A.O. Smith DB-720 thru 1810 User Manual

ZÁ\o Oo

Meets or exceeds ASHRAE/IES 90.1 b-1989 (1992 requirements) Standards.

FEATURES

ALL NON-FERROUS WATERWAYS - All heat exchanger waterways

are 100% copper and bronze. Heavy duty bronze castings and copper

heat exchanger tubes. Immune to thermal shock. Ideal for hydronic

applications.

OPTIMUM ENERGY HEAT TRANSFER - Double row integral finned

copper heat exchanger provides maximum heat transfer. A. O.

Smith’s self-baffling staggered tube design, assures up to 82%

thermal efficiency.

BRONZE REMOVABLE RETURN BENDS - Easily removable, these

allow access and Inspection of individual tubes. These bronze return

bends offer the optimum protection against corrosion or rust found

in cast iron headers.

GASKETLESS WET SECTION - Unique “o” ring design compresses

and forms a water tight seal outside and away from the combustion

chamber. This isolation allows for years of trouble-free service

without gasket leaks.

DURAMAX STAINLESS STEEL BURNERS - Reliable, safe and

quiet. Protects against corrosion and deterioration found with

aluminized burners. Easy slide out burner tray.

LOW-PROFILE DESIGN - Draft diverter is built-in to provide extra

clearances for those tight retrofit applications. Certified by A.G.A./

C.G.A.

AUTOMATIC SAFE CONTROLS - Highest quality controls assure

dependable operation, require practically no attention. Safety shutoff

of pilot and main burners in the event of pilot failure.

INTERMITTENT IGNITION - Standard on all Dura-Max.

COMPACT DESIGN - This rugged unit incorporates a clean, compact

jacket design. Allows for easy access and disassembly. Cool to the

touch. Approved for combustible floor installations. Gas train is

enclosed inside the cabinet.

OTHER FEATURES

• Manual reset high limit • ASME rated pressure relief valve 50#

(345 kPa) • Factory installed safety flow switch • Redundant safety

gas valve • On/Off switch with indicator light.

OPTIONS

• Thermal Balancer Pump Delay • Panel mounted Inlet/outlet dial

thermometers and pressure gauge • Modulation or dual stage firing

• Right end gas and/or water connections • Cupro-Nickel Heat

Exchanger • Side Wall Vent Kits.

CERTIFICATION - A.G.A., C.G.A., FM, ASME 160 psi (1100 kPa).

If the heat exchanger should fail within 10 years,

under the terms of the warranty, A. O. Smith will

furnish a replacement part; installation, labor,

handling and local delivery extra. THIS OUTLINE

IS NOT A WARRANTY. For complete information,

consult the written warranty or A. O. Smith Water

Products Company.

Warranty does not apply to product installed outside

of the United States of America or its territorial

possessions and Canada.

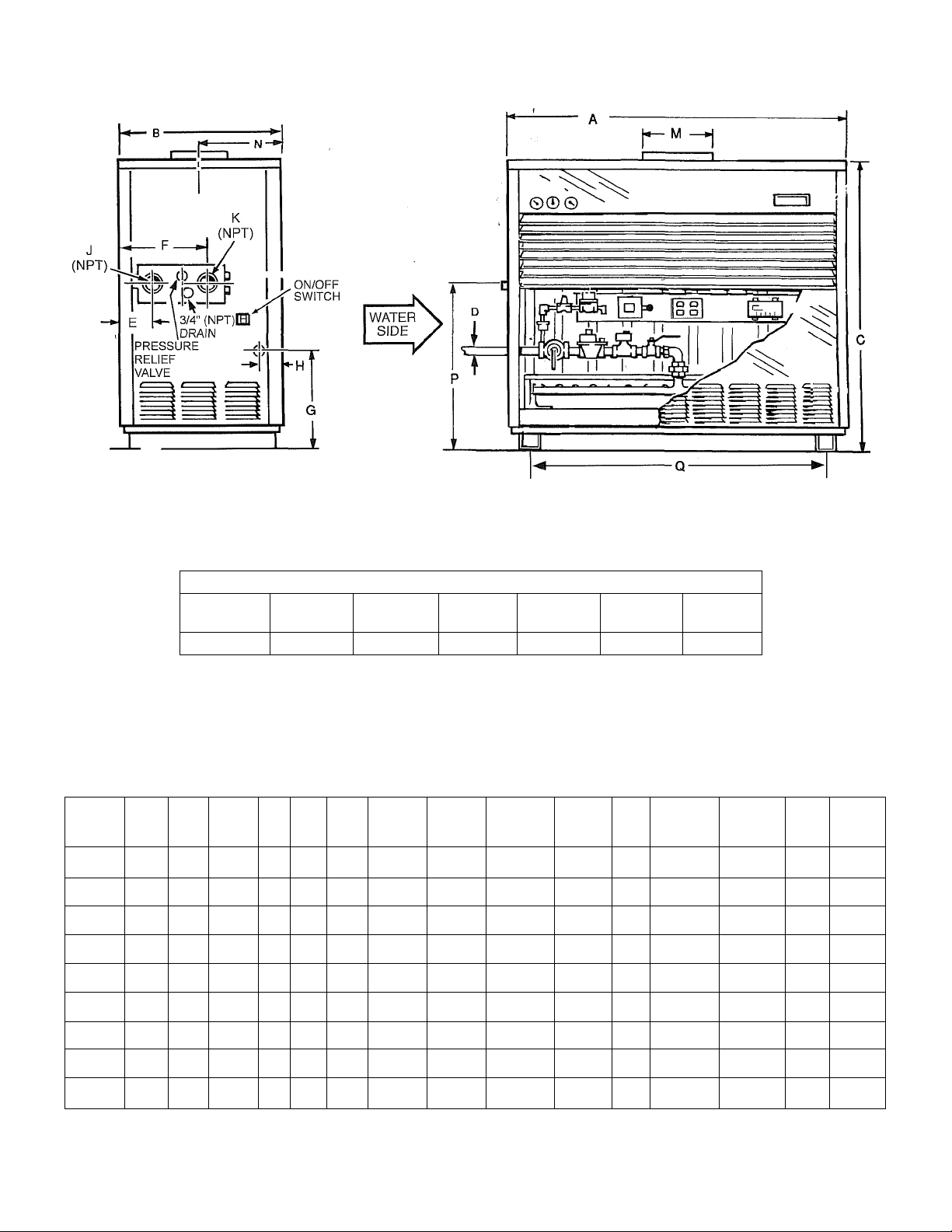

Minimum Clearances To Combustibles In Inches (MM)

Water

Top

Side

All Models 12" (305) 12" (305)

Blank

Side

Rear

6" (152) 6" (152)

Vent Front

6" (152)

Alcove

Additional clearances for service is recommended.

ALL DIMENSIONS IN INCHES (MM)

Model A В

Width Depth

DB-720 46 1/2 29 5/8

DB-840

DB-960 57 3/4 29 5/8

DB-1080

DB-1210 581/2 32 3/4

DB-1350 641/2 32 3/4

DB-1480

DB-1610

DB-1810 82 1/2

(1184) (752)

52 3/16 29 5/8 54 3/4

(1326) (752)

(1467) (752)

52 7/8 32 3/4 58 1 1/4 7 1/2 181/2

(1343) (832) (1473)

(1486) (832)

(1638) (832)

691/2

(1765) (864) (1537)

(1905)

(2095) (864)

34

75 34

(864) (1537)

34

Cabinet

Gas

Height inlet Inlet Outlet

Water Height To Depth To Water

Water

Gas Inlet Gas Inlet inlet/Outlet Relief

C D E F

54 3/4 1 1/4 7 3/4 15 1/2 171/4

(1391) (32) (197) (394)

1 1/4

(1391) (32) (197) (394)

54 3/4 1 1/4 7 3/4 15 1/2

(1391) (32)

(32)

58 1 1/2 7 1/2 18 1/2

(1473) (38)

58 1 1/2

(1473) (38)

1 1/2

60 1/2

60 1/2 2

60 1/2 2

(1537)

(38)

(51)

(51)

15 1/2 17 1/4

7 3/4

(197) (394)

(191) (470)

(470) (472)

(191)

18 1/2 18 9/16

7 1/2

(191) (470)

71/2 18 1/2 19 1/8

(191) (470) (486)

7 1/2 181/2

(191) (470) (486)

7 1/2 18 1/2 19 1/8

(191) (470) (486)

(438) (108) (51)

(438)

171/4

(438)

18 9/16 4 21/2 1 1/4

(472)

18 9/16 4 2 1/2 1 1/4

(472)

191/8

Pressure

G H J L

41/4 2 1

4 1/4 2 1

(108)

41/4

(108) (51) (25)

(102)

(102)

4 2 1/2 1 1/4

(102)

4 1/2 2 1/2 1 1/4

(114) (64) (32)

4 1/2

(114) (64) (32)

4 1/2 2 1/2 1 1/4

(114)

(51) (25)

2 1

(64)

(64)

(64) (32)

21/2 1 1/4

(64)

(25) (305)

(32)

(32)

(32)

Flue

Depth To

Size Flue Center

M N P

12 151/2 321/2

14

(356) (419) (826)

(356)

16

(406)

16

(406)

18

(457) (438) (786)

18

(457)

(457) (349) (787)

(508)

(394)

161/2

14 16 1/2

(419)

17 1/4

(438)

171/4

(438)

171/4

13 3/4

(349)

18 13 3/4 31

20

13 3/4

(349) (787)

Height To Leg Approx.

Inlet/Outlet Width

3015/16

3015/16

30 15/16

Gas supply pressure 13.8" w.c. maximum, 5.5" w.c. minimum. Natural gas only. Electrical requirements -120 VAC; 15 Amps.

Ship.

Weight

Q

341/2 780

(826)

321/2

321/2 42 3/4 950

(826)

(786)

(786)

31

(787)

31

(876)

40 3/16

(1021) (431)

(1086)

40 7/8

(1038)

46 1/2 1,025

(1181)

521/2

(1333)

571/2

(1461)

(1600)

70 1/2

(1791) (567)

(354)

950

(431)

1,000

(454)

(465)

1,100

(499)

1,125

(510)

63

1,150

(522)

1,250

Loading...

Loading...