Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

ATPL250A

PANCoordinator-EK Kit User Manual

USER GUIDE

2

2

Welcome letter introducing the evaluation kit and

its contents.

Boards:

One ATPL250ABNv2 board.

One ATPLCOUP007v2.5 coupling

board (CEN-A frequency band).

One ATPLCOUP002v2 coupling

board (ARIB frequency band).

One ATPLCOUP006v2 coupling

board (FCC frequency band).

Cables:

One micro A/B-type USB cable.

One power cord cable IEC320-C8.

Jumpers:

One voltage jumper with pitch 5.08

mm.

One erase jumper with pitch

2.54mm.

Introduction

This PANCoordinator Evaluation Kit (EK) comprises all necessary resources to develop a complete

G3-PLC PANCoordinator. It implements an Atmel® Cortex™-M7 device acting as MCU host, combined with

ATPL250A modem for PLC (Power Line Communication). ATPL250A is a power line communications base

band transceiver, compliant with the PHY layer of G3-PLC specification.

G3-PLC is a mature, consolidated and worldwide accepted standard for OFDM-based power line

communications, with focus on providing Smart Grid services over electricity distribution networks.

This guide describes how to use the kit and get start with it.

Contents

Features

ATPL250A is a compact and high-efficient device for a wide range of Smart Grid applications such as

Smart Metering (Smart Meters and Data Concentrators), Lighting, Industrial/Home Automation,

Home and Building Energy Management Systems, Solar Energy and Plug-in Hybrid Electric Vehicle

(PHEV) Charging Stations.

ATPL250A G3-PLC device includes enhanced features such as additional robust modes and

frequency band extension.

ATPL250A has been conceived to be bundled with an external Atmel MCU. ATPL250ABN PAN

Coordinator board mounts the ATPL250A transceiver and a SAME70 ARM Cortex M7

microcontroller. This development board provides a full featured platform to develop a complete

communications system based on Power Line Communication technology, providing support for:

– PLC band characterization.

– Noise level measurement.

– Sensitivity level measurement.

– Maximum reachable distance.

– Power consumption.

– Check PLC performance in different bands (CENELEC, FCC, ARIB) setting different PLC

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

coupling boards (provided with this evaluation kit).

– The EK board can be supplied with universal 115-230 VAC 50-60 Hz power input.

– The EK boards include a JTAG interface for MCU debugging and programming purposes, a

UART for debugging purposes, as well as Ethernet connectivity.

3

3

Software application examples available based on G3-PLC Stack:

– Atmel provides an Atmel G3-PLC PHY layer library which is used by the external MCU to take

control of ATPL250A PHY layer device. Three G3-PLC PHY layer example projects are

provided with the kit.

– Atmel G3 Stack (ADP + MAC + PHY) for PAN Coordinator with some user applications is

provided with the EK.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

4

4

Table of Contents

1. Evaluation Kit Specifications ...................................................................................... 7

1.1 Safety recommendations ....................................................................................................................... 7

1.2 Electrical characteristics ........................................................................................................................ 7

2. Evaluation Kit Overview .............................................................................................. 9

2.1 Design support ...................................................................................................................................... 9

2.2 PANCoordinator-EK contents ................................................................................................................ 9

3. ATPL250ABN Hardware............................................................................................. 13

3.1 Overview ............................................................................................................................................. 13

3.2 Features .............................................................................................................................................. 13

3.3 Block diagram ...................................................................................................................................... 16

3.4 Mechanical and user considerations ................................................................................................... 16

3.5 Hardware description .......................................................................................................................... 17

3.5.1 Power supply .......................................................................................................................... 17

3.5.2 Zero crossing detector ............................................................................................................ 18

3.5.3 SAME70Q21 Flash microcontroller ......................................................................................... 18

3.5.4 ATPL250A PLC Transceiver ................................................................................................... 19

3.5.5 PLC Coupling.......................................................................................................................... 20

3.5.6 Peripherals.............................................................................................................................. 22

3.5.7 Interface Ports ........................................................................................................................ 23

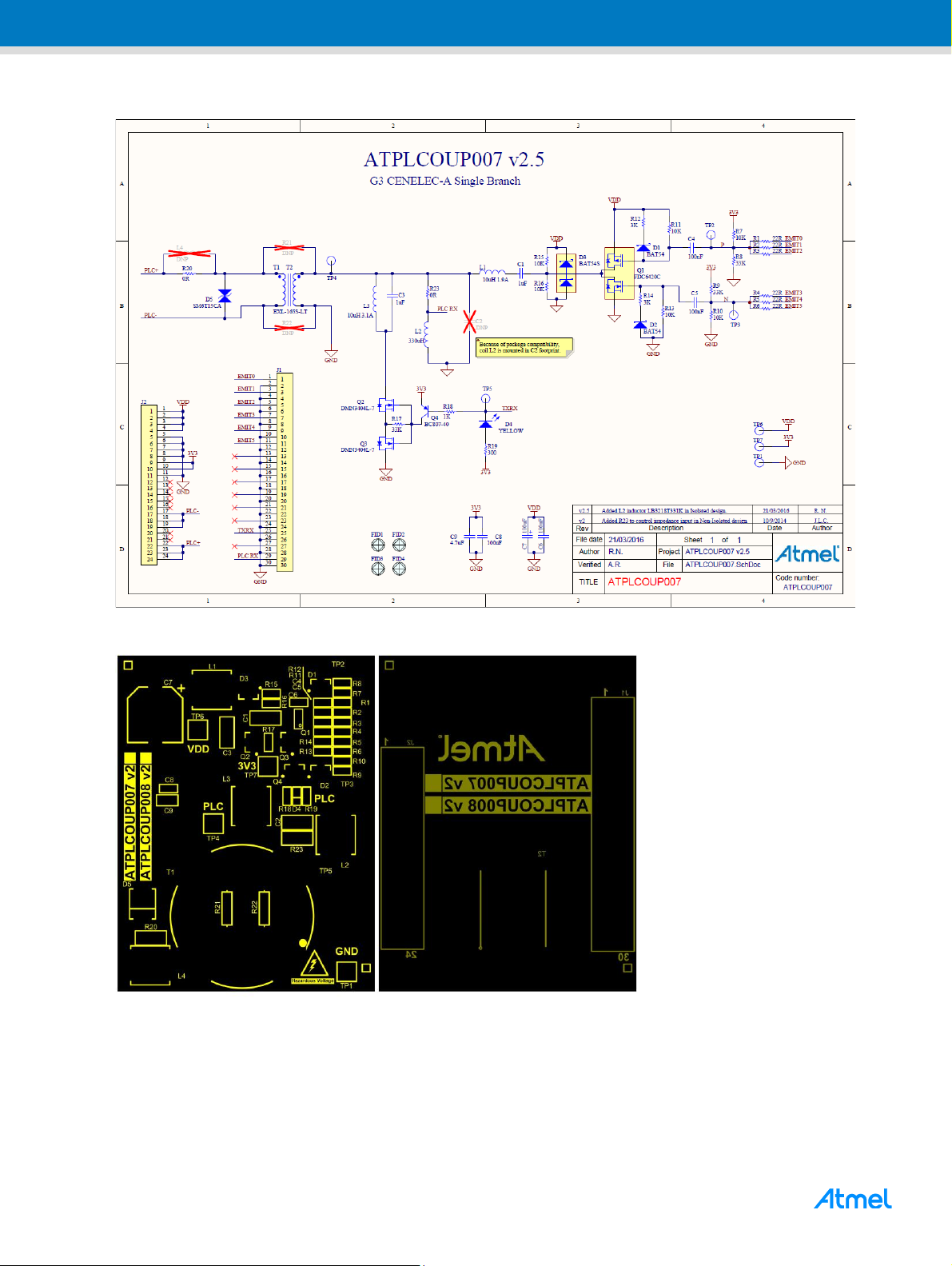

4. ATPLCOUP007 Hardware .......................................................................................... 26

4.1 Overview ............................................................................................................................................. 26

4.2 Features .............................................................................................................................................. 26

4.3 Mechanical and user considerations ................................................................................................... 27

4.4 Hardware description .......................................................................................................................... 27

5. ATPLCOUP002 Hardware .......................................................................................... 28

5.1 Overview ............................................................................................................................................. 28

5.2 Features .............................................................................................................................................. 28

5.3 Mechanical and user considerations ................................................................................................... 29

5.4 Hardware description .......................................................................................................................... 29

6. ATPLCOUP006 Hardware .......................................................................................... 30

6.1 Overview ............................................................................................................................................. 30

6.2 Features .............................................................................................................................................. 30

6.3 Mechanical and user considerations ................................................................................................... 31

6.4 Hardware description .......................................................................................................................... 31

7. PAN Coordinator Evaluation Kit: Getting started .................................................... 32

7.1 Introduction to the embedded system ................................................................................................. 32

7.1.1 IAR Embedded Workbench .................................................................................................... 32

7.1.2 Keil µVision ............................................................................................................................. 32

7.1.3 Atmel Studio 6 ........................................................................................................................ 32

7.1.4 Atmel SAM-ICE JTAG Probe .................................................................................................. 33

7.1.5 J-Link / SAM-ICE JTAG Probe Software & Documentation Pack ........................................... 33

7.1.6 Atmel Software Framework (ASF) .......................................................................................... 35

7.2 PLC application example 1 – PHY Tester ........................................................................................... 36

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

5

5

7.2.1 Atmel PLC PHY Tester tool Installation .................................................................................. 37

7.2.2 Supplying the boards .............................................................................................................. 39

7.2.3 USB connection ...................................................................................................................... 40

7.2.4 Programming the embedded file ............................................................................................. 41

7.2.5 Running the PLC application example 1 ................................................................................. 43

7.3 PLC application example 2 – PHY TX Test Console ........................................................................... 55

7.3.1 Supplying the boards .............................................................................................................. 56

7.3.2 USB connection ...................................................................................................................... 56

7.3.3 Programming the embedded file ............................................................................................. 56

7.3.4 Running the PLC application example 2 ................................................................................. 57

7.4 PLC application example 3 – PHY Sniffer ........................................................................................... 61

7.4.1 ATPL Multiprotocol Sniffer tool Installation ............................................................................. 62

7.4.2 Supplying the boards .............................................................................................................. 64

7.4.3 USB connection ...................................................................................................................... 64

7.4.4 Programming the embedded files ........................................................................................... 65

7.4.5 Running the PLC application example 3 ................................................................................. 65

7.5 Introduction to G3 Stack ...................................................................................................................... 68

7.5.1 FreeRTOS .............................................................................................................................. 68

7.5.2 ASF Integration ....................................................................................................................... 69

7.5.3 Atmel G3-PLC Stack Structure ............................................................................................... 70

7.6 PLC application 4 – PLC Network ....................................................................................................... 72

7.6.1 Supplying the boards .............................................................................................................. 72

7.6.2 USB connection ...................................................................................................................... 72

7.6.3 Programming the embedded files ........................................................................................... 72

7.6.4 Running the PLC application example 4 ................................................................................. 74

8. References ................................................................................................................. 77

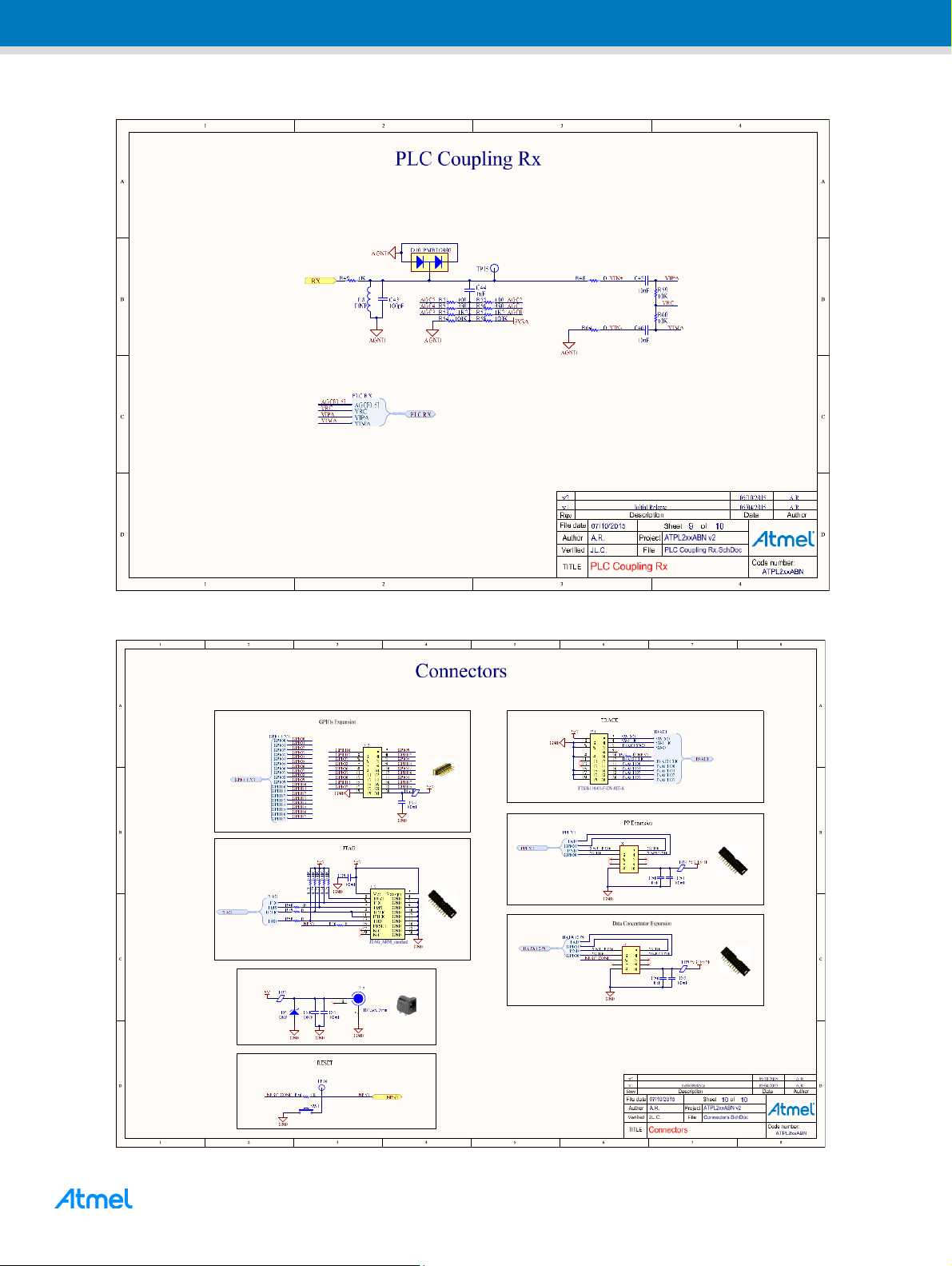

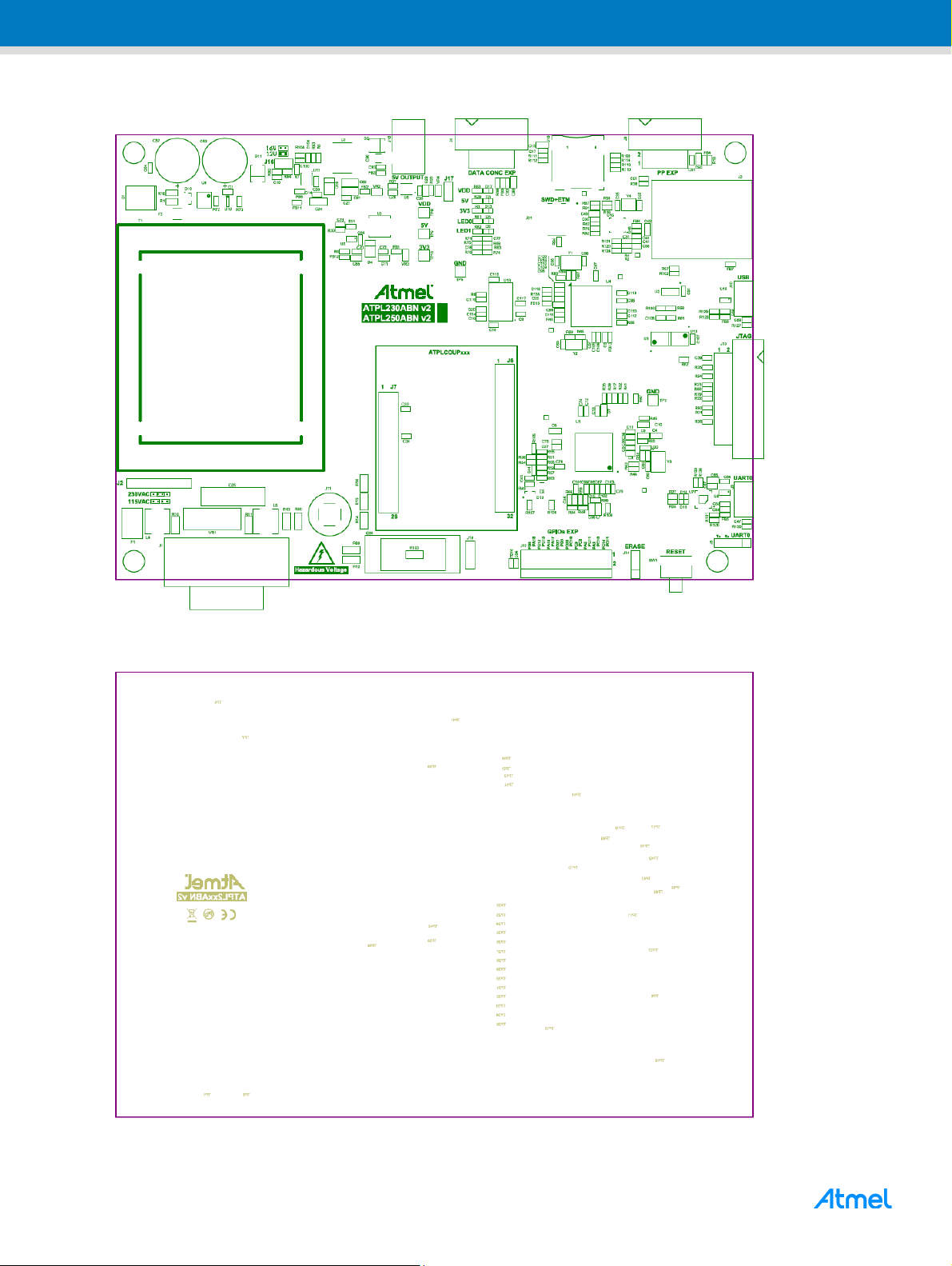

Appendix A Board schemes ......................................................................................... 78

A.1 ATPL250ABNv2 Schemes .................................................................................................................. 78

A.2 ATPLCOUP007v2.5 schemes ............................................................................................................. 85

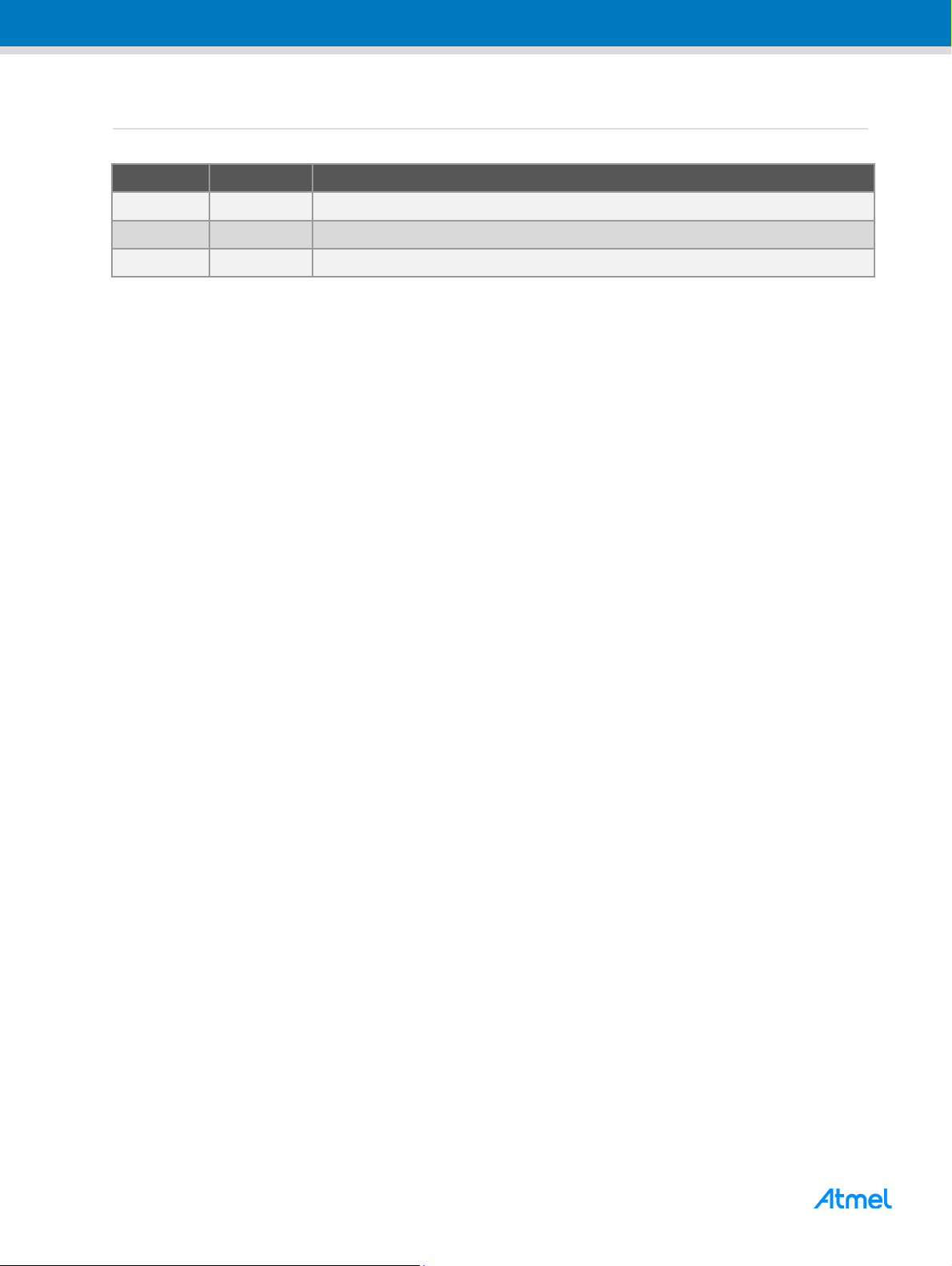

Revision History ................................................................................................................ 88

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

6

6

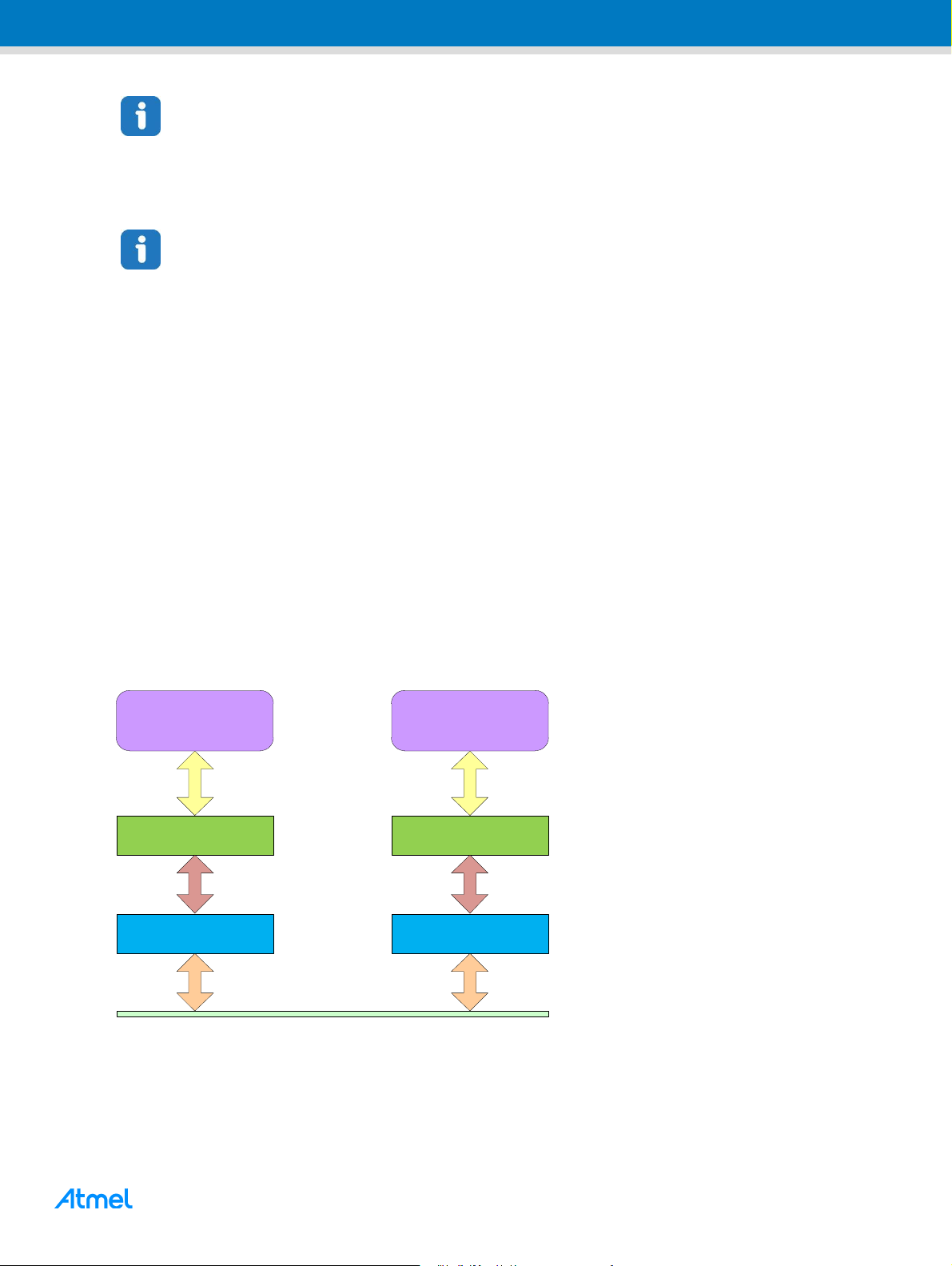

Icon Key Identifiers

Useful Tips and Techniques

Delivers Contextual Information About a Specific Topic

Note to Quality and Performance

Objectives to be Completed

Actions to be Executed Out of the Target

The Expected Result of an Assignment Step

Procedure Which Can Result in Minor Equipment Damage

Procedure With Potential Equipment Damage

Procedure With Imminent Equipment Destruction

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

7

7

A normal use of ATPL250ABN does not require removing the enclosure

cover. If this action is necessary, it must be performed by qualified staff

after being sure that mains connection has been previously removed.

Be careful it is only for indoor use.

Coupling boards’ kits are shipped in a protective anti-static package.

The boards system must not be subjected to high electrostatic

discharge.

We strongly recommend using a grounding strap or similar ESD

protective device when handling the board in hostile ESD

environments (offices with synthetic carpet, for example) without

enclosure. Avoid touching the component pins or any other metallic

element on the board.

ATMEL does not assume responsibility for the consequences arising

from any improper use of this board.

Parameter

Condition

Min.

Typ.

Max.

Unit

AC mains Voltage Range

100

115/230

250

VAC

Mains Frequency

50/60

Hz

Maximum Input Current

200

(1)

mA

Isolation Voltage

ACDC power supply and PLC coupling transformer

3000

VAC

1. Evaluation Kit Specifications

1.1 Safety recommendations

These development boards must be only used by expert technicians. ATPL250ABN is directly powered

from mains grid, so hazardous voltage (100/230VAC) is present on the board. To avoid user access to

dangerous parts, ATPL250ABN must always be used within its enclosure. All required connectors and

configuration jumpers are easily accessible without electrical shock risk.

This development board does not have any switch on mains connection to switch on or off it. It must always

be connected to an easy accessible mains socket.

Do not connect any probe to high voltage sections if the board is not isolated from the mains supply to avoid

damaging of measurement instruments.

ATPL250ABN is a CE mark product which passes EN60950-1 safety standard, EN50065-1, EN50065-2-3,

EN50065-7 EMC and FCC (as current carrier system) standards. It also satisfies Pb-Free and ROHS

directive.

Boards’ kits are intended for further engineering, development, demonstration, or evaluation purposes only.

It is not a finished product except as may be otherwise noted on the board/kit.

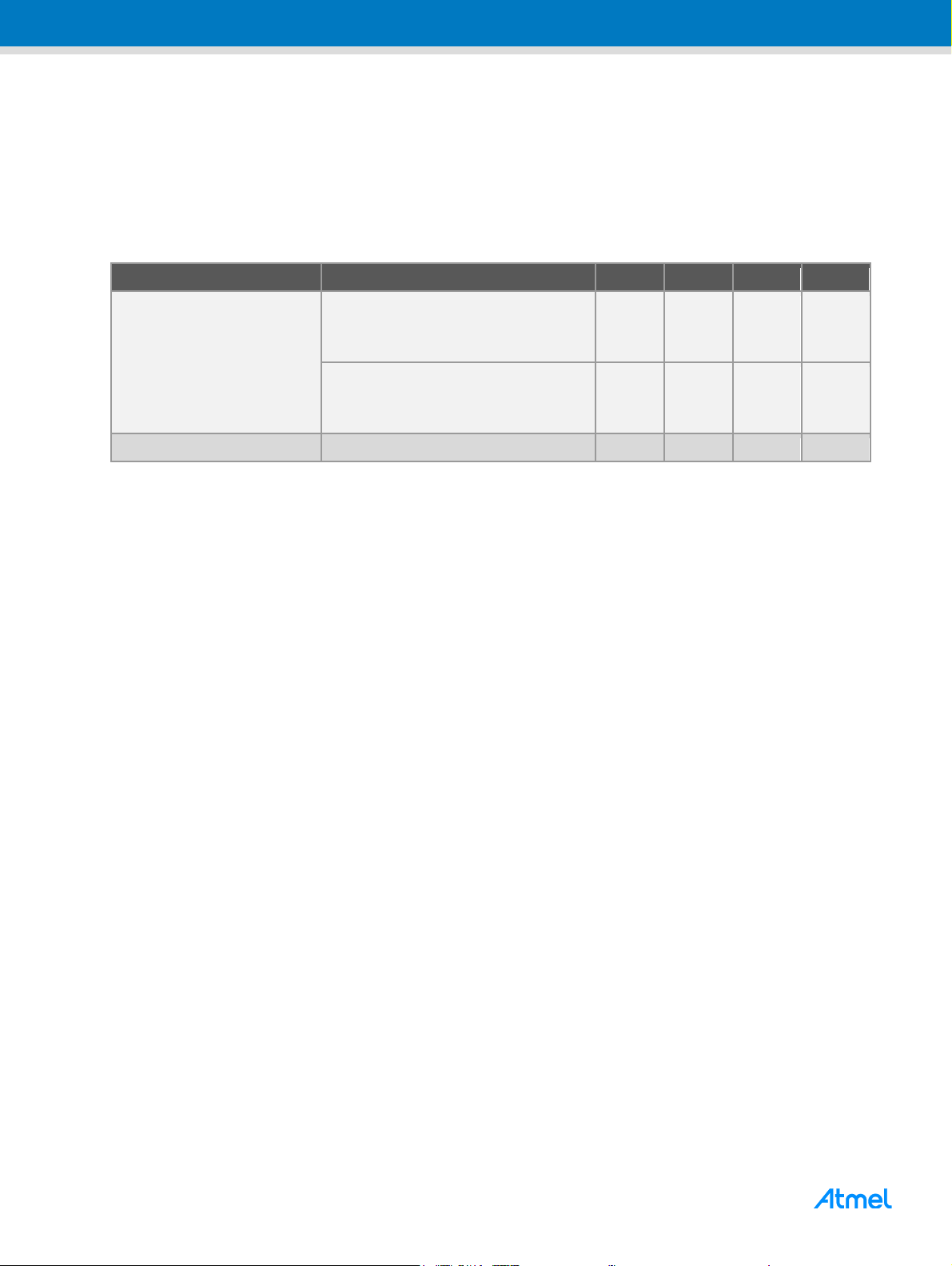

1.2 Electrical characteristics

This section shows the electrical characteristics of the kit’s boards. See the following tables:

Table 1-1. Power Supply Requirements.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

8

8

Parameter

Condition

Min.

Typ.

Max.

Unit

TX Power Consumption

FW: PHY TX Test Console Application

Low Impedance Load (PRIME LISN).

Measured on VDD (16V) DCDC output.

3523

(1)

mW

FW: PHY TX Test Console Application

High Impedance Load (CISPR LISN).

Measured on VDD (16V) DCDC output.

2280

(1)

mW

RX Power Consumption

Measured on 3.3V LDO output

664

(1)

mW

Note that the ATPL250ABN can be supplied either with 100VAC or 230VAC by setting the proper jumpers

(pitch = 5.08mm) in the voltage selector, J2, as depicted in the Figure 7-10. By default, voltage jumper is set

for 230VAC. For more information about power supply, see section 3.5.1.

Note: 1. This maximum input current is measured in the worst case situation, so that, when board is supplied with

a minimum input voltage,100VAC, and the worst consumption conditions. That is when it emits against

very low impedance in higher frequency band and it is supplying an extra board through the DC jack J15.

Table 1-2. Power Supply Requirements.

Note: 1. These measurements were taken with a non-optimized FW (the PHY TX Test Console project included in

the kit with a default configuration in TX mode and RX mode) from a power consumption point of view and

they highly depend on the architecture and efficiency of the power supplies. These measurements

correspond to the whole PCBA design and not only to ATPL250A and ATSAME70 devices. All PCB

peripherals are supplied, i.e. ATPLCOUP007 coupling board emitting in CENELEC-A band. Refer to

Atmel ATPL250A and ATSAME70 datasheets for an optimized power consumption measurement result.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

9

9

2. Evaluation Kit Overview

ATPL250ABN is the name of the development board included in this PAN Coordinator EK. It implements an

ATPL250A analog front end for PLC, supporting G3-PLC, which has been designed to be controlled by an

external Atmel MCU. In this case, Atmel | Smart SAME70 is the device driving ATPL250A PLC analog front

end.

This document describes how to start working with the Atmel PANCoordinator-EK. A complete description

of PC tools, software examples and hardware are provided in this EK.

2.1 Design support

To make it faster and easier for you to evaluate, prototype, develop and program with Atmel products, we

offer a variety of design resources, including development tools, software, boards, kits and documentation.

For any technical support request, please refer to our Design Support webpage:

http://www.atmel.com/design-support/.

There any user can search the Atmel knowledge base to find tips, help topics, and answers to common

questions. In case that the obtained information is not helpful any user can Open a Support Case indicating

a description of the case, product information, etc.

2.2 PANCoordinator-EK contents

PANCoordinator-EK contents –documentation, software and tools- are available online in

https://secure.atmel.com/. To download this information you need a myAtmel account, please access to

www.atmel.com/myAtmel and create your own account After that, please contact with plc@atmel.com,

specifying your myAtmel user name, your company name and email, and request access to the specific

evaluation kit you have acquired. Please do not hesitate to visit our web site to get the last kit updates.

myAtmel EK contents are:

1. A welcome letter, PANCoordinator-EK_WL, introducing the EK and its contents.

2. PANCoordinator-EK Kit User Manual, doc43106.

3. Hardware folder:

a. ATPL250A datasheet, doc43079.

b. Hardware application notes: PLC coupling reference designs, crystal selection guidelines,

layout recommendations, critical design guidelines, etc.

c. EK schemes, PCB layouts, gerbers and BOM files of ATPL250ABN, ATPLCOUP002,

ATPLCOUP006 and ATPLCOUP007 boards.

4. Software folder:

a. G3_va.b.c folder, contains five projects for several IDE tools, IAR, Atmel Studio and Keil

µVision to work in both frequency bands, CENELEC-A, ARIB and FCC bands, see

g3.workspace.same70q21_atpl250abn_v2.zip file:

Apps_Phy_Tester_Tool. This application configures G3-PLC PHY layer and its serial

interface to communicate with Atmel PLC PHY Tester Tool to send and receive PLC

messages from/to the PLC line and check the PLC transmission/reception processes

between ATPL250ABN boards. Atmel PLC PHY Tester tool for PC is available in the

PCTools folder.

Apps_Phy_Tx_Test_Console. This application lets the user to configure a proper set up

to perform both EMC emissions and immunity tests on ATPL250ABN board. These tests

are based on the use of G3 PHY layer with a terminal console firmware that eases the

configuration of several transmission parameters such as modulation, frame data length

and time interval between frames.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

10

We recommend installing the evaluation kit contents in the root C:\ to avoid problems

with very long paths.

The boards must not be subject to high electrostatic discharge. We recommend using a

grounding strap or similar ESD protective device when handling the board in hostile ESD

environments. Avoid touching the components pins or any other metallic elements on the

board.

Apps_Phy_Sniffer_Tool. This application configures G3 PHY layer to monitor the PLC

APPS_DLMS_EMU_COORD_APP. The DLMS Emulator application is an example

APPS_ADP_MAC_SERIALIZED_APP. The ADP and MAC serialization is an application

b. Common software documentation folder. It contains some user guides as the description of the

Atmel G3 firmware stack, doc43081. Document describes in detail all layers from the Atmel G3

implementation as well as configuration options provided, target platforms, default architecture

and the provided solutions by Atmel.

c. Evaluation License Agreement document.

5. PCTools folder:

a. Atmel PLC PHY Tester, PC tool used to monitor point to point PLC transmissions between

Atmel boards.

b. ATPL Multiprotocol Sniffer, PC tool to monitor data traffic in G3-PLC networks using an Atmel

board as sniffer.

c. SAM-ICE™ Drivers. Users may need to install this driver the first time the SAM-ICE is

connected to the PC.

d. USB Drivers (Silicon USB drivers). Users may need to install these drivers the first time the

ATPL250ABN board is connected to the host PC by means of a serial USB connection.

data traffic on ATPL250ABN board and sends via serial communication this traffic to the

ATPL Multiprotocol Sniffer tool. This tool can be downloaded from the PCTools folder.

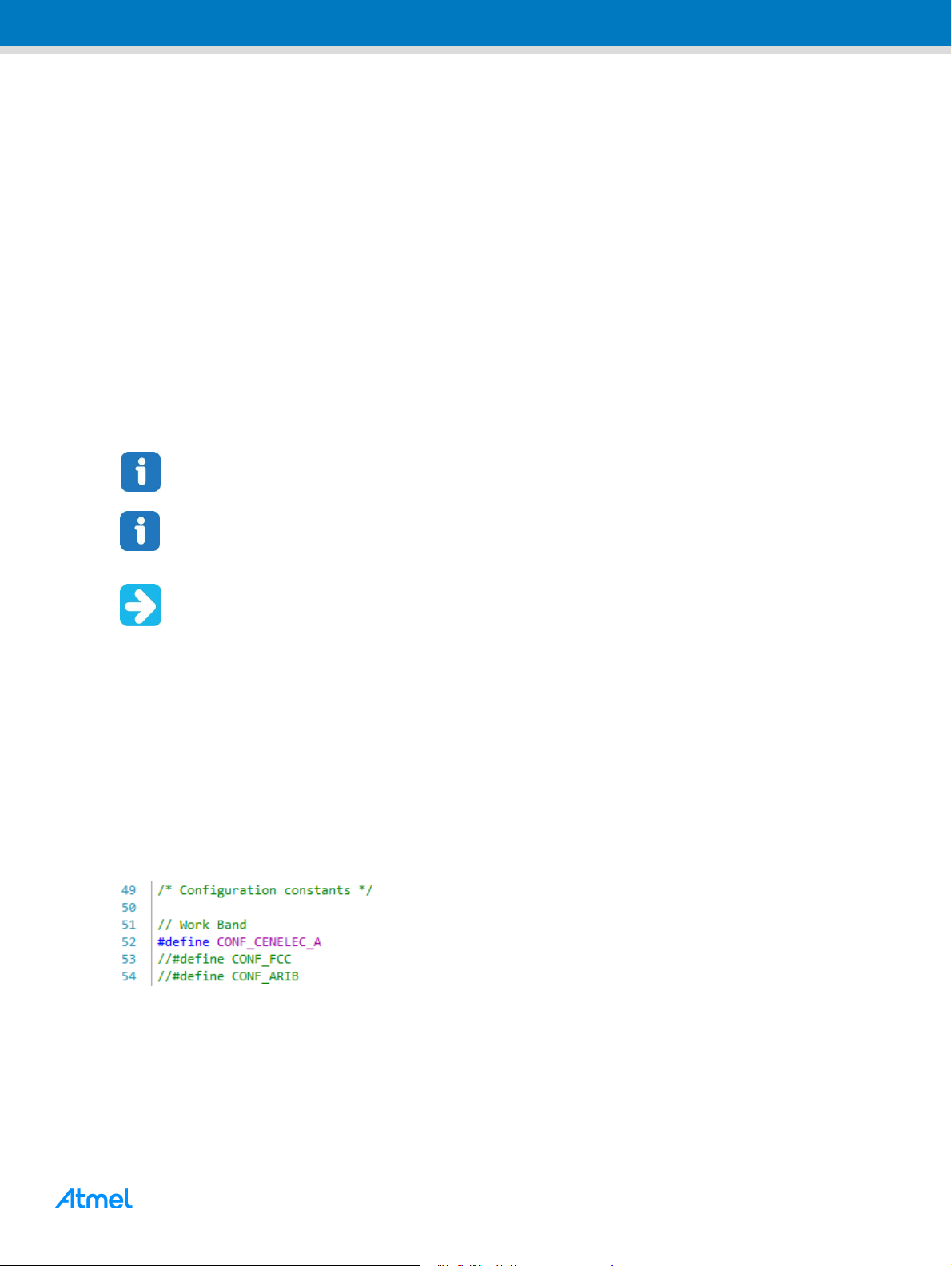

Every coupling board is intended to be used in their corresponding frequency bands only.

By default, sniffer project is compiled for ATPLCOUP007 board. This means that only G3

CENELEC band-A is supported.

using the Atmel G3-PLC stack and show how the G3 API should be used. This

application is provided for Coordinator. Application configure the ATPL250ABN board as

G3 Coordinator. A Device node is required, it is configured with DLMS Emulation

capabilities and simulate the data exchange between the G3 Coordinator and the

Device(s). The Device responds dummy DLMS messages after receiving data requests

from the Coordinator.

example that bring you access to the ADP, MAC and Bootstrap API through a serial

connection. This application could be useful for users that want to make intensive test for

the stack or want to run the upper layers in other CPU.

Unpack and inspect the kit carefully. Contact your local Atmel distributor, should you have any issues

concerning the contents of the kit.

The ATPL250ABN board with the ATPLCOUP007 are encapsulated with methacrylate enclosures and

shipped in protective anti-static foam. The two coupling boards, ATPLCOUP002 and ATPLCOUP006, are

shipped in shielded bags.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

11

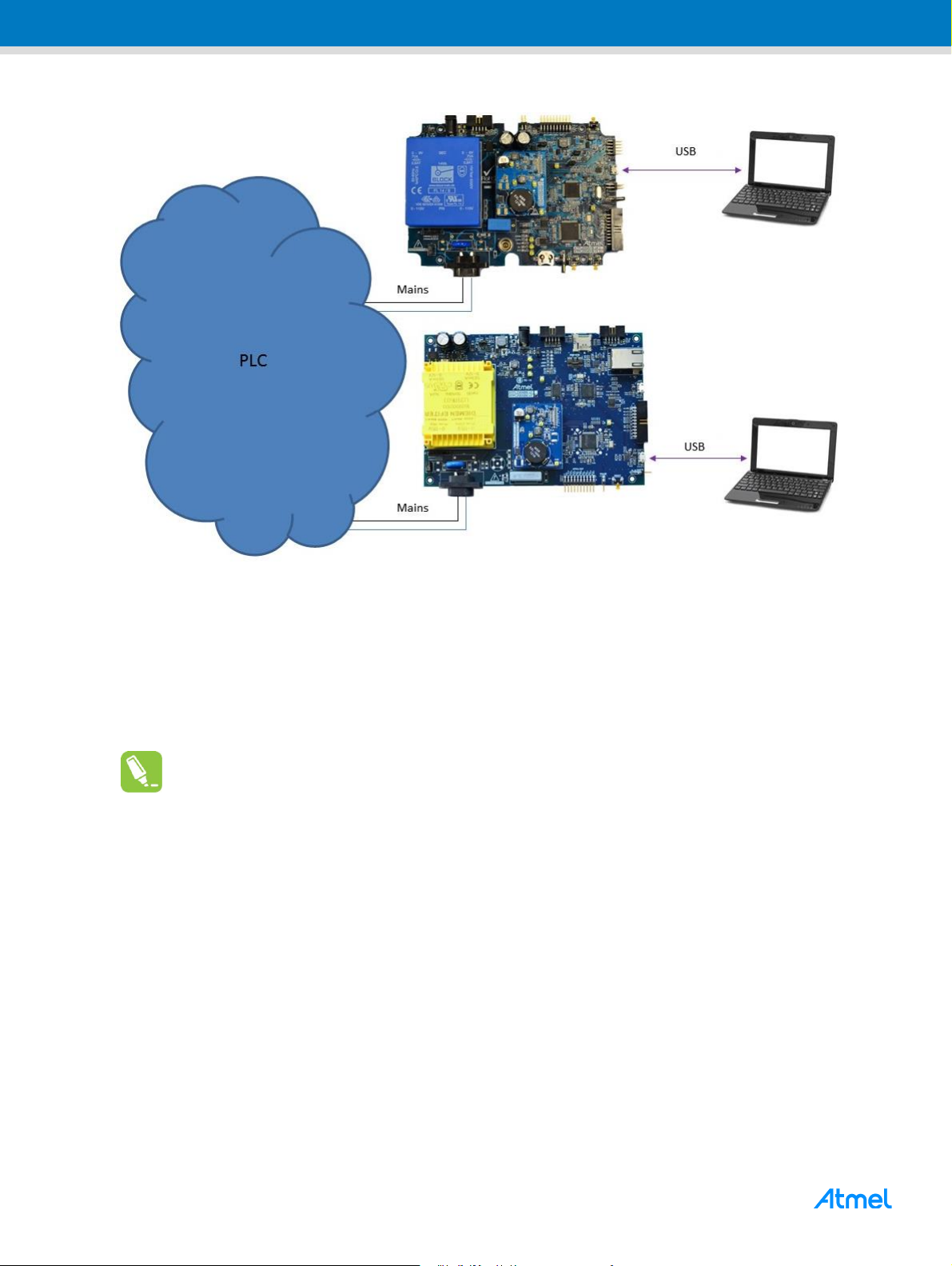

Figure 2-1. Packed Atmel PANCoordinator-EK.

Figure 2-2. ATPL250ABN PAN Coordinator board and with ATPLCOUP007.

ATPL250ABN board is provided with an example application preprogrammed, the G3-PLC PHY Tester

project for SAM4E70Q21. After installing the Atmel PLC PHY Tester PC Tool in your PC, users can

interface with the device and start exploring its capabilities, for example, checking the point to point PLC

transmissions between the two Atmel boards. Please refer to chapter 7.2 for further information.

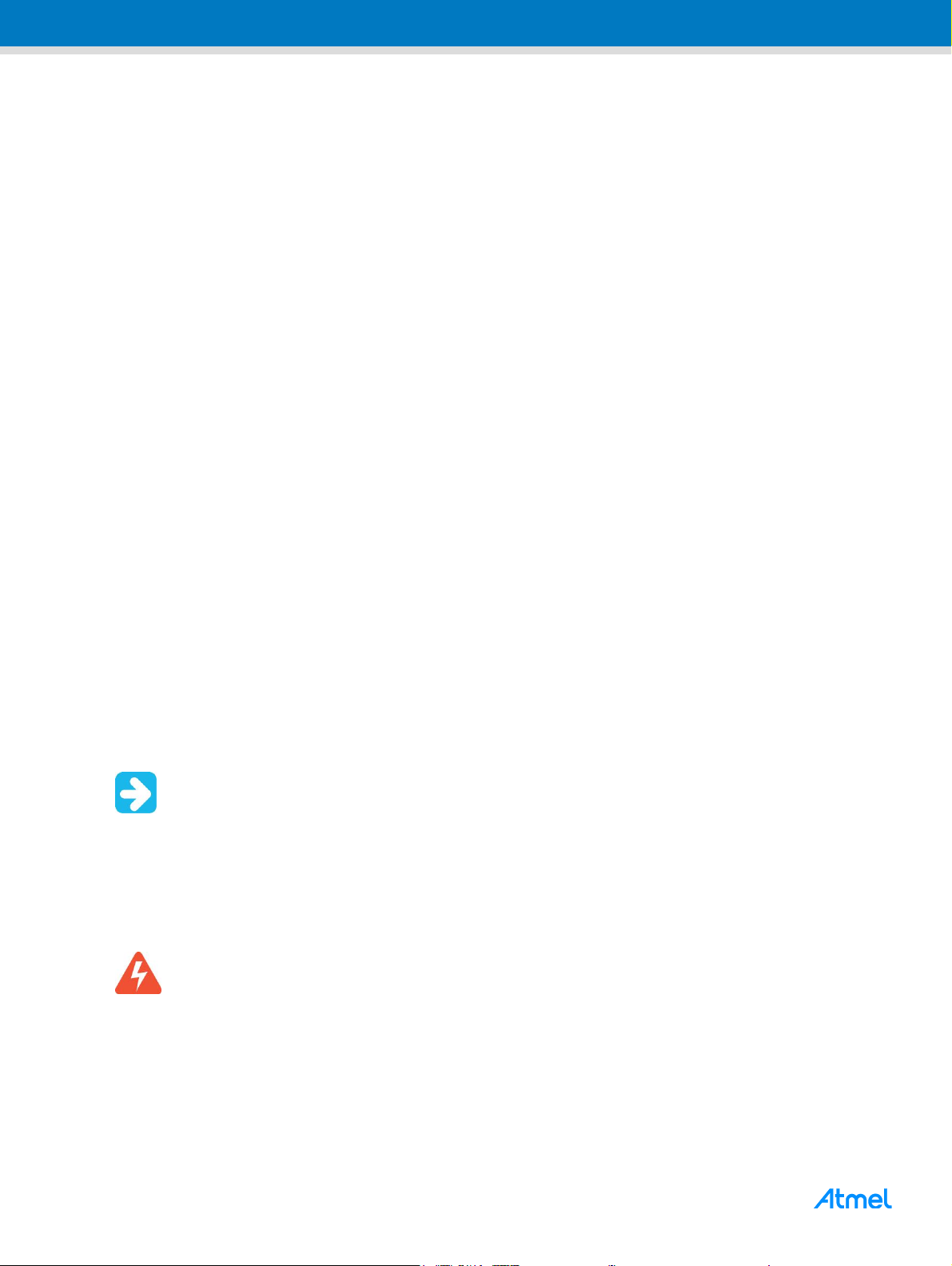

Take into account that the PANCoordinator-EK provides one coupling board for CENELEC-A band, Figure

2-3, set over the ATPL250ABN board. In addition to the ATPLCOUP007 board, evaluation kit adds one

coupling boards for FCC bands, Figure 2-4. And another coupling board for ARIB bands, Figure 2-5.

Depending on the coupling board set in ATPL250ABN board and the PHY configuration parameters

selected in the software project you will send and receive PLC messages in the proper PLC band. So that,

with ATPLCOUP007 board only lets you send and receive PLC messages in CENELEC-A band. And with

ATPLCOUP002 and ATPLCOUP006 board in ARIB or FCC bands respectively.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

12

Figure 2-3. ATPLCOUP007 Coupling board.

Figure 2-4. ATPLCOUP002 Coupling board.

Figure 2-5. ATPLCOUP006 Coupling board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

13

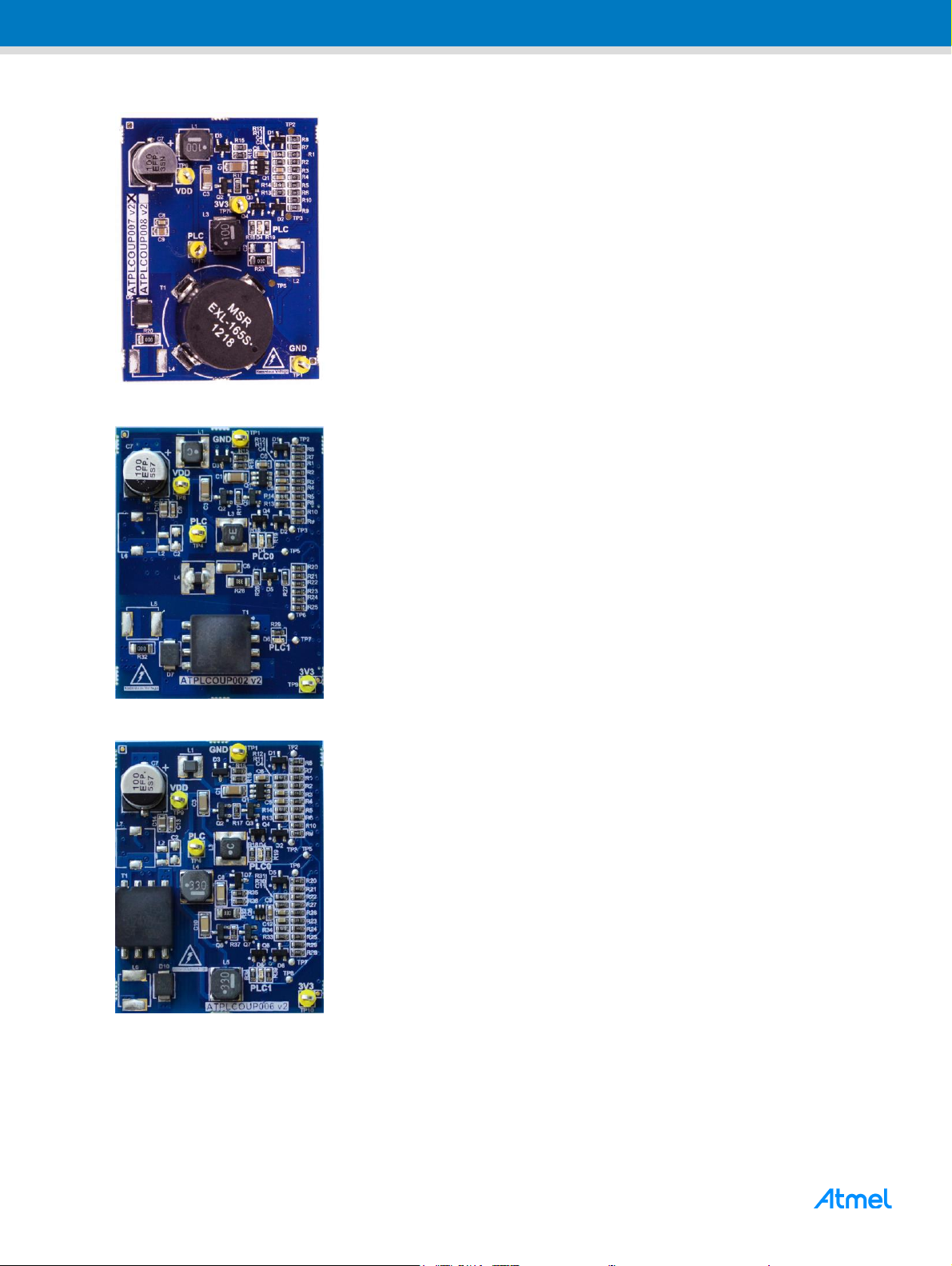

3. ATPL250ABN Hardware

3.1 Overview

This section summarizes the Atmel ATPL250ABN board design. It introduces system-level concepts, such

as power supply, MCU, PLC coupling, memories, peripherals and interface board.

ATPL250ABN is a PAN Coordinator development board based on the ATPL250A, G3-PLC transceiver, and

on the SAME70 ARM Cortex M7 microcontroller. ATPL250ABN PAN Coordinator board provides a platform

to develop a complete communications system over G3-PLC technology.

Figure 3-1. ATPL250ABNv2 PAN Coordinator board.

3.2 Features

The ATPL250ABNv2 board includes the following features:

Power supply:

ATPL250A G3-PLC Transceiver:

– Non switched ACDC isolated power supply: 100-230VAC, 50-60Hz.

– 5 volts rail is accessible by means of a DC Jack connector (J15).

– Selectable 12/16 VDD power supply.

– Implements G3 CENELEC-A, FCC and ARIB profiles (ITU-T G.9903, June 2014).

– Power Line Carrier modem for 50 and 60 Hz mains.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

14

– G3-PLC coherent and continuous amplitude tracking in signal reception.

– Automatic Gain Control (AGC).

– Zero cross detection.

– Embedded PLC Analog Front End (AFE), requires only external discrete high efficient Class D

Line Driver for signal injection.

Support to G3-PLC coupling boards ATPLCOUPxxx.

Mains zero-crossing detector circuit.

SAME70Q21 MCU ARM Cortex-M7:

– Core

ARM Cortex-M7 at up to 300 MHz.

16 Kbytes of ICache and 16 Kbytes of DCache with Error Code Correction (ECC).

Memory Protection Unit (MPU) with 16 zones.

Simple- and double-precision HW Floating Point Unit (FPU).

DSP Instructions, Thumb®-2 Instruction Set.

Embedded Trace Module (ETM) with instruction trace stream, including Trace Port

Interface Unit (TPIU).

– Memories

2048 Kbytes Embedded Flash.

384 Kbytes Embedded SRAM.

Tightly Coupled Memory (TCM) interface with four configurations (disabled, 2 x 32

Kbytes, 2 x 64 Kbytes, and 2 x 128 Kbytes).

16 Kbytes ROM with embedded Boot Loader routines (UART0, USB) and IAP routines.

16-bit Static Memory Controller (SMC) with support for SRAM, PSRAM, NOR and NAND

Flash.

16-bit SDRAM Controller.

– Cryptography

True Random Number Generator (TRNG).

AES: 256-, 192-, 128-bit Key Algorithm, Compliant with FIPS PUB-197 Specifications.

Integrity Check Monitor (ICM). Supports Secure Hash Algorithm SHA1, SHA224 and

SHA256.

External Memories:

– 4Mx16-bit SDRAM.

– 32-Mbit SPI Data Flash.

– TWI EEPROM (do not populate).

– microSD card connector.

Peripherals:

– MCU 24 MHz crystal oscillator.

– MCU 32.768 kHz crystal oscillator.

– VDD and 5V Voltage monitor.

– Reset button.

– User’s LEDs.

– Chip erase.

Interface:

– JTAG debugging port.

– Embedded Trace Module (ETM).

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

15

– High Speed USB 2.0 Device.

– Xplained PRO Master/Slave Interface.

– UARTs over USB and CMOS levels.

– Ethernet 10/100 Mbps.

– Poly-phase Base Node extension header.

– Data Concentrator extension header.

– GPIOs extension header.

Figure 3-2. ATPL250ABNv2 PAN Coordinator board overview.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

16

A normal use of the ATPL250ABN does not require removing the enclosure cover. If this

action is necessary, it must be performed by qualified staff being sure that mains

connection has been previously removed.

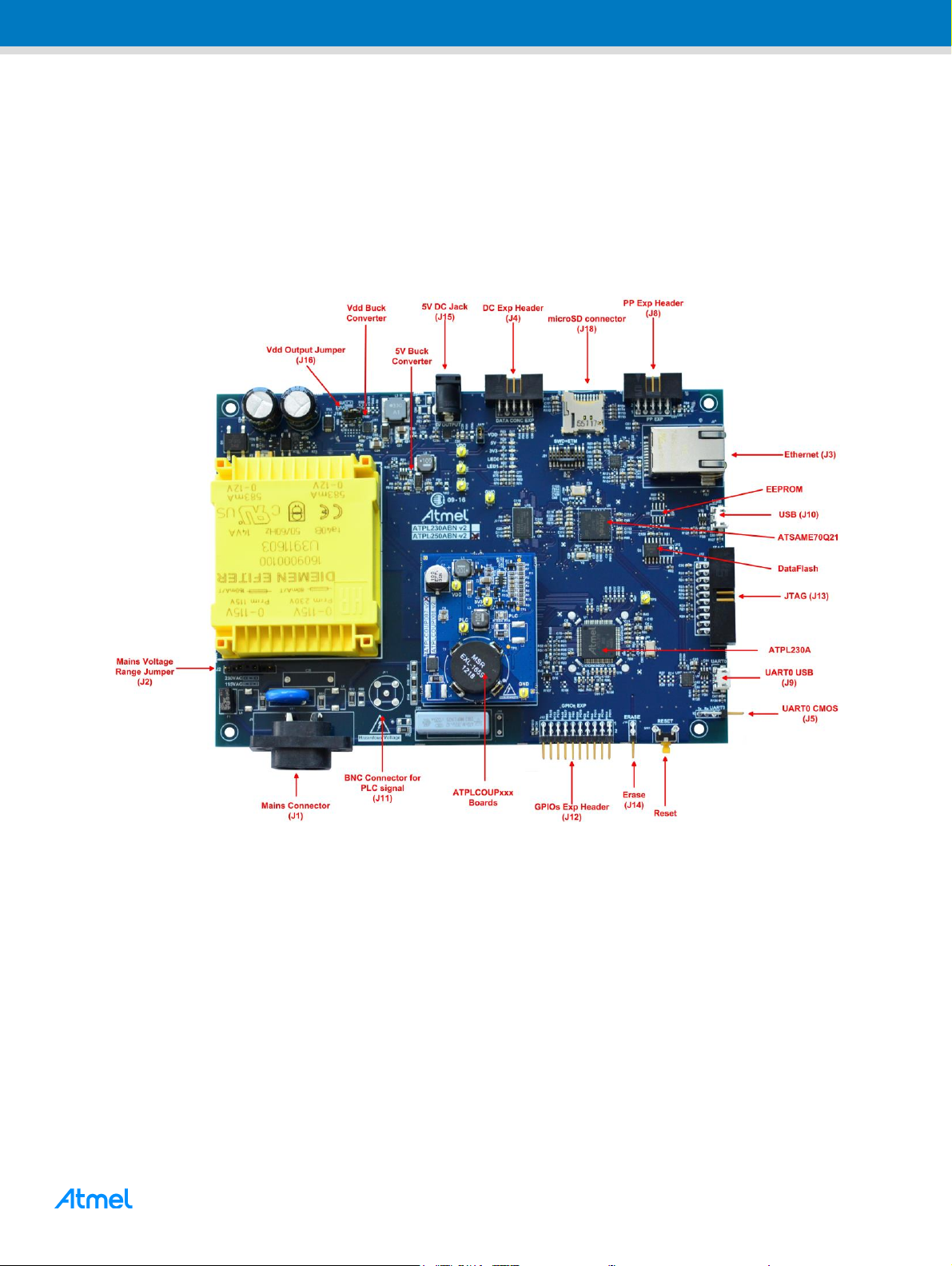

ATSAME70Q21

115/230 VAC

DC/DC

ATPLCOUPxxx Board

MAINS

PLC

RECTIFIER

Zero Crossing

VDD

3V3

2Kb EEPROM

TWI0

SPI + INT

ATPL250A

3V3

User LED’s

Timer Counter Input

PP Exp Header

USART1

USB 2.0 Device

UDP

JTAG / TRACE

JTAG & SWD & TRACE

UARTs CMOS

UART0 & UART1

32Mb SPI

DataFlash

SPI (USART0)

B Micro USB Port

UART

To

USB

24MHz Crystal

RESET

Slow Clock Crystal

12MHz Crystal

Voltage Monitor

10MHz CLK

GPIOs

4Mx16 bit

SDRAM

EBI

AFE

Ethernet

MAC MII

micro SD

Connector

HSMCI

DC Exp Header

UART1

GPIOs Exp Header

GPIOs

3.3 Block diagram

Figure 3-3. ATPL250ABNv2 Block diagram.

3.4 Mechanical and user considerations

This development board is directly powered from mains grid, so hazardous voltage is present on the board.

To avoid user access to dangerous parts, ATPL250ABN must always be used in its enclosure. All required

connectors and configuration jumpers are easily accessible without removing the enclosure cover.

ATPL250ABN is a CE mark product which passes EN60950-1 safety standard and EN50065-1,

EN50065-2-3, EN50065-7 EMC and FCC (as current carrier system) standards. It also satisfies Pb-Free

and ROHS directive.

ATPL250ABN supply voltage is taken from mains grid (100/230VAC, 50-60Hz), J1 connector.

ATPL250ABN dimensions are 178mm x 124mm x 30mm (LxWxH) and the enclosure dimensions are

191mm x 140mm x 48mm (LxWxH).

The operating temperature range is about -10 to 85ºC.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

17

By default, the voltage jumpers’ configuration is for 230VAC. See Figure 7-10.

3.5 Hardware description

In this section the modules of the ATPL250ABNv2 board are described. Take into account that the board’s

BOM; is not a final design, so they include devices that could be no necessary in the customer designs once

the design has been optimized.

Hardware files are contained in the Hardware folder: “.\Hardware\HW_SCH&PCB\ATPL250ABNv2”.

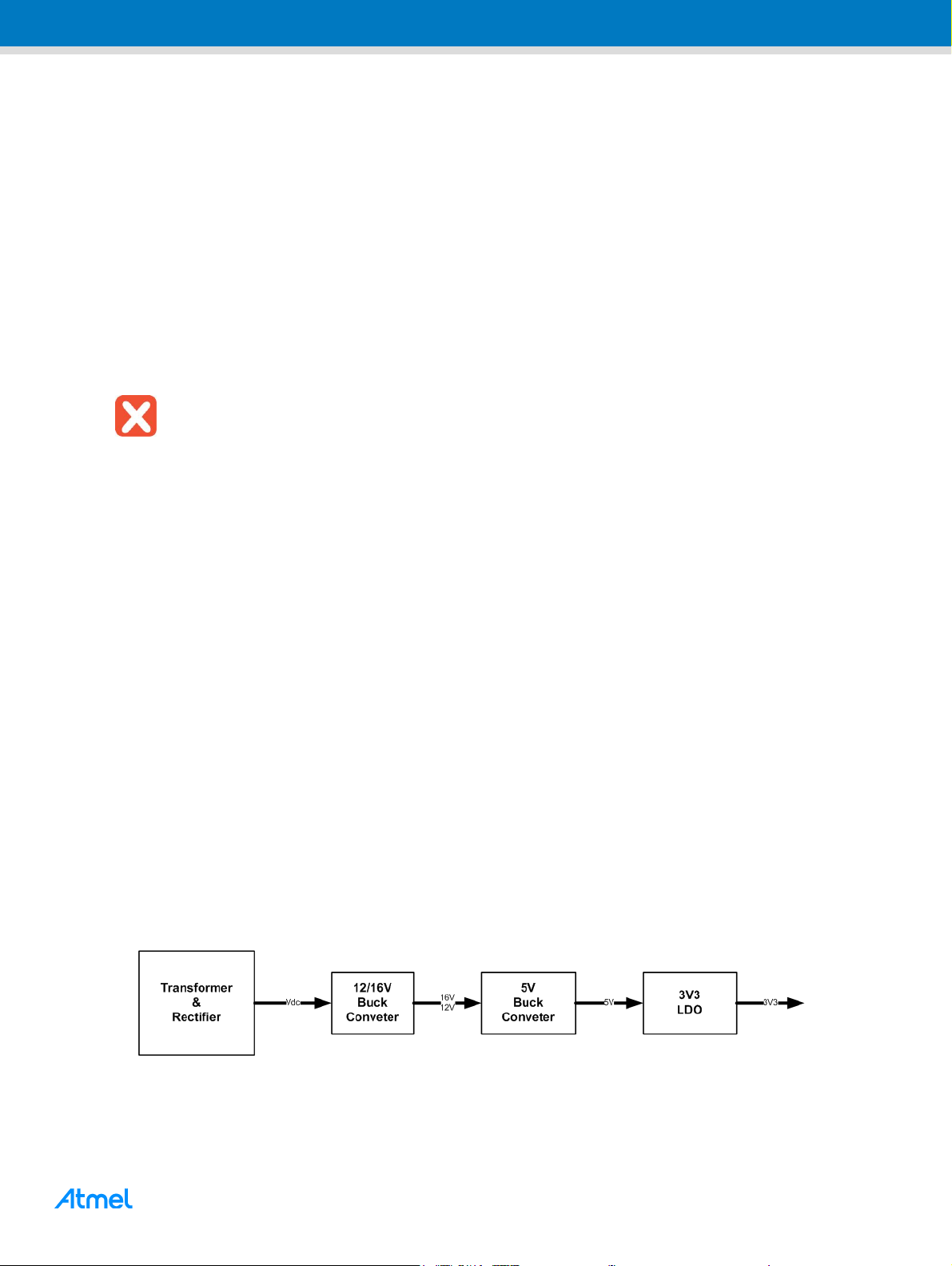

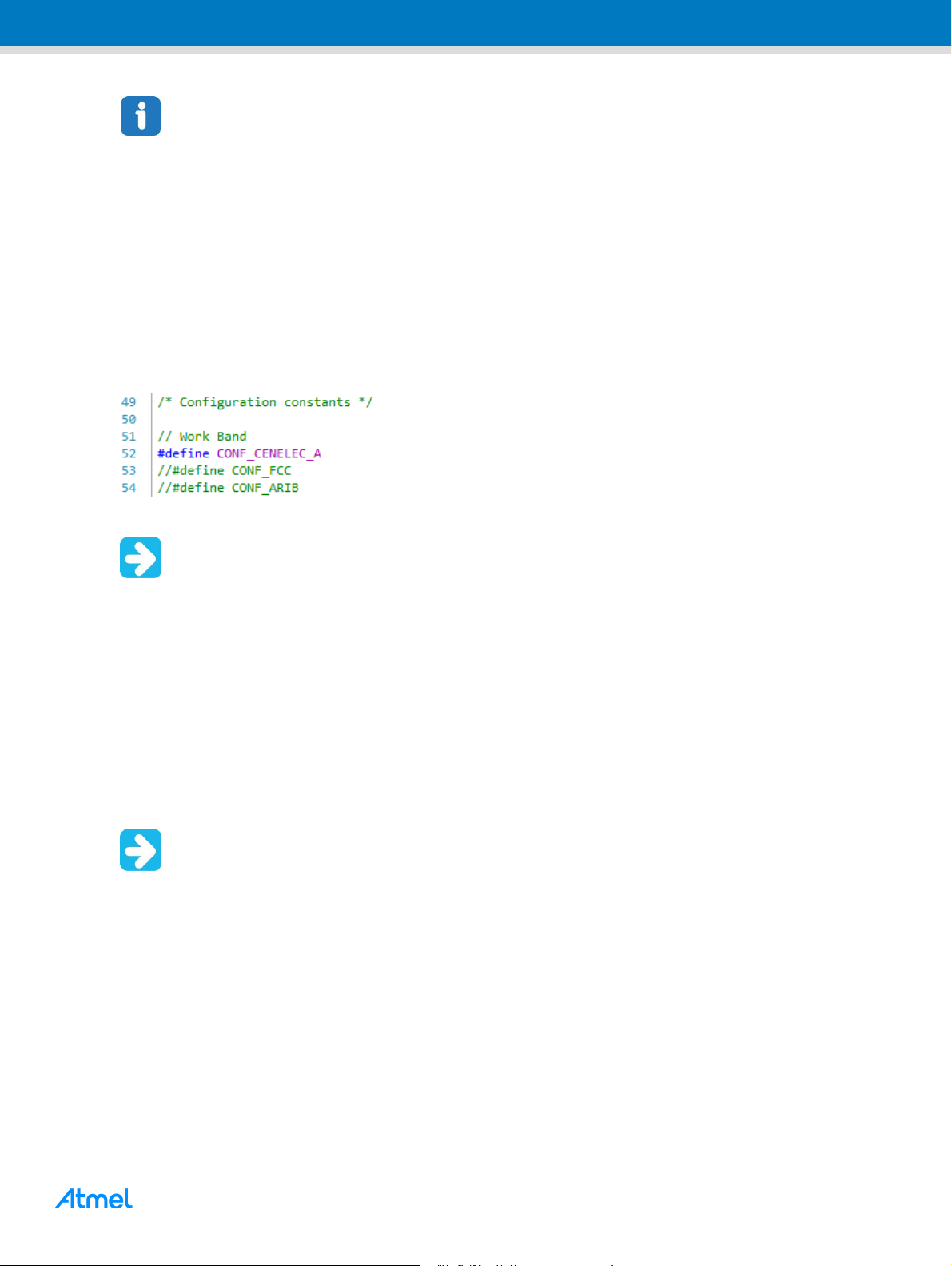

3.5.1 Power supply

ATPL250ABN board can be powered either with 100VAC or 230VAC by setting the proper jumpers in the

voltage selector (J2, Figure A-2). J1 IEC-320-C8 connector allows cable connection to mains grid. This

design uses an encapsulated transformer (T1, Figure A-2) plus a full bridge rectifier (D1, Figure A-2) to

obtain a DC voltage without increasing noise in PLC frequency bands (42 to 472 kHz), as may occur with

switched ACDC power supplies. F1 and VR1 are used as protective devices in the equipment input and F2

protects the transformer output against over current situations.

The maximum transformer output power of 14VA is oversized compared to the maximum current

consumption of ATPL250ABN when it is used as a G3-PLC PAN Coordinator. However, this design is

intended to power up other development kits which may have considerable power consumption if they

include components such TFT displays.

The “V

to generate the regulated DC voltage “VDD”, which is used to power the class D amplifier of the PLC coupling

circuit. The output level of the buck converter is selectable between 12V and 16V by means of jumper J16.

Refer to the application note “PLC Coupling Reference Designs” doc43052 to know how the jumper J16

must be configured depending on the PLC coupling board which is being used.

A second buck converter (U12, Figure A-2) also with switching frequency above the highest PLC frequency

band is used to generate a regulated 5V voltage rail. Despite 5V is not used by any device on ATPL250ABN

board, it may be useful to power other Atmel evaluation kits to form more complex PLC reference designs,

such as data concentrators. The DC Jack connector J15 (J15, Figure A-10) can be used to connect other

board to 5V.

Finally on the power supply chain scheme, a low dropout (LDO) regulator (U13, Figure A-2) is used to

generate the 3V3 voltage rail required by ATPL250A and the MCU. The current consumption from 3V3

voltage rail can be measured connecting an ammeter in the placeholder of jumper J17.

” voltage rail is used as input power of a high switching frequency buck converter (U11, Figure A-2)

DC

Other 1.2V voltage levels are generated by the embedded LDOs on ATPL250A and ATSAME70Q21

respectively. For a more detailed information about these LDOs, refer to ATPL250A and ATSAME70Q21

datasheets.

Figure 3-4. Power supply diagram.

Switching frequency of DCDC buck converters used in this evaluation kit has been chosen to be higher than

maximum PLC frequency band supported by ATPL250A device.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

18

We recommend characterizing the potential impact of the selected SMPS for customer

designs on the G3-PLC frequency band transmission.

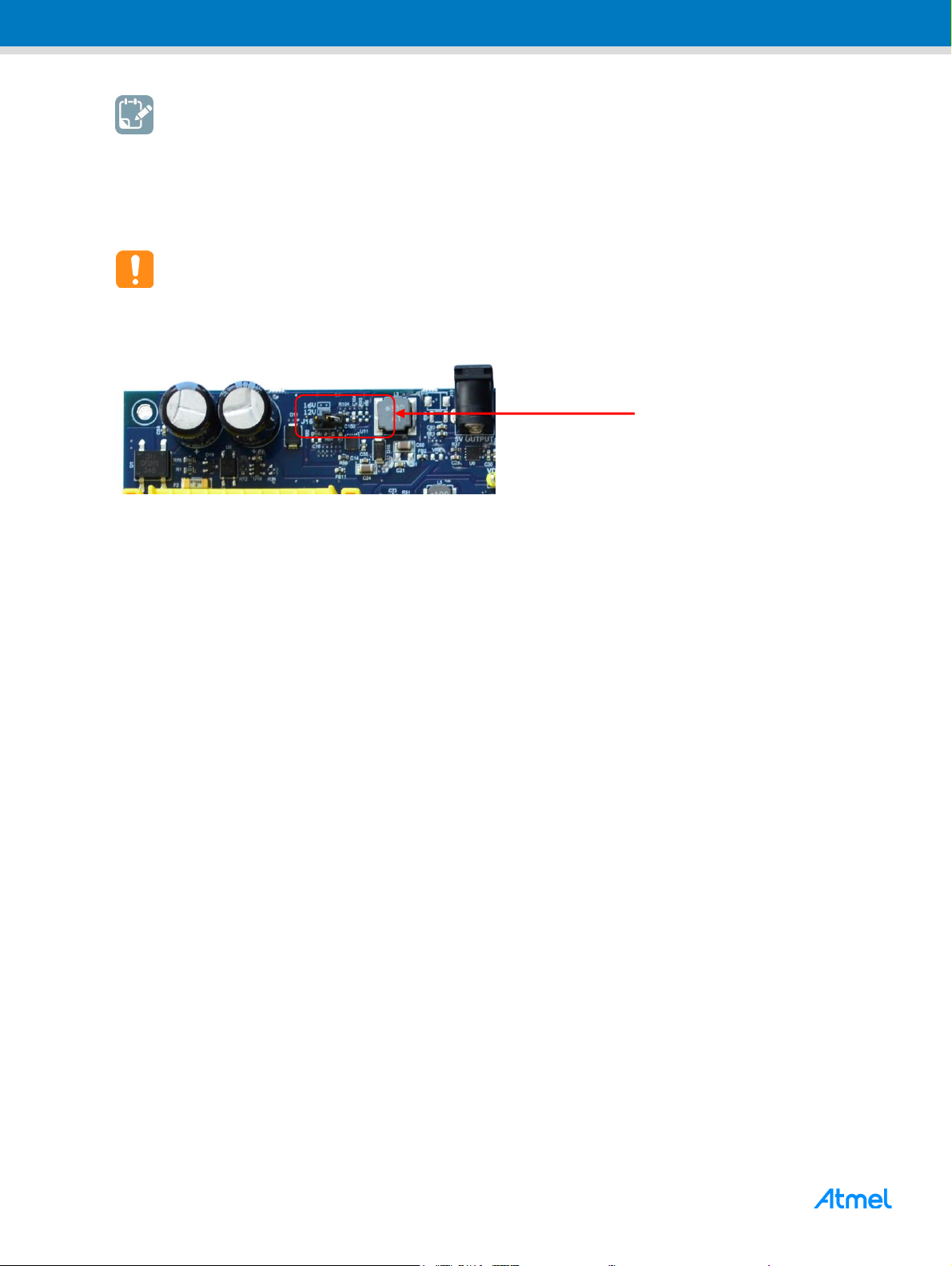

Be careful with the VDD voltage selected, because the PLC coupling driver board

ATPLCOUPXXX could be damaged. Please check the features of these boards to select

the operation voltage.

Jumper

configuration

VDD could be two different voltages, 16 volts or 12 volts, depending on the jumper position. If the jumper is

not placed, the voltage VDD is 16 volts. If the jumper is placed in J16, VDD is 12 volts. By default, the board

has a jumper, so board provides 12 volts. These different voltages are used to supply the PLC coupling

driver board.

Figure 3-5. VDD selection in ATPL250ABN board.

The following test points and LEDs allow to check that these power supplies are operating properly (see

Figure A-2):

VDD: TP6 and green LED D17.

5V: TP5 and green LED D3.

3V3: TP13 and green LED D13.

GND: TP3 & TP4.

3.5.2 Zero crossing detector

Phase identification is an important feature of devices that are connected to a smart grid network, such as

smart meters. A typical implementation is based on measuring the time difference between a specific PLC

frame reception and the last zero crossing event of the mains single-phase to which the device is

connected.

Figure A-2 shows the zero crossing detection circuit, U10, used in ATPL250ABN board, which allows

discerning between rising and falling edges of the mains voltage. The output signal of the detection circuit

“VNR” is connected to a specific input of the ATPL250A and a synchronization algorithm is applied in order

to obtain an accurate measurement of the time between PLC frame reception and zero crossing events.

The “VNR” signal is also connected to a timer counter input pin of the ATSAME70Q21 in order to have also

information about zero crossing events on the microcontroller side.

It is important to note that in products that do not require galvanic isolation between primary and secondary

circuits and the digital reference ground is connected to either line or neutral, a simple zenner diode with

proper current limiting resistors, which considerably reduce the BOM cost, can be used instead of the circuit

mounted in ATPL250ABN.

3.5.3 SAME70Q21 Flash microcontroller

3.5.3.1 SAME70Q21 Overview

The Atmel SAME70Q21 Flash microcontroller is based on the high-performance 32-bit ARM Cortex-M7

RISC processor and includes a floating point unit (FPU). It operates at a maximum speed of 300 MHz and

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

1

19

features 2048 Kbytes of Flash and 384 Kbytes of multiport SRAM, which guarantees a minimum access

latency. The on-chip SRAM can be configured as Tightly Coupled Memory (TCM) or system memory.

The SAME70 offers a rich set of advanced connectivity peripherals including a 10/100 Mbps Ethernet MAC

supporting IEEE 1588, 802.1Qbb, 802.3az, 802.1AS and 802.1Qav. With a simple- and double-precision

HW FPU, advanced analog features, as well as a full set of timing and control functions, the SAME70 is the

ideal solution for industrial automation, home and building control, machine-to-machine communications,

automotive aftermarket and energy management applications.

Furthermore, the peripheral set of SAME70 includes a high-speed USB device port with embedded

transceiver, a high-speed MCI for SDIO/SD/MMC, 16-bit SDRAM interface, 16-bit external bus interface

featuring a static memory controller providing connection to SRAM, PSRAM, NOR Flash, LCD Module and

NAND Flash, 12-bit ITU-R BT.601/656 Image Sensor Interface (ISI), hardware acceleration for AES256,

three USARTs, five UARTs, three TWIs, three SPIs, as well as two 4-channel PWM, four three-channel

16-bit Timers with quadrature decoder logic support, one RTC, Analog Front End interfaces (12-bit ADC,

DAC, MUX and PGA), one 12-bit DAC (2-ch) and an analog comparator.

3.5.3.2 SAME70Q21 Clocking

Besides the embedded RC oscillators of ATSAME70Q21, two crystal oscillators are assembled on

ATPL250ABN board to obtain a more precise and stable system clock reference, Y1 of 12 MHz and Y2,

(Figure A-3). Furthermore, a 24MHz clock signal generated by the PLC transceiver ATPL250A is used by

default as clock input by configuring the high frequency oscillator of ATSAME70Q21 in bypass mode. This

configuration allows reducing the overall BOM cost (12MHz crystal oscillator is not required) while keeping a

stable clock input signal.

A slow clock crystal oscillator of 32.768 kHz (Y2, Figure A-3) is used as SAME70 can be used as calendar

and time base counter.

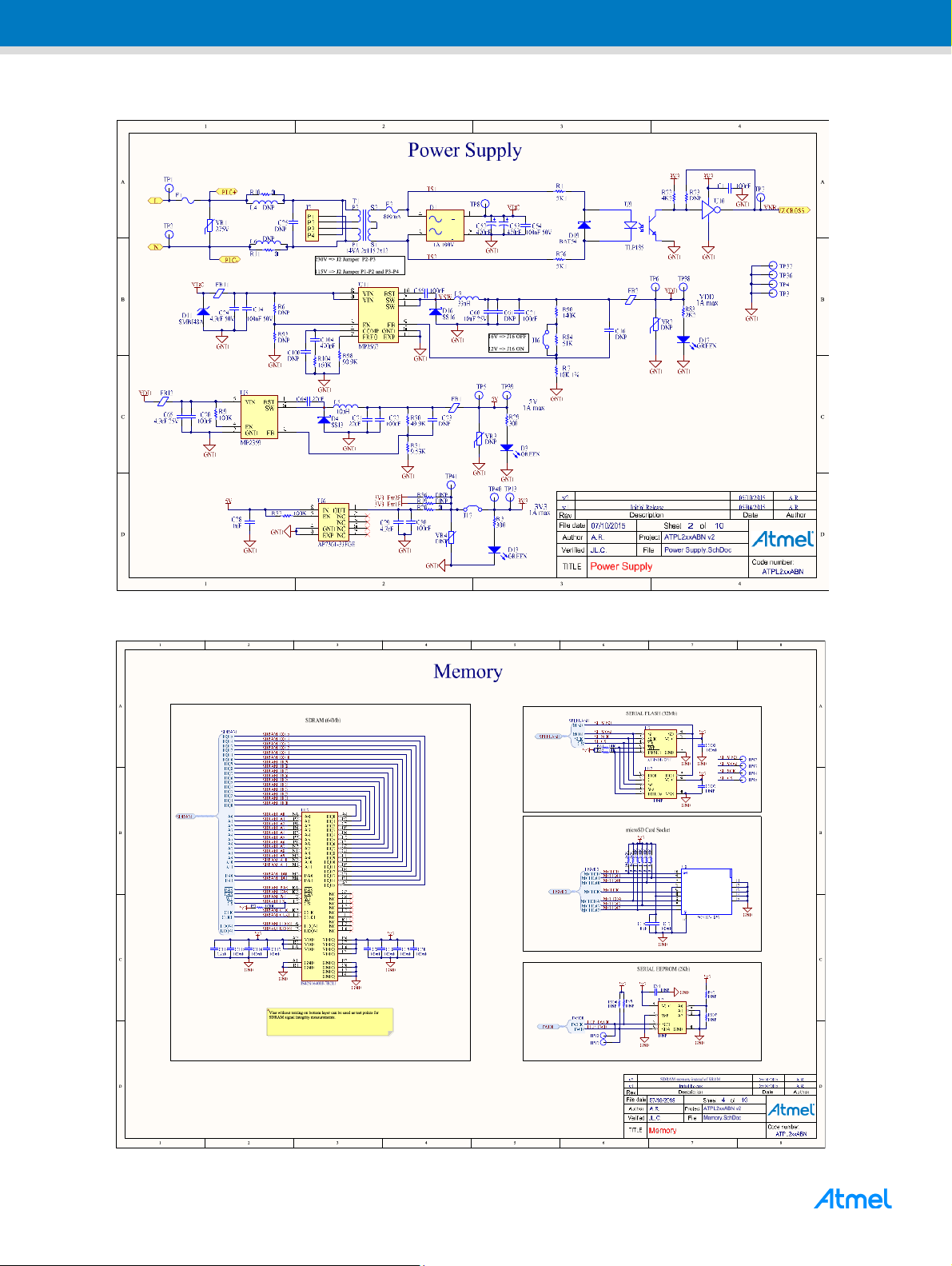

3.5.4 ATPL250A PLC Transceiver

3.5.4.1 ATPL250A Overview

Atmel ATPL250A (U1, Figure A-7) is a power line communications modem, compliant with the PHY layer of

G3-PLC specification. G3-PLC is an open standard technology used for Smart Grid applications like Smart

Metering, Industrial Lighting and Automation, Home Automation, Street Lighting, Solar Energy and PHEV

Charging Stations.

ATPL250A G3-PLC device includes enhanced features such as additional robust modes and frequency

band extension. ATPL250A is able to operate in independently selectable transmission bands up to 472

kHz.

ATPL250A has been conceived to be bundled with an ATMEL MCU running the Physical Layer API and

being controlled by means of a serial synchronous communication interface (SPI).

Please refer to ATPL250A datasheet on the Atmel website or in doc43079 for a detailed description.

3.5.4.2 ATPL250A Clocking

ATPL250A requires a 24MHz crystal oscillator (Y3, Figure A-7). And SAME70Q21 requires a 12 MHz

crystal oscillator (Y1, Figure A-7).

The 24MHz clock signal could be used as internal reference time of the PLC modem, ATPL250A, and also

to generate a 12MHz. So, it could be connected the output clock signal (CLKOUT) of ATPL250A like an

input clock (CLKIN) of SAME70Q21 when ATPL250A is configured in bypass mode. In this way, only one

high frequency crystal oscillator is required. For this option that is mounted by default in the board, R85 is

soldered but R67 and R68 are not populated, and remember that ATPL250A must be configured properly.

Clocking item is widely detailed in the datasheet, doc43079.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

20

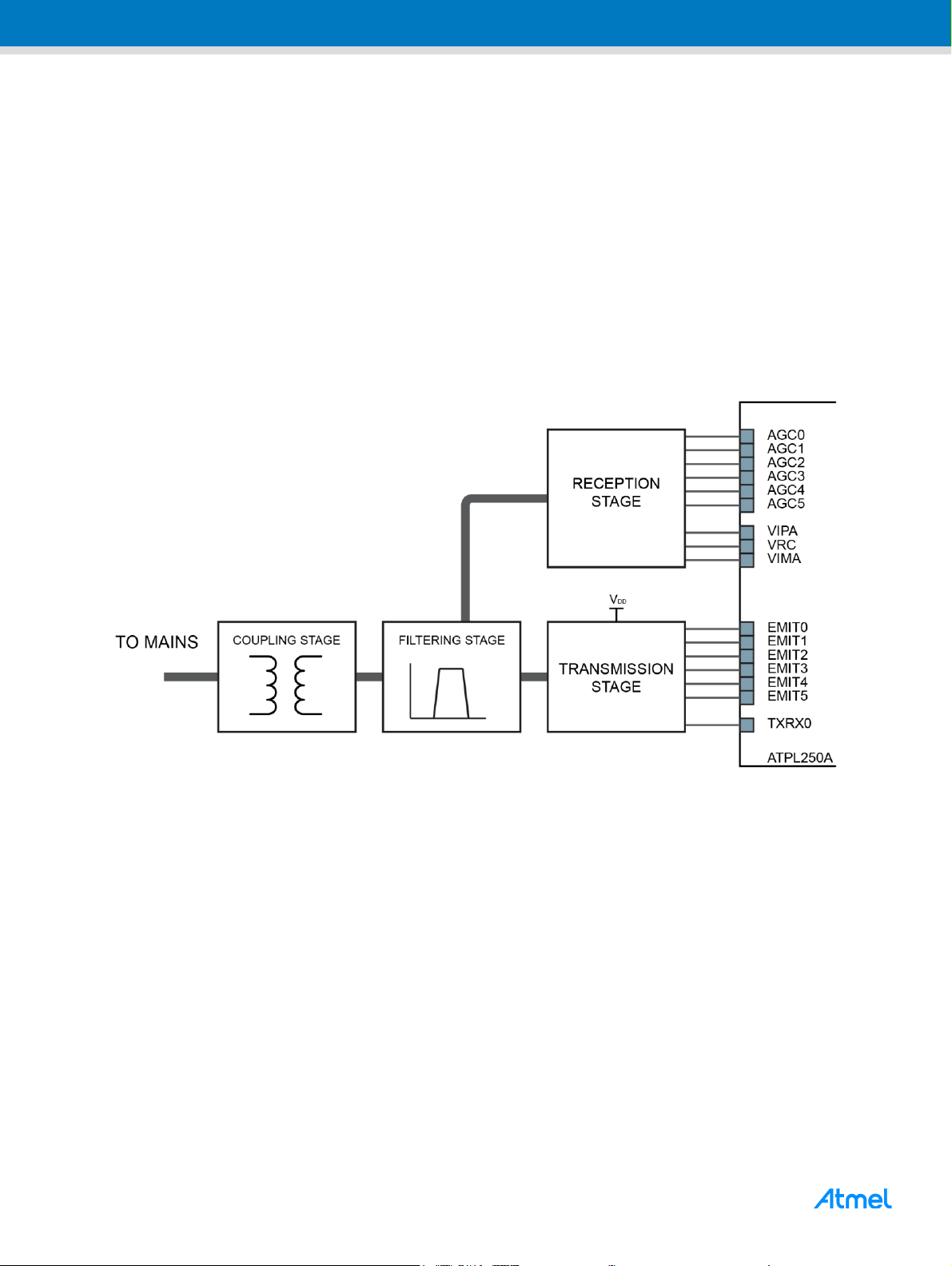

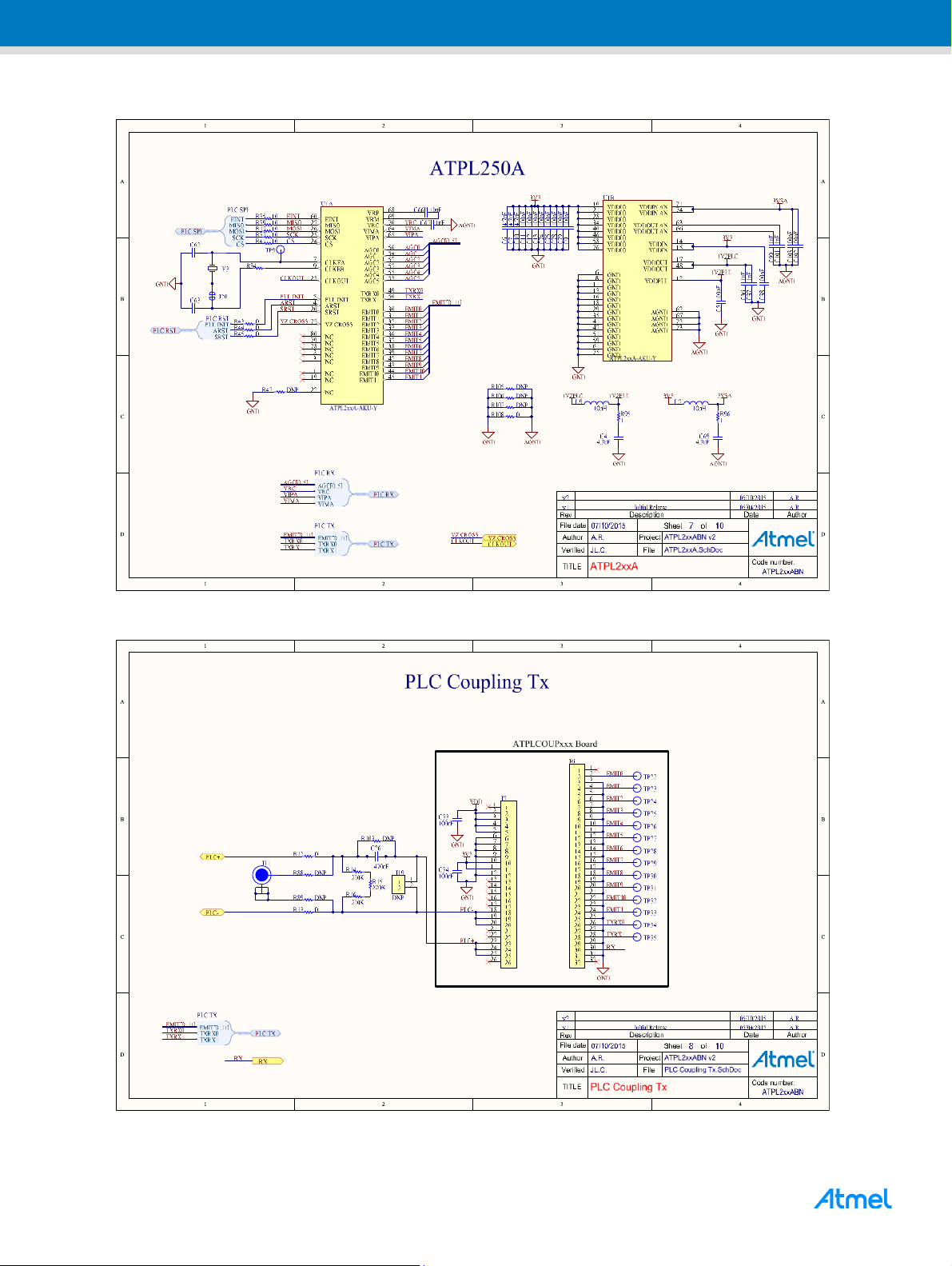

3.5.5 PLC Coupling

Atmel PLC technology is purely digital and does not require external DAC/ADC, thus simplifying the external

required circuitry. Generally Atmel PLC coupling reference designs make use of few passive components

plus a Class D amplification stage for transmission.

Figure A-8 and Figure A-9 show external components required by ATPL250A for PLC reception and

transmission respectively.

PLC coupling reference design is composed by the same sub-circuits:

Coupling Stage.

Reception Stage.

Transmission Stage.

Filtering Stage.

Figure 3-6. PLC Coupling example.

3.5.5.1 Coupling stage

The coupling stage blocks the DC component of the line to/from which the signal is injected / received (i.e.:

50/60 Hz of the mains). This is carried out by a high voltage capacitor (C26, Figure A-8). Coupling stage

could also voltage isolate the coupling circuitry from the external world by means of a 1:1 PLC transformer.

Capacitor is laying out in ATPL250ABN. The optional PLC transformer is included in ATPLCOUP007 board

(voltage isolated), see section 4.

Footprint of BNC connector (J11, Figure A-8) is included in the board, but is not mounted by default.

Removing the R12 and R13 and soldering R88 and R89 resistors, the PLC coupling signal can be isolated

from the mains grid and that connector allows performing measurements of transmitted and received PLC

signal without side effects (noise) coming from the grid.

3.5.5.2 Reception stage

The reception stage adapts the received analog signal to be properly captured by the internal reception

chain. Reception circuit is independent of the PLC frequency band which is being used. It basically consists

on:

Single-pole low pass filter (RC Filter), R49 & C43, Figure A-9.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

21

Automatic Gain Control (AGC) circuit. The AGC circuit avoids distortion (set of resistors used to

attenuate the incoming PLC signal) on the received signal that may arise when the input signal is high

enough to polarize the protective diodes in direct region (D10, Figure A-9).

Driver of the internal ADC. The driver to the internal ADC comprises a couple of resistors (DC biasing

resistors, R59 and R60) and a couple of capacitors (DC decoupling capacitors, C45 and C46). This

driver provides a DC component and adapts the received signal to be properly converted by the

internal reception chain.

3.5.5.3 Transmission stage

The transmission stage adapts the EMIT signals and amplifies them if required (Figure A-8). It can be

composed by:

Driver: A group of resistors which adapt the EMIT signals to either control the Class-D amplifier or to

be filtered by the next stage.

Amplifier: If required, a Class-D amplifier which generates a square waveform from 0 to VDD is

included.

Bias and protection: A couple of resistors and a couple of Schottky barrier diodes provide a DC

component and provide protection from received disturbances.

Transmission stage shall be always followed by a filtering stage.

3.5.5.4 Filtering stage

The filtering stage is composed by band-pass filters which have been designed to achieve high

performance in field deployments complying at the same time with the proper normative and standards.

The in-band flat response filtering stage does not distort the injected signal, reduces spurious emission to

the limits set by the corresponding regulation and blocks potential interferences from other transmission

frequency bands.

The filtering stage has three aims:

Band-pass filtering of high frequency components of the square waveform generated by the

transmission stage.

Adapt Input/Output impedances for optimal reception/transmissions. This is controlled by TXRX

signals.

And, in some cases, Band-pass filtering for received signals.

When the system is intended to be connected to a physical frequency band with high voltage or which is not

electrically referenced to the same point then the filtering stage must be always followed by a coupling

stage.

These components are not implemented on ATPL250ABN board because are dependent on the application

parameters such frequency band transmission. A set of boards known as ATPLCOUPxxx have been design

by to support multiple transmission options supported by ATPL250A. PANCoordinator-EK includes

ATPLCOUP007, ATPLCOUP002 and ATPLCOUP006 boards which are described in chapters 4, 5 and 6

respectively. Other coupling boards have been designed. The Application Note, doc43052, provides a

complete description of Atmel PLC Coupling Reference Designs available.

3.5.5.5 ATPLCOUP boards

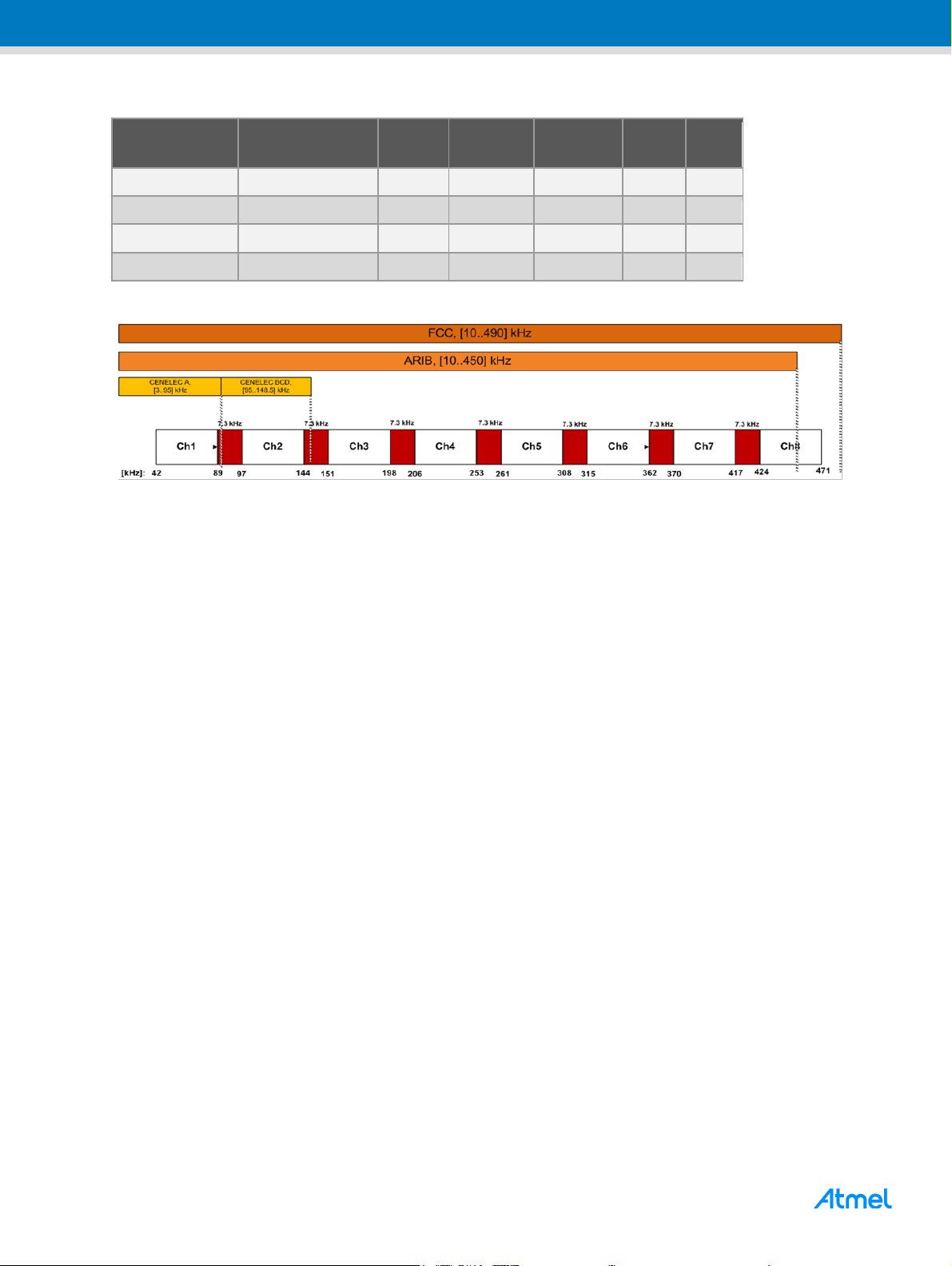

Table 3-1 summarizes the main characteristics of currently available PLC coupling reference designs.

Please refer to Atmel doc43052 for a complete description of ATPLCOUP boards.

This technology only allows one frequency band active at a time.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

22

Board Name

Frequency Band

Branch

Electrical

Isolation

CENELEC

Band

ARIB

FCC

ATPLCOUP002

152-405 kHz

Double

Yes

- X -

ATPLCOUP006

152-489 kHz

Double

Yes - - X ATPLCOUP007

35-91 kHz

Single

Yes A - - ATPLCOUP008

35-91 kHz

Single

No A -

-

Table 3-1. ATPLCOUP boards.

Figure 3-7. FCC & ARIB bands.

3.5.6 Peripherals

These peripherals are not necessary to implement a G3-PLC design, they are included to show some

features of the ATPL250A for a customer designs.

3.5.6.1 SDRAM

The amount of data to be managed by a PAN Coordinator device typically exceeds the embedded SRAM

density of ATSAME70Q21 (384kB). To overcome this limitation, an external SDRAM with 4Mx16-bit density

is used in ATPL250ABN to support a big quantity of connected devices.

3.5.6.2 Data Flash

A 4MB SPI serial DataFlash is used to extend the non-volatile memory capability of ATSAME70Q21 (1MB).

Two different packages (U3 and U12, Figure A-4) are used in ATPL250ABN board to support the pinout of

both the Adesto (former Atmel) family of DataFlash memories and standard serial flash products. Since both

packages use the same chip select signal, only one device can be assembled simultaneously.

3.5.6.3 EEPROM

ATPL250ABN board includes the possibility to mount a serial EEPROM memory connected by Two Wires

Interface, TWI, (U2, Figure A-4) with the SAME70. This device is not assembled by default. Please refer to

AT24Cxx datasheet for a further description on Atmel’s website.

3.5.6.4 microSD card connector

The high speed multimedia card interface (HSMCI) peripheral of ATSAME70Q21 supports the SD memory

card specification V2.0. A microSD card connector with card detection switch is used in ATPL250ABN

board. The card detection feature can be implemented by means of a GPIO with interrupt capability.

3.5.6.5 Voltage Monitor

Two ports (PB2 and PD30) of the ATSAME70Q21 analog front end module are used to monitor the VDD and

5V voltage rails through external voltage divisors, as shown in Figure A-3.

The voltage monitor circuit allows the implementation of multiple applications such as:

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

23

Detection of fault conditions.

Detection of low power mode entering conditions.

Detection of wake-up situations.

Measuring of PLC power amplifier voltage value.

The selected ports for the voltage monitor circuit can also be used as input of the analog comparator in

ATSAME70Q21.

3.5.6.6 Reset

Besides the reset conditions managed by the reset controller peripheral of the ATSAME70Q21, such as

power-on-reset and brown-out monitor, two other reset sources are added at PCB level in ATPL250ABN:

User controller reset switch button (SW1).

The “NRST_CONC” signal on the data concentrator expansion connector, which allows resetting the

The input/output “NRST” pin of ATSAME70Q21 is connected to the “PLL_INIT” input reset pin of the

ATPL250A. Therefore, all reset conditions commented above, generate also a complete reset of the PLC

transceiver. It is important to note that a reset event on “PLL_INIT” disables the “CLKOUT” output pin and, in

case the ATSAME70Q21 is using this clock signal as the external clock input in bypass mode, a reset

condition may lead to a loss of master clock on the microcontroller if a proper configuration is not applied by

firmware. The firmware releases provided by Atmel for the base node reference design take this condition

into account.

base node reference design when it is used in data concentrator topologies.

In addition to the complete reset of the PLC transceiver generated by an assertion of the “PLL_INIT” input,

the “ARST” and “SRST” input reset signals allow also resetting the ATPL250A but in each of these cases

without disabling the external clock on “CLKOUT” pin. Therefore, no special configurations have to be

considered on the microcontroller side related to the clock system configuration. “ARST” and “SRST” are

managed by the GPIOs PE1 and PE2 respectively in ATPL250ABN board.

3.5.6.7 Chip Erase

The 1x2 right angle pin-header J14 marked as “ERASE” (see Figure A-3) is connected to the SAME70 chip

erase pin (PB12) and 3V3. This header can be used to erase the ATSAME70Q21 flash memory by placing

a jumper on the header and pressing the reset switch button. After a while, the erase jumper should be

removed and the PCBA must be turn off and turn on by disconnecting and connecting it again to the mains

grid (flash erasing takes only 200ms).

3.5.6.8 User LEDs

The board incorporates two user LEDs (LED0 & LED1), green and red (D5 & D6, Figure A-3), connected to

GPIOs PA21 and PA22 respectively of the SAME70Q21.

3.5.7 Interface Ports

3.5.7.1 ATSAME70Q21 JTAG/SWD Debug Port

The ATSAME70Q21 JTAG/SWD interface is available in a standard 20 pins male right angle header for

debugging and programming purposes.

Please, refer to ATSAME70Q21 datasheet for a more detailed description of the debug port. It is important

to note that JTAG is only available for boundary scan manufacturing test purposes.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

24

3.5.7.2 Embedded Trace Module (ETM)

The Embedded Trace Macrocell (ETM) is a real-time trace module which delivers unrivalled instruction

trace capture in an area far smaller than traditional trace units, enabling the SAME70 MCU to implement full

instruction trace.

The ETM depends on the Trace Port Interface Unit (TPIU) to export data out of the system. The TPIU

features the following pins:

TRACECLK is the data stream synchronization signal

TRACED0-TRACED3

ATPL250ABN implements a CoreSight™ 20, 20-pin, 50-mil keyed connector (pin seven is removed).

Besides the TPIU signals, the CoreSight connector features also a Serial Wire Debug (SWD) interface.

Considering that the TPIU signals of the ATSAME70Q21 are multiplexed with the GMAC Ethernet RMII

interface, it is not possible to use the ETM if the Ethernet port is enabled. Furthermore, if ETM is used, it is

important to keep the Ethernet PHY IC in reset mode (GPIO PD31 must be asserted low) to avoid signal

collisions.

3.5.7.3 High-speed USB Device 2.0

The ATPL250ABN has a micro-USB receptacle connected to the high-speed USB device 2.0 module of

ATSAME70Q21. To be able to detect when a USB host is attached to ATPL250ABN board, a GPIO (PC17)

is used to detect the VBUS voltage on the connector. The 5V voltage rail provided by the USB host is not

used in ATPL250ABN rather than for detection purpose.

3.5.7.4 Debug UART

The UART0 of ATSAME70Q21 is connected to a CP2105 UART to USB 2.0 bridge to ease PC connectivity

for debugging purposes. The firmware projects provided by Atmel to ease the evaluation of the G3

PHY-layer performance are based on serial interface through UART0.

As shown in Figure A-5, the UART to USB bridge CP2105 is powered from the 3.3V LDO on ATPL250ABN

rather than from the 5V voltage rail of the USB connection. Therefore, ATPL250ABN board has to be

connected to mains if the debugging UART is going to be used.

UART0 signals in CMOS levels are also available in the 3-pins right angle header J5.

3.5.7.5 Ethernet

The ATSAME70Q21 has a built in 10/100 Mbps Ethernet IEEE® 802.3 MAC with a RMII interface that

connects to a Micrel KSZ8081RNA PHY-layer transceiver. The Ethernet input and output differential pairs of

the PHY-layer transceiver are directly connected to a RJ45 Ethernet connector with embedded isolating

signal transformers.

Refer to Figure A-6 for a complete view of the Ethernet PHY-layer transceiver design.

3.5.7.6 Poly-Phase Expansion Header

The 10-pin dual row male header J8 contains the USART transmission and reception signals of

ATSAME70Q21 USART1 and two extra GPIOs. This expansion header is intended to cover poly-phase

PLC base node reference designs in combination with other Atmel evaluation boards.

3.5.7.7 Data Concentrator Expansion Header

The 10-pin dual row male header J4 contains the UART transmission and reception signals of

ATSAME70Q21 UART1 and two extra GPIOs. Furthermore, as commented in section 3.5.6.6, a reset input

of ATPL250ABN board is available as well. This expansion header is intended to cover data concentrator

reference designs in combination with other Atmel evaluation boards.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

25

3.5.7.8 GPIOs Expansion Header

The 2.54mm pitch right-angle header J12 offers access to the I/O ports of the microcontroller that are not

used within the ATPL250ABN board. Refer to ATSAME70Q21 datasheet for a description of the peripheral

functionality available of each GPIO.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

26

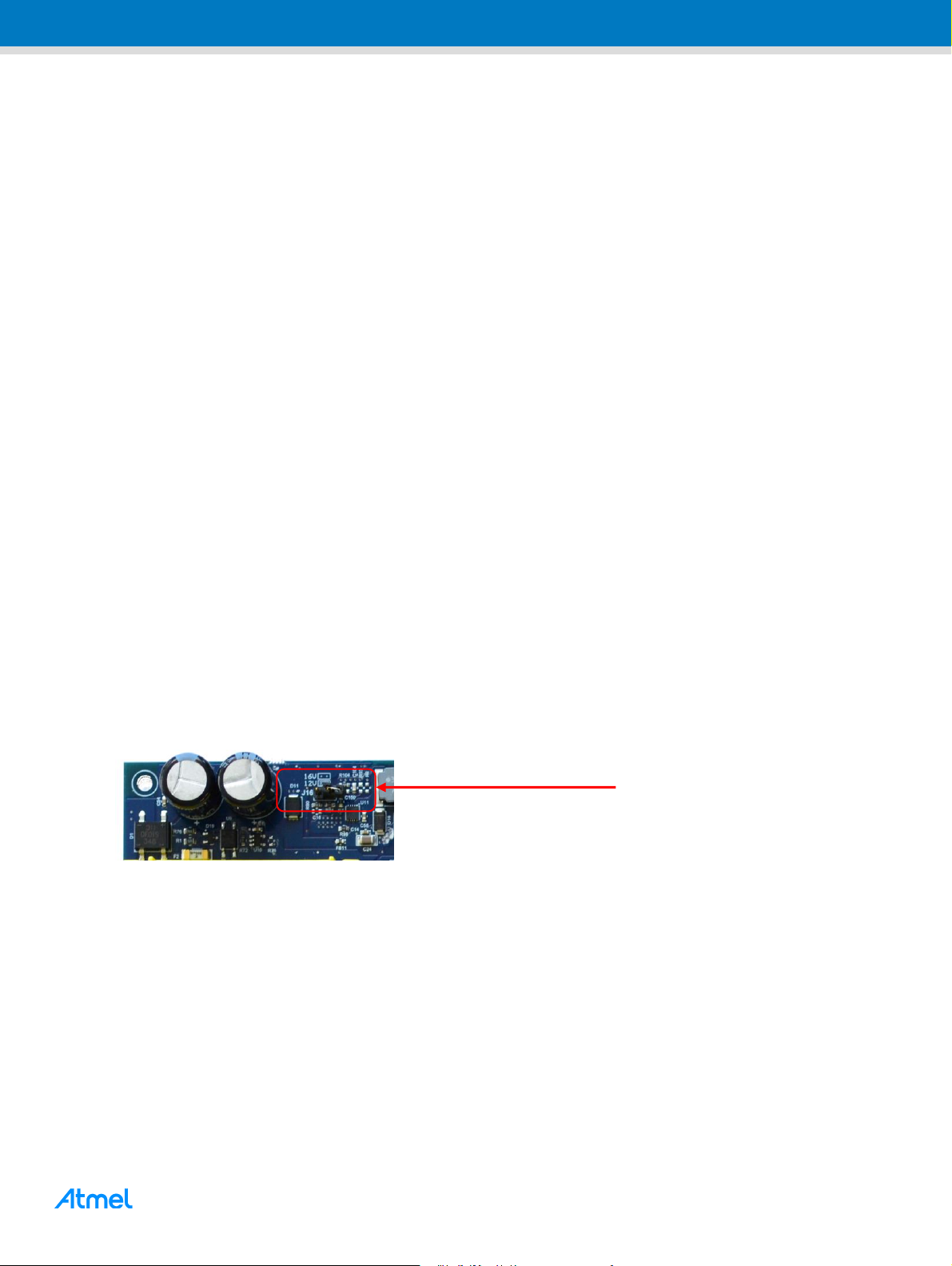

PLC transformer provides

the voltage isolation from

mains.

Test point.

TX led indication.

Test point.

Test point.

Test point.

4. ATPLCOUP007 Hardware

4.1 Overview

ATPLCOUP007 is a PLC coupling board designed to communicate in CENELEC-A band, especially in

G3-PLC band, from 35 to 91 kHz. ATPLCOUP007 mounts a single branch with voltage isolation from mains

to the PLC coupling driver board. The goal of this design is provided to the customers with a cost optimized

performance transmission board in CENELEC-A band for G3-PLC. This board is set by default in the

ATPL250ABN board of the PANCoordinator-EK.

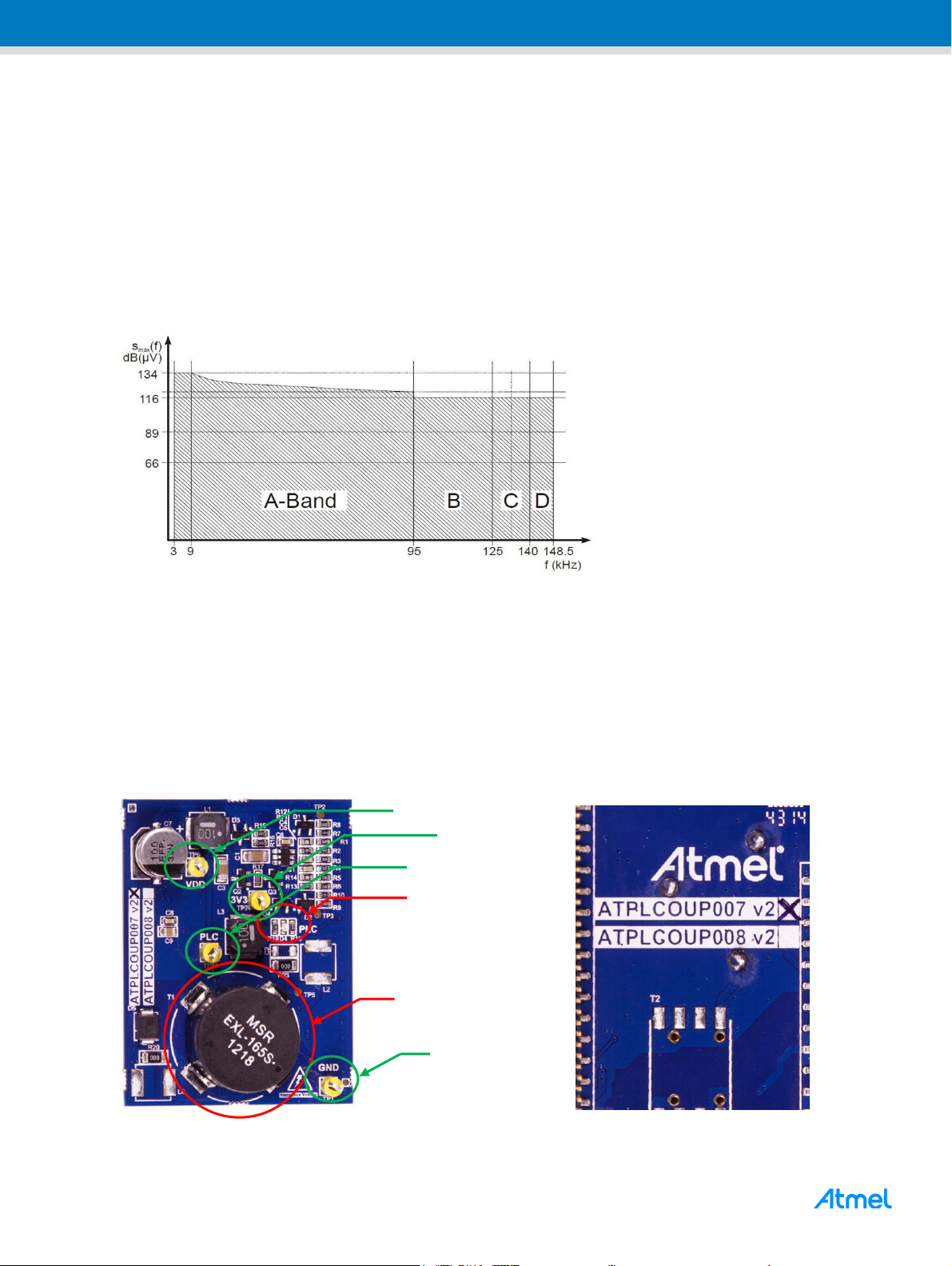

Figure 4-1. CENELEC bands.

4.2 Features

The ATPLCOUP007v2.5 board includes the following features:

Specially designed to communicate in CENELEC-A frequency band (35 – 91 kHz).

Voltage Isolation from mains with a transformer, MSR EXL-165S-LT, soldered in top layer board.

Single branch:

– Low impedance optimized.

Figure 4-2. ATPLCOUP007v2.5 PLC Coupling board (top view).

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

27

Jumper

configuration

4.3 Mechanical and user considerations

ATPLCOUP007 is delivered with the PANCoordinator-EK. Board-to-board SMD connectors, J1 and J2, are

used to connect the ATPLCOUP007 into connectors J6 and J7 of ATPL250ABN board (Figure A-8). These

J1 and J2 connectors are in bottom layer of ATPLCOUP007 and they have the following part numbers:

J1: SAMTEC FTR-130-54-L-S.

J2: SAMTEC FTR-124-54-L-S.

The ATPLCOUP007 board is directly powered from mains grid, so hazardous voltage is present on the

board. To avoid user access to dangerous parts, ATPLCOUP007 must always be used in its enclosure.

ATPLCOUP007 is a CE mark product that passes EN 50065-1, EN 50065-2-3 and EN 50065-7 EMC

standards. It also satisfies Pb-Free and ROHS directive.

ATPLCOUP007 dimensions are 51.5mm x 39.5mm x 18mm (LxWxH).

The operating temperature range is about -40 to 85ºC.

4.4 Hardware description

Hardware files are contained in the Hardware folder: “.\Hardware\HW_SCH&PCB\ATPLCOUP007v2.5”.

ATPLCOUP007 is an isolated reference design which provides a full performance PLC coupling reference

design in terms of output signal level over a wide range of load impedance values while complying with

EN50065-1, EN50065-2-3 and EN50065-7 normative. It supports the frequency band between 35 and 91

kHz of CENELEC-A band.

ATPLCOUP007 is composed of only one transmission branch (single branch) which filtering stage has a flat

band pass response with typical field impedances. It involves a cost optimization in the BOM. For more

information, see PLC coupling reference designs document, doc43052.

Take into account that, when ATPLCOUP007 is connected to ATPL250ABN, VDD voltage must be 12 volts

to avoid damaging the coupling board, so jumper in J16 must be set (see section 3.5.1 and Figure A-2). By

default, the jumper is placed in J16.

Figure 4-3. VDD selection in ATPL250ABN board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

28

Test point.

Test point.

Test point.

Test point.

TX Led indication.

TX Led indication.

PLC transformer provides the

voltage isolation from mains.

5. ATPLCOUP002 Hardware

5.1 Overview

ATPLCOUP002 is a PLC coupling board designed to communicate in ARIB and FCC bands, especially in

bands from 152 to 405 kHz. ATPLCOUP002 mounts a double branch with voltage isolation from mains to

the PLC coupling driver board. The goal of this design is provided to the customers with a full performance

transmission board in ARIB bands. This board is not set by default in the ATPL250ABN board of the

PANCoordinator-EK.

Figure 5-1. FCC and ARIB bands.

5.2 Features

The ATPLCOUP002v2 board includes the following features (see Figure 5-2):

G3 FCC/ARIB bands (152 – 405 kHz).

Double-branch design:

– Low impedance optimized.

– High impedance optimized.

Voltage Isolation from mains with a transformer, VAC T60403K5024X044, soldered in top layer

board.

Figure 5-2. ATPLCOUP002v2 PLC Coupling board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

2

29

Jumper

configuration

5.3 Mechanical and user considerations

ATPLCOUP002 is delivered with the PANCoordinator-EK. Board-to-board SMD connectors, J1 and J2, are

used to connect the ATPLCOUP002 into connectors J6 and J7 of ATPL250ABN board (Figure A-8). These

J1 and J2 connectors are in bottom layer of ATPLCOUP002 and they have the following part numbers:

J1: SAMTEC FTR-130-54-L-S.

J2: SAMTEC FTR-124-54-L-S.

The ATPLCOUP002 board is directly powered from mains grid, so hazardous voltage is present on the

board. To avoid user access to dangerous parts, ATPLCOUP002 must always be used in its enclosure.

ATPLCOUP002 is a CE mark product that passes EN 50065-1, EN 50065-2-3, EN 50065-7 EMC and

STD-T84v1.0 (ARIB) standards. It also satisfies Pb-Free and ROHS directive.

ATPLCOUP002 dimensions are 51.5mm x 39.5mm x 18mm (LxWxH).

The operating temperature range is about -40 to 85ºC.

5.4 Hardware description

Hardware files are contained in the Hardware folder: “.\Hardware\HW_SCH&PCB\ATPLCOUP002v2”.

ATPLCOUP002v2 board is a PLC coupling driver board with double branch design and galvanic voltage

isolation. ATPLCOUP002 has been designed to transmit in ARIB and FCC bands, especially in bands from

260 to 417 kHz.

It has a good performance in terms of transmitted frequency band power over a range of load impedance

values complying with ARIB standard (sections 3.2 and 3.3 of the standard), see ARIB normative.

ATPLCOUP002 is composed of two transmission branches which only differ on the filtering stage. A 12V

power supply voltage for the class-D amplifier is recommended to be used with ATPLCOUP002.

For more information, see PLC coupling reference designs document, doc43052.

Take into account that, when ATPLCOUP002 is connected to ATPL250ABN, VDD voltage must be 12 volts

to avoid damaging the coupling board, so jumper in J20 must be set (see section 3.5.1 and Figure A-2). By

default, the jumper is placed in J16.

Figure 5-3. VDD selection in ATPL250ABN board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

30

TX led indication.

Test point.

Test point.

Test point.

Test point.

PLC transformer provides

the voltage isolation from

mains.

TX led indication.

6. ATPLCOUP006 Hardware

6.1 Overview

ATPLCOUP006 is a PLC coupling board designed to communicate in ARIB and FCC bands, especially in

G3 bands from 152 to 489 kHz. ATPLCOUP006 mounts a double branch with voltage isolation from mains

to the PLC coupling driver board. The goal of this design is provided to the customers with a full performance transmission board in FCC band. This board is not set by default in the ATPL250ABN board of the

PANCoordinator-EK.

Figure 6-1. FCC and ARIB bands.

6.2 Features

The ATPLCOUP006v2 board includes the following features:

Specially designed to communicate in ARIB and FCC frequency bands (152 – 489 kHz).

Voltage Isolation from mains with a transformer, VAC T60403K5024X044, soldered in top layer

board.

Double branch, each one for a range of impedances:

– Low impedance optimized.

– High impedance optimized.

Figure 6-2. ATPLCOUP006v2 PLC coupling board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

31

Jumper

configuration

6.3 Mechanical and user considerations

ATPLCOUP006 is delivered with the PANCoordinator-EK. Board-to-board SMD connectors, J1 and J2, are

used to connect the ATPLCOUP006 into connectors J6 and J7 of ATPL250ABN board (Figure A-8). These

J1 and J2 connectors are in bottom layer of ATPLCOUP006 and they have the following part numbers:

J1: SAMTEC FTR-130-54-L-S.

J2: SAMTEC FTR-124-54-L-S.

The ATPLCOUP006 board is directly powered from mains grid, so hazardous voltage is present on the

board. To avoid user access to dangerous parts, ATPLCOUP006 must always be used in its enclosure.

ATPLCOUP006 is a CE mark product that passes EN 50065-1, EN 50065-2-3, EN 50065-7 EMC and FCC

(as current carrier system) standards. It also satisfies Pb-Free and ROHS directive.

ATPLCOUP006 dimensions are 51.5mm x 39.5mm x 18mm (LxWxH).

The operating temperature range is about -40 to 85ºC.

6.4 Hardware description

Hardware files are contained in the Hardware folder: “.\Hardware\HW_SCH&PCB\ATPLCOUP006v2”.

ATPLCOUP006v2 board is a PLC coupling driver board with double branch design and galvanic voltage

isolation. ATPLCOUP006 has been designed to transmit in ARIB and FCC band, especially in bands from

151 to 472 kHz.

It has a good performance in terms of transmitted frequency band power over a range of load impedance

values complying with FCC standard as current carrier system, see FCC normative. ATPLCOUP006 is

composed of two transmission branches which only differ on the filtering stage. A 12V power supply voltage

for the class-D amplifier is recommended to be used with ATPLCOUP006.

For more information, see PLC coupling reference designs document, doc43052.

Take into account that, when ATPLCOUP006 is connected to ATPL250ABN, VDD voltage must be 12 volts

to avoid damaging the coupling board, so jumper in J20 must be set (see section 3.5.1 and Figure A-2). By

default, the jumper is placed in J16.

Figure 6-3. VDD selection in ATPL250ABN board.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

32

7. PAN Coordinator Evaluation Kit: Getting started

The purpose of this chapter is to provide an introduction to the Atmel PANCoordinator-EK and its

functionalities.

First of all, the software is presented to create, build, program and debug your application using the

appropriate IDE tools (section 7.1).

Chapter 7.2 describes a simple PLC application to check PLC performance in a point-to-point connection

(PHY layer example).

Chapter 7.3 describes the PHY TX Test Console application, which lets you configure a proper setup to

perform both EMC emissions and immunity tests on ATPL250ABN board.

Chapter 7.4 describes the G3 PHY Sniffer project, which, is able to monitor data traffic on the G3-PLC

network.

Chapter 7.5 describes the Atmel G3-PLC Stack and we present you the structure of a G3-PLC project.

Chapter 7.6 explains the setup and operations required to create a smart PLC network using the included

G3 PAN Coordinator example. This network communicates by means of G3-PLC.

Note: The software described in this manual is under the Atmel`s Evaluation License Agreement.pdf

document, available in the Software folder.

7.1 Introduction to the embedded system

The purpose of this section is to guide new users through the initial settings of IAR Embedded Workbench,

Atmel Studio (AS) or Keil µVision, and compile a G3 project. The section shows setup of a G3 project to

generate a debug target that can be loaded into the microcontroller.

Kit projects are supported by IAR 7.70, µVision 5.14 or AS 6.2 versions or above. From this point on, it is

assumed that a working copy of this IDE is installed in your computer. The IAR’s homepage,

http://www.iar.com, is a suitable source to download (i.e.: 30-day time-limited evaluation license). In the

Atmel’s homepage, http://www.atmel.com, is suitable for downloading the Atmel Studio (free download).

Visit http://www.keil.com/ to get a MDK-Lite version.

7.1.1 IAR Embedded Workbench

IAR Embedded Workbench is a high-performance C/C++ compiler assembler, linker, librarian, text editor,

project manager, and C-SPY® Debugger in an integrated development environment for applications based

on 8-, 16-, and 32-bit microcontrollers. IAR Embedded Workbench is compatible with other ARM EABI

compliant compilers and supports the SAM4C core family (example projects are developed only for 7.70

versions or above).

7.1.2 Keil µVision

µVision is a window-based software development platform that combines a robust and modern editor with a

project manager and makes facility tool. It integrates all the tools needed to develop embedded applications

including a C/C++ compiler, macro assembler, linker/locator, and a HEX file generator.

µVision offers a Build Mode for creating applications and a Debug Mode for debugging applications.

Applications can be debugged with the integrated µVision Simulator or directly on hardware.

PLC example projects are developed only for µVision 5.14 versions or above.

7.1.3 Atmel Studio 6

Atmel Studio is the integrated development platform (IDP) for developing and debugging Atmel ARM

Cortex-M and Atmel AVR® microcontroller (MCU) based applications. The Atmel Studio IDP gives you a

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

33

We recommend download and installing the last version of Atmel Studio. You can

download all versions from the following link:

http://www.atmel.com/tools/STUDIOARCHIVE.aspx.

This evaluation kit does not provide an Atmel SAM-ICE.

seamless and easy-to-use environment to write, build and debug your applications written in C/C++ or

assembly code.

Atmel Studio 6 is free of charge and is integrated with the Atmel Software Framework (ASF) — a large

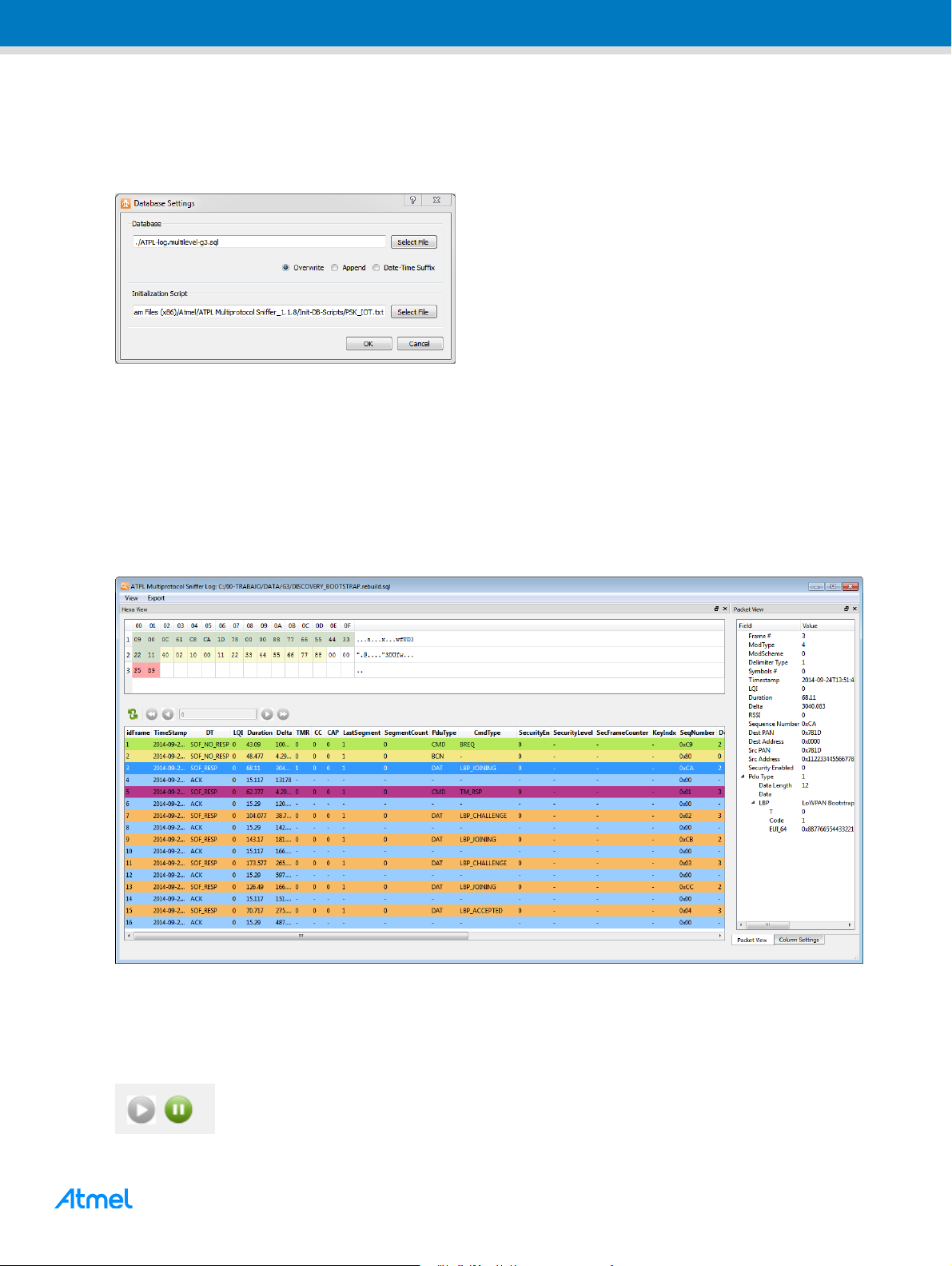

library of free source code with 1,600 ARM and AVR project examples. ASF strengthens the IDP by

providing, in the same environment, access to ready-to-use code that minimizes much of the low-level

design required for projects. Use the IDP for our wide variety of AVR and ARM Cortex-M processor-based

MCUs, including our broadened portfolio of Atmel SAM3 ARM Cortex-M3 and M4 Flash devices.

7.1.4 Atmel SAM-ICE JTAG Probe

Atmel SAM-ICE (a dedicated Atmel J-Link version) is a USB-powered JTAG emulator supporting Atmel

ARM-based microcontrollers.

Atmel SAM-ICE is a JTAG emulator designed for Atmel SAMA5, SAM3, SAM4, SAM7 and SAM9 ARM

core-based microcontrollers, including the Thumb® mode. It supports download speeds up to 720 Kbytes

per second and maximum JTAG speeds up to 12 MHz. It also supports Serial Wire Debug (SWD) and Serial

Wire Viewer (SWV) from SAM-ICE hardware V6.

SAM-ICE support is integrated in most professional integrated development environments (IDEs) such as

IAR, Keil and many others.

More details are available here: http://www.atmel.com/tools/ATMELSAM-ICE.aspx.

Figure 7-1. Atmel SAM-ICE JTAG.

To use Segger tools with Atmel Studio, download Atmel's latest USB driver driver-atmel-bundle-7.0.712.exe

from the following link: https://gallery.atmel.com/Products/Details/07bf16c1-444f-4ac8-8f40-9d4005575dca

or take it from the PCTools folder: “.\PCTools\SAM-ICE_Drivers”. And install the file.

7.1.5 J-Link / SAM-ICE JTAG Probe Software & Documentation Pack

The J-Link / SAM-ICE JTAG software and documentation pack includes:

GDB Server - Support for GDB and other debuggers using the same protocol. GUI & command line

version.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

34

J-Link Configurator - Free utility to manage a various number of J-Links connected to the PC via USB

or Ethernet.

J-Link Commander - Simple command line utility, primarily for diagnostics and trouble shooting.

J-Link Remote Server - Free utility which provides the possibility to use J-Link / J-Trace remotely via

TCP/IP.

SWO Viewer - Free tool which shows terminal output of the target performed via SWO pin.

J-Mem - Memory viewer.

J-Link DLL Updater - Allows updating 3rd party applications which use the J-Link DLL.

Free flash programming utilities - Simple command line utilities which allow programming a bin file

into the internal/external flash memory of popular evaluation boards.

USB driver (Includes driver for J-Links with CDC functionality).

Manuals: UM08001 (J-Link User Guide), UM08003 (J-Flash User Guide), UM08004 (RDI User

Guide), UM08005 (GDB Server User Guide) and UM08007 (Flasher ARM User Guide).

Release notes for J-Link DLL, J-Flash and J-Link RDI DLL.

J-Flash, including sample projects for most popular evaluation boards.

J-Link RDI – Support for ARM RDI standard. Makes J-Link compatible with RDI compliant debuggers.

Installing the software will automatically install the J-Link USB drivers. It also allows the update of

applications that use the J-Link DLL.

The last version of the driver for the SAM-ICE JTAG Probe can be downloaded from the

http://www.segger.com website using the following link: http://www.segger.com/jlink-software.html. The

package for Windows, Setup_JLinkARM_V496b.zip, is located in the following folder: “.\PCTools\SAM-ICE

Driver”.

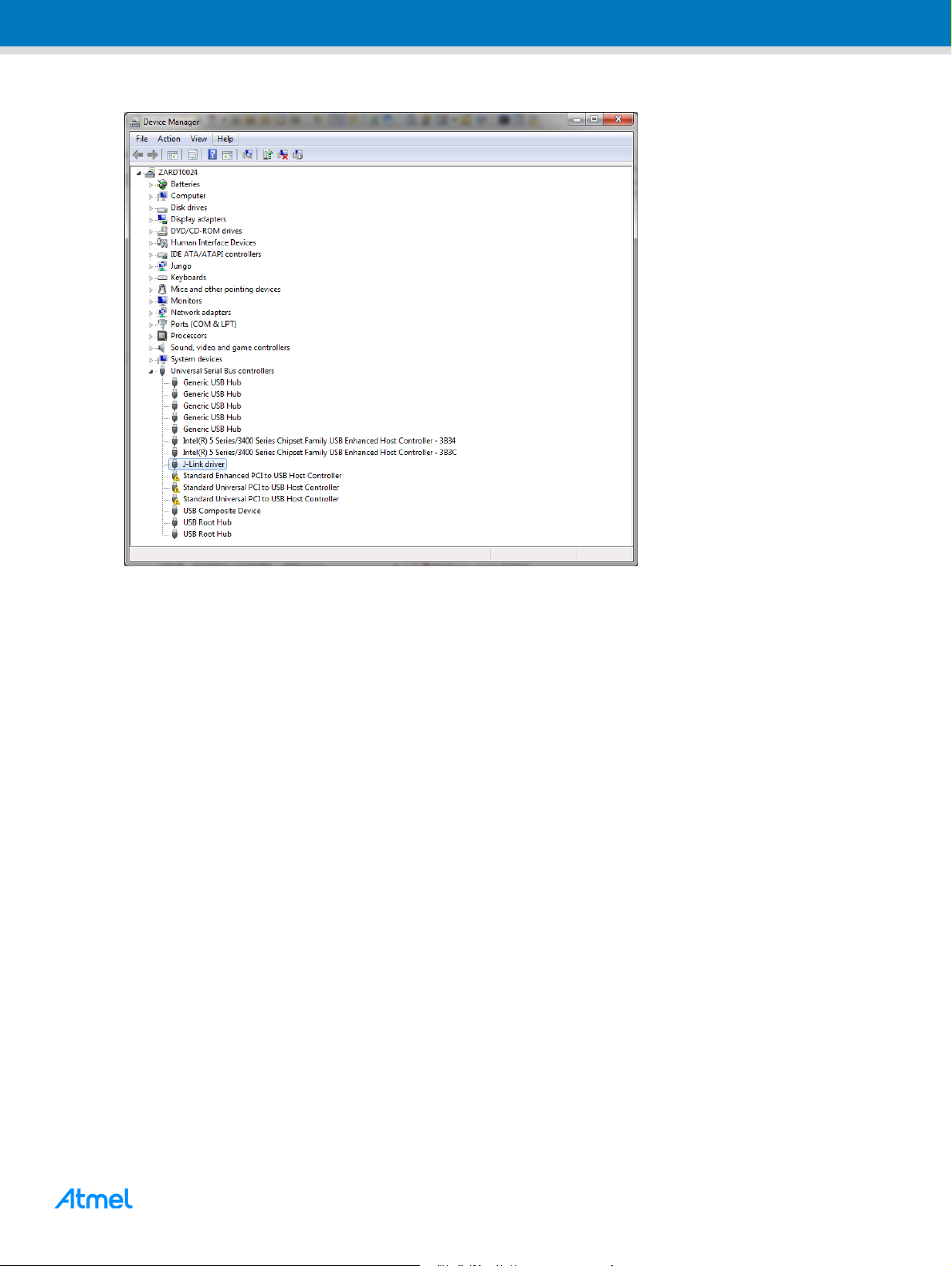

Once drivers have been installed you may verify the driver installation by consulting the Windows

®

device

manager. If the driver is installed and your SAM-ICE is connected to your computer, the device manager

should list the J-Link driver as a node below "Universal Serial Bus controllers" as shown in the following

screenshot.

PANCoordinator-EK Kit User Manual [USER GUIDE]

Atmel-43106C-ATPL- PANCoordinator-EK Kit User Manual-UserGuide_06-Oct-16

3

35

Figure 7-2. Device manager.

1

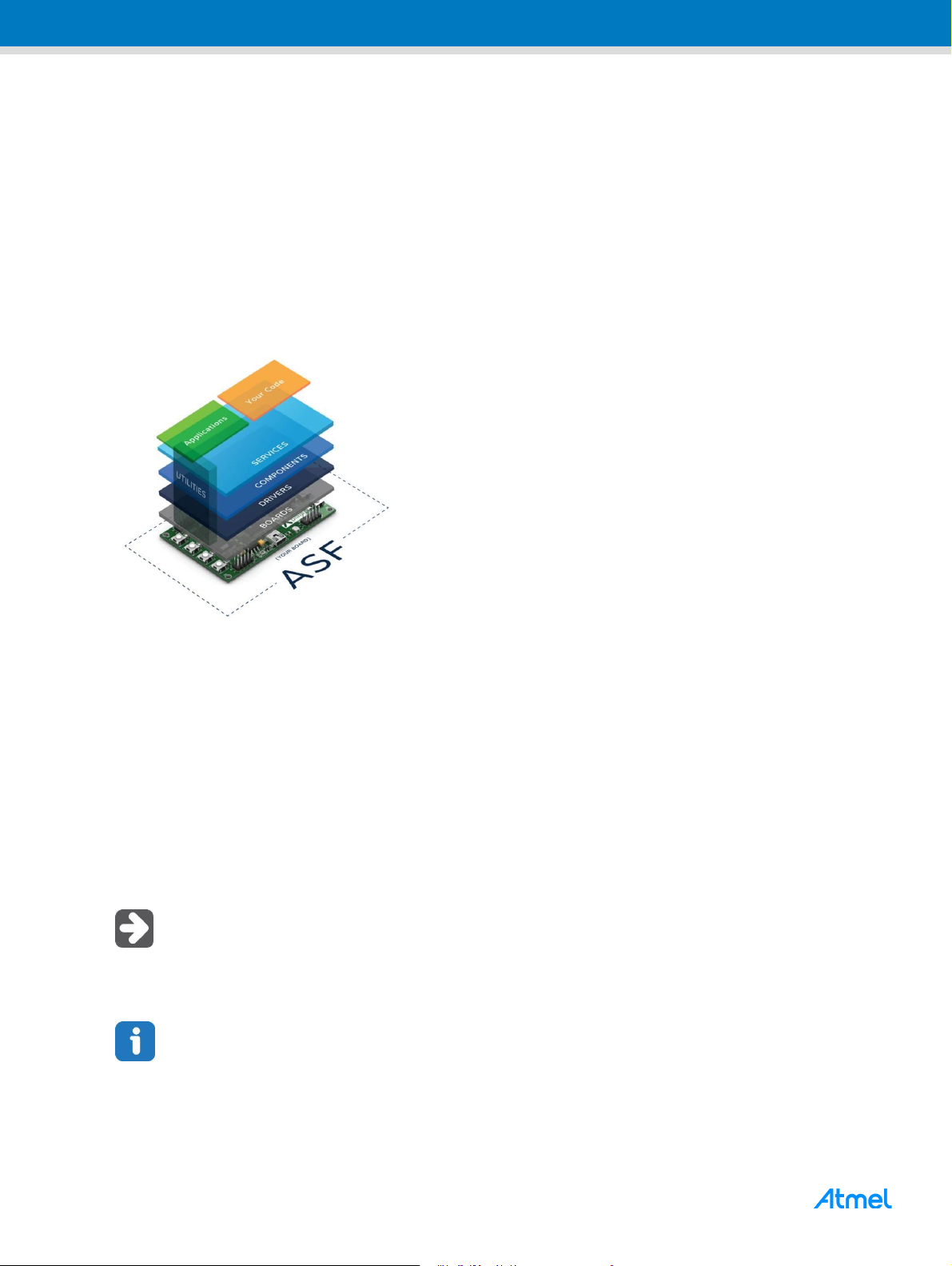

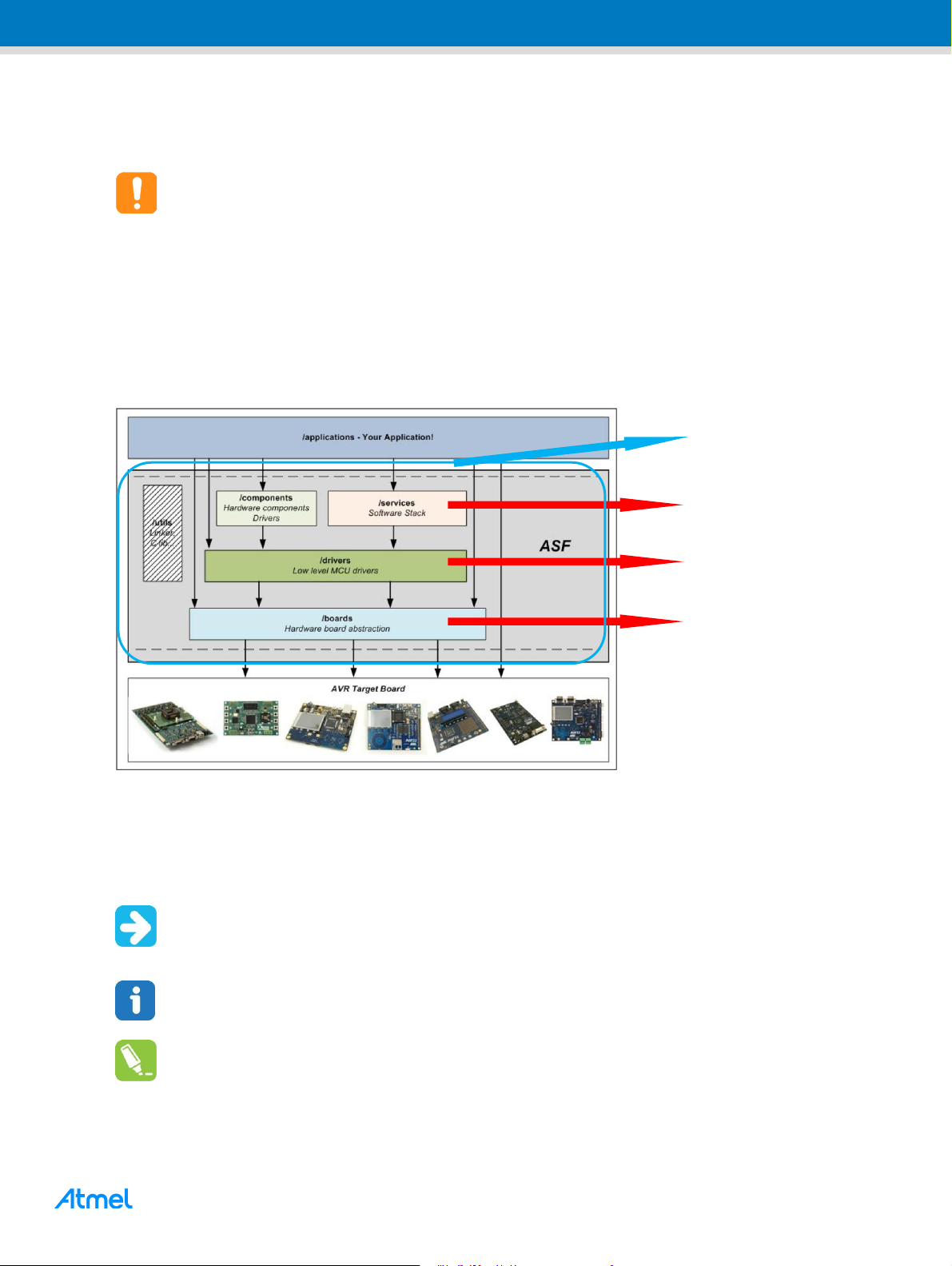

7.1.6 Atmel Software Framework (ASF)

The Atmel Software Framework (ASF) is a collection of embedded software for the Atmel Flash MCUs:

megaAVR, AVR XMEGA, AVR UC3 and SAM devices.

It simplifies the use of our microcontrollers by providing an abstraction to the hardware and high-value

middleware. ASF is designed to be used for evaluation, prototyping, design and production phases. The

intention of ASF is to provide a rich set of proven drivers and code modules developed by Atmel experts to

reduce customer design-time. It simplifies the usage of microcontrollers, providing an abstraction to the

hardware and high-value middleware.

ASF is integrated in the Atmel Studio IDE with a graphical user interface or available as standalone for

GCC, IAR compilers. ASF can be downloaded for free. ASF is an open-source code library designed to be

used for evaluation, prototyping, design and production phases.

The Atmel Software Framework is split in six main parts, the avr32/ directory, the xmega/ directory, the

mega/ directory, the common/ directory, the sam/ directory and the thirdparty/ directory. These six

directories represent the Atmel AVR UC3 architecture, the Atmel megaAVR, the Atmel AVR XMEGA

architecture and the Atmel SAM architecture, what are common between all architectures and finally third

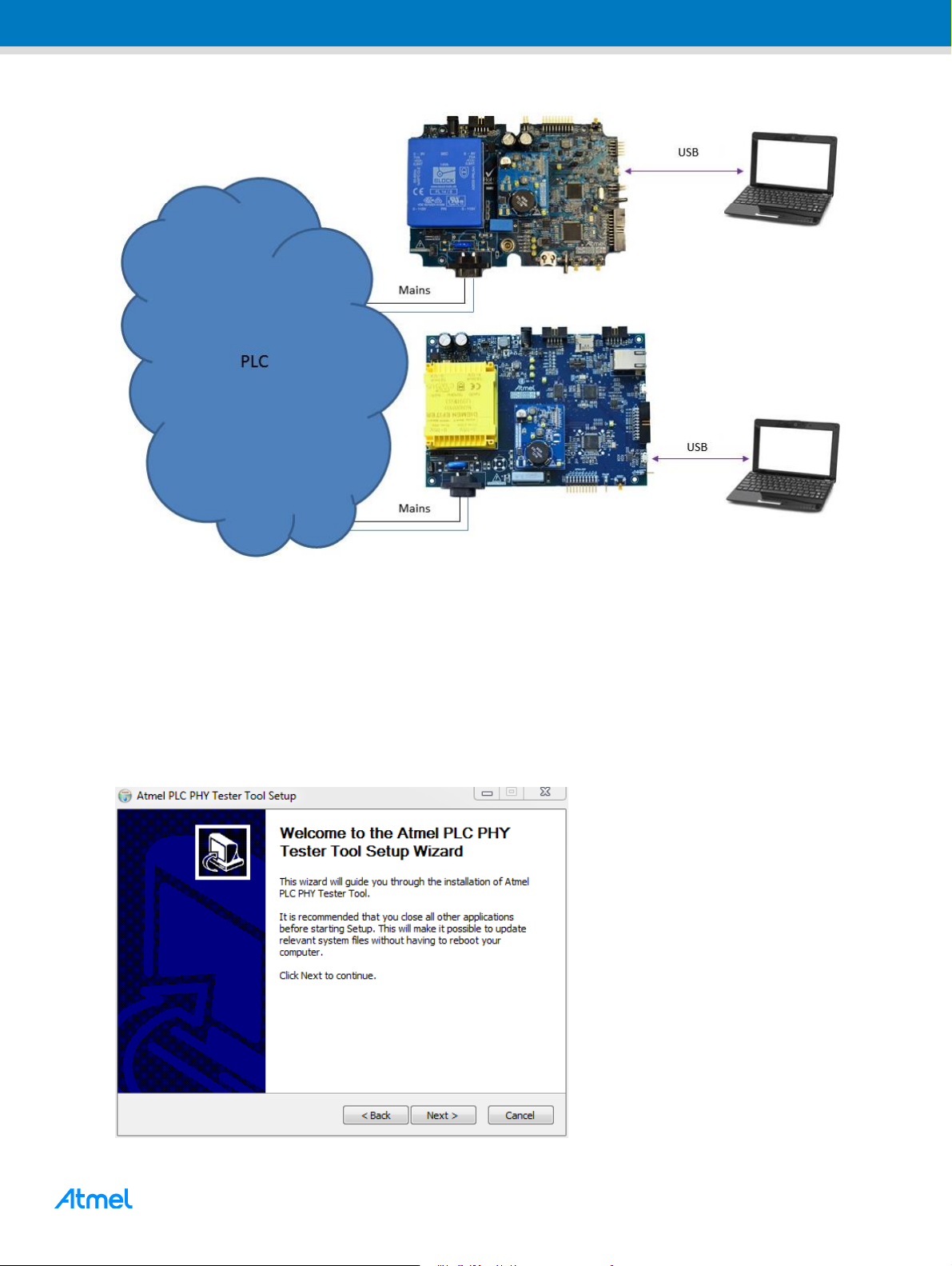

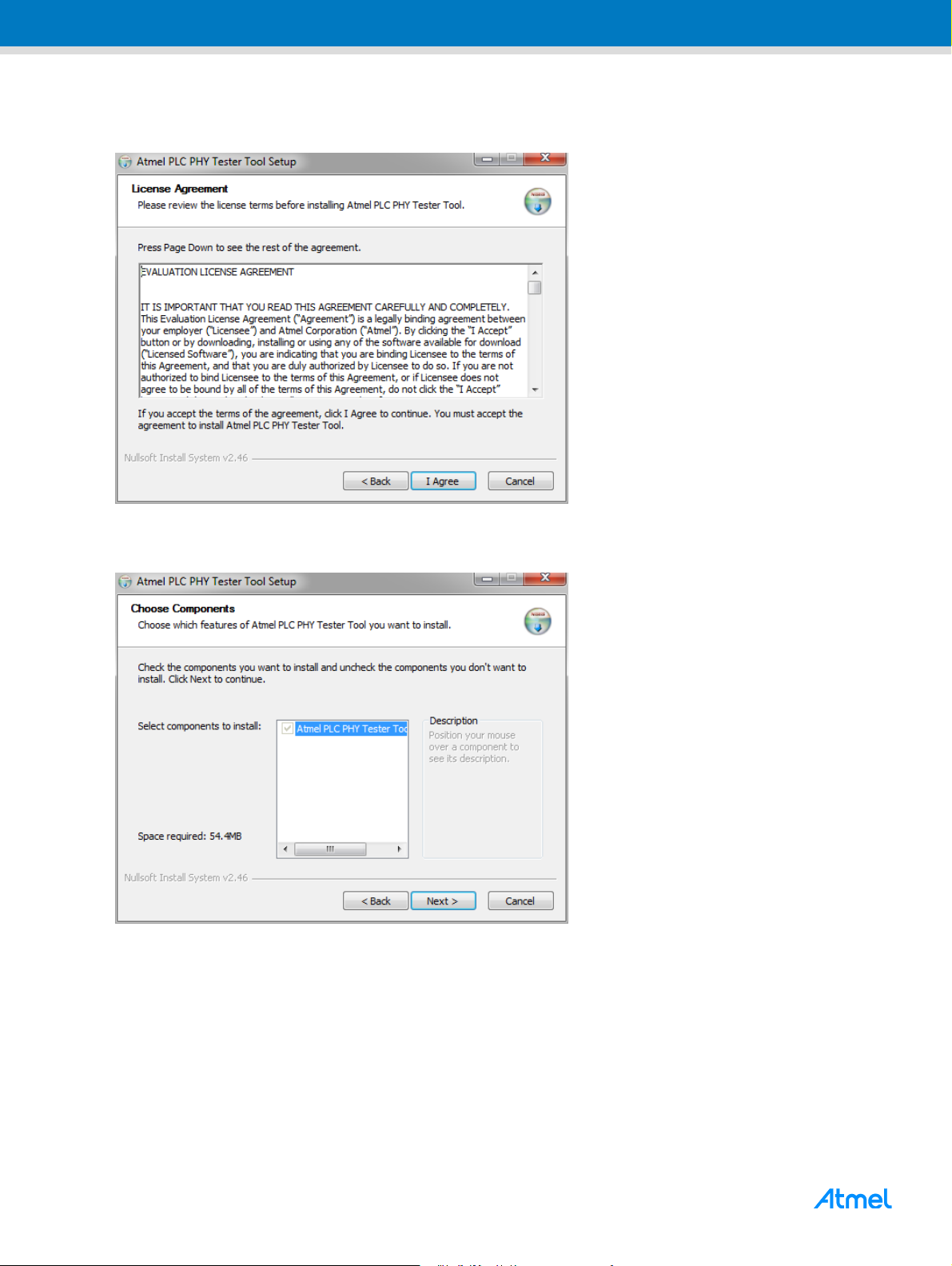

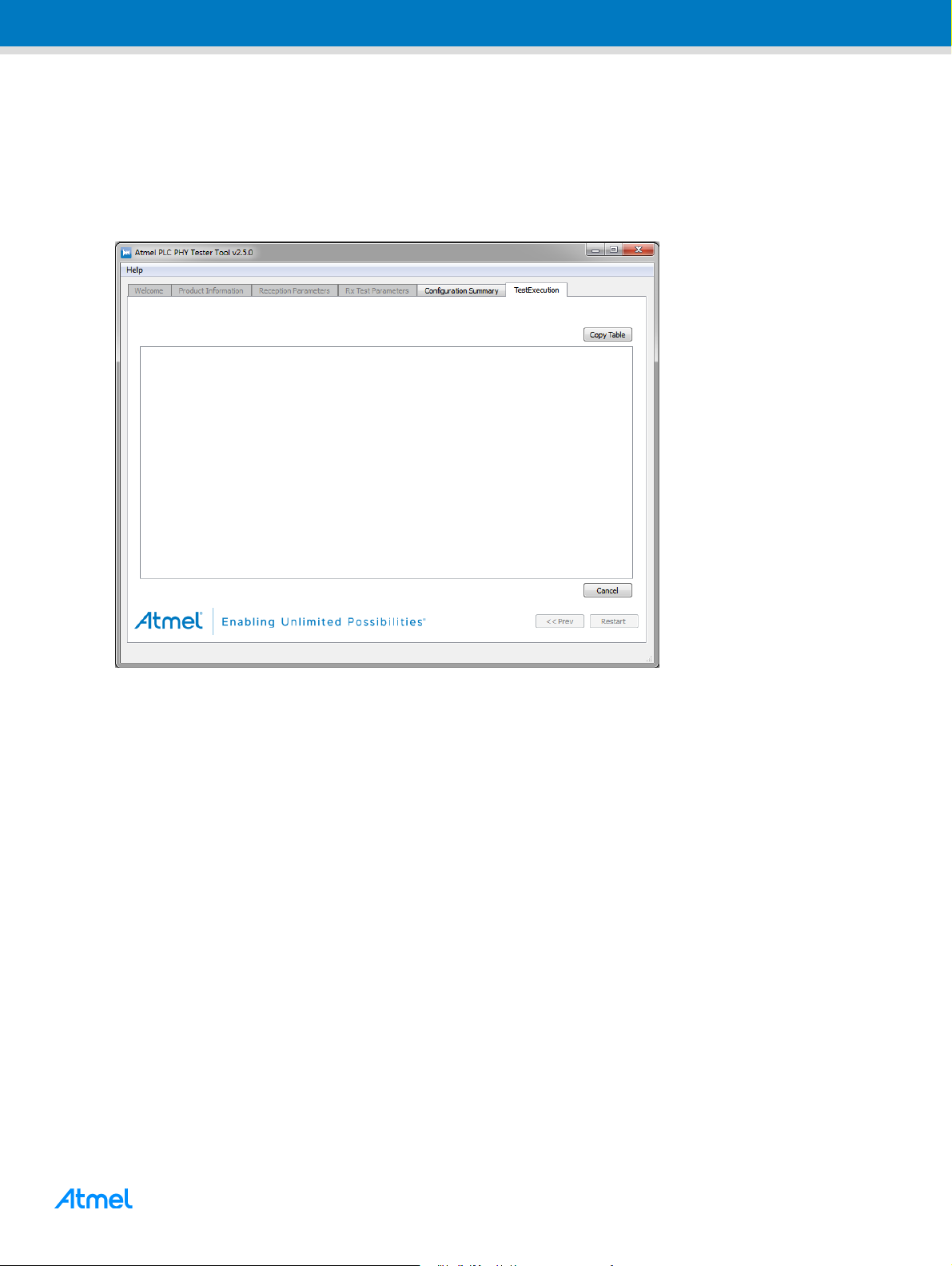

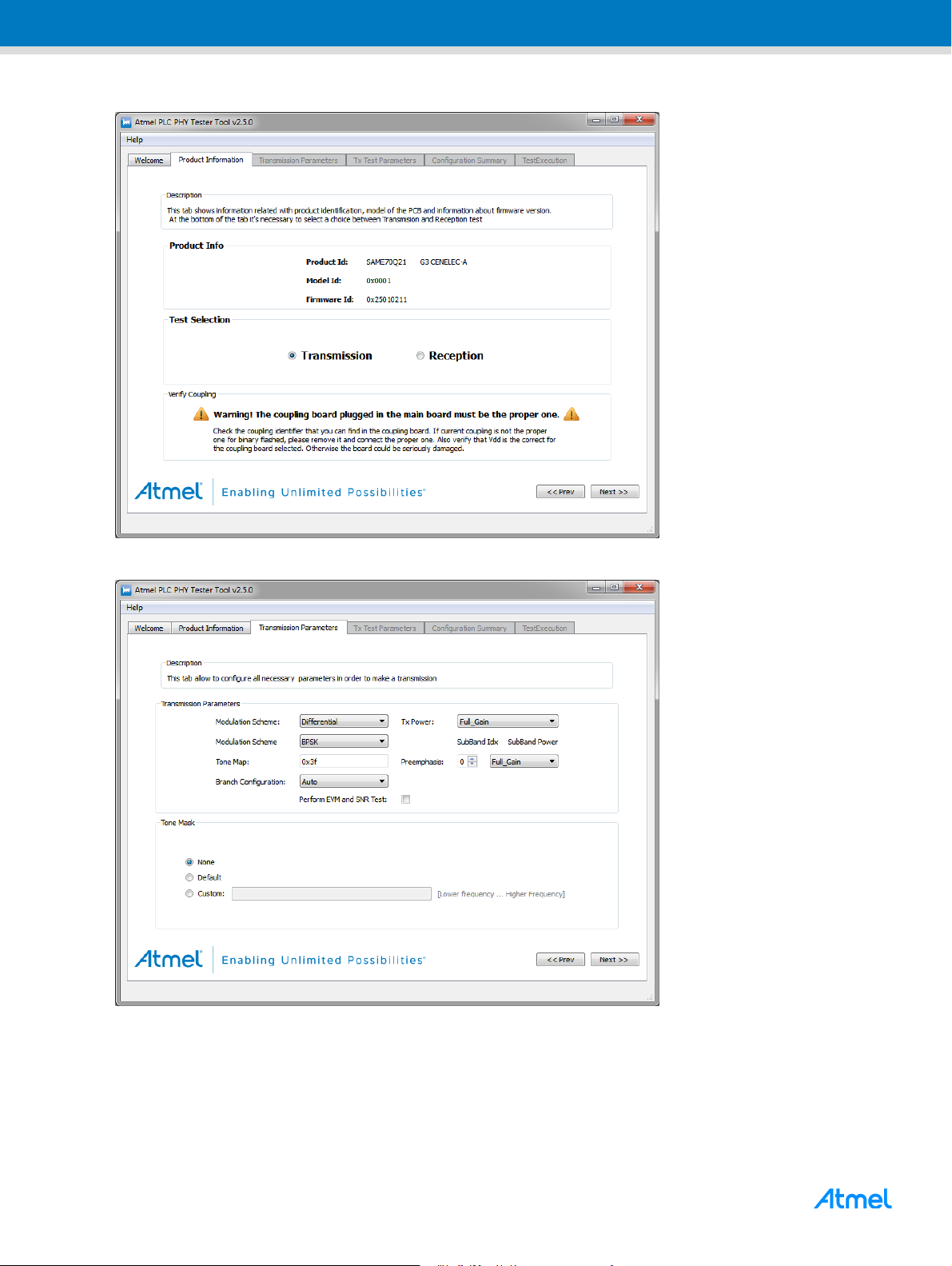

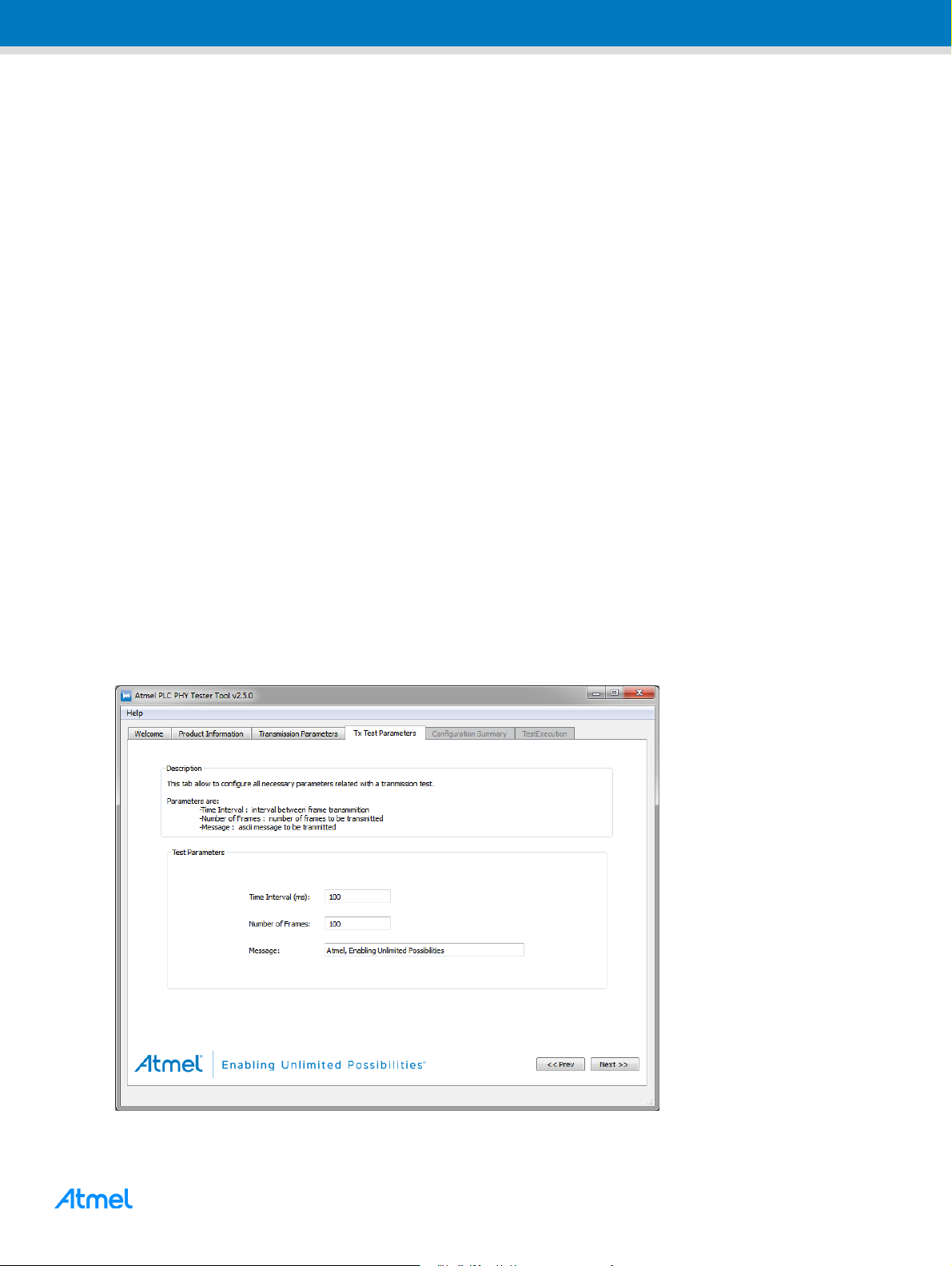

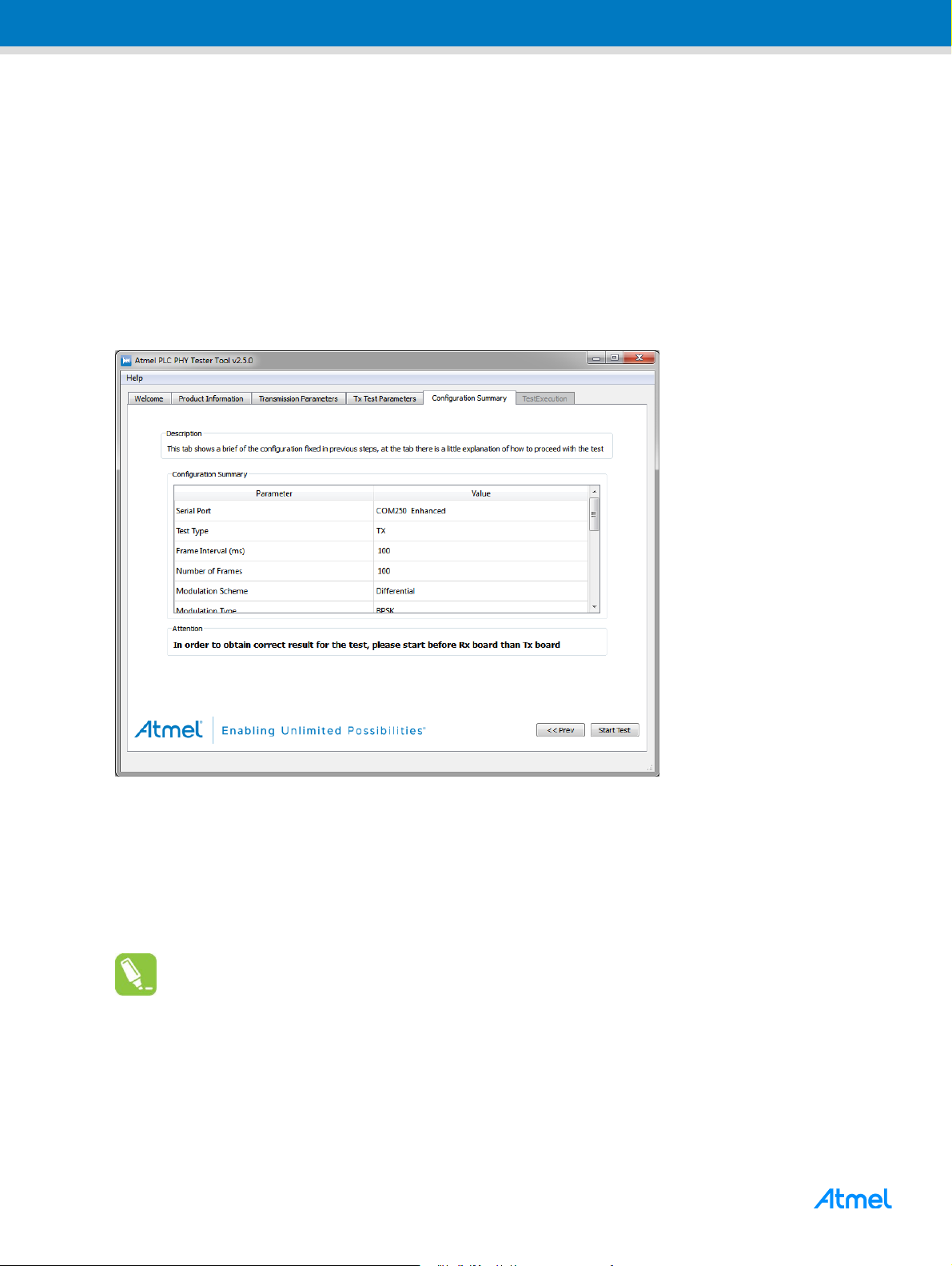

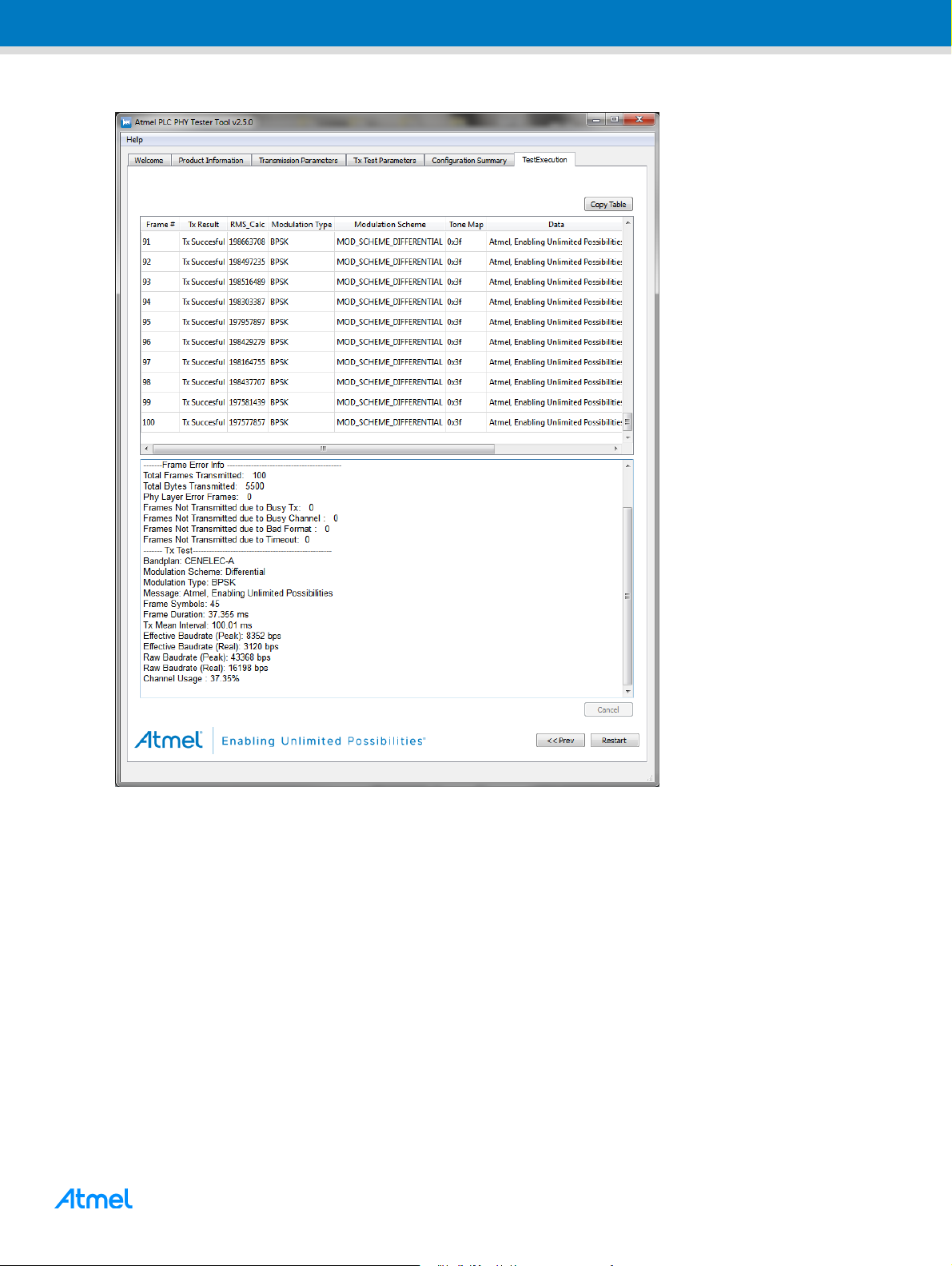

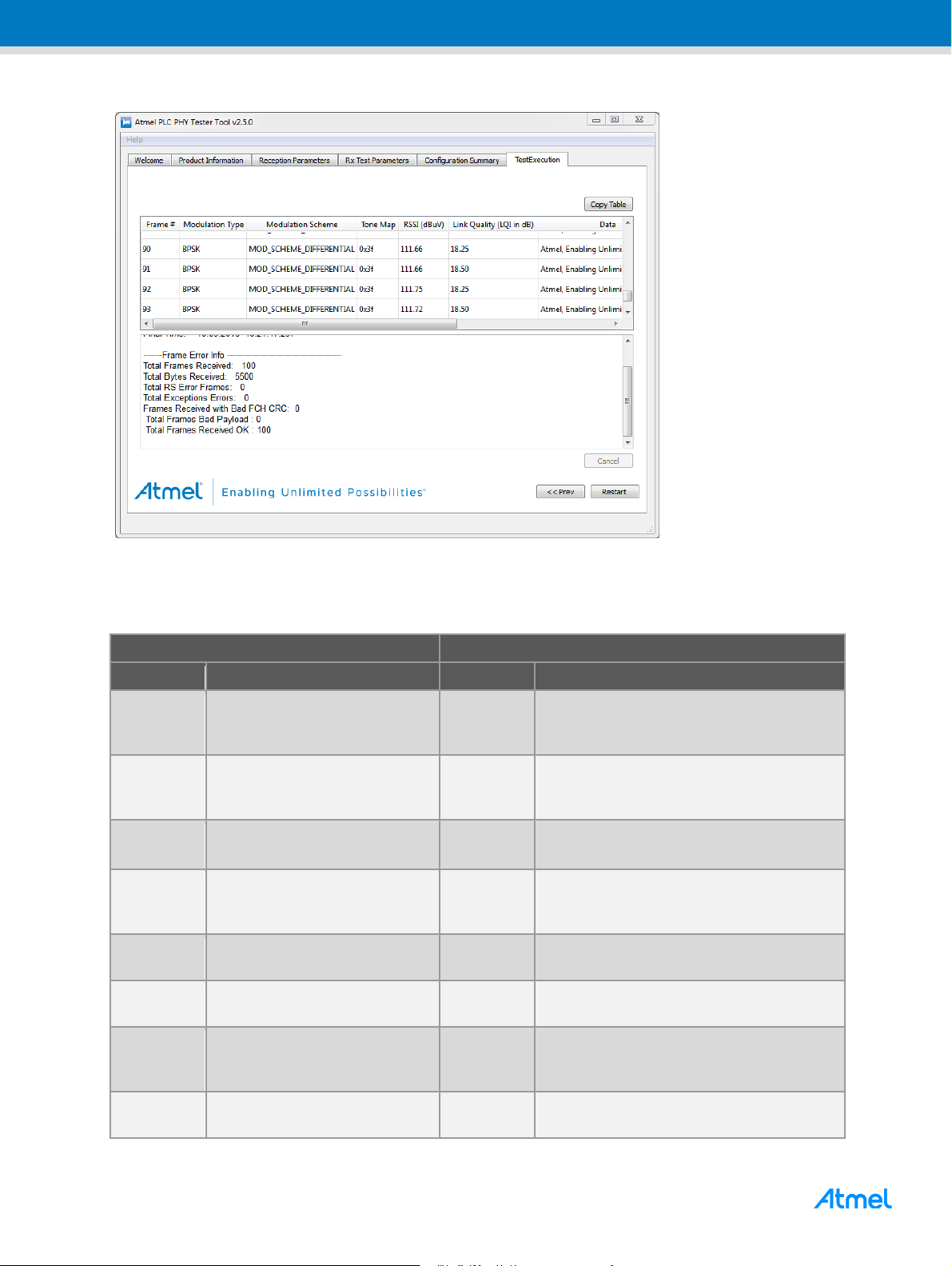

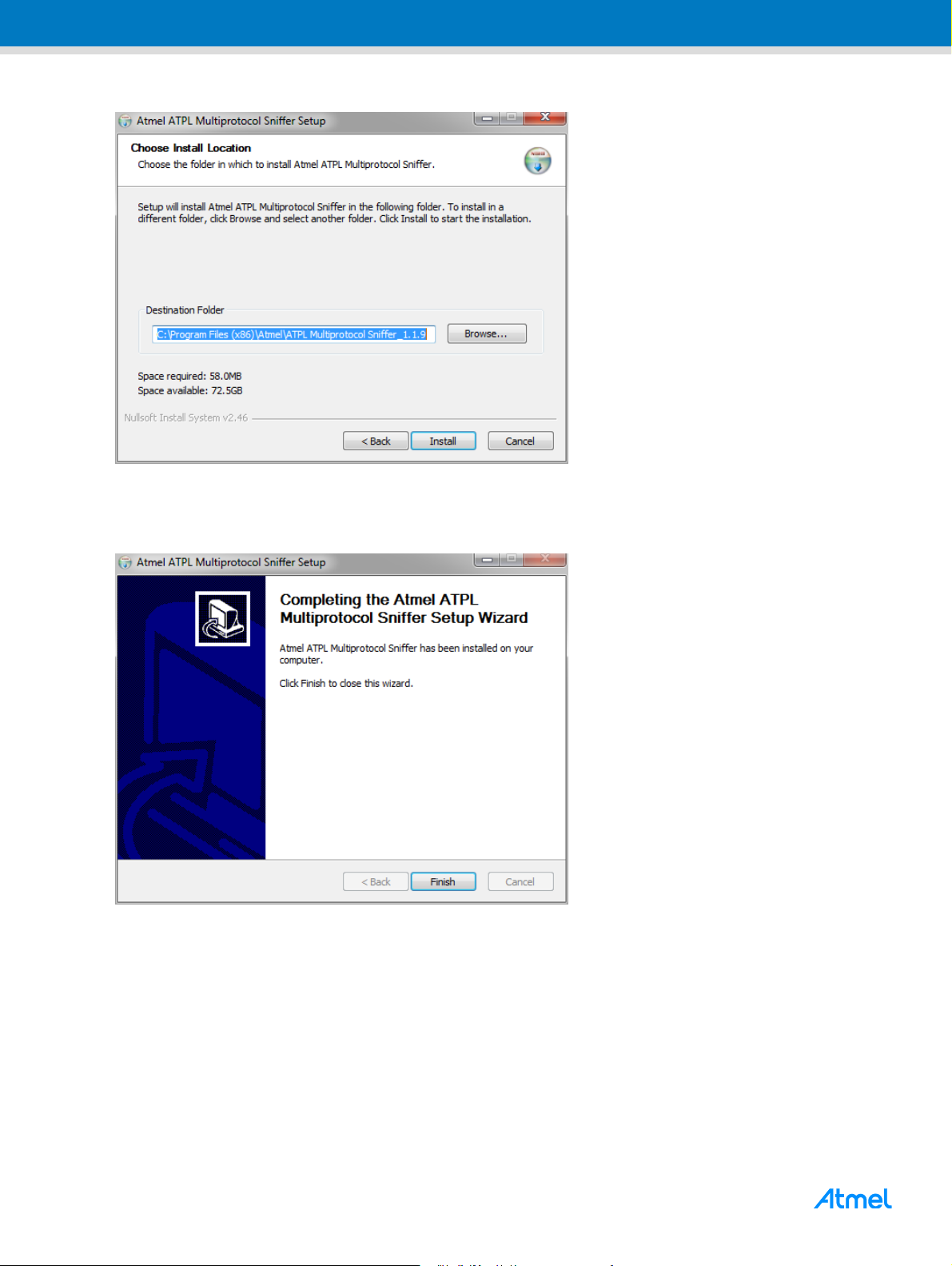

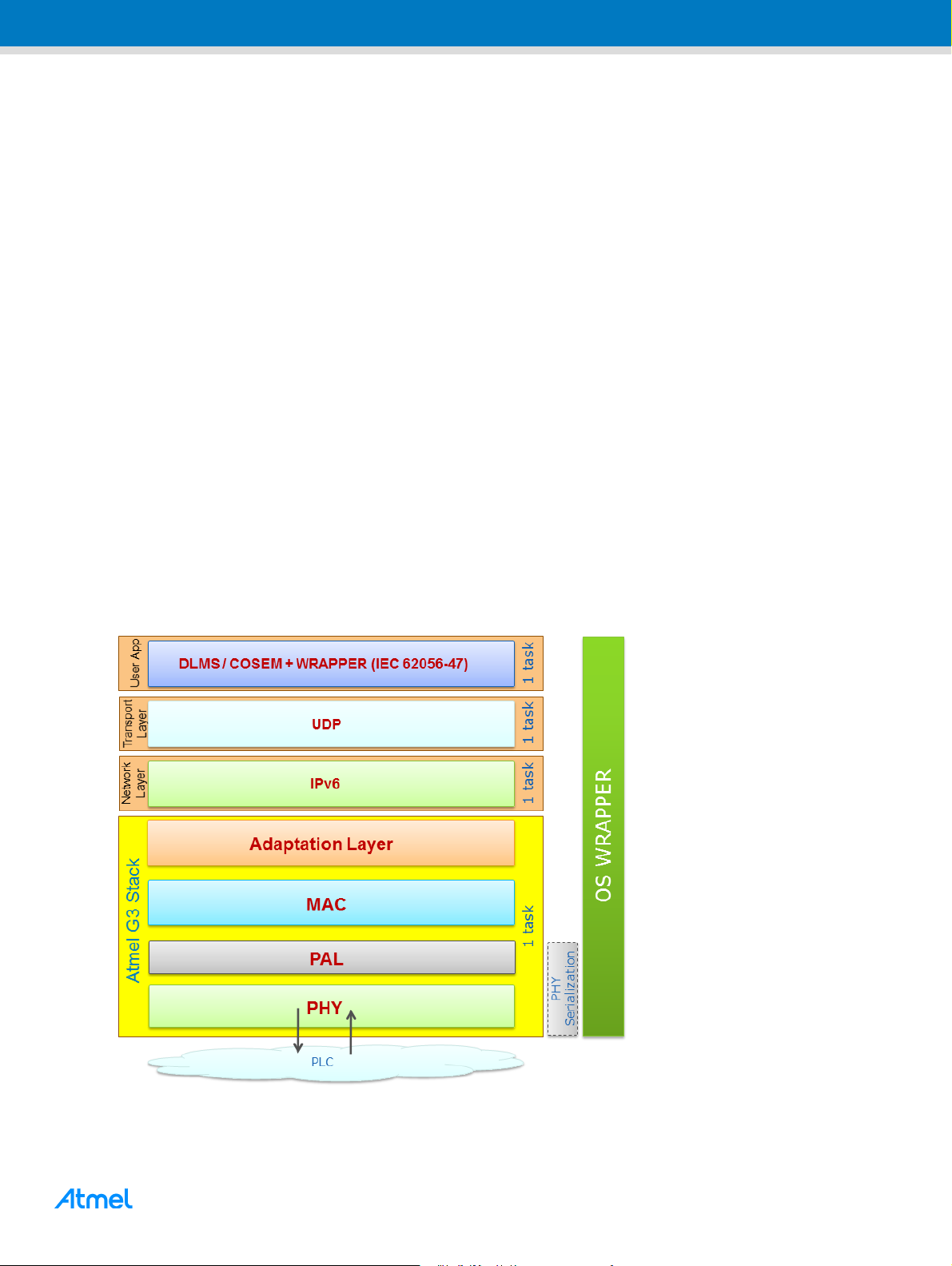

party libraries.