ARI Armaturen ES11 User Manual

Operating and installation instructions

Electronic positioner ES11

Contents

1.0 General information on operating |

2-2 |

|

instructions .................................................. |

||

2.0 Notes on possible dangers......................... |

2-2 |

|

2.1 |

Significance of Symbols .................................... |

2-2 |

2.2 |

Explanatory notes on safety information ............. |

2-2 |

3.0 Storage and transport ................................. |

2-2 |

|

4.0 Description................................................... |

2-3 |

|

4.1 |

Scope of application............................................ |

2-3 |

4.2 |

Operating principle .............................................. |

2-3 |

4.3 |

Technical data ..................................................... |

2-3 |

4.4 |

Split range ........................................................... |

2-4 |

4.5 |

Dimensions.......................................................... |

2-4 |

5.0 Installation ................................................... |

2-5 |

|

5.1 |

General notes on installation............................... |

2-5 |

5.2 |

Installation in Control Cabinet ............................. |

2-5 |

5.3 |

Installation in ARI-PREMIO actuator ................... |

2-6 |

5.4 |

Installation in CS25 to CS27 actuator ................. |

2-7 |

5.5 |

Electrical connection ........................................... |

2-8 |

5.5.1 Circuit diagram .............................................. |

2-8 |

|

5.5.2 Terminal assignments ................................... |

2-9 |

|

5.5.3 Connection conditions................................... |

2-9 |

|

5.6 |

Connection in control cabinet............................ |

2-10 |

5.7 |

Connection in ARI-PREMIO (circuit diagram) ... |

2-11 |

5.7.1 ARI-PREMIO 2,2 - 5 kN .............................. |

2-11 |

|

5.7.2 ARI-PREMIO 12 - 15 kN without integrated |

|

|

|

reversing contactor....................................... |

2-12 |

5.7.3 ARI-PREMIO 12 - 15 kN with integrated |

|

|

|

reversing contactor....................................... |

2-13 |

5.8 |

Connection in ARI-PREMIO (description) ......... |

2-14 |

5.9 |

Connection in CS25 to CS27 actuator |

|

(circuit diagram)...................................................... |

2-15 |

|

5.10 Connection in CS25 to CS27 actuator |

|

|

(description)............................................................ |

2-16 |

|

6.0 Starting up ................................................. |

2-17 |

|

6.1 |

Factory setting ................................................... |

2-18 |

6.2 |

Setting of potentiometer .................................... |

2-18 |

6.3 |

Type of control signal......................................... |

2-18 |

6.4 |

Setting of effective direction SW........................ |

2-18 |

6.5 |

Zero point setting .............................................. |

2-19 |

6.6 |

Slope span setting ............................................ |

2-20 |

7.0 Care and maintenance.............................. |

2-20 |

|

8.0 Troubleshooting ........................................ |

2-21 |

|

9.0 Troubleshooting table .............................. |

2-21 |

|

10.0 Dismantling of the electronic |

2-23 |

|

positioner .................................................. |

||

11.0 Warranty / Guarantee .............................. |

2-23 |

|

12.0 EU declaration of conformity ................. |

2-24 |

|

Rev. 0040601000 1014 englisch

Operating and installation instructions

Electronic positioner ES11

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the fittings. Please contact the supplier or the manufacturer in case of problems which cannot be solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance and repair.

The notes and warnings must be observed and adhered to.

-Handling and all work must be carried out by expert personnel or all activities must be supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to monitor the personnel.

-In addition, current regional safety requirements must be applied and observed when taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time. These Operating Instructions comply with the requirements of EU Directives.

2.0Notes on possible dangers

2.1Significance of Symbols

ATTENTION ! |

|

. . . |

Warning of general danger. |

|

|

|

|

ATTENTION ! |

|

. . . |

Warning of dangerous voltage. |

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION ! ” describe practices, a failure to comply with which can result in serious injury or danger of death for users or third parties or in material damage to the system or the environment. It is vital to comply with these practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating and maintenance instructions as well as technical data (in the operating instructions, product documentation and on the device itself) must also be complied with to the fullest extent in order to avoid faults which in turn can cause serious injury to persons or damage to property.

3.0 Storage and transport

-At -20° to +70°C dry, free from dirt.

-Do not unpack electronics prior to installation.

-Protect against external force (impact, vibration etc.).

-Do not soil or damage type identification plate and wiring diagram on the controller.

Page 2-2 |

Rev. 0040601000 1014 |

Operating and installation instructions

Electronic positioner ES11

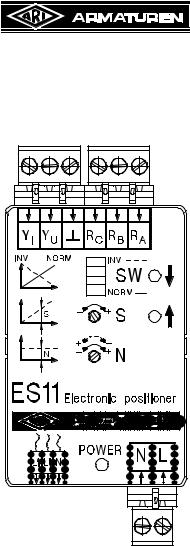

4.0Description

4.1Scope of application

The ES11 electronic positioner is used wherever 3-step actuators (servo drives) are to be activated with standardised electrical signals.

The ES11 electronic positioner is suitable for control cabinet installation as well as installation in servo actuators of the series ARI-PREMIO and ARI-CS25 to CS27.

The ambient conditions have to be conform to the actual electromagnetic compatibility directives. Additional the compatibility to this directives has to be maintained in case of expansion or other changings of the ambient conditions.

4.2 Operating principle

The ES11 electronic positioner converts constant input signals (current signals up to 20 mA, voltage signals up to 10 V) into 3-step output signals. Electrical actuators are connected to the 3-step output signal. The electronic positioner and actuator make up a control circuit.

The actuating signal is selected by means of corresponding terminal connections. LEDs indicate control direction and operation stand-by.

The red and green LEDs facilitate adaptation of the resistor input to the actuating signal.

The settings are made by means of trim potentiometers.

The control stage is galvanically (electrically) isolated from the power input.

ATTENTION !

To facilitate use in 3-conductor wiring, the ground input may be connected to the N contact of the power input only in the 24 V AC version.

The new contact is then referred to as zero potential (0V). Split range operation is possible in steps of 20%.

The effective direction ratio of the actuating signal input to the actuating signal output can be selected with the effective direction selector switch SW.

4.3 Technical data

Operating Voltage |

UB |

24V 50-60Hz |

115V 50-60Hz |

230V 50-60Hz |

|

|

|

-20% +10% |

-20% +10% |

|

-20% +10% |

Operating current without |

IB |

150 mA |

40 mA |

|

20 mA |

load |

|

|

|

|

|

3-step switching current |

IS |

4A / cos 0,5 |

|

|

|

Hysteresis |

|

< 0,6% |

|

|

|

Input signal |

YU |

....10V DC (RI =30 kOhm) |

|

|

|

Input signal |

YI |

....20mA DC (RI =125 Ohm) |

|

|

|

Potentiometer input |

RP |

0....10k , preferably 0....1k |

|

|

|

|

|

(use potentiometer only as a voltage divider) |

|||

Type of enclosure |

|

IP40 (clamps IP20) |

|

|

|

Ambient temperature |

|

-20....+70 °C |

|

|

|

Rev. 0040601000 1014 |

Page 2-3 |

Operating and installation instructions

Electronic positioner ES11

4.4 Split range

In split range mode, it is possible to utilise only part ranges of the entire actuating signal.

For example, the actuating signal 0...20 mA sets the part range 50...100%, which corresponds to the range 10...20 mA.

The part ranges are set with the zero point adjusting screw (N) and with the slope span adjusting screw (S).

Infinitely variable part ranges over 20% are possible.

The smallest possible part ranges are specified in the table below.

0-20% |

0-40% |

0-60% |

0-80% |

0-100% |

|

20-40% |

20-60% |

20-80% |

20-100% |

|

|

40-60% |

40-80% |

40-100% |

|

|

|

60-80% |

60-100% |

|

|

|

|

80-100% |

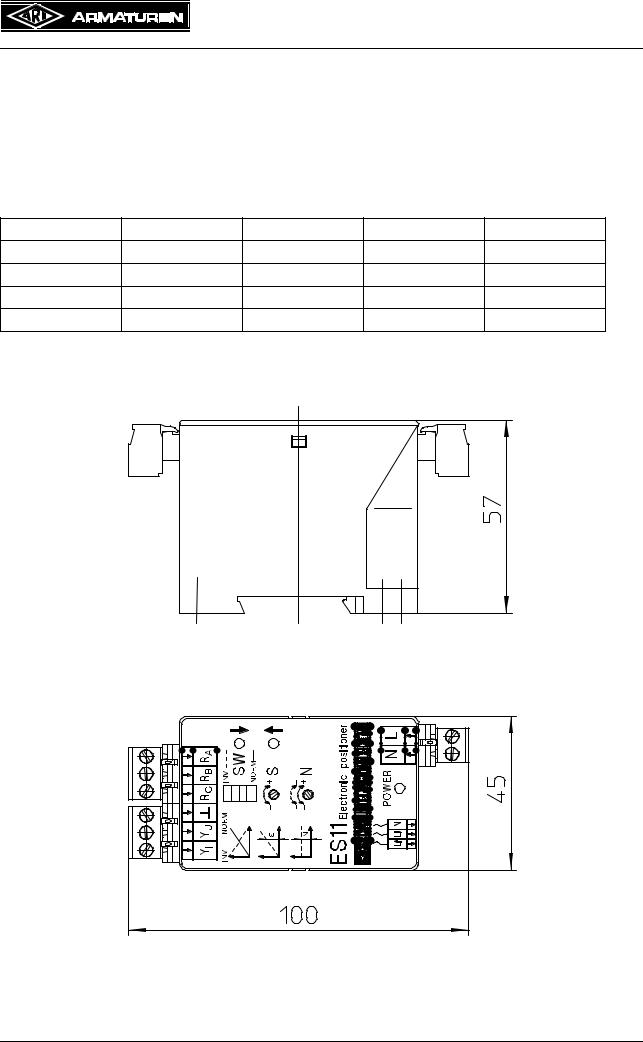

4.5 Dimensions

fig. 1

Page 2-4 |

Rev. 0040601000 1014 |

Operating and installation instructions

Electronic positioner ES11

5.0 Installation

ATTENTION !

Work on electrical systems or equipment must only be carried out by qualified electricians or by trained individuals under the guidance and supervision of a qualified electrician in compliance with regional electrical requirements and regulations.

When connecting electronics the supply line must be disconnected from the mains (not live) during connection work. Non-compliance may result in death, serious injury or substantial damage to property.

-The power supply and data provided on the type identification plate must agree.

-Do not touch live parts when carrying out adjustments.

-Take particular caution at voltages above 24 V!

-Do not disconnect or connect series isolating terminals with the power on!

-Ground connection between N and is only permitted in the 24 V version.

-Only one actuator is to be connected at any one time.

-Do not overshoot the range of the actuator when carrying out adjustments, danger of damage.

-Ensure that the motor connected in the actuator switches off in the end positions based on distance or torque.

5.1General notes on installation

The electronic positioner ES11 can be installed in a control cabinet, in the ARI-PREMIO actuator and in the CS25 to CS27 actuators.

The electronic positioner ES11 can be retrofitted in the ARI-PREMIO actuator.

The electronic positioner ES11 can only be retrofitted under certain conditions in the CS25 to CS27 actuators.

Obtain technical details directly from the manufacturer.

-Regional electrical requirements and regulations must be observed when laying electricity lines and making electrical connections.

-The cable cross-section must always correspond to the relevant input current and the cable length.

-The rated mains voltage and mains frequency must agree with the data on the type identification plate.

Mains power fuse protection, installation side: 6 A max.

5.2 Installation in Control Cabinet

-The controller is mounted on a profile rail in the control cabinet in accordance with DIN 46277.

-The mounting grid for control panel installation is L 58 mm x W 35 mm.

-A connector which can be mounted on rails is provided to facilitate installation in a control cabinet.

Installation parts:

-1 Electronic positioner ES11

-1 Connector for rail mounting

Rev. 0040601000 1014 |

Page 2-5 |

Operating and installation instructions

Electronic positioner ES11

5.3 Installation in ARI-PREMIO actuator

Refer to figures below for installation in ARI-PREMIO actuator.

BC

CB A

fig. 2: Installation RI21 / ES11 ARI-PREMIO 2,2 - 15 kN

Installation procedure:

Carefully remove cover.

AFit mounting bracket (50.80) at point on gear cover provided for this purpose. Secure with two socket head cap screws (50.81) DIN EN ISO 4762 - M4x8.

B/C Secure the electronic positioner ES11 (50.78/79) with two socket head cap screws (50.82) DIN EN ISO 4762 - M4x12 on mounting bracket (50.80).

ATTENTION !

For potentiometer installation, refer to ARI-PREMIO operating and installation instructions.

Installation parts:

-1 Electronic positioner ES11

-1 Mounting bracket ES11/RI21

-2 Socket head cap screws DIN EN ISO 4762 - M4x8

-2 Socket head cap screws DIN EN ISO 4762 - M4x12

-1 1000 Ohm potentiometer

-1 Potentiometer cable

-2 PT screws KB 22x8 WN1412-Zi

-1 Sliding block

-1 Torsion spring

-1 Spring washer 5mbo

- 1 Spur gear

-

-

-

Page 2-6

Operating and installation instructions

Electronic positioner ES11

5.4 Installation in CS25 to CS27 actuator

Refer to figure below for installation in CS25 to CS27 actuator.

fig. 3

Installation procedure:

-Carefully remove cover.

-Loosen capacitor, for this purpose, release corresponding cable ties.

-Secure capacitor plate with screw DIN EN ISO 4762 - M8x10 on to gearbox cover.

-Install capacitor on capacitor plate

-Secure mounting bracket on gearbox cover with two self-tapping screws M4x8 DIN 7500.

-Secure ES11 to mounting bracket with two socket head cap screws DIN EN ISO 4762 - M4x12.

-Connect cable of CS electronic positioner to terminal block and plug into ES11 cable.

-Tie together newly installed cables with cable ties.

-Remove old circuit diagrams from cover and affix new circuit diagram in cover.

ATTENTION !

For potentiometer installation, refer to operating instructions for CS actuators.

Mounting parts:

-1 Electronic positioner ES11

-1 Mounting bracket ES11/RI21

-2 Socket head cap screws DIN EN ISO 4762 - M4x12

-1 Socket head cap screws DIN EN ISO 4762 - M8x10

-1 Capacitor plate

-2 Self-tapping screws DIN 7500 - M4x8

-1 1000 Ohm potentiometer, soldered

-2 Lock rings for potentiometer

-1 Pinion for potentiometer

-1 CS electronic positioner cable

-1 Circuit diagram ES11 + CS25

-2 Cable ties

Rev. 0040601000 1014 |

Page 2-7 |

Operating and installation instructions

Electronic positioner ES11

5.5 Electrical connection

5.5.1 Circuit diagram

fig. 4

Page 2-8 |

Rev. 0040601000 1014 |

Loading...

Loading...