Page 1

02/12/04

Page 1 of 12

3782865

ARB WINCH/NONWINCH BUMPER TO SUIT NISSAN PATHFINDER

2/99 ON

PRODUCT No. 3938020

WARNING

FOR VEHICLES EQUIPPED WITH SRS AIRBAG

WHEN INSTALLED IN ACCORDANCE WITH THESE INSTRUCTIONS, THE FRONT

PROTECTION BAR DOES NOT AFFECT OPERATION OF THE SRS AIRBAG.

TAKE NOTE OF THE FOLLOWING:

• THIS PRODUCT MUST BE INSTALLED EXACTLY AS PER THESE

INSTRUCTIONS USING ONLY THE HARDWARE SUPPLIED.

• IN THE EVENT OF DAMAGE TO ANY BULL BAR COMPONENT, CONTACT

YOUR NEAREST AUTHORISED ARB STOCKIST. REPAIRS OR

MODIFICATIONS TO THE IMPACT ABSORPTION SYSTEM MUST NOT BE

ATTEMPED.

• DO NOT USE THIS PRODUCT FOR ANY VEHICLE MAKE OR MODEL,

OTHER THAN THOSE SPECIFIED BY ARB.

• DO NOT REMOVE LABELS FROM THIS BULL BAR.

• THIS PRODUCT OR ITS FIXING MUST NOT BE MODIFIED IN ANY WAY.

Note:

1 If fitting optional fog lights, fitting kit no. 9381FCK is required.

2 This winch bumper is suitable for Warn 8,000lb, 9,000lb & 9,500HS

winch only.

Tools Required

10, 12,13, 14, 18, 19mm Spanners and Sockets. Phillips head screwdriver , Sharp

Knife.

Drill and 6.5mm or ¼” Bit. Black silicone.

Page 2

02/12/04

Page 2 of 12

3782865

FITTING KIT No. 6171387, 6171391, 6171364

USE

PART No

QTY

DESCRIPTION

BUFFER FITTMENT

6151128

17

NUT FLANGE M6

3162158 1 BUFFER LOWER

3162153

1

BUFFER LHS

3162154

1

BUFFER RHS

LIGHT SURROUNDS TO BAR

3162156 1 LIGHT SURROUND LHS

3162157 1 LIGHT SURROUND RHS

CHROME TUBE FITTMENT

6151255 2 BOLT M12 X 40mm

4581049 2 WASHER FLAT M12

4581050 2 WASHER SPRING M12

6131174

1

CHROME TUBE

MOUNT ASSY TO VEHICLE

3751859L

1

BRACKET IMPACT ABSORBER LHS

3751859R

1

BRACKET IMPACT ABSORBER RHS

4581011 2 WASHER FLAT 27x12x4mm

WING BRACE

BAR TO VEHICLE

3756195L

3756195R

1

1

BRACE WING

BRACE WING

6151256

2

BOLT M6 BUTTON HEAD S/STEEL

4581072 2 WASHER M6 x 19mm

6151017 2 BOLT M6 x 16mm HEX HEAD

6151128 4 NUT M6 FLANGE

4581072 2 WASHER 19x7x1.6mm

WINCH

4581044

4

WASHER 3/8”

CONTROL BOX FITMENT

3756220 1 CONTROL BOX BRACKET

6151017 2 BOLT M6 X 16MM

6151128 4 NUT FLANGE M6

WINCH COVER FITTMENT

6151128 2 NUT FLANGE M6

6151256

2

SCREW M6 S/STEEL BUTTON HEAD

6191001 1 WINCH COVER EXTRUSION

6521031

1

WINCH COVER

4581035

2

WASHER M6

RUBBER EXTRUSION FITMENT

6821116

14

SQUARE PLASTIC PLUG

6151176

14

SCREW SELF TAPPING 12mm 8G

6191002

2

EXTRUSION

3193649

2

MOUNT STRIPS

WINCH BUMPER TO MOUNT

ASSEMBLY

6151255 6 BOLT M12 X 40mm

4581050 6 WASHER SPRING M12

4581007 6 WASHER FLAT M12 LARGE

CB

3162152 2 PLASTIC PLUG DIA16

ROLLER FAIRLEAD FITTMENT

4581049 4 WASHER FLAT M12

NUMBER PLATE FITTMENT

6151017 2 BOLT M6 X 16mm

6151128 2 NUT FLANGE M6

6781408 1 TAPE DOUBLE SIDED

WIRING

180302

10

CABLE TIE

Page 3

02/12/04

Page 3 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

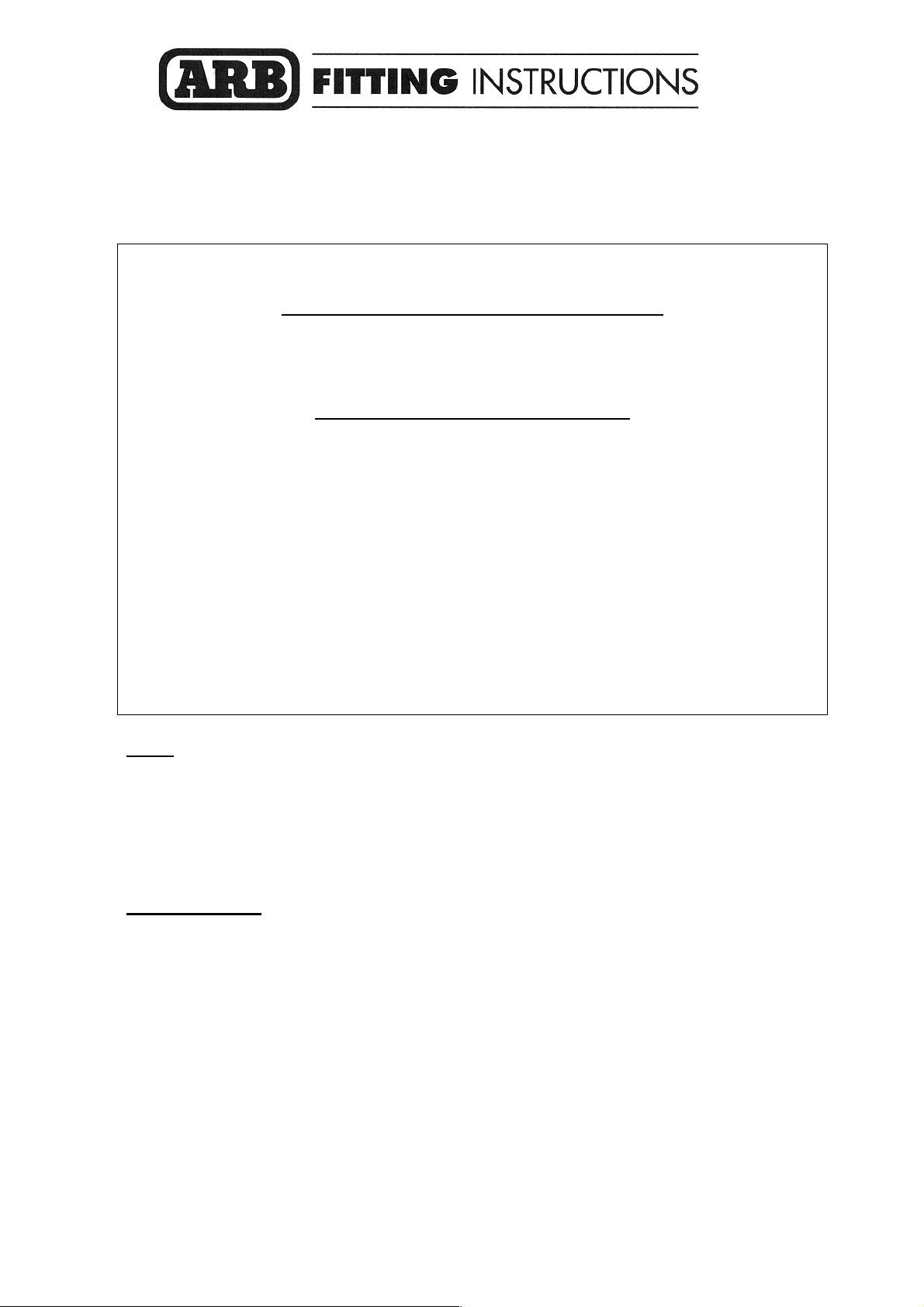

1. 1. Position the lower buffer on the winch

bumper and assemble using the M6 flange

nuts.

2. 1. Insert the side buffers through the holes and

fix using the M6 flange nuts.

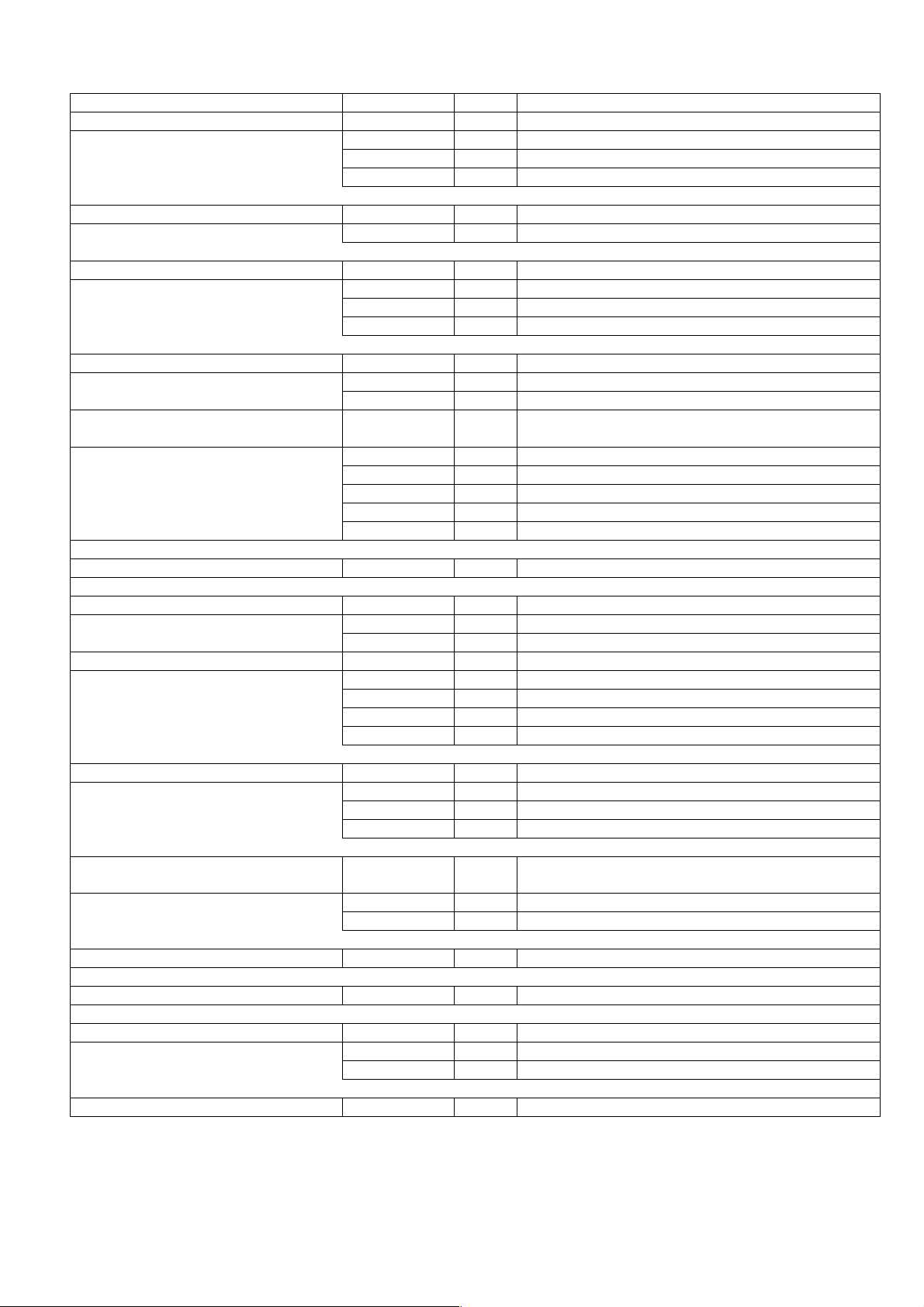

3. 1. Glue the light surrounds to the bar using a

silicone based rubber adhesive. Run the

bead along the cavity on the rear side of the

part. Position the surround to align the inside

edge with the buffer and concentric to the

light.

2. Wipe off any adhesive on the front face of

the bar. Allow adhesive to cure before

continuing.

3. If fitting optional fog lights, do so at this

stage.

Page 4

02/12/04

Page 4 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

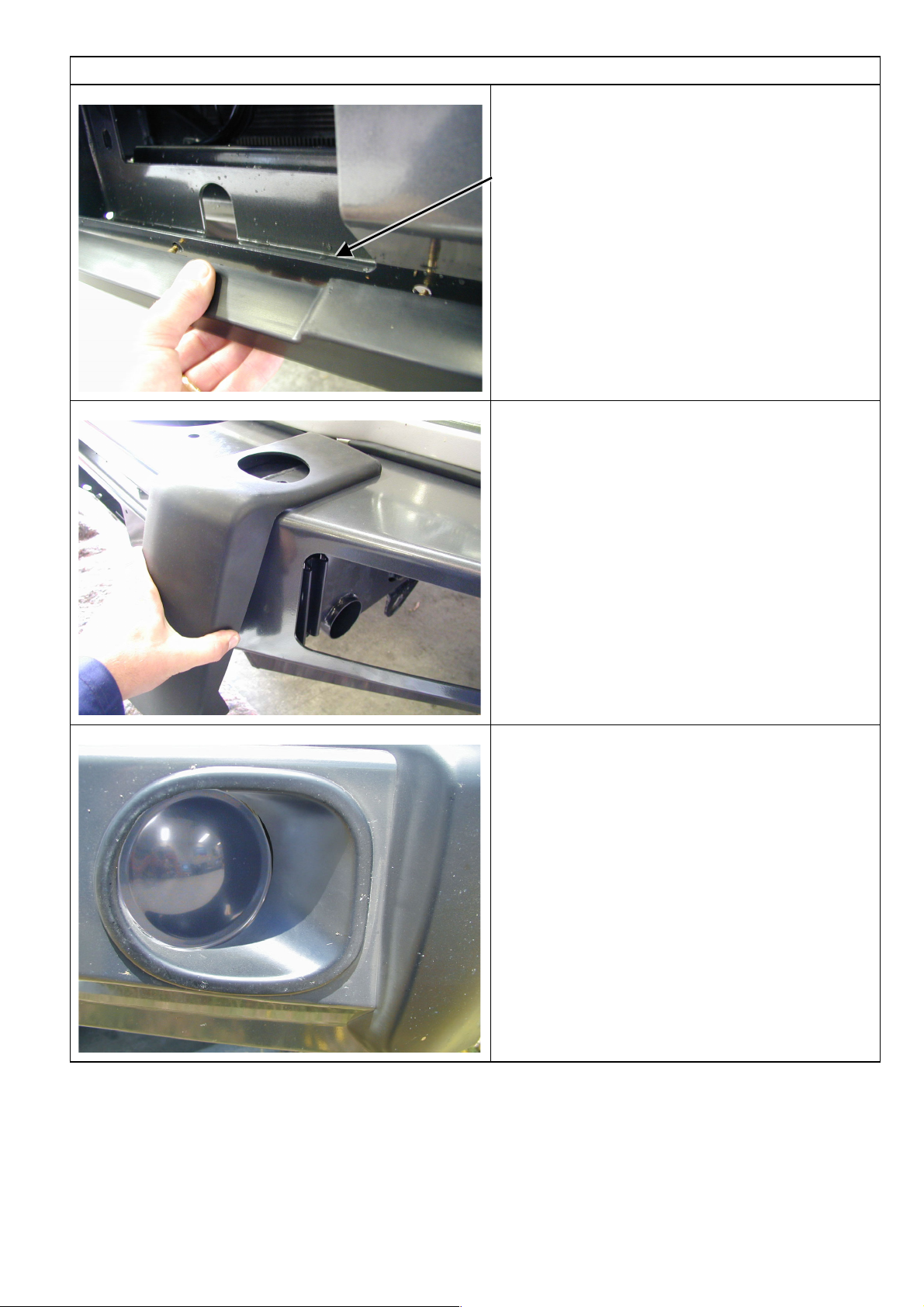

4. 1. Push the top chrome tube through the hole

in the buffer and fasten using the M12 x 40mm

bolts, washers and spring washers.

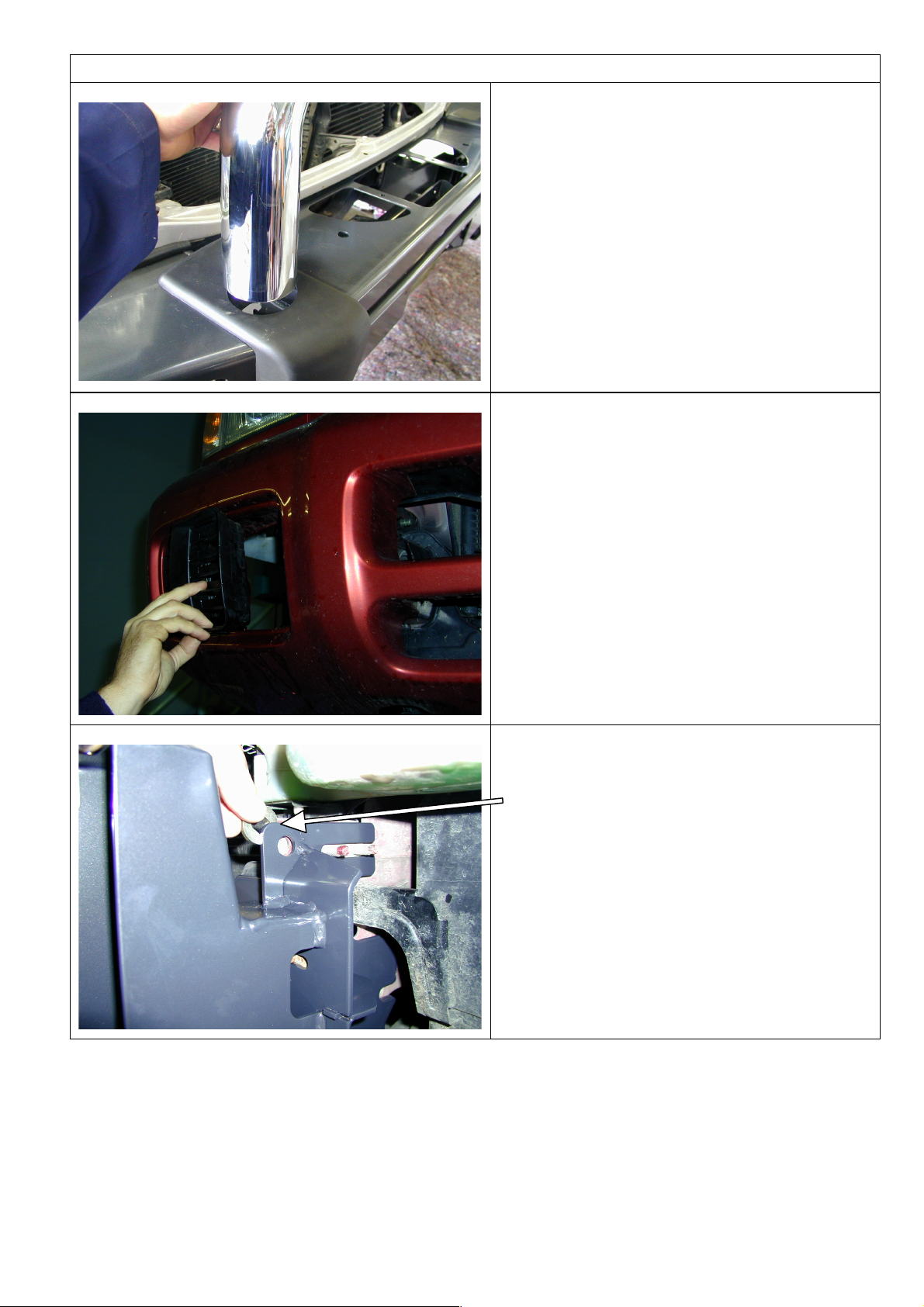

5. 1. Remove the bumper bar.

1. Remove inner guard trims, left and right.

2. Remove Tow Hooks.

3. Remove Impact Absorbers.

NOTE: Set aside all original mounting hardware

and inner guard trims.

6. 1. Mount the Impact Absorber brackets to each

side of the chassis using original fasteners.

2. Fit spacer washer 27 x 12 x 4mm to top hole

of bracket and fasten.

Page 5

02/12/04

Page 5 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

7. 1. Fasten the wing braces to the vehicle using

M6 Hex bolts, washers and flange nuts.

2. On the drivers side undo washer bottle and

carefully cut off retaining hook with a sharp

blade.

3. Pass the wing support brace between the

bottle and the body aligning the holes.

4. Replace the original bolt, clamping the brace

in place.

5. Using a 6.5mm or ¼” drill, drill through

washer bottle brackett using the brace hole

as a guide.

6. Fasten with M6 Hex head bolt and flange nut.

Note: - On passenger side use panel washers

19x7x1.6mm

8. (If fitting the winch.)

1. To place the winch clutch handle in a

convenient location the winch gearbox must

be rotated 2 hole spacings, 72 degrees, in an

anti-clockwise direction when viewed from

the gearbox end. Place the winch on its end

and remove all gearbox bolts. Gently raise

the gearbox just enough to rotate it. Do not

completely remove the gearbox and avoid

damaging the gasket. Refit all bolts and

tighten.

NOTE: Take care not to lift the assembly more

than a couple of millimetres while rotating to the

desired position to avoid unmeshing the gears.

9. 1. To place the winch motor in the correct

location the winch motor must be rotated 90

degrees, in a clockwise direction when

viewed from the motor end. Place the winch

on its end and remove the 2 motor retaining

bolts. Gently raise the motor just enough to

rotate it. Do not completely remove the motor

and avoid damaging the gasket. Refit all bolts

and tighten.

NOTE: Take care not to lift the assembly more

than a couple of millimetres while rotating to the

desired position to avoid unmeshing the gears.

Page 6

02/12/04

Page 6 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

10. 1. Bolt the winch and roller fair lead to the bar

using the bolts supplied. The longer bolts are

used for the two bottom holes through the roller

fair lead.

11. 1. If fitting the XP 9.5 winch, remove the cover from

the control box.

For any other winch, go to step 17.

12. 1. Remove the two cap screws, nuts and spacer

washers that hold the four solenoids in place.

Page 7

02/12/04

Page 7 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

13. 1. Remove the four solenoids from the base of the

control box using the copper bus bar as an aid and

hold to one side.

14.

Before

1. Remove the two bolts in the base of the control box

and reposition them into the more centralised holes

After

15. 1. Place the 4 solenoids over the 2 metal stands that

are facing upwards. Make sure they line up with the

holes in the base.

Page 8

02/12/04

Page 8 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

16. 1. Replace the 2 cap screws, washers and nuts

removed in step 12 above into original holes.

2. Replace the black cover and refit the three cover

screws (DO NOT OVER TIGHTEN)

17.

1. Install the winch and roller fairlead using

bolts, nuts and spring washers supplied by Warn,

and the 4 x 3/8” flat washers supplied in the bolt

kit. Refer to Warn installation instructions for

correct procedure. Adjust winch in slots until the

winch is centralised in the bull bar.

1. Assemble the control box bracket to the

control box using M6 flange nuts.

2. Mount the control box to the bar using M6 X

16 bolts and M6 flange nuts.

NOTE: The gearbox is on the passenger side for

the 8,000lb and 9,000lb. The cable spools from

the bottom for the two winches mentioned.

18. (If not fitting winch)

1. Wrap rubber extrusion around winch cover.

2. Place washers over the winch cover fixing

holes located on the top middle face of the

winch bumper.

3. Place the winch cover on top of the winch

bumper inline with the mount holes.

Bolt together using the M6 button head stainless

steel screws and M6 nuts.

Page 9

02/12/04

Page 9 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

19.

With winch

Without winch

(If fitting with winch.)

1. Peel off one side of the double sided tape

and adhere to the top rear side of the number

plate. Note: Clean the adhering surfaces

before applying tape with an alcohol solvent.

2. Peel off the other side of the tape and bolt to

the winch bumper with the M6 X 16mm bolts

and M6 flange nuts through the lower holes

of the number plate.

3. Press firmly to the top of the number plate so

the tape can properly adhere.

(If not fitting with winch.)

1. Bolt the number plate through the top holes

using M6 X 16mm bolts and M6 flange nuts.

If desired the double sided tape can be used

down the sides of the number plate.

20. 1. The rubber extrusion contains a support

section to assist in the moulding. Remove

this section by tearing at one end. Discard

this section.

2. Insert the square plastic plugs into the square

holes on the top face of the wing.

21. 1. Insert the mount strips inside the channel

section of the rubber extrusion. Make sure

the flap section is on the outer side. Allow

generous even amounts of excess at either

end of the strip so that it can be trimmed

later.

Page 10

02/12/04

Page 10 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

22.

1. Using a Philips head screw driver or cordless

drill with a Philips head tip fix the extrusions

to the top of the wings using the self taping

screws.

23. 1. Using a sharp knife cut the excess rubber in

line with the inside end of the wing. Only cut

the inside excess, the other end will be cut

when the winch bumper is fitted.

24. 1. With the aid of another person carefully place

the bar on the mounting brackets.

2. Horizontally and vertically align the bar to the

body and fasten using the six M12 x 40mm

bolts, large washers and M12 spring

washers. Tighten all bolts so as the large

washer deforms inside the rectangular

cutout.

Page 11

02/12/04

Page 11 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

25. 1. There are two diameter 16 holes located on

the top face of the bar. If no CB aerials are fitted

the holes can be covered with the plastic plugs

provided in the fitting kit.

2. Place the ARB logo on the front face of the

bar in the indentation.

26. (If fitting with winch)

1. Feed the winch cable through the roller fair

lead. Mount the hook to the end of the cable.

27. 1. To replace inner guard trims, reposition on

the vehicle and mark out the edge of the

bullbar wing

2. Using a sharp knife or scissors trim and refit

the guard allowing enough to drill and

position to the bar.

Note: - The trim will sit between the wing brace

and the bullbar wing.

Page 12

02/12/04

Page 12 of 12

3782865

ASSEMBLY SEQUENCE FOR WINCH BUMPER.

28. 1. Trim off excess plastic as shown.

2. With the trim between the brace and the wing

mark, via the hole in the wing, mark with a

felt tip pen or a scriber.

3. Remove the trim and drill using 6.5mm or ¼”

drill bit.

4. Reposition on the vehicle and fasten using

dome head s/steel bolts and flange nuts.

29.

If fitting fog lights, wire the fog lights as described in the fog light fitting instructions

The fog lights can be adjusted to desired angles by the adjustment bolts located at the back of the

light insert. When adjustment is finalised be sure to retighten the fog light bolts.

30. (If fitting with winch)

Connect the winch control box cables to the winch motor. Refer to the Warn handbook for additional

information. Connect the long winch + & - cables to the vehicle after the bar is installed.

Refer to the Warn winch manual for vehicle wiring instructions.

Ensure that these cables are installed well clear of sharp, hot or moving objects. Secure the winch

cables to the vehicle and winch bumper with the supplied cable ties.

Loading...

Loading...