitoring time [

ER1

ERV

].

LBA

(input sensor 1) →

ER2

(virtual temperature) →

(input sensor 2)→

ERR

It clears when input is within the display range.

Check the compressor and hold

the + key at the same time for 3 sec. It clears when

input is within the adequate range.

ER3

(virtual temperature) is not applicable.

(input sensor 3)→

J-194

Refrigeration Temperature Controller

Proper Usage

Cautions during use

● Follow instructions in 'Cautions during use'. Otherwise, It may cause unexpected accidents.

● Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

● Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line filter or varistor at power line and shielded wire at input

signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

● Do not apply excessive power when connecting or disconnecting the connectors of the product.

● Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

● Do not use the unit for other purpose (e.g. voltmeter, ammeter), but temperature controller.

● 24VAC, 12-24VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

● Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

● Install a surge absorber at each end of inductive load coil when controlling high-capacity power relay or inductive load (e.g.

magnet).

● Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

● Do not wire to terminals which are not used.

● This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specifications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-195

Loading...

Loading...