Asko TD70 Service Manual

Service Manual

Tumble Dryer - TD70

Updates ..................................................................................................................................................................................................................................................4

Introduction ......................................................................................................................................................................................................................................... 5

Troubleshooting strategy ..............................................................................................................................................................................................................6

Product overview .............................................................................................................................................................................................................................7

Technical data ......................................................................................................................................................................................................................................9

Component descriptions ..........................................................................................................................................................................................................10

Components and measurement values ...................................................................................................................................................................... 10

Components and function description ........................................................................................................................................................................ 12

Control unit ...................................................................................................................................................................................................................................... 16

Circuit diagram TD70.1 ........................................................................................................................................................................................................ 16

Circuit diagram TD70.2 ........................................................................................................................................................................................................ 18

Circuit diagram TD70.2 HP ................................................................................................................................................................................................ 20

Circuit diagram TD70.2 HWC .........................................................................................................................................................................................22

Circuit diagram TD70.3 ........................................................................................................................................................................................................ 24

Troubleshooting .............................................................................................................................................................................................................................. 26

Fault indicators TD70.1 ......................................................................................................................................................................................................... 26

Fault indicators TD70.2 ......................................................................................................................................................................................................... 27

Fault indicators TD70.3 ......................................................................................................................................................................................................... 29

Other faults ................................................................................................................................................................................................................................. 30

Service menu and settings ........................................................................................................................................................................................................32

Service menu TD70.1 ............................................................................................................................................................................................................32

Service menu TD70.2 ............................................................................................................................................................................................................34

Service menu TD70.3 ............................................................................................................................................................................................................36

Settings ........................................................................................................................................................................................................................................... 38

Activating heating element 2 TD70.1 .................................................................................................................................................................... 38

Activating heating element 2 TD70.2 .................................................................................................................................................................... 38

Activating heating element 2 TD70.3 .................................................................................................................................................................... 38

Store program ...................................................................................................................................................................................................................... 38

Service and installation

Removing top plate and rear panel ............................................................................................................................................................................. 39

Replacing the panel and the control unit ..................................................................................................................................................................41

Transporting a tumble dryer with a heat pump .................................................................................................................................................... 43

Tumble Dryer TD70

Service Manual

Contents

Updates

Rev Date Description Initials

01 2011-09-06 First version FH

02 2011-10-03 BRAND OTHER included FH

03 2011-10-20 New document structure FH

04 2012-01-20 New revision circuit diagram EH

05 2012-05-03 Changed the info about Autofilter BPA

06 2012-05-04 Updated part no control units, irrelevant articles deleted. EH

07 2012-07-05 Troubleshooting TD70 HP, LCD F29, removing back rear included. EH

Service Manual TD70

4

Introduction

You are holding the service manual for TD70 tumble dryers. It should be easy to service a tumble

dryer. It is important that you, as a service technician, are provided the necessary conditions to

work in an efficient and satisfactory manner. Our hope is that this Service & Training Guide is a

useful tool for your daily work.

Asko Appliances AB

SE-534 82 Vara

Sweden

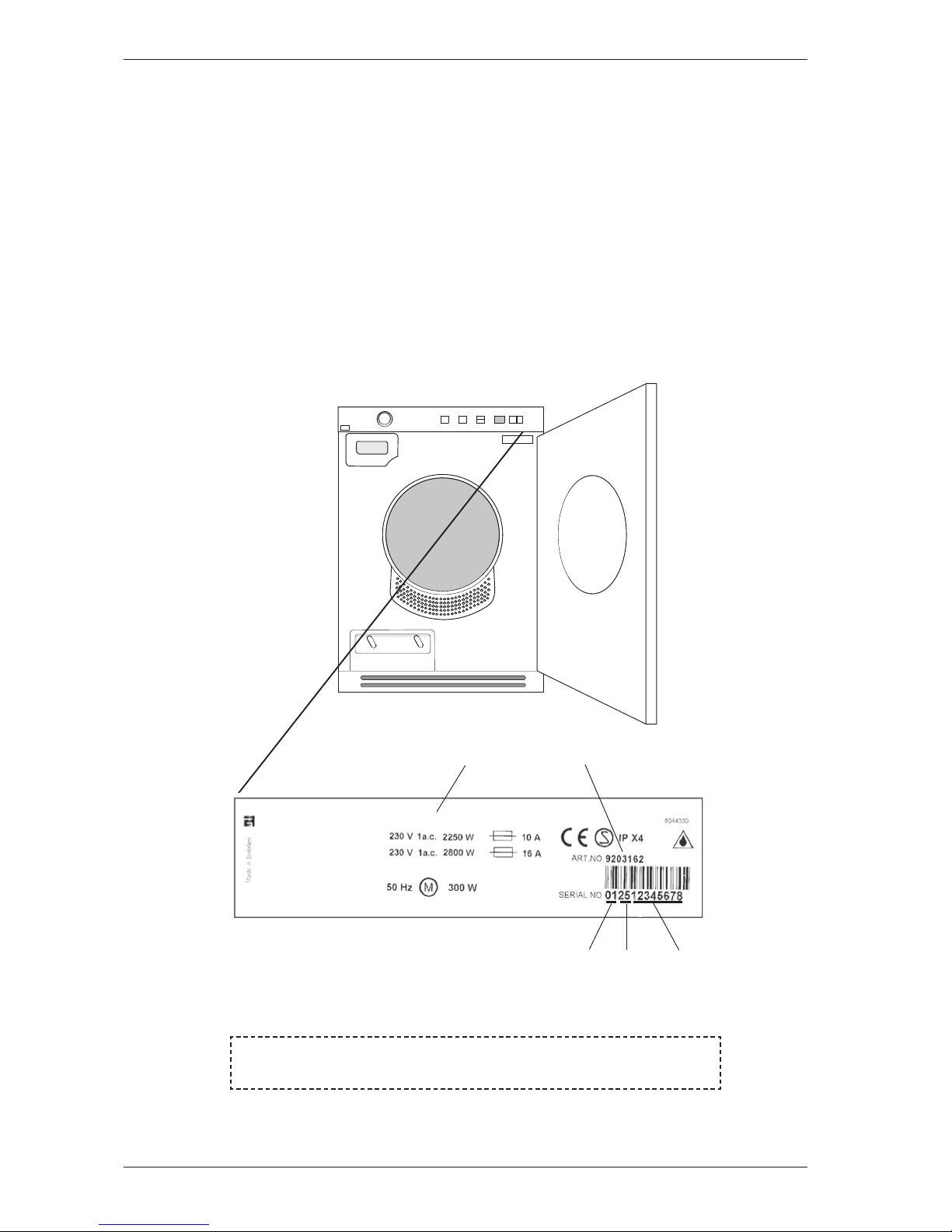

The type designation can be found on the machine plate, which is located on the inside of the

front panel by the door catch (see image below).

Type designation

Product number

TYPE TD70.3

Serial number

Year

Week

OPERATING INSTRUCTIONS

Always have the operating instructions for the machine available during service

Service Manual TD70

5

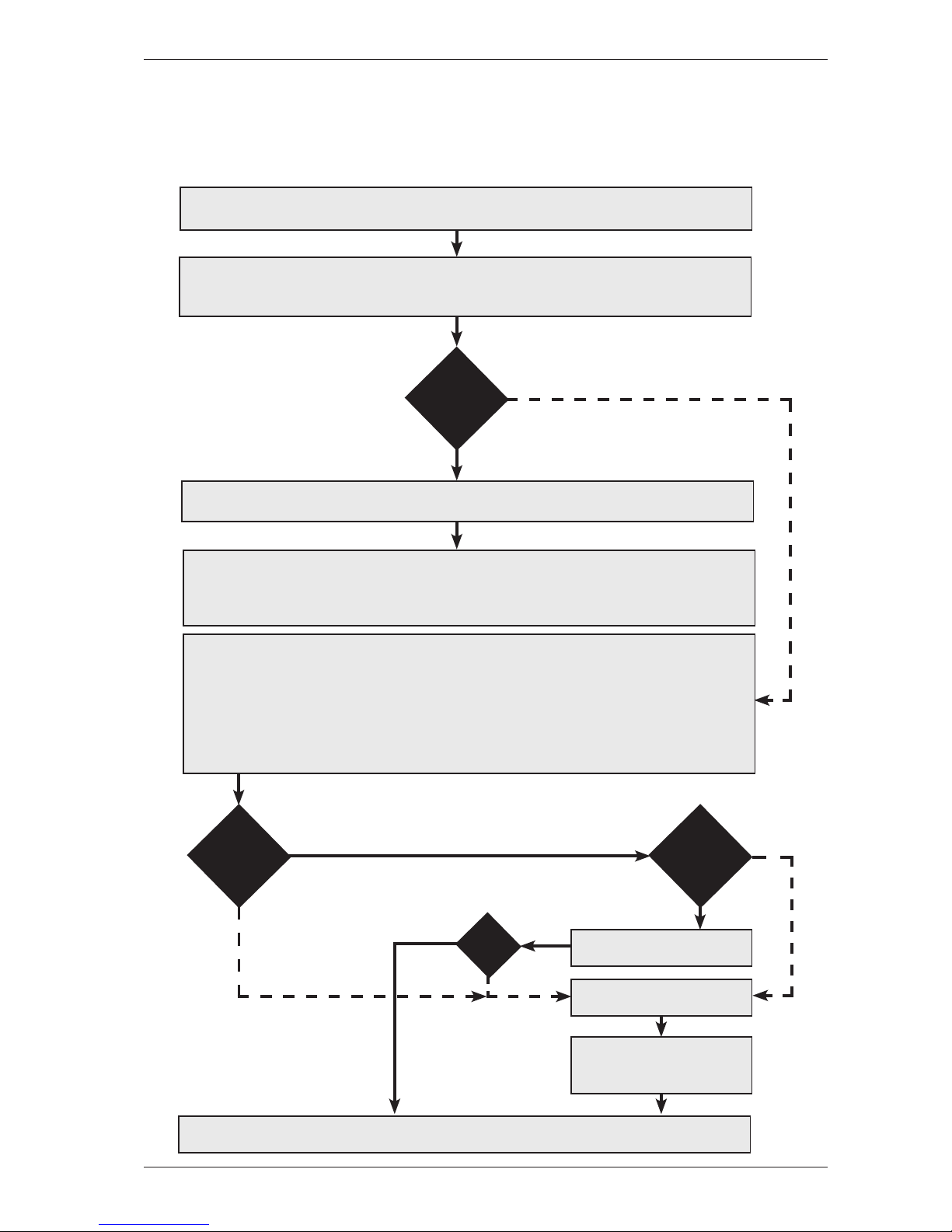

Troubleshooting strategy

Troubleshooting is an important part of the service callout, and as such we have drawn up a

troubleshooting strategy that describes, in broad terms and step by step, what you need to do to find

and diagnose faults arising in our machines.

• Ask the customer to describe the problem.

• Check whether the customer’s description matches the reported fault.

• Check that the machine is correctly installed:

- Electrical connection - Drainage

- Water connection - Machine correctly levelled

Fault

found?

Incorrect installation or external factors that affect performance and functionality (for

example, water pressure, electrical supply, drainage).

The machine operates normally. No deviations can be found. The customer probably

needs to be informed about proper use of the machine. If necessary, also inform the

customer about the warranty conditions and the fact that the customer will be charged

for the service call.

Yes

Open the ser vice menu:

1. Check the settings

2. Run a test cycle

3. Note any fault codes

If the above actions do not uncover the fault:

• Conduct general troubleshooting. Use the documentation available at ServiceSaver

(service manuals, service memos, wiring diagrams and other documents).

Yes

No

No

Fault

diagnosed?

Repair and check

function/safety.

Carry out the actions

suggested by technical

support.

Satisfied customer!

OK?

No

Yes

No

Yes

Fault

found?

Contact technical support

for assistance.

Service Manual TD70

6

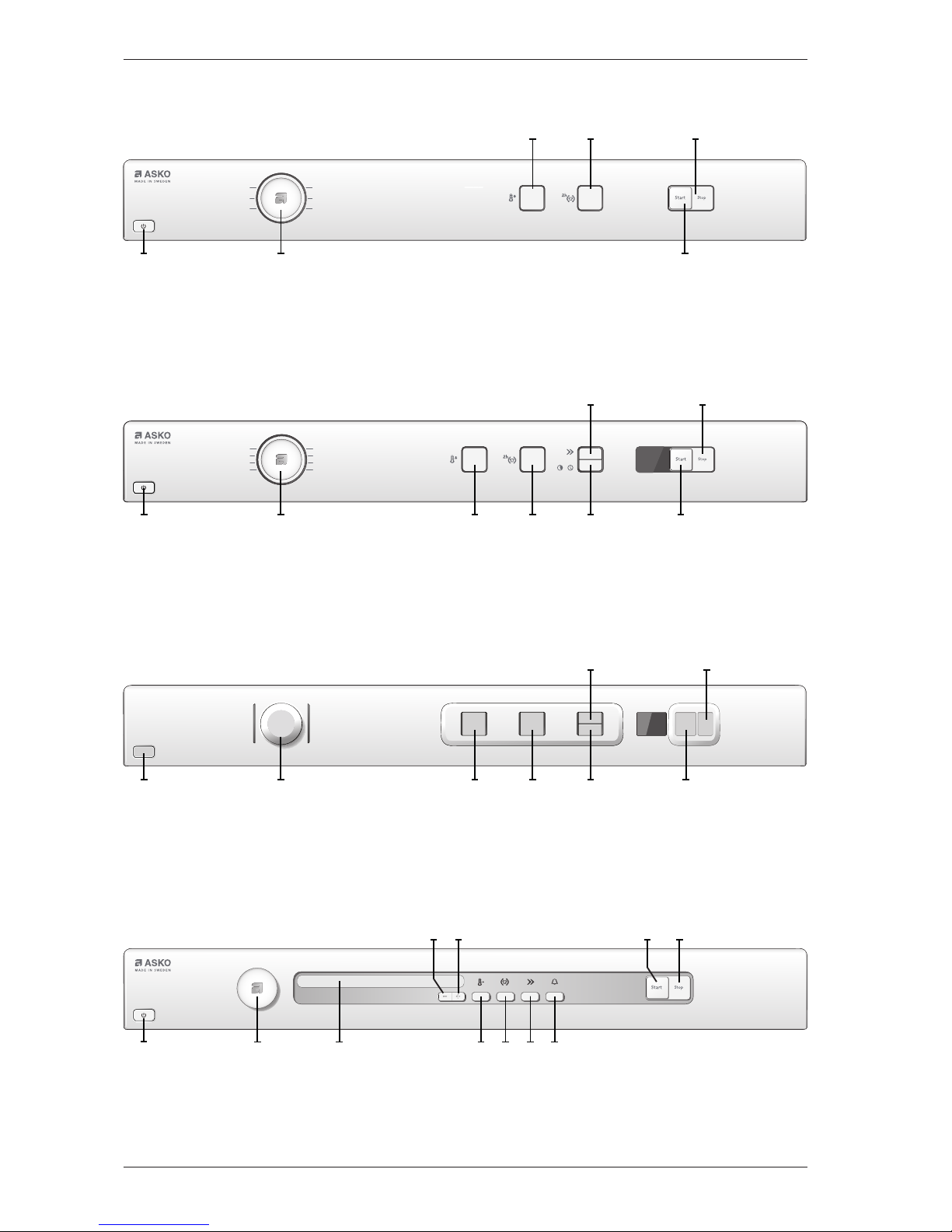

Product overview

Programs: 6

Options: 5

Settings: 1

TD70.1, Paneltype B - (BRAND ASKO)

/

J1 S9S4S3S1 S10

S7 S11

Programs: 4

Options: 2

Settings: 1

TD70.1, Paneltype A - (BRAND ASKO)

J1S1

S10

S7S4 S11

Programs: 6-15

Options: 5

Settings: 1

TD70.2 - (BRAND ASKO)

S3 S9

J1 S4 S6 S7S5DISPLAY

S2 S8

S1

Programs: 6

Options: 5

Settings: 1

TD70.1 - (BRAND OTHER)

J1 S9S4S3S1 S10

S7 S11

Service Manual TD70

7

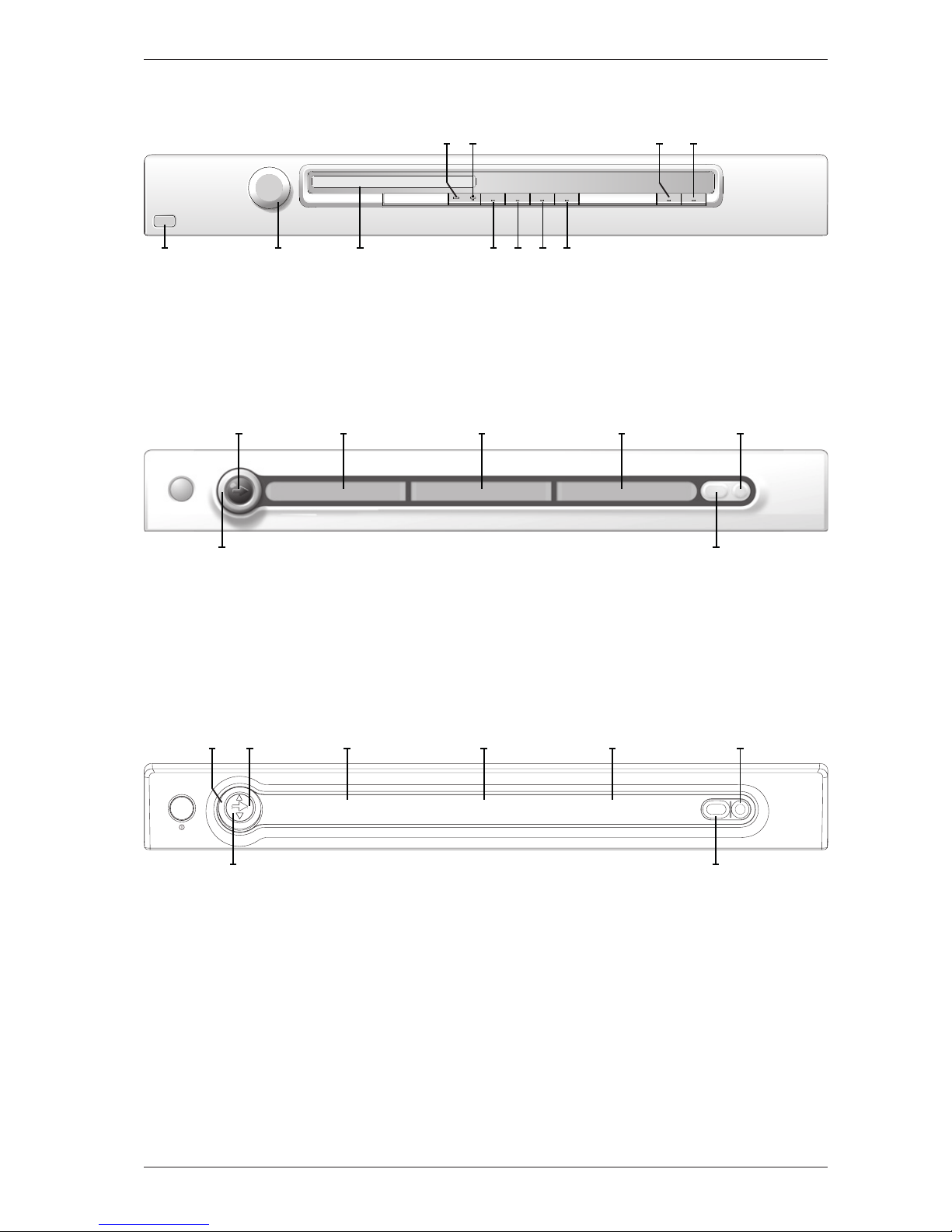

Product overview

Programs: 10, plus settings menu

Options: 5

Settings: 4

TD70.3

S1 S3DISPLAY1 DISPLAY2 DISPLAY3

J1 S2

TD70.3 (Integrerad)

Programs: 10, plus settings menu

Options: 5

Settings: 4

S1 S3

DISPLAY1 DISPLAY2 DISPLAY3

S5 S2

S4

Programs: 6-15

Options: 5

Settings: 1

TD70.2 - (BRAND OTHER)

S3 S9

J1 S4 S6 S7S5DISPLAY

S2 S8

S1

Service Manual TD70

8

Technical information

Height 850 mm

Width 595 mm

Depth 585 mm

Weight 43 kg (Vented)

47 kg (Condenser)

55 kg (Heat pump)

44 kg (Heating Water Circuit)

Cylinder volume 112 litres

Capacity EU 7.0 kg

US/AU 7.0 kg

Speed 50-55 rpm

Connection 1-phase 230 V, 50/60 Hz, (10 A/16 A) **

Rated power 1950 W = 10 A** (Vented/Condenser)

3000 W = 16 A** (Vented)

2500 W = 16 A** (Condenser)

1300 W = 10 A** (Heat pump)

1950 W = 10 A** (Heating Water Circuit)

The control buttons are used to switch between 10 A and 16 A via the software.

Does not apply to Heat Pump or Heating Water Circuit.

Drum material Stainless steel

Outer panels Powder-coated and hot-galvanised sheet steel or stainless steel

Installation Stacked or freestanding

Protection class IP X4

** See type plate.

Technical data

Energy consumption and program times

See the operating instructions for information on energy consumption and program times.

Service Manual TD70

9

Component description

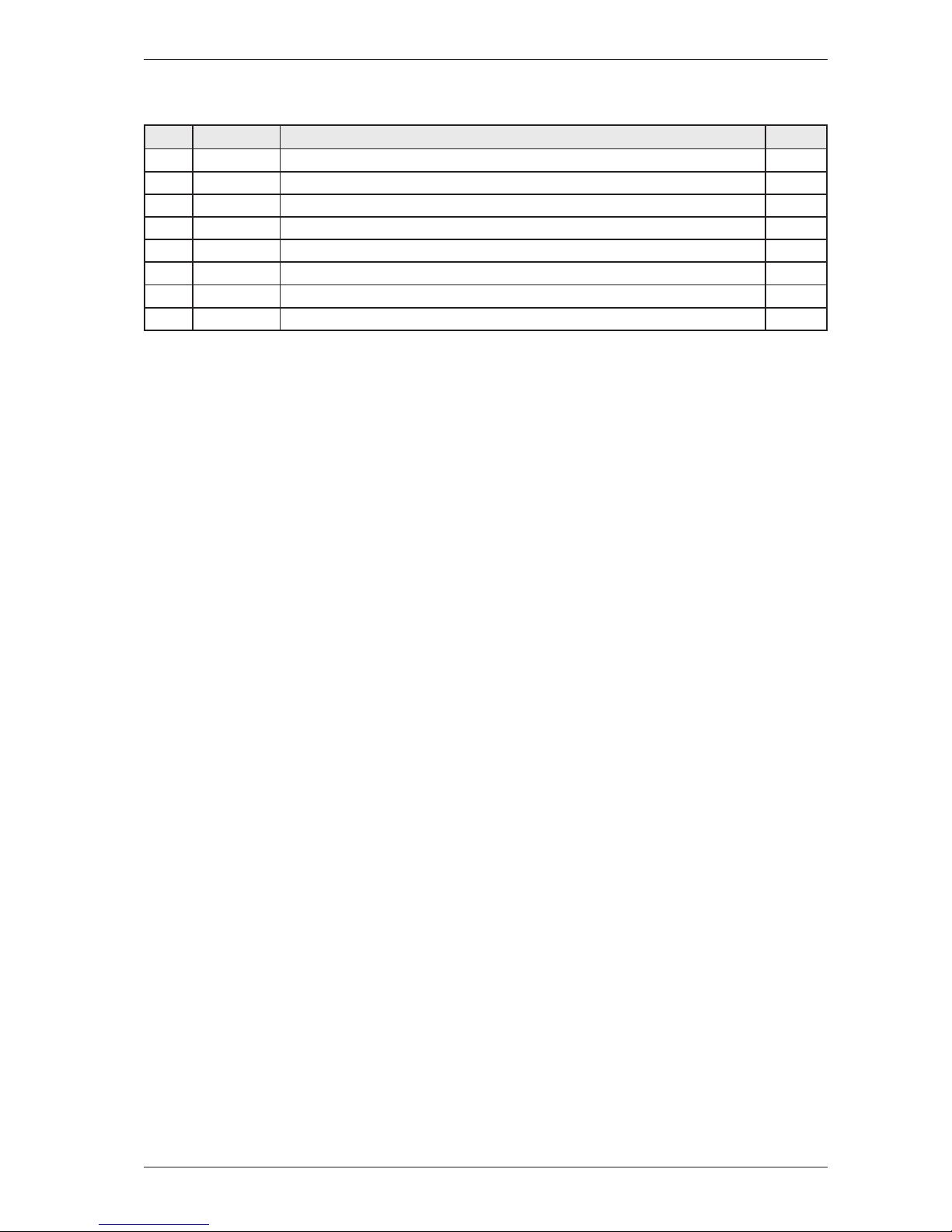

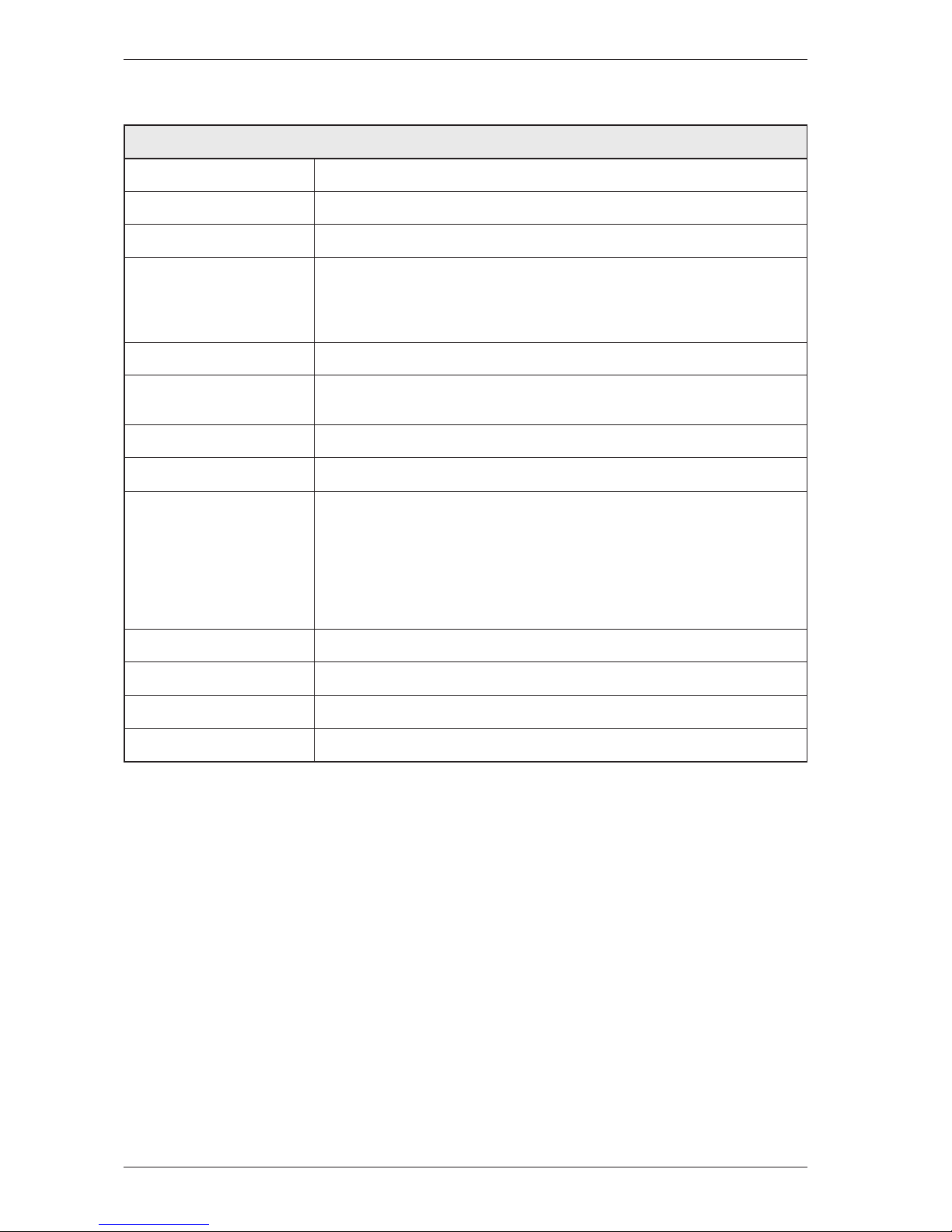

Components and measurement values

The specified resistance values apply at room temperature (about 20°C/68°F). Values within

±10% are considered normal.

Article no. Component Measurement value Comment

80 839 15 Motor 50 Hz,

220/240 V

Winding resistance:

cable colour red-white 26.5 Ω

cable colour red-blue 53.5 Ω

cable colour white-blue 27.0 Ω

Current: 0.7 A; 140 W; 2850 rpm

80 839 16 Motor 60 Hz,

220/240 V

Winding resistance:

cable colour red-white 26.5 Ω

cable colour red-blue 53.5 Ω

cable colour white-blue 27.0 Ω

Current: 0.7 A; 140 W; 3300

rpm

The motor is a 2-pin motor and is

directly connected to the fan for

internal air and the gearing for driving

the cylinder. On condenser dryers, the

motor also drives the fan for ex ternal air.

80 903 13 Capacitor 8 μF 50 Hz

80 903 14 Capacitor 6 μF 60 Hz

80 902 70 Capacitor heat pump 17 μF 50 and 60 Hz

80 821 28 Condensate pump 50 Hz

80 846 48 Condensate pump 60 Hz

80 762 02 EMC-filter with inductor The filter eliminates inter ference to and

from the machine.

80 833 44 Thermistor 4.8 kΩ (at 25°C) The thermistor controls temperature

regulation. If the thermistor is shor tcircuited or detaches from the control

unit, the program is stopped.

80 902 72 Termostat 150 150°C manual reset

The thermostat /overheating cut-out

stops the program if the temperature

becomes too high.

80 902 73 Termostat 135 135°C manual reset

80 902 24 Thermostat 110 110°C automatic

80 761 04 Door switch The front door triggers a door switch

which stops the program when the door

is open. If the door has been opened and

closed during the program the machine

must be restarted using the Start/Stop

button.

Service Manual TD70

10

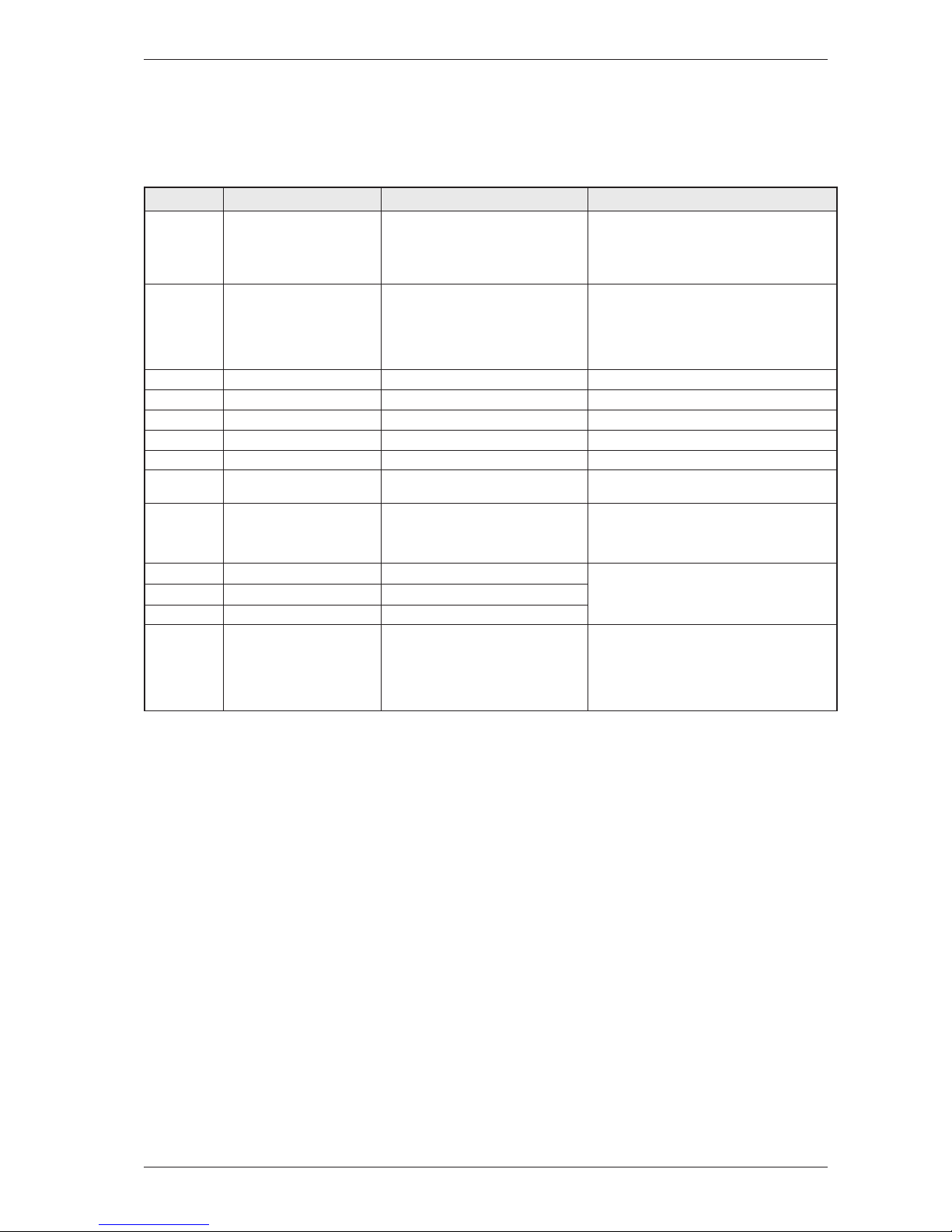

Component description

Article no. Component Measurement value Comment

80 761 03 Microswitch float

Overflow guard

If both containers in the tumble dryer

are full the program is stopped by a float

switch installed in the lower container.

“Over flow” is indicated on the display.

80 824 92 Heating element 1950 W Heater 1: 1950 W, 24.5 Ω

80 915 90 Heating element 2500 WHeater 1: 1950 W, 24.5 Ω

Heater 2: 550 W, 91.4 Ω

80 824 91 Heating element 3000 WHeater 1: 1950 W, 24.5 Ω

Heater 2: 1050 W, 45.5 Ω

80 821 22 Base heat pump

complete

50 Hz

80 821 23 Base heat pump

complete

60 Hz

80 88 415 Reversing valve 1.9 kΩ

88 015 18

88 015 19

Control unit compl.

TD70.1 A

Control unit compl.

TD70.1 B

The control unit contains

microprocessors for controlling

programs, the motor, the heating

elements etc.

88 015 20

88 015 21

Control unit complete

TD70.2

Control unit complete

TD70.2 HP/HWC

88 015 00

88 015 01

Control unit complete

TD70.3

Control unit complete

TD70.3 FI

80 846 49 LED-light compl. LED-technology for the machine’s

internal light.

Service Manual TD70

11

Component descriptions

Components and function description

Here we describe the function and

specification of the most impor tant

components. Cer tain components are found

only in more highly specified machines or in

particular markets. See the Troubleshooting

chapter for fault and information codes.

CU (Control Unit)

The CU (Control Unit) functions as both a

control panel and a logic component. The

control panel is equipped with knobs/buttons

for selecting programs, Start/Stop buttons and

a display. It is an integrated part of the CU

and cannot be replaced separately. The logic

component manages functions needed for

drying programs and diagnosis. The CU has an

internal power supply for the logic component.

In the event of a fault, the CU can diagnose

a number of components and functions, and

a total of 4 fault codes can be displayed. To

facilitate troubleshooting there is a component

testing function in which the outputs are

activated according to a special sequence.

Power supply

Mains voltage, built-in internal voltage

converter for the logic component.

Light

Certain machines have an internal light

that is activated when the door is opened.

LED technology is used to improve energy

efficiency.

Thermistors

The thermistors are of the NTC type (Negative

Temperature Coefficient), which means their

resistance decreases as temperature increases.

Thermistor 1 is in the air duct on the front frame,

after the internal impeller. If there is an interruption

in the thermistor circuit or if it short circuits, the

drying program stops and the display shows

“Thermistor fault”.

Purpose: Measures the temperature of the air that

has passed the load and controls the drying process

and the heating element.

Thermistor 2 is on condenser dryers located after the

condenser and on heat pump dryers located on the

evaportator pipe by the comperssor.

Purpose: Measures the temperature of the

dehumidified air, the value of which is used as a

parameter in the drying process.

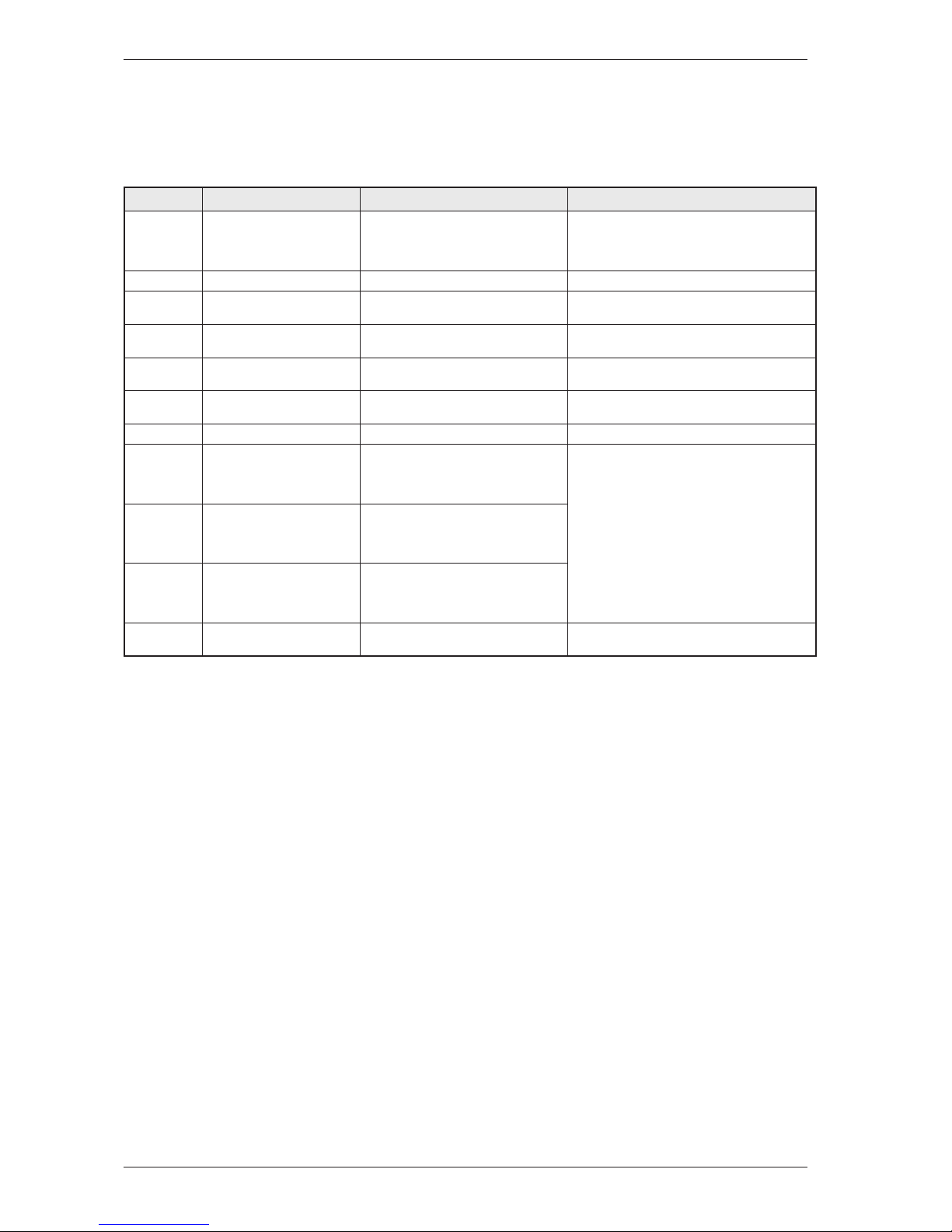

Resistance values for thermistors 1 and 2

Temperature Resistance

20°C 5989

25°C 4869

30°C 3946

35°C 3197

40°C 2598

45°C 2126

50°C 1758

55°C 1471

60°C 1240

65°C 1043

70°C 857

Tolerance : ±1%

Service Manual TD70

12

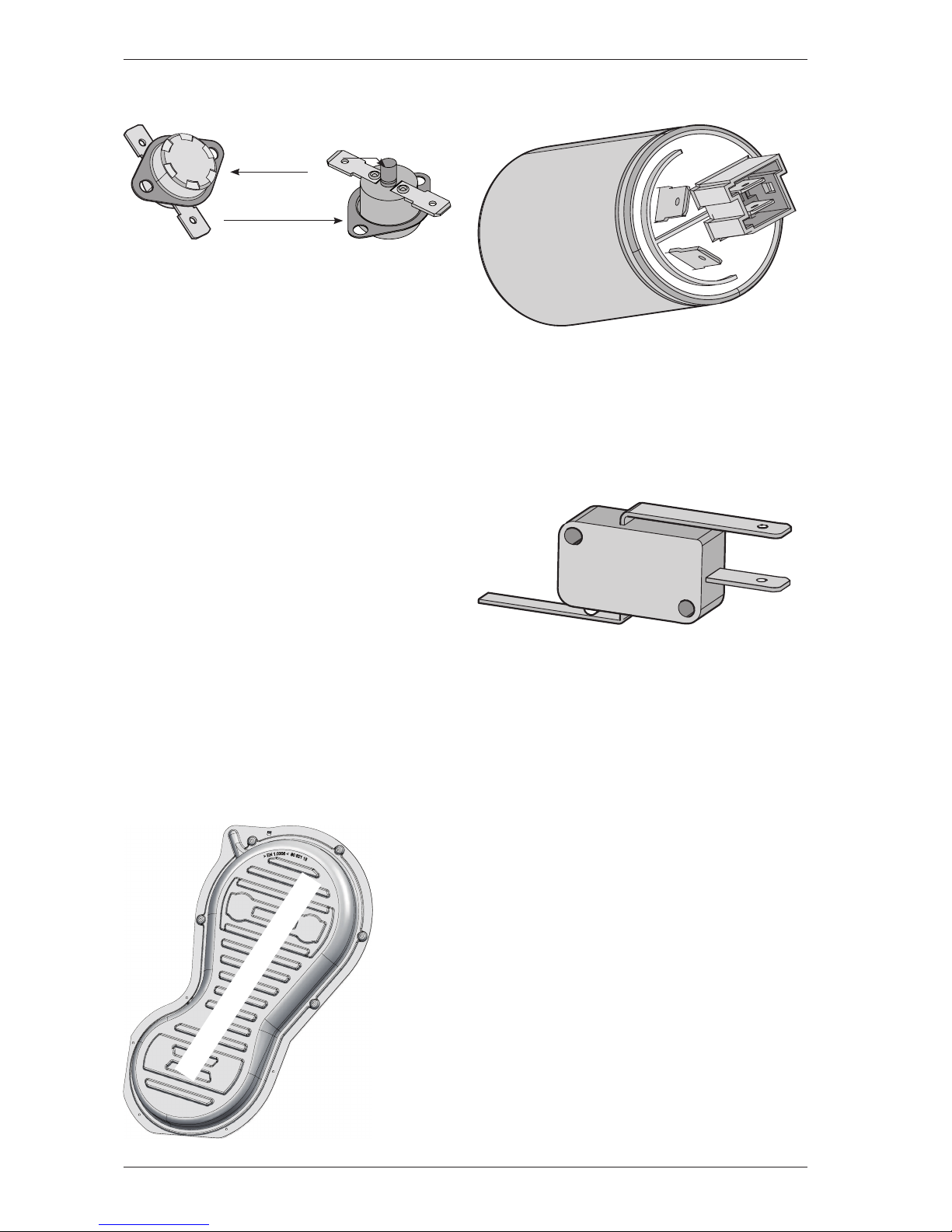

Thermostat and overheating cut-out

The thermostat is installed next to the heating

element and is used to reduce the element output

by turning it off if the ambient temperature

exceeds 135°C (±5°C) for condenser dryers and

110°C (±5°C) for others.

The machine is equipped with a overheating

cut-out, which is available in two versions, one

automatically resettable and one manual. The

overheating cut-out switches off the power supply

to all components if the temperature exceeds

150°C (±5°C) and closes the circuit once the

temperature drops below 135°C (±8°C). The

drying program stops and must be restarted if the

overheating cut-out is triggered.

To reset the manual overheating cut-out,

the cover plate on the machines back must be

removed. Press the button on the overheating cutout for manual reset. The automatic overheating

cut-out resets when the temperature drops below

135°C (±8°C) for condenser dryer and 120°C

(±5°C) for others.

Purpose: The thermostat measures

temperature and controls heating element

output. The overheating cut-out controls the

temperature and cuts the power supply if the

machine overheats.

Cover plate (658 x 483 mm)

EMC filter

The filter is installed next to the cable fasteners

where the connection cable enters the

machine. The filter consists of a number of coils,

condensers and resistors.

Purpose: To eliminate electromagnetic

interference to and from the machine.

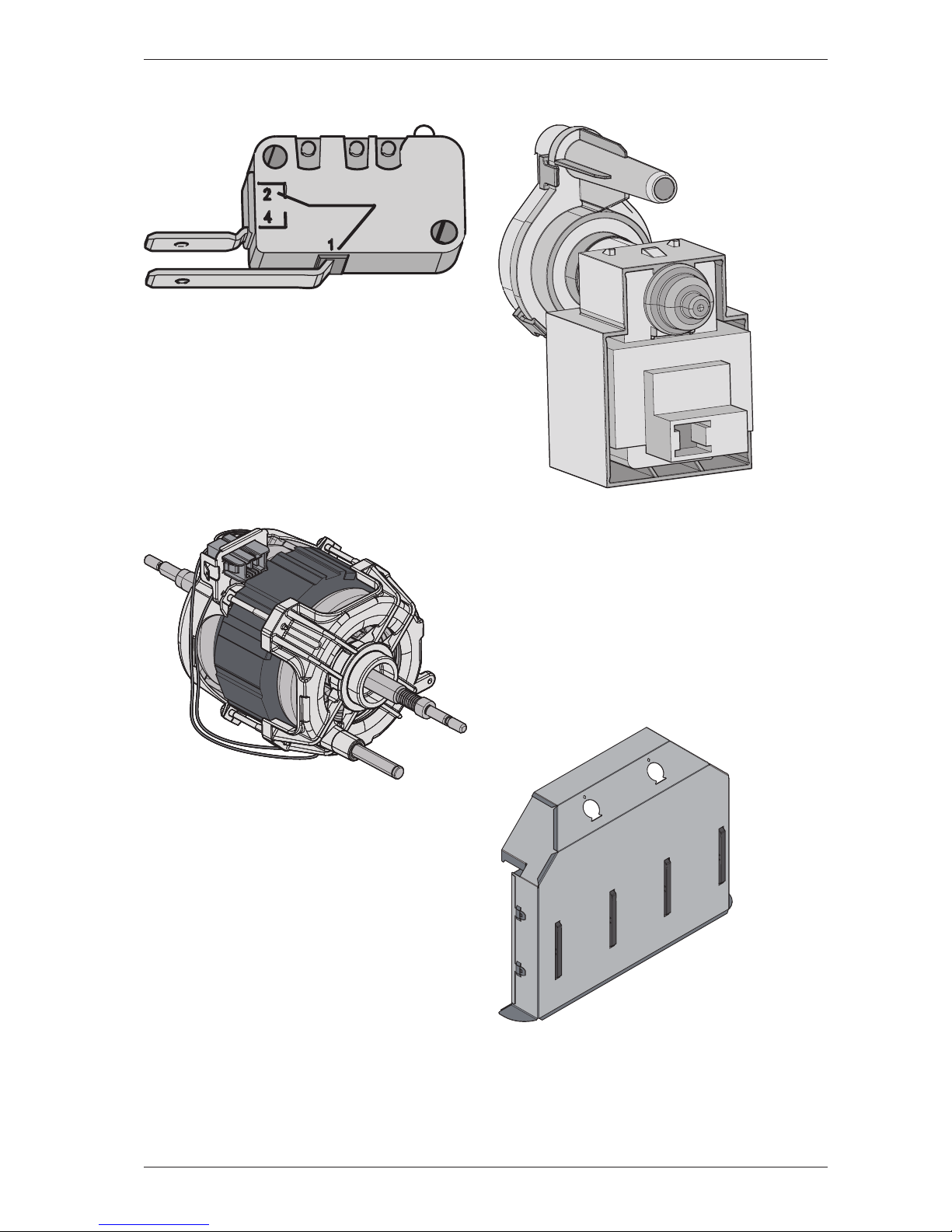

Overflow guard

The overflow guard comprises a microswitch

triggered by a float. When the lower condensed

water container becomes full the float rises and

triggers the microswitch. The microswitch is

normally closed; when activated it opens the

circuit. When the microswitch has been open

for more than 30 seconds, the drying program

stops and the display shows “Over flow”. You

can erase this message by turning the program

selector or pressing the Start/Stop buttons.

Purpose: To provide protection from any

water leaks or flooding from the machine.

Component descriptions

Thermostat

Overheating cut-out

Reset

Service Manual TD70

13

Component descriptions

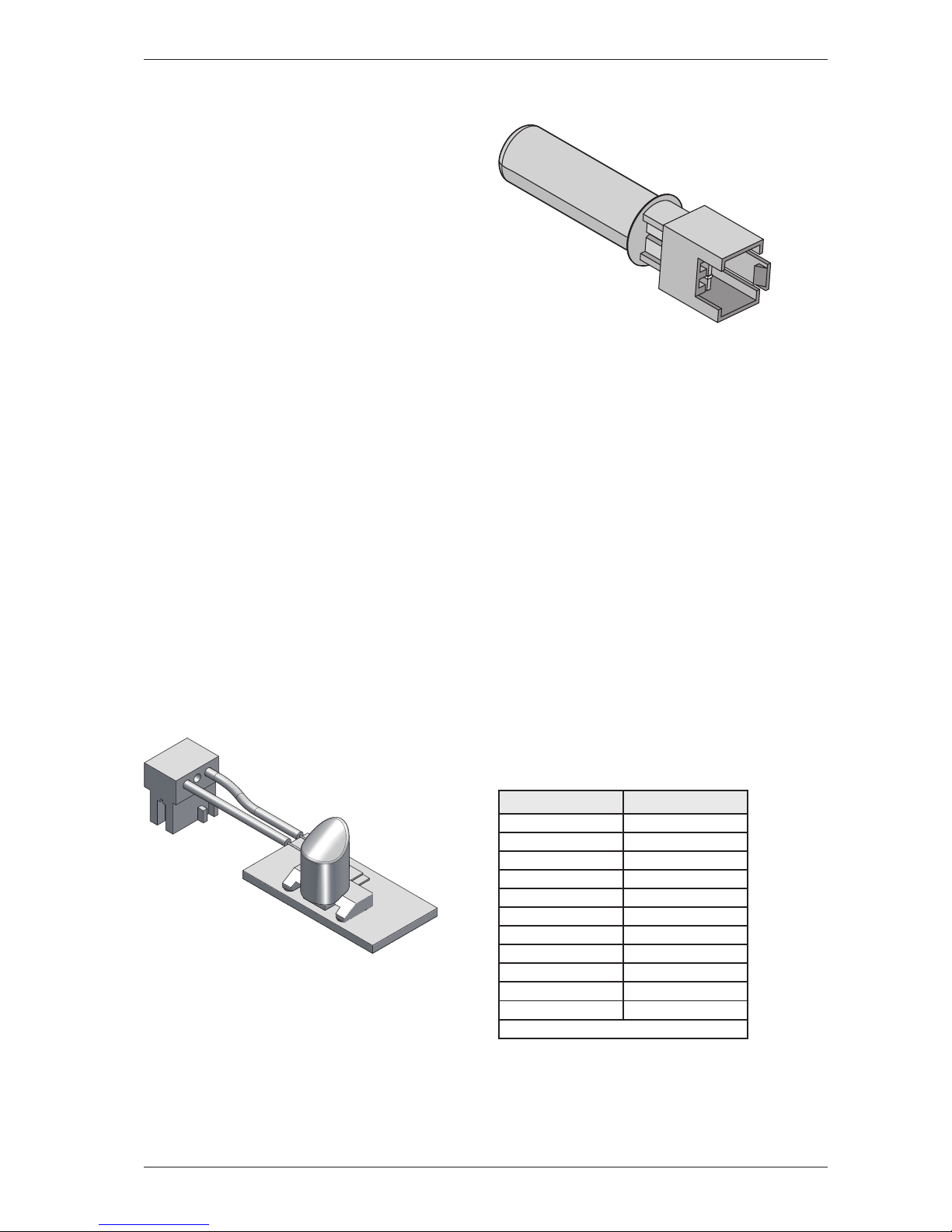

Door switch

The door switch is located in a holder in the

middle of the front support and is activated by

a pin in the front door. The switch is normally

open and closes when the door is closed. If the

front door is opened during operation the CU

stops the drying program. The program starts

from the beginning if restarted.

Purpose: To prevent the machine from running

while the door is open.

Drying motor

The motor is at the bottom and drives the

impeller that is directly fitted to the shaft

journal. The motor is a unit with a belt

tensioner and springs and drives the drying

drum via a poly V-belt.

Purpose: To drive the impeller and drum during

the drying process.

Drainage pump (condenser dryer)

The drainage pump is located in the lower

condensed water container. The condensed

water is pumped to the condensed water

container or directly to the drain. When a

drying program is running, the drainage pump

is activated constantly in cycles of 30 seconds

ON and 210 seconds OFF.

Purpose: To pump condensed water to the

condensed water container or the drain.

Heating element

The heating element is located in the rear section

and consists of two separate heating coils. Each

heating coil is made from resistance wire.

Purpose: To heat the drying air to the right

temperature.

Service Manual TD70

14

Loading...

Loading...