Audi A6´05 323, A6 2005 Service

Audi A6´05

Self-Study Programme 323

Service Training

The new Audi A6 – the most progressive vehicle takes the lead

Design and performance are the main driving

elements on its way to the top position.

Furthermore, the new Audi A6 embodies the

consequent continuation of the familiar Audi brand

values, sports appeal, progressiveness and intrinsic

quality, which are evident in the fourth generation

of this sporty business limousine.

”Vorsprung durch Technik” – this guiding principle is

consistently maintained in the new Audi A6´05

through its innovative technologies.

Highly dynamic chassis technologies are combined

with consumption-optimized drives with the latest

FSI or TDI technology for greater driving pleasure.

Rounded off with servotronic and the 6-stage

tiptronic system with sport programme, the new

Audi A6´05 has optimal driving dynamics as well a

sporty and comfortable tune-up.

The MMI operating system in the interior of the

vehicle is the central control for the extensive

functionalities. The driver-orientated cockpit design

provides a perfect workplace, which is both stylish

and sophisticated. The high functionality is

emphasized by the customer-orientated features in

the safety and convenience function areas.

Preface

NoteReference

Self-study programmes for the Audi A6´05

The Self-Study Programme provides information on the fundamentals of the design and function of new

vehicle models, new vehicle components or new technologies.

The Self-Study Programme is not a Workshop Manual!

Specified values serve only to make the information easier to understand and relate to the software version

that was valid at the time the Self-Study Programme (SSP) was created.

For maintenance and repair work, please make sure to use the current technical documentation.

323_057

323_058

323_059

323_056

SSP 324 Audi A6´05 Chassis

– Front axle technology

– Rear axle technology

– Steering system

– ESP

– Electromechanical parking brake EPB

Order No.:

A04.5S00.07.20

SSP 326 Audi A6 ´05 Electrics

– Networking

– Bus topologies

– Convenience electrics

– Infotainment

Order No.:

A04.5S00.09.20

SSP 323 Audi A6´05

– Introduction to the vehicle

– Body technology

– Passenger protection

– Air conditioning

Order No.:

A04.5S00.06.20

SSP 325 Audi A6 ´05 Engines

and Gears

– 3.0 V6 TDI Common Rail

– 3.2 litre V6 FSI

– Manual gearbox 01X, 02X, 0A3

– 6-stage automatic transmission 09L

– Multitronic 01J

Order No.:

A04.5S00.08.20

Chapter 1 Introduction

Chapter 3 Passenger protection

Contents

Safety system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Airbag control unit J234 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Data exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Belt warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Airbag disabling key switch, front passenger side E224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Seat belts and belt tensioners N153 and N154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Active head restraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Battery cut-off relay J655 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Seat occupied recognition, not for USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Seat occupied recognition for USA market . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Seat occupied recognition control unit J706 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 5 Engine / Gearbox

Overview of available engine / gearbox combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Product highlights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 7 Electrics

Bus topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

In/outputs on control units J393, J519 and J520 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wheel brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ESP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electromechanical parking brake – EPB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Steering system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Wheels / tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Tire pressure control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chaper 2 Body

Contents

Body shell / connection technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Trailer coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 4 Diagnosis

Chapter 6 Chassis

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Convenience automatic air conditioning and convenience automatic

air conditioning plus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CAN networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Components in the Audi A6 ´05 air conditioning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Replacing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Control motor versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

In/output signals at Climatronic control unit J255 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Additional electric air heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Auxiliary / additional heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Air conditioning diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Special tools for the Audi A6´05 air conditioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 8 Air conditioning

VAS 5053 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

VAS 5051 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

VAS 5053/20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Recording the working time using the VAS 5051 / 5052 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6

Introduction

Product highlights

The product features which support the new Audi A6´05 on its way to the top, can be summarised as follows:

One wing is the design, the other wing is the car’s performance.

Performance

Power train s

– Power-controlled power trains, better than

competition

– New FSI technology from motor racing

– New TDI technology common rail II with

Piezo injectors

– Quattro:

– Multitronic

– 6-stage Tiptronic

– Wide selection of motors and gearboxes

Innovation

– FSI

– Common rail II with piezo injectors

– Expanded ESP

– MMI as standard

– Integrated driver cockpit

– Electromechanical parking brake

– Advanced key, adaptive light, LED brake lights,

comfort climate control plus

Driving dynamics

– New dynamic chassis with trapezoidal-link rear

axle and redesigned four-link front axle

– Increased body stiffness + 35 %

– Larger tyre diameter

– Servotronic now standard

– Wider tread widths, front +7 cm, rear +6 cm

– Excellent rear downforce for safe handling

Design

Quality

– Use of intrinsically valuable materials

(aluminium, wood, leather)

– High-quality standard equipment (light-rain

sensor, aluminium trim, active headrests in front,

servotronic, EPB, fog headlights, ...)

– Highest safety standards (5 star Euro NCAP)

– Small gap widths, even joints

Pack age

– Premium vehicle dimensioning

– Rear knee room 8 cm

– Wider shoulder widths, front +23 mm,

rear +6 mm

– Front headroom +7 mm

– Superior luggage compartment volume (546 l) for

front-wheel and quattro models

– Wheelbase +9 cm

Exterior/Interior

– Completely new line design (roofline, shoulder

line, dynamic line)

– Dynamic joint matching

– Coupe-like shape

– Separation edge on rear end

– Single frame

– Double-pipe exhaust for front-wheel and

quattro models

– Full exterior surface painted

Performance

Design

323_038

Driving dynamics

Pack age

Innovation

Pow er trains

Quality

Exterior/Interior

The most

progressive car

takes the lead

7

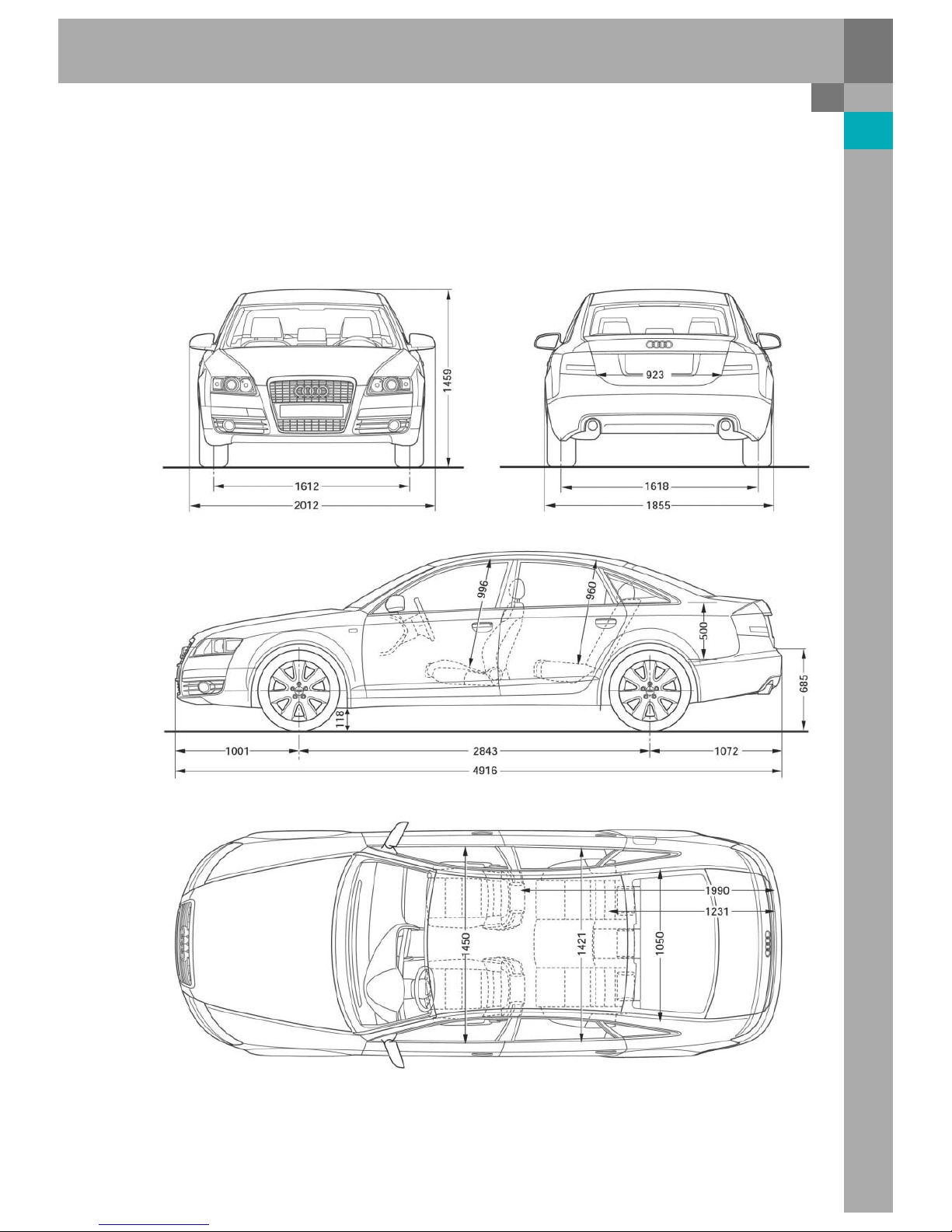

Dimensions

The new Audi A6´05 impresses with its imposing external dimensions.

The vehicle length has been increased to 4.92 m, which corresponds to an increase of 12 cm compared to its

predecessor. The vehicle width has been increased by 4.5 cm to 1.86 m. The height of the new A6´05 has been

increased by 0.8 cm to 1.46 m. The new Audi A6´05 has grown. For the dimensions, please refer to the

diagrams.

323_034

8

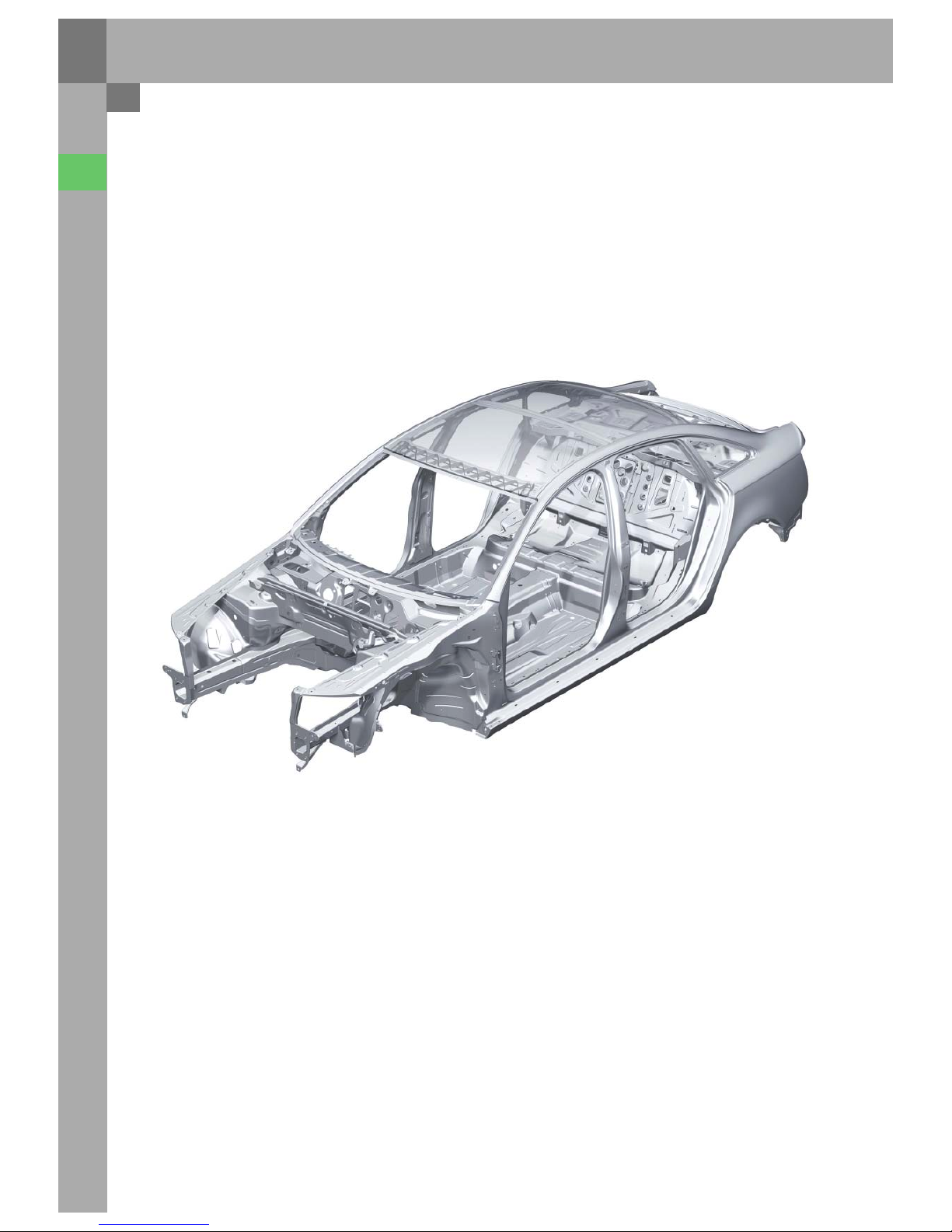

Body shell / connection

technology

The main objectives during the development of the

new Audi A6 body design were the realization of

high passive safety characteristics and improved

rigidity values as a precondition for optimizing

vibration damping characteristics.

Body

In spite of the greater demands compared with

the previous model, the body weight has been kept

at the same level.

A further task during the body development process

is to minimize the number of necessary body

versions.

The new A6´05 uses four body shell versions:

– rigid rear panel

– with opening for loading

– without sliding sunroof

– with sliding sunroof

A standard rear section is used for the front-wheel

drive and quattro vehicles.

323_001

9

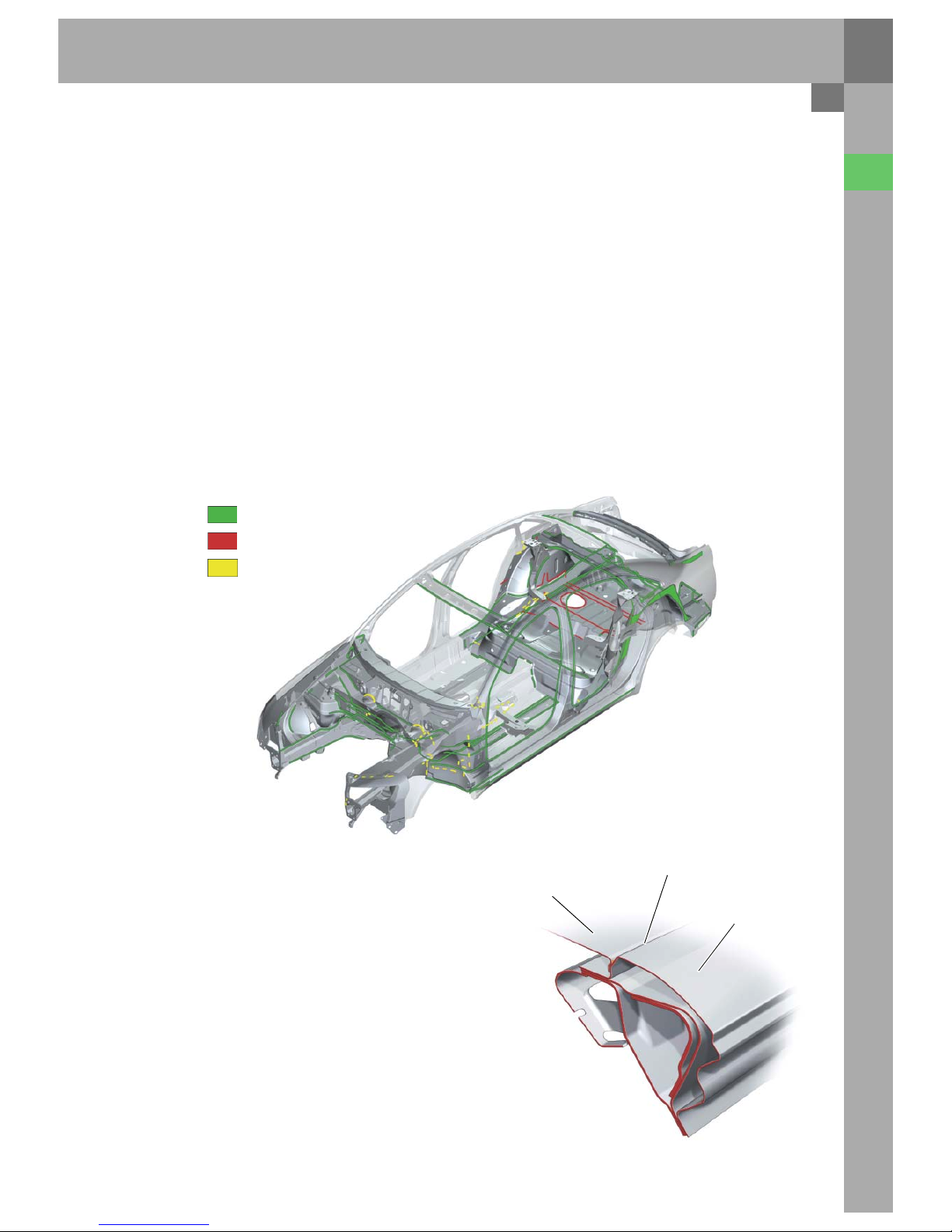

In addition to classic resistance spot welding, the

following connecting techniques are used on the

new A6´05 body shell:

– Spot welding bonding

– Punch riveting

– Clinching (bonnet & rear opening hood)

– Laser soldering

– Laser welding

– as well as MIG soldering

Spot welding bonding, using a high-strength

structural adhesive, is used for particularly

crash-relevant and rigidity determining connections

(length of the bonded seam factor 3 compared with

predecessor).

Spot welding bonding

Laser

323_002

MIG soldering

The Aluminium components are joined to the

galvanized steel sheets by means of punch rivets

and by bonding.

The roof and side panel frame are joined by

laser-soldering.

Poorly accessible components are joined by

laser-welding.

The laser-welding head is smaller and thus has

greater flexibility than comparable spot welding

tongs.

In addition, the weight can be reduced by reducing

the flange widths.

MIG soldering is used for closed sectional bars

which are only accessible from one side,

e.g. longitudinal floor members.

323_003

Roof

Laser-soldered zero joint

Outer side part

These aluminium-steel connections are used on the

following parts in the body:

– in the plenum chamber front panel

– sill reinforcement (with aluminium extruded

section)

– rigid rear panel with rear shelf

10

Body

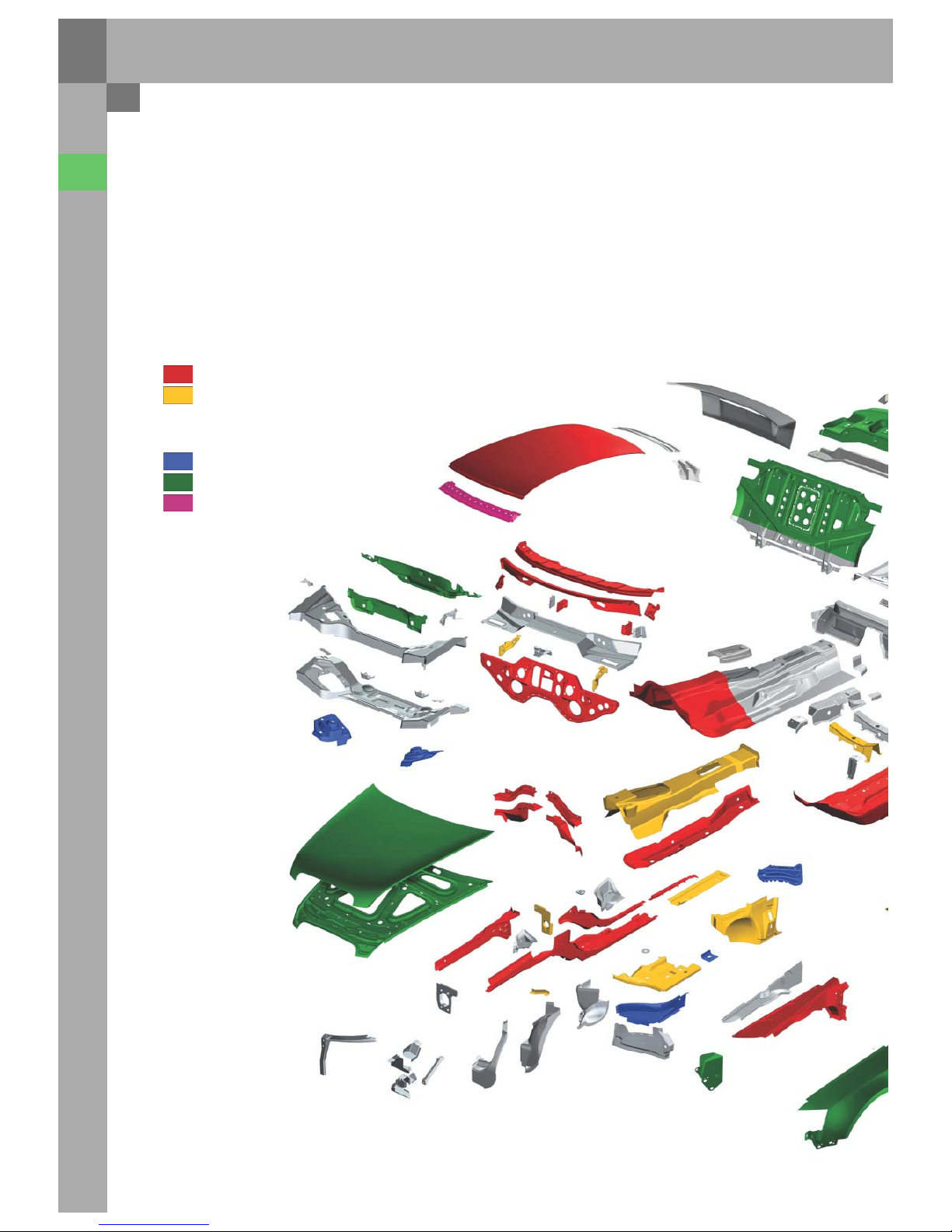

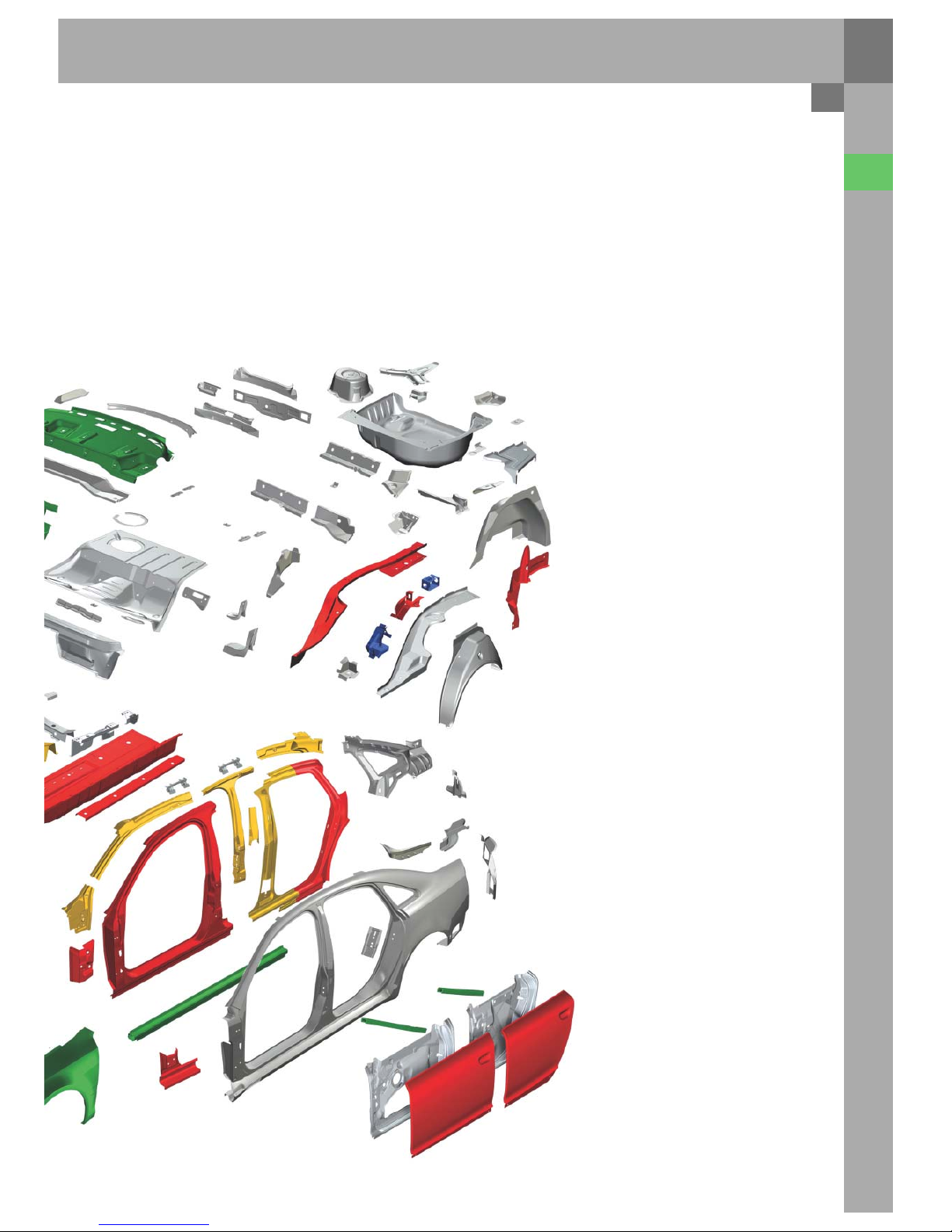

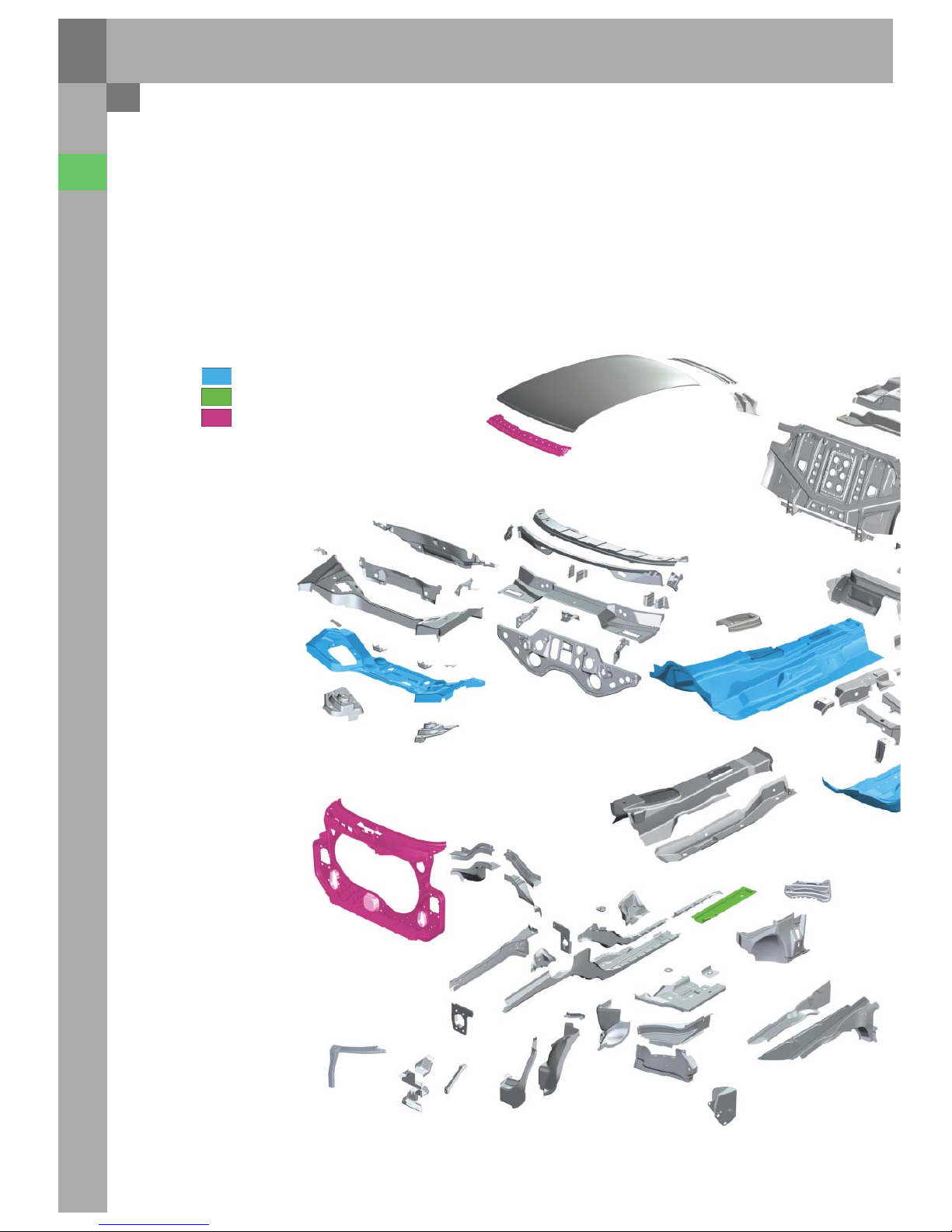

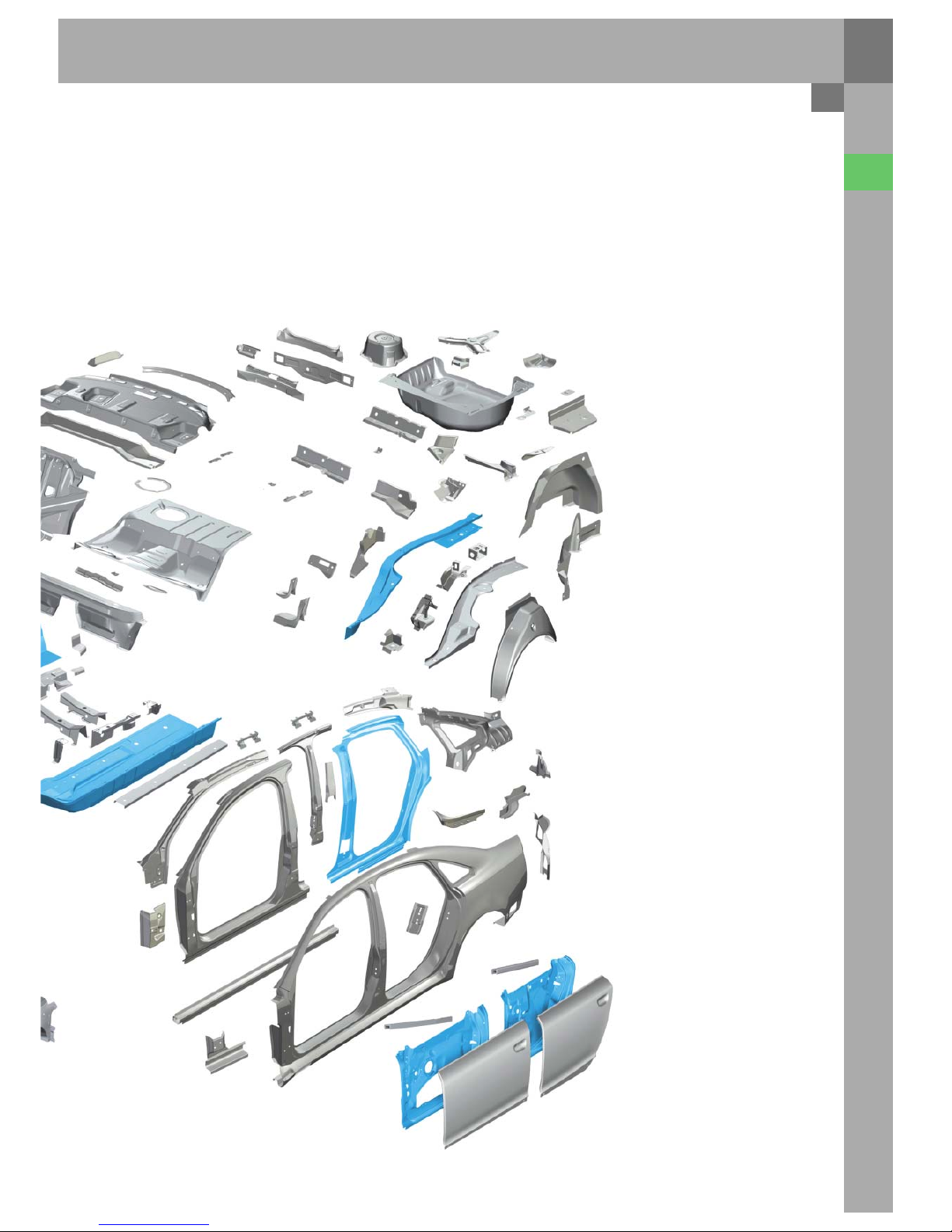

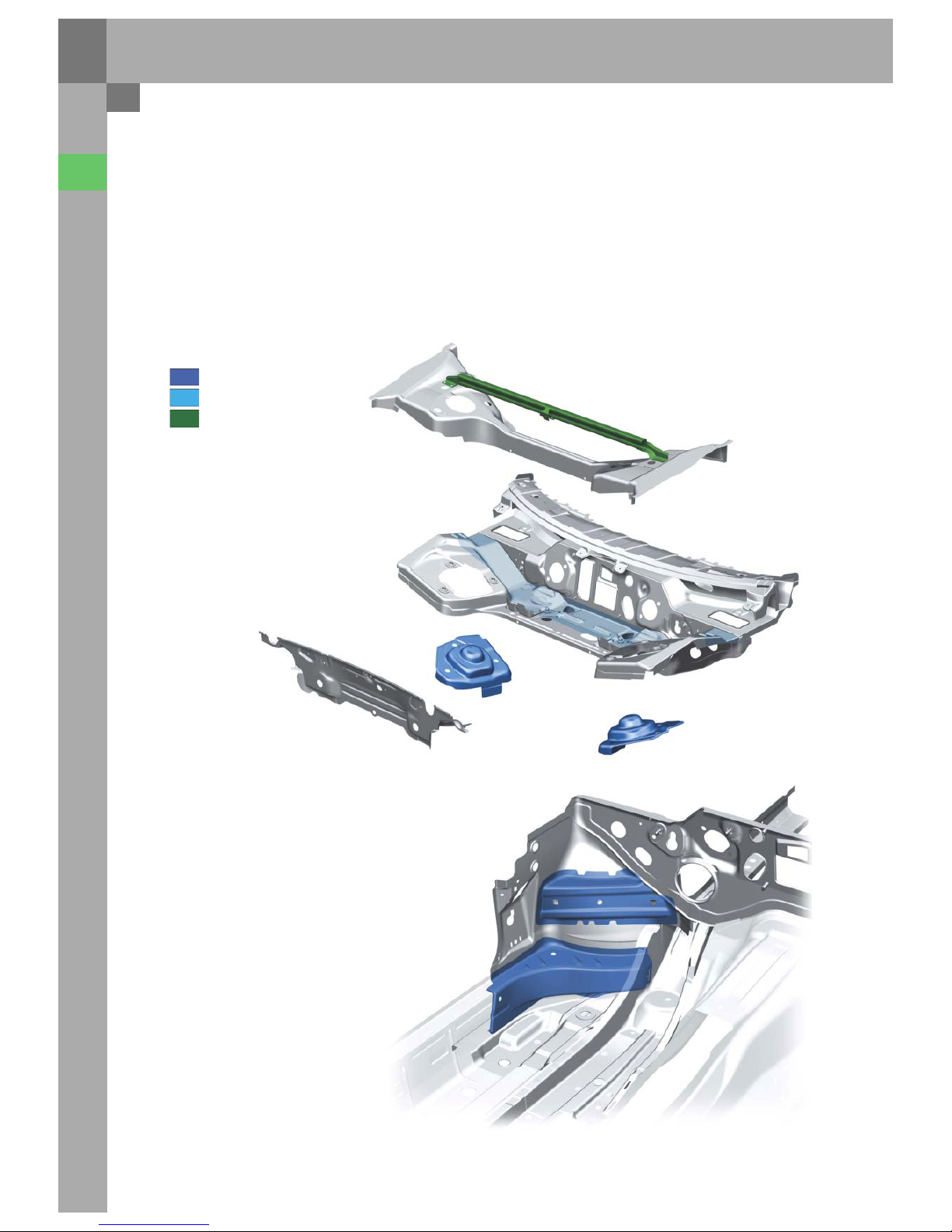

High tensile steels (180 - 300 N/mm²)

Dual-phase steels (340 - 500 N/mm²)

Weight percentage of high-tensile steel sheets

To ta l : 4 5 %

Upper section: 42.3 %

Lower section: 46.7 %

Special steel (600 - 900 N/mm²)

Aluminium

Hybrid co mponent

Materials

In addition to conventional deep-drawing steels, the

following materials are used in the body structure

of the new Audi A6´05:

– High tensile sheet steel

– Special sheet steel

– Aluminium sheets

– Aluminium extruded sections and

– Plastic-ribbed deep-drawing steel component

(hybrid component)

11

Large-volume aluminium extruded sections are

used as sill reinforcements to stiffen the cell

structure in the event of an offset or side crash.

The front roof frame is designed as a hybrid

component in order to reduce the weight.

323_004

High-tensile steel sheets are used especially in

areas which require strengthening and greater

impact resistance.

Special steel sheets are also used in the body

structure, e.g. front wheelhouse cross-member.

The engine bonnet and front mudguards are made

of aluminium.

In addition to the add-on parts in the shell,

aluminium sheets are used in the structure for

large-area components which are not subject to

excessive stress.

12

Body

Blanks

Blanks with different wall thicknesses and material

qualities are used to realize a stress-adapted

material distribution for large-area components

which are subject to high stress.

tailored blanks

tailored-rolled-blanks

hybrid components

Laser-welded blanks, so-called tailored-blanks,

are used for

– the front suspension strut cross member

– front floor panels

– inner side section

– rear longitudinal member

– and door inner panels

13

Tailored-rolled blanks, which have variable rolled

wall thicknesses, have particular advantages.

They can be used to produce continuous material

thickness transitions which meet the local stress

conditions. This technique is used to optimize the

front longitudinal member structure.

In total, a weight reduction of 8 kg (without add-on

parts) was realized through the material selection

being adapted to the respective stress conditions.

An additional weight reduction of 9 kg was realized

by using blanks with different wall thicknesses.

323_005

14

Body

Assemblies

Plenum chamber

One application area for special steel is the chassis

connection in the proximity of the spring and shock

absorber seat.

It was possible to reduce the wall thickness of the

respective parts from 2.5 to 1.4 mm.

The resulting loss of local rigidity was offset by

creating an optimized profile.

323_031

Special steel (600 - 900 N/mm²)

tailored blanks

Aluminium

In addition, a tailored blank is fitted in the plenum

chamber.

This ensures the highest possible energy

absorption in the event of a crash.

At the same time, the necessary rigidity and

stability are ensured during normal driving.

Transverse rigidity is ensured by a rolled sectional

bar as an additional reinforcement.

323_030

Wheelhouse

To ensure an optimum introduction of the crash

energy from the front of the car into the passenger

compartment, special steel components were used

in the proximity of the wheelhouse.

15

323_032

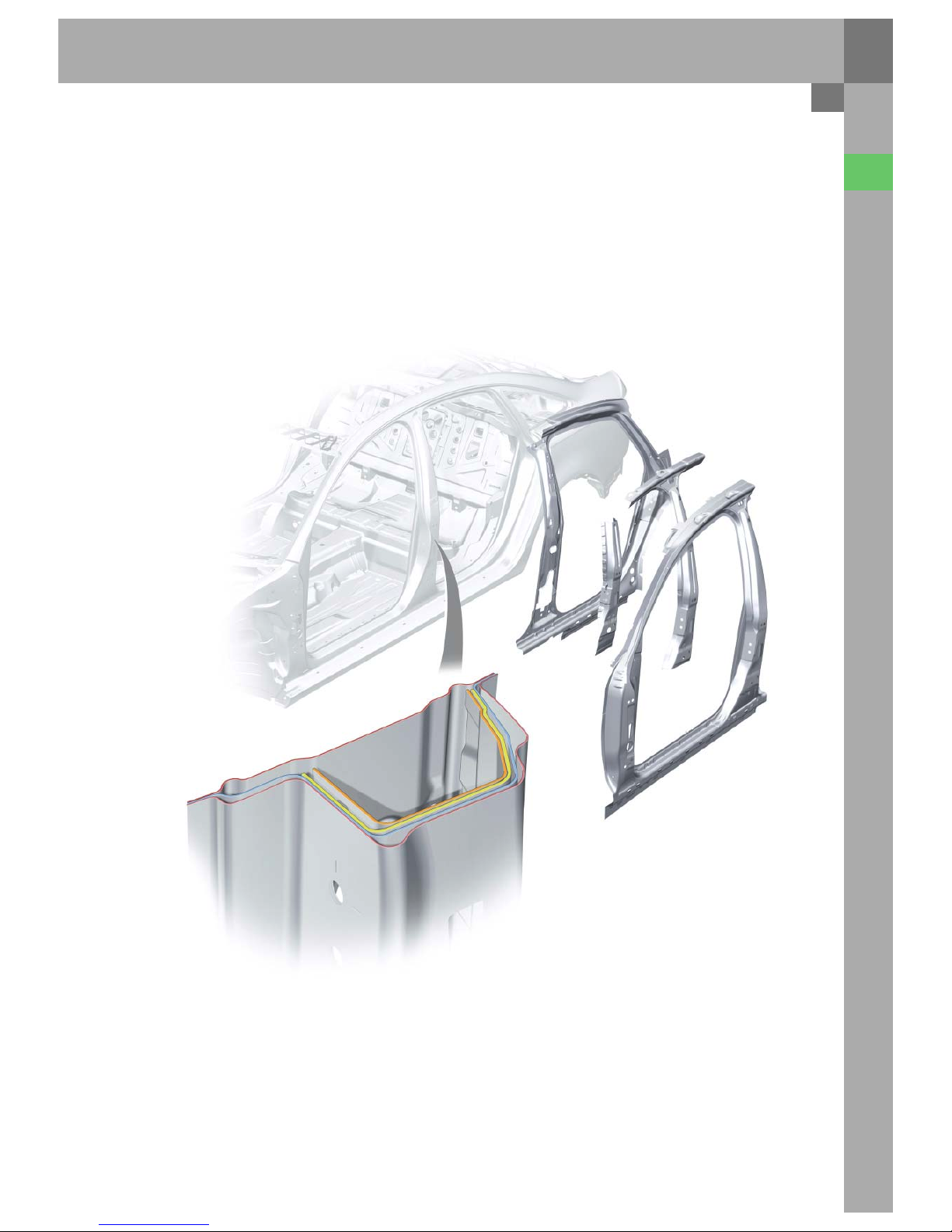

B-pillar

Due to the increased requirements regarding the

strength of the B-pillar, a combination of different

materials is used.

– front inner side section (high tensile steels)

– rear inner side section, tailored blank

(dual-phase steels, high tensile steels)

t = 1.35 mm and 0.8 mm

– B-pillar reinforcement (dual-phase steels)

– B-pillar (dual-phase steels)

16

Body

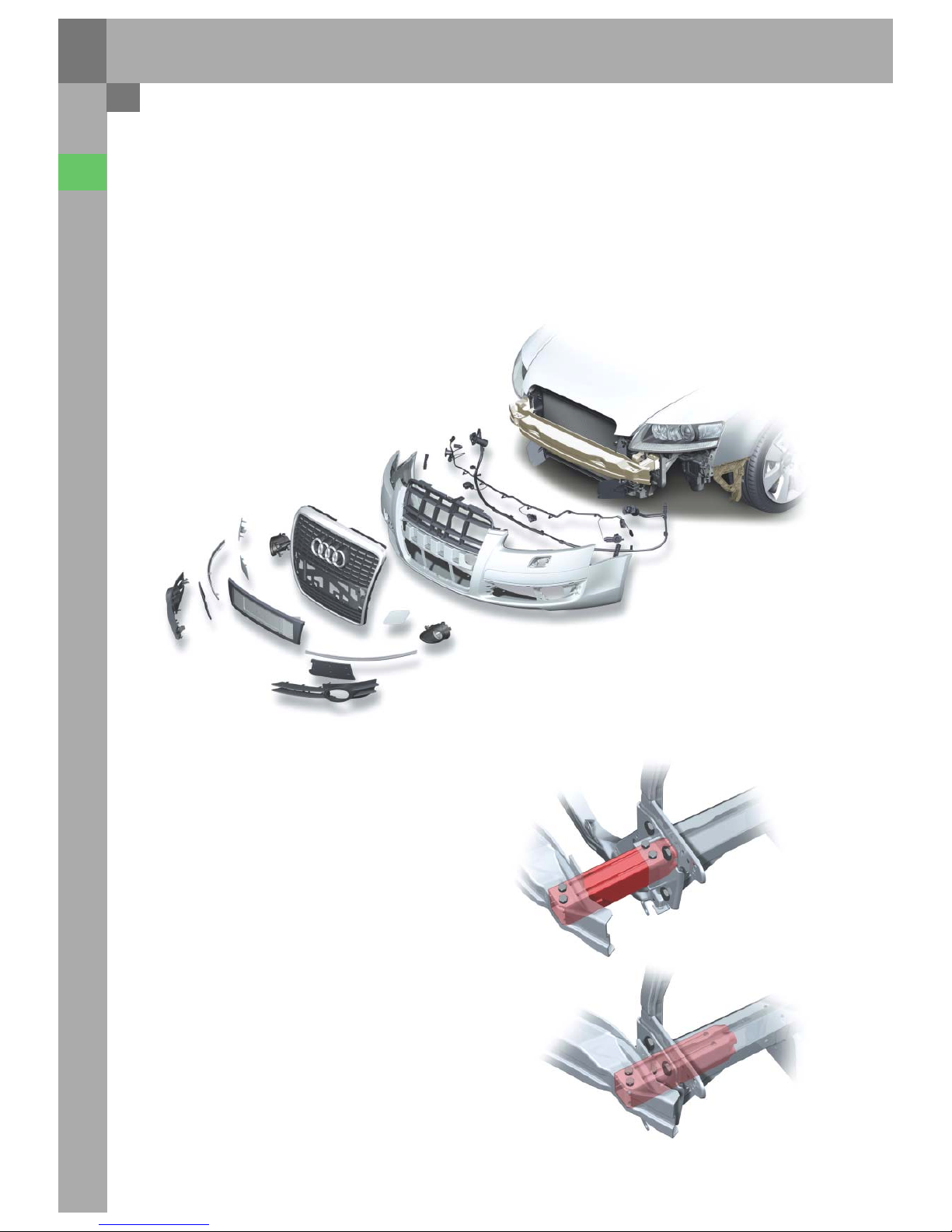

323_006

The bumper support comprises an open aluminium

cross member, which is screwed on to the

longitudinal member using newly developed shear

boxes.

The shear box absorbs the crash energy from all

centrical and slightly diagonal impacts through its

shearing effect.

Expensive damage to the welded vehicle structure

behind it is thus avoided up to a speed of 15 km/h.

In the event of diagonal impacts, the impact energy

is absorbed by the bumper buckling (folding) and

deforming.

The seat for the towing lug is integrated in the

right-hand shear box.

The towing forces are guided centrically into the

longitudinal member.

323_008

The number plate in the radiator grille is integrated

stylishly and harmoniously within the overall

design.

Bumpers

Front bumper

The bumper on the new Audi A6´05 is painted in the

colour of the car.

It comprises the following components:

– Coating

– Top cover

– Towing lug cover

– Radiator grille with chrome frame

– Fog lamps

– Side air inlet grilles

– Bumper support

17

Rear bumper

The rear bumper assembly comprises the coating,

spoiler, towing lug cover and closing part

components. It is mounted on the vehicle by means

of fixed guides on the body. The bumper support

and the bracket for the bumper support are made of

aluminium and are produced by extrusion

moulding.

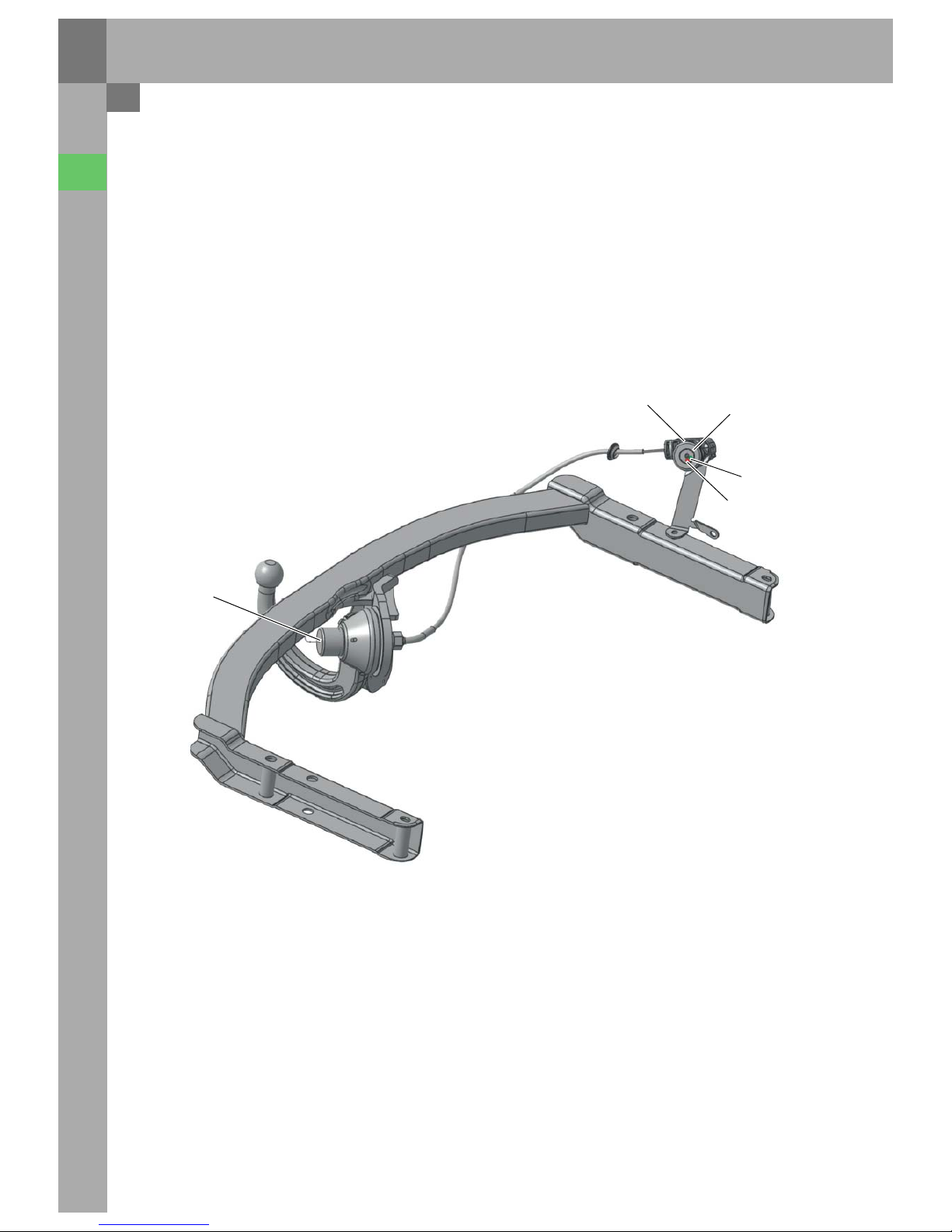

Trailer coupling

The newly developed trailer coupling fitted in

the A6´05 is equipped with a mechanically

swivelling ball rod.

The ball rod swivels around a rotation axis, which is

angled at 45° to the longitudinal axis of the vehicle.

The swivel angle between the swivelled-out towing

position and the idle position behind the bumper

is 180°.

The system is unlocked by means of a handwheel

located in the boot.

323_007

Compared to the previous model, the joints on

the A6´05 have been noticeably reduced.

Due to a special adjusting/holding part below the

rear light, the zero joint between the bumper

coating and side part has been reduced to 0.8 mm.

A parking aid and a mechanically swivelling trailer

coupling are available (optional).

323_010

323_009

18

Body

Control unit for trailer detection J345

Arrangement in the vehicle

The basic function of trailer detector control

unit J345 corresponds to the control unit which has

already been in use since the 2001 Audi A4.

To be used in the Audi A6´05, it was upgraded by the

control function for the swivelling trailer coupling.

It now has the additional task of detecting the

locking status of the mechanically swivelling trailer

coupling and indicating this to the driver.

323_035

F354

K226

K227

Handwheel

F355

19

On pulling the handwheel in the boot, the contact

switch on handwheel F354 is closed. On turning the

handwheel, the locking bolt on the trailer coupling

is unlocked mechanically by a Bowden cable and

the contact switch on locking bolt F355 opens.

After being unlocked, the trailer coupling can be

swivelled out/in mechanically. After being swivelled,

it is automatically locked by spring power. The

contact switches return to their initial position.

The control unit cannot differentiate between a

locked, swivelled-in trailer coupling and a locked,

swivelled-out trailer coupling.

The locking state is indicated by two LEDs in the

handwheel for the trailer coupling. When the green

warning lamp for trailer coupling locked (K226)

lights up continuously, it indicates that the trailer

coupling is swivelled in/out correctly.

323_036

323_033

CHECK

TRAILER

COUPLING

The red warning lamp for trailer coupling

unlocked (K227) flashes when the trailer coupling is

not locked. In addition, a message appears on the

central display in dash panel insert J285.

When terminal 15 is switched off, the warning lamp

for trailer coupling locked (K226) switches off if the

tailgate/boot lid is closed or remains open for

longer than 10 minutes. The warning lamp for trailer

coupling unlocked (K227) switches off if the tailgate/

boot lid is closed or remains open for longer than

20 minutes. The respective warning lamp switches

on again when there is a control unit wake-up or a

CAN wake-up.

20

Passenger protection

Safety system

A top-level safety system: The performance target is

to increase the existing high safety level of the

current Audi fleet.

The compliance with current laws and the

completion User tests, in which the new

Audi A6´05 was to gain a top position in the rating

scheme, were only a part of the extensive safety

requirements. In many cases, additional Audi

in-house requirements increase the requirements

which have to be met by the development team.

Particular attention was paid to a high protection

potential in the event of an accident and the

compatibility. Audis's policy of designing vehicles

with high safety specifications is supplemented

by scientifically gained knowledge of the

actual accident and its effects.

For this, the AARU (Audi Accident Research Unit*)

examines crashes involving relatively new

Audi vehicles.

The development team's task is to analyse and

reconstruct accidents and to draw up potential

improvements.

In addition to this, the AARU evaluates the relevant

accident databases.

The safety system in the Audi A6´05 comprises the

following familiar components:

– Airbag control unit

– Driver and front passenger airbags, two-stage

– Front side airbags

– Sideguards (head airbags)

– Sensors for side crash detection

– Front belt tensioners

The Audi A6´05 has the following new components:

– Crash sensors for the front airbag, the so-called

upfront sensors for frontal crash detection

– Battery cut-off relay

– Sensors for side crash detection in the doors

– Switches in the front belt locks

– Seat occupied recognition in the front passenger

seat

The vehicle can be equipped with side airbags at the

rear and a key switch for deactivating the front

passenger airbag with a corresponding warning

lamp (optional).

The safety system in the Audi A6´05 is rounded off

by the active head restraints in the front seats.

The A6´05 thus constitutes a successful example of

an overall vehicle development aimed at protecting

the passengers.

Due to the different demands and legal

provisions which car makers are subject to in

the different markets, the equipment can vary for

the US American market in particular.

* Audi Accident Research Unit

Note

Observe the respective safety instructions

in the repair guide before carrying out

any work on the airbag system!

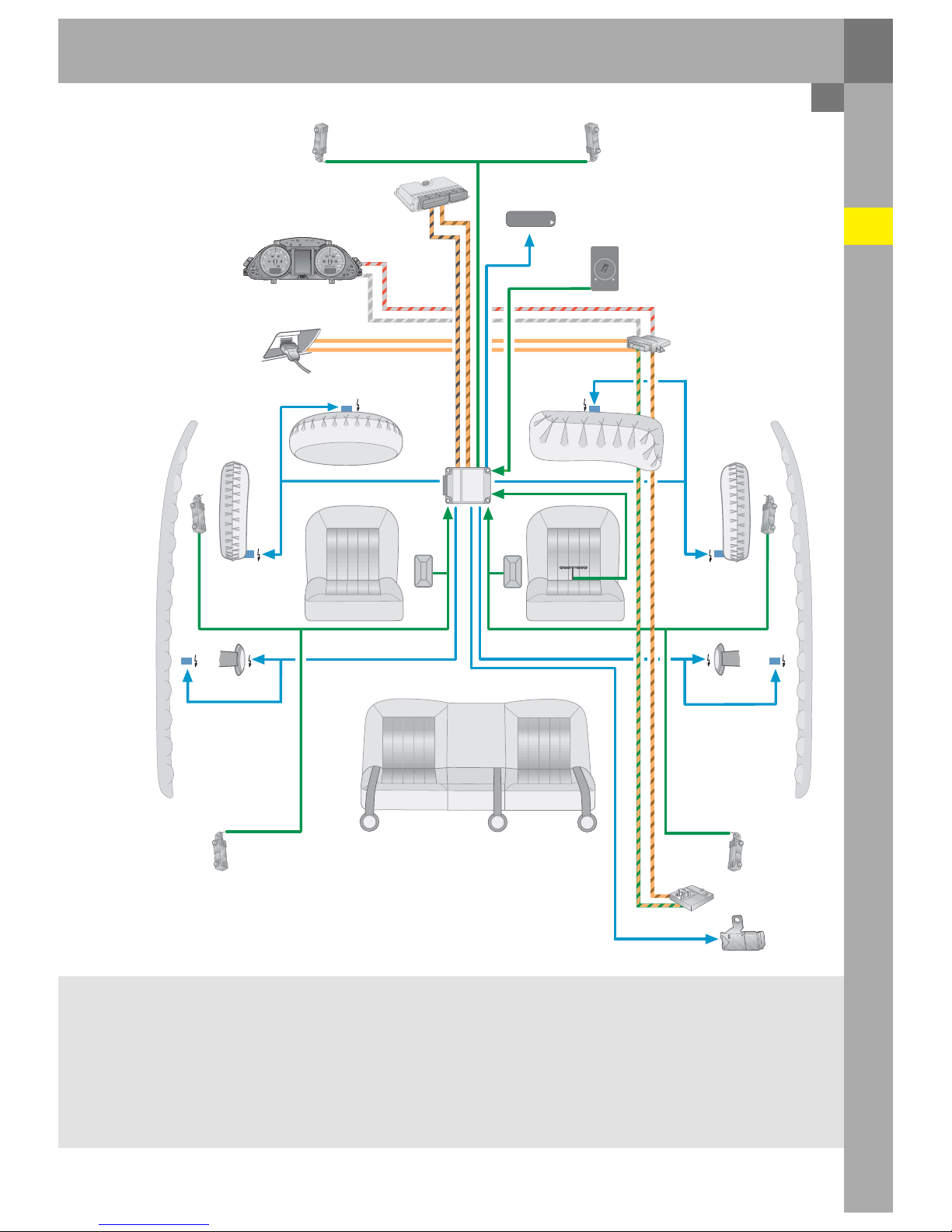

Legend

E224 Airbag disabling key switch, front passenger side

E24 Belt switch, driver side

E25 Belt switch, front passenger side

G128 Seat occupied sensor, front passenger side

G179 Crash sensor for side airbag, driver side (front door)

G180 Crash sensor for side airbag, front passenger side

(front door)

G256 Crash sensor for side airbag, rear, driver side

G257 Crash sensor for side airbag, rear, front passenger side

G283 Crash sensor for front airbag, driver side

G284 Crash sensor for front airbag, front passenger side

21

G256

N251

G179

G180

N153

K14 5

AIRBAG OFF

PASSENGER

N95 / N250 N131 / N132

N252

N154

G257

J5 33

G283

G284

N200

T16

J623

J285

K75 / K19

E224

AUS

EIN

AIRBAG

J655

E24 E25

J2 34

J3 93

N199

G128

326_002

N95 Airbag igniter, driver side

N250 Airbag igniter 2, dr iver side

N131 Airbag igniter 1, front passenger side

N132 Airbag igniter 2, front passenger side

N153 Belt tens ioner ign iter 1, driver side

N154 Belt tensioner igniter 1, front passenger side

N199 Side airbag igniter, driver side

N200 Side airbag igniter, front passenger side

N251 Head airbag igniter, driver side

N252 Head airbag igniter, front passenger side

T16 Plug-in connection, 16x (diagnosis connection)

J234 Airbag control unit

J285 Control unit in dash panel insert

J393 Central control unit for convenience system

J533 Data bus diagnosis interface

J623 Engine control unit

J655 Battery cut-off relay

K19 Warning lamp for belt warning

K75 Airbag warning lamp

K145 Airbag warning lamp, front passenger side, off

(PASSENGER AIRBAG OFF)

22

Airbag control unit J234

The task of the airbag electronics is to detect vehicle

deceleration and evaluate it so that a collision is

reliably detected. The control unit can detect

frontal, side and tail accidents. In addition, the

electronics also have the task of activating the

respective restraint systems (airbags / belt

tensioners) depending on the type of collision and

its severity and activating the Crash output.

The airbag electronics have the following main

tasks:

– Crash detection (front, side, tail)

– Defined triggering of the airbags, belt tensioners

and battery cut-off

– Defined triggering of the second front airbag

stage

– Evaluation of all input information

– Permanent monitoring of the entire airbag

system

– Independent power supply via capacitor for a

defined time (approx. 150 ms)

– Error indication via failure warning lamp

– Storage of error and crash information

– Notification of a crash event to other system

components via drive CAN or discrete

Crash output (conventional cabling)

– Activate belt warning

In addition to the internal sensors in the control

unit, the external crash sensors are also used to

detect vehicle deceleration during impact.

The electronics can only decide when and which

safety components to activate after all the sensor

information has been evaluated by the control unit

electronics.

If an airbag control unit is replaced, then it must be

coded and adapted to the respective.

These functions can only be peformed by means of

the guided fault finding procedure and a diagnosis

tester which can be used online. The Service

technician needs access (with password) to the

”FAZIT” database at Audi.

If the coding or adaptation is not carried out in the

correct manner, malfunctions can occur in other

vehicle systems such as the ESP, for example.

Passenger protection

326_008

23

Airbag warning lamp K75

The airbag warning lamp, which is located in

dash panel insert J285, is triggered via the bus CAN.

If there is no data message from the airbag control

unit, the warning lamp is automatically switched on

from the dash panel insert.

Rear crash detection

In the event of a rear-end crash, the airbag control

unit evaluates the information from the internal

crash sensor and the crash sensors for front

airbags G283 and G284. If their signals exceed a

fixed value, the belt tensioners are ignited and

the battery cut-off relay is activated.

Data exchange

The airbag control unit is integrated within the

drive CAN.

The airbag control unit transmits the following

information on the drive CAN:

– Trigger warning lamp K75

– Activate belt warning

– Diagnosis data

– Crash signal

– Crash information for the actuator test

– ESP data

– Front passenger airbag disabled (for USA only)

The airbag control unit evaluates the following

information from the data bus:

– Dimming of the airbag warning light

Passenger airbag off

Loading...

Loading...