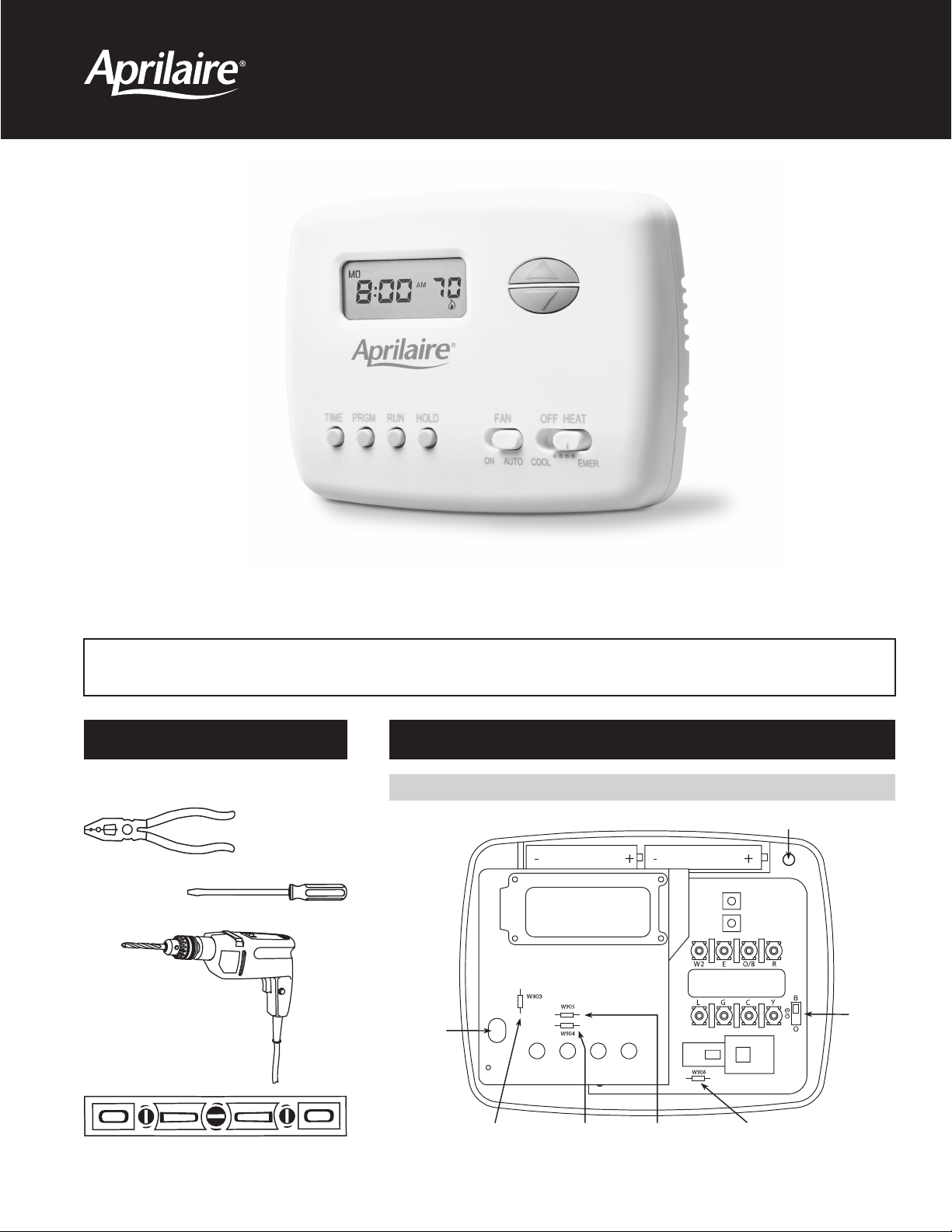

Aprilaire 8265 Installation And Operation Manual

Programmable Thermostat

Model 8265 Installation and Operation Manual

5/2 Day Programmable Heat Pump Thermostat

Failure to follow and read all instructions carefully before installing or operating this control could cause personal

injury and/or property damage. If you have any questions, please call Research Products Corporation at (800) 334-6011.

PREPARATIONS

Assemble tools required as shown below.

Wire cutter/stripper

Flat blade

screwdriver

Electric or cordless

drill with 3/16 inch

drill bit, if needed.

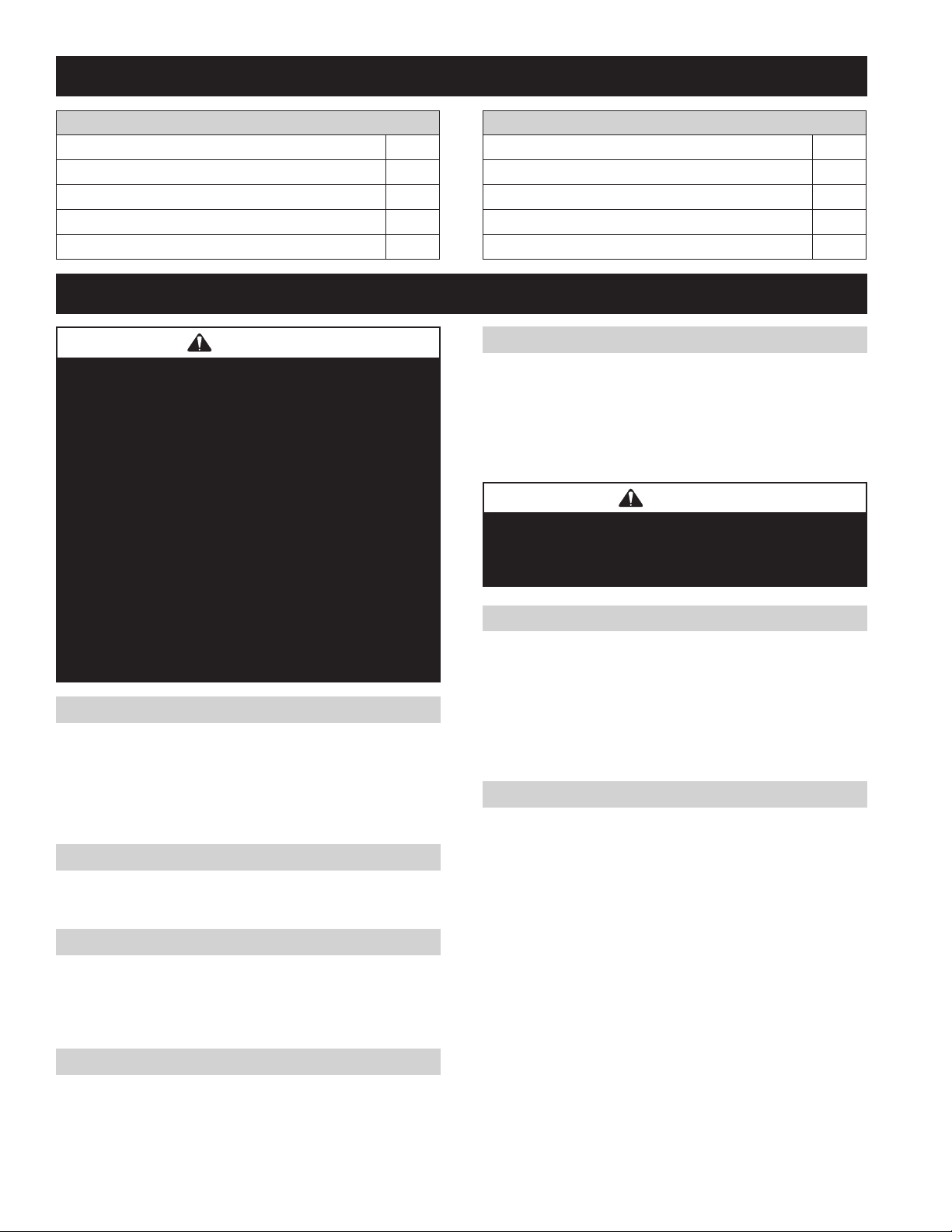

THERMOSTAT DETAILS

FIGURE 1 – Thermostat Base

Mounting

hole

Mounting hole

O/B

Terminal

Selection

Switch

Level

W903

Clip to Disable

Progressive Recovery

Feature

W904 Clip

for Celsius

instead of

Fahrenheit

W905 Clip for

Slow Cycle

instead of

Fast Cycle

W906 for Emergency Heat

Second Stage Fan Control.

Clip for Fan Control by Equipment

instead of by Thermostat.

THERMOSTAT APPLICATIONS

Description

Heat Pump (No Aux or Emergency Heat) Yes

Heat Pump (with Aux or Emergency Heat) Yes

Standard Heat & Cooling Systems No

Standard Heat Only Systems No

Millivolt Heat Only Systems – Floor or Wall Furnaces No

MOUNTING AND WIRING

WARNING

120 volts may cause serious injury from electrical

shock. Disconnect electrical power to the furnace & air

conditioner before starting installation. This thermostat

is not a 120 volt (line voltage) device.

Improper installation may cause serious injury from electrical

shock. This product must be installed by a qualifi ed

heating & air conditioning contractor in accordance with

NEC Standards and applicable local and state codes.

Do not use on circuits exceeding specifi ed voltage.

Higher voltage will damage control and could cause

shock or fi re hazard.

Do not short out terminals on gas valve or primary control

to test. Short or incorrect wiring will damage thermostat

and could cause personal injury and/or property damage.

Thermostat installation and all components of the system

shall conform to Class II circuits per NEC code.

ELECTRIC/GAS JUMPER (FAN OPTION)

If your emergency or auxiliary system will energize the blower, then

jumper W906 on the thermostat base must be cut (see Figure 1).

If your emergency or auxiliary heat system requires that the

thermostat energize the fan circuit, do not cut jumper W906.

If you are unsure of your application, contact a qualifi ed service person.

°F OR °C SELECTION

The factory default setting for temperature display is Fahrenheit.

If you want the temperature in Celsius, clip jumper W904.

FAST OR SLOW CYCLE SELECTION

The factory default setting is fast cycle, which cycles 1st stage with a

temperature swing of approximately 1.2°F and 2nd stage with 0.75°F.

If you prefer slow cycle, clip jumper W905. The 1st stage and 2nd

stage temperature swing will become 1.5°F and 1.2°F respectively.

PROGRESSIVE RECOVERY

This thermostat is set to operate with Progressive Recovery. This

causes the thermostat to start the heating or cooling system early to

have the room temperature reach the program setpoint at the time

the period is to start.

To disable Progressive Recovery, clip jumper W903 (see Figure 1).

2

Description

Standard Central Air Conditioning No

Gas or Oil Heat No

Electric Furnace No

Hydronic (Hot Water) Zone Heat – 2 Wires No

Hydronic (Hot Water) Zone Heat – 3 Wires No

O/B TERMINAL SELECTION SWITCH

The O/B switch on this thermostat is factory set to the “B” position.

This will accommodate the majority of heat pump applications which

require the changeover relay to be energized in HEAT. If the heat

pump being installed with this thermostat requires an “O” terminal

to energize the changeover relay in COOL, the O/B switch must be

moved to the “O” position.

CAUTION

Take care when securing and routing wires so they do

not short to adjacent terminals or rear of thermostat.

Personal injury and/or property damage may occur.

BATTERY LOCATION

This thermostat does not require batteries to operate. The 2 “AAA”

alkaline batteries are for the thermostat to remember the programming

if AC voltage is lost. If the display shows BATT when AC power is

not present, the batteries are low and should be replaced with fresh

“AAA” Energizer® alkaline batteries. To replace the batteries, install

the batteries along the top of the base (see Figure 1). The batteries

must be installed with the positive (+) ends to the right.

CHOOSE A LOCATION TO MOUNT THE THERMOSTAT

MOUNT THE THERMOSTAT…

• Approximately 5 feet above the fl oor. Refer to local codes for

compliance with the Americans with Disabilities Act (ADA).

• On an interior wall in a frequently occupied space where the

temperature is most representative of the zone being controlled

by the thermostat.

• At least 18 inches away from an outside wall.

DO NOT MOUNT THE THERMOSTAT…

• Behind doors, in corners or other dead air spaces.

• In direct sunlight, near lamps or other sources of heat.

• On an outside wall or any wall exposed to an unconditioned space

(a garage for example).

• In the airfl ow path of a supply register, in stairways or near

outside doors.

• On a wall where concealed pipes or ductwork will affect the

thermostat temperature accuracy.

• Near sources of electrical interference, such as arcing switch contacts.

ATTACH THERMOSTAT BASE TO WALL

1. Remove the packing material from the thermostat. Gently pull the

cover straight off the base. Forcing or prying on the thermostat will

cause damage to the unit. Loss of internal programs may result from

static discharge to thermostat circuit board. Please touch a grounded

metal object before handling the thermostat.

2. Connect wires beneath terminal screws on base using appropriate

wiring schematic (see Figures 2 through 4).

3. Place base over wire access hole in wall, level for appearance, and

mark mounting hole locations on wall using base as a template.

4. Move base out of the way. Drill mounting holes with 3/16 inch drill bit.

5. Fasten base loosely to wall using two mounting screws as shown

in Figure 1. Place a level against bottom of base, adjust until level,

and then tighten screws. (Leveling is for appearance only and will not

affect thermostat operation.) If you are using existing mounting holes,

or if holes drilled are too large and do not allow you to tighten base

snugly, use plastic screw anchors to secure sub-base.

FIGURE 2 – Typical wiring diagram for single transformer systems

Changeover

Relay*

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

** Jumper required to use a single Aux Heat for both Second Stage Heat and Emergency

Compressor

Contactor

Fan

Relay

Aux

Relay

(Stage 2)

6. Wire the thermostat. IMPORTANT! ENSURE THE POWER AT

THE HVAC EQUIPMENT IS OFF.

a. Make sure the fan switch is set to Auto and the Mode switch is

set to Off.

b. Strip 3” of cable insulation.

c. Strip 3/8” of insulation from each wire. Do not cut into the wire

when stripping insulation, as this can lead to eventual control

failure.

d. Secure the wires to the thermostat terminal strip according to

the wiring diagram for the model being installed (see Figures

2 through 4). Use a fl at screw driver with a 1/8” tip (terminal

screw driver). Use color coding where possible (i.e. red wire to

R terminal, white wire to W terminal, etc.).

e. Slide excess cable back into the wire entry wall opening and fi ll

the hole with insulation. Failure to seal the hole can cause drafts

to enter the thermostat and affect temperature sensing accuracy.

THERMOSTAT

See Note **

Emergency

Relay

SYSTEM

MONITOR

SWITCH

24 VAC

TRANSFORMER

SYSTEM

Hot

120 VAC

Neutral

(Class II)

FIGURE 3 – Typical wiring diagram for two transformer systems with NO safety circuits

If safety circuits are in only one of the systems, remove the transformer of the system with NO safety circuits.

CUT AND

TAPE OFF!

Hot

120 VAC

Neutral

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

** Jumper required to use a single Aux Heat for both Second Stage Heat and Emergency

24 VAC

Changeover

Relay*

Compressor

Contactor

Fan

Relay

NOTE

See Note **

Emergency

Aux

Relay

(Stage 2)

TWO COMMONS MUST

BE JUMPERED TOGETHER!

Relay

SYSTEM

MONITOR

SWITCH

Limit or

Safety

Switches

THERMOSTAT

SYSTEM

24 VAC

FIGURE 4 – Typical wiring diagram for two transformer systems with safety circuits in BOTH systems

SYSTEM

MONITOR

SWITCH

NOTE

COMMON

Switches

Limit or

Safety

Switches

Limit or

Safety

24 VAC

ACCESSORY

RELAY N.O.

CONTACT

COMMON

THERMOSTAT

SYSTEM

24 VAC

Auxiliary

Heating

Transformer

(Class II)

24 VAC 120 VAC

Heat Pump Transformer

(Class II)

120 VAC

The accessory relay scheme

is required when safety circuits

Limit or

Safety

Switches

Polarity must be observed. If the HOT side of the second transformer is jumpered to the COMMON side of the first transformer a short will be made.

Changeover

Relay*

Compressor

Contactor

* Changeover Relay is energized in COOL when O/B switch is in the “O” position

Changeover Relay is energized in HEAT when O/B switch is in the “B” position

** Jumper required to use a single Aux Heat for both Second Stage Heat and Emergency

Fan

Relay

Relay

(Stage 2)

Damage to equipment will occur when power is restored.

See Note**

Emergency

Relay

Aux

TWO COMMONS MUST

BE JUMPERED TOGETHER!

Hot

120 VAC

TRANSFORMER

Neutral

(Class II)

Limit or

Safety

HOT

Switches

NEUTRAL

NOTE

exist in both systems.

HOT

NEUTRAL

3

Loading...

Loading...