Page 1

K

Service Source

ImageWriter II/L

Page 2

Basics Introduction - 1

Introduction

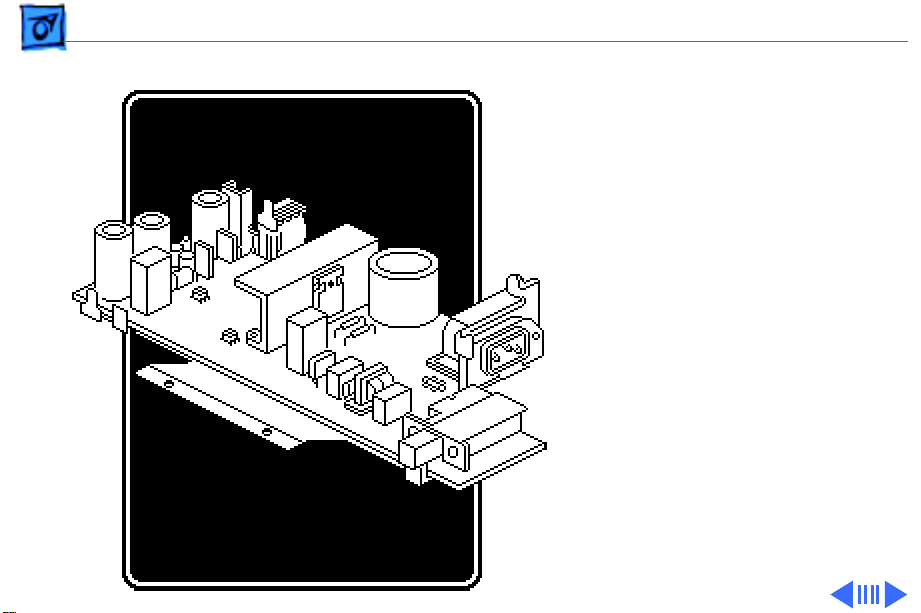

The electrical operation of

the printer consists of five

printed circuit boards,

three motors, and several

switches.

The boards are the power

supply board, main board,

sub PCB board, print head

board, and the operation

panel board.

Page 3

Basics Introduction - 2

The three motors are the

carrier motor, line feed

motor, and the ribbon

position motor.

Switches are the home

position switch, paper-out

sensor switch, and the

ribbon switch.

Page 4

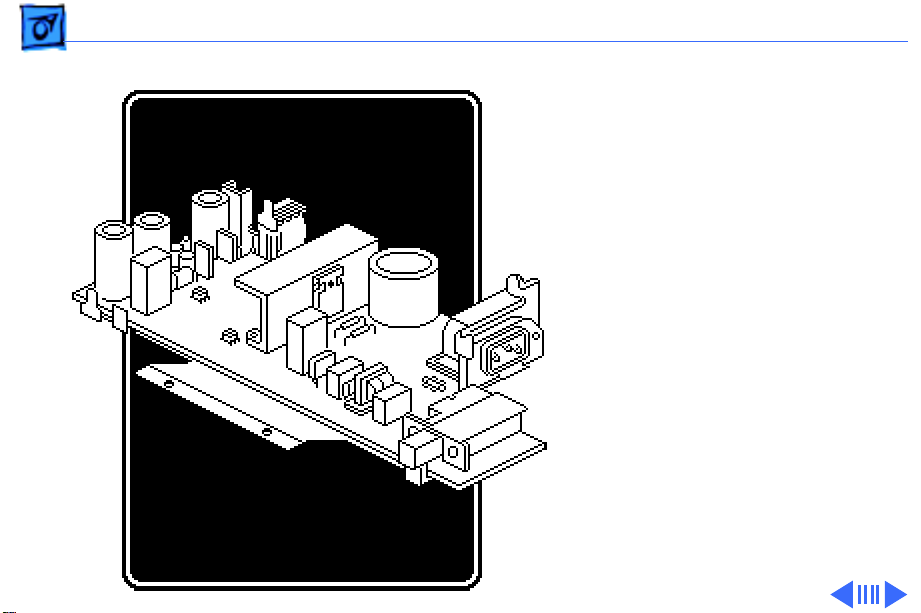

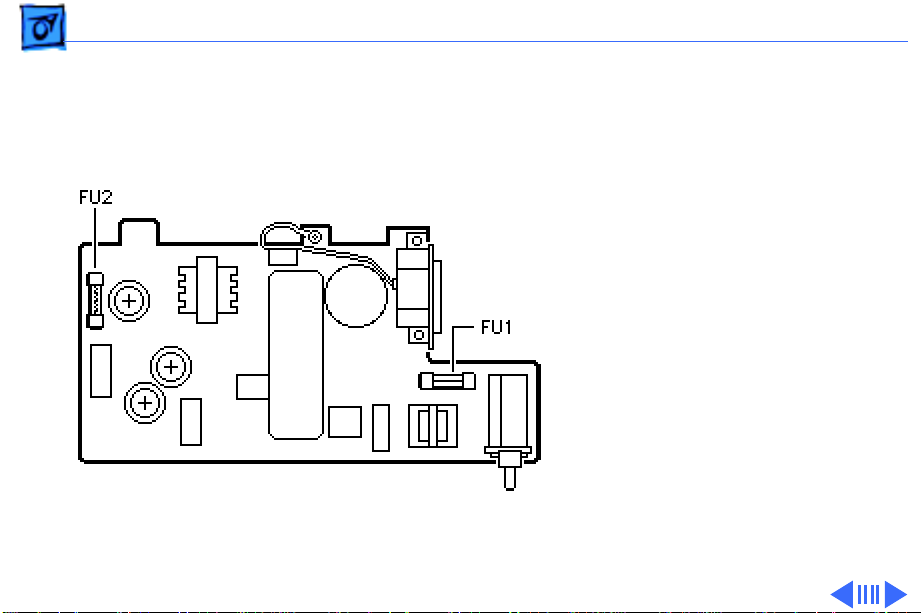

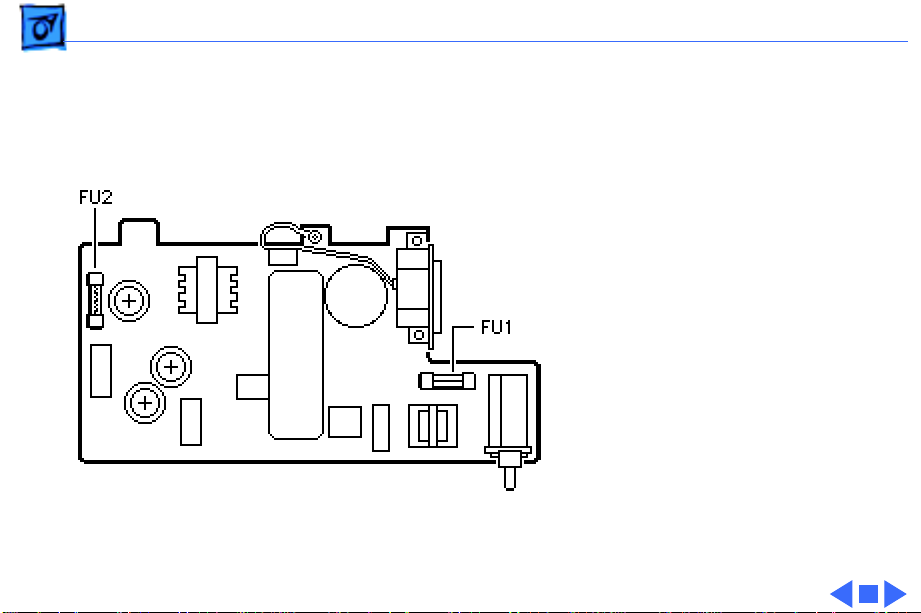

Basics Power Supply - 3

Power Supply

The ImageWriter II/L has a

switching type power supply

that eliminates the need for

a bulky transformer. When

the input AC current is

applied to this board, the

power supply reduces and

rectifies the voltage to the

following DC voltages:

• + 5 V DC

• – 5 V DC

• + 26 V DC

Page 5

Basics Power Supply - 4

The + 5 and –5 V DC voltages

are for logic; the + 26 V DC

is for motor drive. All the

voltages are fed from

connector CN5 on the power

supply board to connector

CN3 on the main board.

From the main board the

voltages are distributed to

the other boards and motors.

Page 6

Basics Power Supply - 5

The power supply has two

fuses to help protect the

electronics—FU1 is a 120 V

2-amp fuse and FU2 is a

125 V 4–amp fuse.

Note:

Although not on the

power supply board, there

is another fuse, FU1, located

on the main board that

protects the + 26 motor

voltage.

Page 7

Basics Power Supply - 6

The on/off power switch is

connected to the power

supply board and disconnects

or connects the main AC

current to the board. The

switch is comprised of a

cable type plunger that is

attached to the power

supply board.

Caution:

is not compatible with the

older ImageWriter II. Do

not attempt to switch the

power supplies between

models.

This power supply

Page 8

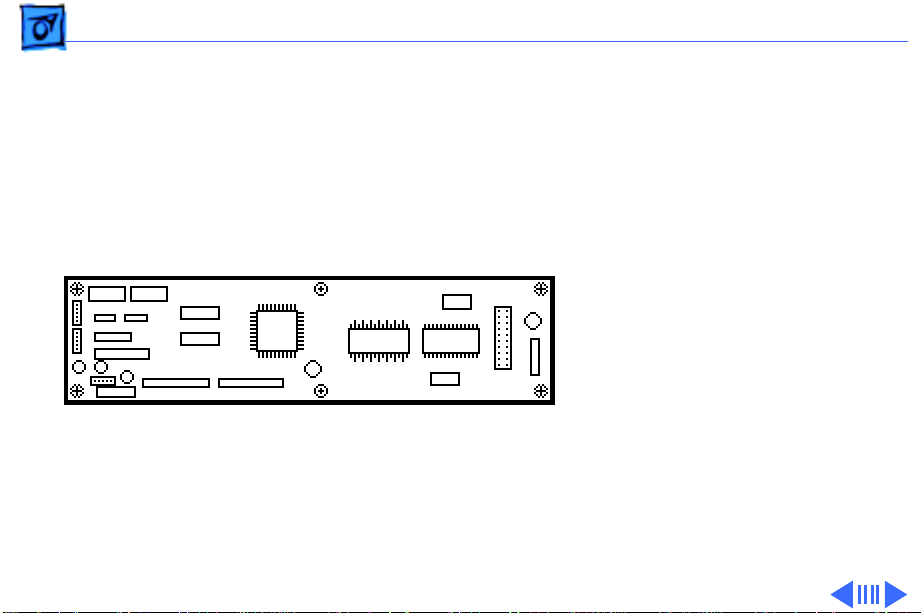

Basics Main Board - 7

Main Board

The main board is the heart

of the printer. Besides

handling the distribution of

the voltages, it also handles

all the logic that controls the

printer. It is also the source

of the drive signals for the

print head. All sensor

signals that affect the

operation of the printer are

fed to this board.

Page 9

ImageWriter II/L Basics - 8

ROM

The ROM (IC10) chip has the start-up

routines and several features such as

character sets and self-test routines built

in.

RAM

The RAM (IC9) is used in the transfer of

data and acts as a buffer. When printing

starts, the data to be printed is transferred

from the host CPU to the RAM on the

printer. From the RAM the data is passed

through the logic and sent to the print head

to print. Turning off the printer clears the

RAM.

Interface Circuits

The interface circuits (IC2 and IC3) on the

main board handle the data transferred

from the host CPU via the sub PCB board.

These circuits also handle the status and

control lines from the printer to the host

CPU.

Print Head Drivers

The print head drivers (IC5 and IC6)

process the print head drive signals from

the CPU and gate array. The signals are sent

to the print head board through CN5.

Page 10

ImageWriter II/L Basics - 9

CPU and Gate Array

The CPU (IC8) along with the gate array

(IC4), handles the logic and decisionmaking of the printer. They combine to

evaluate the status of the printer and issue

commands concerning when to transfer

data, when to start printing, when to run

the motors, and what actually prints. All

the functions of the printer are controlled

by these two devices. The rest of the

circuits are supporting circuits.

Carrier Motor Drivers

The carrier motor circuit is made up of

transistors Q1, Q2, Q12, Q13 and IC1. The

transistors make up a circuit that is used as

common returns from the motor. The

transistors also supply the higher voltage

and current needed to drive the motor. IC1

is a transistor pack that completes the

drive signals circuit when turned on. Each

of the four signals drives a phase of the

motor. These drive signals go to the carrier

motor on the printer through CN2.

Page 11

ImageWriter II/L Basics - 10

Line Feed

The drive circuit is made up of transistors

Q8, Q9, Q10, and Q11. Four drive signals

from the gate array are processed in this

circuit. Higher voltage and current are

added to the phase control signals to turn on

the line feed motor. The signals are sent to

the line feed motor and the ribbon motor

through CN1.

Ribbon Motor Drivers

This circuit is made up of transistors Q3,

Q4, Q5, Q6 and Q7. When turned on, the line

feed motor signals from the gate array are

supplied with more current in the drive

circuit and sent out to the motor. The

common return line is on Q7, which is

turned on for each phase signal sent to the

motor. These signals are sent through CN5.

Page 12

ImageWriter II/L Basics - 11

Reset Circuit

This circuit is used when the printer is

turned on to keep the logic in a reset state

until the voltages are up to correct values.

Once the voltages are at the correct level,

reset is released and the logic is allowed to

start functioning from a known state.

Connector CN6

This connector is a LocalTalk option card

connector. This card allows the printer to

communicate on the LocalTalk network so

that multiple users can use the printer.

Clock Crystals

There are two clock crystals on the main

board. The clock X1 for the gate array IC4

runs at 17.2 MHz. The clock X2 for the CPU

runs at 12 MHz.

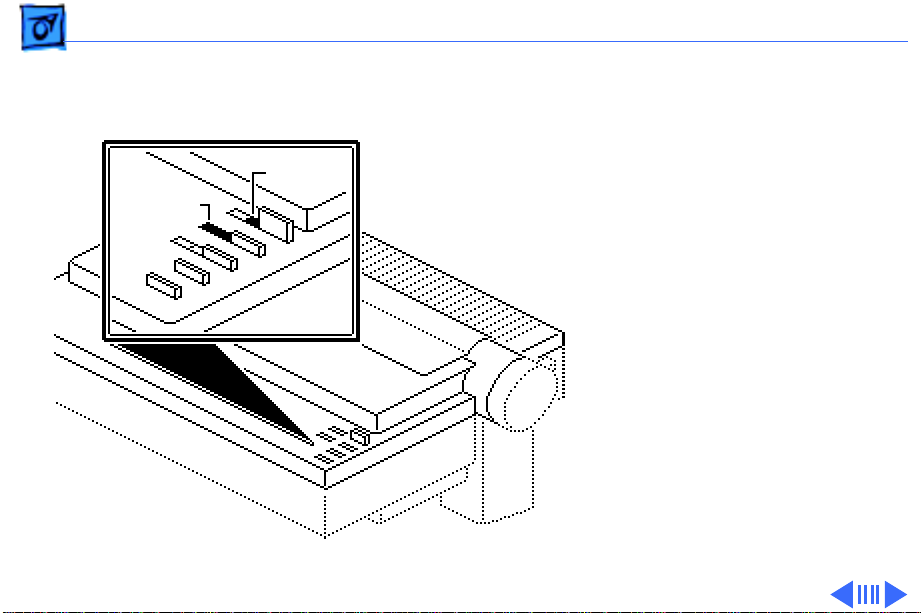

DIP Switches

The configuration DIP switches are mounted

on the main board and can be changed to

make the printer perform in different

modes, or control printer protocols. The

switch settings affect both the CPU and the

gate array logic.

Page 13

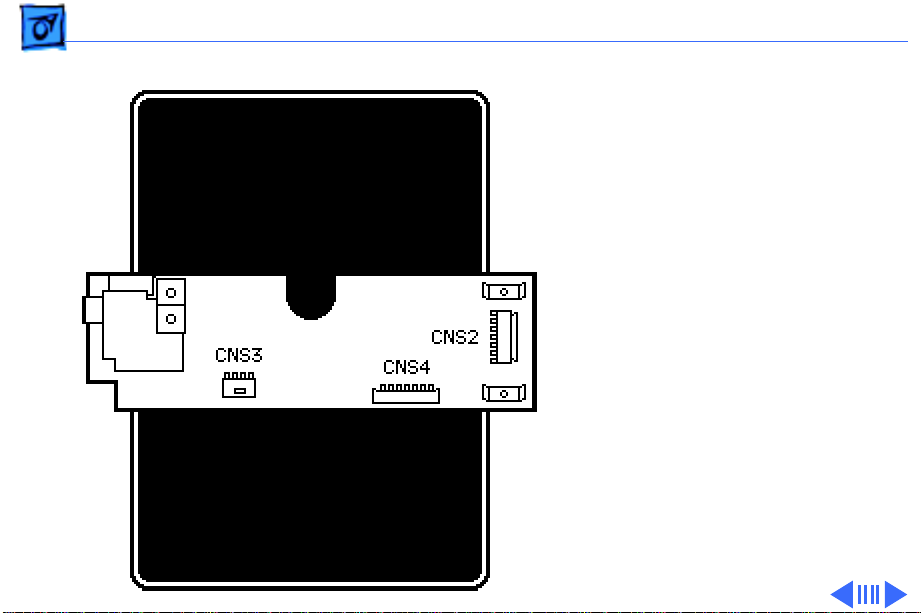

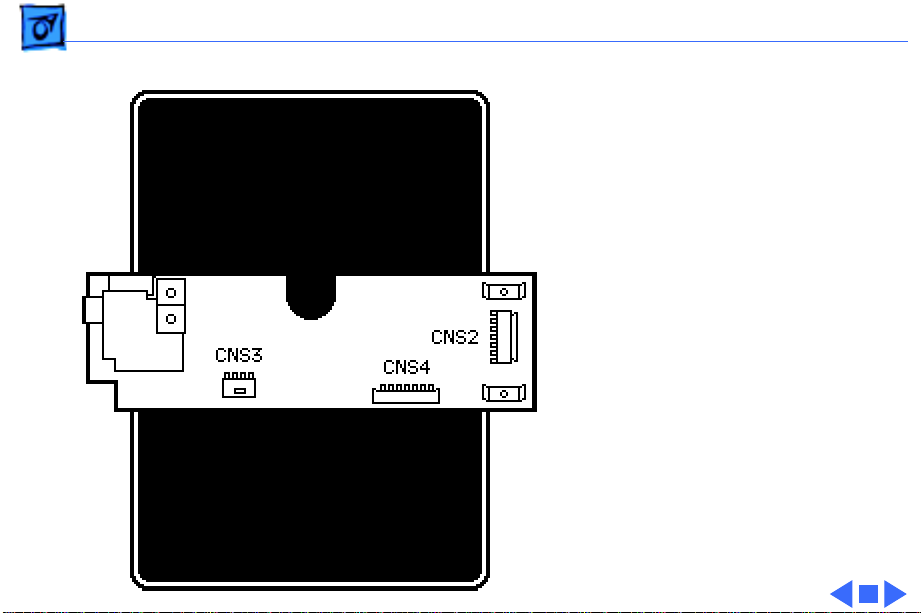

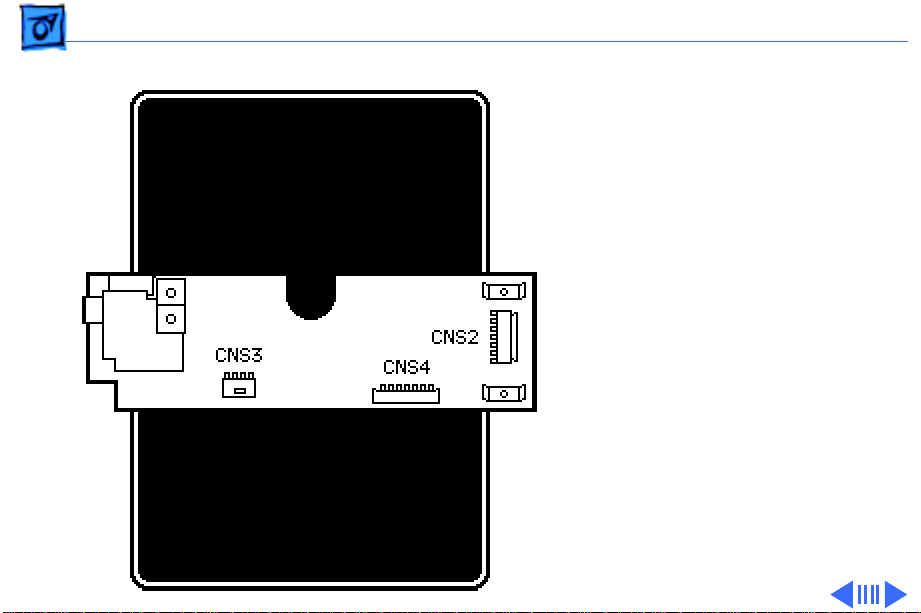

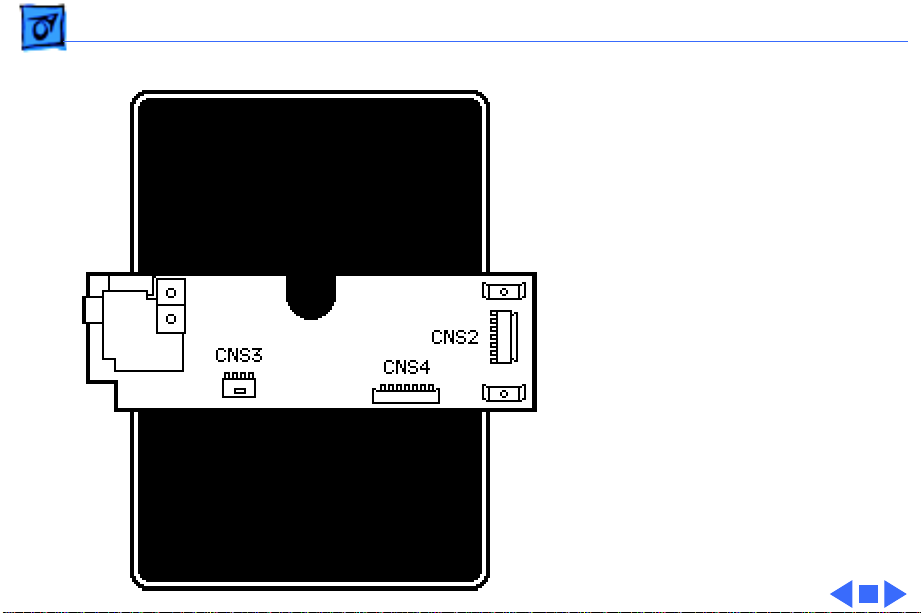

Basics Sub PCB Board - 12

Sub PCB Board

The sub PCB board acts as an

interface board. The

interface cable from the host

CPU is plugged into the

connector CNS1 on this

board. The signals from the

host CPU pass through the

sub PCB board on their way

to the main board. If a cutsheet feeder is attached to

the printer, the signals

pass through the sub PCB

board through CNS2, which

controls the actions of the

feeder.

Page 14

Basics Sub PCB Board - 13

The paper-out sensor wires

go to this board through

CNS3 and are passed along to

the main board.

All the signals coming or

going to the sub PCB board

are sent through CNS4 and

the ribbon cable to the main

board at connector CN4.

Page 15

Basics Print Head Board - 14

Print Head Board

The print head board

receives the print head

drive signals from the main

board through CNH1. The

signals are then sent out on

connector CNH2 to the print

head. This board also handles

the ribbon motor drive

signals and the ribbon

switch signals. If the switch

is activated, a color ribbon

is detected.

Page 16

Basics Print Head Board - 15

This information is sent to

the main board, which in

turn sends controlling

signals to the ribbon motor

to control the position of the

ribbon to allow color

printing.

The home position switch

alerts the CPU that the

carriage is at the far left

side of the printer, which is

home position.

Page 17

Basics Operation Panel Board - 16

Operation Panel Board

The operation panel board

has the switches (select,

print quality, line feed, and

form feed) and indicators

(error, power, print

quality, and select) mounted

on it. It interfaces with the

CPU through CN7 on the

main board. While the power

switch button is located on

the operation panel, it is not

connected to the operation

panel board.

Operation Panel

Page 18

Basics Operation Panel Board - 17

The switch button just

passes through to the switch

mounted on the main frame

underneath the operation

panel.

Operation Panel

Page 19

Basics Operation Panel - 18

Operation Panel

The operation panel consists

Indicator

Lights

Operating

Switches

of operating switches and

indicator lights.

The operating switches are

the buttons with which you

control the printer, and the

indicator lights let you know

what state the printer is in.

Page 20

Basics Operation Panel - 19

Operating Switches

Power Switch

Power Switch

switch turns the printer on

and off.

- The power

Page 21

Basics Operation Panel - 20

Select

Switch

Select Switch

- The select

switch toggles the printer

between a selected (online)

and a deselected (off-line)

state. If printing is in

progress when the select

switch is pressed, the

printer finishes printing

the current line and a

maximum of two additional

lines, and stops printing.

Page 22

Basics Operation Panel - 21

If you want to clear the

buffer, you must turn off

the printer. Pressing the

select switch also clears a

Select

Switch

corrected error condition.

If an out-of-paper

condition exists, pressing

the select switch

temporarily overrides the

error to allow the print of

one line. This process is

repeatable as long as there

is printable data in the

printer buffer.

Page 23

Basics Operation Panel - 22

Print

Quality

Print Quality Switch

- The

print quality switch allows

the user to choose one of

three printing modes.

Pressing the print quality

switch repeatedly changes

the mode from the standard

print mode, to the NLQ print

mode, to the draft print

mode, back to the standard

print mode again. The print

quality switch does not

function unless the printer

is in an off-line

(deselected) state.Ê

Page 24

Basics Operation Panel - 23

Form

Feed

Form Feed

- The form feed

switch does not function

unless the printer is in an

off-line (deselected) state.

When the form feed switch

is pressed, the printer

feeds paper until the next

top of form is reached.

Page 25

Basics Operation Panel - 24

If the switch is pressed and

no paper is present, the

printer assumes a single

sheet is being loaded. The

printer feeds the single

Form

Feed

sheet up to the top of form

position. If the switch is

pressed and paper is

present, the printer

monitors the paper-off

switch while feeding paper.

If the printer detects an

out-of-paper condition

before the top of form is

reached, the printer

assumes that single sheets

are being fed.

Page 26

Basics Operation Panel - 25

For the single sheet case,

four inches of paper motion

is added to the form feed to

ensure that the page is

properly ejected.

Form

Feed

Page 27

Basics Operation Panel - 26

When an automatic cutsheet feeder is present, the

paper-loading sequence is

slightly different. When the

form feed is pressed with no

Form

Feed

paper present, the printer

first rolls the platen to

check if a single sheet had

been inserted. If no paper is

found, the printer loads a

sheet from the automatic

sheet feeder and positions it

at the top-of-form position.

Page 28

Basics Operation Panel - 27

Indicators

Select

Power

Power

light indicates that power is

on.

Select

indicator is lit, the printer

is online, in a ready state so

that a transmission can take

place.

- When lit, the power

- When the select

Page 29

Basics Operation Panel - 28

Print

Quality

Print Quality

- The print

quality light indicates three

modes of operation:

• NLQ–When both the

left and right

indicators are lit, the

printer is in the Near

Letter Quality print

mode.

• Draft–When just the

left indicator is lit,

the printer is in the

Draft print mode.

Page 30

Basics Operation Panel - 29

• Standard–If the right

indicator is lit, the

printer is in the

Standard print mode.

Print

Quality

This is the default

mode when the

printer is turned on.

Page 31

Basics Operation Panel - 30

Error

- The error light has

three ways of indicating an

error condition in the

printer:

Error

• If the error light comes

on steady and stays on

(and the select light goes

off), the printer is out of

paper.

• If the light blinks in a

steady fashion (evenly

spaced blinks), a cover

is open or a left-margin

error has occurred.

Page 32

Basics Operation Panel - 31

• If the light blinks in a

repeating sequence of

one short blink and a

long blink, an

Error

interface

communication or a

RAM check error has

occurred.

Page 33

K

Service Source

Specifications

ImageWriter II/L

Page 34

Specifications Characteristics - 1

Characteristics

Print Methods

Throughput

Print Head

Response Time

Draft Mode: 250 characters per second (cps); 25 in. per second

(ips) at 10 characters per in. (cpi)

Standard Mode: 180 cps; 18 ips at 10 cpi

NLQ Mode: 25 cps

100 in. per minute (ipm) at 80 dpi

9 wires

.0139 in. (.353 mm) nominal

Standard:.0118 in. (.300 mm) nominal

Japan:.0098 in. (.250 mm) nominal

1440 Hz

Page 35

Specifications Characteristics - 2

Life

Graphics Duty Cycle

Character Sets

Ribbon

Standard: 4 by 108 strokes/wire

Japan: 2 by 108 strokes/wire

25% minimum

ASCII (96 characters)

Six European sets

MouseText (32 characters)

Fabric ribbon

Black or four-color (cannot use color with Kanji print head)

Page 36

Specifications I/O Interfaces - 3

I/O Interfaces

Interface

LocalTalk

Operation

Connectors

Data Format

Standard asynchronous

With option board

Asynchronous, switch selectable; Data ready/busy (hardware

handshake), or Xon/Xoff serial protocols

Mini DIN-8

26-pin male (optional)

Asynchronous serial/no parity bit shall be sent

Page 37

Specifications I/O Interfaces - 4

Transmission Speed

Input Buffer

Switch selectable (300, 1200, 2400, and 9600 baud)

254K

Page 38

Specifications Paper Feed - 5

Paper Feed

Method

Accessories

Direction

Type

Thickness

Friction feed, adjustable tractors, and automatic single-sheet

loader

Automatic, cut-sheet feeder

Bidirectional (friction feed or tractor feed)

Single sheets, sprocket feed, multicopy (original + three copies),

single-width labels

.002–.011 in. (.05–.28 mm) equivalent to 15–25 lb. bond

3.5 in. minimum to “n” in. maximum (“n” is typically 11 or 14

for cut sheets)

Page 39

Specifications Electrical - 6

Electrical

Line V oltage

USA/Japan: 85–132 VAC; 48–62 Hz

Europe/Australia: 185–265 VAC; 48–62 Hz

Stand-by:20 W maximum

Operation: 180 W maximum

Page 40

Specifications Physical - 7

Physical

Dimensions

Weight

Height: 5 in.

Width: 17 in.

Depth: 12 in.

25 lb. maximum

Page 41

Specifications Environmental - 8

Environmental

Temperature

Relative Humidity

Operation:10–40°C

Storage: (one year) –40 to 47°C

Transit: (72 hours) –40 to 65°C

Storage: (six months) 10–95%

Page 42

K

Service Source

Troubleshooting

ImageWriter II/L

Page 43

Troubleshooting General/ - 1

General

The Symptom Charts included in this chapter will help you

diagnose specific symptoms related to your product. Because cures

are listed on the charts in the order of most likely solution, try

the first cure first. Verify whether or not the product continues to

exhibit the symptom. If the symptom persists, try the next cure.

(Note: If you have replaced a module, reinstall the original module

before you proceed to the next cure.)

If you are not sure what the problem is, or if the Symptom Charts

do not resolve the problem, refer to the Flowchart for the product

family.

For additional assistance, contact Apple Technical Support.

Page 44

Troubleshooting Symptom Charts /Preliminary Check - 2

Symptom Charts

Preliminary Check

Error light blinks 1 Verify that paper cover is secure.

2 Verify that paper cover magnet is in place.

3 Try known-good software.

4 Verify that option card dip switch SW2-4 is open/off with

no card installed.

Select light off, error light on

Select light does come on1 Verify that paper cover is secure.

1 Add paper or reset paper feed tray.

2 Verify that paper-out sensor works correctly (see Take

Apart).

2 Verify that paper cover magnet is in place.

3 Verify that operation cable under top cover is secure.

Page 45

Troubleshooting Symptom Charts /Preliminary Check - 3

No printing or garbled printing

Software-specific problem

Prints OK for a while; then prints garbage

Overprinting Verify that program is set for correct line spacing and line length.

Light printing 1 Change ribbon cartridge.

1 Check interface cable connection between printer and

computer.

2 Verify that DIP switches (2-1 through 2-4) are set

correctly.

Try known-good software.

Set DIP switch SW2-3 to correct serial protocol.

2 Adjust impression lever (see Adjustments).

3 Check for excessive play in carrier assembly. Make sure

assembly is seated correctly (see Take Apart).

Page 46

Troubleshooting Symptom Charts/Preliminary Check - 4

Erratic carrier motion, loud hum

Printing has

squashed lines;

misregistration

problems with pin

feed paper

Remove black tube-shaped shipping protection from carrier

shaft.

1 For best print quality, instruct customer to place stack of

paper behind printer and no more than three feet below

printer. The paper should have a clear, unobstructed entry

and exit path.

2 Verify that power cord or printer cable does not obstruct

paper path.

3 Avoid printing in top and bottom one inch of paper (the areas

where squashed line and misregistration problems will be

most apparent).

4 Use 20-pound paper.

Page 47

Troubleshooting Symptom Charts /Print Quality - 5

Print Quality

Compressed first or second line

Print is darker or lighter on one side

Top row of dots missing on printout

Power light on, no printing

1 Check position of paper behind printer to ensure there isn’t

anything blocking paper entry or exit.

2 Replace main board.

Remove or install shims. See the Shims topic in the Additional

Procedures chapter.

Perform “Ribbon Adjustment” (refer to Adjustments).

1 Verify that ribbon frame assembly rides on the spiral ridge

on color ribbon cam (see Adjustments).

2 Remove dot head and verify that pins in the connector on dot

head board are not bent.

3 Go to “Indicator Lights” (see Flowcharts).

Page 48

Troubleshooting Symptom Charts/Print Quality - 6

Missing dots 1 Check flexible cable connection.

2 Remove dot head and verify that pins in connector on dot head

board are not bent.

3 Go to “Printing” (see Flowcharts).

Color self-test does not work

When printing from a

Macintosh, characters

sometimes appear

smudged, or top of

form gradually creeps

down page in one-line

increments

1 Verify that color ribbon detect switch operates and wires are

unbroken. If defective, replace switch.

2 Top plate of carrier assembly (under ribbon cartridge) is

not properly engaged with color ribbon cam (see Take Apart

or Adjustments).

Verify that ImageWriter II/L driver software is the most current

version.

Page 49

Troubleshooting Symptom Charts /Carriage Movement - 7

Carriage Movement

Carriage doesn’t move; LEDs are not lit

Carriage doesn’t move; LEDs are lit

Carriage assembly

moves to the left and

does not return to

center

1 Replace main board.

2 Replace power supply board.

1 Replace main board.

2 Replace power supply board.

1 Verify operation of switch on print head board. If switch is

frozen or defective, replace print head board.

2 Verify that metal tab actuating left-side home position

switch is bent correctly. Use a feeler gauge and bend tab 1

mm toward right side.

3 Replace main board.

4 Replace power supply board.

5 Replace flexible ribbon cable.

Page 50

Troubleshooting Symptom Charts/Carriage Movement - 8

Carriage moves to the left and hums very loudly

Carriage assembly grinds or is difficult to move

Carrier binds on left side

Carrier

intermittently locks

up and gives light or

dark print

1 Verify that flexible ribbon cable is properly connected to

main board and to its connector under carriage assembly on

print head board.

2 Replace flexible ribbon cable.

3 Replace power supply board.

1 Replace fuse on main board.

2 Replace power supply board.

Paper guide is too close to platen. Readjust paper guide.

Verify that rear of carrier assembly does not lift. If it does, it is

not seated correctly in the guide rail. Gently push down on rear of

carrier assembly until it snaps into place.

Page 51

Troubleshooting Symptom Charts/Carriage Movement - 9

Self-test produces no

carrier movement

(LEDs are lit)

1 Remove mechanical assembly to ensure that wires to carrier

motor are not pinched. If wires to carrier motor are worn,

replace them.

2 Replace fuse on main board.

3 Replace main board.

Page 52

Troubleshooting Symptom Charts/Paper Feed - 10

Paper Feed

Grinding during paper feed

Paper adjustment lever does not move

1 Remove platen knob to verify that there are no obstructions

in the gears beneath knob.

2 Adjust paper guide (refer to Adjustments).

3 Replace line feed motor.

4 Replace main board.

Verify that power on/off cable is not pinched between lever and

metal frame or plastic case.

Page 53

Troubleshooting Symptom Charts/Miscellaneous - 11

Miscellaneous

Hexadecimal data prints

Power supply goes bad repeatedly

Ribbon jams or does not advance

Power printer off and then on.

Verify that power supply and motor wires are not pinched. If

wires are pinched, lift mechanical assembly and reposition wires.

1 Check gear box on carrier assembly. Verify that gear with

cross (+) sticks through carrier assembly top plate and

engages ribbon cartridge.

2 Verify that ribbon wire is properly installed in gear box

3 Verify that print head wires are not striking platen too hard.

If they are, replace main board. If replacement of main board

does not correct problem, reinstall original main board and

replace print head.

Page 54

K

Service Source

T ak e Apart

ImageWriter II/L

Page 55

Take Apart Covers - 1

Covers

Top Cover

Ribbon Cartridge

Ribbon Cover

Paper Cover

Tractor Cover

No preliminary steps are

required before you begin

this procedure.

Caution:

precautions in Bulletins/

Safety.

Note:

the removal of the top cover,

tractor cover, ribbon cover,

and ribbon cartridge.

Note:

easier, label all cables and

connectors during the takeapart procedure.

Review the ESD

This procedure covers

To make reassembly

Page 56

Take Apart Covers - 2

Paper Cover

Ribbon Cover

Note:

The paper cover

Paper Cover

assembly must be in place

for the printer to work.

Gently pull the paper cover

up and forward and remove

the cover.

Replacement Note:

the paper cover from the

ribbon cover only if the

paper cover is broken and

needs replacement. Push in

the two tabs and separate the

paper cover from the ribbon

cover.

Remove

Page 57

Take Apart Covers - 3

Ribbon Cartridge

Gently pull the tabs apart

Tab

Tab

Ribbon Cartridge

and lift the cartridge out.

Page 58

Take Apart Covers - 4

Top Cover

Captive

Screw

Platen

Knob

Captive

Screw

1 Push the carrier

assembly to the far left.

2 Pull off the platen knob.

3 Loosen the two captive

screws.

Page 59

Take Apart Covers - 5

4 Grasp the top cover on

the left at the part that

goes over the leg.

Latch

5 Release the latch and lift

the cover one inch.

Top Cover

Page 60

Take Apart Covers - 6

6 Gently rotate the cover

toward the front and

turn the cover over.

7 Using your thumb and

forefinger, unlock

connector CN7 and

remove the ribbon cable.

8 Lift off the top cover.

Replacement Note:

Perform the self-test.

Connector CN7

Page 61

Take Apart Covers - 7

Tractor Cover

Tractor Cover

Gently pull the tractor cover

up and forward until the

cover snaps free.

Page 62

Take Apart Operation Panel - 8

Operation Panel

Before you begin, remove

the covers.

Operation Panel

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 63

Take Apart Operation Panel - 9

Cable

Top Cover

Right-

1 Remove the three screws

and lift the operation

panel board from the top

cover.

2 Disconnect the cable

from the operation

panel board.

Operation

Panel

Board

-Left

Page 64

Take Apart Operation Panel - 10

3

Note

: To make

reinstallation easier,

observe the position of

the power switch

Power

Switch

Plunger

plunger and spring.

Remove the spring and

power switch plunger

from the top cover.

Replacement Note:

Perform the self-test.

See the Additional

Procedures chapter.

Top Cover

Page 65

Take Apart Main Board - 11

Main Board

Before you begin, remove

the following:

• Covers

• Option board

Main Board

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 66

Take Apart Main Board - 12

1 Disconnect the three

cable connectors from

the left side of the main

board:

• CN1

• CN2

• CN3

Right-

Main Board

Page 67

Take Apart Main Board - 13

2 Remove the six screws.

3 Tilt the front half of the

board up and gently lift

the board partially out.

Ground Clip

Main Board

Replacement Note:

Make

sure to replace the

ground clip on the screw

at the lower left of the

board.

Page 68

Take Apart Main Board - 14

4

Caution:

release both sides of the

connector before you

pull out the ribbon

cable.

Using a small

screwdriver, unlock

each side of connectors

CN4 and CN5 and

remove the two ribbon

cables.

Make sure you

Replacement Note:

Perform the self-test.

Page 69

Take Apart Print Head and Paper Guide - 15

Print Head and Paper Guide

Before you begin, remove

the covers.

Caution

precautions in Bulletins/

Safety.

Note

have to be removed in order

to remove the paper guide.

: Review the ESD

: The print head does not

Page 70

Take Apart Print Head and Paper Guide - 16

Print Head

1 Lift the paper bail to its

highest position.

2 Set the paper thickness

lever to its widest

setting.

Page 71

Take Apart Print Head and Paper Guide - 17

3 Gently push and hold

aside the white print

head clamp release

lever and slowly lift the

print head straight out of

the connector.

Replacement Note:

Perform the self-test.

Page 72

Take Apart Print Head and Paper Guide - 18

Paper Guide

Remove the two screws and

lift out the paper guide.

Replacement Note:

the paper guide. See the

Adjustments chapter.

Adjust

Page 73

Take Apart Ribbon Cam Assembly - 19

Ribbon Cam Assembly

Before you begin, remove

the covers.

Caution

precautions in Bulletins/

Safety.

Note

of the ribbon cam assembly.

One has a plastic cap and the

other has a hex nut, without

the cap.

: Review the ESD

: There are two versions

Page 74

Take Apart Ribbon Cam Assembly - 20

1 Unscrew the plastic cap

Plastic Cap

from the ribbon cam.

2 Remove the red

Adjustment Ring

adjustment ring and the

spring.

Spring

Plastic Collar

3 Remove the plastic

collar.

Page 75

Take Apart Ribbon Cam Assembly - 21

4

Note

: For versions with

the hex nut, remove the

nut and proceed with the

rest of the procedure.

Using small needlenose

pliers, remove the

retaining clip and two

washers.

5 Remove the vertical

knurled nut.

Page 76

Take Apart Ribbon Cam Assembly - 22

6 Turn and lift off the

ribbon cam.

7 Remove the spring.

Page 77

Take Apart Ribbon Cam Assembly - 23

Replacement Note:

you replace the cam, set the

cam at its lowest setting.

Verify that the two tabs of

the ribbon plate are riding

on the cam ridge. Improper

positioning of the cam can

cause poor-quality prints or

no prints.

Replacement Note

the ribbon cam (see

“Ribbon Cam” in the

Adjustments chapter).

When

: Adjust

Page 78

Take Apart Carrier Assembly Top Plate - 24

Carrier Assembly Top Plate

Before you begin, remove

the covers.

Caution

precautions in Bulletins/

Safety.

: Review the ESD

Page 79

Take Apart Carrier Assembly Top Plate - 25

1

Caution

when you remove the

black plastic arms. You

will break them.

Using a small flat-blade

screwdriver, push out

the black bearing arm.

2 With another small

screwdriver, gently pry

the arm upward at a

slight angle.

3 Move the small arm to

the top.

: Do not use force

Page 80

Take Apart Carrier Assembly Top Plate - 26

4 Gently pull the plastic

bearing straight out and

remove the small

washer.

5 Repeat for the right side.

Replacement Note

bearings are not

interchangeable.

: The

Page 81

Take Apart Carrier Assembly Top Plate - 27

6 Gently pry the top of the

wire clamp from the

carrier assembly and

remove the color ribbon

detect switch wires from

the clamp.

Page 82

Take Apart Carrier Assembly Top Plate - 28

7 Using a jeweler’s

screwdriver, push the

gear assembly tabs

toward the center of the

ribbon plate and lift off

the top plate. Leave the

gear assembly in the

carrier housing.

Page 83

Take Apart Carrier Assembly Top Plate - 29

Color Ribbon Detect Switch

1

Note:

Do not bend the

plastic tabs that hold the

wires.

Carefully pry the wires

out of the embedded track

of the top plate.

Page 84

Take Apart Carrier Assembly Top Plate - 30

2 Turn over the top plate.

Using a small

screwdriver, gently pry

the four latches and at

the same time push

down on the bottom of the

switch so the switch

comes out from the top of

the plate.

Page 85

Take Apart Ribbon Wire and Gears - 31

Ribbon Wire and Gears

Before you begin, remove

the following:

• Covers

• Carrier assembly top

plate

Caution

precautions in Bulletins/

Safety.

: Review the ESD

Page 86

Take Apart Ribbon Wire and Gears - 32

1 Unhook the ribbon wire

from the right side of the

frame, and then from the

left side of the frame.

Remove the ribbon wire.

Page 87

Take Apart Ribbon Wire and Gears - 33

2 Lift the gear assembly

from the carrier

housing.

Replacement Note:

Perform the self-test.

Replacement Note:

sure the wire is

rewrapped with the wire

crossing in front of the

gear. Then secure the

wire on the right side.

Be

Page 88

Take Apart Drive Belt/Carrier Motor - 34

Drive Belt/Carrier Motor

Before you begin, remove

the covers.

Caution

precautions in Bulletins/

Safety.

: Review the ESD

Page 89

Take Apart Drive Belt/Carrier Motor - 35

Drive Belt

1 Loosen the screw on the

pulley tension plate. Do

not remove the screw.

2 Using a large

screwdriver, push

toward the right side

and remove the drive

belt from the right-side

pulley.

Adjustment

Screw

Right Side

Pulley

Carrier

Pulley Arm

Page 90

Take Apart Drive Belt/Carrier Motor - 36

3 Remove the drive belt

from the left-side

pulley.

Page 91

Take Apart Drive Belt/Carrier Motor - 37

4 Remove the screw from

the retaining clip.

5 Using a small flat-blade

screwdriver, pry up the

retaining clip from the

housing and remove the

belt.

Replacement Note:

retaining clip is glued to

the drive belt.

The

Page 92

Take Apart Drive Belt/Carrier Motor - 38

Carrier Motor

Remove the three screws

that secure the carrier

motor and remove the

carrier motor.

Replacement Note:

the self-adhesive damping

pad between the motor and

the frame. Replace the pad if

necessary.

Inspect

Page 93

Take Apart Mechanical Assembly - 39

Mechanical Assembly

Before you begin, remove

the covers.

Caution: Review the ESD

precautions in Bulletins/

Safety.

Page 94

Take Apart Mechanical Assembly - 40

1 Remove the six screws

that hold the mechanical

assembly to the bottom

case.

Note: Do not remove

screw A at the back of the

assembly nearest the left

side. This screw holds

the sub board in place.

Page 95

Take Apart Mechanical Assembly - 41

Replacement Note: Two

screws make the ground

connection between the

power supply plate and the

rest of the mechanical

assembly. If you do not

replace both screws, the

ground is not complete and

logic errors or hazards can

result.

Page 96

Take Apart Mechanical Assembly - 42

2 Remove the two screws

that hold the power

switch cable in place.

3 If the main board is in

the printer, disconnect

the connector at CN3 on

the main board.

Page 97

Take Apart Mechanical Assembly - 43

4 Grasp the middle of the

back tractor bar. With

the other hand hold the

middle of the support

wall and lift the entire

mechanical assembly

from the case.

Page 98

Take Apart Mechanical Assembly - 44

Replacement Note: As you

lower the assembly into

place, make sure to route

the power supply cable

correctly and to align the

power switch cable

correctly. Correct

placement will ensure that

the cables do not pinch when

you lower the assembly into

place.

Page 99

Take Apart Flexible Ribbon Cable - 45

Flexible Ribbon Cable

Before you begin, remove

the following:

• Covers

• Mechanical assembly

• Carrier assembly top

plate

Caution: Review the ESD

Flexible Ribbon Cable

precautions in Bulletins/

Safety.

Page 100

Take Apart Flexible Ribbon Cable - 46

1 Remove the ribbon cable

from connector CN5 on

the main board.

2 Move the carrier

assembly toward the

right side of the carrier

until the assembly is

lined up with the right

edge of the board.

Loading...

Loading...