Page 1

®

Hydronic Heating Boilers

UP TO 82% EFFICIENT H Y DRONI C HEATING BOILERS

MODELS

DB-720

through

The Dura-Max® series offers excellent performance and low-profi le design fl exibility for

both new construction and retrofi t applications. A double-row, integral-fi nned copper

tube heat exchanger provides exceptional heat transfer effi ciency. Each unit features a

small footprint with a built-in draft diverter for extra clearance to simplify installation.

Reliable, quiet, drawer-mounted stainless steel burners resist corrosion, improve

access for easy maintenance.

FEATURES

100% ALL NON-FERROUS HEAT EXCHANGER WATERWAYS

■

All waterways 100% copper, brass or bronze

■

Won’t rust, resists thermal shock

■

Heavy-duty bronze castings and copper heat exchange tubes

■

Bronze removable return bends for easy access and inspection

of individual tubes

GASKETLESS WET SECTION

■

Unique “O”-ring design compresses to form water-tight seal

positioned away from and outside the combustion chamber

■

Isolated location offers optimum protection and years of service

DRAWER-MOUNTED, STAINLESS STEEL DURA-MAX® BURNERS

■

Quiet operation and effi cient, reliable design

■

Protects against corrosion and condensation deterioration

■

Easy slide-out burner tray simplifi es cleaning and maintenance

DB- 1810

COMPACT, LOW-PROFILE DESIGN

■

Built-in draft diverter provides extra clearance in tight, retrofi t installations

■

Clean, compact jacket design for easy access and assembly

■

Cool to touch and approved for combustible fl oors

INTERMITTENT ELECTRONIC IGNITION

■

Eliminates standing pilot, saves energy

■

Includes power ON/OFF switch

CODE COMPLIANCE

■

Meets or exceeds the thermal effi ciency and standby loss requirements

of the U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1

TEN-YEAR HEAT EXCHANGER LIMITED WARRANTY

■

For complete information, consult written warranty or contact A. O. Smith

June 2011R

Low Lead Content

Page 1 of 4

AOSHG30300

Page 2

®

Hydronic Heating Boilers

OTHER DURA-MAX® FEA TURES

MANUAL RESET, HIGH LIMIT

SAFETY FLOW SWITCH

ASME-RATED PRESSURE RELIEF VALVE 50#

REDUNDANT GAS VALVE

DURA-MAX® OPTIONS

CSD-1

CALIFORNIA CODE

THERMAL BALANCER PUMP DELAY

PANEL MOUNTED INLET/OUTLET DIAL

THERMOMETERS AND PRESSURE GAUGE

MODULATING FIRING

DUAL STAGE FIRING

RIGHT END GAS AND/OR WATER CONNECTIONS

CUPRO-NICKEL HEAT EXCHANGER

SIDEWALL VENT KITS

LOW WATER CUTOFF

STANDARD MODELS

MINIMUM CLEARANCES TO COMBUSTIBLES ALL MODELS

Inches CM

TOP 12

WATERSIDE

BLANK SIDE

REAR

VENT

FRONT

* Natural gas only

Gas supply pressure: 13:8” w.c. maximum, 5.5” w.c. minimum

Electrical requirements: 120 VAC, 15 Amps

18

6

6

6

30.5

45.7

15.5

15.5

15.5

Alcove

June 2011R

www.hotwater.com

Page 2 of 4

AOSHG30300

Page 3

®

Hydronic Heating Boilers

INPUT/OUTPUT, FLOW RATE (GALLONS AND LITRES PER MINUTE) AND PRESSURE DROP

20°F/11°C DELTA T 30°F/17°C DELTA T 40°F/22°C DELTA T

MODEL

NUMBER

DB-720

DB-840

DB-960

DB-1080

DB-1210

DB-1350

DB-1480

DB-1610

DB-1810

Pressure drop shown is loss through boiler only, and does not include any additional piping.

BTU/HR.

INPUT

720,000

840,000

960,000 777,600

1,080,000

1,210,000

1,350,000 1,107,000

1,480,000

1,610,000

1,810,000

BTU/HR.

OUTPUT

583,200

680,400

885,600

992,200

1,184,000

1,288,000

1,448,000

MAXIMUM FLOW

GPM LPM

59 223 3.5 1.1 39 149 1.7 0.5 29 111 1.0 0.3

69 260 4.8 1.5 46 173 2.1 0.6 34 130 1.5 0.5

79 297 6.8 2.1 52 198 3.3 1.0 39 149 1.9 0.6

89 339 4.5 1.4 60 226 2.1 0.6 45 169 1.4 0.4

100 379 5.3 1.6 67 253 2.7 0.8 50 190 1.6 0.5

112 423 6.8 2.1 75 282 3.2 1.0 56 212 1.8 0.5

120 453 7.9 2.4 80 302 3.9 1.2 60 226 2.1 0.6

130 492 9.5 2.9 87 328 5.0 1.5 65 246 3.0 0.9

146 554

PRESSURE DROP

FEET

METERS

12.0

3.7 98 369 6.2 1.9 73 277 3.9 1.2

MAXIMUM FLOW

GPM LPM

PRESSURE DROP

FEET

METERS

DIMENSIONS AND SHIPPING WEIGHTS

MAXIMUM FLOW

GPM LPM

PRESSURE DROP

FEET

METERS

MODEL

NUMBER

DB-720

DB-840

DB-960

DB-1080

DB-1210

DB-1350

DB-1480

DB-1610

DB-1810

Water connections on DB-720 through DB-960: 2”

Water connections on DB-1080 through DB-1810: 2-1/2”

INCHES OR

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

Inches

CM

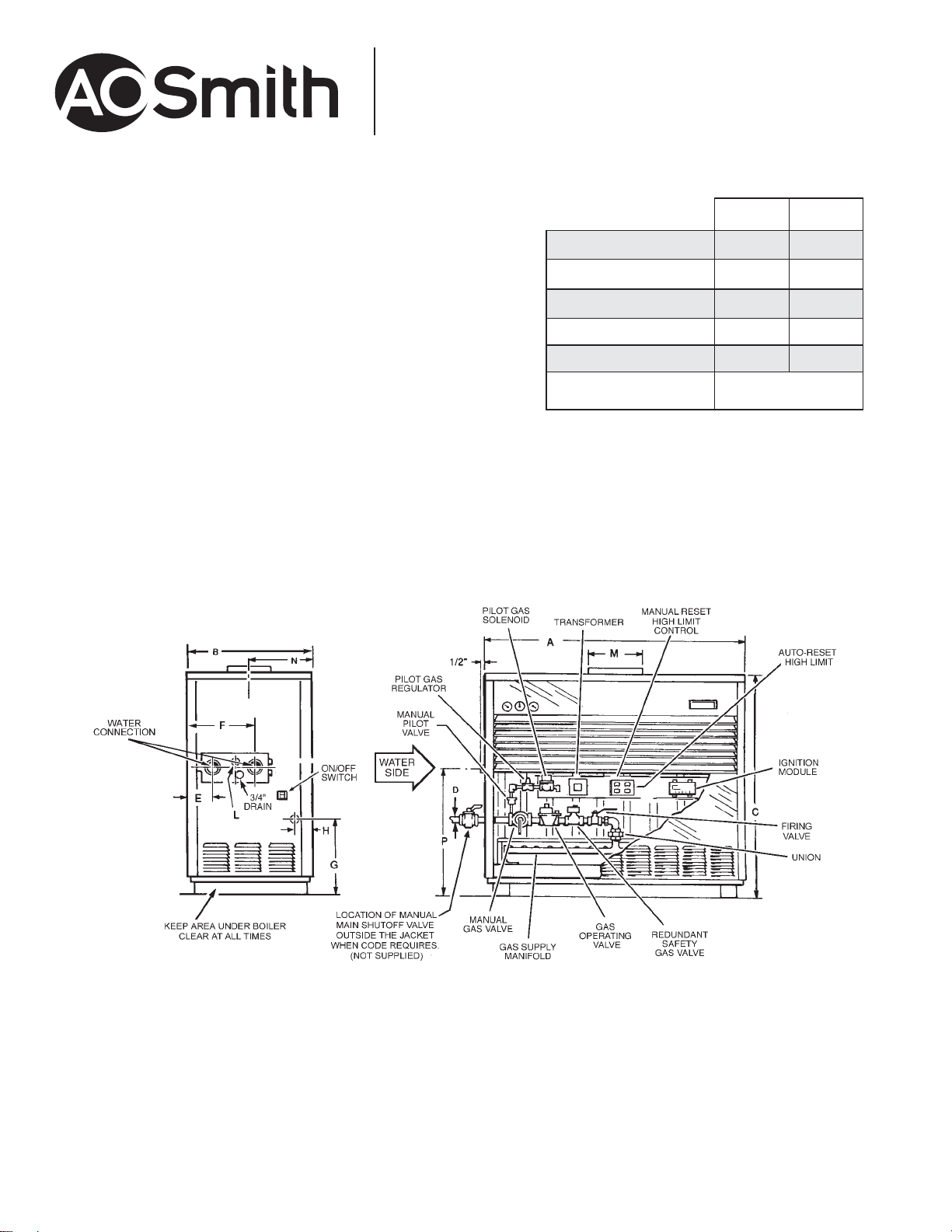

ABCDEFGHLMNP

46-1/2 29-5/8 54-3/4 1-1/4 7-3/4 15-1/2 17-1/4 4-1/4 1 12 15-1/2 32-1/8

118.1 75.2 139.1 3.2 19.7 39.4 43.8 10.8 2.5 30.5 39.4 81.6

52-1/5 29-5/8 54-3/4 1-1/4 7-3/4 15-1/2 17-1/4 4-1/4 1 14 16-1/2 31-1/8

132.6 75.2 139.1 3.2 19.7 39.4 43.8 10.8 2.5 35.6 41.9 79.1 431 Kg

57-3/4 29-5/8 54-3/4 1-1/4 7-3/4 15-1/2 17-1/4 4-1/4 1 14 16-1/2 32-1/8

146.7 75.2 139.1 3.2 19.7 39.4 43.8 10.8 2.5 35.6 41.9 81.6

52-7/8 32-3/4 58 1-1/4 7-1/2 18-1/2 18-9/16 4 1-1/4 16 17-1/4 30-15/16

134.3 83.2 147.3 3.2 19.1 47 47.1 10.2 3.2 40.6 43.8 78.6

58-1/2 32-3/4 58 1-1/2 7-1/2 18-1/2 18-9/16 4 1-1/4 16 17-1/4 30-15/16

148.6 83.2 147.3 3.8 19.1 47 47.1 10.2 3.2 40.6 43.8 78.6

64-1/2 32-3/4 58 1-1/2 7-1/2 18-1/2 18-9/16 4 1-1/4 18 17 1/4 30-15/16

163.8 83.2 147.3 3.8 19.1 47 47.1 10.2 3.2 45.7 45.7 78.6

69-1/2 34 60-1/2 1-1/2 7-1/2 18-1/2 19-1/8 4-1/2 1-1/4 18 13-3/4 31

176.5 86.4 153.7 3.8 19.1 47 48.6 11.4 3.2 45.7 34.9 78.7

75 34 60-1/2 2 7-1/2 18-1/2 19-1/8 4-1/2 1-1/4 18 13-3/4 31

190.5 86.4 153.7 5.1 19.1 47 48.6 11.4 3.2 45.7 34.9 78.7

82-1/2 34 60-1/2 2 7-1/2 18-1/2 19-1/8 4-1/2 1-1/4 20 13-3/4 31

209.6 86.4 153.7 5.1 19.1 47 48.6 11.4 3.2 50.8 34.9 78.7

DIMENSIONS

SHIPPING

WEIGHT

780 Lbs.

354 Kg

950 Lbs.

950 Lbs.

431 Kg

1000 Lbs.

454 Kg

1075 Lbs.

488 Kg

1100 Lbs.

499 Kg

1125 Lbs.

510 Kg

1150 Lbs.

522 Kg

1250 Lbs.

567 Kg

June 2011R

www.hotwater.com

Page 3 of 4

AOSHG30300

Page 4

®

Hydronic Heating Boilers

SUGGESTED SPECIFICATION

The hydronic heating boiler(s) shall be A. O. Smith Dura-Max® model DB ______ with an input rating of ______ BTU/hr and a recovery rating of ________________ BTU/hr at

100°F temperature rise. The boiler(s) shall be design-tested and certified to the ANSI Z21.13 – CSA 4.9 Standards and shall carry the ASME “H” Symbol. The wet section shall be

design-registered in accordance with the requirements of the ASME Code and shall carry an appropriate National Board Number or Canadian Registration Number. All waterways

shall be copper, brass or bronze. The heat exchanger shall be a two (2)-pass design incorporating integral-finned copper tubes . The double-row heat exchanger shall have staggered

tubes. Cast bronze return bends shall be readily removable to permit visual inspection or cleaning without removing the entire wet section assembly. Silicone “O”-ring gaskets shall

form a water-tight seal by compression and shall be isolated from the flue gases by 3/4” board-type ceramic fiber insulation. The heat exchanger assembly shall be hydrostatically

tested to a pressure of 240 psi (1655 kPa) and shall have a maximum working pressure of 160 psi (1100 kPa).The combustion chamber shall be constructed of board-type ceramic

fiber insulation rated to 2300°F (1260°C) which interlocks to form a gas-tight seal and shall be supported in a heavy-gauge corrugated steel frame. The external cabinet shall

incorporate a built-in draft hood and shall be of baked enamel steel construction. It shall be suitable for installation on combustible flooring. The burners shall be a stainless

steel stamped design and shall be mounted in a removable drawer assembly.The burner controls shall be 24 VAC and shall include slow-opening main gas valve for soft ignition,

redundant safety shutoff gas valve, main and pilot pressure regulators, recycling intermittent pilot system with one-second shutdown in the event of pilot flame failure, automatic

recycling high limit, manual reset ECO limit, main and pilot manual cocks and manual firing valve, and an ASME-rated pressure relief valve. The boiler shall be approved by Factory

Mutual (FM).The boiler shall meet or exceed the thermal efficiency and standby loss requirements of the U.S. Department of Energy and current edition of ASHRAE/IESNA 90.1.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

June 2011R

www.hotwater.com

Page 4 of 4

AOSHG30300

Loading...

Loading...