Page 1

APC Silcon

240-320kW 400V UPS

Installation Guide

Copyright 2001 APC Japan Inc

This manual is subject to change without

notice and does not represent a commitment

on the part of the vendor

Page 2

Thank You!

Thank you for chosing the APC Silcon Series UPS. Please read this Installation Guide

thoroughly prior to installing the system. It provides important information on safe and

efficient installation.

The installation and use of this product must comply with national, federal, state, municipal

and local codes.

Safety Symbols used in this manual

WARNING! Indicates a hazard which, if not avoided, could result in injury or death.

CAUTION! Indicates a hazard which, if not avoided, could result in damage to the

product or other property.

NOTICE!

WARNING!

This UPS unit contains hazardous AC and DC voltages. Only qualified electricians should install

the UPS, AC line and external batteries, and must be familiar with batteries and battery

installation.

Before installing, maintaining or servicing the UPS, shut off the UPS and disconnect all sources

of AC and DC power.

As the UPS has no built-in disconnection devices to switch off external AC and DC input power,

ensure that disconnection devices are provided as separate parts in connection with the

installation!

The installer must provide each external disconnecting device for this UPS system with labels

with the following text:

“Isolate the Uninterruptible Power Supply (UPS) as instructed in this guide before working on

circuit”

AC and/or DC voltage will always involve a potential risk of AC voltage at UPS output generated

from either batteries or utility. To avoid equipment damage or personal injury, always assume

that there may be voltage at UPS output.

This system is equipped with an auto-start function. If activated, the system may start without

warning. Refer to the “Programming” section of this guide for information on de-activation.

TEST BEFORE YOU TOUCH!

To reduce the risk of fire or electric shocks, install the UPS and external batteries in a

temperature and humidity controlled indoor area, free of conductive contaminants.

UPS batteries are high-current sources. Shorting battery terminals or DC terminals, DC busbars

can cause severe arcing, equipment damage and injury. A short circuit can cause a battery to

explode. Always wear protective clothing and eye protection and use insulated tools when

working on batteries.

Read and pay attention to this important information.

CAUTION!

This unit contains components sensitive to electrostatic discharge (ESD). If you do not follow the

ESD procedures, you may cause severe damage to electronic components.

990-4056

2 Installation Guide APC Silcon 240-320kW 400V UPS

Page 3

Introduction

1.0 Introduction

Power regulation varies from area to area, and information given in this installation guide can

therefore only be of a general nature. Electricians should therefore always refer to national and

local electrical codes prior to installing the UPS system.

1.1 Tools and Equipment

CAUTION!

Heavy equipment. To prevent personal injury or equipment damage, take extreme care when

handling and transporting UPS cabinet and equipment.

CAUTION!

Ensure that front doors are in place and that internal front cover is fastened by screws before

attempting to lift or transport the system.

This section lists all tools and equipment required to install all UPS configurations. See also

section 4.0 of this guide for further details on connection.

Tools:

• 10mm socket

• 13mm socket-deep

• 17mm socket

• 19mm socket-deep

• 19mm combo wrench

• Small flat head/regular screwdriver

• #3 philips screwdriver

• Compression lug crimping tool

• Knock-out set (for glands)

Equipment:

• Compression lugs for cable terminations

• Cable to Service Bypass Panel from system feeder

• Cable to UPS input from Service Bypass Panel

• Cable to Service Bypass Panel from UPS output

• Cable from Service Bypass Panel to customer distribution

• Cable to UPS input from external batteries/external Battery Breaker Box

(systems with external battery)

• Solid core, control cable to UPS from Service Bypass Panel

• Solid core, control cable to UPS from external batteries/external Battery

Breaker Box

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 3

Page 4

Unpacking

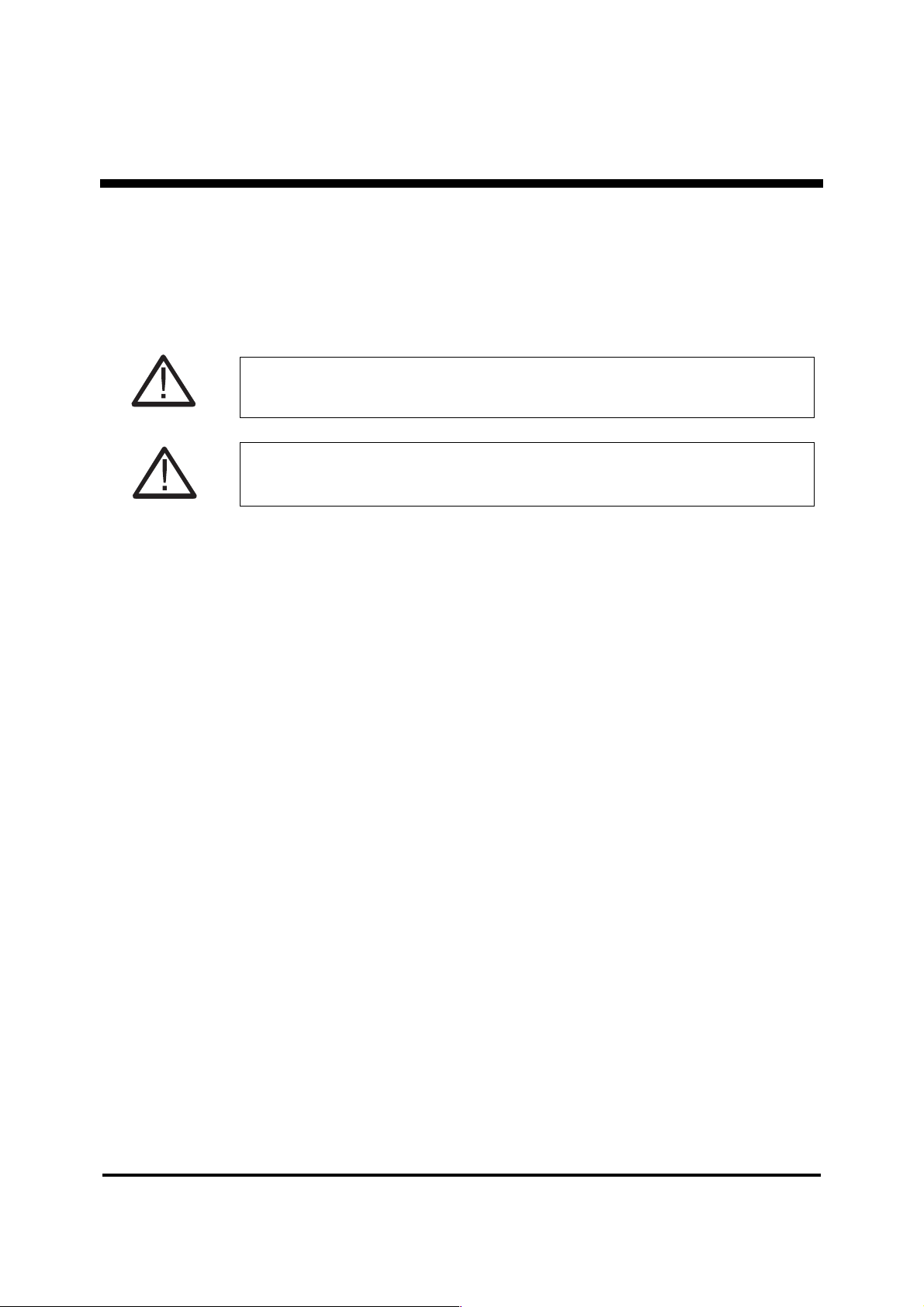

2.0 Unpacking

NOTICE!

Unless otherwise specified by the shipping company use a fork lift to unload equipment from

pallet

1. To unpack UPS unit, remove top and bottom screws from side plates of packaging and lift

up side plates

2. Verify compliance between type label on reverse side of front door and system ordered.

Check input and output voltage

3. Copy type label data to label copy below for easy identification of system

4. Use fork lift to transport system to installation site

SKU SKU

Copy of type label

PLEASE RECYCLE

The shipping materials for the APC Silcon UPS are recyclable. Please save them for later use or

dispose of them appropriately.

990-4056

4 Installation Guide APC Silcon 240-320kW 400V UPS

Page 5

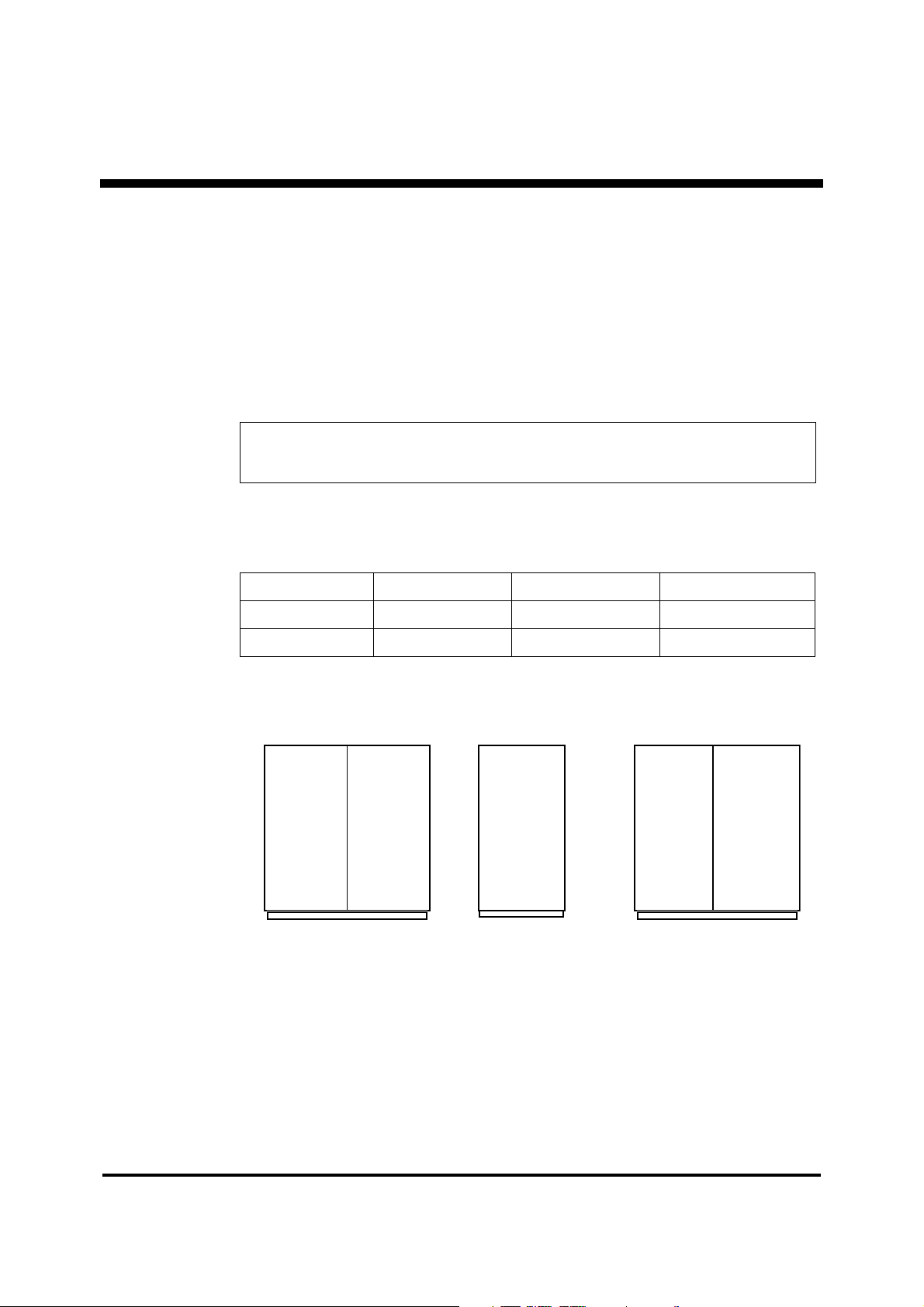

240-320kW

1600 mm wide

1800 mm

APC Isolation

Transformer Module

320kW

1600 mm wide

1800 mm

APC isolation

Transformer Module

240kW

800 mm wide

1800 mm

?

?

Installation

3.0 Installation

3.1 Requirements on Site

All system parts are accessible from front or top of UPS. Cable entries are accessible from

bottom. A 1-metre free space on all sides should be allowed during installation. After

installation of the UPS, leave a free space of 600 mm to the right for system access. (As per

applicable national and/or local codes.)

For ventilation and service purposes allow for free space of minimum 1m above the unit or per

national and/or local codes and in front of UPS. Never install systems in direct sunlight.

NOTICE!

For reliability reasons do not stand on the UPS. Keep the UPS cabinet surface free of any

objects.

3.1.1 Cabinet Dimensions

UPS Height [mm] Width [mm] Depth [mm]

240kW 1800 1600 800

320kW 1800 1600 800

Cabinet

Installation Guide APC Silcon 240-320kW 400V UPS 5

990-4056

Page 6

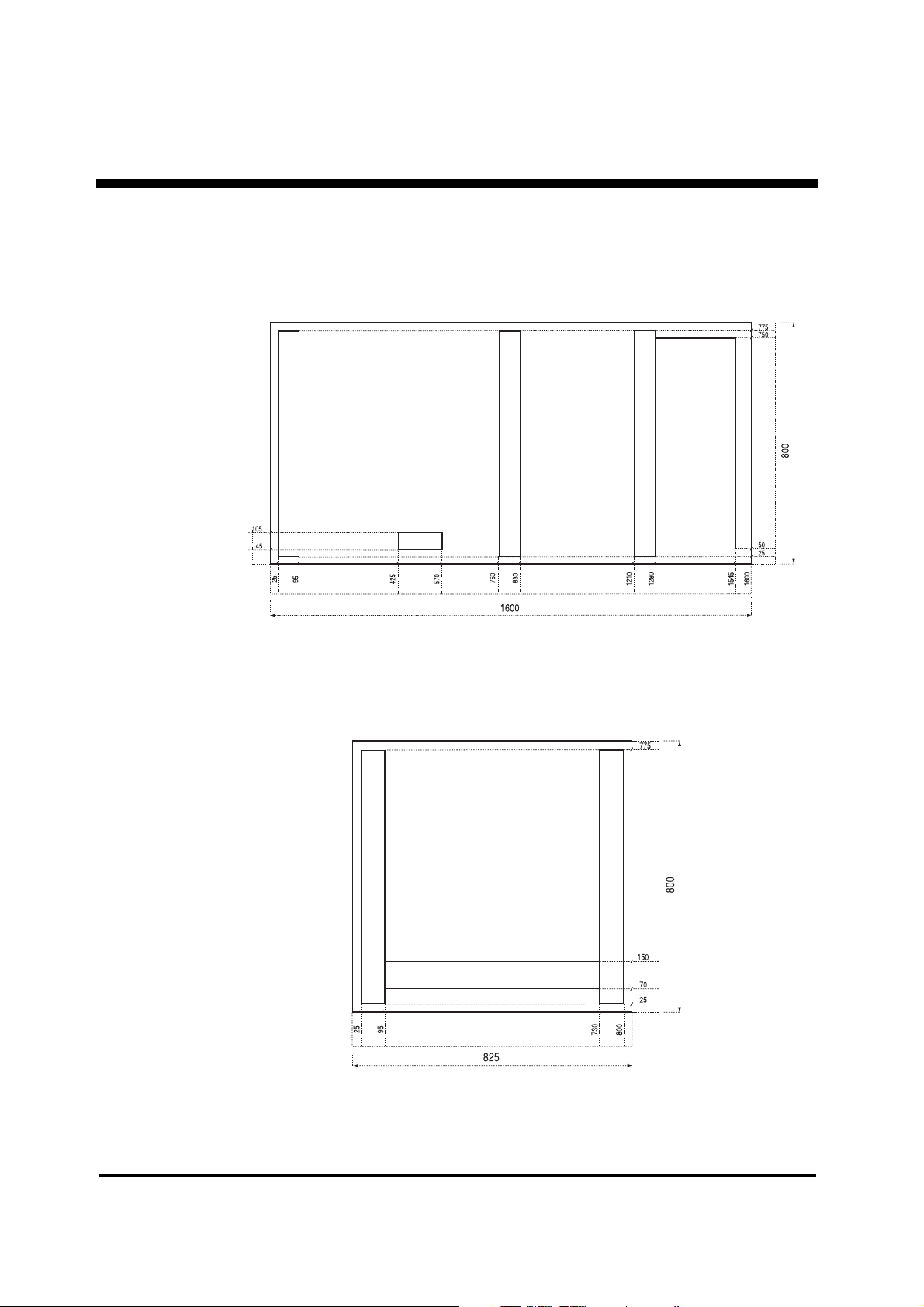

Installation

Power cable entry

com. cable entry

Rear

Front

Rear

Power cable entry

?

3.2 Footprint

3.2.1 1600mm Cabinet for 240-320kW UPS

990-4056

3.2.2 825mm Cabinet for Isolation Transformer or Switch Gear

6 Installation Guide APC Silcon 240-320kW 400V UPS

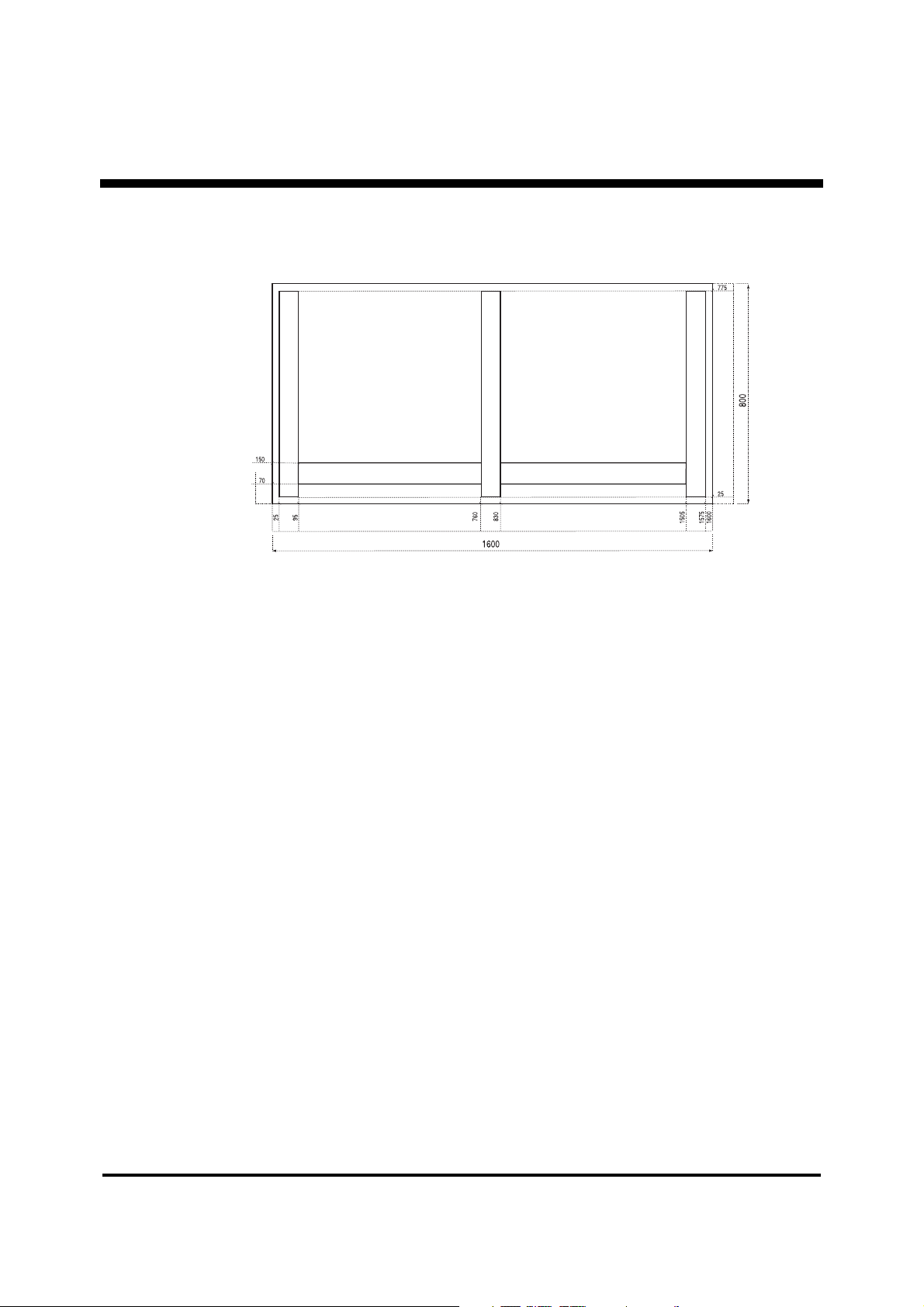

Page 7

Rear

Power cable entry

Front

?

3.2.3 1600mm Cabinet for 320kW Isolation Transformer

Installation

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 7

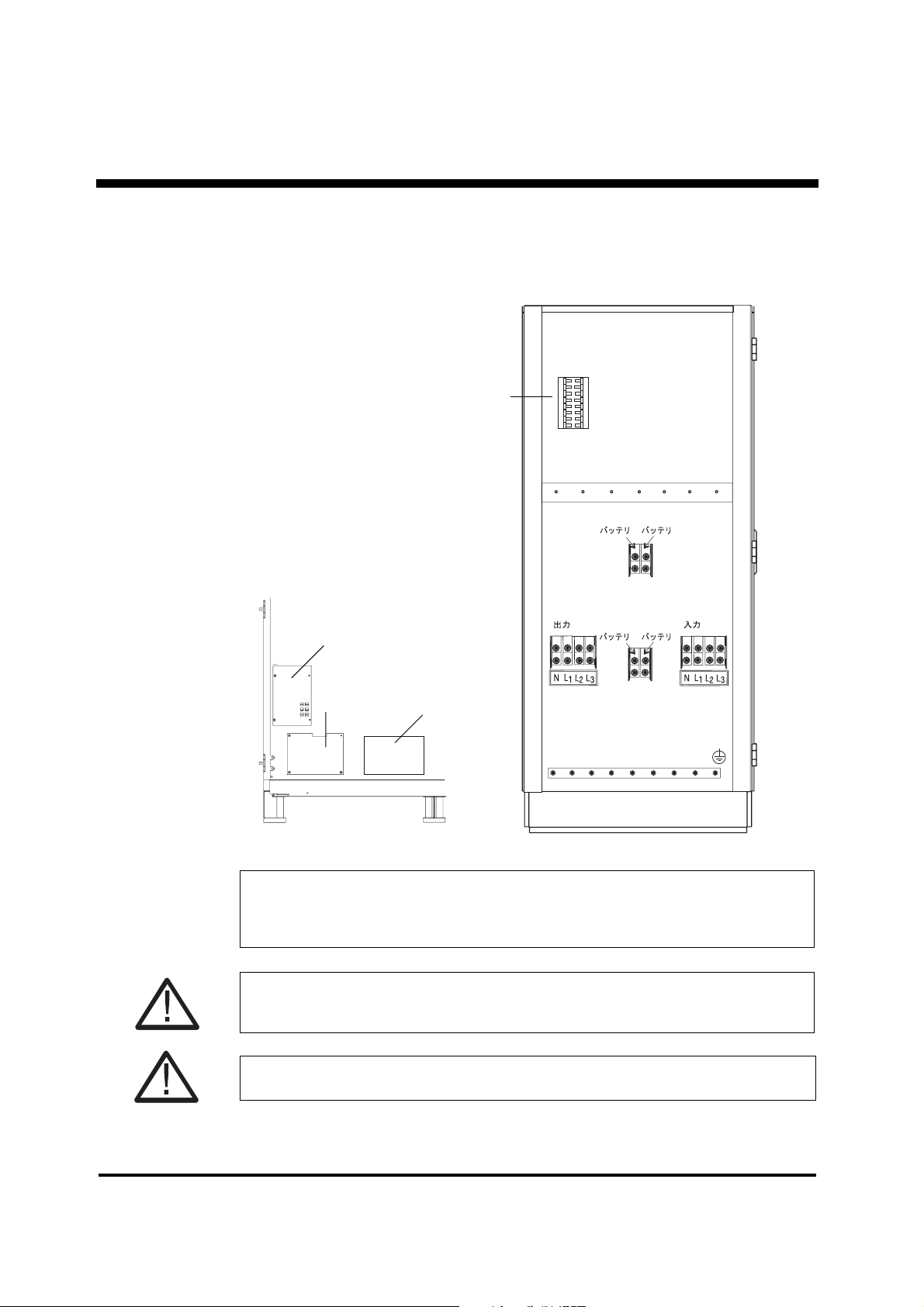

Page 8

External Connection

2 1

2 1

X005 X001

X004:- X003:+

X004:+ X003:-

Right side view

Relay board

Please refer

Battery

Front view

System Integration

Interface

Communication

Interface

Parallel Controller

to “Relay Board” section

4.0 External Connection

4.1 Connecting the UPS

NOTICE!

Check correct phase rotation of mains input voltage!!

Max. input/output cables: 3//300 mm

If there is no neutral input Dzn0 or Dyn11 input isolation transformer is required.

CAUTION!

This UPS unit is an EN 50091-2 product and may cause radio interference in a domestic

environment. Take preventive measures in necessary.

990-4056

8 Installation Guide APC Silcon 240-320kW 400V UPS

CAUTION!

At a switch mode load of 100% the neutral must be rated for 200% output phase current.

2

.

Page 9

External Connection

UPS External

Input

Fuses* FM

[A]

380-415V

240kW 500 2//125 100 400 2//100

320kW 630 2//200 150 500 2//150

* DIN gL types

NOTICE!

All cable dimensions are recommended sizes only.

Refer to local legal regulations.

UPS External Alarm

Cable max.

[mm2]

240kW 2 30 400 2//100

320kW 2 30 500 2//150

PVC cables insulated to withstand ambient temperature of max. 30°C

** Must be rated as external PE cable if mains system is not supplying PE

External

Input Cable

[mm2]

380-415V

External System

External PE

Cable

[mm2]

Earth Cable

[mm2]**

Maximum

External

Output

Fuses*

[A]

External Battery

Breaker

[A]

Output Cable

External Battery

Cable [mm2]

External

[mm2]

NOTICE!

Install gland plate in bottom of unit.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 9

Page 10

External Connection

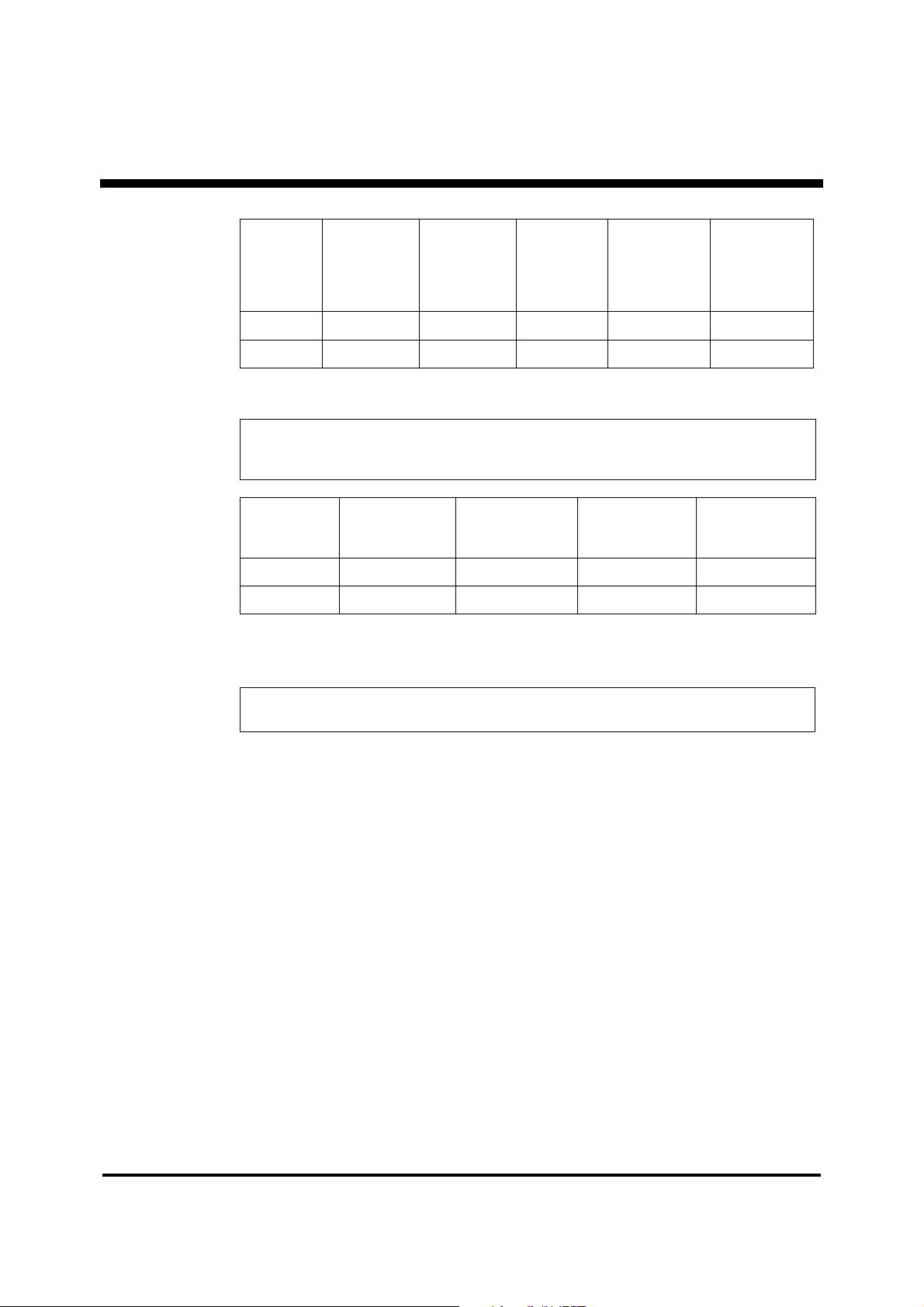

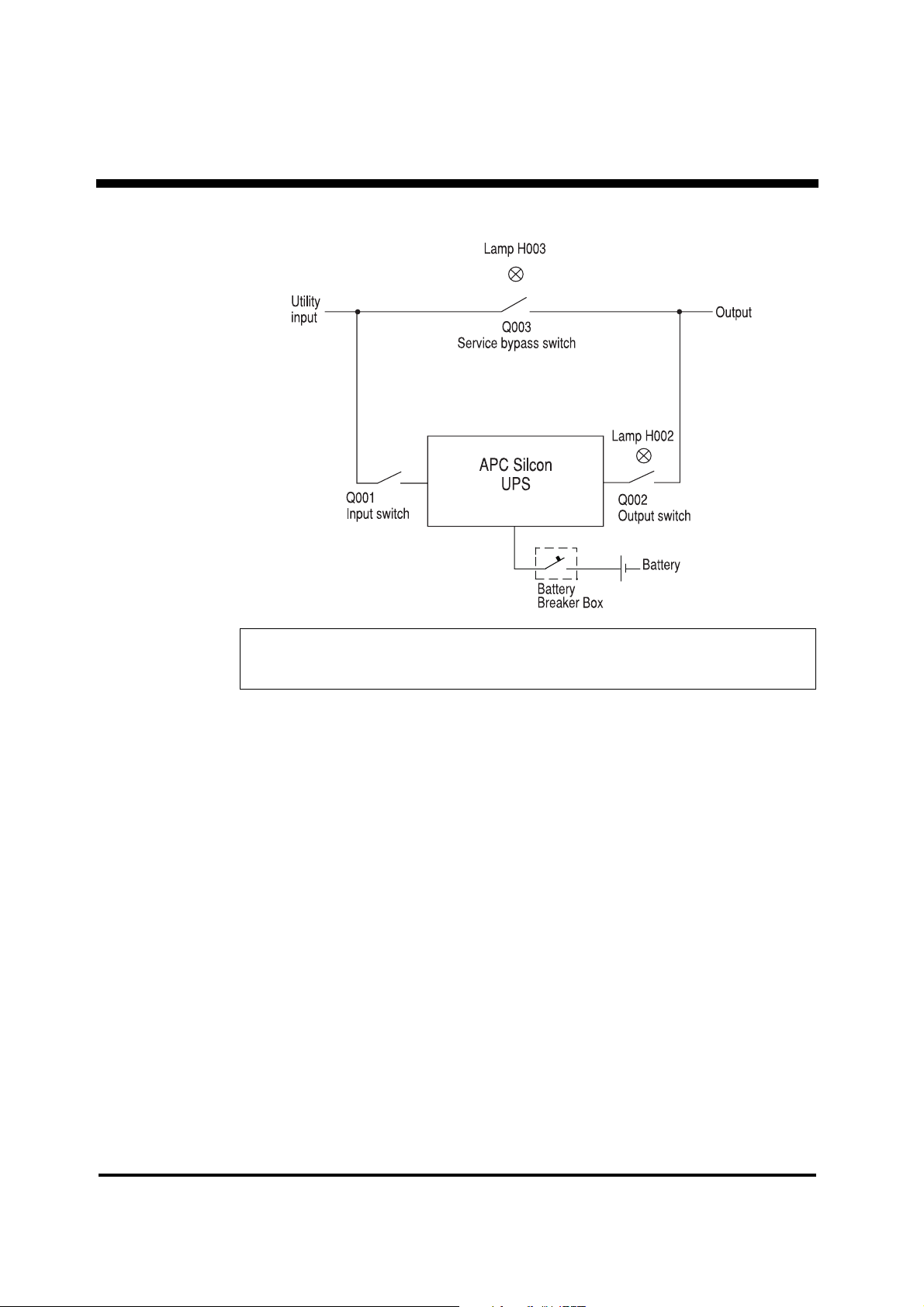

4.2 System Integration Interface

NOTICE!

Consistent use of designations (Q001, Q002, Q003, H002, H003) in diagrams simplifies

information exchange.

System Integration Interface (SII) is the control link between UPS and system main switches

as shown in above diagram. The purpose of the SII is to ensure correct operation of switches

without losing system output power.

Auxiliary contacts on the main switches transmit the SII board inputs. Lamps on Service

Bypass Panel and Battery Breaker Box/Battery Cabinet indicate “green light” for operation of

output switches.

SII board also integrates input facilities for emergency shut-down and temperature

compensation of charge voltage for external battery (use with battery monitor). “Battery

operation” and “Common fault” are two main SII board status relay signals.

990-4056

10 Installation Guide APC Silcon 240-320kW 400V UPS

Page 11

4.2.1 Connections

Blue

Brown

External Connection

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 11

Page 12

External Connection

Terminal Blocks: X003/X004 (Anxiliary Contacts)

When switching Q001, Q002, Battery Breaker 1 or Battery Breaker 2 from “ON or 1” to “OFF

or 0”, the anxiliary contact has to be open BEFORE the corresponding main contacts are

opened. When switching Q001, Q002, Battery Breaker 1 or Battery Breaker 2 the opposite way

from “OFF or 0” to “ON or 1”, the anxiliary contact has to close with a maximum delay of 0.5

seconds from the time the corresponding main contacts are closed.

• This type of auxillary contact is called a “late make” contact. (This also means that it will

“break early” when activated in opposite direction.)

• This auxillary contact is also called “NORMALLY OPEN” (NO), because the auxillary

contact will be open when the main contacts are open.

• Please note that the above term “NORMALLY” has nothing to do with NORMAL UPS

OPERATION MODE.

When switching Q003 from “OFF or 0” to “ON or 1”, the anxiliary contact has to open BEFORE

the corresponding main contacts are closed. When switching Q003 the opposite way from “ON

or 1” to “OFF or 0”, the auxillary contact has to close with a maximum delay of 0.5 seconds from

the time when the corresponding main contacts are opened.

• This type of anxiliary contact is called an “early break” contact. (This also means that it will

“make late” when activated in the opposite direction.)

• The auxiliary contact is also called “NORMALLY CLOSED” (NC), because the auxiliary

contact will be closed when the main contacts are open.

• Please note that the above term “NORMALLY” has nothing to do with NORMAL UPS

OPERATION.

X005 (Output Relays)

Battery operation signals are received with a 30-second delay. This function is inactive during

battery test. Common fault relay facility is programmable (standard factory setting: 10 sec.)

See APC Silcon User Guide for details.

Maximum nominal voltage on contact circuits is 277VAC. If two different phases are involved,

maximum phase to neutral voltage should be below 160VAC. Please note that phase L1 is

already present on the System Integration Interface board, supplied from the Service Bypass

Panel. Therefore, if a phase is needed for alarm or signal purposes, Phase L1 should be used.

990-4056

12 Installation Guide APC Silcon 240-320kW 400V UPS

Page 13

External Connection

Parallel Board

4.3 Parallel Board

CAUTION!

Control cables must be separated from AC and DC power cables.

The built-in parallel board connects two or more UPS systems in parallel, either to obtain

increased system reliability or to obtain higher output power. The parallel board also ensures

correct load-sharing between paralled systems.

NOTICE!

For reliability reasons, APC recommends separate battery packs in redundant/parallel

conigurations.

To prepare the UPS for parallel/redundant mode, disconnect all sources of AC and DC power

supply to the UPS and connect the ribbon cable from the parallel board to the main controller

board (the ribbon cable is delivered with the UPS).

CAUTION!

DO NOT connect ribbon cable between controller and parallel card in single configurations.

Ribbon cable is for parallel operation only.

Complete the parallel system set-up by connecting the external control cables (see below).

Follow the instructions in the “Programming Parameters for Advanced Parallel” section of this

guide to execute necessary re-programming.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 13

Page 14

External Connection

to other parallel units

UPS 1

UPS 2

UPS 3

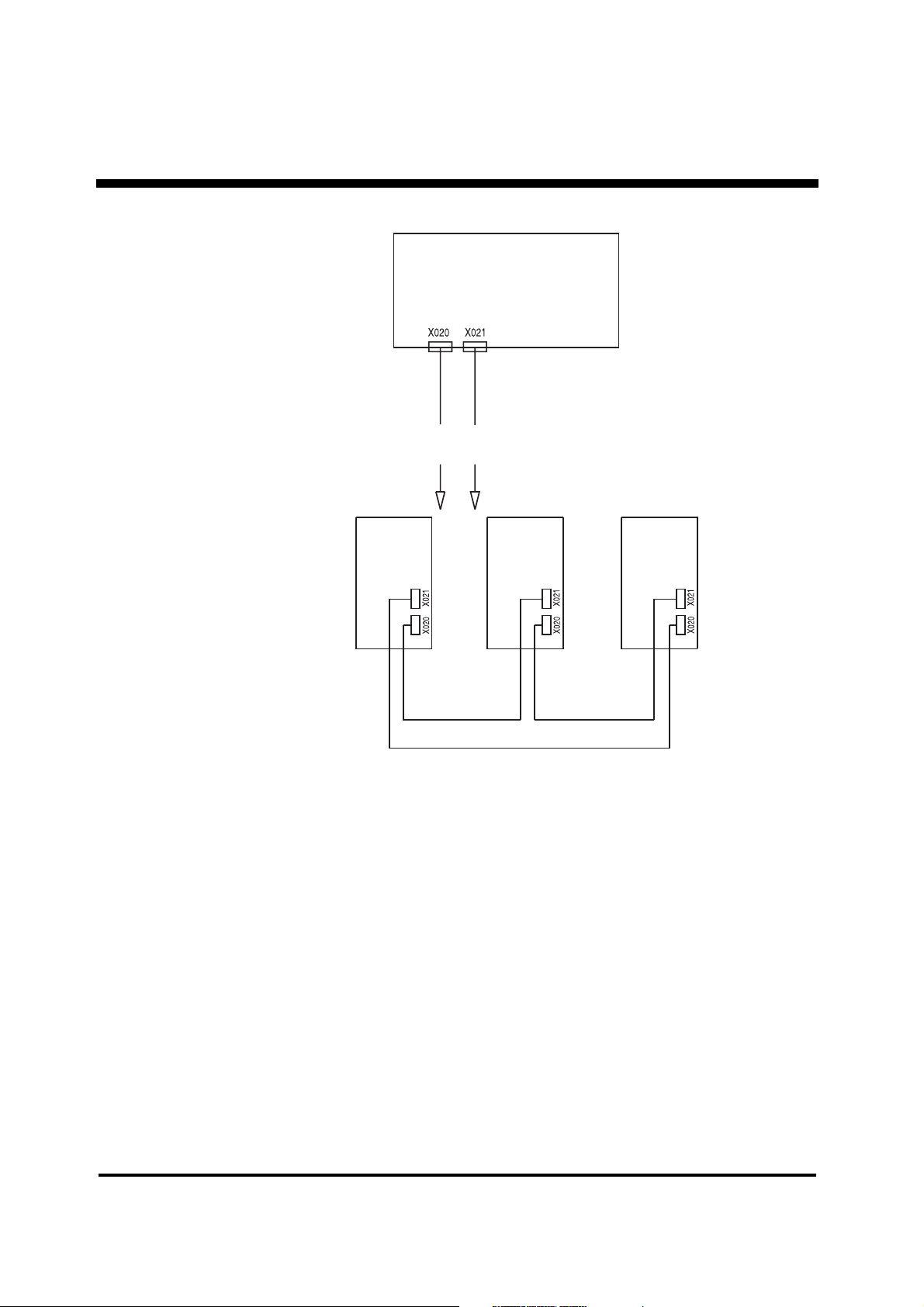

X020:15-pin SUB-D female

X021:15-pin SUB-D female

Parallel Board

External multicore cable with 14 wires + shield

External Control Cables

External multicore cable is equipped with 15-pin SUB-D plug at either end. Connect pin 1 to

pin 1, and pin 2 to pin 2 etc. up to pin 15 - with the exception of pin 8, which is not to be

connected.

990-4056

Shield is connected to plug cover at both ends.

Terminals X020 and X021 for control cables located on parallel board. Connect X020 in UPS1

to X021 in UPS2, and connect X020 in UPS2 to X021 in UPS3 etc. Connect X020 in last UPS

to X021 in UPS1.

Cable is delivered with the UPS.

Power Cables

To optimize load-sharing in parallel operation, external power circuits must be “symmetrical”:

Power input and output cables to have same length and identical cross-sections.

14 Installation Guide APC Silcon 240-320kW 400V UPS

Page 15

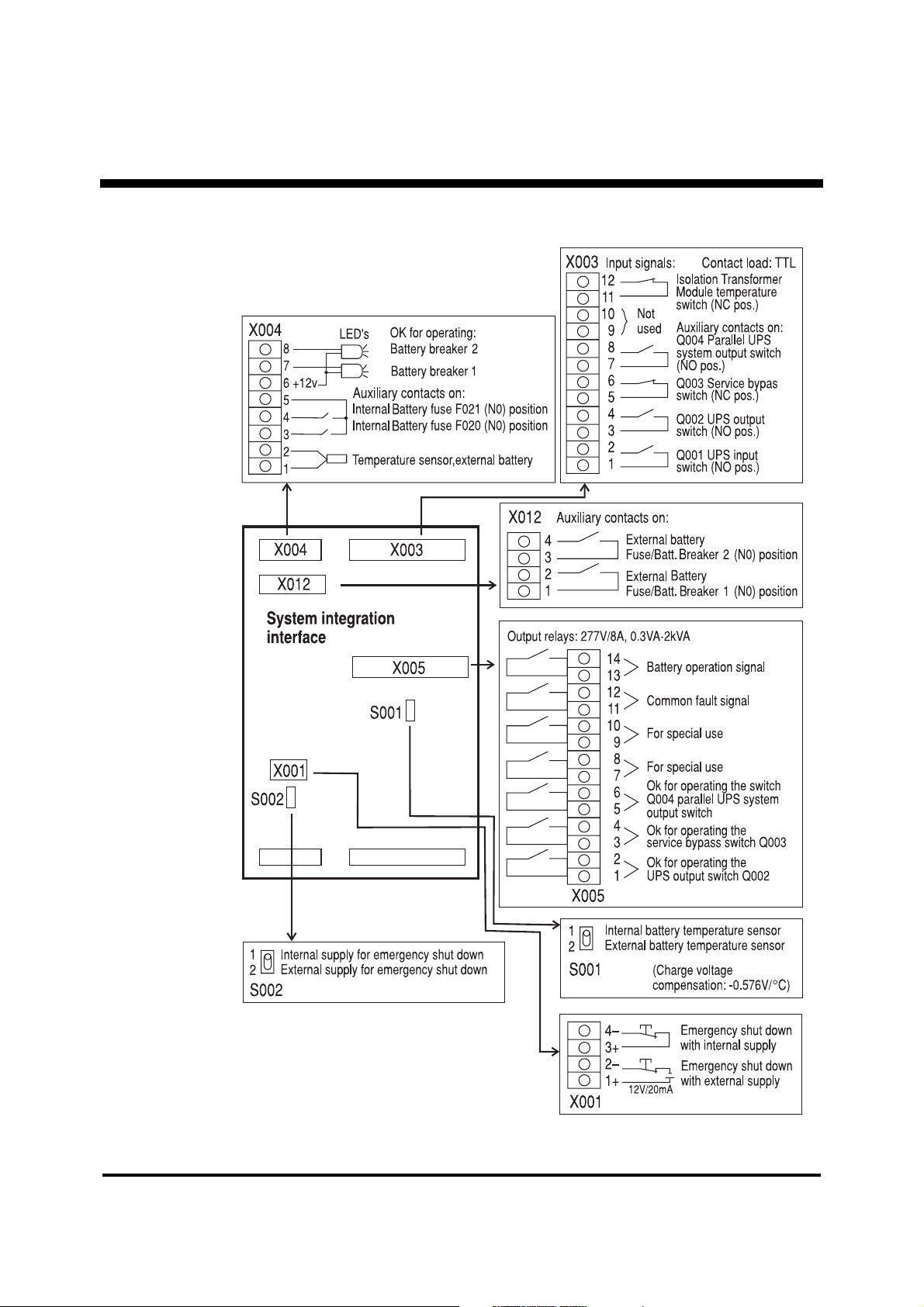

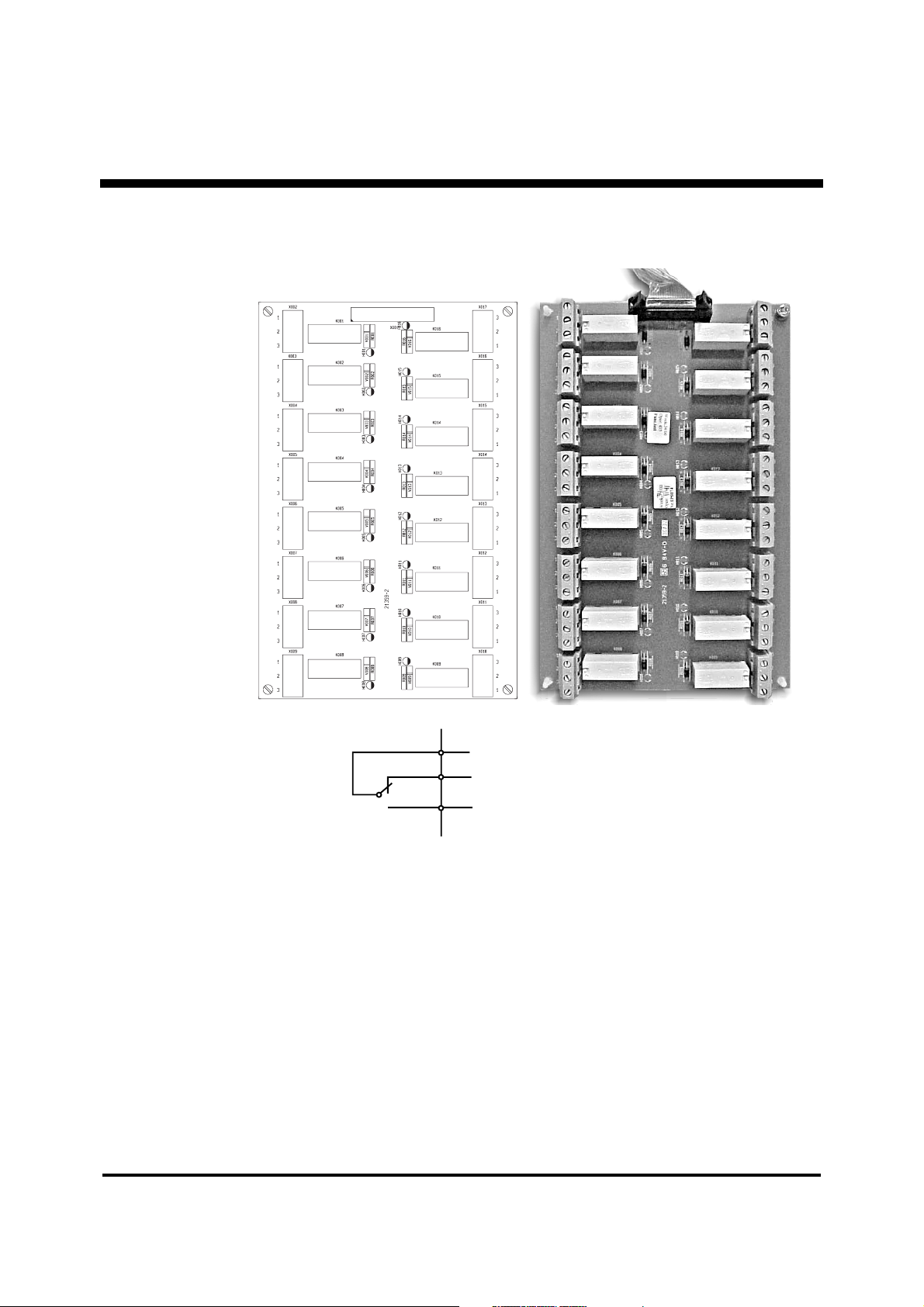

4.4 Relay Board

Maximum load: 8.0A – 250VAC

Minimum load: 0.05A – 6VAC

1

2

3

0.3A – 60VDC

0.05A – 6VDC

External Connection

Relays

All relays are “fail safe”: In alarm modes, relay coil will be de-energized.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 15

Page 16

External Connection

4.4.1 Relay Board/Relay Functions

NOTICE

If alarm mode “Communication to controller lost” is active, ALL relays will indicate failure

Relay Number Message Alarm-trigging Events

1 ## (X002) Mains outside limits Mains voltage RMS outside limits

2 ## (X003) Bypass outside limits Bypass voltage RMS outside limits

3 ## (X004) Output outside limits Output voltage RMS value outside limits

4 (X005) System overload Output load exceeding 100%

5 (X006) Fan fault Blocked or faulty fan

6 (X007) High Equipment

Temperature or

Inverter Fuse Blown

7 (X008) MCCB battery off Battery MCCB/Fuse not closed or released

8 (X009) Normal operation UPS running in normal operation mode

9 ## (X010) Battery operation UPS running in battery operation mode

10 ## (X011) Bypass operation UPS running in bypass operation mode

11 ## (X012) Stand-by operation UPS in stand-by mode

12 (X013) Service bypass

13 ## (X014) Boost charge

14 (X015) Battery voltage

outside limits

15 (X016) Battery condition

16 ## (X017) Common fault All alarms as mentioned above

operation

operation

fault

Mains wave form (fast detector) outside limits

Mains frequency outside limits

Bypass wave form (fast detector) outside limits

Bypass frequency outside limits

Output wave form (fast detector) outside limits

Output frequency outside limits

Delta inverter current limiter active

Main inverter current limiter active

Main inverter failure (temperature too high or fuse blown)

Static switch temperature too high

Delta inverter temperature too high

Magnetic temperature too high

Isolation transformer (option) temperature too high

Battery temperature too high

(status)

(status)

(status)

(Hot stand-by - parallel systems only)

Service bypass switch active

UPS boost-charging on battery

DC voltage too high (shut down)

DC voltage below warning level

DC voltage too low (shut down)

ABM has detected weak battery condition

ABM has detected defect battery

(ABM = Advanced Battery Monitor)

(except relays 8+9+10+11)

Internal power supply fault

System locked in operation mode

Internal memory fault

Internal communication fault

## Delay programmable in configuration stack : “Common fault delay”. Settings 0,10,20,30

seconds.

990-4056

16 Installation Guide APC Silcon 240-320kW 400V UPS

Page 17

External Connection

See section 5.2: System configuration

NOTICE!

Alarm Trigging Events 1-2-3-9-10-11-13 activates the corresponding alarm relay after the delay.

Alarm Trigging Events 4-5-6-7-8-12-14-15 activates the corresponding alarm relay momentarily.

Common fault relay 16 is activated at the same time as relay 1-2-3-4-5-6-7-12-13-14-15, or in

any of the below situations.:

• Internal power supply fault

• System locked in operation mode

• Internal memory fault

• Internal communication fault

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 17

Page 18

External Connection

.

.

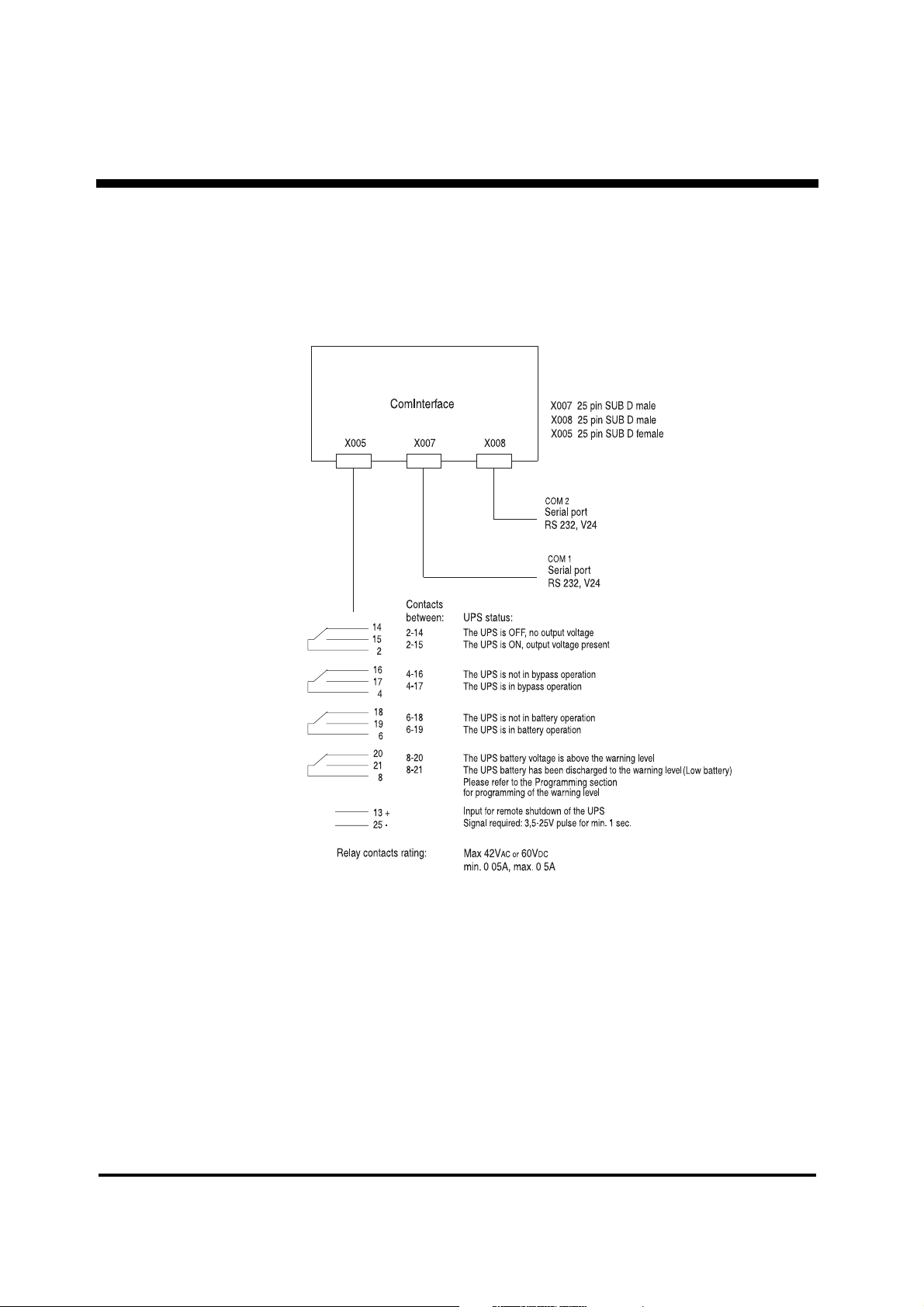

4.5 Communication Interface Board

The 3-port ComInterface is used to establish an interaction between UPS and e.g. a computer

system. Main purpose: To ensure a controlled computer shut-down in case of a mains supply

failure.

4.5.1 Connections

990-4056

18 Installation Guide APC Silcon 240-320kW 400V UPS

Page 19

External Connection

Part of UPS Cabinet

X50 is a 24V supply for Triple Chassis.

Only to be used for this purpose.

Not suitable for telephone equipment.

Triple Chassis must be connected to both

X50 and a serial port.

Serial ports

X50

X008X007

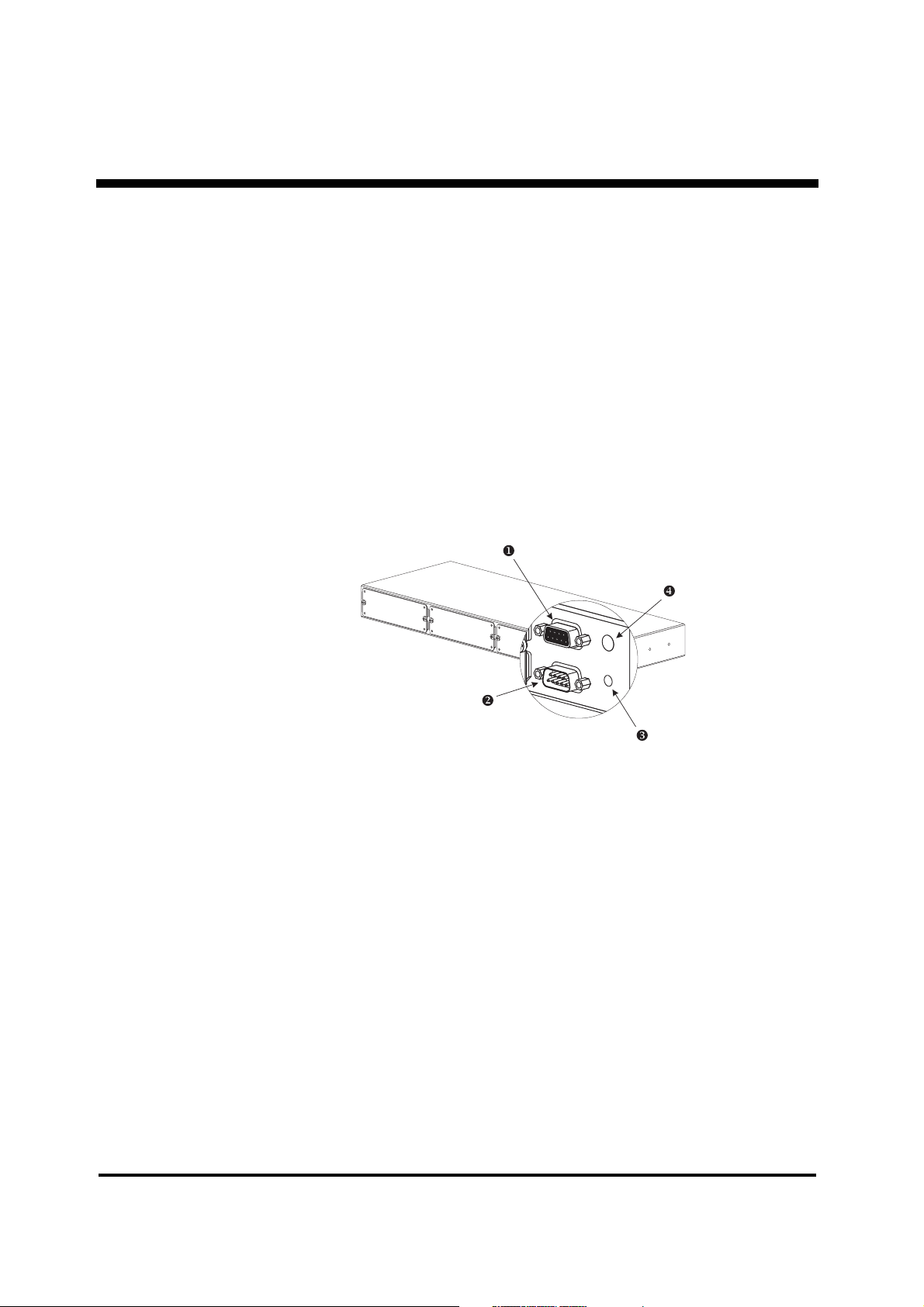

APC Silcon Triple Chassis

4.6 Connecting of APC Silcon Tripel Chassis

The enclosed Triple Chassis must be connected to the serial port on the Communication

Interface Board, and to the 24V supply (cables included). Terminal locations shown below.

For more information please refer to the following section.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 19

Page 20

External Connection

4.7 APC Silcon Triple Chassis

The APC Silcon Triple Chassis (AP9604S) is an American Power Conversion (APC) external

management peripheral that allows you to use monitoring and control management

peripherals with your APC Silcon series UPS. The retrofit model (AP9604SR) is for use with

Silcon series UPSs that are not equipped with a 24 VDC power port.

4.7.1 Safety Warnings

Use the APC Silcon Triple Chassis only in conjunction with an APC Silcon UPS.

Do not connect a computer to any APC Silcon Triple Chassis port using a straight-through

extension cable. Use the communications cable provided with the APC Silcon Triple Chassis.

Connections using a cable made by any other manufacturer may cause damage or improper

operation of the APC Silcon Triple Chassis, the UPS, or the computer.

4.7.2 Product Description

u

x

v

w

Monitoring port

1

To UPS port

2

4.7.2.1 Monitoring Port

The Monitoring port has two functions:

• Connecting to a terminal for configuration of the chassis. For direct connection to the

Monitoring port, you must use the Monitoring cable supplied with the chassis (APC

P/N 940-0024C).

• Connecting to other APC external management peripherals in a daisy chain.

Status LED

3

Optional Power port

4

4.7.2.2 To UPS Port

The “To UPS” port connects the chassis to the UPS, using the Silcon UPS cable (APC P/N 940-

0071). The cable connector plugs into a communications port on an APC Silcon UPS.

990-4056

20 Installation Guide APC Silcon 240-320kW 400V UPS

Page 21

External Connection

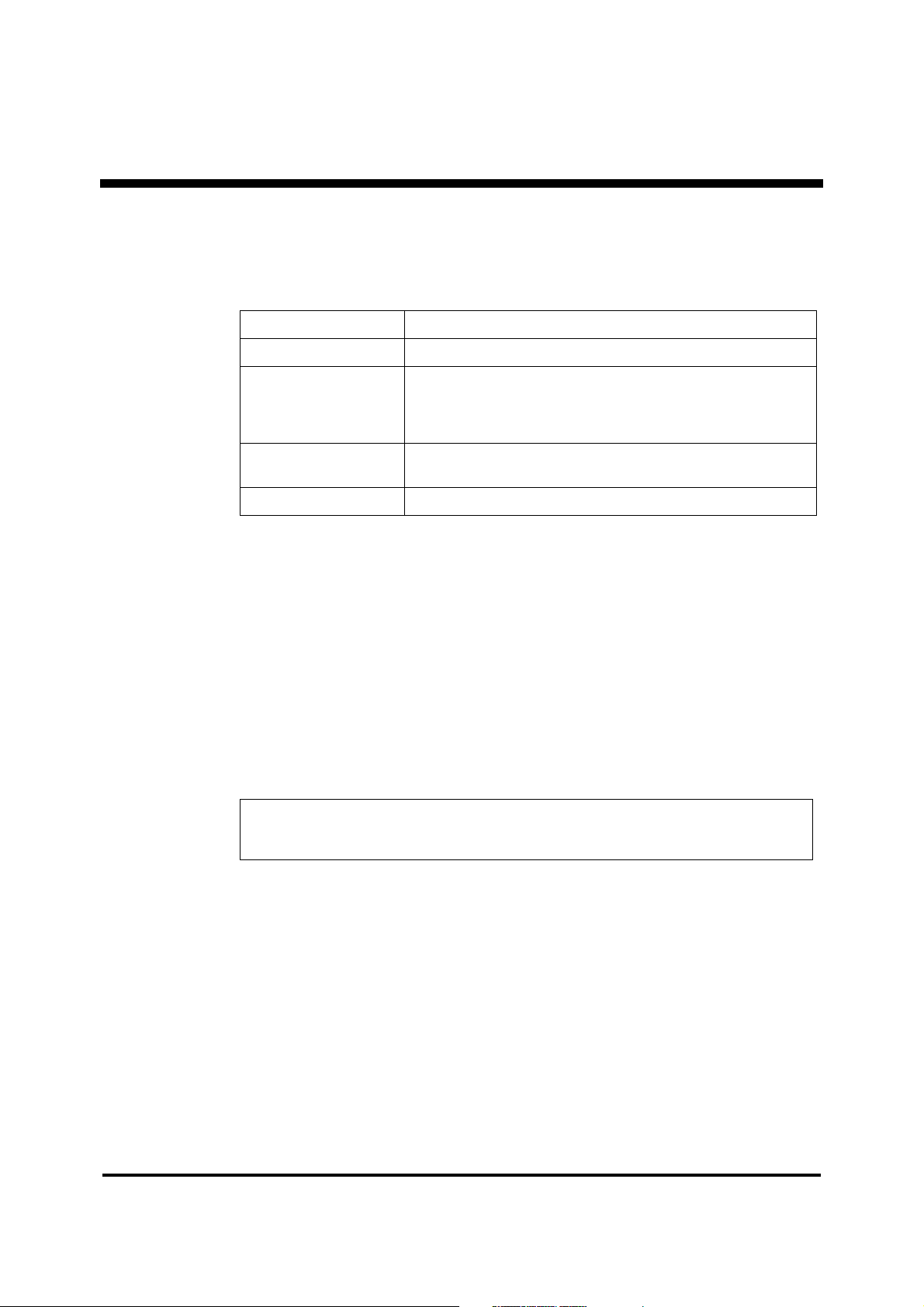

4.7.2.3 LEDs

The APC Silcon Triple Chassis status LED provides important information concerning

operation of the chassis. Refer to the table below for a description of the conditions indicated

by the LED.

IF the LED is… THEN the Silcon Triple Chassis…

off is not receiving power.

has not been configured. See the APC Silcon Management Quick

flashing quickly

(5 times per second)

Start Guide provided with your chassis or the Web/SNMP

Management Card Installation Guide on the CD for more

information.

flashing slowly

(1 time per second)

on is operating normally.

4.7.2.4 Optional Power Input

With the Optional Power input, you can power the APC Silcon Triple Chassis from an external

source, using a 24 VDC power adapter. A universal adapter (AP9505i) or a standard adapter

(AP9505) can be purchased separately from APC.

4.7.3 Installing Management Peripherals

There are two basic types of APC management peripherals that work with the APC Silcon

Triple Chassis:

• Management peripheral cards, which fit into external management peripherals that

are equipped with a card slot.

• External management peripherals, which connect to the Monitoring (or Advanced)

port of other external management peripherals.

NOTICE!

The name “Monitoring” port varies from product to product, but its purpose is the same – to

replicate the UPS communications port.

is powered on but is not communicating with the UPS.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 21

Page 22

External Connection

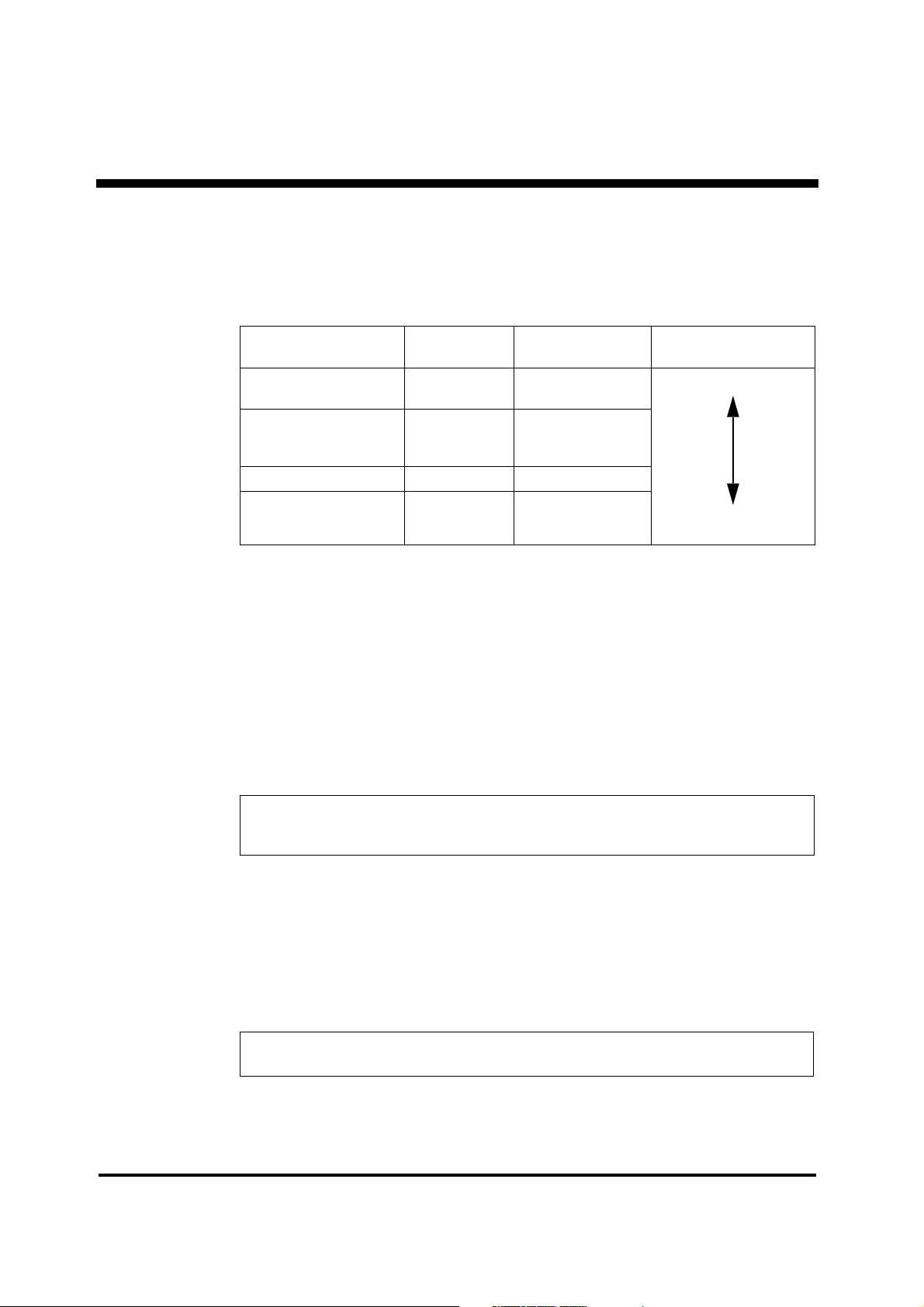

4.7.3.1 Order of Management Peripheral Cards

Because UPS signals are passed between management peripherals, you must install

management peripheral cards in the correct order for them to work together properly. The card

slots are numbered 1 to 3, from left to right, as viewed from the rear of the chassis. The

following table lists the management peripheral cards, their priority, and proper position.

Management Peripheral

Card

Web/

SNMP Management

Card

Out-of-Band Management

Card

(Call-

UPS®II)

Interface Expander AP9607 Second lowest

Environmental Monitoring

Card (Measure-

4.7.3.2 Installing Management Peripheral Cards

To install management peripherals, perform the following steps.

1) Make sure that the chassis is powered off.

2) Install management peripheral cards into the housings on the rear of the chassis. See the

instructions supplied with the cards and the table above.

3) If you are daisy-chaining other APC external management peripherals to the APC Silcon

Triple Chassis: Connect the UPS cable (supplied with the management peripheral) to the

Monitoring port of the chassis and to the “To UPS” port of the other management peripheral

(Share-UPS, MasterSwitch, etc.). See “Daisy-chaining the APC Silcon Triple Chassis”.

4) Power the APC Silcon Triple Chassis and all external management peripherals.

UPS

P/N Priority Position

AP9606 Highest

AP9608 Second-highest

®

II)

AP9612T

AP9612TH

Lowest

High-numbered slot

Low-numbered slot

NOTICE!

If your configuration requires additional power, connect a 24V AC/DC power adapter available

from APC (part number AP9505 or AP9505i) for all models of Triple Chassis.

4.7.3.3 Daisy-chaining the APC Silcon Triple Chassis

If you need more than the three card slots available with the APC Silcon Triple Chassis, or if

you want to use other external management peripherals, you can daisy-chain external

management peripherals together, provided that the total amperage of all installed

management peripherals — cards and external — does not exceed the supplied amperage. (See

“Determining Power Requirements:”).

NOTICE!

When daisy-chaining Triple Chassis units, you may need to use a power adapter.

990-4056

22 Installation Guide APC Silcon 240-320kW 400V UPS

Page 23

External Connection

To add card slots, you can daisy-chain the APC Silcon Triple Chassis with the standard Triple

Chassis (AP9604) management peripheral, installing the APC Silcon Triple Chassis closer to

the UPS.

4.7.4 Powering the APC Silcon Triple Chassis

The APC Silcon Triple Chassis supplies power to the installed management peripheral cards

and to the Monitoring port, allowing you to power multiple management peripherals.

4.7.4.1 AP9604S Power Considerations

The AP9604S model of the APC Silcon Triple Chassis receives its power from the UPS through

the power connector of the Silcon UPS cable. If the total current required by all the installed

management peripherals exceeds 500 mA, you must use a 24 VDC power adapter. To find out

whether you need additional power, see “Determining power requirements”.

4.7.4.2 Power Adapters

APC offers two models of 24 VDC power adapter.

• The standard adapter (AP9505) can provide an additional 400 mA.

• The universal adapter (AP9505i) can provide 850 mA.

4.7.4.3 Using a Power Adapter

To use the adapter, plug it into a protected power outlet and into the Optional Power port of

the APC Silcon Triple Chassis.

NOTICE!

If the power adapter loses power because of a UPS shutdown, its attached management

peripherals may not operate properly, thus adversely affecting the UPS and its protected

equipment.

4.7.4.4 AP9604SR Power Considerations

The AP9604SR model receives its power from the UPS through the supplied 24 VDC universal

adapter. The total current required by your management peripherals must not exceed the 850

mA limit of the power adapter. See ““Determining power requirements”.

4.7.4.5 Determining Power Requirements:

To determine the total amount of current required by your management peripherals, add the

individual current requirements for each management peripheral to be installed with the APC

Silcon Triple Chassis to the current requirements of the chassis itself. Refer to this table

Part # Management Peripheral Draw (mA)

AP9207 Share-UPS 8-port Interface Expander 65

AP9600 Expansion Chassis 30

AP9604 Triple Chassis 20

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 23

Page 24

External Connection

AP9604S[R] APC Silcon Triple Chassis 90

AP9606 Web/SNMP Management Card 110

AP9607 Interface Expander 45

AP9608 Out-of-Band Management Card

(Call-

UPS II)

AP9612 Environmental Monitoring Card (Measure-UPSII) 60

AP9825i Isolated Extension Cable 50

AP9830 Remote Power-Off Device 35

4.7.5 Troubleshooting

The following table shows the solution to common problems with the operation of the Triple

Chassis

Problem Possible Cause Solution

See “Powering the APC Silcon Triple

Chassis”, and verify that you are not

exceeding current requirements.

Configure the Silcon Triple Chassis.

See the APC Silcon Management

Quick Start Guide provided with your

chassis or the Web/SNMP

Management Card Installation Guide

on the CD for more information.

Verify that the supplied UPS cable is

properly connected to the Triple

Chassis and to a communications

port on the UPS.

Status LED is off

Status LED is flashing

quickly

Status LED is flashing

slowly

The chassis is not

receiving adequate

power.

The chassis has not been

configured.

The chassis is not

communicating with the

UPS.

35

You may be able to upgrade the

firmware of the management

peripheral. Call APC Customer

Support.

990-4056

Attached management

peripheral cannot identify

UPS model or nominal

output voltage.

4.7.5.1 If Problems Persist

For problems not covered in the troubleshooting chart or for persistent problems, follow this

procedure:

1) Note the serial number and date of purchase of the APC Silcon Triple Chassis. Contact APC

Customer Support at the phone number or address that is listed in this manual.

2) Be prepared to provide a description of the problem. A technician will help solve the

problem over the phone, if possible, or will give you a return material authorization (RMA)

number.

3) If the APC Silcon Triple Chassis is under warranty, repairs are free of charge. If the

warranty has expired, there will be a nominal charge for repair.

The management

peripheral firmware does

not support 3-phase

UPSs.

24 Installation Guide APC Silcon 240-320kW 400V UPS

Page 25

External Connection

4) Pack the APC Silcon Triple Chassis carefully in its original packaging, if possible. Do not

use polystyrene beads for packing. Damage sustained in transit is not covered under the

warranty. Enclose a letter in the package with your name, address, RMA number, a copy of

the sales receipt, daytime phone number, and payment (if applicable).

5) Mark the RMA number clearly on the outside of the shipping carton. The factory will not

accept any materials without this marking.

6) Return the Triple Chassis by insured, prepaid carrier to the address given to you by APC

Customer Support.

4.7.6 Product Specifications

4.7.6.1 Monitoring Port Pin Assignments

The Monitoring port is a 9-pin communications port. The port operates with no flow control at

a rate of 2400 baud. The data format is 8 data bits with 1 start bit, 1 stop bit, and no parity.

When the Triple Chassis operates with simple signalling, the following limitations and

capabilities apply to the Monitoring port:

• Pins 3, 5, and 6 are open collector outputs which must be pulled up to a common

referenced supply no greater than +40 VDC. The transistors are capable of a noninductive load of 25 mA. Use only Pin 4 as the common.

• The output at Pin 2 generates a low-to-high RS-232 level when the device is

signalling an On Battery condition. The pin is normally at a low RS-232 level.

• The UPS is signalled to shut down when a high RS-232 level is applied to Pin 1 for

4.5 seconds. Shutdown is also dependent on the UPS status.

When the Triple Chassis operates with advanced signalling, the following limitations and

capabilities apply to the Monitoring port:

• Pin 7 is unassigned.

• DC operating voltage is available on Pin 8. This voltage may be from the UPS or from

an external adapter, whichever is greater.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 25

Page 26

External Connection

UPS Shut Down RS-232 Input or

Advanced Mode RS-232 Data RX In

Line Fail RS-232 Output or

Advanced Mode RS-232 Data TX Out

Unregulated

+24 VDC Output

Normally Open

Line Fail Signal

Normally Open

Low Battery Signal

Normally Closed

Line Fail Signal

Common

Chassis

990-4056

26 Installation Guide APC Silcon 240-320kW 400V UPS

Page 27

External Connection

4.7.6.2 Power, Physical, and Environmental Specifications.

Item Specification

Power

Turn on voltage: > 22 VDC

Turn off voltage: < 16 VDC

Current draw (normal operation): 90 mADC

Current draw

(voltage <

Physical

Size (H xW x D): 44 x 432 x 127 mm

Weight: 1.81 kg

Shipping weight: 3.65 kg

Environmental

16 VDC): < 1 mADC

Elevation (above

Operating

Storage

Temperature:

Operating

Storage

Relative humidity:

Operating

Storage

Electromagnetic immunity:

MSL):

0 to 3000 m

0 to 15 000 m

0 to 45˚C

-20 to 70˚C

0 to 95%, non-condensing

0 to 95%, non-condensing

FCC Class A

EN50082-1 verified

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 27

Page 28

External Connection

4.8 APC Silcon Battery Cabinets

IMPORTANT SAFETY INSTRUCTIONS

a The installation of battery drawers in UPS cabinets requires battery knowledge and should be

made or supervised by qualified personnel only. Keep unauthorized personnel away from

batteries.

b Use identical battery types and numbers when replacing batteries. See battery supplier

manual for further details.

c CAUTION - Do not dispose of batteries in a fire. Battery may explode.

d CAUTION - Batteries are fully charged on delivery. Do not short battery terminals or DC

terminals.

e CAUTION - Avoid rough treatment and opening of batteries. Released electrolyte is harmful

to skin and eyes and may be toxic.

f CAUTION - Batteries may cause electric shocks and high voltage short-circuit current. Follow

below precautions when working with batteries:

1 Remove watches, rings and other metal objects.

2 Use tools with insulated handles.

3 Wear rubber gloves and boots.

4 Do not leave tools or metal parts on top of batteries.

5 Disconnect charging source prior to connecting batteries.

Installation and use of this product must comply with all national, federal, state, municipal or

local codes. If you need assistance, please have your UPS model and serial number ready and

call APC, see “How to Contact APC” in this guide.

For more information on the APC World Wide Web site at http://www.apc.com or

www.apc.co.jp.

WARNING!

The entire system contains HAZARDOUS AC/DC VOLTAGES from several power sources.

Some terminals and components are live even with the system being switched off!

ONLY qualified electricians should carry out installations according to national and local codes.

NO UPS types may have built-in batteries when connected to external batteries!

NEVER install batteries not complying with APC specifications. Failing that, the installer takes

over full responsibility!

NEVER lift or transport connected or installed batteries.

NOTICE!

For reliability reasons do not stand on the UPS. keep the UPS cabinet surface free of any objects.

990-4056

28 Installation Guide APC Silcon 240-320kW 400V UPS

Page 29

External Connection

System Integration Interface

Battery Breaker trip for EPO

APC

UPS

Silcon

Diagram - UPS with

Battery Cabinet

(Emergency Power Off)

Battery Cabinet

4.8.0.6 Installation of Batteries

See Installation Guide for Battery Cabinet for:

• Preparing Batteries and UPS

• Dimensions and Weight

• Connecting Batteries

WARNING!

Before proceding, ensure that power supplies have been disconnected from UPS for a minimum

of 5 minutes.

CAUTION!

Follow “Start-up Procedure” in APC Silcon User Guide.

Installation Guide APC Silcon 240-320kW 400V UPS 29

4.9 Battery Breaker Box/Fuse-box

CAUTION!

Batteries connected to a UPS out of service for a period exceeding 8 days may be damaged.

Refer to Section 7.0 Power Disconnection in this guide.

Battery Breaker Box/Fuse-box provides overcurrent and short-circuit protection for UPS

installations with external batteries.

NOTICE!

If battery has been disconnected, refer to Section: - UPS Start Up in the APC Silcon User Guide.

990-4056

Page 30

External Connection

Battery Breaker Box/

Fuse-box

Battery

APC Silcon UPS

?

4.9.1 Battery Breaker Box

990-4056

30 Installation Guide APC Silcon 240-320kW 400V UPS

Page 31

External Connection

Battery 1

Battery 2

Battery 1

Battery 2

UPS

UPS

Main cables are connected directly

to component terminals

?

UPS Ampere

Rating

[A]

240 kW

320 kW

4.9.2 APC Battery Breaker Box Connection Diagram (120-480kW)

400

500

Connection

Cable

[mm2]

2//100

2//150

Max.

shortcircuit

current [kA]

40

40

Dimensions

HxWxD [mm]

1035x835x300

1035x835x300

Weight

[kg]

100

100

X009 LED signal from UPS “OK to operate corresponding MCCB”

X010 MCCB position signals for UPS

X011 Trip for emergency stop (220-240V AC)

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 31

Page 32

External Connection

?

4.9.3 UPS with External Battery in Battery Breaker Box/Fuse-box Configuration

990-4056

32 Installation Guide APC Silcon 240-320kW 400V UPS

Page 33

Programming Parameters

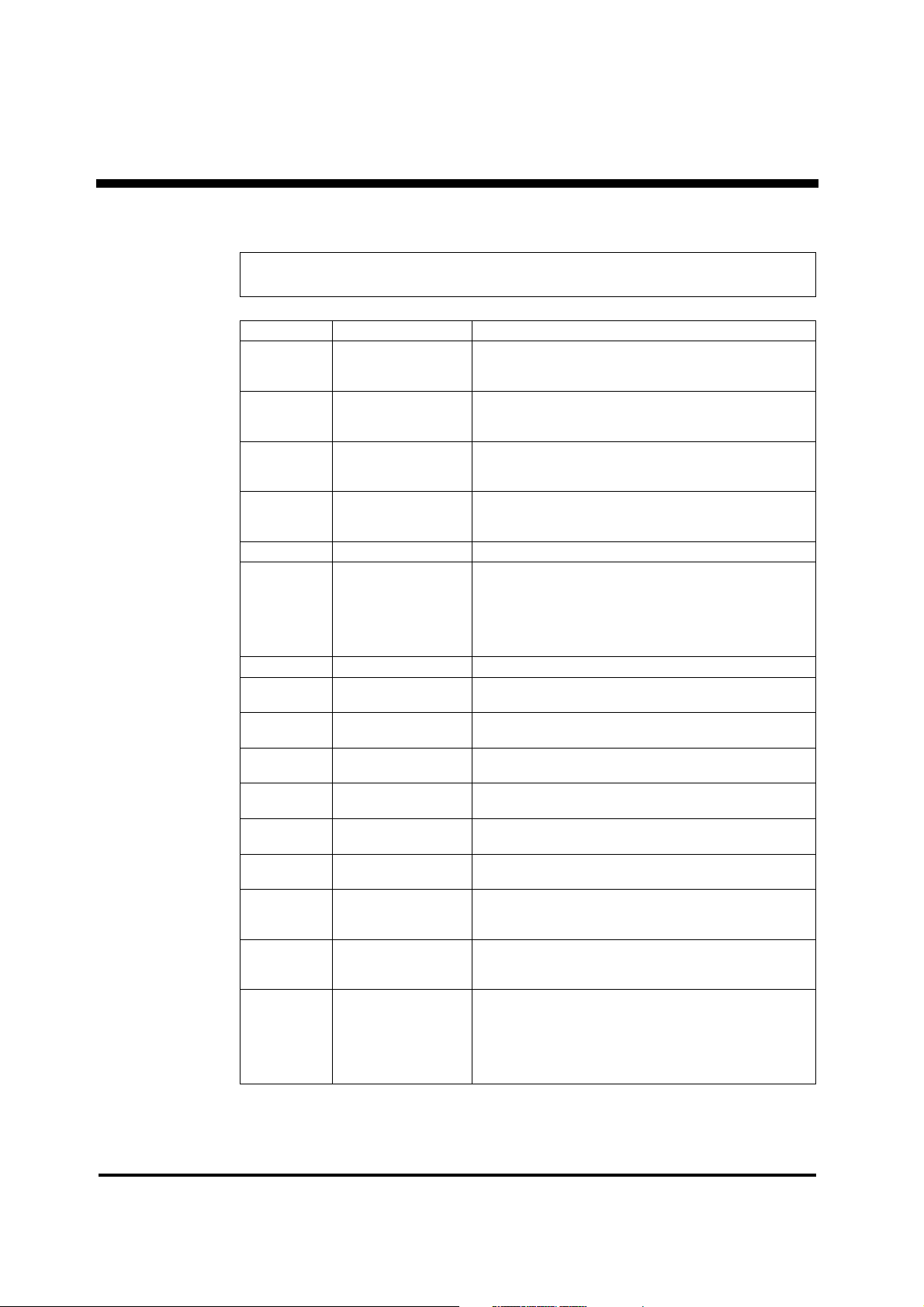

5.0 Programming Parameters

Below table shows operating parameters programmable from keyboard. Only qualified users

should re-set programming parameters.

5.1 Parameters

Parameter Setting* Comments

Bypass operation YES, NO YES will switch the system into bypass mode

GB, D, F

Language

Autostart YES, NO

Remote shutdown active YES, NO

Remote shutdown HIGH, LOW Nature of remote shutdown signal level

Remote shutdown time

Battery capacity test ---

Battery monitor test** ---

Automatic battery test** OFF, 3, 6 months

Battery monitor reset** ---

Boost charge YES, NO YES results in boost charge (10 hours)

Autoboost charge YES, NO

Enter new date YYMMDD Set tolocal date

Enter new time HHMMSS Set to local time (24 hour clock)

DK, S, SF

NL, PL, CZ

E, P, SK, H

0, 1, 2, 3, 4

5, 6, 7, 8, 9

10 min.

Language of text in display

Automatic restart by mains return

(1 min.delay). Ensures quick battery recharge

Shutdown of UPS by remote signal when in

battery operation. Saves battery energy

Time delay on remote shutdown of UPS

Initiates back-up time check.

Time measured from start until it reaches low

DC warning level.

(See User Guide section 6 )

Initiates checks of battery condition by 25%

discharging

Activates the battery monitor test in cyclic

intervals

Press the and key

to resets alarm (flashing light)!

YES results in boost charge after battery

operation. (10 hours)

* Factory settings in bold

** Only for systems with Battery Monitor active

*** Do not leave system running in bypass mode (Static bypass) for extended periodes of time,

as batteries are not recharged in bypass mode.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 33

Page 34

Programming Parameters

Scrolls up

through list

Scrolls down

through list

Stores

parameters/

enter parameter

stack

Silences the

audible alarm

Chooses parameters

Displays time

Exits a mode

Accesses

alarm stack

5.1.1 Programming Keys

NOTICE!

Display accuracy is + 1%, + digit.

990-4056

34 Installation Guide APC Silcon 240-320kW 400V UPS

Page 35

Programming Parameters

5.1.2 Programming Example - Switch to Bypass Operation

NOTICE!

Do not leave in by-pass mode for extended periods in order not to affect battery capacity.

Return to normal operation

Follow same procedure to program other parameters.

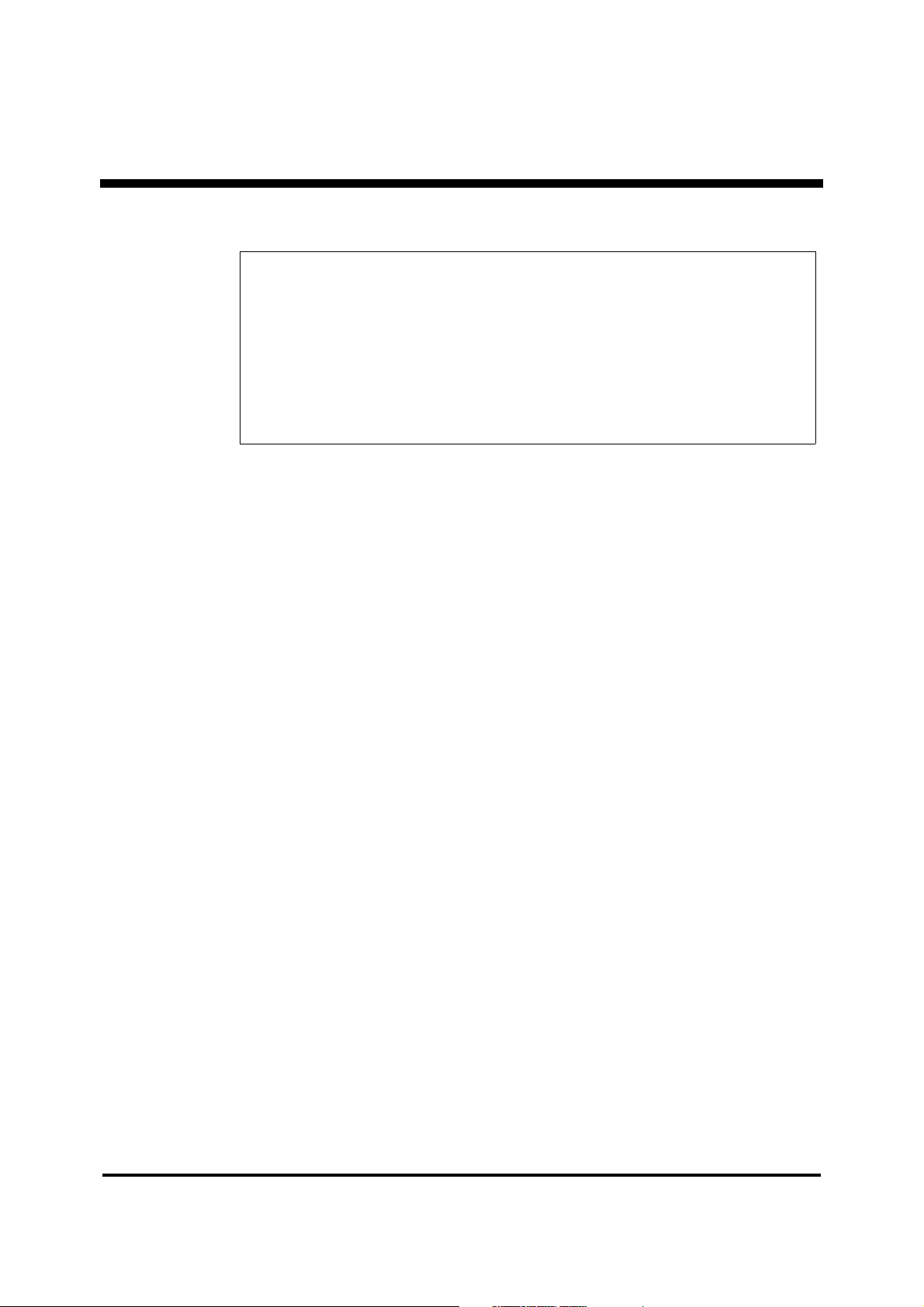

5.2 System Configuration

System configuration parameters are vital for correct system operation and are passwordprotected.

CAUTION!

Incorrect programming may damage battery or cause output voltage to be lost during operation!

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 35

Page 36

Programming Parameters

System Configuration Parameters (password protected)

Parameter Setting* Comments

Enter System no.

Voltage L-L

System Frequency 50/60 Optional selection of frequency

Isolation Transformer Input YES, NO YES if optional input isolation transformer is available

IsolationTransformer

Output

Delta Soft Start Time 1, 10, 20, 40 sec. Input current switching in ramp function. Use higher

External SSW present YES, NO YES for systems with external static bypass switch

Normal Charge Voltage 410-460V

Boost Charge Voltage 438-460V

Low Battery warning 336-384V

Low Battery shut-down 310-336V

Synchronization 0.25, 0.5, 1, 2, 4

High Battery Temperature 15-40°C

Common fault delay 0, 10, 20,

Reset operation mode lock YES, NO YES resets system locked in bypass or battery

Expected back-up time

(min.)

Battery Capacity in (Ah) 0.1-999.9

Highest Station Address 2-9 Highest station address in parallel system

Station Address 1-9 Station address in parallel system

APM Mode Active

(Advanced Power

Management)

APM Test Mode Active YES, NO YES, if APM test mode is active

Battery Connection Common,

380, 400, 415 Optional selection of voltage

YES, NO YES if optional output isolation transformer is available

438V

438V

336V

326V

Hz/sec.

35°C

30 sec.

0.1-999.9

5.0

7.0

Disabled

Redundant +1

Parallel +1

Separate

values for smaller/unstable diesel generators

Setting of float charge voltage at 20°C

(Automatic compensation for temperature deviations)

Setting of boost charge voltage at 20°C

(Automatic compensation for temperature deviations)

Discharged Battery warning

Switches off system at min. permissible battery

voltage

Syncronization speed.

Alarm - Ambient temperature for battery too high

Delay before common fault alarm relay is activated

operation mode caused by system failures (only

applicable for service personnel)

Expected UPS back-up time in minutes when running

at 100% ohmic load. Time used by ABM**

Total Battery capacity in Ah.

Setting used by ABM**.

Use only in parallel systems.

Disabled: Advanced power management off.

Redundant +1: Redundant operation with one unit

being inactive in parallel system

Parallel +1: Redundant operation with all units in

operation.

Common: if common battery is used in parallel system.

Separate: if separate battery is used

* Bold text refers to factory standard setting

**Advanced Battery Monitor

990-4056

36 Installation Guide APC Silcon 240-320kW 400V UPS

Page 37

Programming Parameters

*** If voltage or frequency settings is changed, unit needs to be powered down for the new settings

to take effect.

5.2.1 Programming Example - Change Charge Voltage to 446

NOTICE!

Change charge voltages, battery warning limit, shut down voltage and high battery temperature

limit by entering the actual value. See example above.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 37

Page 38

Programming Parameters

5.2.2 Programming Example - Change to Output Isolation Transformer available

NOTICE!

Change parameters by pressing the key once or several times. See example above.

990-4056

38 Installation Guide APC Silcon 240-320kW 400V UPS

Page 39

Programming Parameters

5.3 Programming Parameters for Advanced Parallel Operation

To use the advanced parallel functions, the following parameters must be programmed:

1. “Station number”

2. “Highest station address”

3. “Advanced power management”

4. “APM test mode active”

5. “Battery connection”

5.3.1 Description of Settings

1. “Station number”

• Valid station numbers: 1-9 stating the UPS parallel address in system.

2. “Highest station number”

• Valid station numbers: 2-9 stating the number of UPSs in system.

3. “Advanced power management”

• “Disabled”: Advanced Power Management is inactive.

• “PARALLEL+1”: Advanced Power Management is activated when the system operates

as PARALLEL N+1, meaning that one system can be isolated without overloading the

remaining systems (N systems/UPSs).

• “REDUNDANT+1”: Advanced power management is activated when the system

operates as REDUNDANT N+1, meaning that one system can be isolated without

overloading the remaining systems (N systems/UPSs) with one spare system.

4. “APM test mode active”

• “No”: Stand-by-time will be 24 hours - on-line time will be 48 hours (xN systems).

• “Yes”: Stand-by-time will be 1 min. - on-line time will be 2 min (xN systems).

5. “Battery connection”

• “Separate”: Separate battery for this UPS.

• “Common”: Common battery in a parallel system.

NOTICE!

“Common”: Common battery in a parallel system. When this setting is chosen, the highest

battery temperature that can be found in the parallelled systems (for charge voltage

compensation).

NOTICE!

Common battery pack is a technical possibility.

However, APC recommend separate battery pack due to a higher safety degree in connection

with redundant/parallel operation.

The UPS system is designed for both situations.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 39

Page 40

Programming Parameters

5.3.2 Programming example

Example with four systems in parallel with separate batteries.

• Programme the station addresses 1-4: 1 for UPS 1, 2 for UPS 2, 3 for UPS 3, and 4 for

UPS 4.

• All UPS systems have to be programmed to “Highest station address”:4.

• If APM is not to be tested, “APM test mode active” must be “NO”.

• If a system is isolated due to service, the station numbers must be reprogrammed for the

remaining active systems starting with number 1 and ending with maximum. number

of active systems. No number must be left in this sequence. Furthermore, “Highest

station address” must be changed to number of active UPSs in parallel.

5.4 Battery Monitor

990-4056

40 Installation Guide APC Silcon 240-320kW 400V UPS

Page 41

Programming Parameters

5.4.1 Installation of new batteries

To avoid false alarms, the above procedure MUST be followed.

NOTICE!

Contact your local dealer if you have any questions regarding changing parameters.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 41

Page 42

Options/Accessories

6.0 Options/Accessories

Please contact your local APC representative for information on options/accessories available

in your region. See “How to Contact APC” in this guide.

6.1 Service Bypass Panel for Single Operation

UPS Exter-nal

System

Input

Fuse

[A]

240kW

320kW

500

630

Max.

Prospective

ShortCircuit

Current

[kA]

45

45

System

Input/

UPS

Input

Cable

[mm2]

**

2x125

2x200

System

Output/

UPS

Output

Cable

[mm2]

**

2x100

2x150

Max.

External

System

Output

Fuse

[A]***

400

500

Max.

Cable

Size/

Stud

Size

M12

M12

Dimensions

HxWxD [mm]

Weight

[kg]

??

*** If no external System Output fuses are available or if it has a higher value than

indicated above, System Output and UPS Output cables should be dimensioned as

System Input and UPS Input cables.

** Sizes according to IEC 364-5-532 for PVC insulated copper cables (max. ambient

temperature: 30

o

C). Installation method B: Insulated conductors in wall conduit.

Also refer to local legal regulations.

Beware that single-phase Switch Mode Power supply loads will increase neutral

current! At a 100% SMPS load, neutral cable should be dimensioned for 200% of

phase current.

* Depth of enclosure includes switch handles

Fixing

Centres

AxB

[mm]

?

?

990-4056

42 Installation Guide APC Silcon 240-320kW 400V UPS

Page 43

Options/Accessories

?

?

6.1.1 Wiring up UPS with SBP in TN-C-S Network

6.1.2 Wiring up UPS with SBP in TN-S Network

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 43

Page 44

Action

1. Press on the keyboard

2. Press or on the keyboard until

3. Press on the keyboard

4. Press on the keyboard

5. Check lamp indication on the Service Bypass Panel

6. Turn the external bypass switch (Q003)

to position ”1“

7. Turn the output switch (Q002) to position ”0“

8. Open the front door and press both the green

”ON“ and the red ”OFF“ keys simultaneously

The acoustic alarm sounds for 30 sec.*

9. Turn the input switch to position ”0“

The red alarm LED below the display lights

and the acoustic alarm sounds for 30 sec.

* The acoustic alarm can be reset by the key

Bypass operation

:NO

Bypass operation

:YES

Display shows

Lamp indication

on Service Bypass Panel

The Green lamp (H003)

above the bypass switch

handle (Q003) lights

The Green lamp (H002)

above the output switch

handle (Q002) lights

Only the lamp (H002)

above the output switch

handle (Q002) lights now

** System OFF **

Display shows

EMERGENCY (UPS not alive)

1. Turn the input switch (Q001) to position ”0“.

2. Turn the output switch (Q002) to position ”0“.

3. Change any released system input fuse(s).

4. Turn the bypass switch (Q003) to position ”1“.

Options/Accessories

6.1.3 Operating The External Service Bypass Switch

990-4056

44 Installation Guide APC Silcon 240-320kW 400V UPS

Page 45

Options/Accessories

** System OFF **

Normal operation

load power %

Display shows

Lamp indication

on Servive Bypass Panel

The Green lamp (H002)

above the output switch

handle (Q002) lights

Now also the green lamp

(H003) above the bypass

switch handle (Q003)

lights

Only the Green lamp

(H003) above the bypass

switch handle (Q003)

lights

Display shows

Bypass operation

:NO

Bypass operation

:YES

:

Bypass operation

:YES

:

Bypass operation

:NO

Normal operation

load power xx %

No lamps on the Service

Bypass Panel light any

longer

10. Press on the keyboard

11. Press or on the keyboard until

12. Press on the keyboard

11. Press on the keyboard

11. Press on the keyboard

Action

1. Turn the input switch (Q002) to position ”0“

2. Open the UPS front door and press the

green "ON” key

3. Press on the keyboard

4. Press or on the keyboard until

5. Press on the keyboard

6. Press on the keyboard

7. Check lamp indication on the bypass panel

8. Turn the output switch (Q002) to position ”1“

9. Turn the bypass switch (Q003) to position ”0“

6.1.3.1 Switching from External Bypass to Normal UPS Operation

Installation Guide APC Silcon 240-320kW 400V UPS 45

990-4056

Page 46

Options/Accessories

Service Bypass Panel (SBP)

Mains Supply System Output

Control

cables

Q003

Q004

Q001bQ001a

Q002b

Q002a

APC Silcon

400V UPS

X020

X021

X020

X021

APC Silcon

400V UPS

Battery

Battery Breaker/

Fuse Box

6.2 Service Bypass Panel for Parallel Redundant Operation

990-4056

46 Installation Guide APC Silcon 240-320kW 400V UPS

Page 47

Options/Accessories

?

6.2.1 Two Parallel Systems with Service Bypass Panel

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 47

Page 48

Options/Accessories

?

6.2.2 Parallel/Redundant Operation with Service Bypass Panel and External

Battery via MCCB

990-4056

48 Installation Guide APC Silcon 240-320kW 400V UPS

Page 49

Options/Accessories

H002a

6.2.3 Operating External Service Bypass Switch for Parallel Systems

6.2.3.1 Bypassing Parallel UPS Systems

CAUTION!

Batteries connected to a UPS out of service for a period exceeding 8 days may be damaged.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 49

Page 50

Options/Accessories

Step 1-4 can be carried out with any of the parallel systems, however this will switch

all systems into bypass operation.

1. Press on the keyboard

2. Press or on the keyboard until

3. Press on the keyboard

4. Press on the keyboard

All systems will transfer to bypass operation

Do not switch off any of the UPS systems

until step 5-8 has been completed.

5. Check lamp indication on the Service Bypass Panel

6. Turn the external bypass switch (Q003)

to position ”1“

7. Turn the output isolator (Q004) to position ”0“

8. Turn the output switches (Q002) to position ”0“

9. Open the front door and press both the green

”ON“ and the red ”OFF“ keys simultaneously in

any of the systems

The acoustic alarm sounds for 30 sec.*

Repeat for (all) other system(s).

10. Turn all input switches (Q001) to position ”0“

The red alarm LED below the display lights

and the acoustic alarm sounds for 30 sec.

* The acoustic alarm can be reset by the key

Bypass operation

:NO

Bypass operation

:YES

Display shows

Lamp indication

on bypass panel

The green lamp (H003)

above the bypass switch

handle (Q003) lights

The green lamp (H004)

above the output isolator

(Q004 and the green lamps

(H002) above the output

switch handles (Q002) lights

The green lamps (H002)

above the output switch

(Q002) light and the green

lamp (H004) above the output

switch (Q004) lights

Now the lamps (H002)

above the output switch

handles (Q002) light and the

green lamp (H004) above the

output switch (Q004) lights

** System OFF **

Display shows

Action

Bypass operation

990-4056

50 Installation Guide APC Silcon 240-320kW 400V UPS

Page 51

Options/Accessories

H002a

6.2.3.2 Switching Parallel System from External Bypass into Normal UPS Operation

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 51

Page 52

Options/Accessories

Action

1. Check that output switch (Q004) is in

position “0”

2. Check that all output switches (Q002)

are in position “0”

3. Turn input switches (Q001) to position “1”

4. Open the UPS front door and press the

green “ON” push-botton

5. Press on the keyboard

6. Press or on the keyboard until

7. Press on the keyboard

8. Press on the keyboard

All systems will transfer to bypass operation

9. Check that all output switches (Q002) are in

position “0”

10. Turn all output switches (Q002) to position ”1“

11. Turn the output switch (Q004) to position ”1“

12. Turn the bypass switch (Q003) to position “0”

** System OFF **

Normal operation

load power 0%

Display shows

Lamp indication

on Service Bypass Panel

The green lamps (H002)

above all the output

switch handles (Q002)

lights.

The green lamp

(H004) above the output

switch (Q004) handle also

lights.

The green lamps (H002)

above all the output switch

handles (Q002) light. The

green lamp (H004) above

the output switch (Q004)

handle and the green lamp

(H003) above the bypass

switch light.

The green lamps (H002)

and (H004) do not light any

longer. (H003) will light

until normal operation.

Bypass operation

:NO

Bypass operation

:YES

Bypass operation

990-4056

52 Installation Guide APC Silcon 240-320kW 400V UPS

Page 53

Options/Accessories

The following can be carried out on any UPS

13. Press on the keyboard

14 Press or on the keyboard until

15. Press on the keyboard

16. Press on the keyboard

All the systems will transfer to normal operation.

Normal operation

load power xx%

Display shows

Bypass operation

:NO

Bypass operation

:YES

No lamps on the bypass

panel lights any longer

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 53

Page 54

Options/Accessories

H002a

6.2.4 Isolating One UPS for Service/Maintenance

In a redundant system, one UPS may be isolated for service/maintenance without affecting

other UPSs.

1. Check that remaining UPS(s) is capable of carrying the load in the event that one UPS is

isolated

2. Switch off system to be isolated for maintenance purposes by pushing green “ON” and red

“OFF” buttons simultaneously

3. To disconnect battery, mains and output, open battery MCCB/fuse and set input switch

(Q001) and output switch (Q002) to position “0”

With Q002 in position “0”, UPS will be operational and may be tested as a single system

without affecting other parallel UPS(s).

6.2.5 Switching Back to Normal Parallel/Redundant Operation

1. Turn input switch (Q001) and output switch (Q002) to position “1”

2. Charge capacitor, connect battery and start up UPS

UPS will automatically switch to normal operation and start load-sharing with other

parallelled UPS(s).

WARNING!

System will discharge built-in capacitors, but check terminal voltage before proceding.

990-4056

54 Installation Guide APC Silcon 240-320kW 400V UPS

Page 55

Options/Accessories

ISU System

Parallel

Operation

System 3

Parallel

Operation

System 2

Parallel

Operation

System 1

Ext.

sync

Source

UPS 2C

UPS 2B

UPS 2A

UPS 1C

UPS 1A

UPS 1B

UPS 3C

UPS 3A

UPS 3B

UPS 4

ISU

5

ISU

4

ISU

2

ISU

1

ISU

3

6.3 Intersystem Synchronization Unit

Intersystem Synchronization Unit System (ISU System)

The ISU system consists of inter-connected ISUs. One ISU system may consist of up to 5 ISUs,

regardles of ISU configuration. The ISU system synchronizes the voltage of parallel operation

systems running in battery operation.

The ISU system may also include one or more external synchronization sources,

e.g. a gen-set or a non-APC Silcon UPS system.

Synchronization accuracy of the ISU is better than 2

Schematic overview of ISU system (example):

o

.

Intersystem Synchronization Unit (ISU)

The ISU is an active part of an ISU system, serving as the interface to the sources and the ISU

system.

The ISU can be connected to a parallel UPS configuration, using the standard parallel

communication controller in the parallel operation system.

(See Intersystem Synchronization Unit User’s Manual for further details.)

6.4

Installation Guide APC Silcon 240-320kW 400V UPS 55

990-4056

Page 56

Options/Accessories

6.5 Remote Display

With the remote display unit data may be displayed at distances of up to 25 m from UPS. For

extended communication distance, see section below.

Remote display may easily be connected to UPS via one of the two serial communication ports

on the communication interface board.

To obtain a transmission distance of up to 3.2 km normal RS232C signal levels must be

converted to a long distance communication standard. The converter must be placed outside

the UPS cabinet.

6.5.1 Extension of Remote Display Communication Distance

Remote display communicates with the UPS through a 3-wire RS232 interface. Remote display

is a DTE (Data Terminal Equipment) employing a SUB-D 9-pin female connector.

Communication speed: 9600 bps.

For communication distances, see Table 1. Insert converters if longer distances are necessary,

or if communication cables are led through magnetically noisy areas. Converters must comply

with local regulations

Table 1: Remote Display Communication Extensions

Standard

(RS232)

Max. distance 80/25 ft/m 10000/3200 ft/m

Converter Manufacture

Art. Code

RS232 BLACK BOX connector Sub-D 25-pin female

BLACK BOX interconnector 4-screw terminal

Two converter boxes are required for a communication distance extension: One

box near the UPS for the conversion from RS232C to a long distance communication standard,

and another box at the other end to convert back to RS232C, which is to be connected to the

No converter BLACK BOX

Short-haul

Modem Async

ME800A-R2

990-4056

56 Installation Guide APC Silcon 240-320kW 400V UPS

Page 57

Options/Accessories

Remote Display. The converter provides optical signal insulation. Both converter boxes must

be supplied by an uninterruptible power source.

6.5.1.1 Connections Without Converter

Connect a 25-pin female Sub-D and a 9-pin male Sub-D connector with a 3-wire shielded cable,

as shown in the table below. Connect shield at one end only.

Pin Connection for Interconnection Cable (without converter):

Host (DTE) Remote Display (DTE)

25-pin female

pin No.

2 (TXD) 2 (RXD)

3 (RXD) 3 (TXD)

7 (GND) 5 (GND)

House (shield) No Connection

6.5.1.2 Connections With Converter

Connections to be made according to converter manual.

Pinconnection example only:

Pin Connections for cable

from host to ME800A-R2.

Host

(DTE)

25-pin female

pin No.

ME800A-R2

(DCE)

25-pin male

pin No.

9-pin male

pin No.

Pin connection for cable from

ME800A-R2 to Remote Display

ME800A-R2

(DCE)

25-pin male

pin No.

Remote Display

(DTE)

9-pin male

pin No.

2 (TXD) 3 3 2 (RXD)

3 (RXD) 2 2 3 (TXD)

7 (GND) 7 7 5 (GND)

House (Shield) No connection No connection House (Shield)

The ME800A-R2 must be set up as a DCE with no RTS/DTR control.

The interconnection cable between the two ME800A-R2 boxes is a 4-wire twisted pair

telephone cable with or without shield. The shield improves noise immunity but reduces

maximum communication distance.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 57

Page 58

Options/Accessories

Rear view

Cable entry from bottom and rear

Rear view Front view

3. Mont back plate

4. Connect cables

1. Turn 180° to loosen

2. Remove front cover

Mains adapter

DP9-F

the 4 screws

X

APC Silcon, DB25-F

Remote Display, DB9-M

6.5.2 Remote Display Installation

6.5.2.1 Connecting RS232C and Mains Adapter

CAUTION!

Wiring for alarm and signal circuit field to be rated 300V (minimum).

6.5.2.2 Remote Display Power Supply

The remote display is supplied by normal AC power with no battery back-up. For UPS data

transmission to remote display to remain unaffected during power failure, the remote display

must be supplied from an uninterruptible power source.

Converters used to extend communication distance must also be supplied from uninterruptible

power sources.

6.5.2.3 Remote Display Cables

RS232C to RS232C cable:

990-4056

Connect shield at one end only!

Rating: Refer to Local/National electrical codes.

Communication voltage +

15VDC

58 Installation Guide APC Silcon 240-320kW 400V UPS

Page 59

Options/Accessories

6.5.3 Remote Display Use

The remote display is an inactive unit unable to influence the operation of the UPS: Some of

the alarms visible on the internal display are also available on the remote display (See the

Alarm section in the APC Silcon User Guide).

6.5.3.1 Initiating the Remote Display

After having connected the supply the display will show:

Remote Display: “APC Silcon UPS”

6.5.3.2 Communication Fault

Communication fault between UPS and remote display will appear in the display as follows:

“Data transmission interrupted”

6.5.3.3 Remote Display Setting

Use # Stack to select language and type of UPS connected to remote display.

Parameter Setting Comments

Language GB,D,F,DK, S, SF,NL, PL, CZ,

E, P, SK, H, I

Host SDC charger, DP300E, 300E Type of UPS connected to remote

6.5.3.4 Operation

See the Operation section in the APC Silcon User Guide.

6.5.3.5 Display of Measured Value

See Display of Measured Value in the APC Silcon User Guide.

Time reading not visible from the remote display.

6.5.3.6 Alarms

See Alarms section in the APC Silcon User Guide.

Language

display

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 59

Page 60

Options/Accessories

1600 mm wide

1800mm

?

APC Isolation

Transformer Module

320kW

800 mm wide

1800mm

APC Isolation

Transformer Module

120kW

?

6.6 Isolation Transformer

Isolation

Transformer

280kVA

370kVA

*Actual dimensions may vary

UPS Height

240kW

320kW

[mm]*

1800

1800

Width

[mm]*

1200

1300

Depth

[mm]*

800

800

Weight

[kg]

1500

1950

990-4056

60 Installation Guide APC Silcon 240-320kW 400V UPS

Page 61

Example of Transformer Configuration (Yyno)

Input

Output

E

G

G

Options/Accessories

NOTICE!

APC isolation transformers are available in various configuration. Contact your local APC

representative for further information. See “How to Contact APC” in this guide.

Installation Guide APC Silcon 240-320kW 400V UPS 61

990-4056

Page 62

Options/Accessories

?

6.6.1 Connecting Isolation Transformer

Isolation

Transformer

280kVA 240kVA 500 2//125 100 2//125 2

*DIN gL types

PVC cables insulated to withstand a maximum ambient temperature of 30

Isolation

Transformer

370kW 320kVA 630 2//200 150 2//200 2

*DIN gL types

PVC cables insulated to withstand a maximum ambient temperature of 30°C

990-4056

UPS External

Input Fuses*

FM [A]

380-415V

UPS External

Input

Fuses* FM

[A]

380-415V

External

Input Cable

2

]

[mm

380-415V

External

Input Cable

2

]

[mm

380-415V

External

PE Cable

2

]

[mm

External PE

Cable

2

]

[mm

External

Output

Cable

2

]

[mm

o

C

External

Output

Cable

2

]

[mm

External

Temp.

Signal Cable

2

]

[mm

External

Temp. Signal

Cable

2

]

[mm

62 Installation Guide APC Silcon 240-320kW 400V UPS

Page 63

Options/Accessories

NOTICE!

If an MCCB is used in stead of external input fuses, the MCCB load capacity must be 8xIn

(nominal current) for minimum 10 ms.

NOTICE!

Check correct phase rotation of mains input voltage! Maximum input/output cables: 3//300 mm

If input neutral is not available, an optional Dzn0 or Dyn11 input isolation transformer must be

used.

NOTICE!

All external cable dimensions are recommended sizes only. Refer to local legal regulations.

NOTICE!

Make sure that gland plate is installed in bottom of cabinet.

CAUTION!

At 100% switch mode load, neutral must be rated for 200% phase current.

2

.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 63

Page 64

Options/Accessories

6.6.2 Wiring up UPS with External Yyn0 Isolation Transformer at Output

WARNING!

Isolation transformer provides galvanic isolation between mains supply and load. Load will loose

galvanic isolation if isolation transformer is bypassed

NOTICE!

Refer to local legal regulation for wiring information.

990-4056

64 Installation Guide APC Silcon 240-320kW 400V UPS

Page 65

Options/Accessories

?

6.6.3 Wiring up UPS with External Yyn0 ?????? Isolation Transformer at Input

WARNING!

Isolation transformer provides galvanic isolation between mains supply and load. Load will loose

galvanic isolation if isolation transformer is bypassed.

NOTICE!

Refer to local legal regulation for wiring information.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 65

Page 66

Options/Accessories

6.6.4 Wiring up UPS with External Optional Dzn0 Isolation Transformer at Input

WARNING!

Isolation transformer provides galvanic isolation between mains supply and load. Load will loose

galvanic isolation if isolation transformer is bypassed.

NOTICE!

Refer to local legal regulation for wiring information.

990-4056

66 Installation Guide APC Silcon 240-320kW 400V UPS

Page 67

Options/Accessories

6.6.5 Wiring up UPS with External Optional Dzn0 Isolation Transformer at Output

WARNING!

Isolation transformer provides galvanic isolation between mains supply and load. Do not bypass

isolation transformer in order to avoid damaging circulation currents and to prevent load from

loosing galvanic isolation.

NOTICE!

Refer to local legal regulation for wiring information.

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 67

Page 68

Options/Accessories

6.6.6 Wiring up UPS with External Optional Dyn11 Isolation Transformer at Input

WARNING!

Isolation transformer provides galvanic isolation between mains supply and load. Do not bypass

isolation transformer in order to avoid damaging circulation currents and to prevent load from

loosing galvanic isolation.

NOTICE!

Refer to local legal regulation for wiring information.

990-4056

68 Installation Guide APC Silcon 240-320kW 400V UPS

Page 69

System Specifications

7.0 System Specifications

7.1 Technical Data

Voltage 3x380/400/415V

Input Voltage tolerance

Normal operation

Bypass operation

Frequency 50Hz/60Hz

Input power factor load 25% minimum 0.97

Current distortion Max. 5%

Output Voltage 3x380/400/415V

Voltage tolerance ±1% static symmetrical load±

Voltage distortion max. 3% linear load

Load power factor 0.9 lead to 0.8 lag

Frequency 50Hz/60Hz (mains synchronized)

Overload capacity

Mains operation

Mains operation

Battery operation

Bypass operation

General Ambient temperature 0-40°C (Temperatures above 25°C will

Humidity

Protection class

Safety

Emission and Immunity

Static bypass switch

Auto restart

Economy mode

±15%

±10% (standard)

±4, 6, 8% (programmable)

±6 standard

±0.5-8% (programmable)

load 100% minimum 0.99

±3% static symmetrical load

±5% 0-100% load step

max. 6% non-linear load

0.1% free-running

+

200% - 60 seconds

125% - 10 minutes

150% - 30 seconds

125% - continuous

reduce battery lifetime)

Max. 95% non-condensing

IP30

EN 50091-1

CE Mark

EN 50091-2

Built-in

Programmable

Programmable

7.2 Dimensions / Weight

Type Height [mm] Width [mm] Depth [mm] Weight [kg]

240kW 1800 1600 800 1400

320kW 1800 1600 800 1400

990-4056

Installation Guide APC Silcon 240-320kW 400V UPS 69

Page 70

Warranty

8.0 Warranty

8.1 APC Silcon Series Limited Factory Warranty

APC warrants that the unit, when properly installed and commissioned by APC or APC authorized

service personnel, shall be free from defects in materials and workmanship for a period of (1) year

from the date of installation or maximum 18 months after manufacturing. In the event that the unit

fails to meet the foregoing warranty, APC shall for a period of one (1) year repair or replace any

defective parts, without charge for on-site labor and travel if trained & authorized APC personnel

has conducted start-up of the unit.

An APC Start-Up Service must be performed/completed by APC or APC authorized service

personnel or the on-site factory warranty will be voided and replacement of defective parts only will

be covered. APC shall have no liability and no obligation to repair the installed unit if non-authorized

APC personnel performed the start-up and such start-up caused the unit to be defective.

APC SHALL NOT BE LIABLE UNDER THE WARRANTY IF ITS TESTING AND EXAMINATION

DISCLOSE THAT THE ALLEGED DEFECT IN THE PRODUCT DOES NOT EXIST OR WAS

CAUSED BY PURCHASER’S OR ANY THIRD PERSON’S MISUSE, NEGLIGENCE, IMPROPER

INSTALLATION OR TESTING, UNAUTHORIZED ATTEMPTS TO REPAIR OR MODIFY, OR ANY

OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE, OR BY ACCIDENT, FIRE,

LIGHTNING OR OTHER HAZARD.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, BY OPERATION OF LAW OR

OTHERWISE, OF PRODUCTS SOLD, SERVICED OR FURNISHED UNDER THIS AGREEMENT

OR IN CONNECTION HEREWITHIN. APC DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY, SATISFACTION AND FITNESS FOR A PARTICULAR PURPOSE. APC’S

EXPRESS WARRANTIES WILL NOT BE ENLARGED, DIMINISHED, OR AFFECTED BY AND NO

OBLIGATION OR LIABILITY WILL ARISE OUT OF, APC’S RENDERING OF TECHNICAL OR

OTHER ADVICE OR SERVICE IN CONNECTION WITH THE PRODUCTS. THE FOREGOING

WARRANTIES AND REMEDIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES

AND REMEDIES. THE WARRANTIES SET FORTH ABOVE, CONSTITUTE APC’S SOLE

LIABILITY AND PURCHASER’S EXCLUSIVE REMEDY FOR ANY BREACH OF SUCH

WARRANTIES. APC’S WARRANTIES RUN ONLY TO PURCHASER AND ARE NOT EXTENDED

TO ANY THIRD PARTIES.

IN NO EVENT SHALL APC, ITS OFFICERS, DIRECTORS, AFFILIATES OR EMPLOYEES BE

LIABLE FOR ANY FORM OF INDIRECT, SPECIAL, CONSEQUENTIAL OR PUNITIVE

DAMAGES, ARISING OUT OF THE USE, SERVICE OR INSTALLATION, OF THE PRODUCTS,

WHETHER SUCH DAMAGES ARISE IN CONTRACT OR TORT, IRRESPECTIVE OF FAULT,

NEGLIGENCE OR STRICT LIABILITY OR WHETHER APC HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES.

990-4056

70 Installation Guide APC Silcon 240-320kW 400V UPS

Page 71

Appendix

Main Input

Breaker

Field

Wiring*

Battery Bank**

UPS Module

Service Bypass Panel

Field

Wiring

Output

Breaker

*

** Internal Batteries available for 40kW units and smaller

*

*

Q1

Q2

Q3

* Not supplied by APC

9.0 Appendix

9.1 Table 1. Installation Planning Data

Installation Planning Data

APC Silcon Series