Page 1

AIS® 3000

10-30kVA

208V

Site Preparation and

Installation Manual

Page 2

Page 3

AIS® 3000 10-30kVA 208V

Site Preparation and Installation Manual

w

w

w

w

w

w

.a

.a

p

p

c

c

.c

.c

o

o

m

m

ww

w

ww

w

.apc.com

.apc.com

IMPORTANT SAFETY INSTRUCTIONS

– SAVE THESE INSTRUCTIONS

This manual contains important instructions for the ISVT series that should be

followed during installation and maintenance of the UPS and batteries.

Page 4

Page 5

Contents

Introduction ............................................................1

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warning/note symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Environmental symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

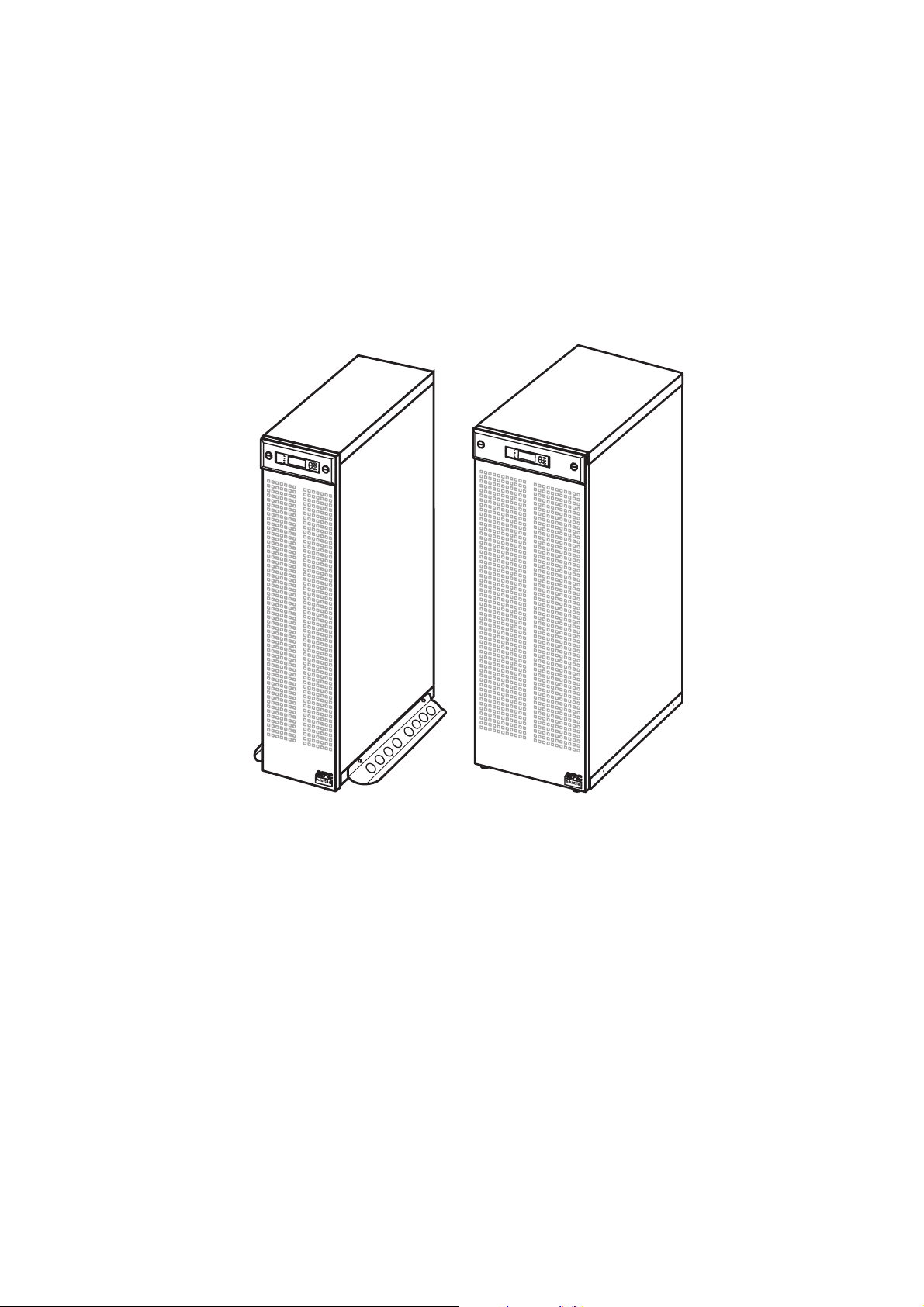

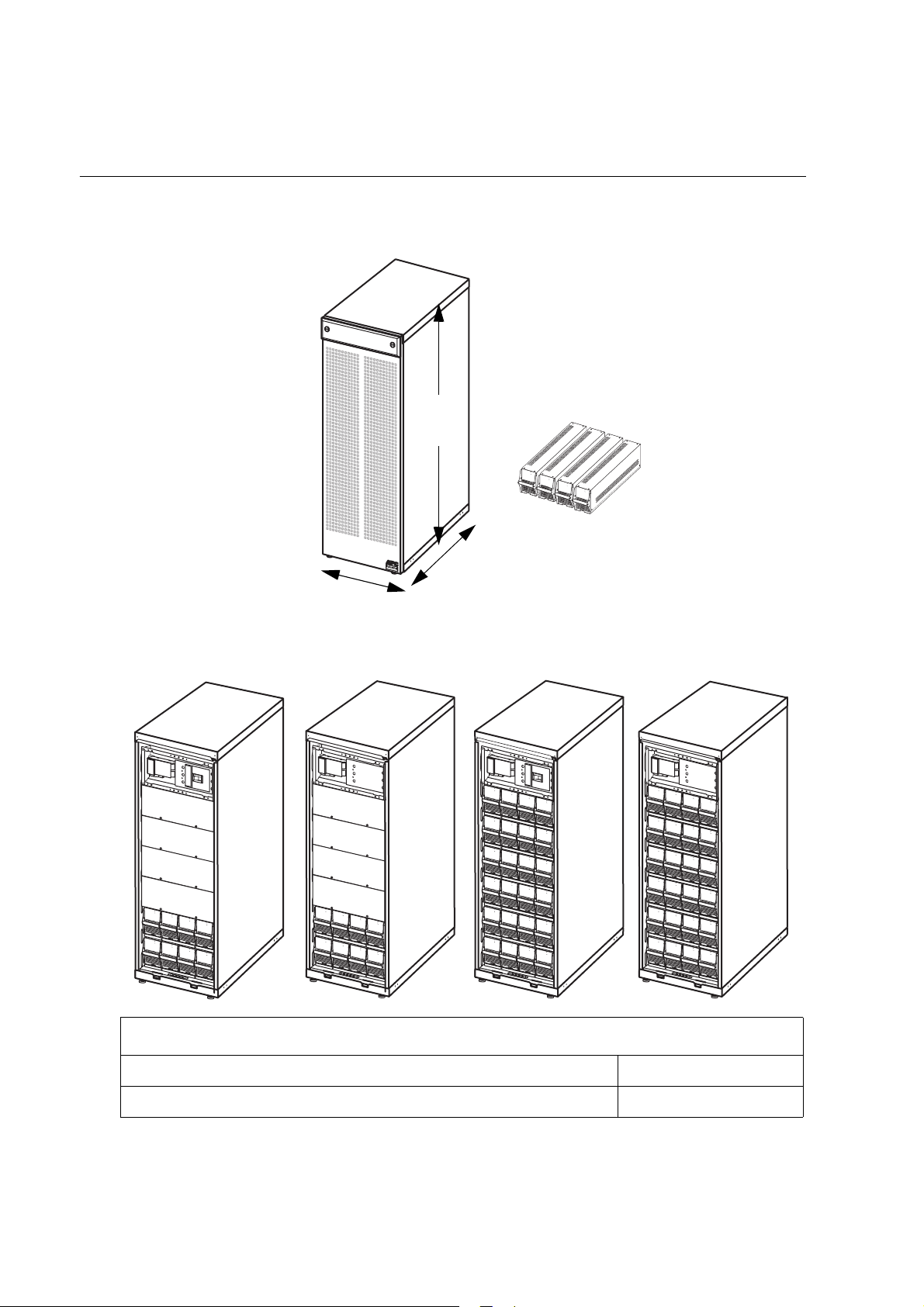

UPS Family Range and Components . . . . . . . . . . . . . . . . . . . . . 3

13.85in/352mm Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

20.59in/523mm Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System sizes, part nos., number of Battery Modules and

weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Part number coding: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conduit Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Stabilizing Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Extended Run Battery Enclosure (XR Enclosure) and

Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Part Numbers for XR Enclosures . . . . . . . . . . . . . . . . . . . . . . . . 9

Part Number for Battery Module . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance Bypass Panels with Power Distribution Capability . 9

Floor anchoring and battery securing equipment . . . . . . . . . . 10

Site Preparation (UPS and XR) ................................11

Installation Space Requirements . . . . . . . . . . . . . . . . . . . . . . . 11

Clearance for 20.59in/523mm Enclosures . . . . . . . . . . . . . . . . 11

Clearance for 20.59in/523mm Enclosures in installations

including an XR Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Clearance for stand-alone 13.85in/352mm Enclosures . . . . . . . 13

Clearance for 13.85in/352mm Enclosures in installations

including XR Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 i

Page 6

Floor Anchoring Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Drilling floor holes for floor anchoring . . . . . . . . . . . . . . . . . . . 15

Hole positions for floor anchors (stand-alone Enclosures) . . . . . 15

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Heat dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Audible noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Recommended source connections . . . . . . . . . . . . . . . . . . . . . 18

Recommended current protection . . . . . . . . . . . . . . . . . . . . . . 19

Minimum setting of breakers for 10kVA UPS . . . . . . . . . . . . . . 20

Minimum setting of breakers for 15kVA UPS . . . . . . . . . . . . . . 20

Minimum setting of breakers for 20kVA UPS . . . . . . . . . . . . . . 21

Minimum setting of breakers for 30kVA UPS . . . . . . . . . . . . . . 21

Recommended phase-conductor sizes [AWG] for a 86°F

(30°C) temperature environment . . . . . . . . . . . . . . . . . . . . . . . 22

EPO switch wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Basic Wiring Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical Installation ............................................ 25

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Total-Power-Off Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System-Electrical Information . . . . . . . . . . . . . . . . . . . . . . . . . 29

Source connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input/Output Wiring – Single Mains (default) . . . . . . . . . . . . . 32

Wiring procedure - single mains . . . . . . . . . . . . . . . . . . . . . . . 32

Input/Output Wiring – Dual Mains . . . . . . . . . . . . . . . . . . . . . 34

Wiring procedure - dual mains . . . . . . . . . . . . . . . . . . . . . . . . . 34

ii AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 7

Communication Wiring to EPO and Optional Equipment . . . . 36

Pin connections J106 (XR Enclosure) and J108 (EPO) . . . . . . . 37

Pin connections J106 (UPS) to J200 (XR Enclosure - option) . . . 37

XR Enclosure, APC MBP, and Generator Control wiring . . . . . . 38

Pin connections J108 (for EPO wiring options) . . . . . . . . . . . . 39

General Charge Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Charge setting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Leveling Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting the leveling feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Floor Anchoring (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Battery securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wiring Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 44

Installation Site Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

LIMITED FACTORY WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . 47

APC product covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Terms of warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Non-transferable warranty extends to first purchaser for use . . 47

Assignment of warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Drawings, descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Warranty claims procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 iii

Page 8

Page 9

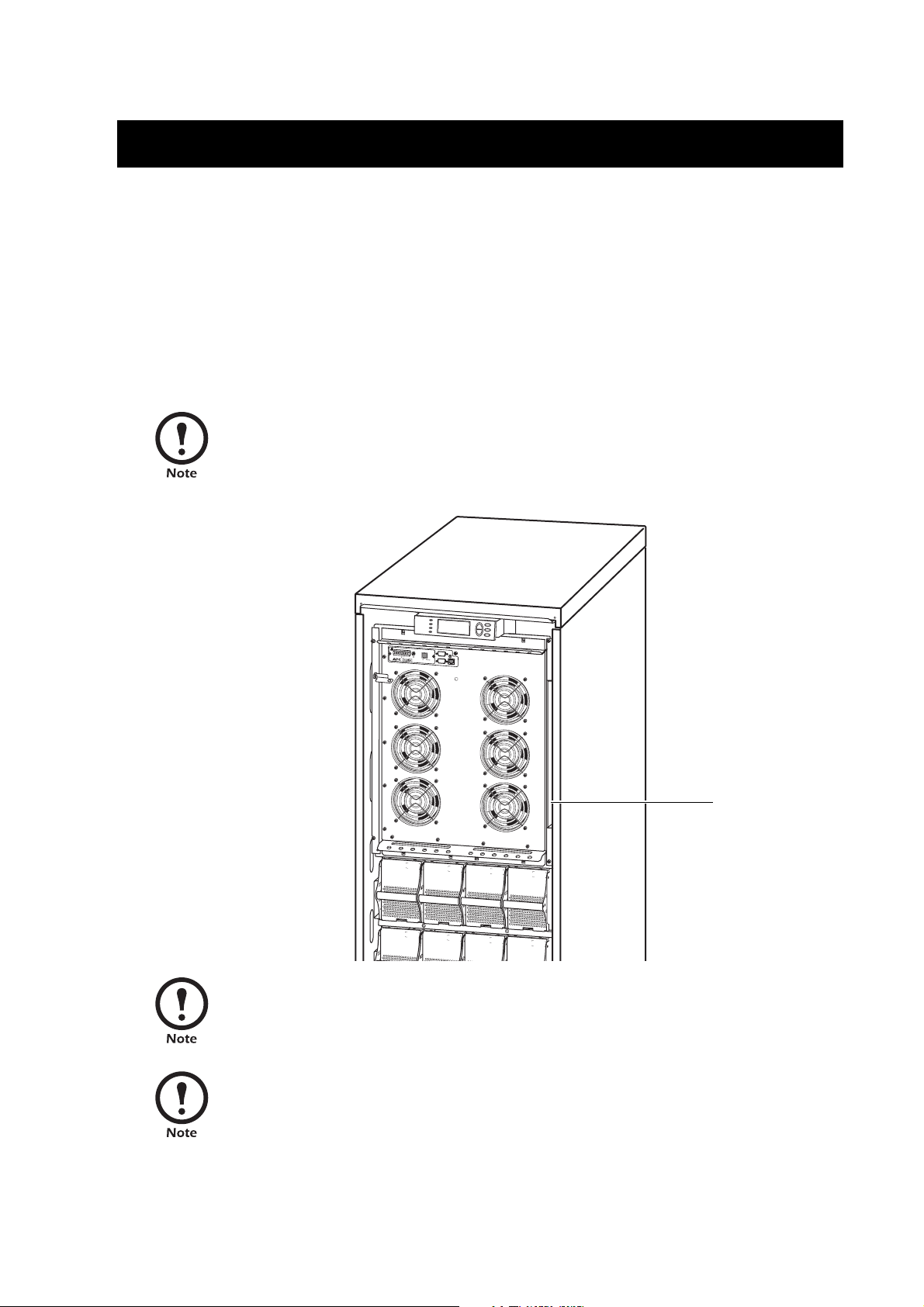

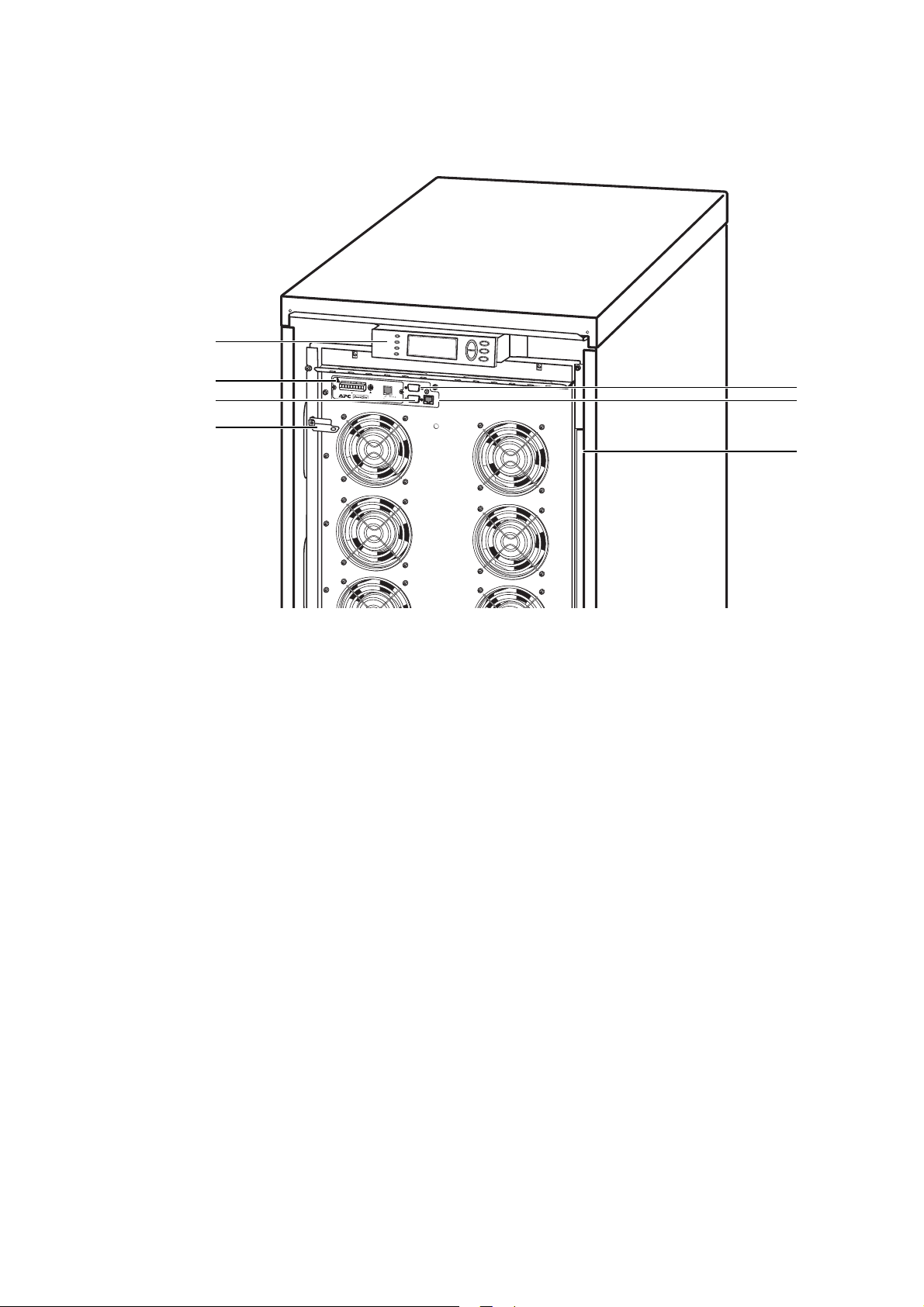

Introduction

Welcome to the Site Preparation and Installation Manual for the AIS® 3000. This manual contains

information on how to prepare your site for the installation of the UPS and optional APC equipment

(also available at www.apc.com) and instructions on how to carry out the electrical and mechanical

installation.

Separate manuals are available on:

• Receiving and Unpacking - part # 990-1961

• Operation - part # 990-1962

The user manuals are provided in the documentation storage area at the top right corner

on the UPS (behind the Front Panel).

O

u

tp

u

t

P

w

r

!

Z

o

n

e

P

ro

b

e

1

0

/1

0

0

B

a

s

e

-T

R

eset

1

0

/1

0

0

A

P

9

6

1

9

N

e

t

w

o

rk

M

a

n

a

g

e

m

e

n

t

C

a

r

d

E

M

Documentation

storage

S

e

r

ia

l

:

M

o

d

e

l:

S

e

r

ia

l

:

M

o

d

e

l:

BATTERY UNIT

S

e

r

ia

M

o

d

BATTERY UNIT

l

:

e

l

:

S

e

r

M

o

d

BATTERY UNIT

BATTERY UNIT

ia

l

:

e

l:

S

e

M

o

S

e

r

M

o

d

BATTERY UNIT

r

ia

l:

d

e

l:

BATTERY UNIT

ia

l:

e

l

:

S

e

M

o

S

e

r

M

o

d

BATTERY UNIT

r

ia

l

:

d

e

l

:

BATTERY UNIT

i

a

l:

e

l

:

For more information on APC products and services, visit us at www.apc.com

Most illustrations show 20.59in/523 mm Enclosures but apply to both Enclosure sizes.

Any differences between the two Enclosure sizes will be addressed in the manual.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 1

Page 10

General Safety Instructions

This guide contains important instructions that should be followed when handling the UPS, Battery

Enclosures, and Batteries.

Warning/note symbols

WARNING!

Risk of electric shock.

CAUTION!

Read this information to avoid equipment damage.

Indicates important information.

Indicates that more information is available on this subject in a different section of this

manual.

Indicates that more information is available on the same subject in a different manual.

Environmental symbols

Temperature Ventilation

Humidity Dust/Fumes Altitude

requirements

2 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 11

UPS Family Range and Components

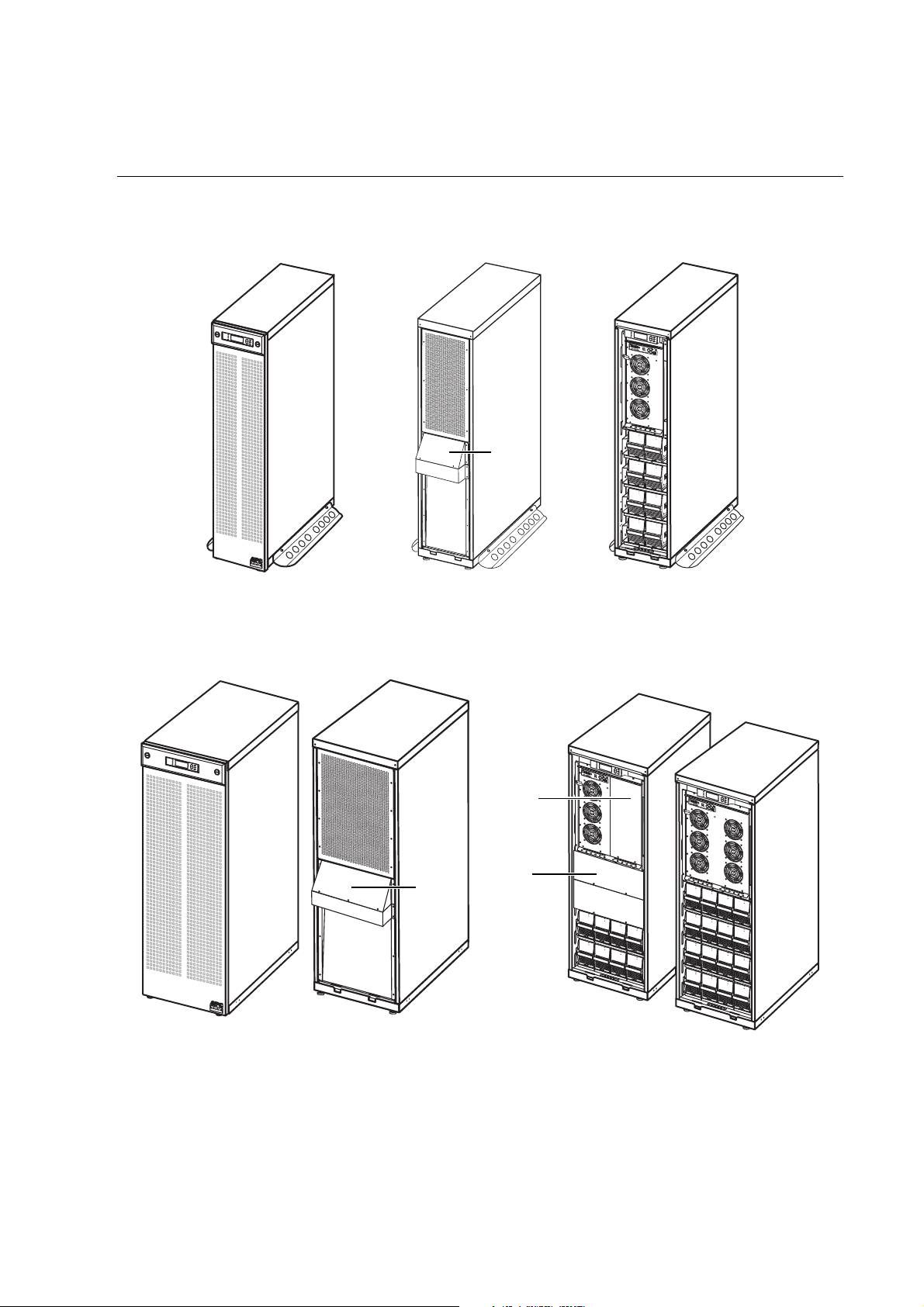

13.85in/352mm Enclosures

!

O

u

t

p

u

t

P

w

r

Z

o

n

e

P

r

o

b

e

1

0

/

1

0

0

B

a

s

e

T

R

e

s

e

t

1

0

/

1

0

A

0

P9

61

9

Ne

tw

or

k

Ma

na

gem

e

nt C

ar

d

E

M

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TERY

U

NIT

S

e

r

i

a

l

:

M

o

d

e

l

Conduit

Box

www.apc.com

www.apc.com

Front view Rear view Front view without cover

:

B

A

T

TE

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TTE

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

10-15kVA

RY

UN

I

T

RY

U

N

IT

R

Y

U

N

I

T

R

Y

U

N

I

T

20.59in/523mm Enclosures

www.apc.com

www.apc.com

Front view Rear view

Conduit

Box

Blin d plate

covers

any em pty

Power

Module bay

Blind plates

cover

any empty

battery bays

!

O

u

t

p

u

t

P

w

r

Z

o

n

e

P

r

o

b

e

1

R

0

/

e

1

s

0

e

0B

t

a

s

e

T

A

P

9

6

1

9

N

e

tw

1

0

o

/

1

r

k

0

M

0

a

n

a

g

e

m

e

n

t

C

a

r

d

E

M

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

od

el

:

B

A

T

T

E

R

Y

U

N

I

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

el

:

B

A

T

T

E

R

Y

U

N

I

T

Front view without co ver

10-15kVA

!

O

u

t

p

u

t

P

w

r

Z

o

n

e

P

r

o

b

e

1

R

0

/

e

1

s

0

e

0

t

B

a

s

e

T

A

P

96

1

9

N

e

t

1

w

0

o

/

1

r

k

0

M

0

a

n

a

g

e

m

en

t

C

a

r

d

E

M

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TT

E

RY

U

NIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

ERY

U

NIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

AT

T

E

R

Y

U

NI

T

S

e

r

i

a

l

:

M

o

d

e

l:

B

A

T

TERY

U

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

T

TE

R

Y

UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TE

RY

UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

AT

T

E

RY

UN

IT

NIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TE

R

Y

UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

T

TE

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

AT

TERY

UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TE

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

T

TE

RY

UN

IT

S

e

r

i

a

l

:

M

o

d

el

:

B

A

TTER

Y

U

NIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TE

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

TE

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

el

:

B

A

TT

ER

Y

U

NIT

Front view without cover

20-30kVA

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 3

Page 12

Introduction – UPS Family Range and Components

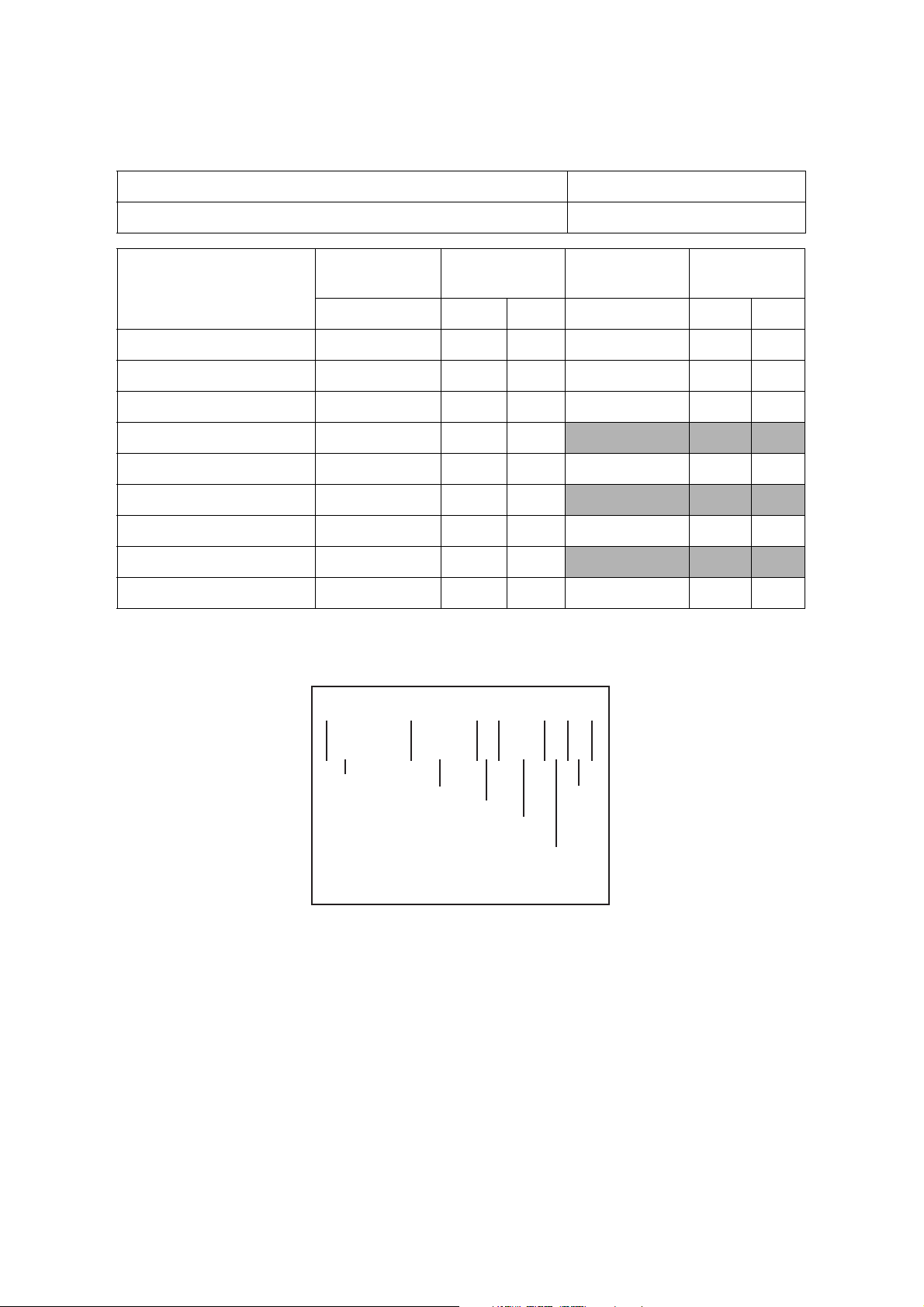

System sizes, part nos., number of Battery Modules and weights

Height (identical for all Enclosure sizes) 58.66in/1490mm

Depth (identical for all Enclosure sizes) 33.62in/854mm

System Size/ Enclosure

width

10kVA 13.85in/352mm ISVT10KF1B2S 678.8 308.7 ISVT10KF2B2S 889.9 404.7

10kVA 20.59in/523mm ISVT10KF1B4S 759.4 345.4 ISVT10KF2B4S 970.5 441.4

10kVA 20.59in/523mm ISVT10KF3B4S 1181.6 537.4 ISVT10KF4B4S 1392.7 633.4

15kVA 13.85in/352mm ISVT15KF2B2S 889.9 404.7

15kVA 20.59in/523mm ISVT15KF2B4S 970.5 441.4 ISVT15KF3B4 1181.6 537.4

15kVA 20.59in/523mm ISVT15KF4B4S 1392.7 633.4

20kVA 20.59in/523mm ISVT20KF2B4S 1037.9 472.0 ISVT20KF3B4S 1249.0 568.0

20kVA 20.59in/523mm ISVT20KF4B4S 1460.1 664.0

30kVA 20.59in/523mm ISVT30KF3B4S 1251.2 569.0 ISVT30KF4B4S 1462.3 665.0

Part number coding:

Installed

weight

Installed

weight

APC Part No. lbs kg APC Part No. lbs kg

ISVT10KF1B2S

ISVT 10K F 1B 2* S

Product

kVA

Voltage

1 Batt.

Module

*) 4 = max. 4 Battery Modules

With

start-up

service

Max.

2 Batt.

Modules

4 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 13

Introduction – UPS Family Range and Components

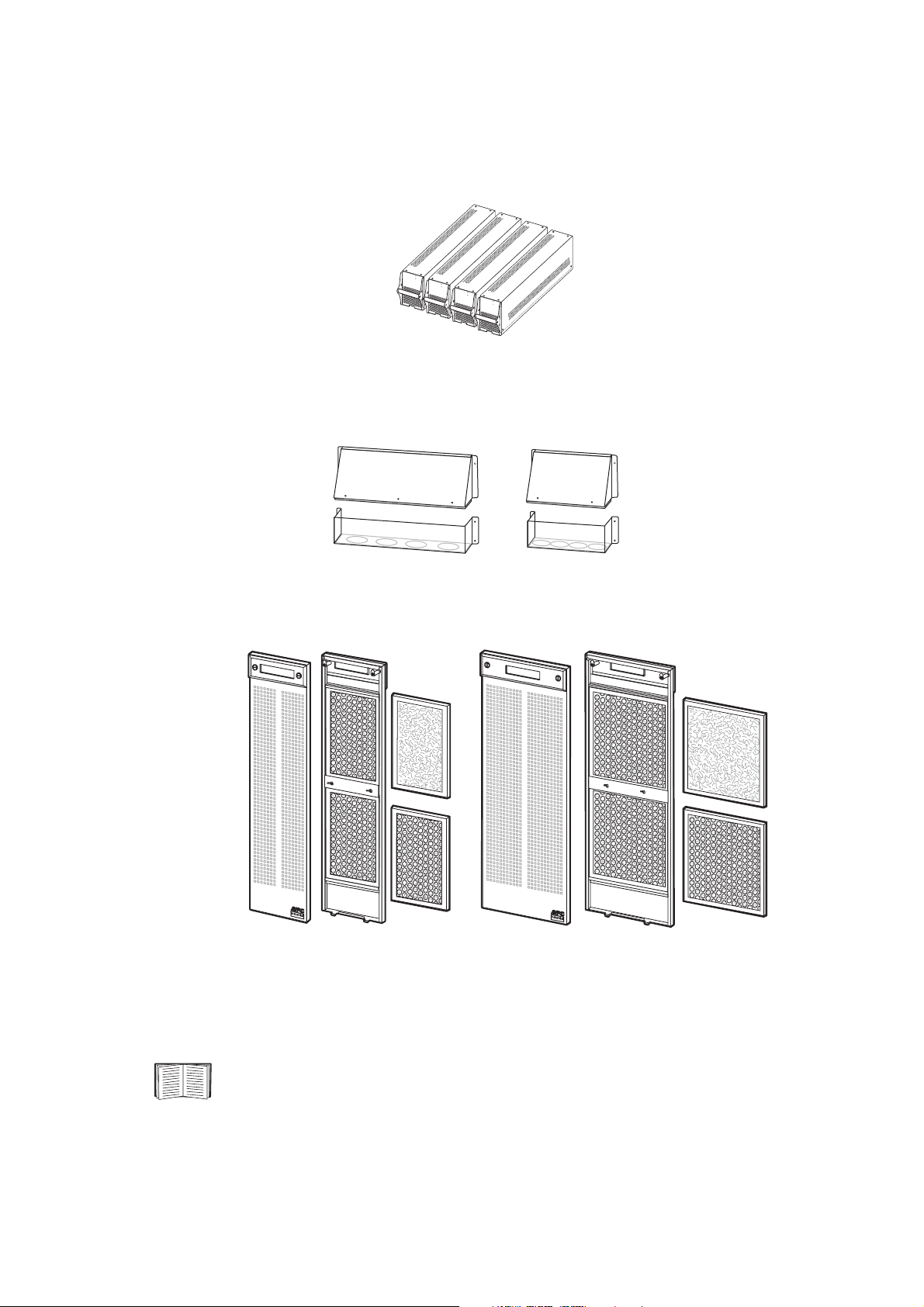

Battery Module

One Battery Module consists of 4 Battery Units (shipping in the UPS Enclosure).

S

e

r

i

a

l

:

Mo

del:

BATT

ERY

UNIT

S

e

ri

a

l

:

Mo

del:

B

ATT

ERY

UNIT

S

e

r

ia

l

:

Mo

del:

B

ATTER

Y UN

IT

S

e

r

i

a

l

:

Mo

d

el:

B

ATT

ERY

UNIT

4 x 52.8lb / 4 x 24kg

Conduit Box

Conduit Box for

20.59in/523mm

Enclosure

Front Panel overview

Conduit Box for

13.85in/352mm

Enclosure

www.apc.com

www.apc.com

Front Panel

for 13.85in/

352mm

Enclosure

13.85in/

352mm

Enclosure

from rear

with filters

Filter seen

from front

and rear

Front Panel

for 20.59in/

523mm

Enclosure

www.apc.com

www.apc.com

20.59in/

523mm

Enclosure

from rear with

filters

Filter seen

from front

and rear

Front Panel attachment procedure described in the Front Panel section.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 5

Page 14

Introduction – UPS Family Range and Components

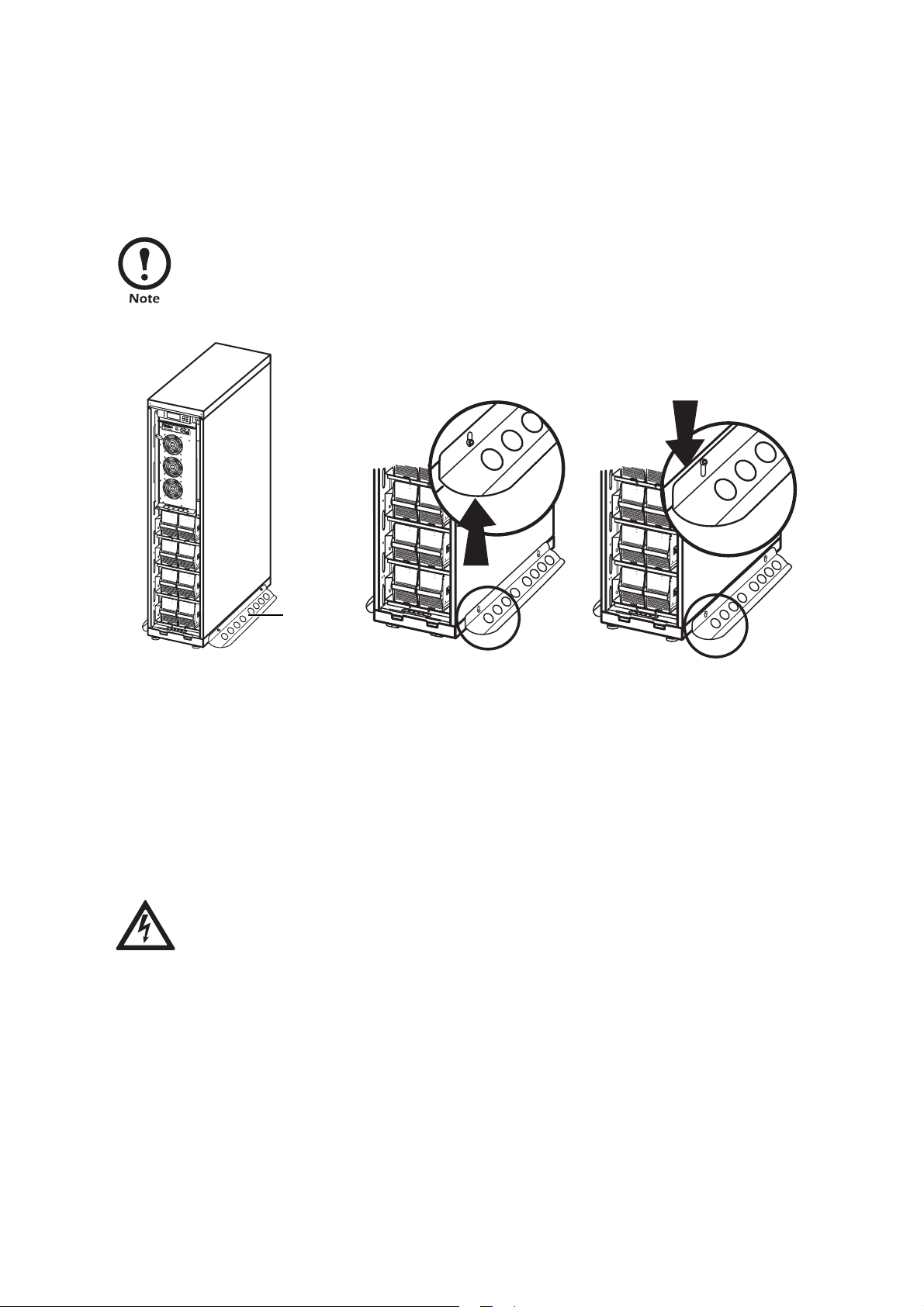

Stabilizing Bracket

Always install the Stabilizing Brackets on the 13.85in/352mm Enclosure (shipped with the UPS) to

enhance the stability of the Enclosure.

In non-seismic areas, it is not necessary to bolt the Stabilizing Bracket to the floor.

Attach the Stabilizing Bracket to the UPS Enclosure only, re-using the screws used to

secure the UPS to the pallet during shipment.

!

O

u

t

p

u

t

P

w

r

Z

o

n

e

P

r

o

b

e

1

0

/

1

0

0

B

a

s

e

T

R

e

s

e

t

1

0

/

1

0

A

0

P

9

6

1

9

Ne

t

wo

r

k

M

an

a

g

em

e

nt

C

ar

d

EM

S

e

ria

l

:

M

od

el

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ri

a

l

:

M

o

d

e

l:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

BATTERY UNIT

S

e

r

i

a

l

:

M

o

d

e

l

:

BATTERY UNIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BATTERY UNIT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

Stabilizing

S

e

ri

a

l:

M

o

d

el

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l:

M

o

d

el

:

B

A

T

T

E

R

Y

U

N

I

S

T

e

r

i

a

l:

M

o

d

e

l:

B

A

T

T

E

R

Y

U

N

IT

S

e

ri

al

:

M

o

d

el:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

ia

l:

M

od

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

er

i

a

l:

M

od

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

ia

l

:

M

od

el

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

ia

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

T

Bracket

If the Enclosure needs to be moved after Stabilizing Brackets have been attached to the Enclosure,

the Stabilizing Brackets must be pushed up into their high position.

Loosen the two screws of both Stabilizing Brackets, and push the bracket up into the high

position.

When the Enclosure has reached its new position, push the Bracket into its “down” position

again, and tighten the screws.

WARNING!

For stability reasons, do not remove Stabilizing Brackets from 13.85in/352mm

Enclosures.

6 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 15

User interface

Introduction – UPS Family Range and Components

O

ut

p

u

t

P

w

r

!

Z

o

n

e

P

r

o

be

1

0

/1

0

0

B

as

e

-T

R

e

s

e

t

1

0

/10

0

A

P

9

6

1

9

N

e

tw

o

r

k

M

a

n

a

g

e

m

e

n

t

C

a

rd

E

M

Display: user-control interface used to configure the functionality, monitor the system, set alarm

thresholds, and to provide audible and visual alarms.

Network Management Card with Environmental Monitor (AP9619): used for remote system

control and monitoring, e-mail notifications etc. See separate manual for the AP9619.

®

Computer-interface port for the connection of computers with APC Powerchute

Mechanical bypass lever: used to bypass the upstream utility power around the UPS to support

software.

the load directly = internal mechanical bypass operation.

Service port (for APC maintenance personnel only).

Display port for the connection of display communication cable.

Documentation storage.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 7

Page 16

Options

Extended Run Battery Enclosure (XR Enclosure) and Battery Module

XR Enclosure with Front Panel

XR Enclosure with DC

Breaker, fuses and 2

Battery Modules

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

er

ial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

T

S

erial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

erial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

20.59in / 523mm

XR Enclosure with

DC fuses only

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

S

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

Se

rial:

M

o

d

e

l

:

B

A

T

T

E

R

58.66in/

Battery Module

1490mm

S

e

r

ia

l:

M

o

d

e

l

:

B

A

T

TE

R

Y

UN

IT

S

e

r

i

a

l

:

M

o

d

e

l:

B

A

T

T

E

RY

UN

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

TT

E

R

Y

U

NI

T

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TT

E

R

Y

U

N

IT

www.apc.com

www.apc.com

33.62in/

854mm

XR Enclosure with DC

Breaker, fuses

and 6 Battery Modules

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

e

ria

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

ri

a

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

Se

T

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

e

ri

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

ial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

Y

U

N

I

S

T

e

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Y

U

N

I

S

T

e

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

T

S

eri

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

T

S

er

ial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

e

ri

al

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

er

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

er

i

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ri

al

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

erial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

Se

T

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ri

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

XR Enclosure with

DC fuses only

Se

r

ial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

Se

T

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

ial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

Se

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

Se

ri

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

Se

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

eri

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

T

S

e

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

Se

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

eri

a

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ria

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

al

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

er

ial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

ia

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

er

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

ri

al:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

erial

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

Se

ria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

rial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

S

T

eria

l:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

XR Enclosure weights:

2 Battery Modules 903.3lbs / 410.8kg

6 Battery Modules (4 of the modules are shipped separately on a pallet) 1747.8lbs / 794.8kg

8 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 17

Battery Module weight

4 units = 1 Battery Module 4x52.8lb / 4x24kg

Part Numbers for XR Enclosures

XR Enclosure

Enclosure with 2 Battery Modules (expandable to 6), and DC breaker: ISVTBXR2B6S

Enclosure with 2 Battery Modules (expandable to 6), without DC breaker: ISVTXR2B6S

Enclosure with 6 Battery Modules, and DC breaker: ISVTBXR6B6S

Enclosure with 6 Battery Modules, without DC breaker ISVTXR6B6S

Part Number for Battery Module

Introduction – Options

Battery Module

Battery Module SYBT4

Maintenance Bypass Panels with Power Distribution Capability

Further details on APC Maintenance Bypass Panel (MBP) with Power Distribution

Capability are available on www.apc.com.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 9

Page 18

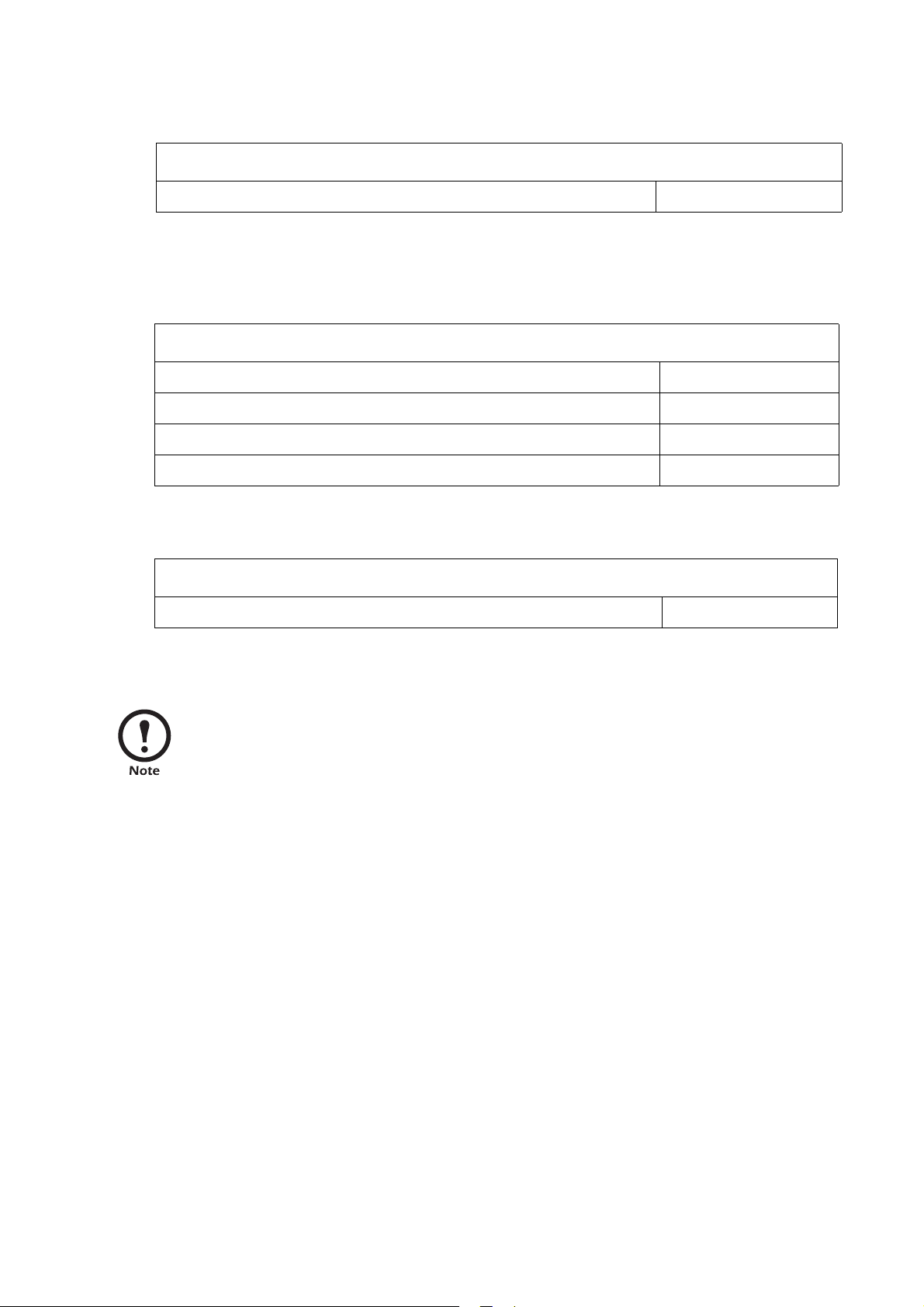

Introduction – Options

MBP (wall-mount)

37.36in/

949mm

29.53in/ 750mm

7.48in/190mm

The Maintenance Bypass Panel provides overcurrent protection to the entire UPS system. It is also

used to bypass the utility power around the UPS instead of through the system, e.g. when UPS

maintenance is carried out.

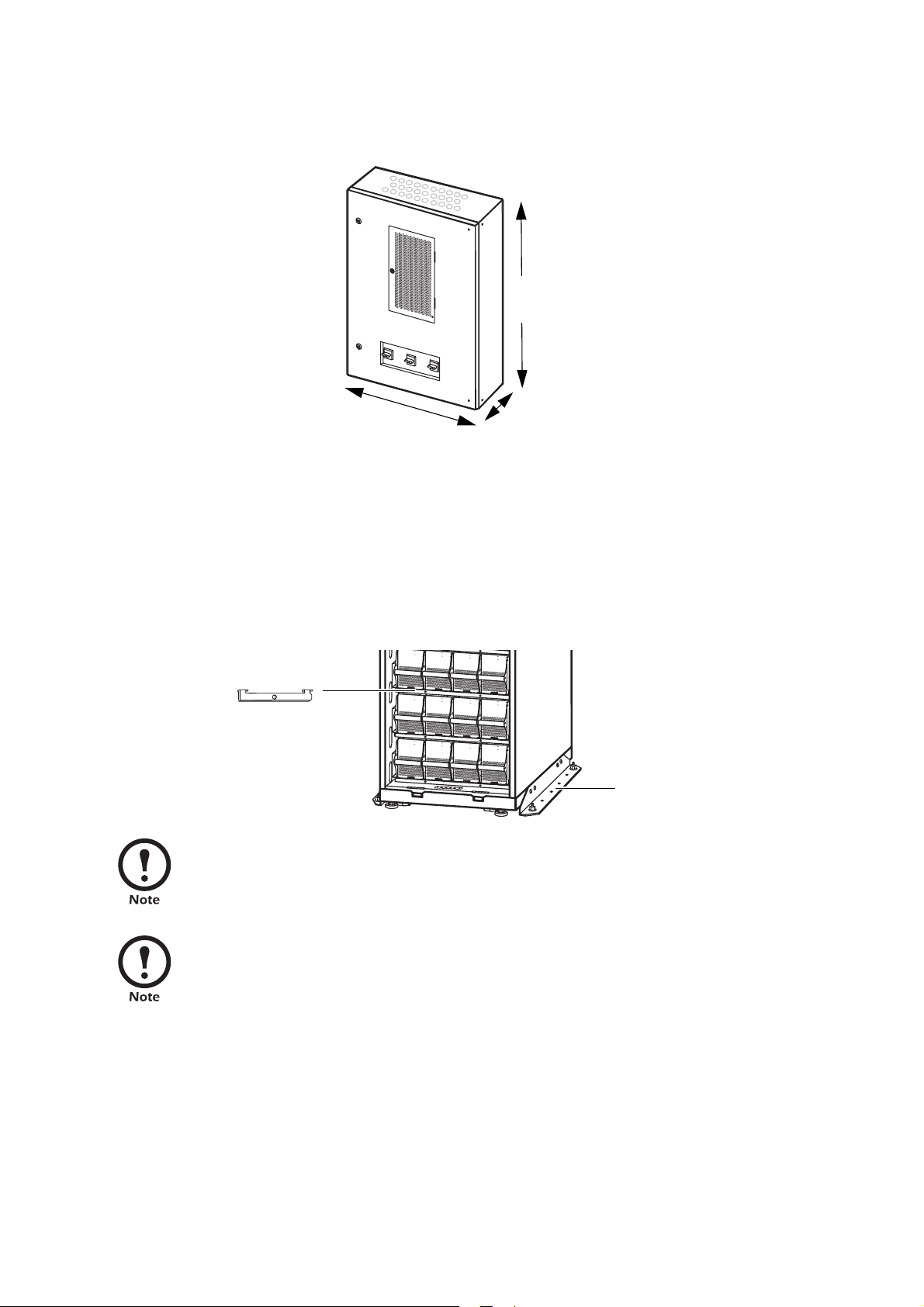

Floor anchoring and battery securing equipment

In seismic areas, each Battery Module must be secured with a Battery Securing Bracket.

S

erial:

M

o

d

e

l

:

Serial:

M

o

d

e

l

:

Serial:

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

Serial:

M

o

d

e

l

:

N

I

T

B

A

T

T

E

R

Y

U

Serial:

M

o

d

e

l:

N

I

T

B

A

T

T

E

R

Y

U

Serial:

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

I

T

Serial:

M

o

d

e

l

:

Serial:

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

I

T

Se

rial:

M

o

d

e

l

:

Serial:

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

I

T

Reuse transport

brackets as Floor

Anchoring Brackets

Battery Securing Bracket

B

A

T

T

E

R

Y

U

S

erial:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

S

erial:

M

o

d

e

l:

B

A

T

T

E

R

Y

U

Floor-anchoring bolts are not provided with the UPS. Purchase the floor anchors locally.

For more details on optional APC equipment for the AIS® 3000, contact APC Technical

Support in the U.S. at 800-555-2725. For other countries, see technical support numbers

on rear cover.

10 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 19

Site Preparation (UPS and XR)

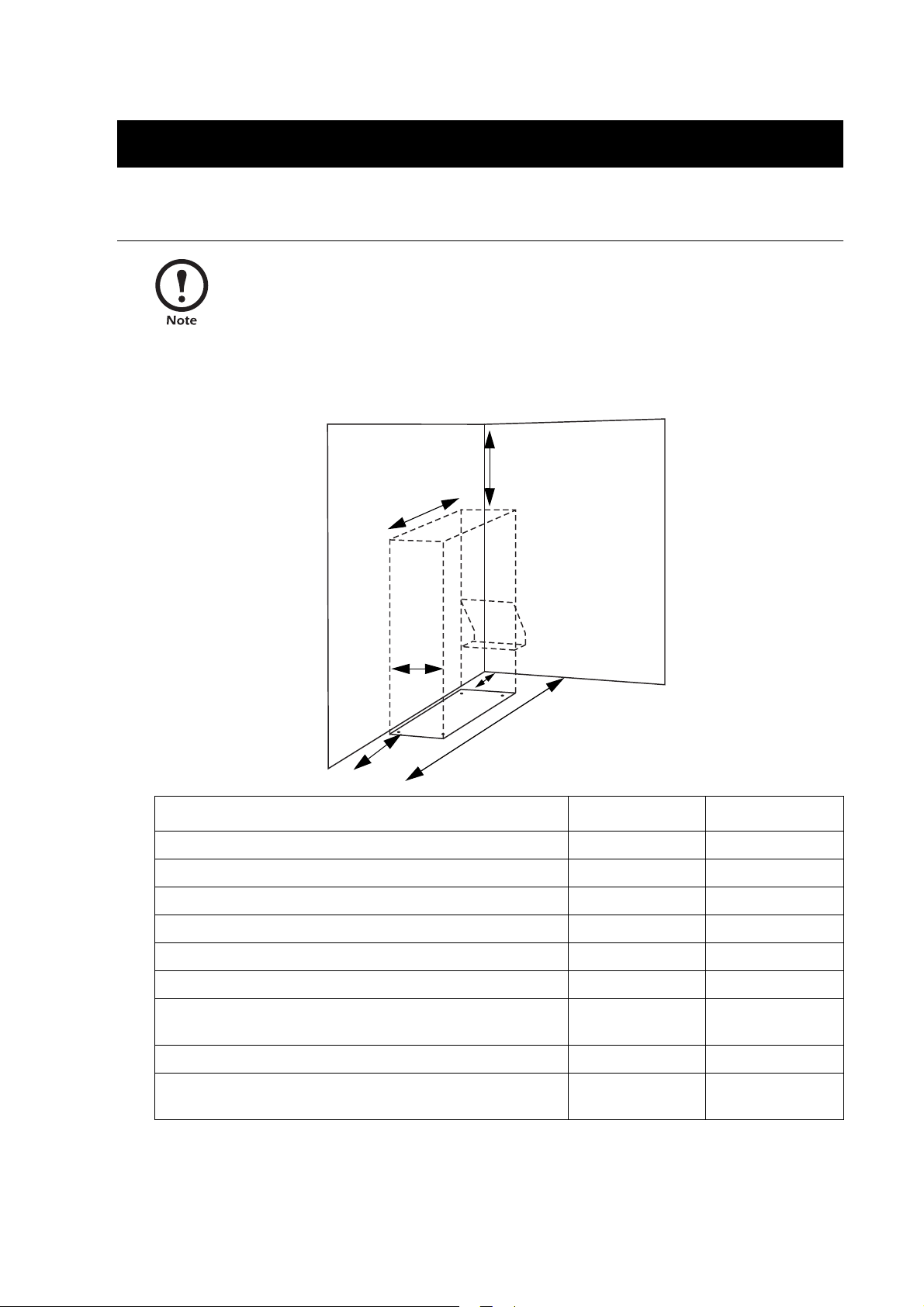

Installation Space Requirements

Allow for enough working space behind the Enclosure for electrical work to be carried

out (e.g. if you want to connect an XR Enclosure at a later stage).

Clearance for 20.59in/523mm Enclosures

(A)

(B)

UPS

Conduit Box (F)

(C)

(E)

Space requirements in mm

Minimum clearance above Enclosure (A) 20 508

Enclosure depth (B) 33.62 854

Enclosure width (C) 20.59 523

Minimum free rear space for ventilation* (D) 4 100

Minimum front clearance (E) 39.37 1000

Conduit Box, depth (F) 3.46 88

No side clearance required (add width of Enclosure Stabilizing

Brackets for floor anchoring if applicable)*

Stabilizing Bracket width 3.34 85

(D)

(G)

00

Total installation depth, inclusive of Front Panel, Conduit Box

and minimum front and rear clearances (G)

*) All physical installations must comply with NEC 110.26.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 11

80.39 2042

Page 20

Site Preparation (UPS and XR) – Installation Space Requirements

Clearance for 20.59in/523mm Enclosures in installations including an XR Enclosure

As floor anchoring is carried out prior to wiring (and to busbar connection between UPS

and XR Enclosures if applicable), allow for sufficient working space behind the unit for

electrical work to be carried out (including busbar connections between Enclosures if

applicable).

(A)

(B)

UPS

(C)

XR

Conduit Box (F)

(D)

(C)

(G)

(E)

Space requirements in mm

Minimum clearance above Enclosures (A) 20 508

Enclosure depth (B) 33.62 854

Enclosure width (C) 20.59 (x 2) 523 (x 2)

Minimum free rear space for ventilation* (D) 4 100

Minimum front clearance (E) 39.37 1000

Conduit Box, depth (F) 3.46 88

No side clearance required (include width of Stabilizing Bracket

00

for floor anchoring if applicable)*

Stabilizing Bracket width 3.34 85

Total installation depth, inclusive of Front Panel, Conduit Box

80.39 2042

and minimum front and rear clearances (G)

*) All physical installations must comply with NEC 110.26.

12 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 21

Site Preparation (UPS and XR) – Installation Space Requirements

Clearance for stand-alone 13.85in/352mm Enclosures

(A)

(B)

UPS

Conduit Box (F)

(C)

(D)

Stabilizing Bracket,

left and right

(E)

(G)

Space requirements in mm

Minimum clearance above UPS (A) 20 508

UPS depth (B) 33.62 854

UPS width 13.85 352

Minimum free rear space for ventilation* (D) 4 100

Minimum front clearance (E) 39.37 1000

Conduit Box, depth (F) 3.46 88

No side clearance required (add width of Stabilizing

00

Bracket for floor anchoring if applicable)*

Stabilizing Bracket width 3.34 85

Total installation depth, inclusive of Front Panel, Conduit

80.39 2042

Box and minimum front and rear clearances (G)

*) All physical installations must comply with NEC 110.26.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 13

Page 22

Site Preparation (UPS and XR) – Installation Space Requirements

Clearance for 13.85in/352mm Enclosures in installations including XR Enclosures

(A)

(B)

UPS

(C1)

XR

(C2)

(D)

(E)

Conduit Box (F)

(G)

Space requirements in mm

Minimum clearance above Enclosures (A) 20 508

Enclosure depth (B) 33.62 854

Enclosure width (C1) 13.85 352

Enclosure width (C2) 20.59 523

Minimum free rear space for ventilation* (D) 4 100

Minimum front clearance (E) 39.37 1000

Conduit Box, depth (F) 3.46 88

No side clearance required (add width of Stabilizing Bracket for

00

floor anchoring if applicable)*

Stabilizing Bracket width 3.34 85

Total installation depth, inclusive of Front Panel, Conduit Box

80.39 2042

and minimum front and rear clearances (G)

*) All physical installations must comply with NEC 110.26.

For the stability of 13.85/352 mm stand-alone Enclosures, the transport brackets (re-use

of brackets used to secure the UPS to the shipping pallet) must always be mounted on

both sides of the UPS. Follow the Floor Anchoring procedures.

14 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 23

Floor Anchoring Preparation

If floor anchoring and battery securing is required in your area, read this section. If not,

proceed to Operating Environment. However, if you install a 13.85in/352mm

Enclosure, it must always be equipped with the Enclosure Stabilizing Bracket for

enhanced stability (not necessary to bolt the Enclosure Stabilizing Bracket to the floor

in non-seismic areas).

Drilling floor holes for floor anchoring

If your UPS installation requires floor anchoring and battery securing, the UPS

installation must be anchored to the floor, re-using the brackets that secured the Enclosure

to the pallets during shipment. For easy determination of where to drill the holes, refer to

the applicable drawings below indicating hole positions and size.

Hole positions for floor anchors (stand-alone Enclosures)

Floor

anchor

hole

Floor

anchor

hole

5.11in/

130mm

5.11in/

130mm

5.11in/

130mm

5.11in/

130mm

5.11in/

130mm

Rear Rear

Top v iew of bottom

plate of 20.59in/523

mm Enclosure

22.63in/575mm 15.9in/404mm

Floor anchor hole

25.59in/650mm

Floor anchor hole

Floor

anchor

hole

Top view of

bottom plate

of 13.85in/352

mm Enclosure

Castor

Floor

anchor

hole

Refer to this drawing for floor anchor positions for 20.59in/523mm Enclosures.

Refer to this drawing for 13.85in/352mm Enclosures.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 15

Page 24

Site Preparation (UPS and XR) – Floor Anchoring Preparation

Recommended minimum number of floor bolts per Enclosure: 4 (1 in each corner).

Recommended floor bolt size: 5/16in/8mm.

Floor Anchoring procedure described in the Installation section of this manual.

16 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 25

Operating Environment

Operating conditions

Install the UPS in an indoor, temperature-controlled area, free of conductive

contaminants.

Temperature

Range:

32° to 104°F /

0° to 40°C

Heat dissipation

Audible noise

Keep Ventilated

Front-to-Rear

Airflow (see

space

considerations)

Relative

Humidity: <95%

Non-condensing

No Conductive

Dust or

Corrosive

Fumes

Altitude derating table:

3000ft/914m: 100% load

4500ft/1371m: 95% load

6000ft/1828m: 91% load

8000ft/2438m: 86% load

10000ft/3048m: 82% load

UPS size BTU/hr at fully charged batteries

10kVA 1,774

15kVA 2,866

20kVA 3,624

30kVA 5,486

10-15kVA 20-30kVA

Audible noise at 100% load:

(measured 1.09yard/1m from the

UPS)

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 17

64dBA 67dBA

Page 26

Site Preparation (UPS and XR) – Operating Environment

Recommended source connections

The UPS must be supplied from a 208Y/120V 4W + GND 60Hz source.

CAUTION!

Verify clockwise phase-rotation (L1, L2, L3) and make sure a neutral connection is

present.

See also Recommended Wiring for a 86°F (30°C) Temperature Environment.

18 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 27

Recommended current protection

AC output over-current protection and AC output disconnect must be provided by the

customer.

Dual/single

mains

Connection 10kVA 15kVA 20kVA 30kVA Notes

configuration

Site Preparation (UPS and XR) – Operating Environment

Single Mains/bypass

input

Dual Mains input 35A breaker

Dual Bypass input 35A breaker

Any Output 35A fast-

35A breaker

(30 kAIC)

(30 kAIC)

(30 kAIC)

acting class

J fuse

60A breaker

(30 kAIC)

60A breaker

(30 kAIC)

60A breaker

(30 kAIC)

60A fast-

acting class

J fuse

80A breaker

(30 kAIC)

80A breaker

(30 kAIC)

80A breaker

(30 kAIC)

80A fast-

acting class

J fuse

125A breaker

(30 kAIC)

125A breaker

(30 kAIC)

125A breaker

(30 kAIC)

125A fast-

acting class

J fuse

1,2

1,2

3,4

Note 1:

If the available fault current of the installation is below 30kA, a lower kAIC-rated breaker can be

used.

Note 2:

For breaker settings, refer to below table listing available overload currents.

Note 3:

If the available fault current of the installation is less than 1200A for the 10kVA and 15kVA UPS

sizes, and below 2300A for the 20kVA and 30kVA UPS sizes, a breaker (of the same value as for the

bypass input) can be used.

Note 4:

Recommended maximum rating of a single-fuse configuration if the internal bypass is to be protected

during a load short-circuit.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 19

Page 28

Site Preparation (UPS and XR) – Operating Environment

Minimum setting of breakers for 10kVA UPS

Overload

Event

Internal fault 2kA 1.7kA 14kA <10ms 1

800%

overload

bypass

operation

150%

overload

normal/battery

operation

125%

overload

normal/battery

operation

Continuously 34A 31A 31A

Mains input Bypass input Output Duration Notes

– 223A 223A 500ms

– – 42A 30s

– – 35A 60s

Note 1: For the output value, the short-circuit-level is indicated.

Minimum setting of breakers for 15kVA UPS

∞

Overload

Event

Internal fault 2.5kA 2.1kA 14kA <10ms 1

800%

overload

bypass

operation

150%

overload

normal/battery

operation

125%

overload

normal/battery

operation

Continuously 51A 46A 46A

Mains input Bypass input Output Duration Notes

– 333A 333A 500ms

– – 63A 30s

– – 52A 60s

∞

Note 1: For the output value, the short-circuit-level is indicated

20 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 29

Minimum setting of breakers for 20kVA UPS

Site Preparation (UPS and XR) – Operating Environment

Overload

Event

Internal fault 4 kA 3.4kA 14 kA <10ms 1

800%

overload

bypass

operation

150%

overload

normal/battery

operation

125%

overload

normal/battery

operation

Continuously 68A 62A 62A

Mains input Bypass input Output Duration Notes

– 444A 444A 500ms

– – 84A 30s

– – 70A 60s

Note 1: For the output value, the short-circuit-level is indicated.

Minimum setting of breakers for 30kVA UPS

∞

Overload

Event

Internal fault 5 kA 4.2 kA 14 kA <10 ms 1

800%

overload

bypass

operation

150%

overload

normal/battery

operation

125%

overload

normal/battery

operation

Continuously 102A 92A 92A

Mains input Bypass input Output Duration Notes

– 667A 667A 500ms

– – 125A 30s

– – 105A 60s

∞

Note 1: For the output value, the short-circuit level is indicated.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 21

Page 30

Site Preparation (UPS and XR) – Operating Environment

Recommended phase-conductor sizes [AWG] for a 86°F (30°C) temperature

environment

UPS/AWG sizes Mains input

[AWG]

10kVA 8 8 1

15kVA 6 6 1

20kVA 4 4 1

30kVA 1 1 1

AC output

[AWG]

DC input

[AWG], 75°C Wire

Use Molex lug type or equivalent, and crimp to manufacturer’s specifications.

Cable Size

[AWG]

12 YA12CL2TC38 MD7-34R W12CVT 0.2in/6mm

8 YA8CL2TC38 MD7-34R W8CVT 0.2in/6mm

6 YA6CL2TC38 MD7-34R W5CVT 0.2in/6mm

4 YA4CL2TC38 MD7-34R W4CVT 0.2in/6mm

Cable Lug Type Crimping Tool Die Terminal Bolt

Diameter

1 YA1CL2TC38 MD7-34R W1CVT 0.2in/6mm

)

WARNING!

At 100% non-liniear load (EN50091-3 standard), the neutral shall be rated for 200%

phase current.

EPO switch wiring

The UPS must be connected to either a dry contact or a 24VDC Emergency Power Off (EPO) switch.

See EPO wiring options in this manual.

22 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 31

Basic Wiring Overview

AC input power

DC power

Communication Interface

AC power (output)

XR Enclosure(s)

(Optional, 4 Max.)

Maintenance

Bypass Panel

(Optional Equipment)

EPO

UPS

Input

power

APC recommends that you request a wiring diagram from the electrician after completed

electrical installation. A wiring diagram is useful for subsequent service and

troubleshooting.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 23

Page 32

Site Preparation Checklist

System components. Have you –

5

5

Site Preparation. Have you –

5

5

Arrival Preparation. Have you –

5

5

determined minimum battery runtime requirement based on load (kW and kVA) and selected the

correct APC XR Enclosures (ISVTBXR2B6S, ISVTXR2B6S, ISVTBXR6B6S, ISVTXR6B6S)

and Battery Unit (SYBT1). Always install a whole Battery Module (4 Battery Units) at a time.

considered Service Program or Extended Warranty plan?

considered correct operating space, floor strength (see Installation Space Requirements), cooling,

and environment (see Operating Environment).

reviewed all electrical work to determine wiring requirements?

verified that space and handling equipment are available to receive the XR Enclosure? (Including

unloading the XR Enclosure from the delivery truck).

scheduled an authorized electrician to install the XR Enclosure?

24 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 33

Electrical Installation

Front Panel

Removal

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TTE

S

e

RY UN

r

i

a

l

:

IT

M

o

d

e

l

:

BA

TT

ERY UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TTE

S

e

RY UN

r

i

a

l

:

IT

M

o

d

e

l

:

B

ATT

ERY

U

NIT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TTE

S

e

RY

r

i

a

l

:

U

NIT

M

o

d

e

l

:

BAT

TE

RY UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

ATT

ERY

S

e

r

i

a

l

:

UN

IT

M

o

d

e

l

:

BA

T

TER

Y U

NIT

www.apc.com

www.apc.com

To remove a Front Panel, use a coin or similar, and turn the 2 black lock devices on either side

www.apc.com

www.apc.com

of the Display in direction of each other to vertical level.

Pull the Front Panel outwards to disengage the locking device at the top of the Enclosure.

Lift the Front Panel free of the two slots at the bottom of the Enclosure.

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 25

Page 34

Electrical Installation – Front Panel

Installation

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TT

ER

S

e

r

i

a

Y

l

:

U

NIT

M

o

d

e

l

:

B

AT

T

ER

Y UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BA

TT

E

S

e

RY

r

i

a

l

:

UN

IT

M

o

d

e

l

:

B

ATT

E

RY

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

BATT

ERY

S

e

r

i

a

l

:

UN

IT

M

o

d

e

l

:

BA

TT

ER

Y UN

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

AT

TER

S

e

r

i

a

Y UN

l

:

IT

M

o

d

e

l

:

B

AT

TERY

UN

IT

www.apc.com

www.apc.com

To install a Front Panel, insert the two guide taps positioned at the bottom of the Front Panel

www.apc.com

www.apc.com

into the two slots at the bottom of the Enclosure.

Push the Front Panel against the Enclosure to engage the locking device at the top of the

Enclosure.

To secure the Front Panel, use a coin or similar to turn the 2 black lock devices on either side of

the Display away from each other (left lock counterclockwise, right lock clockwise) to

horizontal level.

26 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 35

Total-Power-Off Procedure

WARNING!

Risk of electric shock - parts inside the UPS and XR Enclosure are energized from the

battery supply even when the AC power is disconnected. Before electrical installation

begins, follow the Total-Power-Off procedure to completely de-energize the system.

O

u

t

p

u

t

P

w

r

!

Z

o

n

e

P

r

o

b

e

1

0

/

1

0

0

B

a

s

e

T

R

e

s

e

t

1

0

/

1

0

0

A

P

9

6

1

9

N

e

t

w

o

r

k

M

a

n

a

g

e

m

e

n

t

C

a

r

d

E

M

ON

OFF

Utility/Mains

breaker

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

S

e

r

i

a

N

l

:

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

S

e

r

i

a

N

l

:

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

S

e

r

A

i

a

l

:

T

T

E

R

Y

U

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

S

Y

e

r

i

U

a

l

:

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

S

e

r

A

i

a

l

:

T

T

E

R

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

S

e

r

A

i

a

l

:

T

T

E

R

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

S

e

r

A

i

a

l

:

T

T

E

R

Y

U

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

IT

UPS

Set the DC disconnect switch on the XR Enclosure (if available) to the OFF position.

Remove all batteries from the system, or, alternatively, pull out all batteries to the red

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

IT

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

S

e

R

r

i

a

l

:

Y

U

N

I

T

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

B

A

T

T

E

R

Y

U

N

I

T

XR Enclosure

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

IT

S

e

r

i

a

l

:

M

o

d

e

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

S

e

r

i

a

l

:

M

o

d

e

l

:

B

A

T

T

E

R

Y

U

N

I

T

l:

BATTERY UNIT

disconnect line shown on the battery. To ensure solid stability, do not pull batteries out beyond

the red disconnect line unless completely removing them from the Enclosure.

Set the utility/mains breaker to the OFF or LOCKED-OUT position. If the UPS has dual mains

supply, set both supplies to the OFF or LOCKED-OUT position.

Refer to Seismic Anchoring in the Electrical Installation Manual for instructions on how

to remove Seismic Battery Brackets (if applicable).

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 27

Page 36

Electrical Installation – Total-Power-Off Procedure

WARNING!

Correct lock-out procedures at utility/mains breaker must be followed. If necessary,

install a padlock.

28 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 37

System-Electrical Information

WARNING!

All electrical power and power control wiring must be installed by a qualified

electrician, and must comply with local and national regulations for maximum power

rating.

UPS ratings

Input voltage / Bypass voltage (V) 3-phase

Input current (nominal, per phase) (A) 24.6 36.9 49.3 73.9

Maximum input current per phase (continuous, at

minimum mains voltage)

Input current protection for mains source or single

mains supply (external to UPS, not supplied) (A)

Input current protection for bypass source in dual mains

configuration (external to UPS, not supplied) (A)

Input frequency (Hz) range 40-70 40-70 40-70 40-70

Output voltage (on line). (V)

Minimum and maximum values (+/- 1%)

Output current (nominal, per phase) (A) 27.8 43.3 55.5 83.3

Maximum output current

(in bypass only at 110% overload per phase)

10 kVA

8 kW

208Y/

120V

27.1 40.6 54.2 81.3

3x35 3x60 3x80 3x125

35 60 80 125

120/208 120/208 120/208 120/208

30.5 45.8 51.1 91.6

15 kVA

12 kW

3-phase

208Y/

120V

20kVA

16 kW

3phase

208Y/

120V

30 kVA

24 kW

3-phase

208Y/

120V

Bypass input current (A)

(in bypass only at 110% overload, per phase)

Neutral output current (with 100% switch mode load)

(A)

Output current protection (external to UPS, not

supplied) (A)

Output frequency range (Hz) 50/60 50/60 50/60 50/60

DC overcurrent protection and disconnect switch for

external safety:

DC voltage rating of the battery supply

Maximum available short-circuit current

AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957 29

30.5 45.8 51.1 91.6

48.1 74.9 96.0 144.1

40 60 80 125

23

+/- 192

10 kA

35

+/- 192

10 kA

46

+/- 192

10 kA

69

+/- 192

10 kA

Page 38

Electrical Installation – System-Electrical Information

Source connections

WARNING!

The UPS must be supplied from a 208Y/120V 4W + GND 60Hz source.

CAUTION!

Verify clockwise phase-rotation (L1, L2, L3) and make sure a neutral connection is

present.

For recommended source connections, see The Site Preparation section.

CAUTION!

The installation must comply with all local and national codes.

Refer to NEC Articles 310-15, 310-16 for further information.

30 AIS® 3000 10-30kVA, 208V, Site Preparation and Installation Manual – 990-1957

Page 39

Wiring

Make sure the UPS is in its location of use before wiring begins.

CAUTION!