Autonics KT-502H SERIES Instruction Manual

DRW190788AA

Autonics

Temperature Transmitters

with HART protocol

KT-502H SERIES

I N S T R U C T I O N M A N U A L

Please read the following safety considerations before use.

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid

※

hazards.

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1.Fail-safe device must be installed when using the unit with machinery that may cause seri-

ous injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, economic loss or re.

2.Do not use the unit in the place where ammable/explosive gas, high humidity, direct sun-

light, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in explosion or re.

3.Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or malfunction.

4.For installing the unit, ground it exclusively and use over AWG 11(4mm²) ground cable.

Failure to follow this instruction may result in electric shock.

5.Do not disassemble or modify the unit.

Failure to follow this instruction may result in re or electric shock.

6.Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

Caution

A

1.Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

2.Use a dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in re or electric shock.

3.Keep the product away from metal chip, dust, and wire residue which ow into the unit.

Failure to follow this instruction may result in re or product damage.

Ordering Information

~

Item Description

①Mounting bracket

②Input range

Input Type and Range

~

Input type Input range ( ) Input range ( )

RTD

Resistance

transmitter

Thermocouple

Analog Voltage

※

The above specications are subject to change and some models may be discontinued

without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions

(catalog, homepage).

Thank you for choosing our Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

KT

c=J-c=J

0 Without bracket 1 With bracket

1: To order this unit, write the temperature sensor type

and the input range.

502H

·c

DPt100Ω

DPt500Ω

DPt1000Ω

Cu50Ω

Cu100Ω

Ni100Ω

Ni500Ω

Ni1000Ω

Resistance (Ω)

B (PtRh30-PtRh6) 0 to 1820 32 to 3308

E (NiCr-CuNi)

J (Fe-CuNi)

K (NiCr-Ni)

N (NiCrSi-NiSi)

R (PtRh13-Pt)

S (PtRh10-Pt)

T (Cu-CuNi)

200 to 850

200 to 250

200 to 250

50 to 150

50 to 150

60 to 180

60 to 180

60 to 150

0 to 400Ω

0 to 2000Ω

270 to 1000

210 to 1200

270 to 1372

270 to 1300

50 to 1768

50 to 1768

270 to 400

10-

75mV

100-100mV

100-500mV

100-2000mV

(-270 to 1372, K)

0

□

① ②

328 to 1562

328 to 482

328 to 482

58 to 302

58 to 302

76 to 356

76 to 356

76 to 302

-

454 to 1832

346 to 2192

454 to 2501.6

454 to 2372

58 to 3214.4

58 to 3214.4

454 to 752

-

"F

Specications

Series KT-502H

Power supply 10.5-45VDC (with backlight LCD)

Display method

Display range -19999 to 99999

Set ing method HART-protocol (no setting key)

Response time 1 sec

RTD

Thermocouple K, J, T, E, N, S, B, R

Resistance trans. (Ω) 0 - 400Ω, 0 - 2000Ω

Input type

Voltage trans. (mV)

Output DC4-20mA (2-wire)

Accuracy ±0.3%

Alarm Below 3.8mA, Over 20.5mA / Sensor break 3.6mA

Load max. (V power supply - 7.5V)/0.22A

Galvanic insulation 2kVAC (input/output)

Ambient temp. -20 to 70 ℃, storage: 20 to 80 ℃

Environ-

I

ment

Ambient humi. 0 to 85%RH, storage: 0 to 85%RH

I

Explosion class

Protection structure IP67

Material Body: Aluminum (AlDc.8S), Cover O-Ring: Buna N

Weight

※1: The explosion class specication is acquired and managed by KONICS.

※2: The weight includes packaging. The weight in parenthesis is for unit only.

※Environment resistance is rated at no freezing or condensation.

※1

※2

PV display part : 7-segment 5-digit

Parameter display part : 14-segment 8-digit

52-bar meter

DPt100Ω, DPt500Ω, DPt1000Ω

Ni100Ω, Ni500Ω, Ni1000Ω

Cu50Ω, Cu100Ω

-

10 - 75mV

-

100 - 100mV

-

100 - 500mV

-

100 - 2000mV

Ex d IIC T6

Approx. 1.4 kg (approx. 1.2 kg)

(character size: W4×H8mm),

(character size: W2.6×H4.8mm),

Error Display and Troubleshooting

Display Error Troubleshooting

ERR05

ERR06

ERR07

ERR08

~

Connect a HART communicator and set temperature range as below by a HART

communicator.

~

I

I

Temperature sensor A, B or all sensors

are disconnected.

Temperature sensor B is disconnected.

When PV is lower than the low-limit

value of set temperature range.

When PV is higher than the high-limit

value of set temperature range.

Temperature Range Setting

Online (Generic)

1. Device Setup

2. PV

3. PV Ao

4. PV LRV

5. URV SAVE

1. PV LRV

2. URV

HELP HOME

PV LRV

0.000 deg C

0.000

HELP DEL ESC ENTER

1. PV LRV

2. URV

HELP HOME

PV URV

100.000 deg C

100.000

HELP DEL ESC ENTER

1. PV LRV 0.000 deg C

2. URV 100.000 deg C

HELP SEND HOME

- WARNING -

Pressing ' OK ' will

change device output

put 100P in manual

- WARNING -

Return control 100P

To automatic control

1. PV LRV 0.000 deg C

2. URV 100.000 deg C

HELP HOME

O K

①

②

③

④

⑤

⑥

When the set temperature range is correct,

⑦

⑧

⑨

Check the temperature

sensor.

Check low-limit value of the

set temperature range.

Check high-limit value of the

set temperature range.

Press the

Select the '4. PV LRV' by , keys

and press the

key for 3 sec.

~

key.

[:±]

l!l

III

Select '1. PV LRV' (Low temperature range)

and press the

Set

Low temperature range and press

the (F4) key.

IENTERI

[:±]

key.

Select '2. URV' (High temperature

range) and press the

Set

High temperature range and press

the

(F4) key.

IENTERI

press the

Press the

Press the

I

SEND

IOKI

IOKI

[:±]

(F2) key.

I

(F4) key.

(F4) key.

key.

Check the set temperature range.

Press the

HART communication is OFF.

IHOMEI

(F3) key.

Current Trim Adjustment

Connect a HART communicator and adjust current trim as below by a HART

communicator.

①

1. Device Setup

2. PV

3. PV Ao

4. PV LRV

5. URV

1. Process Variables

2. Diag/Service

3. Basic Setup

4. Detailed Setup

5. Review

1. Test device

2. Loop test

3. Calibration

4. D/A trim

WARN-Loop should be

removed from

automatic control

Connect reference

meter

Setting d dev

output to 4mA

Enter meter Value

4.000

Fid dev output 4.000

mA equal to reference

meter ?

1. Yes

2. No ABORT ENTER

Setting d dev.

output to 20mA

Enter meter Value

20.000

Fid dev output 20.000

mA equal to reference

meter ?

1. Yes

2. No ABORT ENTER

NOTE-Loop may be

returned to automatic

control

Diag/Service

1. Test device

2. Loop test

3. Calibration

4. D/A trim

Device Disconnected

1. Oine

2. Online

3. Frequency Device

4. Utility

ABORT O K

ABORT O K

ABORT O K

HELP DEL ABORT ENTER

ABORT O K

HELP DEL ABORT ENTER

ABORT O K

HELP SAVE HOME

RETRY QUIT

Select the '1. Device Setup' by

,

keys and press the key.

②

Select the '2. Diag/Service' by

,

keys and press the key.

l!l

III

③

Select the '4. D/A trim' by

and press the

④

Press the

⑤

Press the

⑥

Press the

⑦

Press the

~

IOKI

IOKI

IOKI

IENTERI

(F4) key.

(F4) key.

(F4) key.

~

,

l!l

key.

(F4) key to set 4 mA

III

display value.

⑧

If output display value is correct, select

'1. Yes' and press the

IENTERI

key. If not, select '2. No' and press

the (F4) key and re-set the

IENTERI

display value.

E.g.) If output display value is 3.89mA,

select 3.89 and press the

(F4) key.

⑨

Press the

⑩

Press the

display value.

⑪

If output display value is correct, select

(F4) key.

IOKI

(F4) key to set 20mA

!ENTER!

'1. Yes' and press the

key. If not, select '2. No' and press

the (F4) key and re-set the

IENTERI

display value.

⑫

Press the

⑬

Press the

⑭

Press the

⑮

Press the

(F4) key.

IOKI

(F3) key.

IHOMEI

(F3) key.

I QUIT I

(F3) key to complete

Q1']

IENTERI

!ENTERI

the adjustment.

keys

(F4)

(F4)

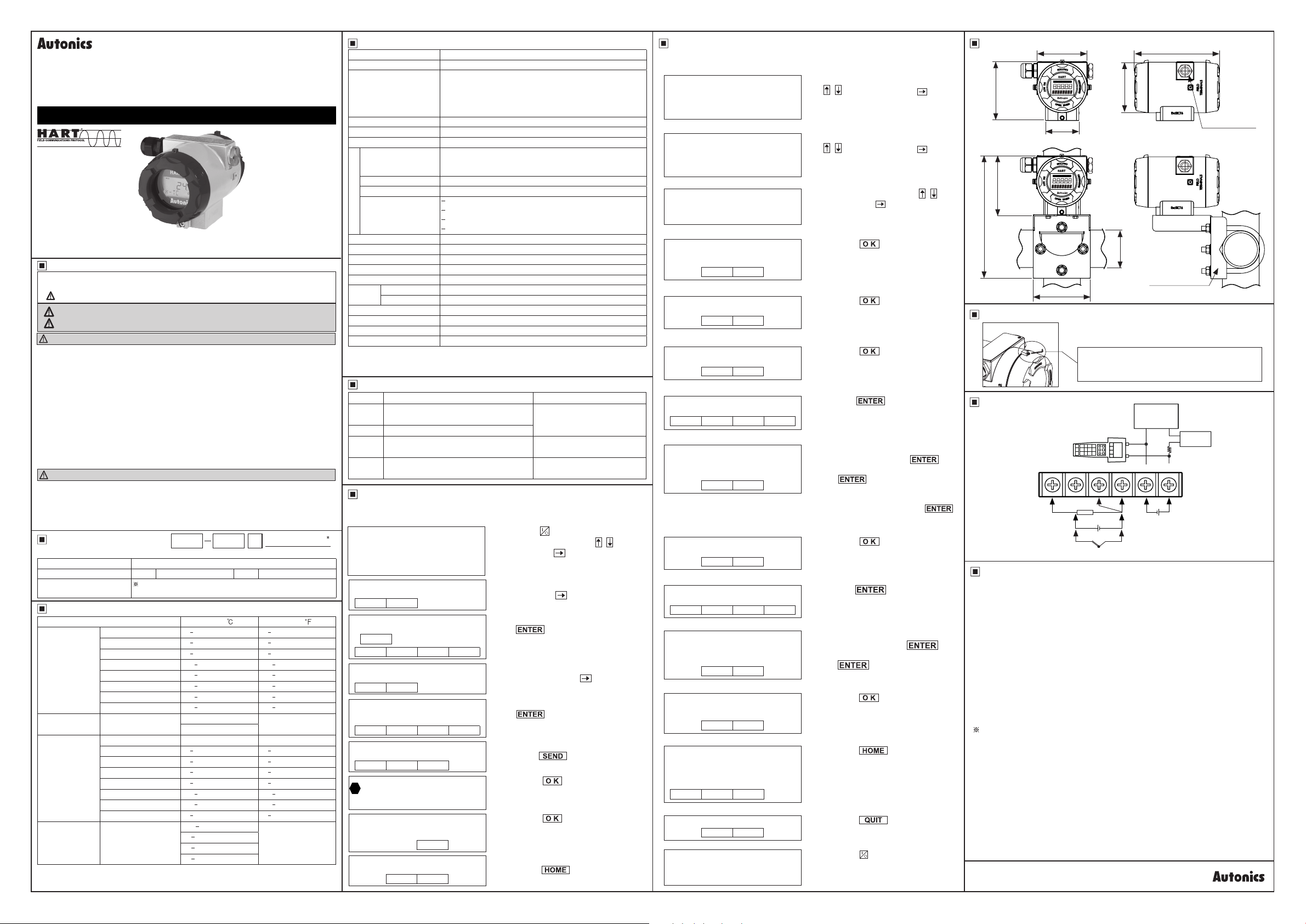

Dimensions

96

83

Ø83

55

142

(unit: mm)

2- (1/2 14NPT)

● Mounting bracket

96

200

DN50

(2B Pipe)

Mounting bracket

94

Opening Cover

To open the cover, unscrew the M3 × 6L headless

bolt using a 1.5 hexagon wrench and rotate the

cover.

Connections

HART

Communicator

1 2 3 4 5 6

11~11~~11

A B b

RTD

mV

+ -

TC

8

+ -

Cautions During Use

~

1. Follow instructions in 'Cautions during Use'.

O herwise, it may cause unexpected accidents.

2. Power supply should be insulated and limited voltage/current or Class 2, SELV power

supply device.

3. Keep away from high voltage lines or power lines to prevent inductive noise.

Do not use near he equipment which generates strong magnetic force or high frequency

noise.

4. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

5. The explosion-proof standard of his unit is Ex d IIC T6, protection structure of this unit is

IP67 and the range of max. surface temperature is below 85℃.

Use the veried explosion-proof electric connection (cable gland or sealing t ing)

6. This unit may be used in the following environments.

①Indoors (in the environment condition rated in 'Specications')

②Altitude max. 2,000m

③Pollution degree 2

④installation Category II

The explosion-proof unit is certied and the same specications which is reported to

*

Korea Gas Safety Corporation. (This unit is manufactured following by the announcement 2013-54 of Ministry of Employment and Labor of Korea.)

Indicator

Recorder

DCS

Controller

-

+

Power supply

10.5-45VDC

Power

Supply

Min. 250Ω

Autonics

Loading...

Loading...