ARI Armaturen STEVI 463 User Manual

Operating and installation instructions

3-way control valves - STEVI® 423 / 463

Series 423 |

Series 463 |

Contents

1.0 |

General information on operating |

|

|

|

instructions ..................................................... |

2 |

|

2.0 |

Notes on possible dangers............................ |

2 |

|

2.1 |

Significance of symbols .......................................... |

2 |

|

2.2 |

Explanatory notes on safety information ................. |

2 |

|

3.0 |

Storage and transport ................................... |

2 |

|

4.0 |

Description...................................................... |

3 |

|

4.1 |

Scope of applications .............................................. |

3 |

|

4.2 |

Operating principles ................................................ |

3 |

|

4.3 |

Diagram................................................................... |

4 |

|

4.3.1 Mixing plug design.............................................. |

4 |

||

4.3.2 Diverting plug design ......................................... |

4 |

||

4.4 |

Technical data ......................................................... |

5 |

|

4.5 |

Marking ................................................................... |

5 |

|

5.0 |

Installation....................................................... |

5 |

|

5.1 |

General notes on installation................................... |

5 |

|

5.2 |

Requirements at the place of installation ................ |

6 |

|

5.3 |

Installation instructions concerning actuators ......... |

6 |

|

6.0 |

Putting the valve into operation.................... |

7 |

|

7.0 Care and maintenance................................... |

8 |

7.1 Replacement of stem sealings ............................... |

8 |

7.1.1 Stuffing box packing design ............................... |

8 |

7.1.2 Bellows seal design ........................................... |

9 |

7.1.2.1 Bellows seal and mixing plug........................ |

9 |

7.1.2.2 Bellows seal and diverting plug................... |

10 |

7.2 Replacement of internal parts ............................... |

11 |

7.2.1 Replacement of plug and stem ........................ |

11 |

7.2.1.1 Mixing plug design ....................................... |

11 |

7.2.1.2 Diverting plug design .................................. |

12 |

7.2.2 Replacement of the seat ring........................... |

12 |

7.3 Tightening torques................................................ |

13 |

7.3.1 Tightening torques for hexagon nuts .............. |

13 |

7.3.2 Tightening torques for seat rings .................... |

13 |

8.0 Troubleshooting........................................... |

13 |

9.0 Troubleshooting table ................................. |

14 |

10.0 Dismantling the valve or the top part ...... |

15 |

11.0 Warranty / Guarantee ................................. |

15 |

12.0 EC declaration of conformity.................... |

16 |

Rev. 0040318000 0410 englisch

Operating and installation instructions 3-way control valves - STEVI® 423 / 463

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings. Please contact the supplier or the manufacturer in case of problems which cannot be solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance and repair.

The notes and warnings must be observed and adhered to.

-Handling and all work must be carried out by expert personnel or all activities must be supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to monitor the personnel.

-In addition, current regional safety requirements must be applied and observed when taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives.

2.0Notes on possible dangers

2.1Significance of symbols

ATTENTION ! |

|

. . . |

Warning of general danger. |

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION ! ” describe practices, a failure to comply with which can result in serious injury or danger of death for users or third parties or in material damage to the system or the environment. It is vital to comply with these practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating and maintenance instructions as well as technical data (in the operating instructions, product documentation and on the device itself) must also be complied with to the fullest extent in order to avoid faults which in turn can cause serious injury to persons or damage to property.

3.0 Storage and transport

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

-Valve mountings such as actuators, handwheels, hoods must not be used to take external forces, e.g. they are not designed for use as climbing aids, or as connecting points for lifting gear.

-Suitable materials handling and lifting equipment should be used.

See catalog sheet for weights.

-At -20°C to +65°C.

-The paint is a base coat to protect against corrosion during transportation and storage. Do not damage paint protection.

Page 2 |

Rev. 0040318000 0410 |

Operating and installation instructions 3-way control valves - STEVI® 423 / 463

4.0Description

4.1Scope of applications

Valves are used for „controlling the flow of liquids, gases and vapours in chemical and other processing plants and for plant engineering“.

ATTENTION !

- Refer to the data sheet for applications, limits on use and possibilities.

-Certain media require or preclude the use of special materials.

-The valves are designed for standard operating conditions. If conditions exceed these requirements, e.g. aggressive or abrasive media, the operator should state the higher requirements when ordering.

-Valves made from grey cast iron are not authorised for use in systems subject to TRD 110.

The information complies to the Pressure Equipment Directive 97/23/EC.

It is the responsibility of the machine planner to ensure compliance. The special markings on the valve must be taken into account.

Refer to the catalogue sheet to see which materials are used in standard versions. Please contact the supplier or the manufacturer if you have any questions.

4.2 Operating principles

ARI control valves are especially suitable for actuation by pneumatic or electrical actuators. Depending on the mode of operation, two different execution methods are possible:

1.Execution with mixing plug

2.Execution with diverting plug

The execution with the mixing plug is the standard execution method.

This execution method is to be chosen when the valve is also employed as a mixer

(2 entrances, 1 exit.)

In exceptional cases, the execution with the mixing plug can also be employed as a diverting plug (1 entrance, 2 exits). This requires, however, low differential pressures and stable propulsion.

The execution method with the diverting plug is only to be employed with the operation of diverting.

Explanation:

Mixing operation |

|

|

|

|

|

Diverting operation |

|

|

|

|

|

||||||||

AB |

|

|

|

|

|

A |

AB |

|

|

|

|

|

|

A |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

B |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Rev. 0040318000 0410 |

Page 3 |

Operating and installation instructions 3-way control valves - STEVI® 423 / 463

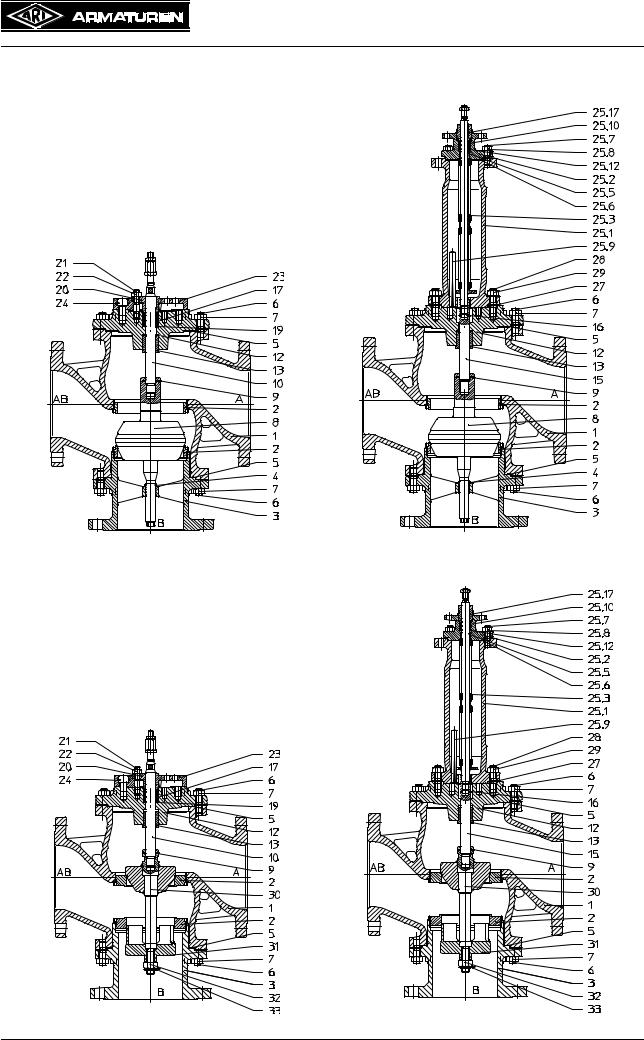

4.3 Diagram

4.3.1 Mixing plug design

Fig. 1: Series 423 |

Fig. 2: Series 463 |

4.3.2 Diverting plug design

Fig. 3: Series 423 |

Fig. 4: Series 463 |

Page 4 |

Rev. 0040318000 0410 |

Operating and installation instructions 3-way control valves - STEVI® 423 / 463

4.4 Technical data for

-Principal dimensions

-Pressure-temperature-ratings, etc. refer to datasheet.

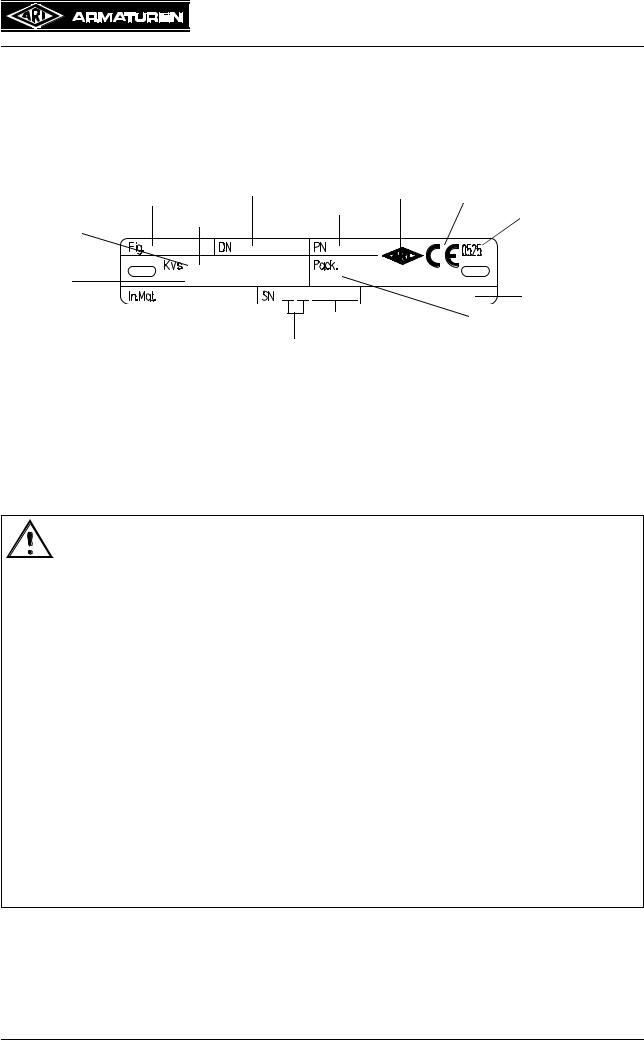

4.5 Marking

|

Type-Number Flow |

Nominal diameter |

Manufacturer |

CE-marking |

|

Nominal pressure |

Notified body |

||

Kvs-value |

characteristic |

|

||

|

|

|||

Plug |

|

Customer-specific |

design |

Serial-No. |

information |

Material of |

Stem sealing |

|

Year of manufacture clear speech |

|

|

internal parts |

(1. and 2. position) |

|

Fig. 5

Address of manufacturer: refer to item 11.0 Warranty / Guarantee

5.0Installation

5.1General notes on installation

The following items should be taken into account besides the general principles governing installation work:

ATTENTION !

- Remove flange covers if present.

-The interior of valve and pipeline must be free from foreign particles.

-Note installation position with reference to flow, see mark on valve.

-Steam line systems should be designed to prevent water accumulation.

-Lay pipelines so that damaging transverse, bending and torsional forces are avoided.

-Protect valves from dirt during construction work.

-Connection flanges must mate exactly.

-Connecting bolts for pipe flanges should be mounted preferably from the counter flange side (hexagon nuts from the valve side).

-Valve mountings such as actuators, handwheels, hoods must not be used to take external forces, e.g. they are not designed for use as climbing aids, or as connecting points for lifting gear.

-Suitable materials handling and lifting equipment should be used.

Refer to data sheet for weights.

-Keep the thread and shaft of the stem free from paint.

-Centre gaskets between the flanges.

-Strainers or filters should be installed before the valves.

-Planners / construction companies or operators are responsible for positioning and installing products.

-The valves are designed for application, not influenced from weather.

-For application outside or in adverse environments like corrosion-promoting conditions

(sea water, chemical vapours, etc.), special constructions or protective measures are recommended.

Rev. 0040318000 0410 |

Page 5 |

Loading...

Loading...