Page 1

REPAIR MANUAL

PRODUCT: DISHWASHER

MODEL: L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

The information included in this Ariston Repair Manual may change without notice. Please see our web site

www.usservicenet.com for updates, corrections or additions.

Pages:

1 - 33

Page 2

REPAIR MANUAL

SAFE SERVICE PRACTICES

This Repair Manual is intended for persons having electrical and mechanical training and a level of knowledge

of these subjects generally considered acceptable in the Appliance Service Industry. Ariston cannot be

responsible, nor assumes any liability for injury or damages of any kind arising from the use or misuse of

the information contained in this Repair Manual.

If you have any questions regarding the proper diagnosis, repair or operation of any Ariston Appliance, please

contact the Ariston Customer Care Center or your Service Representative.

SERVICING SAFEGAURDS:

To avoid personal injury and/or property damage, it is important that safe servicing practices be observed at all times. Examples of

safe service practices are listed below but are not limited to the following:

1) Never attempt a product repair if you have any doubts as to your ability to complete the repair in a safe and

satisfactory manner.

2) Before servicing or removing an appliance:

- Disconnect power to the appliance.

- Turn off the gas / LP supply.

- Turn off the water supply.

3) Never interfere with the proper operation of any safety device.

4) Use only genuine factory replacement parts as substitutions may interfere with compliances to home safety codes or standards.

5) It is extremely important that all safety ground connections be reestablished prior to the completion of the service call. Failure to

do so will result in a hazardous condition being created.

6) Prior to returning the appliance back into active service, ensure the following:

- All electrical connections are correct and secure.

- Electrical leads are properly dressed and secured away from sharp edges, high temperature components and moving parts.

- All non-insulated electrical terminals, connectors, heaters, etc. are adequately spaced away from metal parts or panels.

- All safety grounds (both internal and external) are correctly and securely connected.

- All access panels are properly and securely reassembled.

Page: i

Page 3

L 63 / LL 64 / LL 65

REPAIR MANUAL

LI 640 / LI 670 / LI 700

TABLE OF CONTENTS

Page

1. Model and Serial Number Location ................................................................................................1

2. Rack Rollers - Upper & Lower........................................................................................................ 2

3. Upper Spray Arm............................................................................................................................ 2

4. Lower Spray Arm............................................................................................................................ 3

5. Outer Door Panel............................................................................................................................ 4

6. Control Panel .................................................................................................................................. 5

7. Outer Door Skin.............................................................................................................................. 6

8. Soap Dispenser and Water Temperature NTC............................................................................... 7

9. Door Spring Adjustment and Door Latch........................................................................................7

10. Kick Plate .......................................................................................................................................8

11. Door Extension............................................................................................................................... 9

12. Water Valve..................................................................................................................................10

13. Float Switch and Pressure Switch................................................................................................ 11

14. Lower Component Access - Base Pane Removal........................................................................12

15. Lower Components...................................................................................................................... 13

16. Drain Motor................................................................................................................................... 14

17. Main Motor and Pump.................................................................................................................. 15

18. Heater Assembly.......................................................................................................................... 17

19. Turbidity Sensor (LI 670 / LI 700 Models Only)............................................................................................ 18

20. Water Softener............................................................................................................................. 19

Page: ii

Page 4

L 63 / LL 64 / LL 65

REPAIR MANUAL

LI 640 / LI 670 / LI 700

TABLE OF CONTENTS Cont.

Page

21. High Pressure Switch................................................................................................................... 20

22. Fan Motor (LL 65 / LI 700 Models Only)......................................................................................................20

23. Water Inlet and Turbine................................................................................................................21

24. Fault Codes..................................................................................................................................22

25. Schematics................................................................................................................................... 23

Page: iii

Page 5

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

LI 700 S LL 64 S

This Dishwasher Repair Manual uses the LI 700 S model for all repair instructions and demonstrations. The

technical similarities between the LI 700 S and the other LI , L and LL models will allow the repair techniques

described and demonstrated to be applied without difficulty to the other models not shown.

Page: iv

Page 6

REPAIR MANUAL

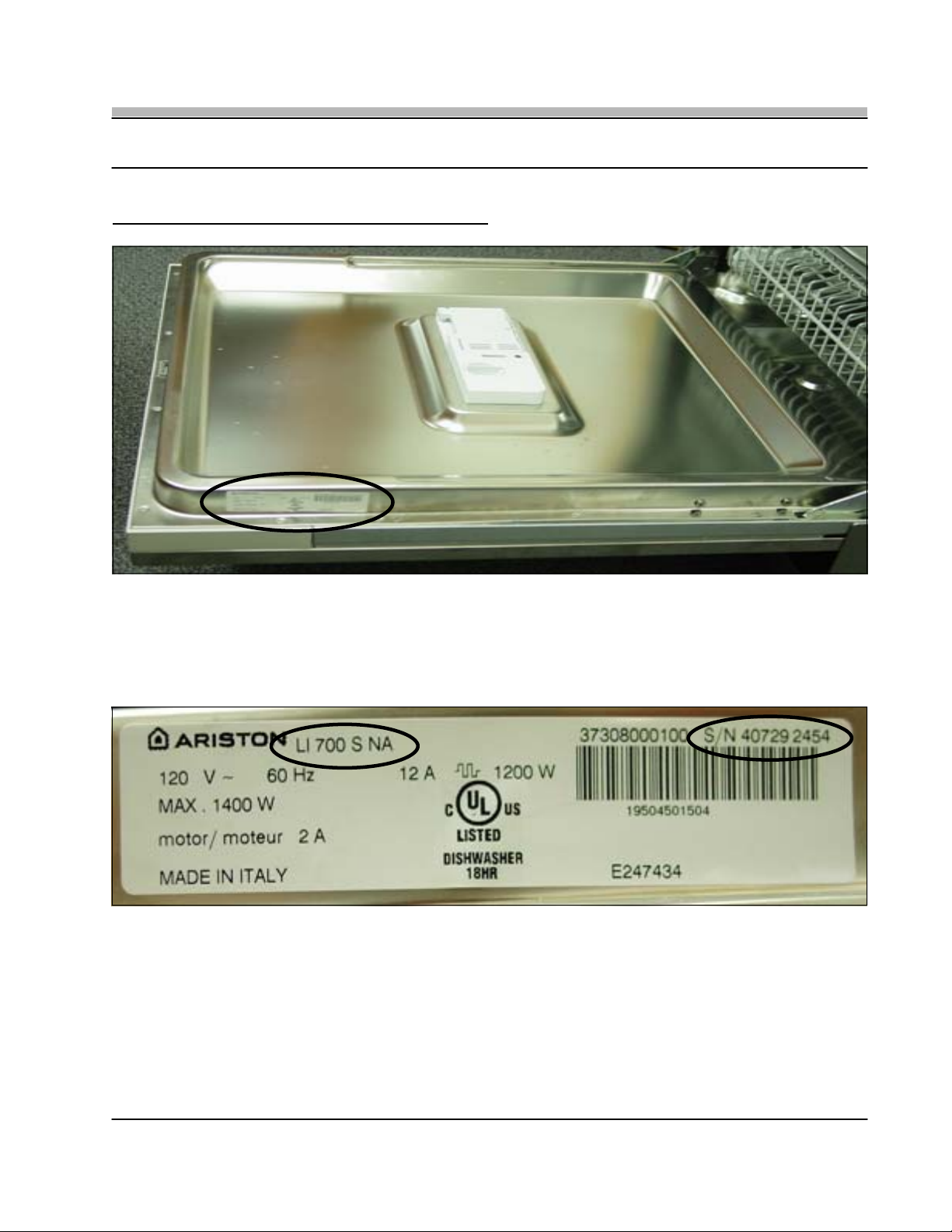

1. MODEL and SERIAL NUMBER LOCATION

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 1-1

• The Model and Serial Number Tag is located on the right side of the Inner Door Panel (Fig. 1-1). The Model shown is a LI 700 S

with a Serial Number of 407292454 (Fig. 1-2).

Note: Numbers located to the left of the nine (9) digit Serial Number are not required on the Warranty Claim Form.

Fig. 1-2

Page: 1

Page 7

REPAIR MANUAL

2. RACK ROLLERS - Upper & Lower

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

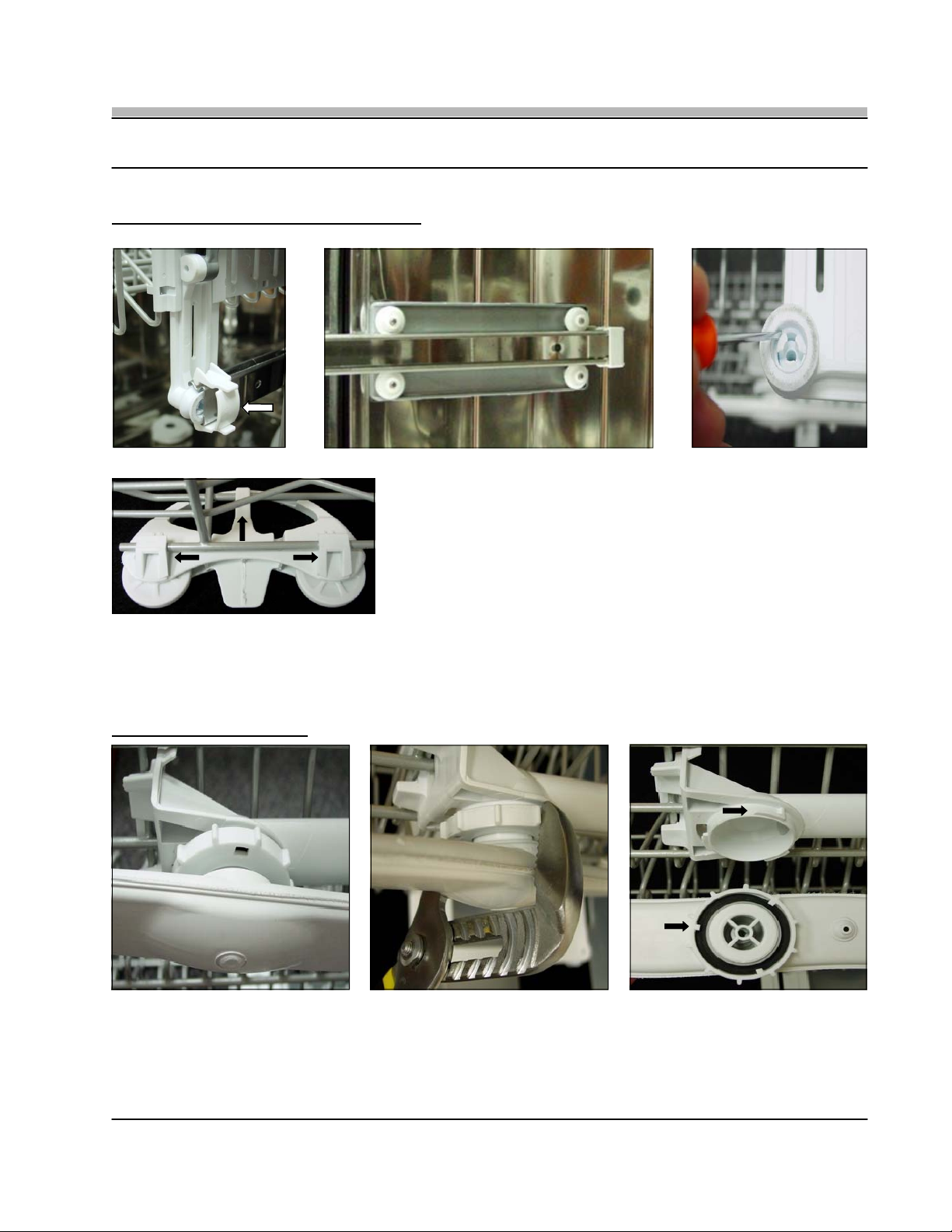

Fig. 2-1

Fig. 2-2

Fig. 2-3

• The Upper Rack can be removed by releasing the Rail Clip and slidin g the

Rack out from the Rail (Fig. 2-1). If the Upper Rack Roller Assembly must be

replaced (Fig 4-2) first remove the Side Panel (see Section 22) and then

remove the four (4) 8mm bolts that mount the Roller Assembly to the Tank.

• Once the Upper Rack has been removed, the Rack Roller Wheels can be

replaced by gently prying the Hub Clips inward with a small screwdriver and

Fig. 4-4

then moving the Roller Wheel out and off the Hub (Fig. 2-3).

• The Lower Rack Roller Assemblies are held in place using three (3) tension clips (Fig 2-4). Grasping the Roller Assembly and

applying downward force will disengage the Roller Assembly from the Rack.

3. UPPER SPRAY ARM

Fig. 3-1 Fig. 3-2 Fig. 3-3

• To remove the Upper Spray Arm (Fig. 3-1) gently grasp the Locki ng Ring with a Channel Locks and turn Counter-Clockwise

(Fig. 3-2); note the Tab and Slot locking configuration (Fig. 3-3).

TECH NOTE: When Replacing the Spray Arm make sure that it is tightened completely onto the Locking Ring.

Page: 2

Page 8

4. LOWER SPRAY ARM

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

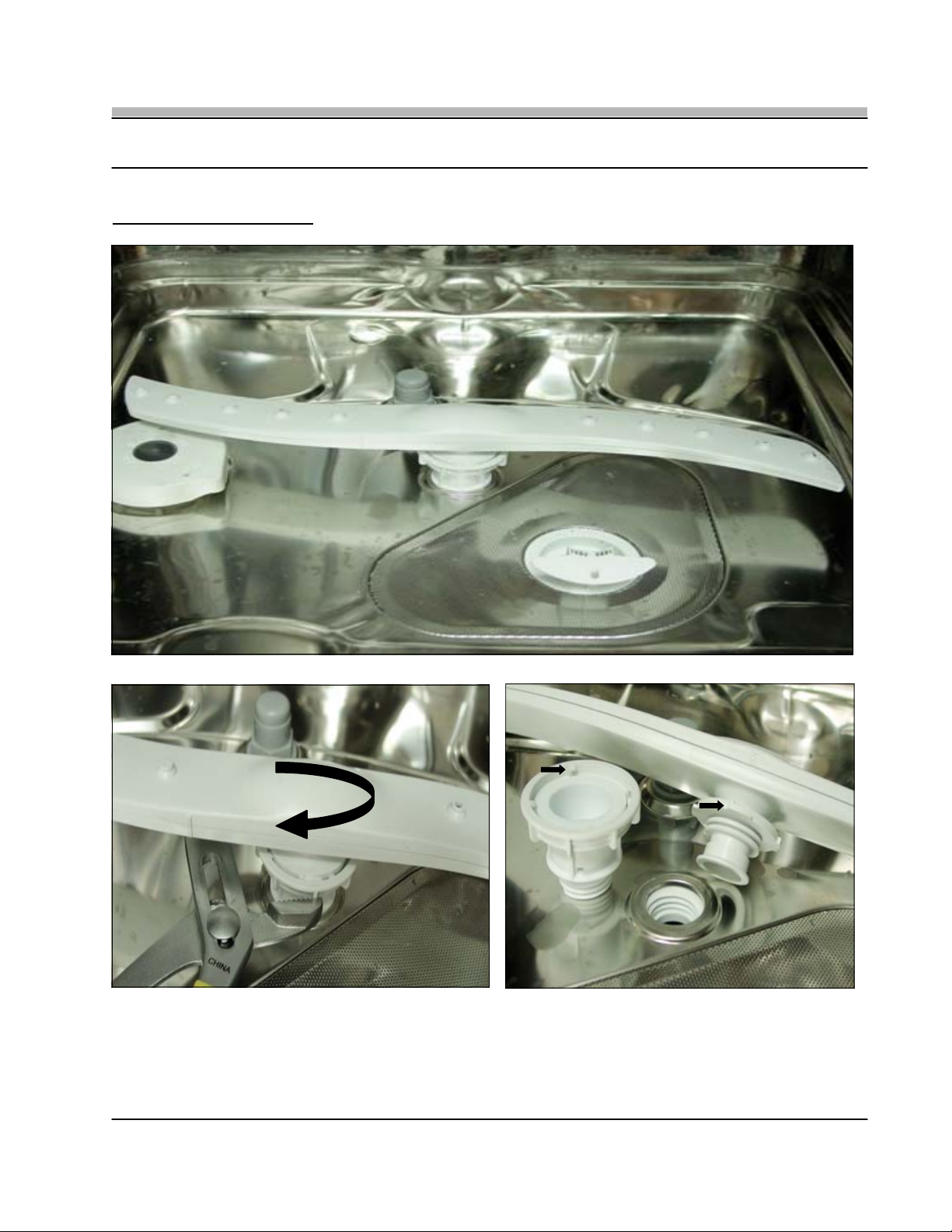

Fig. 4-1

Fig. 4-2

Fig. 4-3

• To remove the Lower Spray Arm (Fig. 4-1) hold the Spray Arm Locking Ring with a Channel Locks and then turn the Spray Arm

Clockwise (Fig. 4-2). The Locking Ring Assembly can also be removed by rotating it Counter-Clockwise; note the Tab and Slot

locking configuration (Fig. 4-3).

TECH NOTE: When Replacing the Spray Arm make sure that it is tightened completely onto the Locking Ring.

Page: 3

Page 9

5. OUTER DOOR PANEL

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

A

B

• The Outer Door is held in place using four (4) Phillips screws (Fig. 5-1). Screw “A” is a

single screw located on the bottom left and right corners of the Inner Door Panel. Screw

“B” is just below the Phillips screw that holds the Outer Door Skin (Fig. 5-2).

• With the four (4) screws removed raise the Door to an upright position and t hen slide

the Outer Door Panel down and out from the Alignment Channel (Fig. 5-3).

• When replacing the Outer Door insert the Alignment Pin into the Channel and then raise

the Door Panel up until it is even with the top of the Control Panel (Fig. 5-4).

TECH NOTE: To prevent damage to the Outer Door, Alignment Pins, or Channel, make

sure to support the weight of the Door as you remove or replace it.

A

B

Fig. 5-1

B

Fig. 5-2

Fig. 5-3

Fig. 5-4

Page: 4

Page 10

6. CONTROL PANEL

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 6-1

Fig. 6-2

Fig. 6-3

• To remove the Control Panel (Fig. 6-1), remove the six (6) Phillips Control Panel screws from the Inner Door Panel (Fig 6-2). With

the screws removed the Control Panel will lay forward and is now accessible for repair (Fig. 6-3).

TECH NOTE: The Outer Door must be removed first (see Section 5) before removing the Control Panel Screws.

Page: 5

Page 11

7. OUTER DOOR SKIN

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

A

B

A

B

B

Fig. 7-1

• To remove the Outer Door Skin, first remove the Outer Door Panel ( see Section 5). Now remove the four (4) remaining Phillips

screws. Two (2) screws “A” are located half way up the Inner Door Panel and screws “B” are located above the Outer Door Panel

screws (Fig. 7-1 & 7-2). With the Outer Door Skin removed you have access to the Soap Dispenser (Fig. 7-3) and Door Hinges.

TECH NOTE: The Control Panel does not have to be

removed to remove the Outer Door Skin.

Fig. 7-2

Fig. 7-3

Page: 6

Page 12

REPAIR MANUAL

8. SOAP DISPENSER and WATER TEMPERATURE NTC

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 8-1

• To remove the Soap Dispenser (Fig. 8-1), first remove the Actuator Solenoid wiring and then the six (6) Phillips screws that mount

the Dispenser to the Inner Door. The Dispenser can then be removed and replaced as a complete assembly.

OPERATION: The Actuator Solenoid is energized twice during a complete cycle. The first actuation releases the Detergent and

also aligns the Dispenser Linkage for the second actuation which releases the Rinse Agent.

TECH NOTE: Located on the upper right corner of the Dispenser is the Water Temperature NTC. The NTC is hard wired to the

Main Control Board. If the NTC proves faulty the Main Control Board must be replaced. Also, Dishwasher Models

L63 / LL64 / LI 640 / LI 670 incorporate a Magnetic Reed Switch to activate the Rinse Aid LED. Models LL 65 &

LI 700 use a Turbidity Sensor, see Section 19 for details.

9. DOOR SPRING ADJUSTMENT and DOOR LATCH

Fig. 9-1

• To adjust the tension on the Outer Door turn the two (2) 5mm Allen Screws Clockwise for

more spring tension and Counter Clockwise for less spring tension (Fig. 9-1).

• The Door Latch can be adjusted using a 7mm Nut Driver (Fig. 9-2)

Fig. 9-2

Page: 7

Page 13

10. TOE KICK

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

A

Fig. 10-1 Fig. 10-2

• The Toe Kick is a tension fit and mounts into the Side Support Plates “A” located on the left and right lower corners of the

Dishwasher. The Toe Kick is held in place and adjusted using a dimple stamped into the Toe Kick (Fig. 10-1). Once the Toe Kick is

inserted into the Support Plate you can adjust the Toe Kick to the required height by simply sliding it up or down (Fig. 10-2).

To remove the Toe Kick firmly pull it toward you.

TECH NOTE: When installing the Toe Kick remember that it fits inside the left and right Side Support Plates (Fig. 10-2).

A

Page: 8

Page 14

11. DOOR EXTENSION

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 11-1

Fig. 11-3

Fig. 11-4

• The Door Extension (Fig. 11-1 & 11-2) is secured to the Dishwasher using two

(2) tension clips (Fig. 11-3 & 11-4) on both the left and right sides. The tension

clips insert into cut-outs on the left and right Side Support Plates (Fig. 11-5).

• To remove the Door Extension, first release the center clip (Fig. 11-2). Then

push out on the right side, this will disengage the locking clips.

TECH NOTE: Access to the Door Extension can be made easier if the

Dishwasher Door is opened slightly. Do not attempt to pull the

Door Extension forward to remove, this may damage the

locking clips.

• When re-installing the Door Extension make sure to align the lower corners

onto the small rail that is located on the bottom of the Side Support Plate

(Fig.11-6). Once in position on the rail, the Door Extension can be pivoted into

place and the tension clips locked it into position.

Fig. 11-2

Fig. 11-5

INSIDE LEFT CORNER

Fig. 11-6

Page: 9

Page 15

12. WATER VALVE

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 12-1

Fig. 12-2

Fig. 12-3

• To access the Water Valve, first remove the Toe Kick (see Section 10) and the Door Extension (see Section 11) (Fig. 12-1). The

Water Valve is held in place with two (2) Phillips screws (Fig. 12-2), remove the two screws and the Valve can be easily accessed.

TECH NOTE: A new Valve Hose Clamp (Fig. 12-3) is included with the replacement Water Valve, but the old Clamp can be

reused if carefully removed.

Page: 10

Page 16

REPAIR MANUAL

13. FLOAT SWITCH and PRESSURE SWITCH

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 13-1

Fig. 13-2

Fig. 13-3

Fig. 13-4

• To access the Float Switch or Pressure Switch, first remove the Toe Kick (see Section 10) and the Door Extension (see Section

11) then remove the four (4) Phillips screws that hold the Lower Access Panel to the Dishwasher (Fig. 13-1). With the screws

removed the Lower Access Panel can be moved down and out allowing access to the two components (Fig. 13-2).

Float Switch: (Fig. 13-3) Can be checked for continuity or for water in the Base Pan.

Pressure Switch: (Fig.13-4) Can be checked for continuity.

Page: 11

Page 17

REPAIR MANUAL

14. LOWER COMPONENT ACCESS - BASE PAN REMOVAL

Front Adjustable Rear Legs (7mm)

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 14-1

Rear View

Fig. 14-3

Fig. 14-2

• TO ACCESS THE LOWER

C O M P O N E N T S T H E

DISHWASHER MUST BE

REMOVED FROM THE

CABINET.

• With the Dishwasher removed

from the cabinet, remove the

Base Pan Screws, there are

three (3) Phillips screws on the

lower front of the unit (Fig. 14-1)

and three (3) Phillips screws on

the rear (Fig. 14-2).

• Carefully place the Dishwasher

on its back and remove the

Base Pan (Fig. 14-3). The

Lower Components are now

accessible.

Page: 12

Page 18

15. LOWER COMPONENTS

A

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

B

• With the Bottom Pan removed you have access to the following components:

A: Water Softener.

B: Main Motor and Pump.

C: Heater.

D: Drain Motor.

E: Turbo Dry Fan Motor (only on the LL 65 / LI 700 Models).

C

D

E

Fig. 15-1

Page: 13

Page 19

16. DRAIN MOTOR

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 16-1

Fig. 16-2

Fig. 16-3

• To remove the Drain Motor (Fig. 16-1), first loosen the Drain Hose Clamp and Drain Hose, then remove the single Phillips

mounting screw. (Fig. 16-2). The Drain Motor is secured to the Sump using a tab and slot twist lock mount. With the Drain Hose

and mounting screw removed twist the Drain Motor Clockwise to remove (Fig.16-3).

TECH NOTE: For a better seal lubricate the new Drain Motor Gasket before installing, and make sure all three (3) Tabs are

secured into the corresponding slots, then twist the motor into position.

Page: 14

Page 20

17. MAIN MOTOR and PUMP

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 17-1

Fig. 17-2

Fig. 17-3

• To remove the Main Motor and Pump Assembly (Fig. 17-1), first remove the Vibration Damper from the rear of the Motor by prying

it away from the Motor with a screwdriver (Fig. 17-2). Next remove the Motor and Pump Assembly from the three (3) hose

connections (Fig. 17-3) See TECH NOTE below.

TECH NOTE: The Motor Assembly can be removed from the three (3) hoses without undoing the Hose Clamps. Easily work the

Pump out and off the Hoses, the Clamps can now be reused if necessary.

Page: 15

Page 21

REPAIR MANUAL

17. MAIN MOTOR and PUMP Cont.

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 17-4

Fig. 17-6

Fig. 17-5

Fig. 17-7

• Once the Main Motor and Pump has been removed from the Dishwasher (Fig. 17-4) it can be separated and the Motor or Pump

replaced. To separate the Motor from the Pump, first remove the two (2) Phillips screws located on the left and right sides of the

pump (Fig. 17-5). Next, using a 13mm socket and regular screwdriver loosen the Pump Impeller from the Motor Shaft By turning it

clockwise (Fig. 17-5). The Motor or Pump can now be replaced (Fig. 17-6)

• The LL 65 and the LI 700 Models have a Top Rack Wash feature. The Top Rack Wash is controlled by a Solenoid Valve on the

pump that when energized blocks the flow of water to the Lower Wash Arm. If required the Solenoid can be replaced by removing

the four (4) Phillips screws that mount it to the Pump (Fig. 17-7). The complete Pump Assembly does not have to be replaced.

Page: 16

Page 22

18. HEATER ASSEMBLY

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 18-1

Fig. 18-2

• To remove the Heater Assembly, first remove the Drain Motor as described in Section 16 (Fig. 18-1). With the Drain Motor

removed you have full access to the Heater Assembly (Fig. 18-2).

Page: 17

Page 23

18. HEATER ASSEMBLY Cont.

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 18-3

Fig. 18-4

• With the Drain Motor removed, remove the two Heater Assembly Clamps (Fig. 18-3) and then gently separate the Heater

Assembly from the two (2) Hoses.

OPERATION: The Heater is a Flow-Through design that also incorporates an internal High Limit (Fig. 18-4). Both the Heating

Element and the High Limit can be checked for continuity, but the Heater is replaced as a complete assembly.

19. TURBIDITY SENSOR (LI 670 / LI 700 Models Only)

Fig. 19-1

Fig. 19-2

• The LI 670 and LI 700 Dishwasher models incorporate a Turbidity Sensor that measures water clarity and may adjusts cycle times

if required. The Turbidity Sensor is a small PC Board mounted inside a black housing attached to the input of the Heater Assembly

Hose. To replace, simply open the housing and remove the PC Board.

Page: 18

Page 24

20. WATER SOFTENER

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Fig. 21-2

Fig. 20-1

Fig. 20-3

• All Dishwasher models are equipped with a built in Water Softener. The Water Softener Assembly is a self contained unit and

should rarely require servicing (Fig. 20-4). However, a Solenoid Valve located on the Water Softener Assembly (Fig. 20-1) may

require replacing. The Water Softener and Solenoid Valve is replaced as a complete assembly.

• To replace the Assembly, remove the Water Softener Cap from inside the Dishwasher (Fig. 20-2), then remove the retaining nut

(Fig. 20-3). Next, uninstall the Dishwasher and remove the Base Pan as explained in Section 12. Remove the Softener Hoses and

replace the Water Softener as a complete assembly (Fig. 20-4).

OPERATION: The Softener Indicator LED will light

every thirty (30) wash cycles

indicating that the salt in the Softener

needs to be refilled.

TECH NOTE: After the Softener has been filled with

salt. the LED will remain on for five (5)

cycles even if the Softener is full.

It is possible to reset the LED by

pouring a cup of water into the sump

before the beginning of a new cycle.

Fig. 20-4

Page: 19

Page 25

21. HIGH PRESSURE SWITCH

Fig. 21-1

L 63 / LL 64 / LL 65

REPAIR MANUAL

LI 640 / LI 670 / LI 700

• The High Pressure Switch (Fig. 21-1) is located on the output hose of the

Pump that supplies the Lower Wash Arm. The High Pressure Switch is

Normally Closed (NC) during Dishwasher operation.

OPERATION: When the Dishwasher Filters become completely clogged

water flow through the Pump is reduced and the High

Pressure Switch contacts open. The open contacts

indicate to the Control Board that a Filter Fault exists and

the Control Board will alternately drain and fill the

Dishwasher until the Filters are clear (Filter Cleaning Cycle).

TECH NOTE: In Fig. 21-1 The Main Motor and Pump have been removed

to allow a better view of the Switch. The High Pressure

Switch can be removed and replaced without

removing the

Main Motor or Pump Assembly.

22. FAN MOTOR (LI 670 / LI 700 Models Only)

Fig. 22-1

Fig. 22-2

• The Fan Motor Assembly can be accessed by removing the eight (8) Phillips screws that attach the Right Side Panel to the

Dishwasher (Fig. 22-1). The Fan Motor Assembly consists of a large plastic Condensation Chamber and Motor (Fig. 22-2).

• To replace the Fan Motor, unscrew the Upper Vent Cover from inside the Dishwasher (arrow on Fig. 22-3) and slide the

Condensation Chamber out from the side of the Dishwasher. The Fan Motor Assembly and Condensation Chamber is replaced as

a complete assembly.

Fig. 22-3

Page: 20

Page 26

23. WATER INLET and TURBINE

Fig. 23-1 Fig. 23-2 Fig. 23-3

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

• Located on the Left Side of the Dishwasher is the Water Inlet and Turbine. The Water Inlet allows incoming water from the Water

Solenoid to flow into the Dishwasher as well as provide water to regenerate the Resins in the Water Softener Tank. To access the

Water Inlet remove the eight (8) Phillips screws that attach the Left Side Panel (Fig. 23-1). With the Panel removed you have

access to the Water Inlet (Fig. 23-2).

• The Turbine (Fig. 23-3 & 23-4) measures the incoming water flow via

a Magnetic Reed Switch.

OPERATION: The Main Control Board monitors the pulses coming

from the Reed Switch and calculates if too little or

too much water is entering the Dishwasher. The

Turbine works in conjunction with the Pressure

Switch to ensure the correct amount of water enters

the Dishwasher. The Turbine is also a safety over

flow device to protect against overfilling.

Fig. 23-4

Page: 21

Page 27

24. FAULT CODES

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 22

Page 28

25. SCHEMATIC L63

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 23

Page 29

25. SCHEMATIC L64

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 24

Page 30

25. SCHEMATIC L65

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 25

Page 31

25. SCHEMATIC LI640

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 26

Page 32

25. SCHEMATIC LI670

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 27

Page 33

25. SCHEMATIC LI700

REPAIR MANUAL

L 63 / LL 64 / LL 65

LI 640 / LI 670 / LI 700

Page: 28

Loading...

Loading...