Page 1

RTM-ATCA-736X-DD

Installation and Use

P/N: 6806800L82C

June 2014

Page 2

©

Copyright 2014 Artesyn Embedded Technologies, Inc.

All rights reserved.

Trademarks

Artesyn Embedded Technologies, Artesyn and the Artesyn Embedded Technologies logo are trademarks and service marks of

Artesyn Embedded Technologies, Inc.© 2014 Artesyn Embedded Technologies, Inc. All other product or service names are the

property of their respective owners.

Intel® is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

Java™ and all other Java-based marks are trademarks or registered trademarks of Oracle America, Inc. in the U.S. and other countries.

Microsoft®, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

Microsoft Corporation.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

Industrial Computer Manufacturers Group.

UNIX® is a registered trademark of The Open Group in the United States and other countries.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Artesyn assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Artesyn reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Artesyn to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

an Artesyn website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Artesyn.

It is possible that this publication may contain reference to or information about Artesyn products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Artesyn intends to announce such Artesyn products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Artesyn.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Artesyn Embedded Technologies Artesyn Embedded Technologies

Marketing Communications

2900 S. Diablo Way, Suite 190

Tempe, Arizona 85282

Lilienthalstr. 17-19

85579 Neubiberg/Munich

Germany

Page 3

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Advanced RTM Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3 I/O PICMG Standards Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4 I/O Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.1 Ports 1-2, Ethernet 1000Base-T (RJ-45) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.5 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6 Disk "Request Eject" Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.7 Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.8 Software Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.9 Products Supported by this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.10 Identification Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2 Installation and Removal of the Rear Transition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Important Information about Your Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3.1 Safety Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3.2 Observe Maximum Module Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4 Before You Install Or Remove the RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.4.1 Observe ESD Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.4.2 Watch for Bent Pins or Other Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.5 Use Caution When Installing or Removing RTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.5.1 Preserve EMI Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.5.2 Understand Hot Swap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.6 Verify Slot Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.7 Installing the Advanced Rear Transition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.8 Removing the Advanced Rear Transition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.9 Verifying the Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.10 SAS Drive Carrier Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.11 SAS Drive Carrier Assembly Removal (Eject) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

3

Page 4

Contents

Contents

Contents

3 SAS RAID Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 Hard Disk Drive Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3 SAS Boot BIOS Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4 Brief Theory of BIOS Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5 Boot BIOS Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.1 Launching the Boot BIOS Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.2 BIOS Launch: Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.5.3 Adapter Properties Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.6 RAID Firmware Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.6.1 BIOS, RAID Properties Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.6.2 BIOS, RAID Create New Array and Global Hot Spare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 Mechanical and Connector Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.1 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.3 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.4 Environmental Specifications and Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.1.5 NEBS Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1.6 Electromagnetic Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Connectors and Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.2.1 1000Base-T Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2.2 Zone 3 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2.2.1 Connector J30, Power Supply for Advanced RTM . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2.2.2 Connector J30, Storage and Management Infrastructure Pin Assignments . 52

4.2.2.3 Connector J32, PCI-Express and Test Infrastructure Pin Assignments . . . . . . 53

5 IPMI Functions List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.2 IPMI and Management Controller (IPMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3 Sensor Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3.1 RTM E-Keying Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4 Supported IPMI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 5

Contents

5.4.1 Disk IPMI ’raw’ Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.4.1.1 Disk Eject, Deactivation Request to Power-off Disk . . . . . . . . . . . . . . . . . . . . . . 62

5.4.1.2 Approve Disk Eject Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4.1.3 Read OEM Manufacturing in DCA EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4.1.4 Write OEM Manufacturing Data Contents in DCA EEPROM . . . . . . . . . . . . . . . 64

5.5 Communication Mechanisms for Disk Extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.1 Typical Module Insertion, All Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.2 Typical Module Slave Extraction Mode (Normal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.3 Typical Module Extraction, Standalone Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6 MMC Firmware Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2 The ipmitool Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.1 Synopsis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.2.4 Command Syntax Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

5

Page 6

Contents

Contents

Contents

6

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 7

List of Tables

Table 1-1 I/O Ports Available On RTM Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 1-2 LEDs On RTM Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 1-3 Available Board Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 1-4 RTM-ATCA-736X-DD Identification Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 2-1 Maximum RTM Module Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 4-1 RTM-ATCA-736X-DD Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 4-2 Environmental Specifications for the RTM-ATCA-736X-DD . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 4-3 EMC Emission Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 4-4 Connector Port Identification snd Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 4-5 10/100/1000 Management Port Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 4-6 Connector P30, Management infrastructure Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . 52

Table 4-7 Connector J30, Management Infrastructure Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . 52

Table 4-8 Connector J32, Miscellaneous RTM Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 4-9 Connector J32, Miscellaneous RTM Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 5-1 Sensor Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-2 Standard FRU Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 5-3 RTM E-Keying Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 5-4 Supported IPMI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 5-5 IPMI Raw Command Disk Removal Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 5-6 IPMI Raw Command to Approve Disk Power Eject Request . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 5-7 IPMI Raw Command to Read OEM Manufacturing from Drive Carrier Assembly . . . . . . . . 63

Table 5-8 IPMI Raw Command to Read FRU Data from Hard Disk Assembly . . . . . . . . . . . . . . . . . . . . . 64

Table 5-9 Disk Eject jumper Position vs. Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 5-10 MMC Sensor Description for Disk FRU State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 6-1 Ipmitool Options Relevant To Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

7

Page 8

List of Tables

8

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 9

List of Figures

Figure 1-1 RTM-ATCA-736X-DD Functional Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . 17

Figure 1-2 RTM-ATCA-736X-DD Back Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

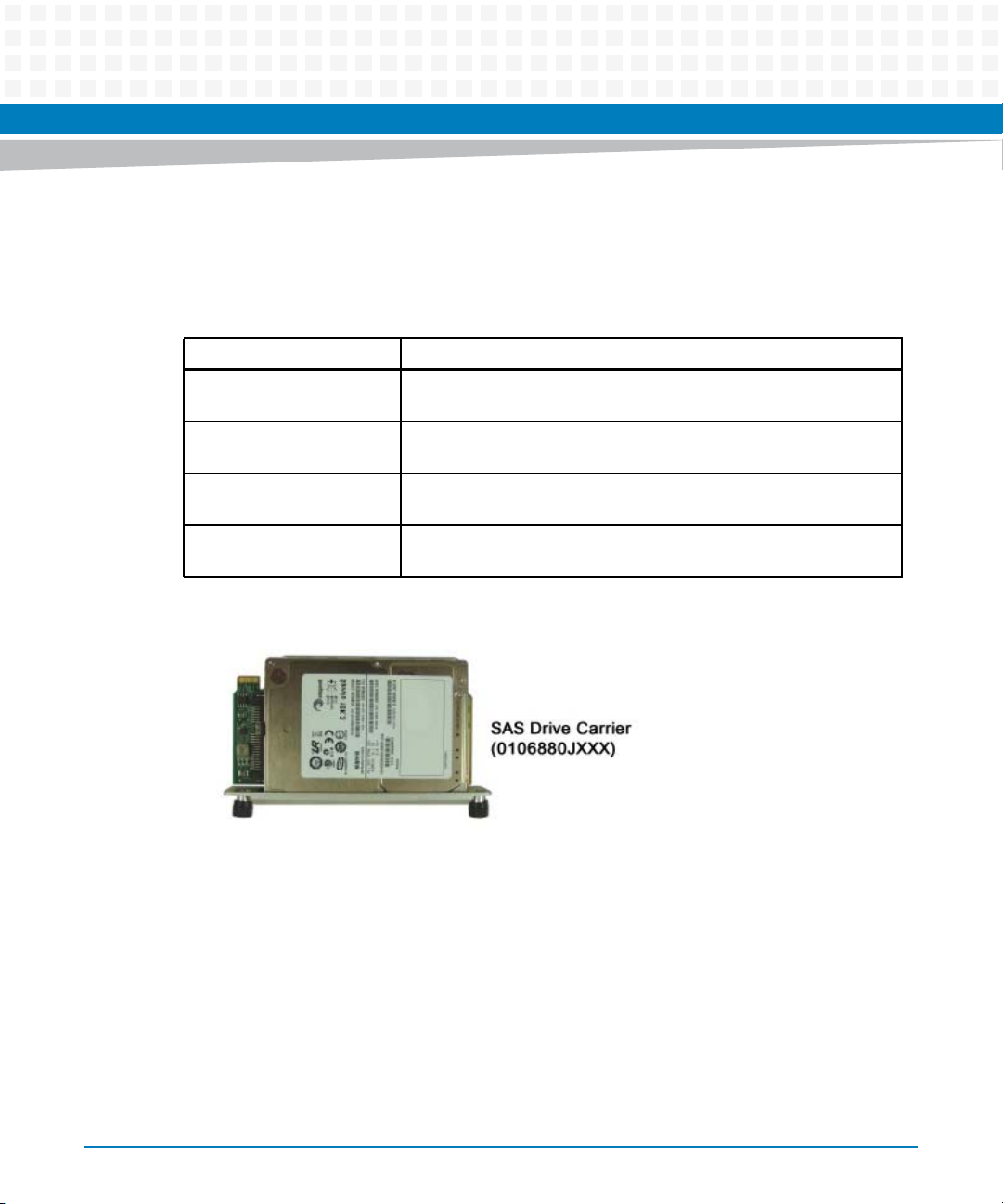

Figure 1-3 SAS Drive Carrier (0106880JXXX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

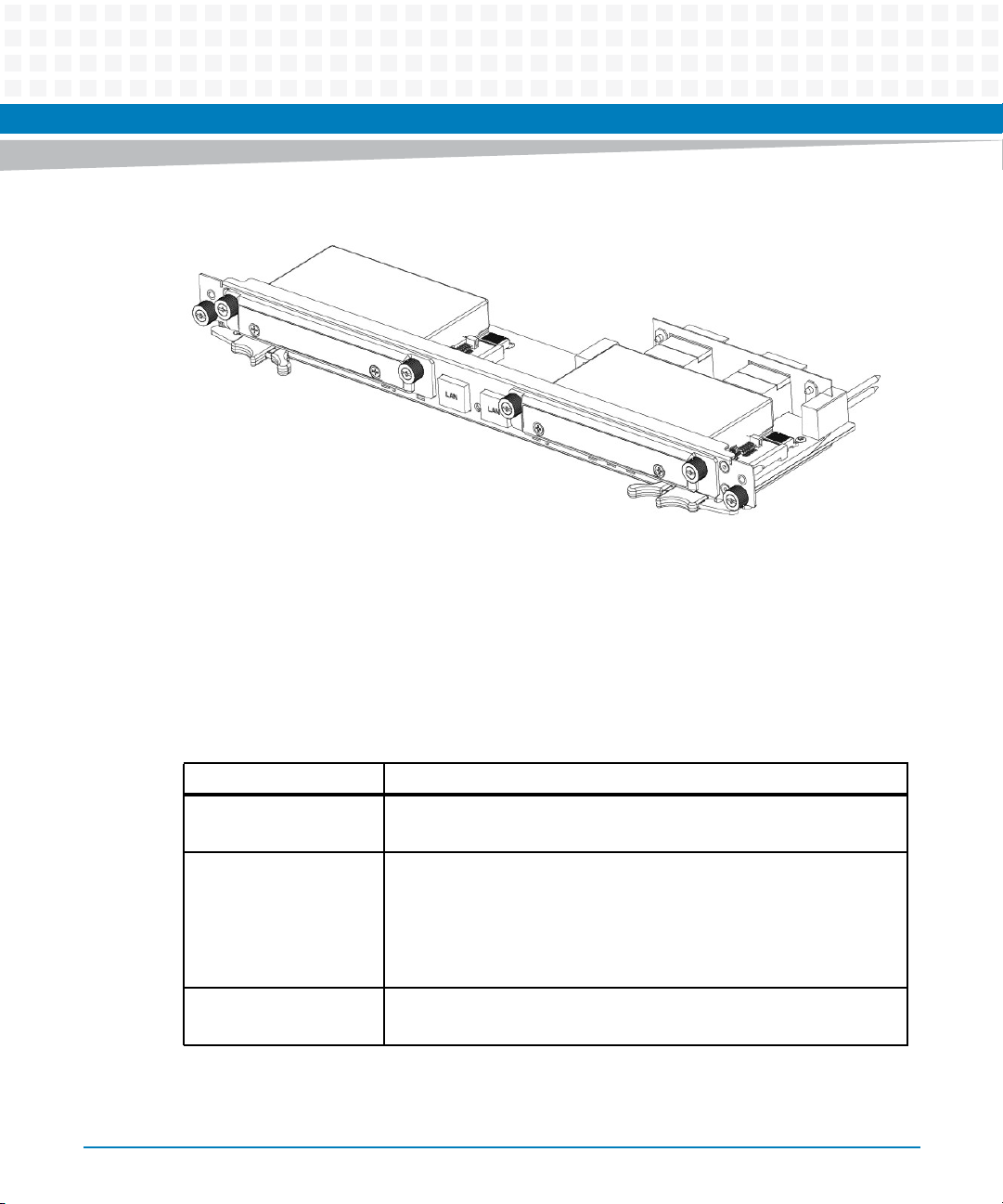

Figure 1-4 RTM-ATCA-736X-DD Top View (with disks installed) . . . . . . . . . . . . . . . . . . . . . . . . . 21

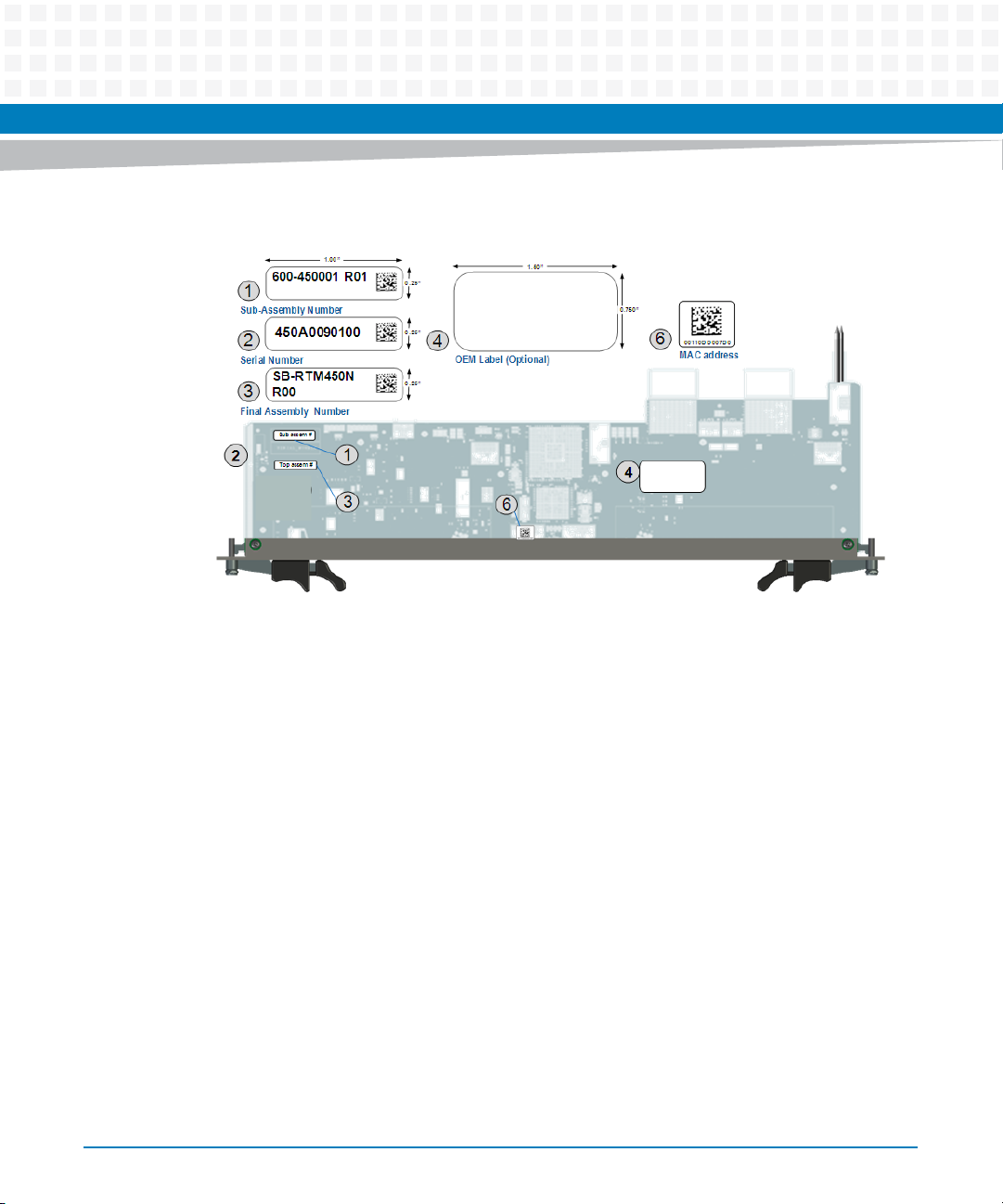

Figure 1-5 RTM-ATCA-736X-DD Diagram Showing Identification Label Locations . . . . . . . . . 22

Figure 1-6 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2-1 Injector / Ejector Latch and Locking Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-2 Drive Carrier Assembly (0106880JXXX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 2-3 Drive Carrier Assembly (DCA) Orientation for Installation . . . . . . . . . . . . . . . . . . . . 35

Figure 3-1 SAS BIOS Start Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-2 SAS BIOS Adapter Properties, RTM Status and Configuration . . . . . . . . . . . . . . . . . . 40

Figure 3-3 SAS BIOS RAID Level Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 3-4 SAS BIOS, Create New RAID Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 4-1 RTM-ATCA-736X-DD Rear Transition Module Connectors . . . . . . . . . . . . . . . . . . . . 48

Figure 4-2 10/100/1000 Mb Management Port Pin Location Diagram . . . . . . . . . . . . . . . . . . . 49

Figure 4-3 Zone 3, Connector Port Pin Location Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 5-1 Locations of Disk Eject Jumper and Disk Eject Buttons . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 5-2 Disk FRU State Diagram, Slave Mode (Normal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 5-3 Disk FRU State Diagram, Stand-alone Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

9

Page 10

List of Figures

10

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 11

About this Manual

Overview of Contents

This manual supports RTM-ATCA-736X-DD, Rear Transition Module (RTM) with two 1000BaseT Ethernet Ports.

This manual is divided into the following chapters and appendices:

Introduction provides an RTM-ATCA-736X-DD overview.

Installation contains the procedures for installing and removing the RTM-ATCA-736X-DD.

SAS RAID Details provides detailed information on the RTM-ATCA-736X-DD SAS RAID

capabilities.

Mechanical and Connector Information provides mechanical, electrical, environmental, and

other relevant information.

IPMI Functions List provides the details for the function list of the Intelligent Platform

Management Interface.

MMC Firmware Upgrade Procedure provides instructions for upgrading the IPMC (Intelligent

Platform Management Controller) firmware.

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

AMC Advanced Mezzanine Card

ARP Address Resolution Protocol

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

11

Page 12

About this Manual

Conventions

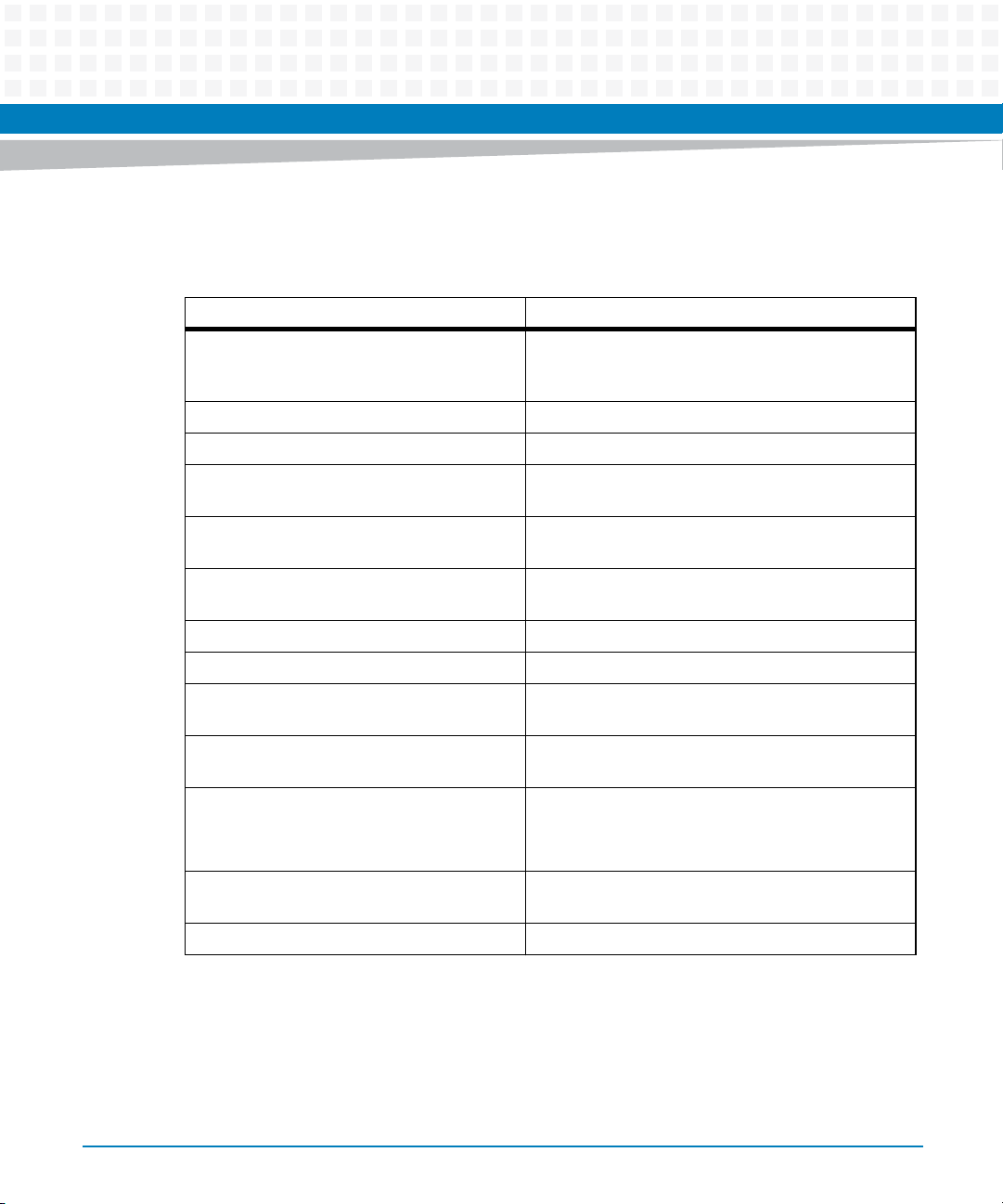

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

Courier + Bold Used to characterize user input and to separate it

Reference Used for references and for table and figure

About this Manual

0 through F), for example used for addresses and

offsets

or commands in body text

from system output

descriptions

12

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

and parameter description

... Repeated item for example node 1, node 2, ..., node

12

.

.

.

.. Ranges, for example: 0..4 means one of the integers

| Logical OR

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 13

Notation Description

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information.

About this Manual

Summary of Changes

This manual has been revised and replaces all prior editions.

Part Number Publication Date Description

6806800L82A April 2011 General access release

6806800L82B May 2012 Updated SAS Drive Carrier Assembly Installation on

6806800L82C June 2014 Re-branded to Artesyn.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

page 32.

13

Page 14

About this Manual

About this Manual

14

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 15

Introduction

1.1 Overview

The RTM-ATCA-736X-DD is a rear transition module (RTM) designed specifically to work with

the Artesyn ATCA-736x processor blade family. The RTM features a two-port 1 Gb Ethernet

controller, a four-port SAS controller and two removable disk cards called SAS Drive Carriers.

The disk cards each hold one 2.5" disk, and fit wholly within the RTM thermal envelope to

provide an environment for proper disk cooling.

Functionally, the RTM-ATCA-736X-DD utilizes two PCI Express buses to connect with the

Ethernet and SAS controllers. The Ethernet controller provides two 1000Base-T Ethernet

connections using RJ45 copper media jacks on the RTM back panel. These ports are compatible

with commodity off-the-shelf, non-proprietary CAT-5E or similar cables.

The SAS controller provides four SAS/SATA ports that each operates at 3 Gb/s. Two SAS ports

route to the removable disks, and two SAS ports route back to the Zone 3 connector for

additional storage expansion. For example, the front blade can add more storage by routing

these ports to disks or to a SAS expander.

Chapter 1

Finally, the RTM-ATCA-736X-DD includes numerous indicator LEDs and a modular

management controller (MMC) with a hot swap notification mechanism to coordinate disk

servicing the front blade OS. The MMC also performs intelligent monitoring and management

tasks and conforms to the PICMG 3.0 and AMC.0 R2 specification.

1.2 Advanced RTM Features

The RTM-ATCA-736X-DD is an 8U (355.6 mm x 80mm) single slot Rear Transition Module that

includes the following interfaces and features:

Intel 82580, Dual 1Gb Ethernet controller (PCI Express Gen 2.0)

Two Ethernet 1000Base-T ports (RJ45)

LSI SAS1064E, Quad 3 Gb SAS controller (PCI Express Gen 1.0a)

Two removable SAS Drive Carriers (0106880J0XX)

RAID 0,1, and 1E capability, with boot

SAS Expander support, up to 122 disks

Handle Ejector switch for hot swap

One recessed push button switch for front blade reset

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

15

Page 16

Introduction

Two recessed push button switches for disk FRU eject request

Temperature and voltage sensors

OOS, health, alarm, and hot swap LEDs

On-board MMC controller for management activities (IPMI)

1.3 I/O PICMG Standards Compliance

The RTM-ATCA-736X-DD is fully compliant with the following PCI Industrial Computer

Manufacturers Group (PICMG) specifications:

PICMG 3.0 Rev 3.0

PICMG AMC.0 Rev2.0 compliance

IPMI v1.5 Intelligent Platform Management Interface Specification

PCI Express 2.0 and 1.0a specifications

1.4 I/O Interfaces

The RTM-ATCA-736X-DD mounts to the ATCA carrier blades using zone-3 connectors,

conforming to PICMG 3.0 ATCA specification revision 3. Internally, the RTM-ATCA-736X-DD

connects zone-3 and the RTM faceplate as follows:

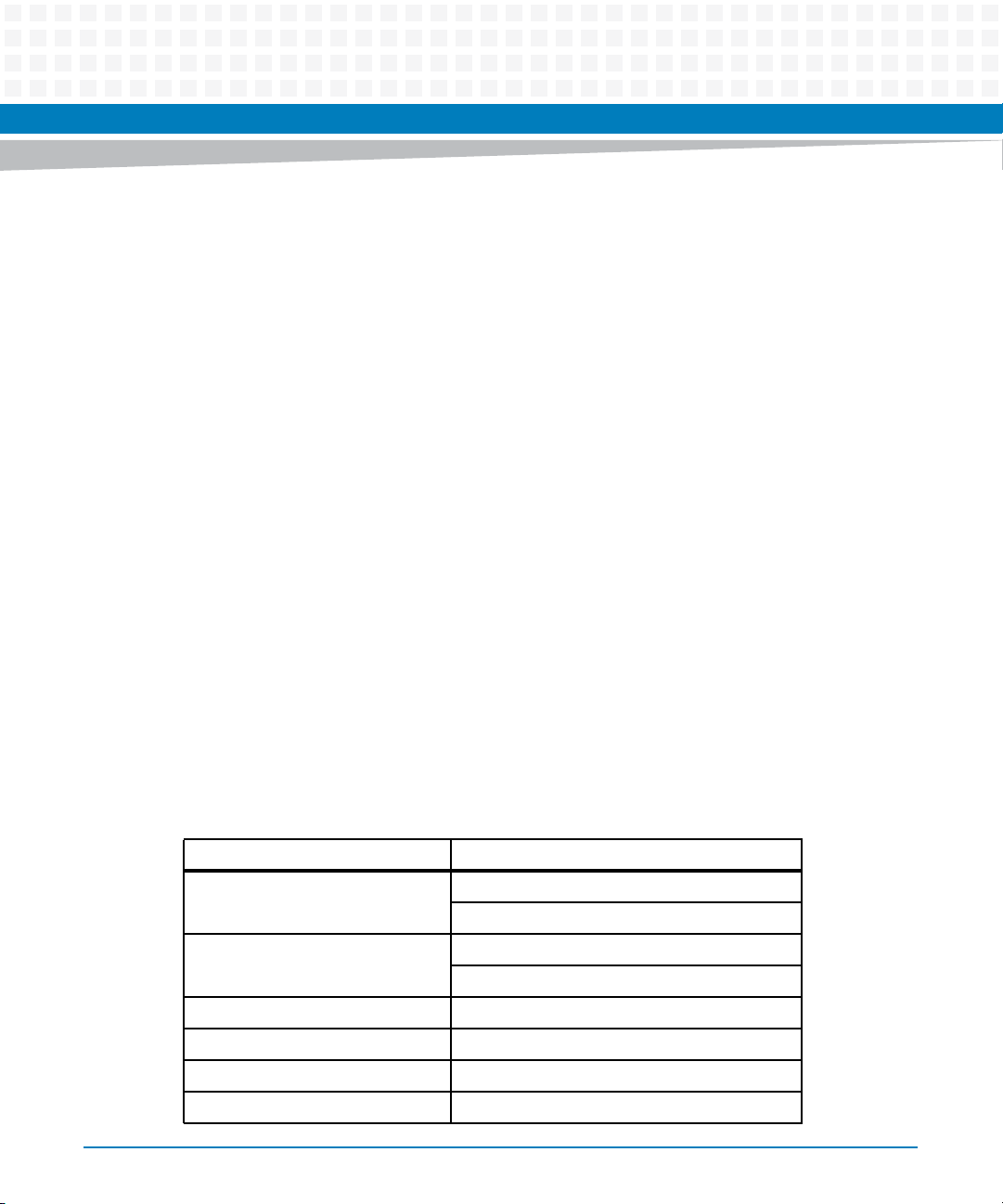

Table 1-1 I/O Ports Available On RTM Faceplate

RTM Zone-3 Electrical Signaling RTM Faceplate

PCIe v1.0, x4 bus #1 Port 1 RJ45 1000Base-T

PCIe v1.0, x8 bus #2 SAS disk field replaceable assembly #1

DCA_SAS, x2 Routes to secondary ports of each SAS drive

LSI_SAS, x2 NA (Routes to LSI Controller)

IPMI - to MMC device on RTM NA

Power NA

16

Port 2 RJ45 1000Base-T

SAS disk field replaceable assembly #2

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 17

Figure 1-1 RTM-ATCA-736X-DD Functional Interconnect Diagram

Introduction

1.4.1 Ports 1-2, Ethernet 1000Base-T (RJ-45)

Each of these ports route to an Intel® 82580DB Ethernet controller accessed by the front blade

using PCI express signaling. These ports employ an RJ-45 connector with integrated LED for

link (green) and activity (amber). Each port auto negotiates to 10/100/1000BASE-T.

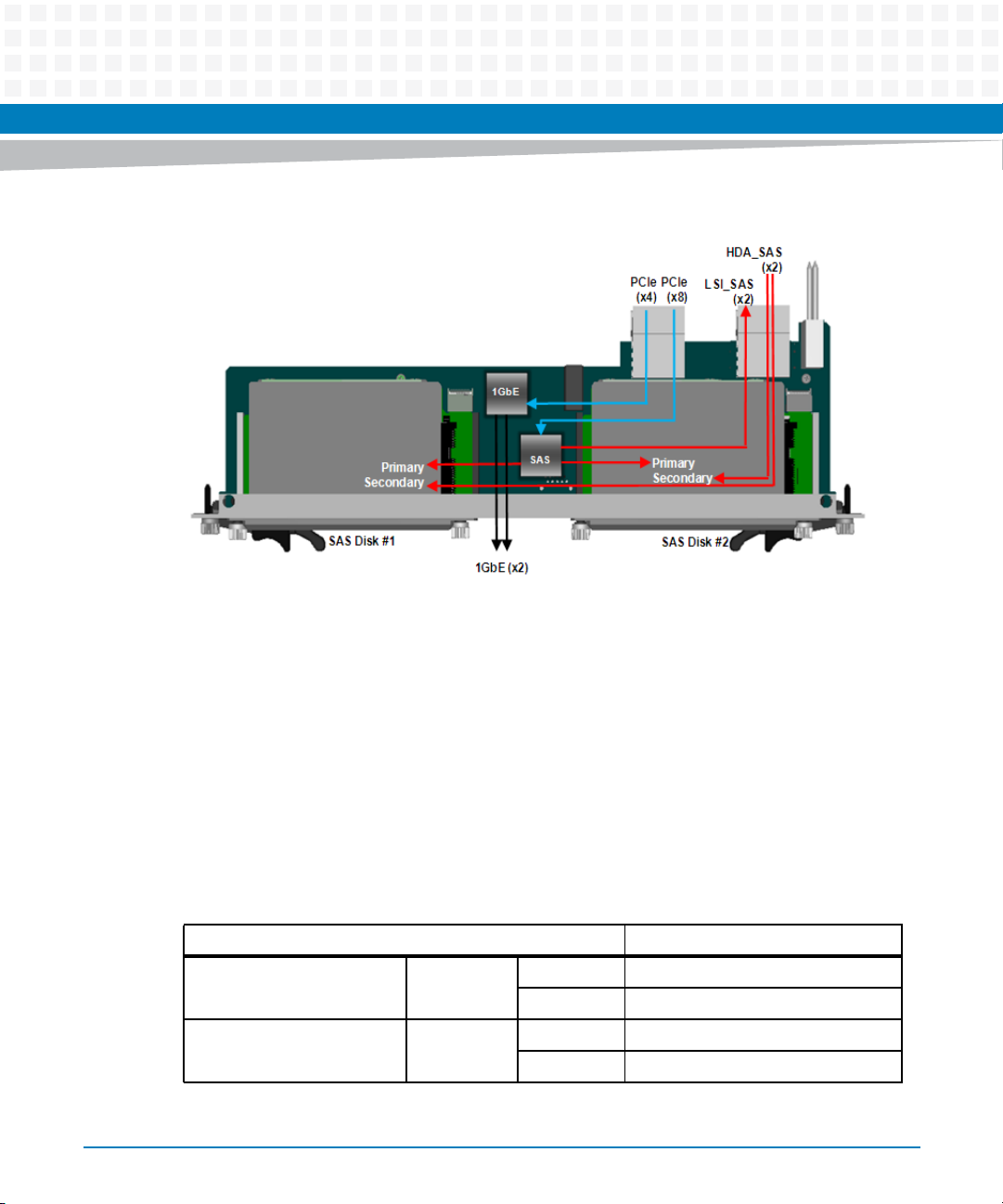

1.5 LEDs

The following LEDs are located on the panel of the RTM-ATCA-736X-DD.

Table 1-2 LEDs On RTM Faceplate

LED RTM Faceplate

Ethernet Activity Amber On LAN management activity LED

Off No activity

Ethernet Link Green On LAN management LINK LED

Off No link

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

17

Page 18

Introduction

Table 1-2 LEDs On RTM Faceplate (continued)

LED RTM Faceplate

Hard Disk Status #1 and #2 None Off SAS Drive Carrier not installed

Hot Swap (HS) Blue On Management power available to the

Green Off Disk in service

Green Blink Disk I/O on SAS port A

Amber Blink Preparing for removal

Amber On Ready/Safe for removal

module and the module can safely

be extracted

Off The module is operational and is

unsafe for extraction

Long Blink Delay before module is activated

Short Blink Delay before module is de-activated

Fault or “Out of Service”

(OOS)

In Service (IS) Green On 12V payload power is being supplied

Attention (ATN) Amber On/Off This LED is controlled by higher layer

Amber/Red On Module fault set by shelf manager or

12V payload power not detected.

Off No module fault 12V payload power

is being supplied to board

to board

Off 12V payload power is not detected

Amber/ Red Off This LED is multicolored

(red/green/yellow) and is programmable by IPMC.

software, such as middle ware or

applications.

18

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 19

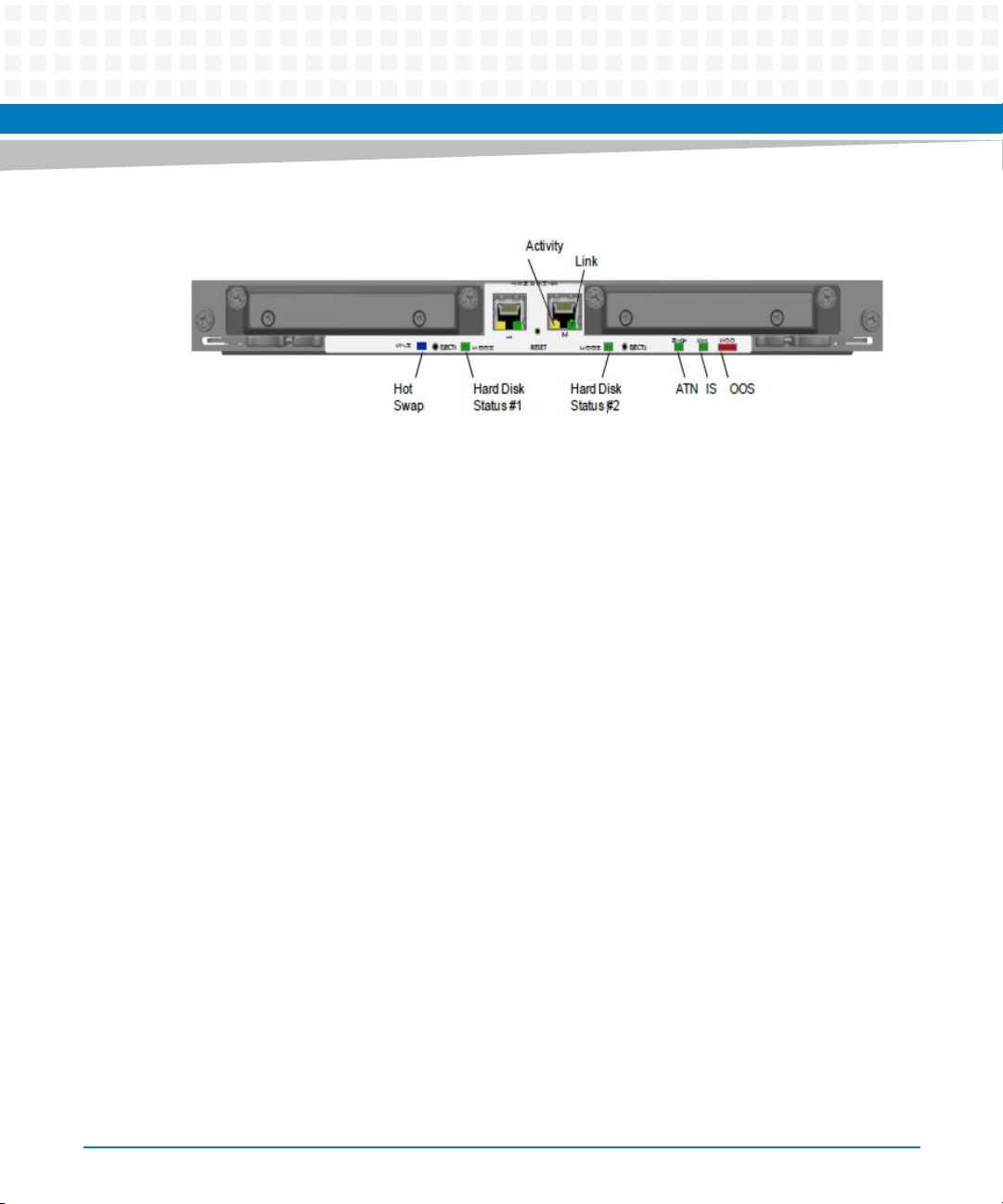

Figure 1-2 RTM-ATCA-736X-DD Back Panel LEDs

1.6 Disk "Request Eject" Button

The RTM-ATCA-736X-DD includes a pair of recessed eject buttons that is marked on the panel

near port 1 (Figure 1-2). Using a thin pointed object, such as a paper clip, a user can depress the

eject button. This action will send a message to the front blade requesting the disk ejection

reset. If granted, the corresponding hard disk status light will turn amber.

Introduction

1.7 Reset Button

The RTM-ATCA-736X-DD includes a recessed reset button that is located between the two

Ethernet ports (see Figure 1-2). Using a thin pointed object, such as a paper clip, a user can

depress the reset button. This action will send a message to the front blade requesting a

payload reset. If granted, the host blade and all peripherals will experience a warm reset.

1.8 Software Support

Except for the drivers for the 82580 Ethernet controller (driver distributed by Intel) and for the

SAS1064E controller (driver distributed by LSI) , RTM-ATCA-736X-DD requires no other special

software to operate. When shipped from the factory, the expander is un-zoned and configured

for table routing.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

19

Page 20

Introduction

1.9 Products Supported by this Manual

The information in this manual applies to the following Artesyn products:

Table 1-3 Available Board Variants

Marketing Number Description

RTM-ATCA-736X-DD-300 RTM for the ATCA-736X product series, 2X GBE, 2X 147GB SAS HDD

included (ROHS 6/6)

RTM-ATCA-736X-DD-600 RTM for the ATCA-736X product series, 2X GBE, 2X 300GB SAS HDD

included (ROHS 6/6)

RTM-ATCA-736X-1K2 RTM for the ATCA-736X Pproduct series, 2X GBE, 2X 600GB SAS HDD

included (ROHS 6/6)

RTM-ATCA-736X-DD RTM for the ATCA-736X product series, 2X GBE, 2X HDD carrier kits,

no HDD included (ROHS 6/6)

Figure 1-3 SAS Drive Carrier (0106880JXXX)

20

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 21

Figure 1-4 RTM-ATCA-736X-DD Top View (with disks installed)

1.10 Identification Labels

Introduction

At manufacturing time, several labels are affixed to the RTM-ATCA-736X-DD as shown below.

For proper identification of the RTM module, use these barcode labels to accurately determine

the module identity. The barcode labels provide the following information:

Table 1-4 RTM-ATCA-736X-DD Identification Labels

Label Description

Label 1: Artesyn

Sub-Assembly P/N

Label 2: Artesyn

Serial number (S/N)

Label 3: Final Assembly

P/N

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

P/N = Sub-Assembly Part Number

Rev = Assembly Revision (Refer to Bill Of Material)

S/N Format :AAA = Assembly Number (440)

L =Location of manufacturer (S)

Y = Calendar year of manufacturer ( 2010=0, 2011=1)

MM = Calendar month of manufacturer (March = 03)

SSSS = Sequence number (reset each month) (1234)

P/N = Final Assembly Part Number

Rev = Assembly Revision

21

Page 22

Introduction

Figure 1-5 RTM-ATCA-736X-DD Diagram Showing Identification Label Locations

22

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 23

Introduction

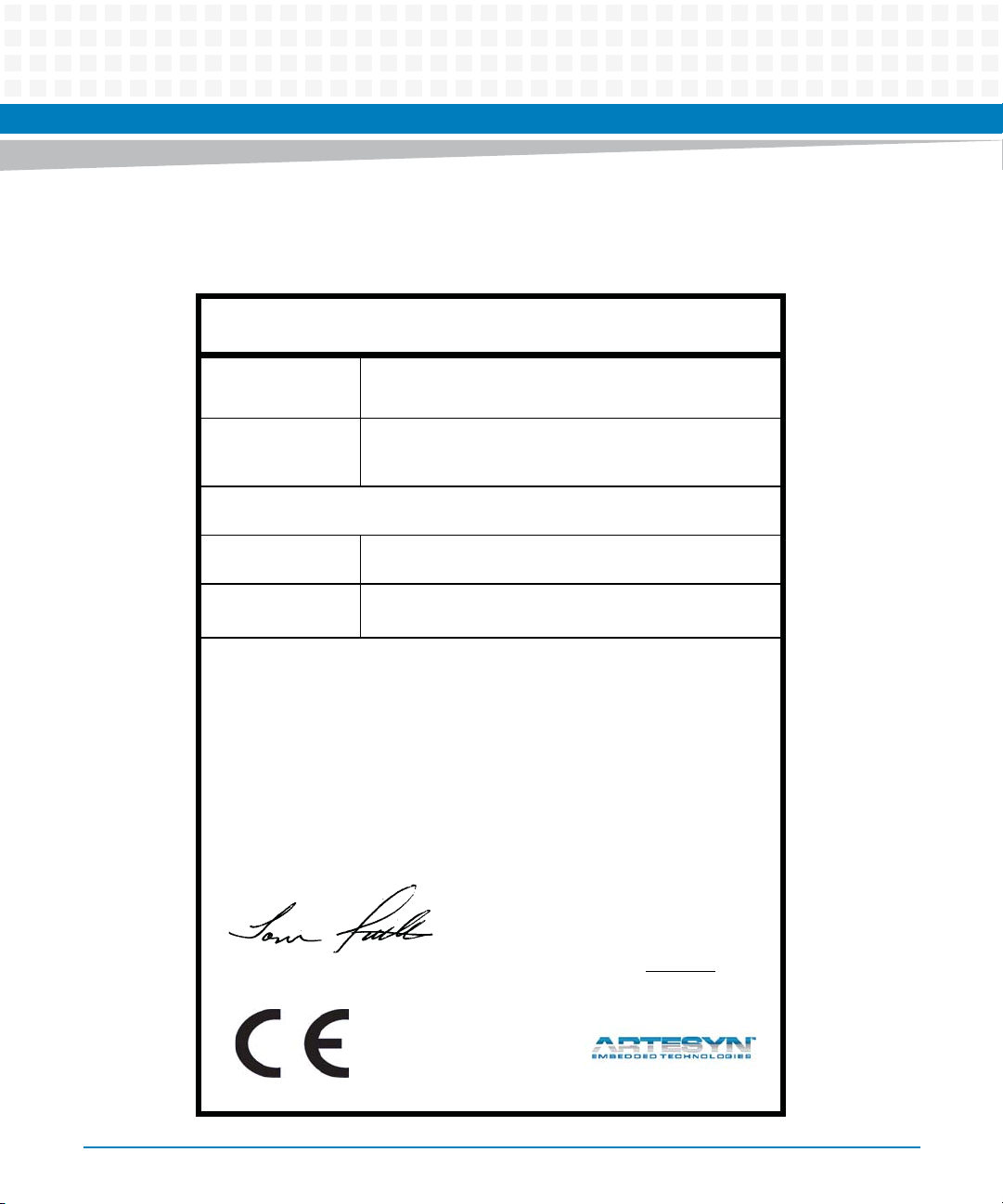

The following figure contains the Declaration of Conformity for RTM-ATCA-736x-DD series.

Figure 1-6 Declaration of Conformity

E

C Declaration of Conformity

According to EN 17050-1:2004

Manufacturer’s Name:

Manufacturer’s Address:

Declares that the following product, in accordance with the requirements of 2004/108/EC, 2006/95/EC,

2011/65/EU and their amending directives,

Product:

Model Name/Number:

has been designed and manufactured to the following specifications:

EN55022:2010

EN55024:2010

ETSI EN 300 386 V1.5.1 (2010-10)

IEC 60950-1:2005 (2nd Edition), EN60950-1:2006+A11:2009

2011/65/EU RoHS Directive

As manufacturer we hereby declare that the product named above has been designed to comply with the relevant sections of the above referenced specifications. This product complies with the essential health and safety

requirements of the above specified directives. We have an internal production control system that ensures

compliance between the manufactured products and the technical documentation.

Artesyn Embedded Technologies

Embedded Computing

Zhongshan General Carton Box Factory Co. Ltd. No 62, Qi

Guan Road West, Shiqi District, 528400 Zhongshan City

Guangdong, PRC

Rear Transition Module for the ATCA-7365, -737X-, 747X– Product

Series

RTM-ATCA-736X-10G, RTM-ATCA-736X-10G-SP,

RTM-ATCA-737X-10G, RTM-ATCA-736X-DD-1K2,

RTM-ATCA-736X-DD-300, RTM-ATCA-736X-DD-300

___________________________________________________ ___

Tom Tuttle, Manager, Product Testing Services Date (MM/DD/YYYY)

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

06/10/2014

______

23

Page 24

Introduction

24

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 25

Chapter 2

Installation

2.1 Overview

This chapter contains the procedures for installing and removing the RTM-ATCA-736X-DD

RTM.

2.2 Installation and Removal of the Rear Transition Module

The RTM-ATC A-736X-DD can be installed into an ATCA shelf (chassis) with a midplane made for

front and rear board installations. The module must be installed in the slot directly behind the

host ATCA node board. These back-to-back slots have common pins to enable passing of

signals using the Zone-3 connector complex.

2.3 Important Information about Your Chassis

Before installing the rear transition module, verify the module's part number to ensure that the

correct rear transition module is being installed into the system. For information on identifying

the rear transition module, see Products Supported by this Manual, on page 20.

2.3.1 Safety Statement

The RTM-ATCA-736X-DD is designed to comply with IEC60950-1, and is intended to be used

with similarly tested AdvancedTCA products that have a user's guide detailing user installation

of module accessories.

2.3.2 Observe Maximum Module Current Requirements

There are several manufacturing options for the RTM. Be sure to validate that the host chassis

can supply the RTM slot with these maximum current requirements.

Table 2-1 Maximum RTM Module Current Requirements

RTM-ATCA-736X-DD

Module Current

+12 V (spin up < 100 sec) 0.55 A (6.6 W) 1.9 A (22.9 W) (staggered spin-up)

(No Disk) RTM-ATCA-736X-DD (Two SAS Disk)

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

25

Page 26

Installation

Table 2-1 Maximum RTM Module Current Requirements (continued)

RTM-ATCA-736X-DD

Module Current

+12 V normal operating 0.55 A (6.6 W) 1.63 A (19.6 W)

OFF STATE LESS THAN 0.4 W LESS THAN 0.4 W

(No Disk) RTM-ATCA-736X-DD (Two SAS Disk)

2.4 Before You Install Or Remove the RTM

Boards may be damaged if improperly installed or handled. Please read and follow the

guidelines in this section to protect your equipment.

2.4.1 Observe ESD Precautions

Artesyn strongly recommends that you use an antistatic wrist strap and a conductive foam pad

when installing or upgrading a system. Electronic components, such as disk drives, computer

boards, and memory modules, can be extremely sensitive to electrostatic discharge (ESD).

After removing the component from its protective wrapper or from the system, place the

component flat on a grounded, static-free sur face (and, in the case of a board, component side

up). Do not slide the component over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing an

antistatic wrist strap (available at electronics stores) that is attached to an active electrical

ground. Note that a system chassis may not be grounded if it is unplugged.

2.4.2 Watch for Bent Pins or Other Damage

Bent pins or loose components can cause damage to the board, the backplane, or other system

components. Carefully inspect your board and the backplane for both pin and component

integrity before installation. Bent pins caused by improper installation or by boards with

damaged connectors could void the warranty for the backplane or boards.

If a system contains one or more damaged pins, power off the system and contact your local

sales representative to schedule delivery of a replacement chassis assembly.

26

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 27

Installation

2.5 Use Caution When Installing or Removing RTM

When first installing boards in an empty chassis or onto a carrier card, we recommend that

you start at the left of the card cage and work to the right.

When inserting or removing a board in a slot adjacent to other boards, use extra caution to

avoid damage to the pins and components located on the primary or secondary sides of the

boards.

2.5.1 Preserve EMI Compliance

To preserve compliance with applicable standards and regulations for electromagnetic

interference (EMI), during operation, all front and rear openings on the chassis or board

faceplates must be filled with an appropriate card or covered with a filler panel. If the EMI

barrier is open, devices may cause or be susceptible to excessive interference.

2.5.2 Understand Hot Swap

Your RTM is electrically designed for hot swap within a fully powered chassis. To facilitate hot

swap, there is a blue LED on the rear faceplate. This LED is under software control.

If your system is using software that provides full hot swap capabilities, the software will

illuminate the blue hot swap LED on the rear faceplate when software has stopped and it is safe

to remove the advanced rear transition module.

If your system does not have hot swap-aware software running, the behavior of the blue LED is

not determined. In this case, you may need to manually shut down applications or operating

systems running on the board prior to board removal, even if the blue LED is lit.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

27

Page 28

Installation

Powering down or removing a board before the operating system or other software running on

the board has been properly shut down may cause corruption of data or file systems.

Depending on the type of front blade the RTM is connected to, hot swapping the RTM will

cause the front board to power down its payload. Please consult Artesyn Embedded

Technologies documentation of the relevant front board for further details about RTM hot

swap.

2.6 Verify Slot Usage

Prevent possible damage to module components by verifying the proper slot usage for your

configuration.

2.7 Installing the Advanced Rear Transition Module

28

This section describes a recommended procedure for installing the RTM module in a chassis.

Before you install your module, please read all cautions, warnings, and instructions presented

in this section.

Handling modules and peripherals can result in static damage. Use a grounded wrist strap,

static-dissipating work surface, and antistatic containers when handling and storing

components.

Insert the board by holding the module handles. Do not exert unnecessary pressure on the

faceplate.

Hot swap compliant modules may be installed while the system is powered on. If a module is

not hot swap compliant, you should remove power to the slot or system before installing the

module. Please consult Artesyn Embedded Technologies documentation of the relevant front

board for further details about RTM hot swap.

Installation Process

1. Verify that you have taken the necessary antistatic precautions.

2. Go to the back of the system and choose an appropriate slot for the rear transition module.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 29

Installation

Rear transition modules must be installed in-line behind the accompanying node board. For

example, if the accompanying node board is going to be installed in slot 3, its rear transition

module must be installed at the back of the system in slot 3.

3. Remove the slot filler panel from the selected node board slot, if necessary.

4. Prepare the module by loosening the locking screws and opening the injector/ejector latch

at the top of the module as shown in the figure below.

Figure 2-1 Injector / Ejector Latch and Locking Screw

5. Carefully align the edges of the module with the guides in the appropriate slot.

Look into the enclosure to verify correct alignment of the rails in the guides. Align the edges

of the module with the card cage rail guides in the appropriate slot.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

29

Page 30

Installation

6. Keeping the module aligned with the guides, apply equal and steady pressure and slide the

module in until the injector/ejector mechanism engages with the retention bars.

7. Position your thumbs at the top and bottom of the RTM; simultaneously push in the module

and rotate the injector/ejector mechanisms inward to its closed position to seat and secure

the RTM. DO NOT FORCE THE BOARD INTO THE SLOT.

8. Tighten the two module retention screws to secure the module into the shelf.

9. Power on the system, if necessary. Refer to your system manual for instructions on correctly

powering on the system. Once power is applied to the chassis, the internal MMC controller

runs a self-test that runs for approximately 10 seconds. Upon a successful power up selftest, the blue hot swap LED will blink and then turn off, indicating that the module has been

placed in operation.

2.8 Removing the Advanced Rear Transition Module

The RTM-ATCA-736X-DD RTM is hot-swappable and can be removed from the chassis without

powering down its associated node board if supported by the front board. Please consult

Artesyn Embedded Technologiesdocumentation of the relevant front board for further details

about RTM hot swap. This section describes a recommended procedure for removing a board

module from a chassis.

Before you remove your module, please read all cautions, warnings, and instructions presented

in this section. Hot swap compliant modules may be removed while the system is powered on.

If the chassis is not hot swap compliant, you should remove power to the slot or system before

removing the module.

Removing an RTM

1. Loosen the locking screws on the rear transition module.

2. Rotate the top ejector handle to half way (HW) position. Do not remove the module

immediately.

3. If your host module is running a hot swap-aware software, the action of rotating the ejector

lever will start the shutdown process on the board. The software will slowly blink the blue

hot swap LED indicating the module is in the process of being deactivated.

4. Once the module has been deactivated, the blue LED will illuminate steadily. Once this is

done, you can extract the module by pulling on the module handle.

30

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 31

Note: Powering down or removing a board before the operating system or other software

running on the board has been properly shut down may cause corruption of data or file

systems.

5. If your board or system is not running hot swap-aware software, the blue LED may

illuminate without regard to software processes still running on the board. Be sure to

manually shut down applications or operating systems running on the board prior to board

removal.

6. Carefully pull the module from the chassis.

7. If the card slot is to remain empty, install a filler panel in the slot.

2.9 Verifying the Hardware Installation

This section provides information to verify the installation of the RTM-ATCA-736X-DD module.

Manually inspect the module power LED on the RTM panel. Refer to Figure "RTM-ATCA-736X-

DD Back Panel LEDs" on page 19.

Installation

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

31

Page 32

Installation

2.10 SAS Drive Carrier Assembly Installation

The RTM-ATCA-736X-DD can accommodate two SAS drive carrier assembly. These assemblies

support disk serviceability and hot swap without removing the RTM. This section describes the

recommended procedure for installing the drive carrier assembly.

Figure 2-2 Drive Carrier Assembly (0106880JXXX)

32

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 33

Installation

To install a DCA, follow these steps:

1. Verify that you have taken the necessary antistatic precautions.

2. Place the hard disk insulator on the top of the SAS-PCB assembly.

3. Align the insulator holes with the holes on the board.

4. Place the hard disk on the top of the insulator, such that it is aligned with the board SATA

connector.

5. Slide the hard disk into the SATA connector.

6. Flip assembly on its back and align the SAS-PCB holes with the insulator and hard

disk holes.

7. Attach the drive support bracket to the side of the hard disk.

8. Tighten the four flat head screws to secure the drive support bracket to the hard

disk.

9. Tighten the two pen head screws to fix the hard disk, insulator, and SAS-PCB

together.

10.Assemble the front panel bezel to the disk drive assembly using two flat head

screws.

2.11 SAS Drive Carrier Assembly Removal (Eject)

The RTM-ATCA-736X-DD can accommodate two SAS Drive Carrier Assemblies (DCA). These

assemblies support disk serviceability and hot swap without removing the RTM. This section

describes the recommended procedure for removing the hard disk assembly.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

33

Page 34

Installation

To remove a DCA, follow these steps:

1. Locate the hole marked "EJECT" corresponding to DCA #1 or #2. Insert a paperclip about 0.5

inches to engage a spring-loaded plastic micro switch.

Note: Removing a DCA without properly preparing the operating system or other software

using the disk, may cause corruption of data or file systems.

2. The corresponding DCA status LED will blink in amber color for approximately five seconds.

The blink indicates the DCA is being de-activated.

3. Once the module has been de-activated, the DCA status LED illuminates steady amber.

4. Loosen the locking thumbscrews on the DCA. Carefully pull the module from the chassis.

34

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 35

5. If the card slot is to remain empty, install a filler panel in the slot.

Figure 2-3 Drive Carrier Assembly (DCA) Orientation for Installation

Installation

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

35

Page 36

Installation

36

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 37

SAS RAID Details

3.1 Overview

This chapter provides detailed information on the RTM-ATCA-736X-DD SAS RAID capabilities.

3.2 Hard Disk Drive Controller

The RTM-ATCA-736X-DD includes an LSI SAS 1064e hard disk drive controller with the

following features:

Four-lane PCIe interface (full duplex 2.5 Gb/sec)

Four SAS ports (3.0 Gb/sec) with 1 port routed to each hard disk drive slot.

3.3 SAS Boot BIOS Features

Chapter 3

The Boot BIOS for Intel/AMD-based platforms is stored on the flash device located on the

module.

The SAS boot BIOS supports the following features:

Support multiple SAS controllers

Apply global properties stored in flash

Selection and configuration for up to 256 adapters

Automatic INT13 drive mapping for SAS drives

SAS topology discovery, including expander traversal

Apply PHY transceiver properties

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

37

Page 38

SAS RAID Details

3.4 Brief Theory of BIOS Operation

If Boot is enabled, the boot BIOS will scan for SAS hard disks (HD) connected to the RTM.

Discovered disk(s) are enumerated with drive letters and appended to a master list of “devices”

discovered on the host. Upon scan completion, the host will serially inspect the master list of

devices beginning with drive A, and attempt to boot from the first device it finds with a boot

record.

The boot feature is enabled by default on this product.

3.5 Boot BIOS Configuration Utility

The BIOS configuration utility is stored in a flash device located on the RTM module. LSI

Corporation authored the BIOS used on the RTM module. The sections that follow will provide

the user a summary of the BIOS configuration capabilities.

3.5.1 Launching the Boot BIOS Configuration Utility

The boot BIOS allows you to change the default configuration of your RTM module. When the

BIOS loads, the following message appears on your monitor:

Press Ctrl-C to start LSI Configuration Utility...

This message remains on your screen for about five seconds, giving you time to start the utility.

After you press CTRL+C, the message changes to:

Please wait, invoking LSI Configuration Utility...

38

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 39

After a brief pause, your computer monitor displays the main menu of the BIOS Configuration

Utility.

Not all devices detected by the Configuration Utility can be controlled by the BIOS. Devices

such as tape drives and scanners require loading a device driver specific to that peripheral.

The BIOS Configuration Utility allows parameters to be modified for these devices.

3.5.2 BIOS Launch: Main Menu

When the boot BIOS Configuration Utility is launched, the main menu appears. This screen

displays a scrolling list of all the SAS controllers visible in the system, along with PCI Express

identification information. Use the arrow keys to select the RTM module you wish to modify,

and press ENTER to view and modify module properties.

SAS RAID Details

Figure 3-1 SAS BIOS Start Menu

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

39

Page 40

SAS RAID Details

3.5.3 Adapter Properties Menu

This menu provides the top level view of module status and manageable attributes. Using the

arrow keys, move to the menu item you wish to select and press ENTER.

Figure 3-2 SAS BIOS Adapter Properties, RTM Status and Configuration

3.6 RAID Firmware Capability

The RTM-ATCA-736X-DD product includes additional firmware to construct RAID volumes

using a disk on the RTM and a disk externally connected to the RTM. Please consult your host

blade documentation to verify this capability.

40

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 41

3.6.1 BIOS, RAID Properties Menu

This menu allows the user to select the desired RAID level for a volume definition. Using the

arrow keys, move to the menu item you wish to select and press ENTER.

Figure 3-3 SAS BIOS RAID Level Configuration Menu

SAS RAID Details

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

41

Page 42

SAS RAID Details

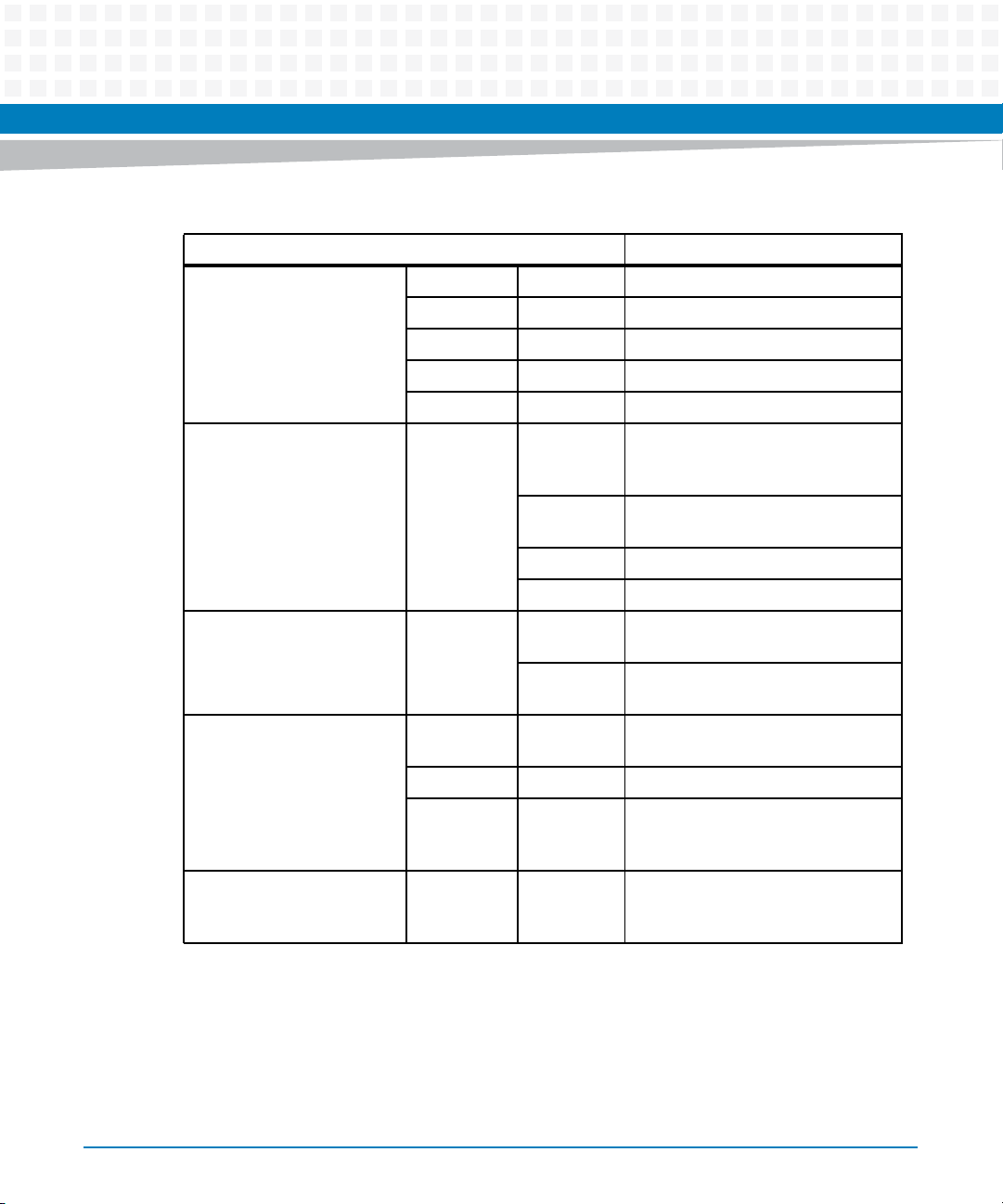

Menu Text RAID Level Description

None Default. All discovered disks are presented to the host blade

or CPU, with no RAID function.

IS Volume

(Integrated Stripe)

IM Volume

(Integrated Mirror)

IME volume

(Integrated Mirror

Enhanced)

RAID0 Two or more disks are grouped to provide a capacity

aggregation function. The advantage is the multiplicative

performance and capacity effect of four spindles working in

concert to store or retrieve data for the host.

RAID1 Two disks are grouped to provide a mirror function. By

definition, two drives our bounded such that every write to

one drive is mirrored on the second. If a failure occurs with

either drive, the data is still accessible through the surviving

drive.

RAID1E Three or more disks are grouped to provide a mirror function

using an algorithm extension to permit use with many drives.

If a failure occurs with any drive, data is still accessible through

the surviving drives.

3.6.2 BIOS, RAID Create New Array and Global Hot Spare

This menu enables the user to choose the disks that will comprise new RAID volumes or global

hot spares. Using the keyboard arrow keys, highlight the drives in the "RAID DISK" column, and

use the space bar to change to "Yes" or "No", "Yes" if the disk will be a member of the new array

and "No", if otherwise. Alternatively, highlight the drives in the "Hot Spr" (global hot spare)

column, and use the space bar to change to "Yes" or "No", "Yes" if the disk will be a member of

the global hot spare and "No", if otherwise. A maximum of two drives may be designated as a

global hot spare.

42

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 43

SAS RAID Details

In this screen shot example, a total of four drives were detected. Two are marked to become

the IM (RAID1) volume, and a third is designated as a global hot spare for the volume. Press the

"C" key to create the volume.

Figure 3-4 SAS BIOS, Create New RAID Array

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

43

Page 44

SAS RAID Details

44

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 45

Mechanical and Connector Information

4.1 Specifications

This section provides mechanical, electrical, environmental, and other relevant information.

4.1.1 Physical Dimensions

The RTM-ATCA-736X-DD is an 8U (355.6 mm) height board with 80 mm depth for standard

applications. It complies with PICMG 3.0 Revision 3.0 specification. The RTM-ATCA-736X-DD is

keyed to conform to the PICMG 3.0, Keying of ATCA Boards and Backplanes specification.

4.1.2 Weight

The weight of the RTM-ATCA-736X-DD is listed below.

Chapter 4

Table 4-1 RTM-ATCA-736X-DD Weight

Description

RTM Board 570 g 1000 g

RTM board in shipping box 1125 g 1555 g

4.1.3 Power Requirements

There are several manufacturing options for the RTM. Be sure to validate that the host chassis

can supply the RTM slot with these maximum current requirements. See Table "Maximum RTM

Module Current Requirements" on page 25.

RTM-ATCA-736X-DD (No

disks)

RTM-ATCA-736X-DD (Dual disks

installed)

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

45

Page 46

Mechanical and Connector Information

4.1.4 Environmental Specifications and Compliance

The environmental specifications for the RTM-ATCA-736X-DD assembly are presented in the

table below.

Table 4-2 Environmental Specifications for the RTM-ATCA-736X-DD

RTM with rotating SAS Disk Media

Specification

Operating Voltage +12V +/- 5% (payload power) +12V +/- 5% (payload power)

Operating Temperature (normal) +5°C to +40°C +0°C to +49°C

Installed RTM without Disks

Operating Temperature (short term) -5°C to +55°C (Consult disk drive

manufacturer for warranty

implications)

Storage Temperature -40 °C to 70°C -40 °C to 100°C

Operating Temperature Gradient 11°C /H (max) 11°C /H (max)

Storage Temperature Gradient 20°C /H (max) 20°C /H (max)

Shipping Temperature Gradient 20°C /H (max) *1 20°C /H (max)

Operating Humidity 5% to 85% (non condensing) 5% to 90% (non condensing)

Storage Humidity 5% to 90% (non condensing) 5% to 90% (non condensing)

Shipping Humidity 5% to 90% (non condensing) No condensation

Condensation No condensation No condensation

Altitude, operating (relative to sea

level)

Altitude, non-operating (relative to

sea level)

Shock, operating 980 m/s2 (100G) / 1 ms duration 500G / 0.5msec duration

Shock, non-operating 3,920 m/s2 (400G) / 1 ms duration 1000G / 0.5msec duration

Vibration, operating 0.6 mm (5 to 20Hz) / 9.8 m/s2 (1G)

-305 to +3,048 m (-1000 to +10,000

feet)

-305 to +12,192 m (-1000 to

+40,000 feet)

(20 to 300Hz) or less Note: At

random seek write/read and default

on retry setting with log sweep

vibration.

+0°C to 70°C

(-1000 to +40,000 feet)

(-1000 to +40,000 feet)

2.17 GRMS (5-700Hz)

46

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 47

Mechanical and Connector Information

Table 4-2 Environmental Specifications for the RTM-ATCA-736X-DD (continued)

RTM with rotating SAS Disk Media

Specification

Vibration, non-operating 3.1 mm (5 to 20Hz) / 49m/s2 (5G)

RoHS 6 of 6 compliant 6 of 6 compliant

MTBF Not calculated 972,226 hours (@25C)

Installed RTM without Disks

3.13 GRMS (5-800Hz)

(20 to 300Hz) or less. Note: At

power-off state after installation

4.1.5 NEBS Compliance

NEBS certifications are performed by integrator at a system level (chassis, ATCA, shelf

managers, etc.). The RTM module will not preclude the system from passing NEBS.

4.1.6 Electromagnetic Compliance

The board is designed and implemented to minimize electromagnetic emissions,

susceptibility, and the effects of electrostatic discharge.

Table 4-3 EMC Emission Compliance

Standard Description

US: FCC 47 CFR Part 15 Class A FCC Class A emissions requirements (United States)

ICES-003 2004 Class A Class A Interference-causing Equipment standard (Canada)

VCCI V-3/2007.04 Class A Class A ITE emissions requirements (Japan)

Europe Commercial: EN5022:2006 Class A, ITE Class A ITE emissions requirements (EU, Europe)

AS/NZS CISPR 22:2005 Class A, ITE Class A ITE emissions requirements (Australia)

Europe Commercial: EN

55022:1998/A1:2000/A2:2003

Europe Commercial: EN

55024:1998A1:2001/A2:2003

Europe Commercial: EN 61000-4-2,3,4,5,6: 2001 EMC Electrostatic discharge immunity

Immunity for ITE equipment

Immunity for ITE equipment

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

47

Page 48

Mechanical and Connector Information

4.2 Connectors and Pin Assignments

This section provides position and pin-out details of all connectors available on the RTM-ATCA736X-DD.

Table 4-4 Connector Port Identification snd Location

1 Disk FRU # 1 4 Zone 3 connector

2 1000BASE-T Ethernet 5 RTM alignment pin

3 Disk FRU # 2

Figure 4-1 RTM-ATCA-736X-DD Rear Transition Module Connectors

48

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 49

4.2.1 1000Base-T Ethernet Ports

Two Ethernet ports are provided on the rear panel of the RTM using an RJ-45 style shielded

connectors. Each of these ports route to an Intel® 82580 Ethernet controller, and accessed by

the front blade through PCI express signaling. Each port auto negotiates to 10/100/1000BASET.

Table 4-5 10/100/1000 Management Port Connector Pin Assignments

Pin Signal Name Pin Signal Name

1 LAN0_A+ 5 LAN0_C-

2 LAN0_A- 6 LAN0_B-

3 LAN0_B+ 7 LAN0_D+

4 LAN0_C+ 8 LAN0_D-

Mechanical and Connector Information

Figure 4-2 10/100/1000 Mb Management Port Pin Location Diagram

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

49

Page 50

Mechanical and Connector Information

4.2.2 Zone 3 Connectors

The RTM-ATCA-736X-DD routes several I/O signals to the Zone-3 connector complex

consisting of connectors J30 and J32. These connectors enable expansion using rear transition

modules (RTM) whose "J" connectors mirror the "P" connectors located on the carrier module.

All of these connectors utilize a 4-pin per column type available from Tyco electronics (PN#

1469048-1, http://www.tycoelectronics.com).

The connector pin-outs are presented from the point of view of ATCA blade, such that:

"TX" refers to ATCA blade as the signal source, and RTM as the signal receiver.

"RX" refers to ATCA blade as signal receiver, and RTM as the signal source.

50

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 51

Mechanical and Connector Information

Figure 4-3 Zone 3, Connector Port Pin Location Diagram

4.2.2.1 Connector J30, Power Supply for Advanced RTM

The RTM-ATCA-736X-DD draws power from +12 V and the +3.3 V management voltages

through the P30 connector. The RTM will convert the main 12 V payload power into 1.0 V, 1.8

V, 2.5 V and 3.3 V by using DC/DC converters.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

51

Page 52

Mechanical and Connector Information

4.2.2.2 Connector J30, Storage and Management Infrastructure Pin Assignments

The following table presents the RTM-ATCA-736X-DD J30 connector pin assignments and

descriptions:

Table 4-6 Connector P30, Management infrastructure Pin Assignments

Row Interface A B C D E F G H

1 88_Serial

_RXD

2 SAS LSI_SAS[

3]TX+

3 SAS LSI_SAS[

2]TX+

4 USB USB+ USB- n.c. n.c. SATA[1]TX+SATA[1]TX-SATA[1]RX+SATA[1]RX-

5 n.c. n.c. n.c. n.c. n.c. n.c. n.c. n.c.

6 PCIe-10 3 P10_Rx0+P10_Rx0- P10_Tx0+P10_Tx0- P10_Rx1+P10_Rx1- P10_Tx1+P10_Tx1-

7 PCIe-10 3 P10_Rx2+P10_Rx2- P10_Tx2+P10_Tx2- P10_Rx3+P10_Rx3- P10_Tx3+P10_Tx3-

8 Test P10_Clk1

00+

9 IPMB IPMB_SCLIPMB_SDAV3P3_M

10 POWER VP12 VP12 n.c. n.c. n.c. ENABLE_NI2C_CLK I2C_DAT

88_Serial

_TXD

LSI_SAS[

3]TX-

LSI_SAS[

2]TX-

P10_Clk1

00-

TDO TDI n.c. n.c. PS1_N POWERGOOD

LSI_SAS[

3]RX+

LSI_SAS[

2]RX+

88_PCIE_

RST

GMT

LSI_SAS[

3]RX-

LSI_SAS[

2]RX-

JTAG_TRSTJTAG_TCKJTAG_TMS88_SHIFT

n.c. reserved 88_PS0_N88_RST_

DCA2_SA

S_TX+

DCA1_SA

S_TX+

DCA2_SA

S_TX-

DCA1_SA

S_TX-

DCA2_SA

S_RX+

DCA1_SA

S_RX+

_CLK

KEY_N

DCA2_SAS_RX-

DCA1_SAS_RX-

88_LATCH_CLK

88_RST_OUT_N

Table 4-7 Connector J30, Management Infrastructure Signal Descriptions

88_Serial_RXD O LVTTL Serial line receives data to the front board CPU.

88_Serial_TXD I LVTTL Serial line transmits data from the front board CPU.

V3P3_MGMT +3.3V Management Power is used exclusively for management power.

PS1_N O RTM Presence signal. The front board reads this active low signal to determine

if an RTM is present and fully inserted.

52

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 53

Mechanical and Connector Information

Table 4-7 Connector J30, Management Infrastructure Signal Descriptions (continued)

POWERGOOD O Open Drain. When low indicates to RTM that it is fully inserted and that MMC

can start execution. Logic high shall keep MMC in reset state. This signal shall

have a pull-up resistor.

LSI_SAS[ ] I/O LVDS. These transceiver pairs connect to the LSI SAS controller, port2 and

port3. Some front blades route these ports to the Zone2 update channel

where additional disks may reside.

DCA1_SAS[] I/O LVDS. These transceiver pairs route to the secondary SAS por t of the hard drive

located on DCA (drive carrier assembly) #1

DCA2_SAS[] i/O LVDS. These transceiver pairs route to the secondary SAS port of the hard drive

located on DCA (drive carrier assembly) #2

SATA[ ] I/O (Unused) LVDS. These transceiver pairs are driven by a storage controller on

the host blade.

USB I/O (Unused) USB bidirectional, differential data pin pair

TDO, TDI Test Data In/Out signals as defined in JTAG. The RTM provides a bypass circuit

to propagate this signal and complete the test data chain (that is, TDI connects

to TDO)

P10_Rx, P10_Tx,

P10_Clk100+

88_PCIE_RST PCIE Reset driven by host blade.

IPMB_SCL,

IPMB_SDA

VP12 12V Payload Power, enabled after successful E-keying, as outlined in the AMC.0

(Unused) LVDS. Port #10 PCI express differential signal pairs for transmit

receive and 100MHz reference Clock

IPMI/I2C serial-bus clock and data signals, as defined in AMC.0 specification.

specification.

4.2.2.3 Connector J32, PCI-Express and Test Infrastructure Pin Assignments

The RTM-ATCA-736X-DD , J31 connector pin assignments and descriptions appear below.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

53

Page 54

Mechanical and Connector Information

Table 4-8 Connector J32, Miscellaneous RTM Signal Descriptions

Row Interface A B C D E F G H

3

1 PCIe-9

2 PCIe-9

3 PCIe-8

4 PCIe-8

5 PCIe-7

6 PCIe-7

7 PCIe-6 P6_Rx0+ P6_Rx0- P6_Tx0+ P6_Tx0- P6_Rx1+ P6_Rx1- P6_Tx1+ P6_Tx1-

8 PCIe-6 P6_Rx2+ P6_Rx2- P6_Tx2+ P6_Tx2- P6_Rx3+ P6_Rx3- P6_Tx3+ P6_Tx3-

P9_Rx0+ P9_Rx0- P9_Tx0+ P9_Tx0- P9_Rx1+ P9_Rx1- P9_Tx1+ P9_Tx1-

3

P9_Rx2+ P9_Rx2- P9_Tx2+ P9_Tx2- P9_Rx3+ P9_Rx3- P9_Tx3+ P9_Tx3-

2

P8_Rx0+ P8_Rx0- P8_Tx0+ P8_Tx0- P8_Rx1+ P8_Rx1- P8_Tx1+ P8_Tx1-

2

P8_Rx2+ P8_Rx2- P8_Tx2+ P8_Tx2- P8_Rx3+ P8_Rx3- P8_Tx3+ P8_Tx3-

2

P7_Rx0+ P7_Rx0- P7_Tx0+ P7_Tx0- P7_Rx1+ P7_Rx1- P7_Tx1+ P7_Tx1-

2

P7_Rx2+ P7_Rx2- P7_Tx2+ P7_Tx2- P7_Rx3+ P7_Rx3- P7_Tx3+ P7_Tx3-

9 PCIe P9_Clk100+P9_Clk1

00-

10 POWER VP12 n.c. n.c. VP12 n.c. 88

P8_Clk100+P8_Clk1

00-

P7_Clk1

00+

P7_Clk1

00-

P6_Clk100+P6_Clk1

00-

88_ DI 88_ D0

_PS0_N

1

PCIe ports 8 and 7 may be combined to function as single x8 PCI-express port through BIOS settings. Port 8 become

bits 4-7.

2

PCIe ports 10 and 9 may be combined to function as single x8 PCI-express port through BIOS settings. Port 10

become bits 4-7.

3

PCIe ports 10,9,8,7 may be combined to function as single x16 PCI-express port through BIOS settings. Port 10

becomes bits 15-12.

Table 4-9 Connector J32, Miscellaneous RTM Signal Descriptions

Connector Description

P9_Rx, P9_Tx, P9_Clk100+ (Unused) Port #9 PCI express differential signal pairs for transmit and receive; and

100MHz reference clock

P8_Rx, P8_Tx, P8_Clk100+ Route to LSI 1064E Port #8 PCI express differential signal pairs for transmit and

receive; and 100 MHz reference clock

P7_Rx, P7_Tx, P7_Clk100+ Route to LSI 1064E. Port #7 PCI express differential signal pairs for transmit and

receive; and 100 MHz reference clock

P6_Rx, P6_Tx, P6_Clk100+ Route to Intel 82580. Port #6 PCI express differential signal pairs for transmit

receive and 100 MHz reference clock

54

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 55

Mechanical and Connector Information

Table 4-9 Connector J32, Miscellaneous RTM Signal Descriptions (continued)

Connector Description

VP12 12V Payload Power, enabled after successful E-keying, as outlined in the AMC.0

specification.

88 _PS0_N Ac tive low RTM present signal.PS0_N is tied to logic GND on the ATCA blade. PS0_N

(Connector J32) and PS1_N (Connector J30) shall be connected through a diode on

the RTM. Logic low on PS1_N indicates that RTM is present and fully inserted.

Consult Artesyn documentation of the relevant front board for further details how to set PCIe

lane width.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

55

Page 56

Mechanical and Connector Information

56

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 57

IPMI Functions List

5.1 Overview

The RTM-ATCA-736X-DD module includes an MMC device for reporting status information to

the ATCA blade. This MMC utilizes an Intelligent Platform Management Interface (IPMI) which

will communicate with the AdvancedTCA. This MMC controls and monitors the following:

Hot swap communication with the shelf manager

Inlet air temperatures

Voltage monitoring

FRU information

Drives OOS (out of service), IS (in service) and ATN (attention) LEDs

5.2 IPMI and Management Controller (IPMC)

Chapter 5

The design features an IPMI controller consisting of a 16-bit microcontroller, flash and SRAM.

The microcontroller uses I2C interface to communicate the shelf management controller

(ShMC), and sensors and MMC devices on AdvancedMC modules and the RTM, if installed.

An I2C connection provides the communication path between the MMC and the

temperature sensor.

Support hot swap operation as defined for AMC modules in PICMG AMC.0 specification

"Fail-safe flash update" - if interrupted at anytime, the MMC firmware is still able to respond

and re-flash.

"I2C hang recovery" - able to detect and recover from an I2C bus hang.

5.3 Sensor Data Records

The MMC monitors the status of the module and provides this data so it can be read by the shelf

manager. Below are the SDRs that the RTM-ATCA-736X-DD module creates.

Table 5-1 Sensor Data Records

# Sensor UNR UC UNC LNC LC LNR ID String

0x07 1.0 1.105 1.075 1.055 0.955 0.935 0.905 +1V0

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

57

Page 58

IPMI Functions List

Table 5-1 Sensor Data Records

# Sensor UNR UC UNC LNC LC LNR ID String

0x03 1.2 1.324 1.294 1.265 1.147 1.118 1.088 +1V2

0x08 1.8 1.985 1.935 1.895 1.715 1.675 1.625 +1V8

0x02 3.3 V 3.605 3.505 3.462 3.162 3.105 3.005 +3V3

0x04 12.0 V 13.603 13.438 13.053 11.018 10.633 10.412 +12V0

0x05 Board Temp

(LM75)

0x06 Inlet Temp

(LM60)

0x0B 12 V to Disk N/A N/A N/A N/A N/A N/A +12V0 SLOT1

0x0C 12 V to Disk N/A N/A N/A N/A N/A N/A +12V0 SLOT2

51.320 60.740 70.160 N/A N/A N/A Board Temp

60.000 70.000 80.000 N/A N/A N/A Inlet Temp

The RTM-ATCA-736X-DD includes the standard FRU data records per the IPMI Platform

Management FRU Information Storage Definition, Board Info Area. The RTM-ATCA-736X-DD

includes additional FRU records as defined in the PICMG 3.0 specification.

Table 5-2 Standard FRU Data Records

Board Information

Ver sio n 1

Language Code EN (English)

MFG date.time See note *1

Manufacturer Emerson Network Power

Product Name RTM-ATCA-736X-DD

Serial Number AAALYMMssss (See note *2)

58

Part Number 0106812K0XX

*1. Manufacturing time is defined as 'minutes since 1/1/96' in the IPMI FRU spec.

*2. Serial Number format: AAALYMMssss

AAA = 431 part code (denotes RTM-ATCA-736X-DD)

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 59

L =Location of manufacturer (S)

Y = Calendar year of manufacturer (2008 = 8)

MM = Calendar month of manufacturer (March = 03)

SSSS = Sequence number (reset each month) (1234)

5.3.1 RTM E-Keying Port Assignments

Table 5-3 RTM E-Keying Port Assignments

IPMI Functions List

Port

Port

0 PCIe 02h, AMC.1 PCI

1 PCIe 02h, AMC.1 PCI

2 PCIe 02h, AMC.1 PCI

3 PCIe 02h, AMC.1 PCI

4 PCIe 02h, AMC.1 PCI

Name Link type Link type extension

Express

Express

Express

Express

Express

Asymmetric

match Link Designator

0000b, Gen1-NSSC 01b 100h, AMC.1 Type

1, Group 0

0000b, Gen1-NSSC 01b 100h, AMC.1 Type

1, Group 0

0000b, Gen1-NSSC 01b 100h, AMC.1 Type

1, Group 0

0000b, Gen1-NSSC 01b 100h, AMC.1 Type

1, Group 0

0000b, Gen1-NSSC 01b 100h, AMC.1 Type

1, Group 0

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

59

Page 60

IPMI Functions List

5.4 Supported IPMI Commands

The MMC communicates with the carrier controller through the local IPMB-L bus of the carrier

and responds to all mandatory commands for AMC Module Management Controllers, as well

as some optional ones.

Table 5-4 Supported IPMI Commands

IPMI/PICMG

Command

IPM Device "Global" Commands

Get Device ID 17.1 App 01h Mandatory

Broadcast "Get Device ID" 17.9 App 01h Mandatory

Messaging Commands

Send Message 18.7 App 34 h Optional

/AMC Spec NetFn CMD MMC Req

Event Commands

Platform Event 23.3 S/E 02 h Mandatory

Sensor Device Commands

Get Device SDR Info 29.2 S/E 20 h Mandatory

Get Device SDR 29.3 S/E 21 h Mandatory

Reserve Device SDR Repository 29.4 S/E 22 h Mandatory

Get Sensor Reading Factors 29.5 S/E 23 h Optional

Set Sensor Hysteresis 29.6 S/E 24 h Optional

Get Sensor Hysteresis 29.7 S/E 25 h Optional

Set Sensor Threshold 29.8 S/E 26 h Optional

Get Sensor Threshold 29.9 S/E 27 h Optional

Set Sensor Event Enable 29.10 S/E 28 h Optional

Get Sensor Event Enable 29.11 S/E 29 h Optional

Rearm Sensor Events 29.12 S/E 2A h Optional

Get Sensor Event Status 29.13 S/E 2B h Optional

Get Sensor Reading 29.14 S/E 2D h Mandatory

FRU Device Commands

60

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

Page 61

IPMI Functions List

Table 5-4 Supported IPMI Commands (continued)

IPMI/PICMG

Command

Get FRU Inventory Area Info 28.1 Storage 10 h Mandatory

Read FRU Data 28.2 Storage 11 h Mandatory

Write FRU Data 28.3 Storage 12 h Mandatory

AdvancedTCA™ Commands

Get PICMG Properties 3-9 PICMG 00 h Mandatory

FRU Control 3-22 PICMG 04 h Mandatory

Get FRU LED Properties 3-24 PICMG 05 h Mandatory

Get LED Color Capabilities 3-25 PICMG 06 h Mandatory

Set FRU LED State 3-26 PICMG 07 h Mandatory

Get FRU LED State 3-27 PICMG 08 h Mandatory

/AMC Spec NetFn CMD MMC Req

Get Device Locator Record ID 3-29 PICMG 0D h Mandatory

AMC® Commands

Set AMC Port State 3-27 PICMG 19 h Mandatory

Get AMC Port State 3-28 PICMG 1A h Mandatory

5.4.1 Disk IPMI ’raw’ Commands

The MMC on the RTM includes several custom commands developed to facilitate management

of the Hard Disk Assemblies (DCA). Please consult your ATCA carrier or shelf documentation for

the exact syntax to send a raw command, as it will vary with each ATCA supplier.

RTM-ATCA-736X-DD Installation and Use (6806800L82C)

61

Page 62

IPMI Functions List

5.4.1.1 Disk Eject, Deactivation Request to Power-off Disk

This command produces the same response as pressing one of the disk eject buttons on the

RTM panel.

Before ejecting a drive, the user should ensure the OS has released the drive, meaning it has

to be unused. This usually requires unmounting any file systems on it, and terminating any

raw partition use.

Upon completion of the OS removal preparations, the user may issue an IPMI raw command

and subsequently illuminate the disk FRU hot swap LED.

Table 5-5 IPMI Raw Command Disk Removal Request

Raw Command Description

netfn 0x2E

cmd 0xA0

data 0xA4 0x76 0x00 0xZZ

Where 0xZZ indicates the disk drive:

0x01 is disk#1, 0x02 is disk#2.

Any other 0xZZ value will trigger completion code 0xCC

Return code 0x00 - Success

0xCC - Invalid Data in Request

Return Data 0xA4 0x76 0x00

5.4.1.2 Approve Disk Eject Request