Page 1

K

Service Source

Color StyleWriter

4100 and 4500

Page 2

K

Service Source

Basics

Color StyleWriter 4000 Series

Page 3

Basics Overview - 1

Overview

The Color StyleWriter 4000

Series printers are desktop

color bubble-jet printers

for personal use.

Page 4

Basics Overview - 2

Color StyleWriter 4500 and 4100 Differences

The Color StyleWriter 4500 and the Color StyleWriter

4100 differ in the following ways:

• Color StyleWriter 4500 can produce photo-quality

prints.

• Color StyleWriter 4500 can print on banner (zfold) paper.

• Color StyleWriter 4500 prints slightly faster than

the Color StyleWriter 4100.

Page 5

Basics Overview - 3

Ink Cartridge Configurations

The Color StyleWriter 4500 and 4100 can be configured

with

• Color ink cartridge

• High-performance black ink cartridge

The Color StyleWriter 4500 can also be configured with

• Color ink cartridge

• PhotoGrade ink cartridge.

In the Color StyleWriter 4500, replace the black cartridge

with the PhotoGrade ink cartridge for photo-quality

printing.

Page 6

Basics Overview - 4

Troubleshooting LEDs

The Color StyleWriter 4500

and 4100 have two LEDs,

Resume

Power

Power and Resume, that can

aid in troubleshooting the

printer. See the

Troubleshooting chapter for

more information.

Page 7

Basics Overview - 5

Ink-jet Technology

Overview

Thermal ink-jet technology involves applying heat to a tiny

measure of ink until it expands and forms a bubble. As the

bubble continues to expand and burst, it is propelled

through one of the nozzles on the ink cartridge. This process

is repeated up to 8,000 times per second.

Each ink cartridge on the Color StyleWriter 4500 and 4100

has 48 nozzles. On the black ink cartridge, all 48 nozzles

are used for black ink. On the color and PhotoGrade

cartridges each color (cyan, magenta, and yellow) has 16

nozzles each.

Page 8

Basics Overview - 6

Photo Printing Technology

The Color StyleWriter 4500 uses multiple dye-load

technology to produce photorealistic print-outs. Two ink

cartridges are used to produce these results: the color and

the photo ink cartridges. The color cartridge contains cyan,

magenta, and yellow inks. The PhotoGrade cartridge contains

cyan, magenta, and yellow inks mixed with a black pigment.

The three additional colors in the PhotoGrade cartridge

quadruples the number of ink color ratios that can be

printed in a given area. The resulting colors produced from

the PhotoGrade cartridge are more subtle shades and hues.

The PhotoGrade cartridge also produces smaller ink

droplets, which can be layered on top of each other to vary

the intensity.

Page 9

Basics Ink Cartridge Identification - 7

Ink Cartridge Identification

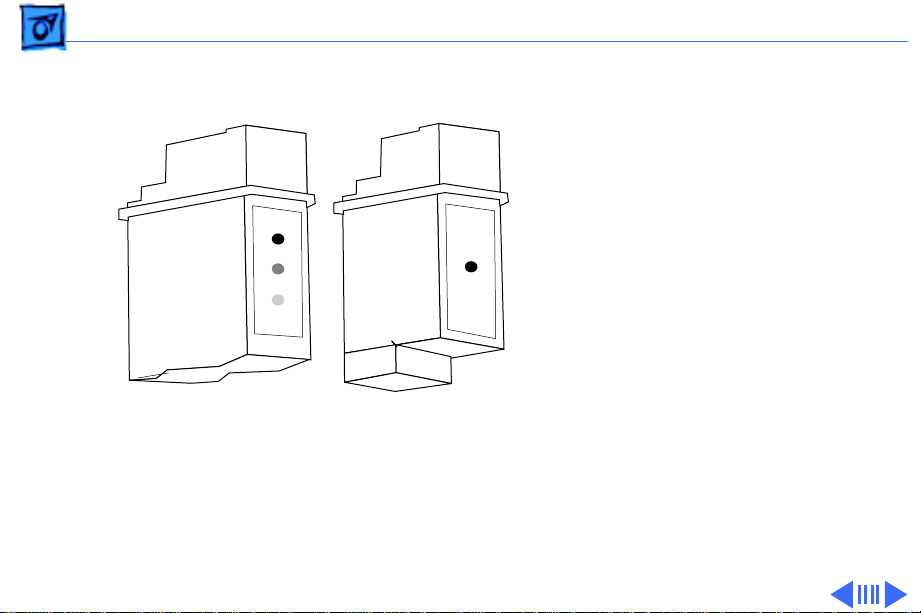

Color Cartridge

Black Cartridge

Caution:

printer’s ink on your hands

or clothes. Although the ink

is water soluble, it contains

dyes that will stain.

Note:

StyleWriter 4500 includes

three ink cartridges: black,

color, and PhotoGrade.

The Color StyleWriter 4100

includes only the black and

color cartridges.

Do not get the

The Color

Page 10

Basics Ink Cartridge Identification - 8

High-Performance, Black-Only Ink Cartridge

The black ink cartridge contains black ink only.

Color Ink Cartridge

The color ink cartridge contains cyan, magenta, and yellow

inks.

Color PhotoGrade Ink Cartridge

The PhotoGrade ink cartridge contains cyan, magenta, yellow

inks and black pigment.

Important:

cartridge and PhotoGrade paper. For photorealistic results,

the kit contents must be used together. These parts cannot be

used in the Color StyleWriter 4100.

The Color StyleWriter 4500 includes the ink

Page 11

Basics Ink Cartridge Identification - 9

Identifying Replacement Ink Cartridges

The ink cartridges used

with the Color StyleWriter

4100 and 4500 have a

6105

generic cartridge labels.

There is no Apple logo or

Apple part number on the

cartridge. To identify a

cartridge, refer to the

small numeric part number

on the label. This number

can be cross-referenced to

the appropriate Apple

Marketing number in the

chart that follows.

Page 12

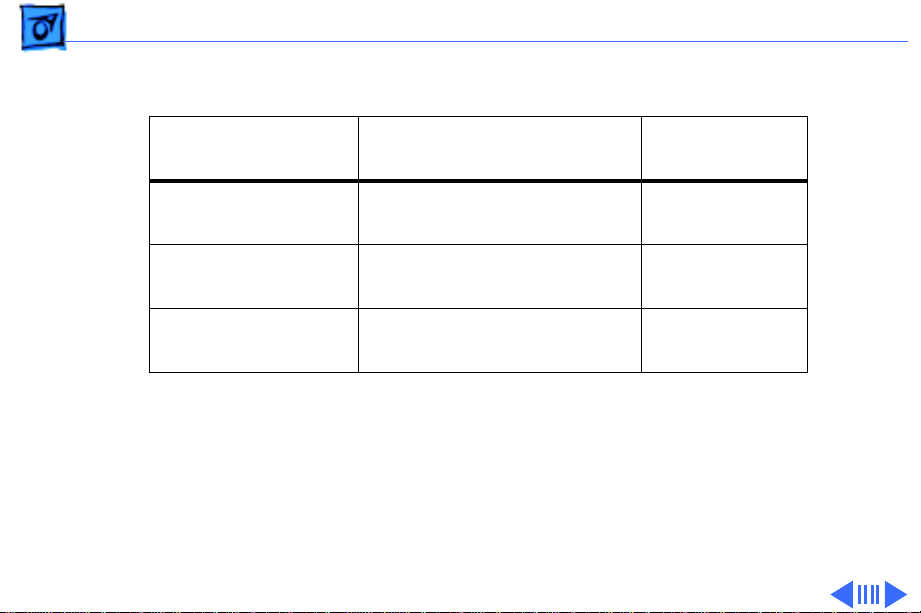

Basics Ink Cartridge Identification - 10

Identify ink cartridges by cross referencing the chart below.

Apple Marketing

Part Number

Product Description HP Cartridge

M5694G/A Color Ink Cartridge (CSW

4100 & 4500)

M5693G/A Black Ink Cartridge (CSW

4100 & 4500)

M5692G/A Color PhotoGrade Ink

Cartidge (4500 only)

Note

: Apple ink cartridges can be found at most Apple authorized dealers, as well as

most office product and computer superstores. Catalog and mail order houses which

specialize in Macintosh products, such as MacWarehouse, MacMall, and MacZone carry

a complete selection of genuine Apple Printer Supplies. You can also call the Apple

Reseller Referral number at 1-800-538-9696, which will refer you to an

authorized Apple dealer in your area.

6107

6106

6104

Page 13

Basics Recommended Paper - 11

Recommended Paper

Apple recommends Apple

Color Ink-Jet PREMIUM

PLUS Coated Paper. It is the

coated paper of choice to use

with the Color StyleWriter

4100 and 4500 ink-jet

printer.

• Letter size p/n M4792G/

A

• A4-size p/n M4791G/A.

Page 14

Basics Printing a Photograph - 12

Printing a Photograph

The Color StyleWriter 4500 has the capability to produce

photo-quality printouts. Follow these procedures

1 Remove the black print cartridge and replace it with the

PhotoGrade Ink cartridge.

2 Load the PhotoGrade paper into the sheet feeder so the

whiter side faces you.

Page 15

Basics Printing a Photograph - 13

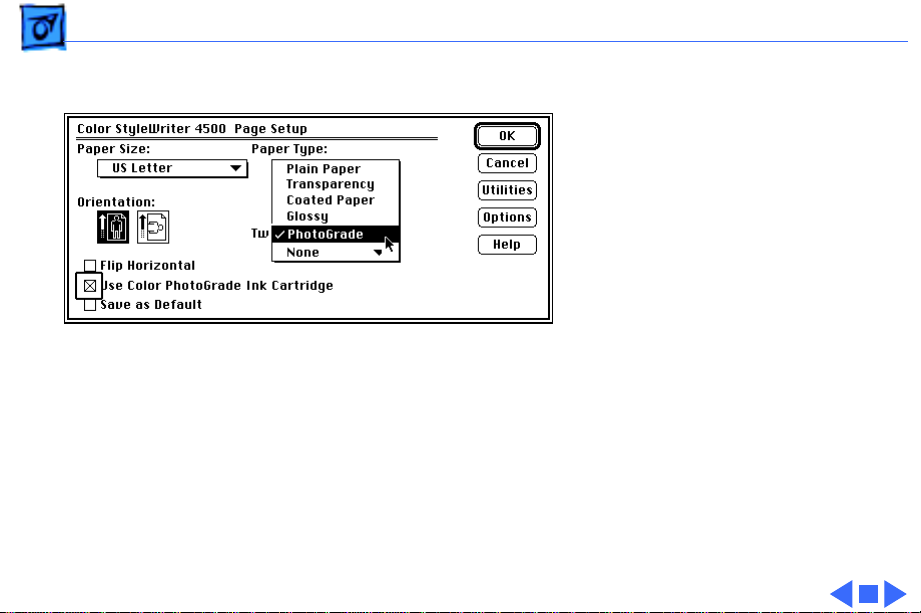

3 Choose Page Setup from

the File menu.

4 In the Page Setup dialog

box, select PhotoGrade

from the Paper Type

pop-up menu.

5 Select the “Use Color

PhotoGrade Ink

Cartridge” option.

6 Click Print.

Page 16

Basics Printing a Banner - 14

Printing a Banner

Follow these steps to print

on banner (z-fold) paper

using the Color StyleWriter

4500.

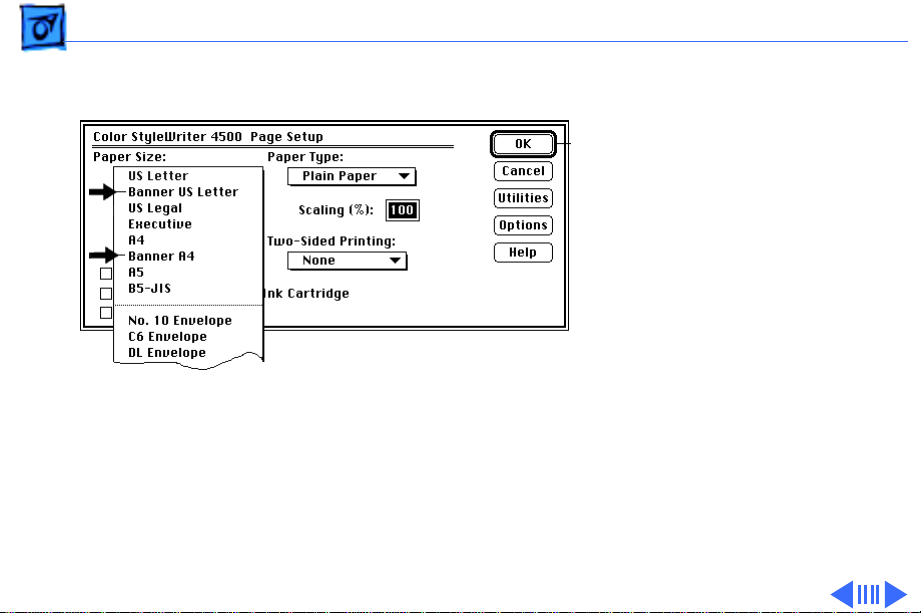

1 Choose Page Setup from

the File menu.

2 In the Page Setup dialog

box, choose either

Banner US Letter or

Banner A4 from the

Paper Size pop-up

menu.

Page 17

Basics Printing a Banner - 15

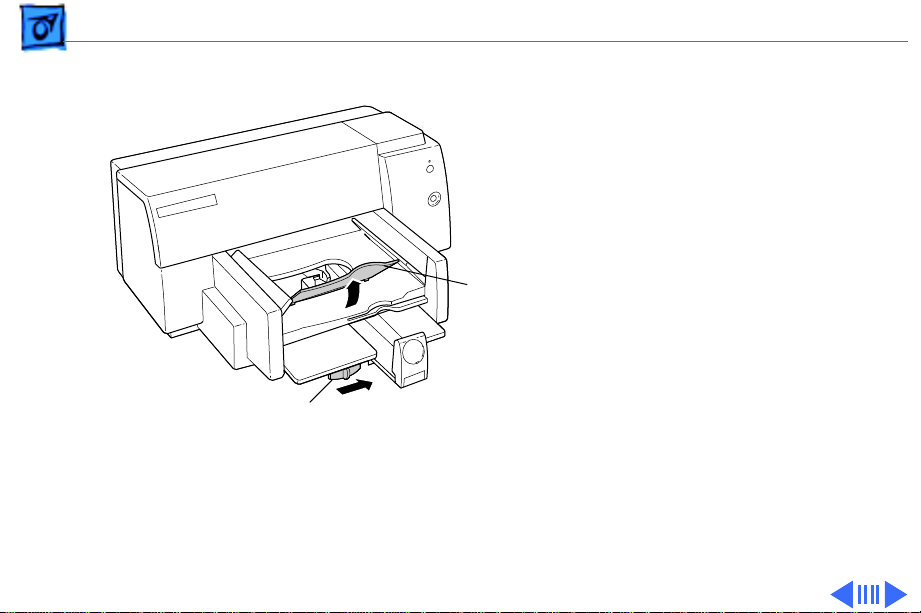

3 Slide the banner lever

to the right until it

clicks into place.

4 Remove all paper from

the input tray.

5 Flip up the banner

Banner

Support

support in the output

tray.

6 Put the paper in the

input tray, with a torn

Banner Lever

edge at the top of the

stack, facing lengthwise

into the printer.

Page 18

Basics Printing a Banner - 16

7 Slide the paper width and

length adjusters so they

touch the edges of the

stack of paper.

8 Click Print.

Note:

When printing

stops, press the Resume

button as many times as

necessary to advance the

remaining banner paper

out of the printer.

Page 19

Basics Special Servicing Considerations - 17

Special Servicing Considerations

Banner Calibration

After replacing the logic board or ink cartridges you must

re-calibrate the Color StyleWriter 4500 banner printing.

Performing this calibration requires using the Color

StyleWriter 4500 Banner Calibration utility found in the

Diagnostic folder on the Companion CD. Refer to Additional

Procedures for more information.

Capping Assembly Replacement

If a Color StyleWriter 4100 or 4500 printer is brought in

for service, and the customer has had the printer for

awhile, replace the capping unit.

Capping Assembly 4100: 922-3010

Capping Assembly 4500: 922-2855

Page 20

Basics - 18

Mechanical Assembly Screws

Important:

screws (for any reason) that are not called out in the Take

Apart chapter for the Color StyleWriter 4000 Series.

Doing so will put the printer out of alignment and will

require installing a new mechanical assembly.

Do not touch/remove mechancial assembly

Page 21

K

Service Source

Specifications

Color StyleWriter 4000 Series

Page 22

Specifications Characteristics - 1

Characteristics

Print Methods

Throughput

Serial bubble jet ink-on-demand

Best

:

Up to one page per minute with the black ink cartridge

Up to .3 page per minute for color

Normal

Up to three pages per minute with the black ink cartridge

Up to .8 page per minute for color

Draft

Up to five pages per minute with the black ink cartridge

Up to 1.7 pages per minute for color

Actual speed depends on the documents printed and the Macintosh

:

:

used.

Page 23

Specifications Characteristics - 2

Note:

The Color StyleWriter 4100 prints at slightly slower

rates: up to four pages per minute with the black ink cartridge,

and up to 1.4 pages per minute for color.

Interfaces

• High-speed serial RS-422 port supports serial connection

• Printer can be hooked up to LocalTalk, but not as a shared

printer.

Page 24

Specifications Graphics - 3

Graphics

Resolution

Black:

Best: 600 x 600 dpi

Normal: 600 x 300 dpi

Draft: 300 x 300 dpi

Color & Black:

All Modes (plain paper): 300 x 300 dpi

All Modes (other media paper): 600 x 300 dpi

Color & Photo

Best & Normal (photograde paper): 600 x 300 dpi

Note:

photo ink cartridge.

:

The Color StyleWriter 4100 cannot print using the

Page 25

Specifications Print Media - 4

Print Media

Cut Sheets

Labels

Plain paper, coated (recommended for color picture output)

Color PhotoGrade paper (required for photorealistic color output)

LTR, LGL, Executive, A4, A5, B5

U.S. Letter (LTR): 8.5 x 11 in. (215.9 mm x 279.4 mm)

U.S. Legal (LGL): 8.5 x 14 in. (215.9 mm x 355.6 mm)

U.S. Executive: 7.25 x 10.5 in. (184.1 x 266.7 mm)

A4: 8.3 x 11.7 in. (210 mm x 297 mm)

A5: 5.8 x 8.3 in. (148.5 x 210 mm)

B5: 7.2 x 10.1 in. (182 x 257 mm)

Weight: 16-36 lb. Capacity: 100 sheets

Avery paper labels designed for inkjet printers

Letter, A4

Capacity: 25 sheets.

Page 26

Specifications Print Media - 5

Banner

Cards

Transparencies

U.S. Letter Banner: 8.5 x 11 in. (216 x 279 mm)

U.S. A4 Banner: 8.5 x 14 in. (216 x 356 mm)

Weight: 20 lbs. Capacity: 20 sheets

Note:

The Color StyleWriter 4100 cannot print on banner

paper.

U.S. 4 x 6: 4 x 6 in. (101.6 x 152.4 mm)

U.S. 5 x 8: 5 x 8 in. (127 x 203.3 mm)

A6: 4.1 x 6 in. (105 x 148.5 mm)

Height: 3.9 x 5.8 in. (100 x 148 mm)

Weight: 29-53 lbs. Capacity: 30 cards

Coated transparencies, most inkjet transparencies

Capacity: 50 sheets

Page 27

Specifications Print Media - 6

Envelopes

#10: 9.5 x 4.12 in. (241.3 x 104.4 mm)

DL: 4.33 x 8.66 in. (110 x 220 mm)

C6: 4.49 x 6.38 in. (114 x 162 mm)

A2: 4.375 x 5.75 in. (111 x 146 mm)

Weight: 20-24 lbs. Capacity: 20 envelopes

Page 28

Specifications Printable Area - 7

Printable Area

Paper, Labels, & Transparencies

U.S. Letter

U.S. Legal

U.S. Executive

A4

: 8.3 x 11.7 in. (210 mm x 297 mm)

Top margin:.26 in. (6.6 mm)

Bottom margin:.59 in. (14.9 mm)

Left & right margins: .25 in. (6.4 mm)

A5

: 5.8 x 8.3 in. (148.5 x 210 mm)

Top margin: 26 in. (6.6 mm)

Bottom margin: .84 in. (21.3 mm)

Left & right margins: .25 in. (6.4 mm)

B5

: 7.2 x 10.1 in. (182 x 257 mm)

Top margin: 26 in. (6.6 mm)

Bottom margin: .59 in. (14.9 mm)

Left & right margins: .25 in. (6.4 mm)

: 8.5 x 11 in. (215.9 mm x 279.4 mm)

: 8.5 x 14 in. (215.9 mm x 355.6 mm)

: 7.25 x 10.5 in. (184.1 x 266.7 mm)

Page 29

Specifications Printable Area - 8

Envelopes

Cards

#10

: 9.5 x 4.12 in. (241.3 x 104.4 mm)

DL

: 4.33 x 8.66 in. (110 x 220 mm)

C6

: 4.49 x 6.38 in. (114 x 162 mm)

A2

: 4.375 x 5.75 in. (111 x 146 mm)

Top margin: .84 in. (26 mm)

Bottom margin: .29 in. (6.6 mm)

Left & right margins: 0.125 in. (3.2 mm)

U.S. 4 x 6

U.S. 5 x 8

A6

: 4.13 x 6 in. (105 x 148.5 mm)

Height

Top margin: 0.26 in. (6.6 mm)

Bottom margin: 21.3 in. (.84 mm)

Left & right margins: 0.25 in. (6.4 mm)

: 4 x 6 in. (101.6 x 152.4 mm)

: 5 x 8 in. (127 x 203.3 mm)

: 3.9 x 5.8 in. (100 x 148 mm)

Page 30

Specifications Ink Cartridges - 9

Ink Cartridges

Type

Ink Color

Shelf Life

Black ink cartridge with integrated ink tank and print head

Three-color ink cartridge with three ink tanks (cyan, magenta,

yellow) and integrated print head

Color PhotoGrade ink cartridge with three ink tanks and integrated

print head

Black

Color (Cyan, magenta, yellow)

PhotoGrade (Cyan, magenta and yellow dyes, and Black pigment)

6 months (installed in printer)

18 months (in original package)

Page 31

Specifications Ink Cartridges - 10

Print Cartridge Life

Typical Usable Ink

Number of Nozzles

Black ink cartridge

650 pages at 5% coverage

Color ink cartridge

350 pages at 15% coverage

PhotoGrade ink cartridge

250 pages at 15% coverage

Black ink cartridge

40 ml

Color & PhotoGrade ink cartridges

7.6 ml per tank

Black ink cartridge

48 nozzles

Color and PhotoGrade ink cartridges

48 nozzles (16 per color)

Page 32

Specifications Environmental - 11

Environmental

Acoustic Noise Level

Temperature

Humidity

Best: 48 dB

Normal: 50 dB

Draft: 52 dB

Operating: 41–104°F (5-40°C)

Storage: -40-140°F (-40-60°C)

10–80% (noncondensing)

Page 33

Specifications Electrical - 12

Electrical

Electrical Requirements

Power Consumption

AC power adapter

U.S./Japan: 102-132 VAC, 60 Hz ± 3%

UK/Australia: 204-264 VAC, 50 Hz

Europe: 196-253 VAC, 50 Hz

Powered Off (plugged in): 2 W

Powered On (non-printing): 4.5 W

Powered On (printing): 12 W

Page 34

Specifications Physical - 13

Physical

Dimensions

Weight

Height: 7.9 in. (199 mm)

Width: 17.2 in. (436 mm)

Depth: 16 in. (405 mm)

11.6 lb (5.3 kg)

Page 35

K

Service Source

Take Apart

Color StyleWriter 4000 Series

Page 36

Take Apart Output Tray - 1

Output Tray

Output Tray

Output Tray

1 Slide the output tray out

and remove it from the

printer.

Page 37

Take Apart Access Door - 2

Access Door

Access Door

No preliminary steps are

required before you begin

this procedure.

Note:

Removing the access

door is not required, but it

may allow you to remove the

top cover more easily.

Page 38

Take Apart Access Door - 3

1 Pull the access door off

Hinge

Hinge

Access Door

of the two hinges on the

top cover.

Page 39

Take Apart Banner Lever - 4

Banner Lever

Before you begin, remove

the output tray.

Note:

The Color StyleWriter

4100 does not include the

Banner Lever.

Banner Lever

Page 40

Take Apart Banner Lever - 5

1 Rest the printer on its

side with the bottom

facing you.

2 Move the banner level to

the right.

Hole

3 Insert a small flatblade

screwdriver into the

access hole of the

printer’s base.

4 Push and release the

latch.

5 Pull the banner lever off

of the base.

Banner Lever

Page 41

Take Apart Length Adjuster - 6

Length Adjuster

No preliminary steps are

required before you begin

this procedure.

Length Adjuster

Page 42

Take Apart Length Adjuster - 7

Length Adjuster

Latch

Opening #2

Latch

Opening #1

1 Rest the printer on its

side.

2 Pull the length adjuster

straight out until it

stops.

3 Press and release latch

at opening #1 with a

flatblade screwdriver.

while holding latch, pull

the length adjuster out

until is catches at

second opening.

4 Repeat step at opening

#2. Pull length

adjuster from top cover.

Page 43

Take Apart Input Tray - 8

Input Tray

Before you begin, remove

the output tray.

Page 44

Take Apart Input Tray - 9

1 Set the printer down on

its base.

2 Using a T-20 Torx

screwdriver, remove

the two screws from the

Input Tray.

Note:

To remove all

remaining screws inside

the printer, use a T-10

Torx screwdriver.

Screw

Screw

Input Tray

Page 45

Take Apart I/O Cover - 10

I/O Cover

No preliminary steps are

required before you begin

this procedure.

I/O Cover

Page 46

Take Apart I/O Cover - 11

1 Rest the printer on its

side.

2 Locate the two holes (A

and B) on the base near

the I/O cover.

I/O Cover

Hole

Hole

3 Insert a jeweler’s

screwdriver into the

holes, and push the

latches straight in until

they unsnap from the

base.

4 Rotate the I/O cover

away from the base along

its hinges and lift it

from the top cover.

Page 47

Take Apart Top Cover - 12

Top Cover

Top Cover

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

Note

: Keypad and keypad

cable are part of the top

cover.

Page 48

Take Apart Top Cover - 13

1 Rest the printer upright

Connector

Logic Board

on a flat surface.

2 Disconnect the keypad

cable from the

Top Cover

connector on the logic

board.

Note:

To prevent damage to

Keypad

the keypad cable, you must

disconnect it before

removing the top cover.

Page 49

Take Apart Top Cover - 14

3 Locate the five latches on

the base of the printer:

three on the right and

two on the left.

4 Starting with the latch

nearest the input tray,

Latch

Latch

use a small flatblade

screwdriver to

disconnect the latches.

Push the latches

towards the outside of

the printer, and at the

same time, pull the

cover away from the

bottom of the printer.

Note:

It may be easier to

unlatch the right side

Latch

Latch

first.

Page 50

Take Apart Top Cover - 15

5 After all five latches are

Top Cover

released, lift off the top

cover.

Caution:

Be careful when

lifting off the top cover.

The edges along the base

may be sharp.

Important:

Do not remove

or loosen any screws

that are not described in

the following

procedures. Doing so

may affect print quality

and require replacement

of the entire mechanical

assembly.

Page 51

Take Apart Pressure Plate - 16

Pressure Plate

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Pressure Plate

Page 52

Take Apart Pressure Plate - 17

1 Press the pressure

Pressure Plate

plate latch outward.

2 Lift up the left side of the

pressure plate.

Pressure Plate Latch

3 Remove the pressure

plate.

Page 53

Take Apart Base - 18

Base

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Base

Page 54

Take Apart Base - 19

Note:

The printer is not

Paper Motor

attached to the base by any

screws or retainer clips

1 Lift the printer from the

base.

2 Remove the ESD clip

from the base.

Base

ESD Clip

Replacement Note:

The

ESD clip must touch the

bottom of the paper

motor to ensure proper

grounding.

Page 55

Take Apart Logic Board - 20

Logic Board

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Logic Board

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 56

Take Apart Logic Board - 21

Note:

The logic board contains NVRAM, which contains the

information used to determine the position of the banner

lever. Replacing the logic board, mechanical assembly,

drive gear, or paper feed motor requires re-calibration of

the printer.

See “Banner Calibration” in Additional Procedures for more

information.

Note:

The Color StyleWriter 4100 does not provide

banner printing. No calibration is required for that

printer.

Page 57

Take Apart Logic Board - 22

Ribbon cables

Screw

Screw

J9

J10

J11

J12

Screw

Screw

1 Disconnect the ribbon

cables by loosening each

end of the black plastic

tab securing the ribbon

cables to the logic board.

2 Disconnect the

remaining four cables:

• J9: Carriage Motor

• J10: Service Station

• J11: Sensor board

• J12: Paper motor

±

Warning: Connector

J9 should be removed

carefully to prevent the

connector from pulling

apart.

Page 58

Take Apart Logic Board - 23

bb

Ri

Screw

Screw

on cables

J9

J10

J11

Screw

J12

Screw

Screw

3 Using a T-10 Torx

screwdriver, remove

the four mounting

screws.

4 Remove the logic board

from the printer.

Page 59

Take Apart Ground Bracket - 24

Ground Bracket

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Logic board

Ground Bracket

Page 60

Take Apart Ground Bracket - 25

Screw

Ground Bracket

Screw

1 Remove the two screws

from the ground bracket.

2 Lift and remove the

bracket from the

printer.

Note:

Once the ground

bracket is removed, the

remaining parts comprise

the mechanical assembly.

The base is not included with

the mechanical assembly.

Page 61

Take Apart Sensor Board - 26

Sensor Board

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Logic board

• Ground Bracket

Sensor Board

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 62

Take Apart Sensor Board - 27

1 Spread the latches

outward.

2 Tilt the sensor board

forward and remove it

along with its cable.

Latch Latch

Sensor Board

Replacement Note:

Put

the cable through the

chassis opening. Insert

the bottom of the sensor

board first. Tilt the

board away from the

chassis and align the

guide pin against the

board’s centering guidehole. Rotate the sensor

board toward the chassis

and snap it into place.

Page 63

Take Apart Flex Support - 28

Flex Support

Flex Support

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Logic board

• Ground Bracket

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 64

Take Apart Flex Support - 29

1 Pull the flex support

Flex Support

straight up and remove

it from the chassis.

Page 65

Take Apart Capping Assembly - 30

Capping Assembly

Capping Assembly

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 66

Take Apart Capping Assembly - 31

Capping Assembly

Latch Latch

1 Press and release the

two retaining latches.

2 Remove the capping

assembly from the

printer.

Caution:

Do not touch the

rubber caps on the

capping assembly.

Finger oils can damage

the ink cartridge pens.

Note

: Rubber cap parts

can crack and wear over

time causing premature

failure of the print

nozzles. Inspect the

capping assembly when

the unit is in for repair.

Page 67

Take Apart Purge Unit - 32

Purge Unit

Purge Unit

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Capping assembly

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 68

Take Apart Purge Unit - 33

Note:

You can remove the

purge unit without first

removing the encoder strip

Screw

and carriage belt only if you

use a long screwdriver.

1 Disconnect the cable

attached to the motor.

2 Remove the two screws.

3 Lift the purge unit up

and out to remove it

from the printer.

Screw

Cable Purge Unit

Page 69

Take Apart Carriage Motor - 34

Carriage Motor

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Capping assembly

• Purge Unit

Carriage Motor

Caution:

precautions in Bulletins/

Safety.

Review the ESD

Page 70

Take Apart Carriage Motor - 35

1 Relax tension on the

Screws

Carriage Belt

Cable

Carriage Motor

Idler Hub

carriage belt by pushing

in on the idler hub.

2 Lift the carriage belt off

the carriage motor

pulley.

3 Disconnect the carriage

motor cable from the

logic board.

±

Warning:

J9 should be removed

carefully to prevent the

connector from pulling

apart.

4 Remove the two screws

at the top of the carriage

motor.

Connector

Page 71

Take Apart Idler Hub - 36

Idler Hub

Idler Hub

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution: Review the ESD

precautions in Bulletins/

Safety.

Page 72

Take Apart Idler Hub - 37

1 Relax tension on the

Carriage Belt

carriage belt by pushing

in on the idler hub.

2 Lift the carriage belt off

the carriage motor

pulley.

Idler Hub

Idler Hub

Carriage Belt

Carriage Belt

3 Slide the idler hub out of

the tension bracket.

Page 73

Take Apart Tension Bracket - 38

Tension Bracket

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Idler hub

Caution: Review the ESD

precautions in Bulletins/

Safety.

Tension Bracket

Page 74

Take Apart Tension Bracket - 39

1 Squeeze the tension

bracket together.

Tension Bracket

2 Once the spring tension

is relaxed, swing the

tension bracket and

spring clear of the

chassis.

3 Lift the tension bracket

and spring off the

chassis.

Page 75

Take Apart Paper Motor - 40

Paper Motor

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution: Review the ESD

precautions in Bulletins/

Safety.

Note: The “Paper Motor”

Paper Motor

topic includes the paper

motor and the cluster gear.

Page 76

Take Apart Paper Motor - 41

1 Disconnect the paper

motor cable.

Screw

2 Remove the two screws

and remove the paper

motor from the printer.

Note: (4500 only)

Replacing the logic

board, mechanical

assembly, drive gear,

Paper

Motor

Drive

Gear

or paper feed motor

requires re-calibration

Screw

of the printer.

See “Banner

Calibration” in

Cable

Additional Procedures

for more information.

Page 77

Take Apart Paper Motor - 42

3 Remove the drive gear.

Drive Gear

Page 78

Take Apart Rear Rail - 43

Rear Rail

Rear Rail

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution: Review the ESD

precautions in Bulletins/

Safety.

Page 79

Take Apart Rear Rail - 44

1 Remove the two screws

attaching the real rail to

Screw

Rear Rail

Screw

the chassis.

2 Remove the rear rail

from the chassis.

Replacement Note: The

access door sensor lever

must be installed before

replacing the rear rail.

Page 80

Take Apart Front Cover Actuator - 45

Front Cover Actuator

Front Cover

Actuator

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Rear rail

Caution: Review the ESD

precautions in Bulletins/

Safety.

Page 81

Take Apart Front Cover Actuator - 46

1 Rotate the front cover

Front Cover Actuator

actuator forward and

pull it off.

Replacement Note: You

must put the front cover

actuator on before attaching

the rear rail. The actuator

must be in the up position

when attaching the rear rail.

Page 82

Take Apart Encoder Strip - 47

Encoder Strip

Encoder Strip

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution: Review the ESD

precautions in Bulletins/

Safety.

Page 83

Take Apart Encoder Strip - 48

1 Push in the encoder

spring to relax the

tension on the encoder

Encoder

Spring

strip.

2 Disengage the strip

from the right carriage

rod bracket.

3 Slide the free end of this

strip through the

carriage and disconnect

it from the encoder

spring.

Encoder

Strip

Replacement Note: The

encoder strip is

unidirectional, so there

is no specific back or

front orientation.

Page 84

Take Apart Shaft Clip - 49

Shaft Clip

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

Caution: Review the ESD

precautions in Bulletins/

Safety.

Shaft Clip

Page 85

Take Apart Shaft Clip - 50

1 Flex the shaft clip away

from the chassis.

Replacement Note: The

shaft clip must be positioned

correctly to avoid paper

jams and to ensure proper

grounding. Position the clip

so the clip’s tab will fit into

the rod’s circular groove.

Apply downward force on the

clip until the clip latches

into place. On the base, make

sure the clip is inside and

touching the base.

Page 86

Take Apart Carriage Rod - 51

Carriage Rod

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Rear rail

• Idler hub

• Tension bracket

• Encoder strip

• Shaft clip

Shaft Clip

Page 87

Take Apart Carriage Rod - 52

Note: Handle the carriage

Carriage Rod

Carriage Rod

rod and carriage unit

carefully. Damage to either

part can affect print quality.

1 Lift the left end of the

carriage rod from the

left bracket.

2 Pull the rod out of the

right bracket and

through the carriage

unit.

Replacement Note: The

carriage rod and

carriage unit are not

replaceable. You may

remove them only to

access other parts.

Page 88

Take Apart Carriage Belt - 53

Carriage Belt

Carriage Belt

Before you begin, remove

the following:

• Output tray

• Banner lever

• Length adjuster

• Input tray

• I/O cover

• Top cover

• Rear rail

• Idler hub

• Tension bracket

• Encoder strip

• Shaft retainer clip

• Carriage rod

Page 89

Take Apart Carriage Belt - 54

Caution: Review the ESD

Carriage Belt

Carriage Unit

precautions in Bulletins/

Safety.

Note: Handle the carriage

unit carefully. Damage to it

can affect print quality.

1 Turn the carriage unit

upside down and grasp

the belt.

2 Form a loop with the belt

and lift it free from the

carriage.

Replacement Note: The

carriage unit is not

replaceable. You may

remove it only to access

other parts.

Page 90

Take Apart Mechanical Assembly - 55

Mechanical Assembly

Before you begin, remove

the following:

• Output Tray

• Banner lever

• Length adjuster

• Input Tray

• I/O cover

• Top cover

• Logic board

• Ground bracket

• Base

Page 91

Take Apart Mechanical Assembly - 56

Note: The base is not

included with the mechanical

assembly.

1 Remove the ESD clip

from the base.

2 Lift the mechanical

assembly from the base.

The mechanical

assembly is not attached

to the base by any

screws or retainer clip.

Important: See Replacement

Note on next page.

ESD Clip

Base

Page 92

Take Apart Mechanical Assembly - 57

Replacement Note: (4500

only) Replacing the logic

board, mechanical

assembly, drive gear, or

paper feed motor requires

re-calibration of the

printer.

See “Banner Calibration” in

Additional Procedures for

more information.

Page 93

Take Apart Paper Out Actuator - 58

Paper Out Actuator

Before you begin, remove

the following:

• Output Tray

• Banner lever

• Length adjuster

• Input Tray

• I/O cover

• Top cover

Page 94

Take Apart Paper Out Actuator - 59

1 With a jeweler’s

screwdriver, very

gently pry the plastic

arm up and over the

metal tab on the chassis.

Note: The plastic is

extremely fragile.

2 With the arm disengaged,

slide the paper out

actuator to the right.

3 Free the actuator from

underneath the carriage

rod to remove it from

the printer.

Page 95

K

Service Source

Troubleshooting

Color StyleWriter 4000 Series

Page 96

Troubleshooting General - 1

General

The Symptom Charts included in this chapter will help you

diagnose specific symptoms related to your product. Because cures

are listed on the charts in the order of most likely solution, try

the first cure first. Verify whether or not the product continues to

exhibit the symptom. If the symptom persists, try the next cure.

(Note: If you have replaced a module, reinstall the original module

before you proceed to the next cure.)

If you are not sure what the problem is, or if the Symptom Charts

do not resolve the problem, refer to the Flowchart for the product

family.

For additional assistance, contact Apple Technical Support.

Page 97

Troubleshooting Error Messages and LEDs - 2

Error Messages and LEDs

The Color StyleWriter 4500 and Color StyleWriter 4100 have

two LEDs that can aid in troubleshooting the printer: Resume LED

and Power LED. To interpret these LEDs, refer to Symptom

Charts/LEDs later in this chapter.

Resume

Power

Page 98

Troubleshooting Error Messages and LEDs - 3

The printer software also gives error messages to pinpoint

errors.

Make sure the printer is hooked up to a Macintosh and that the

Color StyleWriter 4100/4500 printer driver software is

installed.

Page 99

Troubleshooting Diagnostic Tests and Sample Pages - 4

Diagnostic Tests and Sample Pages

The following table summarizes the diagnostic tests and sample

pages that you can run using the Power and Resume buttons.

Perform the tests with printer power on and plain paper in the

paper tray; press and hold down the Power button while pressing

the Resume button. For more information, refer to Additional

Procedures.

Diagnostic Test/Printout Power Button Resume Button

Sample Page HOLD DOWN Press once (hold briefly)

Continuous Sample Page HOLD DOWN Press 10 times

Diagnostic Self Test HOLD DOWN Press 5 times

Extended Diagnostic Test HOLD DOWN Press 12 times

Clean Print Heads/Ink Cartridges HOLD DOWN Press 7 times

Page 100

Troubleshooting Symptom Charts/Operation - 5

Symptom Charts

Operation

No power 1 Check power cable connections and recycle power to printer.

2 Replace power adapter and retest.

3 Reseat logic board connectors. Replace logic board.

4 Replace main cover with control panel board.

Does not print 1 Refer to LEDs later in this chapter.

2 Turn on printer and restart computer.

3 Check interface cable and connector. Replace interface cable.

4 Open Chooser and verify correct printer driver and port.

5 Replace printer driver.

6 Reseat logic board connectors. Replace logic board.

Loading...

Loading...