Page 1

TM

Built tough with maximum efficiency

MODELS DB/DW-720-1810

NATURAL GAS-FIRED COMMERCIAL CROSS FLOW COPPER BOILERS

FOR HYDRONIC HEATING AND HOT WATER SUPPLY

WITH ELECTRONIC INTERMITTENT PILOT IGNITION AND

INSTALLATIONS

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

WARNING: If the information in this manual

is not followed exactly , a fire or explosion may

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch;

do not use any phone in your

building.

· Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

· If you cannot reach your gas

supplier, call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMA TION RELA TIVE T O YOUR SAFETY .

READ THOROUGHLY BEFORE INSTALLING AND

USING THIS APPLIANCE.

A DIVISION OF A.O.SMITH CORPORA TION

EL P ASO, TX McBEE, SC RENTON, WA

STRATFORD, ONTARIO

VELDHOVEN, THE NETHERLANDS

www.hotwater.com

PLEASE

PRINTED IN U.S.A. 2221 0302

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

1

SUPERSEDES PART NO. 20031 1-000 REV. 4 & 210265-000 REV . 0

PART NO. 211680-000 REV . 00

Page 2

CONTENTS

Page

FOREWORD................................................................................ 2

REPLACEMENT PAR TS .............................................................. 2-3

ROUGH-IN DIMENSIONS/CAPACITIES ...................................... 3-4

Installation Clearances.............................................................. 3

Levelling ................................................................................... 3

FEATURES................................................................................... 5

Safety Relief V alves.................................................................. 5

Electronic Intermittent PIlot Ignition Control .............................. 5

Manual Reset High T emperature Safety Limit Control ............... 5

Automatic Reset High T emperature Control .............................. 6

Thermal Balancer ..................................................................... 6

Safety Flow Switch................................................................... 6

INSTALLA TION INSTRUCTIONS ................................................. 7

Required Ability ........................................................................ 7

Location ................................................................................... 7

Air Requirements ..................................................................... 7-8

Venting the Boiler ..................................................................... 8-9

Gas Connections...................................................................... 9

Purging .................................................................................... 10-1 1

High Altitude Installations ......................................................... 11

Wiring Connections.................................................................. 1 1-12

Servicing Wiring And/Or Control .............................................. 1 2

SYSTEM EQUIPMENT INSTALLA TION ....................................... 12

Water Supply Line.................................................................... 12

Expansion T ank ........................................................................ 12

Vent V alves .............................................................................. 12

System Headers ...................................................................... 12

Cooling Piping .......................................................................... 12

Safety Flow Switch................................................................... 12-13

Circulating Pump...................................................................... 13-14

Page

Low Water Cutoff ..................................................................... 1 4

T ank T emperature Control ........................................................ 14

SYSTEM INSTALLA TION ............................................................. 14

Conventional Space Heating Installation ................................... 14-15

Installation As Boiler Replacement ............................................ 15-17

Linear-T emp Space Heating Applications.................................. 17

Linear-T emp Space Heating Installations .................................. 17-20

Wiring and Schematic Diagrams .............................................. 21-26

HOT WA TER SUPPL Y APPLICA TIONS ....................................... 27-32

Water Line Connections ........................................................... 27

Hard Water Conditions............................................................. 27

ST ART-UP AND OPERA TING INSTRUCTIONS .......................... 32

LIGHTING AND OPERATING INSTRUCTIONS ........................... 33

Internal Contaminants .............................................................. 34

Precautions .............................................................................. 34

Checking and Adjusting the Input............................................. 34

Pilot Burner .............................................................................. 34

Main Burner ............................................................................. 34-35

PRE-TROUBLESHOOTING ......................................................... 35

TROUBLESHOOTING.................................................................. 35-38

GENERAL MAINTENANCE.......................................................... 39

Relief V alve .............................................................................. 39

Venting Maintenance ................................................................ 39

Heat Exchanger Preventive Maintenance.................................. 39

Deliming ................................................................................... 39-40

Deliming Solvents..................................................................... 40

Removing Light Deposits of Scale ............................................ 40

Removal of an Existing Boiler From A Common Venting

System ................................................................................ 40

LIMITED WARRANTY .................................................................. 41

FOREWORD

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE USING APPLIANCE.

Detailed installation diagrams are in this manual. These diagrams

will serve to provide the installer with a reference for the materials

and method of piping suggested. IT IS NECESSARY THAT ALL

WATER AND GAS PIPING AND THE ELECTRICAL WIRING BE

INSTALLED AND CONNECTED AS SHOWN IN THE DIAGRAMS.

CHECK THE DIAGRAMS THOROUGHLY BEFORE STARTING

INSTALLATION TO AVOID POSSIBLE ERRORS AND TO

MINIMIZE TIME AND MATERIALS COST.

This design complies with the latest edition of the

CSA 4.9 low-pressure boiler.

Particular attention should be given to the installation of

thermometers at the locations indicated in the diagrams as these

are necessary for checking the operation of the boiler.

MAKE SURE THE GAS ON WHICH THE BOILER WILL OPERA TE

IS THE SAME AS THAT SPECIFIED ON THE UNIT RATING PLATE.

The boiler installation must conform to these instructions and the

requirements of the local authority having jurisdiction.

Where required by the authority having jurisdiction, the installation

must conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

In the absence of local code requirements, the boiler installation

must conform to the most current

National Fuel Gas Code, ANSI

Z223.1 and/or CAN/CSA-B149.1-00 installation codes.

ANSI Z21.13

These manuals can be purchased from the CSA International,

8501 East Pleasant Valley Road, Cleveland, OH 44131 or 178

Rexdale Boulevard, Toronto, Ontario Canada, M9W 1R3.

REPLACEMENT PARTS

Replacement parts may be ordered through A. O. Smith dealers,

authorized servicers or distributors. Refer to the Yellow Pages for

where to call or contact (in United States) the A.O. Smith Water

Products Company, 5621 West 115th Street, Alsip, IL 60803,

1-800-433-2545 or (in Canada) A.O. Smith Enterprises Ltd., 768

Erie Street, Stratford, Ontario, Canada N5A 6T3, 800-265-8520.

When ordering parts be sure to state the quantity, part number and

description of the item including the complete model and serial

number as it appears on the product. Refer to the parts lists for

more information.

For Technical Assistance call A.O. Smith Technical Information

Center at 1-800-527-1953.

WARNING

THE INLET/OUTLET WATER MANIFOLD ON YOUR A. O. SMITH

UNIT INCORPORATES AN “O RING" WATER SEAL ASSEMBLY.

THE MANIFOLD IS NOT DESIGNED TO SUPPORT THE WEIGHT

OF THE WATER PIPING SYSTEM. AS ON ALL BOILER

INSTALLA TIONS, SPECIAL CARE MUST BE TAKEN TO ENSURE

PROPER SUPPORT.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE EQUIPMENT

ROOM WHERE THE BOILER IS INSTALLED EVER BE UNDER

NEGATIVE PRESSURE. PARTICULAR CARE MUST BE TAKEN

WHEN EXHAUST FANS, COMPRESSORS, AIR HANDLING

EQUIPMENT, ETC., MA Y INTERFERE WITH THE COMBUSTION

AND VENTILATION AIR SUPPLIES OF THIS BOILER.

2

Page 3

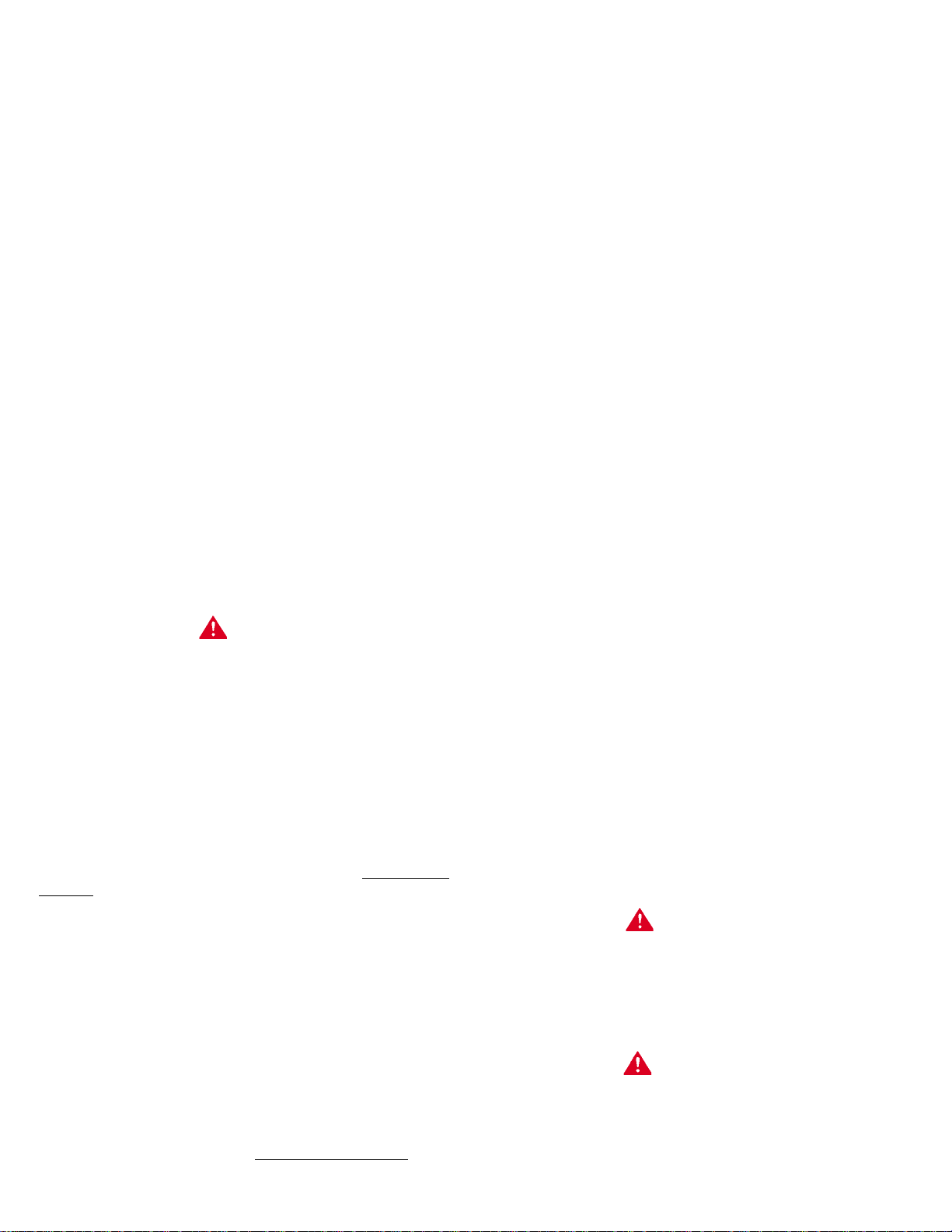

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation.

"Verify proper operation after servicing."

ROUGH-IN DIMENSIONS/

CAPACITIES

INST ALLA TION CLEARANCES

Two inch clearance is allowable from combustible construction for

hot water pipes.

Sufficient clearance should be provided at one end of the boiler to

permit access to heat exchanger tubes for cleaning. Maximum

operating water supply pressure 160 psi. Gas supply pressure:

13.8" w.c. max., 5.5" w.c. min.

Sufficient area should be provided at the front and sides of the unit

for proper servicing. Clearances of 48" in front and 24" on sides is

recommended. In a utility room installation, the door shall be wide

enough to allow the boiler to enter or to permit the replacement of

another appliance.

These boilers are approved for installation on combustible flooring

in an alcove with minimum clearance to combustibles See chart

below.

W ARNING

AN AMPLE SUPPL Y OF AIR MUST BE PROVIDED

FOR PROPER COMBUSTION AND VENTILA TION.

LEVELLING

Each unit should be checked after installation to be certain that it is

level.

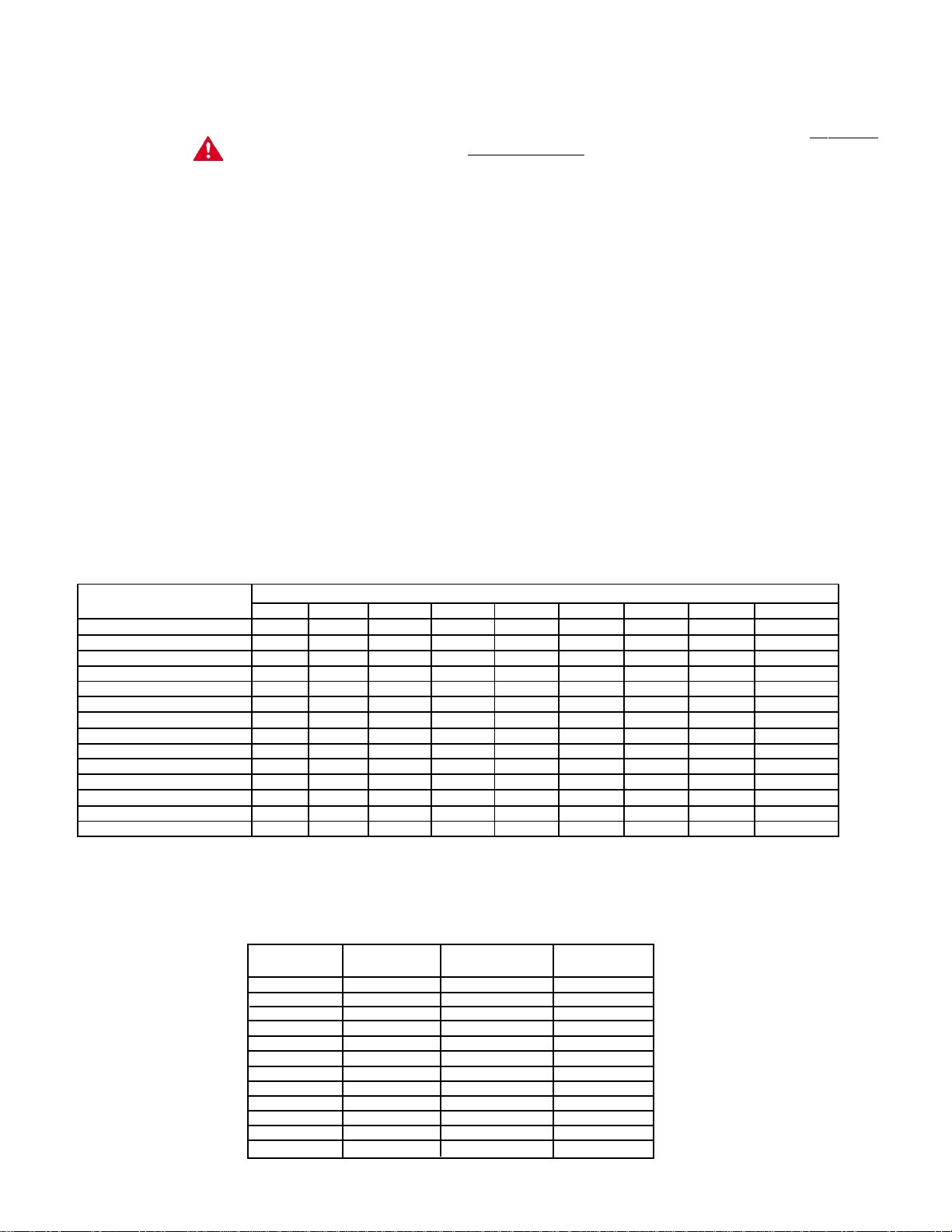

TABLE 1, ROUG H-IN DIMENSI ONS

Models

Dimensions inches mm inches mm inches mm inches mm inches mm inches mm inches mm inches mm inches mm

A

46 1/2 1181 52 1/5 1326 57 3/4 1467 52 7/8 1343 58 1/2 1486 64 1/2 1638 69 1/2 1765 75 1905 82 1/2 2096

B

29 5/8 752 29 5/8 752 29 5/8 752 32 3/4 832 32 3/4 832 32 3/4 832 34 864 34 864 34 864

C

54 3/4 1391 54 3/4 1391 54 3/4 1391 58 1473 58 1473 58 1473 60 1/2 1537 60 1/2 1537 60 1/2 1537

D

E 7 3/4 197 7 3/4 197 7 3/4 197 7 1/2 191 7 1/2 191 7 1/2 191 7 1/2 191 7 1/2 191 7 1/2 191

F 15 1/2 394 15 1/2 394 15 1/2 394 18 1/2 470 18 1/2 470 18 1/2 470 18 1/2 470 18 1/2 470 18 1/ 2 470

G

H

J

K 2 NPT 2 NPT 2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT

L 1 NPT 1 NPT 1 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT

M

N

W

Approx.

Shipping

Weight.

1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/2 NPT 1 1/2 NPT 1 1/2 NPT 2 NPT 2 NPT

17 1/4 438 17 1/4 438 17 1/4 438 18 9/16 471 18 9/16 471 18 9/16 471 19 1/8 486 19 1/8 486 19 1/8 486

4 1/4 108 4 1/4 108 4 1/4 108 4 102 4 102 4 102 4 1/2 114 4 1/2 114 4 1/2 114

2 NPT 2 NPT 2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT 2 1/2 NPT

12 305 14 356 14 356 16 406 16 406 18 457 18 457 18 457 20 508

15 1/2 394 16 1/2 419 16 1/2 419 17 1/4 438 17 1/4 438 17 1/4 438 13 3/4 349 13 3/4 349 13 3/4 349

32 1/8 816 31 1/8 791 32 1/8 816 30 15 /16 786 30 15/16 786 30 15/16 786 31 787 31 78 7 31 787

780 lbs 354 Kg. 950 lbs 431 Kg 950 lbs 431 Kg 1000 lbs 454 Kg 1075 lbs 48 8 Kg. 1100 lbs 499 Kg 1125 lbs 510 Kg 1150 lbs 522 Kg 1250 lbs 567 Kg

DW-1810DW-1210 DW-1350 DW-1480 DW-1610DW-720 DW-840 DW-960 DW-1080

Minimum Clearances T o Combustibles

Water Blank

T op Side Side Rear Vent Front

All Models 12" (305mm) 18" (457mm) 6" (155mm) 6" (155mm) 6" (155mm) Alcove

3

Page 4

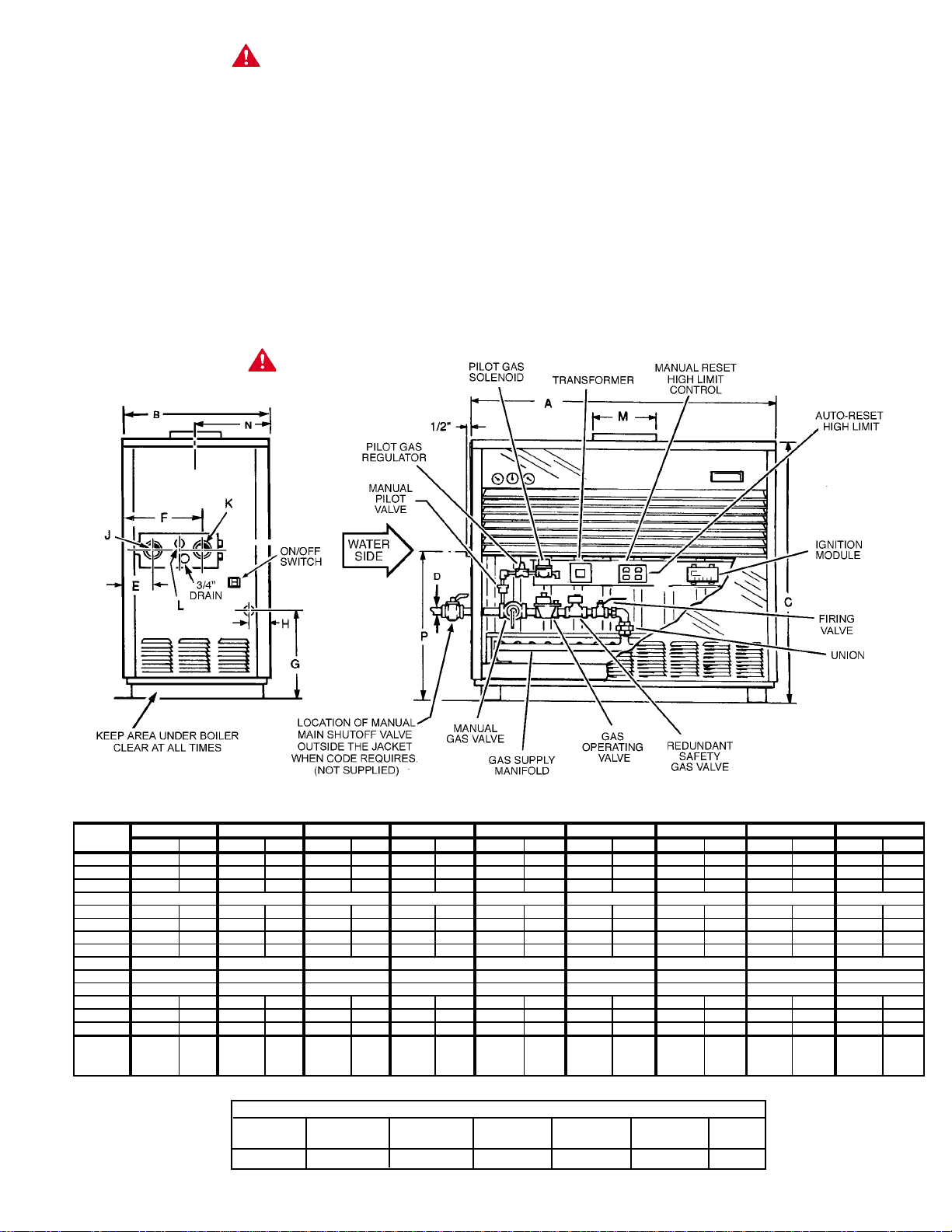

WARNING

Your Dura-Max boiler is not designed to operate with a boiler inlet water temperature of less than

100°F (38°C). Colder inlet water temperatures will result in significant condensation developing on

the heat exchanger. This situation can cause a corrosive environment for the heat exchanger,

burners and venting resulting in premature damage, which could result in serious personal injury or

death.

For systems that use large volumes of cold water or system utilizing heavy water draws (Cer-Temp),

condensation can be prevented by using a by-pass loop. See page 16.

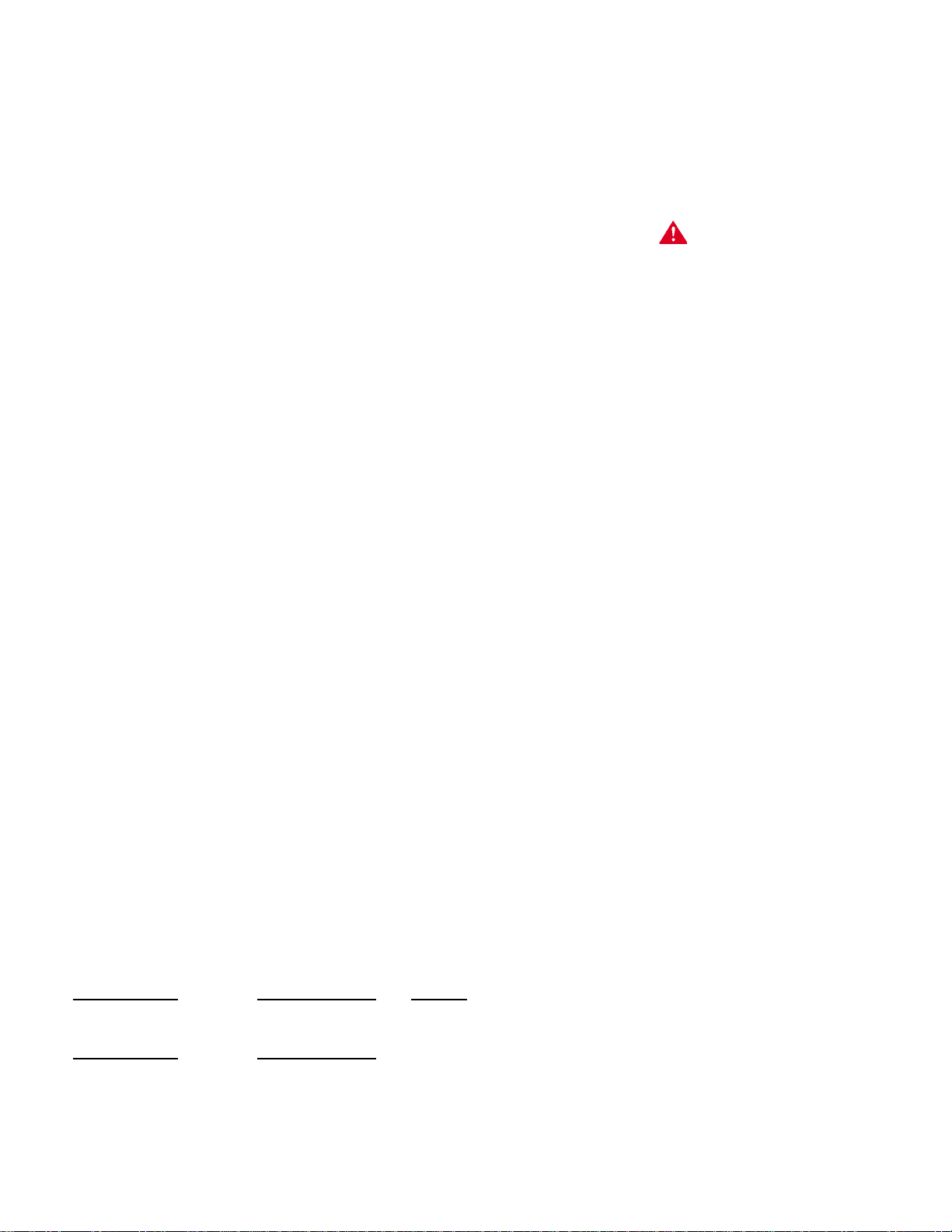

TABLE 2, PRESSURE DROP

Model

DW-720

DW-840

DW-960

DW-1080

DW-1210

DW-1350

DW-1480

DW-1610

DW-1810

Temp Rise

FC

Flow Rate

GPM LPM ft

20 11.1 59 223 3.5 1.1

30 16.7 39 149 1.7 0.5

40 22.2 29 111 1.0 0.3

20 11.1 69 260 4.8 1.5

30 16.7 46 173 2.1 0.6

40 22.2 34 130 1.5 0.5

20 11.1 79 297 6.8 2.1

30 16.7 52 198 3.3 1.0

40 22.2 39 149 1.9 0.6

20 11.1 89 339 4.5 1.4

30 16.7 60 226 2.1 0.6

40 22.2 45 169 1.4 0.4

20 11.1 100 379 5.3 1.6

30 16.7 67 253 2.7 0.8

40 22.2 50 190 1.6 0.5

20 11.1 112 423 6.8 2.1

30 16.7 75 282 3.2 1.0

40 22.2 56 212 1.8 0.5

20 11.1 120 453 7.9 2.4

30 16.7 80 302 3.9 1.2

40 22.2 60 226 2.1 0.6

20 11.1 130 492 9.5 2.9

30 16.7 87 328 5.0 1.5

40 22.2 65 246 3.0 0.9

20 11.1 146 554 12.0 3.7

30 16.7 98 369 6.2 1.9

40 22.2 73 277 3.9 1.2

HdLoss*

M

TABLE 3, RECOVERY CAPACITIES

MODEL BTUH KW C 11.1C 16.6C 20C 22.2C 27.7C 30C 33.3C 38.8C 40C 44.4C 50C 55.5C 60C 61.1C 66.6C 70C 72.2C 77.7C

DB/DW-720

DB/DW-840

DB/DW-960

DB/DW-1080

DB/DW-1210

DB/DW-1350

DB/DW-1480

DB/DW-1610

DB/DW-1810

INPUT

720,000 GPH 3,535 2,356 1,964 1,767 1,414 1,309 1,178 1,010 982 884 785 707 655 643 589 561 544 505

840,000 GPH 4,124 2,749 2,291 2,062 1,649 1,527 1,375 1,178 1,145 1,031 916 825 764 750 687 655 634 589

960,000 GPH 4,713 3,142 2,618 2,356 1,885 1,745 1,571 1,346 1,309 1,178 1,047 943 873 857 785 748 725 673

1,080,000 GPH 5,367 3,578 2,982 2,684 2,147 1,988 1,789 1,534 1,491 1,342 1,193 1,073 994 976 895 852 826 767

1,210,000 GPH 6,013 4,009 3,341 3,007 2,405 2,227 2,004 1,718 1,670 1,503 1,336 1,203 1,114 1,093 1,002 954 925 859

1,350,000 GPH 6,709 4,473 3,727 3,355 2,684 2,485 2,236 1,917 1,864 1,677 1,491 1,342 1,242 1,220 1,118 1,065 1,032 958

1,480,000 GPH 7,176 4,784 3,987 3,588 2,870 2,658 2,392 2,050 1,993 1,794 1,595 1,435 1,329 1,305 1,196 1,139 1,104 1,025

1,610,000 GPH 7,806 5,204 4,337 3,903 3,122 2,891 2,602 2,230 2,168 1,952 1,735 1,561 1,446 1,419 1,301 1,239 1,201 1,115

1,810,000 GPH 8,776 5,851 4,875 4,388 3,510 3,250 2,925 2,507 2,438 2,194 1,950 1,755 1,625 1,596 1,463 1,393 1,350 1,254

F 20F 30F 36F 40F 50F 54F 60F 70F 72F 80F 90F 100F 108F 110F 120F 126F 130F 140F

211 LPH 13,379 8,920 7,433 6,690 5,352 4,955 4,460 3,823 3,716 3,345 2,973 2,676 2,478 2,433 2,230 2,124 2,058 1,911

246 LPH 15,609 10,406 8,672 7,805 6,244 5,781 5,203 4,460 4,336 3,902 3,469 3,122 2,891 2,838 2,602 2,478 2,40 1 2,230

281 LPH 17,839 11,893 9,911 8,920 7,136 6,607 5,946 5,097 4,955 4,460 3,964 3,568 3,304 3,243 2,973 2,832 2,74 4 2,548

316 LPH 20,317 13,545 11,287 10,158 8,127 7,525 6,772 5,80 5 5,644 5,079 4,515 4,063 3,762 3,694 3,386 3,225 3,126 2,902

354 LPH 22,762 15,175 12,646 11,381 9,105 8,430 7,587 6,50 4 6,323 5,691 5,058 4,552 4,215 4,139 3,794 3,613 3,502 3,252

395 LPH 25,396 16,931 14,109 12,698 10,158 9,406 8,465 7,256 7,054 6,349 5,644 5,079 4,703 4,617 4,233 4,031 3,907 3,628

433 LPH 27,162 18,108 15,090 13,581 10,865 10,060 9,054 7,761 7,545 6,791 6,036 5,432 5,030 4,939 4,527 4,311 4,179 3,880

472 LPH 29,548 19,699 16,416 14,774 11,819 10,944 9,849 8,442 8,208 7,387 6,566 5,910 5,472 5,372 4,925 4,690 4,546 4,221

530 LPH 33,219 22,146 18,455 16,609 13,288 12,303 11,073 9,491 9,227 8,305 7,382 6,644 6,152 6,040 5,536 5,273 5,111 4,746

U.S. Gallons/Hr and Li t res/Hr at TEMPERAT URE RIS E I NDICATED

4

Page 5

FEA TURES

IMPORTANT

Only qualified personnel shall perform the initial firing of the heater.

At this time the user should not hesitate to ask the individual any

questions regarding the operation and maintenance of the unit.

Lighting and Operating instructions are included at the rear of this

manual. By using this checklist the user may be able to make

minor operational adjustments and save unnecessary service calls.

However, the user should not attempt repairs which are not listed

under the USER column.

SAFETY RELIEF V ALVES

Your local code authority may have other specific relief valve

requirements not covered below.

and pilot gases are cut off during the “OFF” cycle. Pilot gas ignition

is proven by the pilot sensor. Main burner ignition will not occur if

the pilot sensor does not first sense pilot ignition.

FIGURE 2

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE WHICH MAY CAUSE TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO AVOID WATER DAMAGE A DRAIN LINE MUST BE

CONNECTED TO A SAFETY RELIEF VALVE TO DIRECT

DISCHARGE TO A SAFE LOCA TION. A DRAIN LINE MUST NOT

BE REDUCED FROM THE SIZE OF THE VALVE OUTLET AND IT

MUST NOT CONT AIN ANY V ALVES BETWEEN THE BOILER AND

THE RELIEF VALVE OR THE RELIEF VALVE AND THE DRAIN

EXIT. IN ADDITION, THERE SHOULD NOT BE ANY

RESTRICTIONS IN A DRAIN LINE NOR SHOULD IT BE ROUTED

THROUGH AREAS WHERE FREEZING CONDITIONS MIGHT

OCCUR. DO NOT THREAD OR CAP THE DRAIN LINE EXIT.

RESTRICTING OR BLOCKING A DRAIN LINE WILL DEFEA T THE

PURPOSE OF THE RELIEF VALVE AND MAY CREATE AN

UNSAFE CONDITION. INSTALL A DRAIN LINE WITH A

DOWNWARD SLOPE SUCH THAT IT NATURALLY DRAINS

ITSELF.

If any safety relief valve is replaced, the replacement valve must

comply with the latest version of the ASME Boiler and Pressure

Vessel Code, Section IV (“HEATING BOILERS”). Select a relief

valve with a discharge rating NOT less than the boiler input, and a

set pressure NOT exceeding the working pressure of any component

in the system.

An ASME rated temperature and pressure relief valve must be

installed on each and every water storage tank in a hot water supply

system.

The storage tank temperature and pressure relief valve must comply

with the applicable construction provisions of the Standard for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21 or CAN/CSA-B149.1 (latest edition). The valve

must be of the automatic reset type and not embody a single-use

type fusible plug, cartridge or linkage.

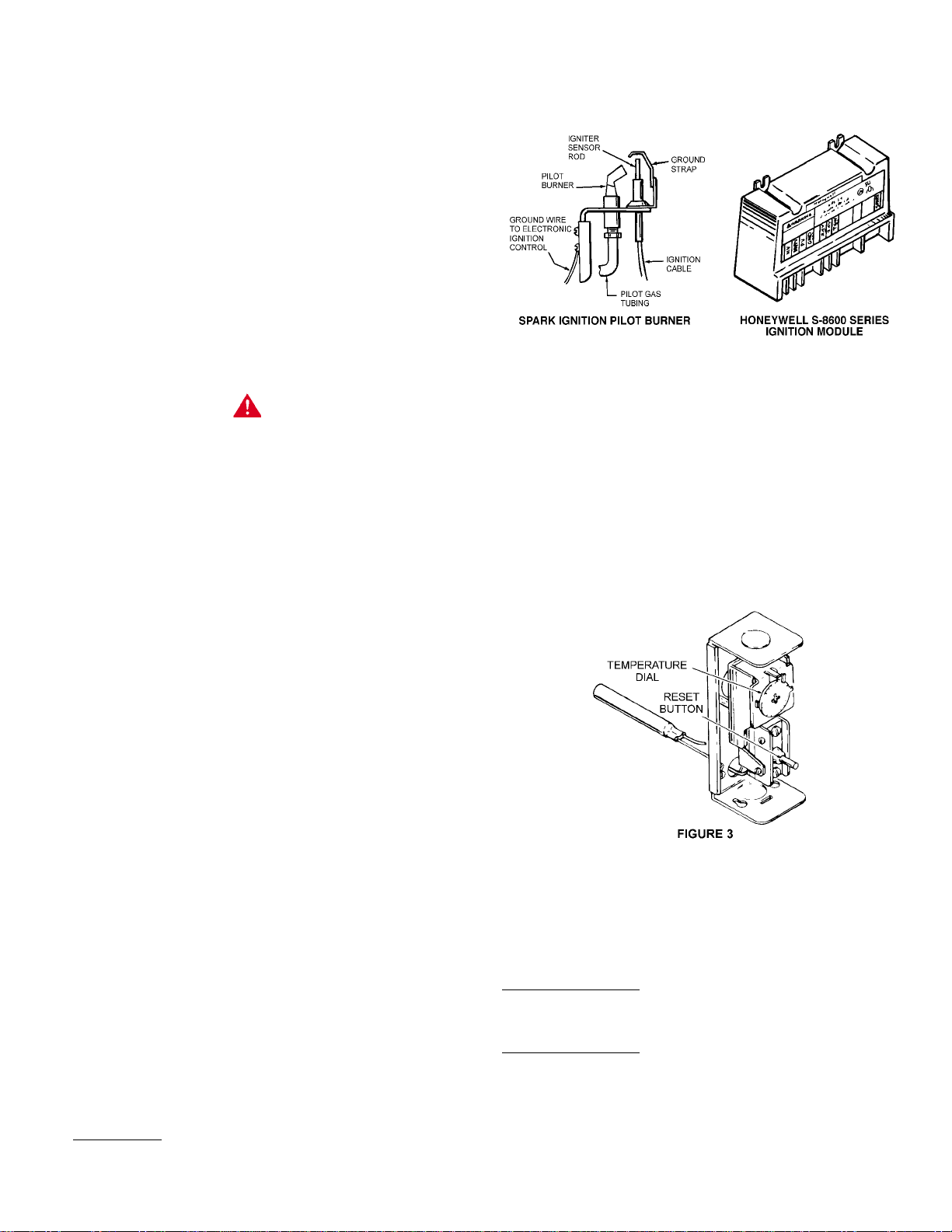

ELECTRONIC INTERMITTENT PILOT

IGNITION CONTROL

ALL MODELS - The solid state ignition control, fig. 2, ignites the

pilot burner gas by creating a spark at the pilot assembly . Pilot gas

is ignited and burns during each running cycle. The main burner

5

On natural gas models the igniter control continues to operate

(creating a spark) until the pilot burner is ignited or the ignition

system shuts down. Shut down occurs automatically if the pilot

burner does not ignite within 15 seconds. The unit then waits for

(5) minutes and retries ignition (standard models).

The electronic intermittent pilot ignition control and the 100% lockout

control are non-adjustable devices.

(See troubleshooting steps on page 40). If pilot is not lit and sensed

within the flame establishing timing for each module, the appliance

will shut down.

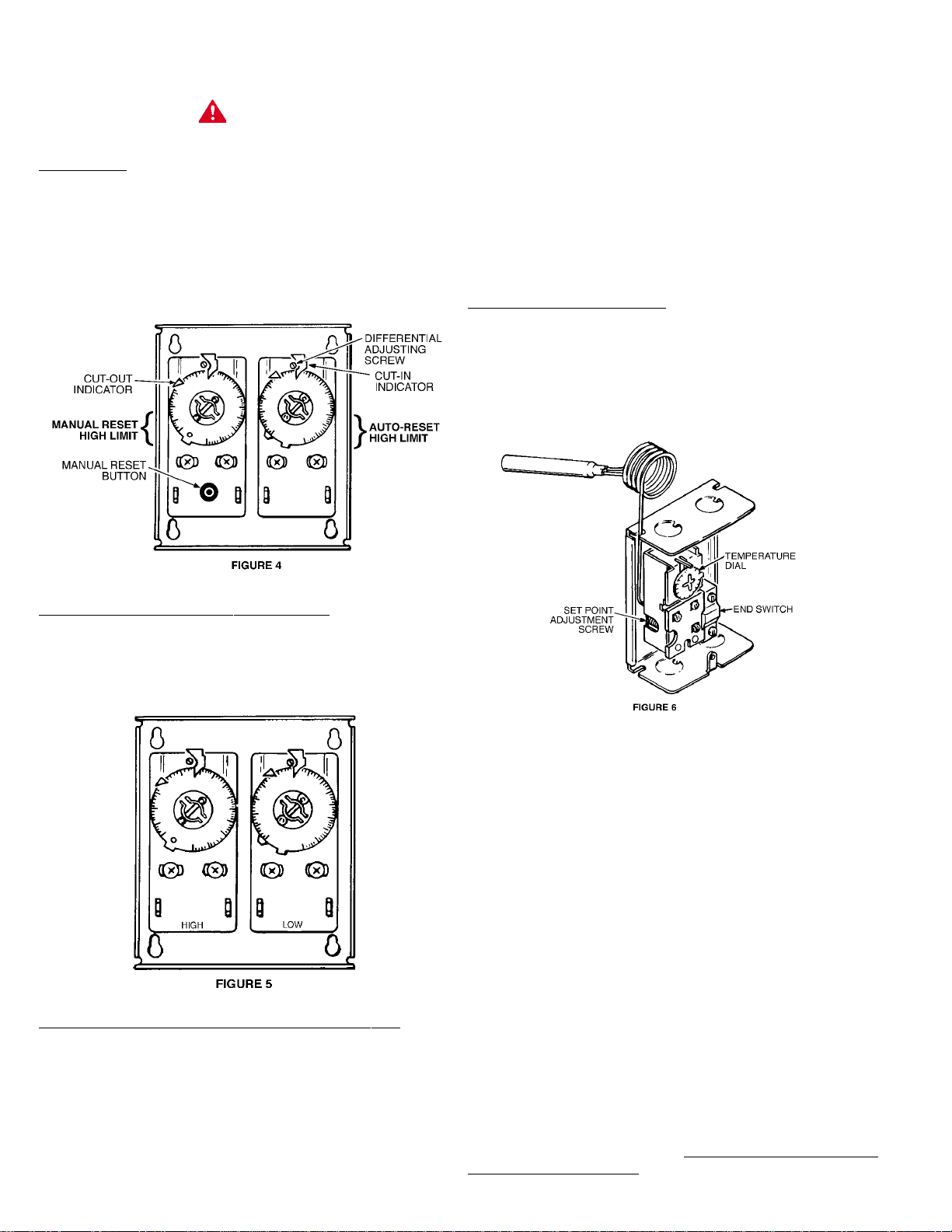

MANUAL RESET HIGH TEMPERA TURE

SAFETY LIMIT CONTROL

This device senses water temperature in the boiler. When water

temperature exceeds dial setting, power to main gas valve is

interrupted and the boiler is shut down.

HOT WATER SUPPLY - Manual reset - factory set at 210°F (100°C).

Water temperature must drop at least 20°F (11°C) before reset is

possible.

HYDRONIC HEA TING - Manual reset - factory set at 250°F (121°C).

Water temperature must drop at least 20°F (11°C) before reset is

possible.

Single stage and modulating units use a combined control as shown

in fig. 4.

Dual stage models are equipped with a limit like one shown in

figure 3.

Page 6

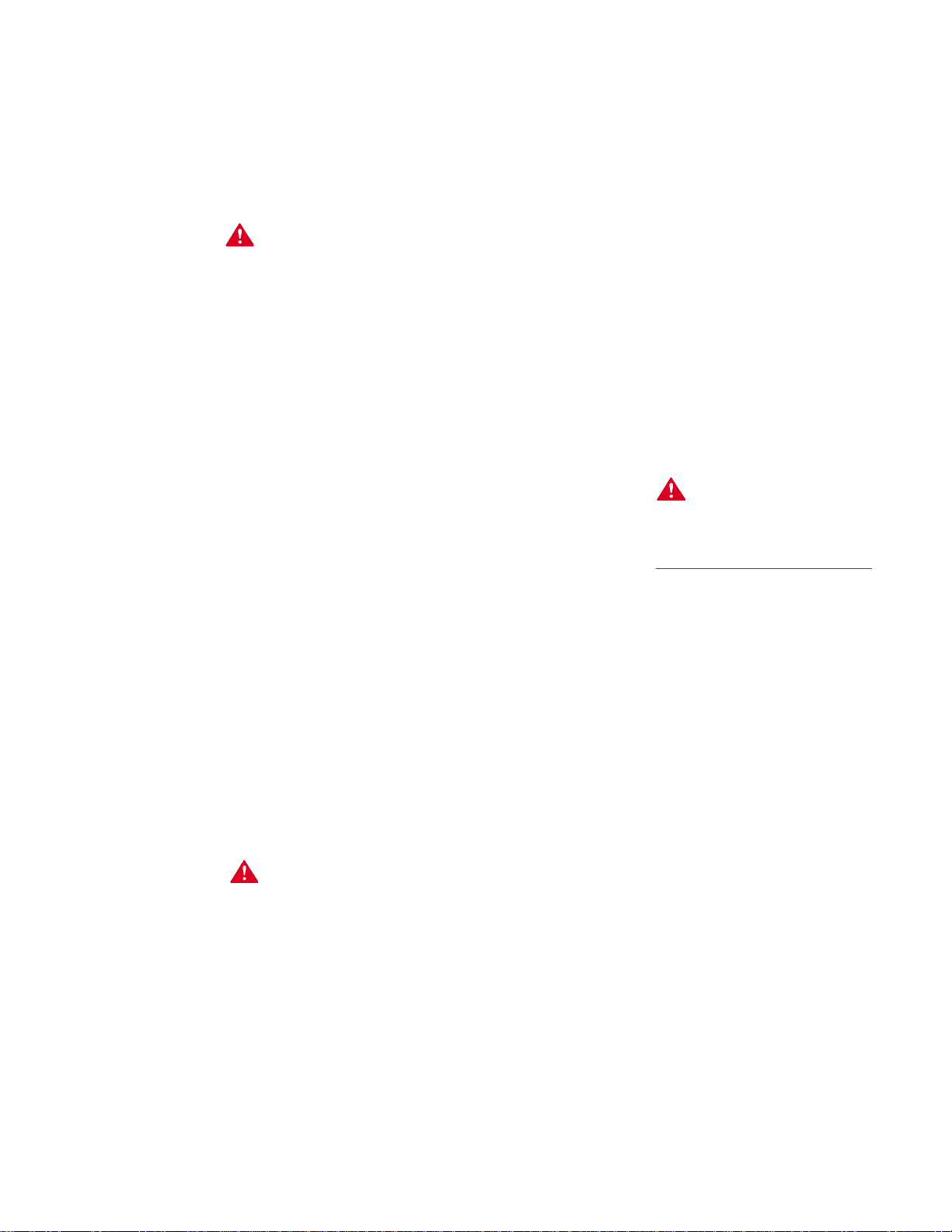

AUTOMATIC RESET

HIGH TEMPERATURE LIMIT CONTROL

CAUTION

LIMIT CONTROLS ARE NOT TO BE USED AS THERMOSTATS.

The heater operation with above set points will be as follows:

1) When heater temperature rises to LO thermostat setting the

main gas valve will close its second stage operator to drop

input to approximately 50% of total input.

ALL MODELS - This limit is a safety device wired in series with the

ignition system. Set the limit control dial to a minimum of 10°F

(6°C) above the maximum designed system temperature. If the

boiler outlet water temperature should exceed the high limit setting,

the main gas valves will close but the circulator will continue to

operate. Maximum adjustable setting is 240°F (116°C) for boilers

and 200°F (93°C) for hot water supply heaters. The differential is

adjustable from 5°F (3°C) to 45°F.

SINGLE ST AGE AND MODULATING MODELS - Are equipped with

the limit like the one shown in fig. 4.

2) System conditions will determine if temperature rise at LO

thermostat sensor location will continue to rise until shut-off

by high limit or drop causing heater to go back to full input.

Other system design temperatures will require resetting of the dial.

Total span of temperatures (HI dial cut-off point to LO dial cut-on

point) should not be less than temperature drop of the system.

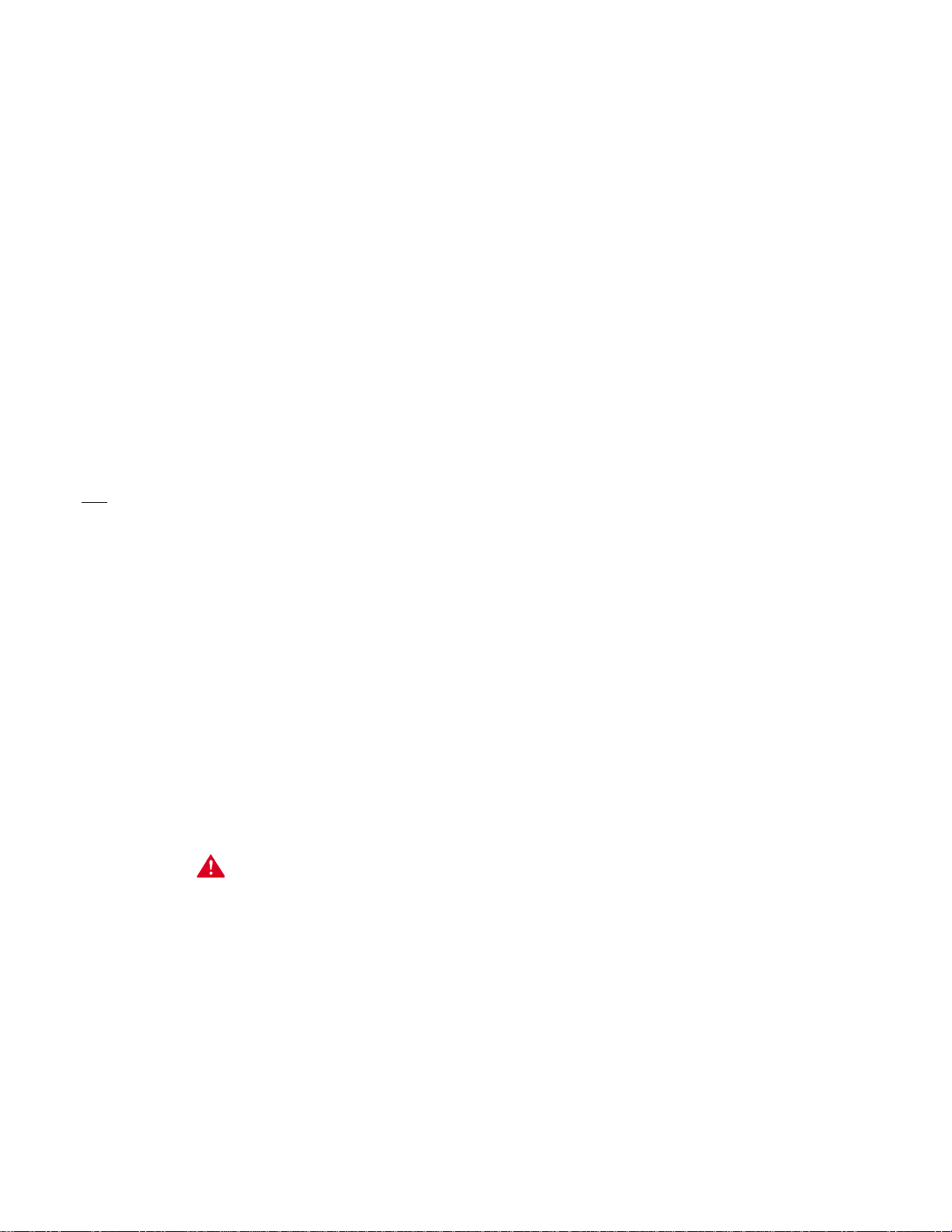

MODULATING MODELS ONLY

These boilers are factory equipped with a modulating gas valve

that automatically controls the outlet water temperature by

modulating or proportioning the rate of gas thus maintaining a

desired constant outlet water temperature regardless of varying

flow rates.

Gas valves either close or open to full gas input, depending upon

heat requirement.

DUAL STAGE MODELS ONLY - HIGH/LOW OPERATOR

These boilers are factory equipped with a (combination) temperature

controller to provide high and low firing rates for smooth operation.

(fig. 5).

The temperature dials should be adjusted to have the HI dial set as

a limit to be 10°F (6°C) above desired boiler temperature. These

boilers are shipped with the HI dial set to 200°F (93°C) with a 15°F

(8°C) differential, the LO dial set to 160°F (71°C) with a 10°F (6°C)

differential.

Set temperature controller for desired outlet water temperature.

(fig. 6).

Adjust the set point for the desired operating temperature by turning

the set point adjusting screw on the front of the case until the desired

value is reached on the set point indicating dial. The set point is

calibrated to be at the center of the proportioning range, (see the

manufacturers instructions for complete information on testing and

calibrating this control.)

THERMAL BALANCER

This device serves as a pump shutdown delay switch to balance

the boiler water temperature to system temperature before the pump

stops. Overshooting of boiler temperature is prevented and stack

loss after shutdown is minimized.

SAFETY FLOW SWITCH

The safety flow switch is a safety device which must be installed at

the water outlet of the unit to prevent main burner operation in the

event of inadequate water flow through the boiler.

This switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward water flow. Do not install the switch where

the water flow is downward.

6

Page 7

INST ALLA TION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS BOILER REQUIRES

ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN

IN THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING,

GAS SUPPLY AND ELECTRICAL WORK ARE REQUIRED.

If the boiler is installed above the level of heating system terminal

units, a low water cutoff device must be installed in the boiler outlet

at the time of installation.

For installation locations with elevations above 2,000 feet (610 M),

refer to the HIGH ALTITUDE INSTALLATIONS section of this

manual for input reduction procedure.

CHEMICAL VAPOR CORROSION

WARNING

THE INLET/OUTLET WATER MANIFOLD ON YOUR A. O. SMITH

UNIT INCORPORATES AN "O RING" WATER SEAL ASSEMBLY.

THE MANIFOLD IS NOT DESIGNED TO SUPPORT THE WEIGHT

OF THE WATER PIPING SYSTEM. AS ON ALL BOILER

INSTALLA TIONS, SPECIAL CARE MUST BE TAKEN TO ENSURE

PROPER SUPPORT.

LOCATION

When installing the boiler, consideration must be given to proper

location. Location selected should be as close to the stack or

chimney as practical with adequate air supply and as centralized

with the piping system as possible. This location should also be

such that the gas ignition system components are protected from

water (dripping, spraying, etc.) during appliance operation and

service [circulator replacement, control replacement, etc.].

THE BOILER MUST NOT BE INSTALLED ON CARPETING.

THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE BOILER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE BOILER

OR CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE

ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

Heat exchanger corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also, air

which is brought in contact with the water boiler should not contain

any of these chemicals. If necessary, uncontaminated air should

be obtained from remote or outside sources.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST BE

PROVIDED FOR PROPER COMBUSTION AND VENTILATION

IN ACCORDANCE WITH SECTION 5.3, AIR FOR COMBUSTION

AND VENTILA TION, OF THE NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR 7.2, 7.3 OR 7.4 OF CAN/CSA B149.1-00,

INSTALLA TION CODES, OR APPLICABLE PROVISIONS OF THE

LOCAL BUILDING CODES. AN INSUFFICIENT SUPPLY OF AIR

MAY RESULT IN A YELLOW, LUMINOUS BURNER FLAME,

CARBONING OR SOOTING OF THE FINNED HEAT

EXCHANGER, OR CREA TE A RISK OF ASPHYXIA TION. DO NOT

OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION

AIR.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN P AN SHOULD BE INST ALLED UNDER THE BOILER. Such

pans should be fabricated with sides at least 2-1/2" (64 mm) deep,

with length and width at least 2" (51 mm) greater than the

dimensions of the boiler and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES IN

ROOMS OR AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE IGNITER OR MAIN BURNER FLAMES

CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES PERMIT

OPERATION OF GAS APPLIANCES IF INSTALLED 18 INCHES

OR MORE ABOVE THE FLOOR. THIS MAY REDUCE THE RISK

IF LOCATION IN SUCH AN AREA CANNOT BE AVOIDED.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE BOILER.

OPEN CONT AINERS OF FLAMMABLE MA TERIAL SHOULD NOT

BE STORED OR USED IN THE SAME ROOM WITH THE BOILER.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion, and

draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction; weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation, and draft hood dilution must be obtained from outdoors

or spaces freely communicating with the outdoors. The installation

instructions for confined spaces in tightly constructed buildings must

be followed to ensure adequate air supply.

CONFINED SPACE

(a) U. S. INSTALLATIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN OR

WITHIN 12 INCHES (30 CM) OF THE ENCLOSURE TOP AND

ONE IN OR WITHIN 12 INCHES (30 CM) OF THE ENCLOSURE

BOTTOM. Each opening shall have a free area of at least one

square inch per 1000 Btuh (2,208 mm2of per kw) of the total input

of all appliances in the enclosure, but not less than 100 square

inches (645 cm2).

7

Page 8

If the confined space is within a building of tight construction, air for

combustion, ventilation, and draft hood dilution must be obtained

from outdoors. When directly communicating with the outdoors or

communicating with the outdoors through vertical ducts, two

permanent openings, located in the aforementioned manner, shall

be provided. Each opening shall have a free area of not less than

one square inch per 4000 Btu/hr (551 mm

2

per kw) of the total

input of all appliances in the enclosure. If horizontal ducts are

used, each opening shall have a free area of not less than one

square inch per 2000 Btu/hr (1101 mm

2

per kw) of the total input of

all appliances in the enclosure.

(B) CANADIAN INSTALLATIONS

Ventilation of the space occupied by the boiler(s) shall be provided

by an opening for ventilation air at the highest practical point

communicating with outdoors. The total cross- sectional area shall

be at least 10% of the area of the combustion air opening but in no

case shall the cross-sectional area be less than 10 square inches

(6500 mm²).

1. DRAFT HOOD

The integral draft hood, louvers or cabinetry must not be altered.

Provision must be made if the boiler is installed in confined space

or a small boiler room to accommodate draft hood spillage and

avoid risks described above. The upper air opening called for in

the AIR REQUIREMENTS section of this manual is for this purpose.

2. VENT CONNECTION

The minimum distance from adjacent public walkways, adjacent

buildings, openable windows and building openings shall not be

less than those values specified in the National Fuel Gas Code,

ANSI Z223.1 and/or CAN/CSA B149.1-00, Installation Codes:

Stack or chimney must be a minimum height of 12" (305 mm)

above the annual snow fall to prevent blockage.

Building materials must not come in contact with combustion

products from stack or chimney, due to the degrading properties of

flue products.

In addition to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1 square

inch per 7,000 BTUH (315 mm²/kw) up to and including 1,000,000

BTUH

plus 1 square inch per 14,000 BTU (158 mm2/kw) in excess

of 1,000,000 BTUH. This opening(s) shall be located at, or ducted

to, a point neither more than 18" (450 mm) nor less than 6 inches

(150 mm) above the floor level.

Where power vented equipment is used in the same room as the

boiler, sufficient air openings must be supplied.

UNDERSIZED OPENINGS MAY RESULT IN INSUFFICIENT AIR

FOR COMBUSTION.

Where an exhaust fan is installed in the same room with a boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT WITH AN INCREASED

RISK OF ASPHYXIATION.

VENTING THE BOILER

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE

BOILER MUST BE FOLLOWED TO AVOID CHOKED

COMBUSTION OR RECIRCULATION OF FLUE GASES. SUCH

CONDITIONS CAUSE SOOTING OR RISKS OF FIRE AND

ASPHYXIATION.

SINGLE WALL OR TYPE B VENTING MAY BE USED WITH

THESE BOILERS. ALL LOCAL UTILITY, STATE/ PROVINCIAL,

REGULATIONS ON VENTING MUST BE FOLLOWED.

VENT SIZING, INSTALLATION AND TERMINATION SHALL BE

IN ACCORDANCE WITH PART 7, VENTING OF EQUIPMENT,

OF THE NATIONAL FUEL GAS CODE, ANSI Z223.1, OR SECTION

7, VENTING SYSTEMS AND AIR SUPPLY FOR APPLIANCES,

OF THE CAN/CSA B149, INSTALLATION CODES, OR

APPLICABLE PROVISIONS OF THE LOCAL BUILDING CODES.

Materials may be protected from flue products by use of metal or

copper sheeting.

Flue products must have a minimum clearance of 4 feet (1.22 m)

horizontally from, and in no case above or below, unless a 4-foot

(1.22 m) horizontal distance is maintained, from electric meters,

gas meters, regulators and relief equipment.

The Canadian B149.1-00, Installation Code specifies a 6 foot

horizontal vent terminal clearance to gas and electric meters and

relief devices (this clearance is specified as 4 feet in the U.S. under

the National Fuel Gas Code, ANSI/Z223.1). Therefore instruction

provision 1.34.1-b19(d), which specifies compliance with the 4 foot

clearance, as applies in the U.S. only, and the B149.1-00 Installation

Code applies in Canada.

Vent connections must be made to an adequate stack or chimney

and shall be in accordance with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1, or Section 7, Venting

Systems and Air Supply for Appliances, of the CAN/CSA-B149.100, Installation Codes, or applicable provisions of the local building

codes. Size and install proper size vent pipe. Do not reduce pipe

size to less than that of the draft hood outlet unless permitted by

local code.

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet [1.2 m]),

noncombustible hangers suitable for the weight and design of the

materials employed to prevent sagging and to maintain a minimum

upward slope of 1/4" per foot (21mm/m) from the boiler to the vent

terminals. Dampers or other obstructions must not be installed in

the vent. Be sure that the vent connector does not extend beyond

the inside wall of the chimney.

Where a continuous or intermittent back draft is found to exist the

cause must be determined and corrected. A special vent cap may

be required. If the back draft cannot be corrected by the normal

methods or if a suitable draft cannot be obtained, a blower type

flue gas exhauster may be employed to ensure proper venting and

correct combustion (where permitted by local code). Contact your

A. O. Smith dealer for power vent instructions.

8

Page 9

WARNING

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

3. CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by most local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the common vent or

chimney at a point ABOVE the flue pipe from the oil furnace.

UL/ULC listed doublewall type B-1 gas vents, through 24" (610

mm) diameter, can be installed in heated and unheated areas and

can pass through floors, ceilings, partitions, walls and roofs,

provided the required clearance is observed.

At the time of removal of an existing boiler, the following steps

shall be performed with each appliance remaining connected to

the common venting system. Perform these steps while the other

appliances remaining connected to the common venting system

are not in operation.

GAS CONNECTIONS

WARNING

THIS BOILER IS NOT INTENDED TO OPERA TE A T GAS SUPPL Y

PRESSURE OTHER THAN SHOWN ON THE RATING PLATE.

EXPOSURE TO HIGHER GAS SUPPL Y PRESSURE MA Y CAUSE

DAMAGE TO GAS VALVES WHICH CAN RESULT IN FIRE OR

EXPLOSION. IF OVERPRESSURE HAS OCCURRED SUCH AS

THROUGH IMPROPER TESTING OF GAS LINES OR

EMERGENCY MALFUNCTION OF THE SUPPLY SYSTEM, THE

GAS VALVES MUST BE CHECKED FOR SAFE OPERATION.

MAKE SURE THAT THE OUTSIDE VENTS ON THE SUPPLY

REGULATORS AND THE SAFETY VENT VALVES ARE

PROTECTED AGAINST BLOCKAGE. THESE ARE PARTS OF

THE GAS SUPPLY SYSTEM, NOT THE BOILER. VENT

BLOCKAGE MAY OCCUR DURING ICE BUILD-UP OR SNOW

STORMS.

WHEN LOCAL CODES REQUIRE A MAIN MANUAL SHUTOFF

VALVE OUTSIDE THE BOILER JACKET, A SUITABLE MAIN

MANUAL SHUTOFF VALVE MUST BE INSTALLED IN A

LOCATION COMPLYING WITH THOSE CODES.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

APPROVED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

— Seal any unused openings in the common venting system.

— Visually inspect the venting system for proper size and

horizontal pitch and determine there is not blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

— Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes dryers

and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and

bathroom exhaust fans, so they will operate at maximum speed.

Close fireplace dampers.

— Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will

operate continuously.

— Test for spillage at the draft hood relief opening after five

minutes of main burner operation. Use the flame of a match

or candle, or smoke from a cigarette, cigar or pipe.

— After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning appliance to their

previous conditions of use.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG

OR SEDIMENT TRAP) UPSTREAM OF THE GAS CONTROLS,

MUST BE INCORPORATED IN THE PIPING. The dirt leg must be

readily accessible and not subject to freezing conditions. INST ALL

IN ACCORDANCE WITH RECOMMENDATIONS OF SERVING

GAS SUPPLIERS. REFER TO

Z223.1 AND/OR CAN/CSA-B149.1-00.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve gas inlet.

Fittings and unions in the gas line must be metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

The boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psi (3.5 kPa).

The boiler must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping systems at test pressures equal to

or less than 1/2 psi (3.5 kPa).

The boiler and its gas connection must be leak tested before placing

the boiler in operation.

Provisions for vent, bleed and gas relief lines (when applicable).

NATIONAL FUEL GAS CODE, ANSI

9

Page 10

PURGING

Gas line purging is required with new piping or systems in which

air has entered.

CAUTION

PURGING SHOULD BE PERFORMED BY PERSONS

EXPERIENCED IN THIS TYPE OF GAS SERVICE TO A VOID RISK

OF FIRE OR EXPLOSION. PURGE DISCHARGE MUST NOT

ENTER CONFINED AREAS OR SP ACES WHERE IGNITION CAN

OCCUR. THE AREA MUST BE WELL VENTILATED AND ALL

SOURCES OF IGNITION MUST BE INACTIVA TED OR REMOVED.

2A. SIZING GAS SUPPLY LINE (For single boiler installations

and for installations of multiples of two or three of same size

boilers).

Use table 1, which is taken from ANSI booklet Z223.1,

NATIONAL

FUEL GAS CODE, and/or CAN/CSA-B149.1-00 to size iron pipe

or equivalent gas supply line. Table 4 is based on a pressure drop

of 0.3 inches of water and a specific gravity of 0.60 which is

approximately for natural gas. (LP gas has an S.G. of about 1.53).

If the service pressure is five inches water column or less, use one

pipe size larger than specified in table 1 in order to minimize pressure

drop in the line.

BEFORE PLACING THE BOILER IN OPERATION, CHECK FOR

GAS LEAKAGE. Use soap and water solution or other material

acceptable for the purpose in locating gas leaks. DO NOT USE

MATCHES, CANDLES, FLAME OR OTHER SOURCES OF

IGNITION FOR THIS PURPOSE.

1. CORRECT GAS

Make sure the gas on which the boiler will operate is the same as

that specified on the boiler rating plate. Do not install the boiler if

equipped for a different type gas, consult your gas supplier. These

boilers are designed to operate on natural gas only.

T ABLE 4

MAXIMUM CAP ACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR (BASED UPON A PRESSURE DROP OF

0.3 INCH WA TER COLUMN AND 0.6 SPECIFIC GRA VITY GAS)

Length in Feet (Meters) Nominal Iron Pipe Size, Inches (NPT)

From Gas Meter 1 /2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4

10 (3) 132 278 520 1,050 1,600 3,050 4,800 8,500 17,500

20 (6) 92 190 350 730 1,100 2,100 3,300 5,900 12,000

30 (9) 73 152 285 590 890 1,650 2,700 4,700 9,700

40 (12) 63 130 245 50 0 760 1,450 2,300 4,100 8,300

50 (15) 56 115 215 44 0 670 1,270 2,000 3,600 7,400

60 (18) 50 105 195 40 0 610 1,150 1,850 3,250 6,800

70 (21) 46 96 180 370 560 1,050 1,700 3,000 6,200

80 (24) 43 90 170 350 530 990 1,600 2,800 5,800

90 (27) 40 84 160 320 490 930 1,500 2,600 5,400

100 (30) 38 79 150 305 460 870 1,400 2,500 5,100

125 (38) 34 72 130 275 410 780 1,250 2,200 4,500

150 (46) 31 64 120 250 380 710 1,130 2,000 4,100

175 (53) 28 59 1 10 225 350 650 1,050 1,850 3,800

200 (61) 26 55 100 210 320 610 980 1,700 3,500

*The heating value of natural gas is approximately 1050 Btu/ft³.

Propane (L.P .) gas has a heating value of approximately 2500 Btu/ft³.

2B. SIZING GAS SUPPLY LINE (For multiples of over three boilers

of same size or for multiple installations of two or more mixed

sizes).

Capacities in cubic feet per hour of 0.60 specific gravity gas for

different sizes and lengths are shown in table 4. No additional

allowance is necessary for an ordinary number of fittings.

Where it is necessary to use more than the average number of

pipe fittings i.e. elbows, tees, and valves in gas supply line, use a

pipe larger than specified to compensate for increased pressure

drop.

Multipliers To Be Used W ith T able 1 When Applying The

Gravity Factor To Other Than .60 Specific Gravity

Specific Specific

Gravity Multiplier Gravity Multiplier

.35 1.31 1.00 .78

.40 1.23 1.10 .74

.45 1.16 1.20 .71

.50 1.10 1.30 .68

.55 1.04 1.40 .66

*.60 (Nat.) 1.00 *1.50 (Prop.) .63

.65 .96 1.60 .61

.70 .93 1.70 .59

.75 .90 1.80 .58

.80 .87 1.90 .56

.85 .84 *2.00 (Butane) .55

.90 .82 2.10 .54

*Use these correction factors if exact specific gravity of the gas is not known.

TABLE 5

10

Page 11

Applications of the gravity factor converts the figures given in table

1 to capacities with another gas of different specific gravity. Such

application is accomplished by multiplying the capacities given in

table 1 by the multipliers shown in table 5.

To determine the size of each section of gas piping in a system

within the range of table 4 proceed as follows:

HIGH ALTITUDE INSTALLATIONS

IN CANADA

Acceptance of these models for use at altitudes above 2000 feet

(610 m) is based on field test of the individual installation by the

provincial/state authority having jurisdiction.

• Determine the gas demand of each appliance to be attached to

the piping system. When table 4 is to be used to select the

piping size, calculate the gas demand in terms of cubic feet per

hour for each piping system outlet. The gas demand for an

appliance can be found by dividing its heat input rate by the

gas’s heating value.

• Obtain or determine the length of piping from the gas meter or

service regulator to the appliance(s).

• In table 1, select the row showing the distance to the most remote

outlet or the next longer distance if the table does not give the

exact length. This is the only distance used in determining the

size of any section of gas piping. If the gravity factor is to be

applied, the values in the selected row of table 4 are multiplied

by the appropriate multiplier from table 5.

• Total the gas demands of all appliances on the piping system.

Enter table 4, on the left hand side, at the row equal to or just

exceeding the distance to the most remote outlet. Select the

pipe size in the row with a capacity equal to or just exceeding

the total gas demand. This is the required main gas supply line

size leading away from the gas meter or regulator. To determine

the pipe size required for each branch outlet leading away from

the main supply line, determine the gas demand for that outlet.

Enter table 4 on the same row, and select the branch pipe size

for a capacity equal to or just exceeding the demand at that

outlet. The main line can be resized for a lesser capacity after

each branch outlet, since the gas demand is reduced. Total the

gas demands of all remaining appliances branching off

downstream on the main gas line. Re-enter table 4 in the same

row and select the appropriate pipe size with adequate capacity.

Repeat the branch sizing and main line re-sizing for any

remaining appliances in the system.

EXAMPLE

Job Condition:

Determining the required gas pipe size for a system composed of

two A. O. Smith 720 boilers and two 960 boilers to be installed as

a multiple group, 50 lineal feet from meter. Gas to be used has a

.60 specific gravity and heating value of 1,000 Btu per cubic foot.

IN THE U.S.A.

WARNING

INSTALLATIONS ABOVE 2000 FEET REQUIRE REPLACEMENT

OF THE BURNER ORIFICES IN ACCORDANCE WITH SECTION

8.1.2 OF THE NATIONAL FUEL GAS CODE (ANSI Z223.1).

FAILURE TO REPLACE THE ORIFICES WILL RESULT IN

IMPROPER AND INEFFICIENT OPERATION OF THE APPLIANCE

RESUL TING IN THE PRODUCTION OF INCREASED LEVELS OF

CARBON MONOXIDE GAS IN EXCESS OF SAFE LIMITS WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

Y ou should contact your gas supplier for any specific changes which

may be required in your area.

Ratings specified by manufacturers for most boilers apply for

elevations up to 2000 feet (610 m). For elevations above 2000 feet

(610 m) ratings must be reduced by a rate of 4% for each 1000 feet

(305 m) above sea level.

Example: A Dura-Max is rated at 720,000 Btu/hr. (211 kw) input at

sea level. To operate the boiler at 5000 feet (1524 m) it must be

derated by 20% (4% x 5) to a new rating of 576,000 Btu/hr. (169

kw) input.

The input reduction is primarily achieved by reducing the size of

the main burner orifices. T o do this, the main burner orifices require

replacement with orifices sized for the particular installation

elevation. When ordering, be sure to state the model number and

the altitude of the location where the boiler is being installed.

Upon field deration of the boiler, adjustment to the gas pressure

regulator is required. See CHECKING AND ADJUSTING THE

INPUT in this manual for inlet and manifold pressure requirements.

Also, due to the input rating reduction required at high altitudes,

the output rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for applications.

WIRING CONNECTIONS

1. CONVENTIONAL INSTALLATIONS

Solution:

Two 720 Boilers = 1,440,000 Btuh (422 kw)

Two 960 Boilers = 1,920,000 Btuh (562 kw)

Total Btuh Input = 3,360,000 Btuh = (984 kw)

Total Btuh Input = 3,360,000 Btuh = 3,360 cf/h

Btu per Cubic Foot of Gas 1,000

With a cubic foot per hour demand of 3,360 and with 50 lineal feet

of gas supply line, table 4 shows a pipe size of 3" is required.

NOTE: For other than .60 specific gravity, apply multiplier factor

as shown in table 5.

11

All electrical work must be electrically bonded to ground in

accordance with the requirements of the authority having jurisdiction

or, in the absence of such requirements, with the National Electrical

Code, ANSI/NFPA 70 and/or the Canadian Electrical Code Part 1,

CSA C22.1, Electrical Code.

The electrical connections must be made so that the circulator will

operate before the gas valve opens. At no time may the controlling

system allow the burner to fire when there is no water flow through

the boilers.

AN ELECTRICAL GROUND IS REQUIRED TO REDUCE RISK

OF ELECTRIC SHOCK OR POSSIBLE ELECTROCUTION. Make

the ground connection to the screw provided in the electrical supply

junction box on the boiler.

Page 12

IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED WITH THE

APPLIANCE, MUST BE REPLACED, IT MUST BE REPLACED

WITH TYPE 105°C WIRE OR ITS EQUIVALENT, EXCEPT FOR

THE FLAME SENSOR AND IGNITION CABLE WHICH ARE 250°C.

SERVICING WIRING AND/OR CONTROL

SYSTEM HEADERS

Split systems with individual supply and return lines from the boiler

room should normally have this piping connected to supply and

return manifold headers near the boiler. To achieve good water

distribution with minimum pressure drop for several circuits,

manifolds should be larger than system loops.

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation.

Verify proper operation after servicing.

SYSTEMS EQUIPMENT

INSTALLATION

The following is a brief description of the equipment required for

installations noted in this manual. All installations must comply

with local codes.

The boilers described in this manual may be used for space heating

or for the heating of potable water. If the heater is to be used for

hydronic space heating, follow the descriptions given for equipment

required for installation on pages 12 through 31. However, if units

are to be used for heating potable water, the information describing

specific systems is found starting on page 32. Installations must

comply with all local codes.

WATER SUPPLY LINE

These boilers can be used ONLY in a forced circulation hot water

heating system. Since most forced circulation systems will be of

the closed type, install the water supply line as shown on piping

diagrams, fig’s. 10 and 14.

The circuits should be spaced on the header at a minimum of 3"

(76 mm) center to center. Install a balancing cock in each return line.

Manifold headers are recommended for split systems with or without

zone valves and also those installations with zone circulators. If

the system is to be split at remote points, good practice requires

special attention be given to main pipe sizing to allow balancing of

water flow.

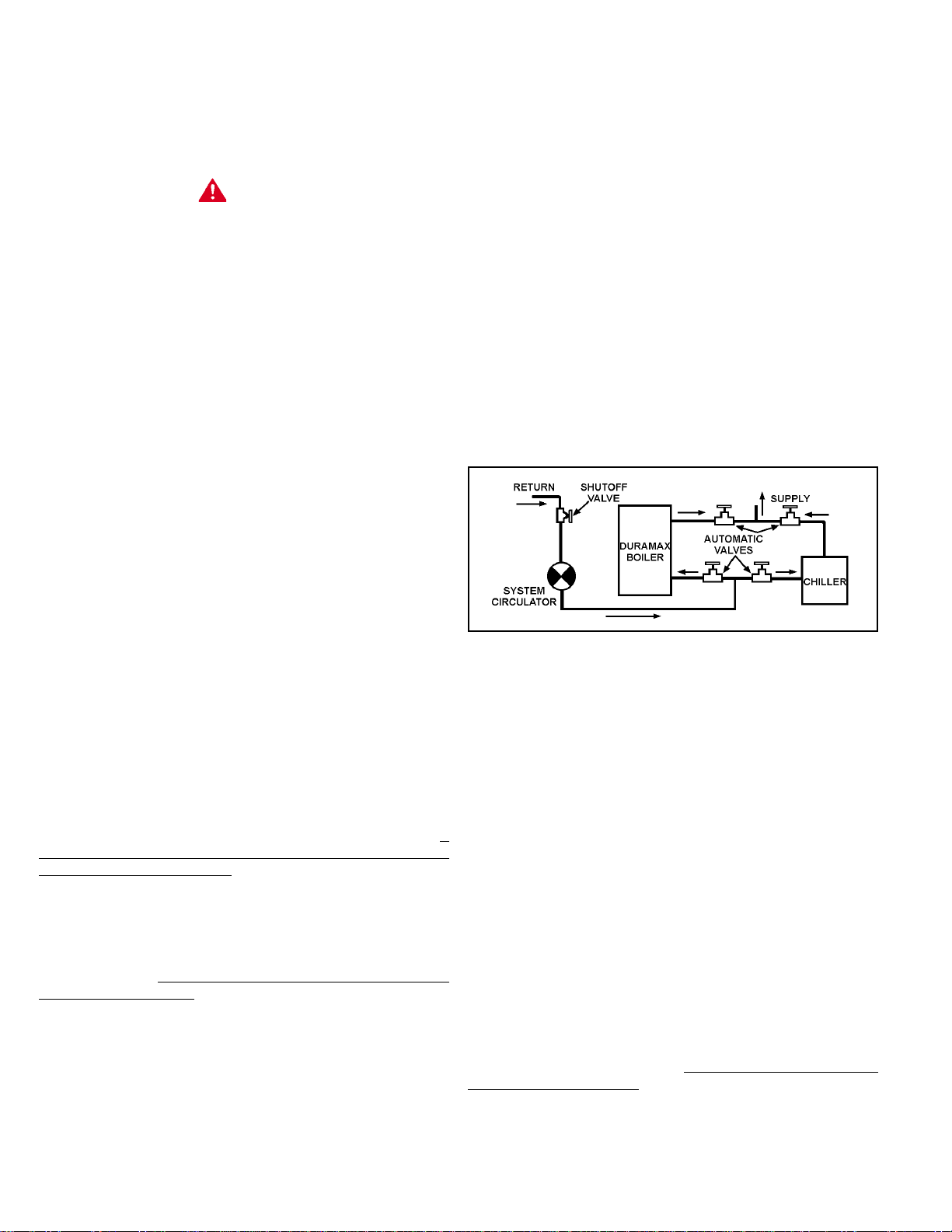

COOLING PIPING

The boiler, when used in connection with a refrigeration system,

must be installed so the chilled medium is piped in parallel with the

boiler with appropriate valves to prevent the chilled medium from

entering the boiler. See figure 7.

FIGURE 7

Fast filling of large pipe, old radiator installations (where high

pressures are not available) requires bypassing of the pressure

reducing valve. Generally, pressure purging is not possible with a

well pump system. High point air venting is essential. For details,

refer to OPERATING INSTRUCTIONS section of this manual.

If the system is of the open type, a pressure reducing valve will not

be required as the water supply to the system will be controlled by

a manually operated valve. An overhead surge tank is required.

MINIMUM PRESSURE OF 15 PSI MUST BE MAINTAINED ON

THE BOILER AT ALL TIMES to ensure avoidance of potential

damage to the boiler which may not be covered by the warranty.

EXP ANSION T ANK

If the system is of the closed type, install an expansion tank as

shown in fig. 10.

system is very important and is directly related to the total water

volume of the system. Refer to ASME or other reliable specifications

for sizing.

An air separator as shown in the piping diagrams is recom- mended

especially for modern commercial hydronic systems.

The sizing of the expansion tank for a closed

VENT VALVES

It is recommended that automatic, loose key or screwdriver type

vent valves be installed at each convector or radiator.

Water temperature in the heating system must be reduced to less

than 100°F before cooling system is started, or damage to the

chiller unit may occur.

The boiler piping system of a hot water boiler connected to heating

coils located in air handling units where they may be exposed to

refrigerated air circulation must be equipped with flow control valves

or other automatic means to prevent gravity circulation of the boiler

water during the cooling cycle.

A

Primary/secondary pumping of both the chiller(s) and the boiler(s)

is an excellent winter-summer change-over method, because

cooling flow rates are much more than heating flow rates. In this

way each system (heating or cooling) is circulated independently.

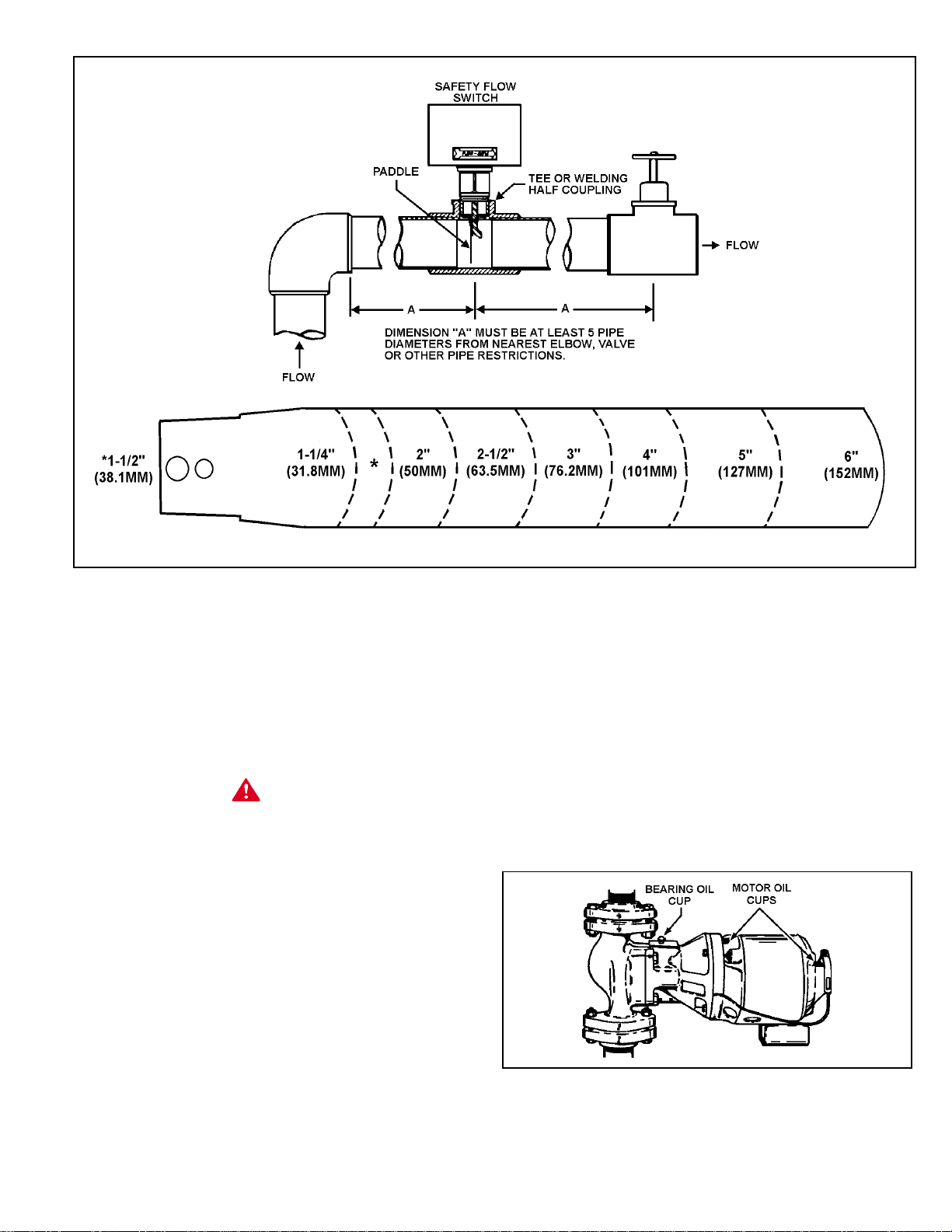

SAFETY FLOW SWITCH

The safety flow switch is a safety device which must be installed at

the water outlet of the unit to prevent main burner operation in the

event of inadequate water flow through the boiler.

This switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward water flow. Do not install the switch where

the water flow is downward.

For best performance mount the switch in a section of pipe where

there is a straight run of at least 5 pipe diameters on each side of

the flow switch (i.e. do not locate adjacent to valves, elbows, orifices,

etc.).

12

Page 13

FIGURE 8

The flow switch shall be mounted in the top opening of the reducing

tee and provide adequate paddle length in the flow stream. For

example in a 2" pipe installation use a 2" x 2" x 1" reducing tee. For

2" or 3" pipe use the paddle segments as supplied. For other pipe

sizes (i.e. 2-1/2") trim the paddle to the proper pipe size, see fig. 8.

If a standard tee is used, install a face or hex bushing in the top

opening. The paddle must be adjusted or trimmed to the size of

the pipe in which it will be installed.

CAUTION

The paddle must not touch any part of the tee into which it is

installed. Screw the flow switch in position so the flat of the paddle

is at right angles to the flow. The arrow on the side case must

point in the direction of the flow.

To adjust the flow rate setting:

1. Remove the flow switch cover.

2. For higher flow rate—turn the range adjusting screw clockwise.

3. For lower flow rate—turn the range adjusting screw

counterclockwise.

Where units are installed in multiples, each boiler must be

individually protected by a safety flow switch.

THE CIRCULATING PUMP MUST BE PROPERLY SIZED FOR

YOUR APPLICATION.

Water hardness, system pressure drop and temperature rise across

the boiler all affect how large a circulating pump must be.

Running "hard water" too slowly through the boiler can result in

damage due to lime or scale accumulation.

Running "soft water" too quickly through the boiler can result in

damage due to velocity flow erosion.

T able 4 has been designed to assist in determining operating ranges.

Use this chart as a guide when sizing pumps.

FIGURE 9

CIRCULA TING PUMP

Dura-Max boilers are designed to operate over a wide range of

temperatures and flow rates.

13

Although each circulator that requires oil is oiled and operated by

the manufacturer, IT MUST BE OILED AGAIN BEFORE BEING

OPERATED. Oil the three oil cups (2 on the motor, 1 on the pump)

as instructed on the oil tube supplied with the unit, fig. 9.

Page 14

Thereafter, during the heating season, lubricate the three oil cups

at least once every four months. Combination heating/cooling

systems or water heating (Cer-temp) systems should be lubricated

every four months year-round.

all cases, that the water temperature be set for the lowest

temperature which satisfies the user's hot water needs. This will

also provide the most energy efficient operation of the water heater

and minimize scale formation.

Use 2 or 3 teaspoonfuls in bearing oil cups, fig. 9, and 10 or 12

drops in the motor oil cups. Use No. 20 non-detergent motor oil.

Follow the same oiling procedure if a replacement circulator is

installed into the system.

LOW WATER CUTOFF

A low water cutoff is a safety device which is installed in the boiler

piping to prevent the boiler from firing in the event of inadequate

water levels in the boiler system.

Where required by local code, this optional device is to be installed

in the boiler piping at a level above that of the heat exchanger.

A float type or an electronic probe type low water cutoff may be

used. The manufacturers installation instructions must be followed.

A hot water boiler installed above radiating level or as required by

the Authority having jurisdiction, must be provided with a low water

cutoff device at the time of boiler installation.

T ANK TEMPERATURE CONTROL

The water temperature in the storage tank is controlled by the Tank

Temperature Control. The sensing element is mounted inside the

hot water storage tank, see fig. 24.

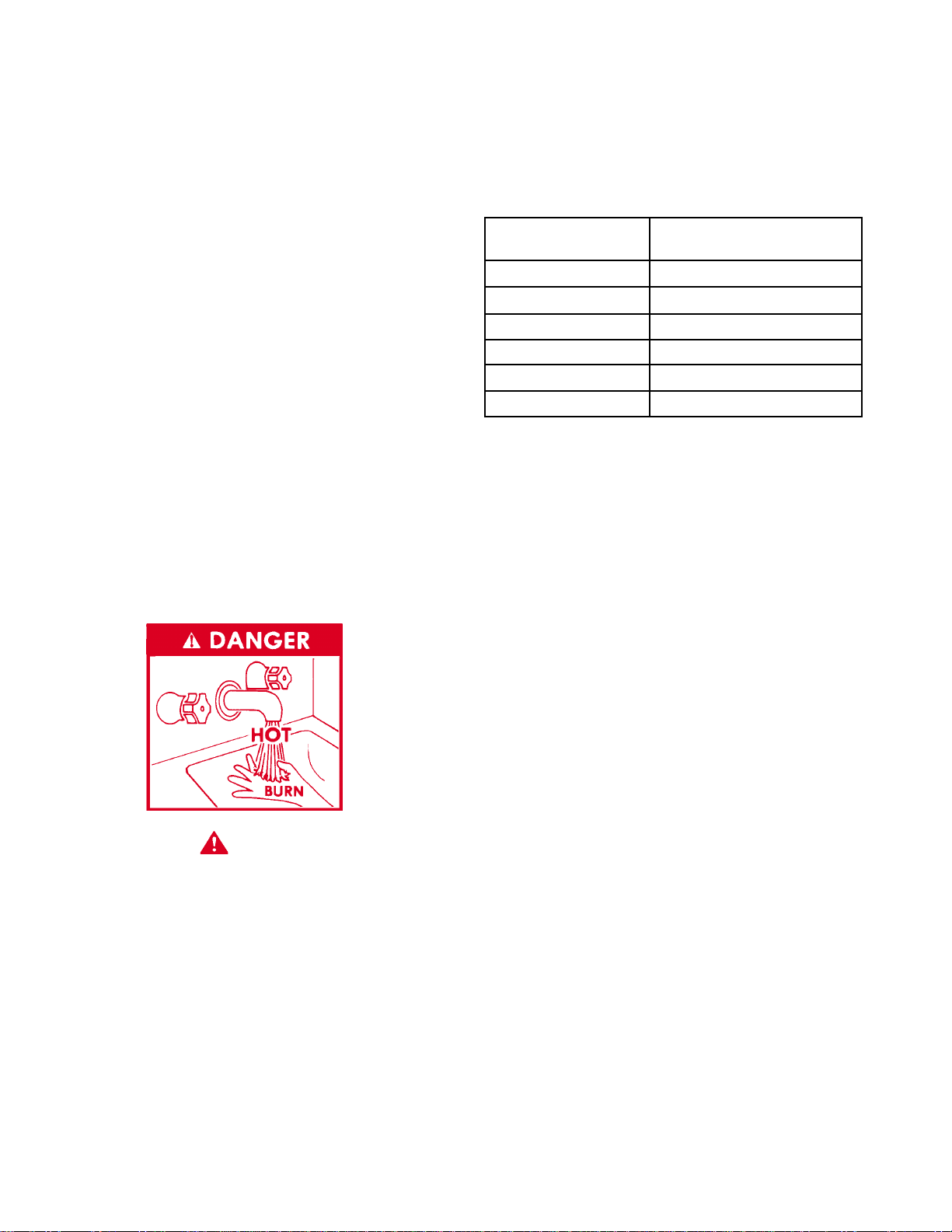

SETTING THE WATER TEMPERATURE AT 120°F (49°C) WILL

REDUCE THE RISK OF SCALDS. Some states require settings at

specific lower temperatures. T able 6 below shows the approximate

time-to-burn relationship for normal adult skin.

Temperature Time to Produce 2nd & 3rd

Setting Degree Burns on Adult Skin

Over 170°F (77°C) Nearly instantaneous

160°F (71°C) About 1/2 second

150°F (65°C) About 1-1/2 seconds

140°F (60°C) Less than 5 seconds

130°F (55°C) About 30 seconds

120°F or less (49°C) More than 5 minutes

TABLE 6

USE ANTI-SCALD V ALVE(S) in the hot water system to reduce the

risks of scalds at points of use such as lavatories, sinks and bathing

facilities.

A change in water temperature in the storage tank lower than the

Tank Temperature Control setting will cause the sensor to close its

contacts and consequently, energize the boiler.

If the Tank Temperature Control is out of calibration, replace it with

a new one; do not attempt to repair this control.

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD

BURNS RESULTING IN SERIOUS PERSONAL INJURY AND/OR

DEATH. THE TEMPERATURE AT WHICH INJURY OCCURS

VARIES WITH THE PERSON'S AGE AND TIME OF EXPOSURE.

THE SLOWER RESPONSE TIME OF CHILDREN, AGED, OR

DISABLED PERSONS INCREASES THE HAZARDS TO THEM.

NEVER ALLOW SMALL CHILDREN TO USE A HOT WATER T AP

OR TO DRAW THEIR OWN BATH WATER. NEVER LEAVE A

CHILD OR DISABLED PERSON UNATTENDED IN A BATHTUB

OR SHOWER.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA

WHERE THE GENERAL PUBLIC DOES NOT HA VE ACCESS TO

SET TEMPERATURES.

The tank temperature control is adjustable from 100°F to 220°F

(38°C to 104°C). It is recommended that lower water temperatures

be used to avoid the risk of scalding. It is further recommended, in

SYSTEM INSTALLATION

GENERAL

If the system is to be filled with water for testing or other purposes

during cold weather and before actual operation, care must be taken

to prevent a downdraft entering the boiler or freezing air from

contacting the system. Failure to do so may cause the water in the

system to freeze with resulting damage to the system. Damage

due to freezing is not covered by the warranty.

Good practice requires that all piping, etc., be properly supported.

CONVENTIONAL SP ACE HEA TING INST ALLA TION

Modern fin type boilers are exceptionally fast heating units. The

low water volumes in relation to firing rates require special attention

to water flow rates for smooth, efficient operation. These

considerations for the A. O. Smith copper heat exchanger boilers

are covered below.

Refer to page 5 for tables on these units showing “flow rate vs.

pressure drop and temperature rise”.

Figure 10 shows a typical installation of the boiler.

A system with several flow controlled zones, or with a 3-way mixing

valve system which could present a flow rate to the boiler of less

than that required for a maximum of 50°F (10°C) temperature rise

at the minimum firing rate, should be designed with compensating

bypasses at the boiler.

14

Page 15

A system bypass should be installed as shown in fig. 10 to prevent

boiler circulation starvation when the system zones call for reduced

flow.

This bypass may also be used with multiple boilers manifolded for

reverse-return flow. The system bypass would be installed from

boiler outlet to suction side of pump.

Standard Dura-Max models are factory equipped for Single Stage

Firing only.

Dura-Max models may be factory equipped for Dual Stage Firing.

The gas valve automatically steps gas input down from full input

to approximately 50% total input. System conditions will then

determine if boiler will shut down or if unit will return smoothly to

full input.

Dura-Max models may also be equipped with modulation which

automatically adjusts the boiler output to match the system heat

loss and variations of system water flow. Minimum firing rate is 50%.

INST ALLA TION AS BOILER REPLACEMENT

Installation as boiler replacement on an old system with large

water volume may result in condensation within the boiler on cold

starts. This condensing of water vapor in the combustion area

can be prevented if a portion of the system water flow is diverted

past the boiler to cause an increase in boiler temperature rise.

INSTALL IN ACCORDANCE WITH

ALL LOCAL CODES.

WHEN BLOW DOWN VALVE IS

REQUIRED, INSTALL IN PLACE OF

THE DRAIN VAL VE SHOWN.

DB INST ALLATION

FIGURE 10

15

Page 16

NOTES:

1. BUILDING TEMPERATURE CONTROLS SUPPLY ELECTRIC POWER TO BUILDING CIRCULA T OR.

2. MAIN FLOW SWITCH PROVES MAIN WATER FLOW BEFORE ENERGIZING, SEQUENCING AND

RESETTING CONTROLS.

3. OUTDOOR THERMOSTAT REQUIRED IF BUILDING CONTROLS DO NOT PROVIDE AUTOMATIC

SHUT-DOWN OF RESET CONTROLS DURING WARM WEATHER.

16

Page 17

BYP ASS BALANCING

With systems where water temperature can be expected to drop

appreciably due to long standby periods, or heavy draw down, a

bypass pipe of at least 1" size with a balancing cock should be

installed between the boiler inlet and outlet (see fig. 10). When

the system first starts, the valve should be slowly opened until the

condensing ceases. This adjustment remains at a permanent

setting to establish required temperature rise across the boiler.

LINEAR-TEMP SP ACE HEA TING APPLICA TIONS

Controlling of these systems is decided mainly by the type of

building system controlling that is desired. A single boiler

installation might be controlled directly from space temperature

thermostat(s). Multiple boiler installations are more effective when

the boilers are sequenced in and out of operation by some form of

main water temperature controller. With one or two boilers,

individual control set at progressive temperature may be used.

For more than two boilers, electronic sequencing controlling is

recommended.

Individual controls, or the separate stages of a step controller,

should fire a boiler and also start the boiler loop circulator whenever

that boiler is fired. Some large installations may require the firing

of more than one boiler per stage.

The system or primary circulator may or may not be controlled by

the boiler sequencer. When this pump is operated through the

first switch of any type of step controller, care should be taken to

determine if a motor starter is needed due to insufficient switch

capacity.

Figure 11 shows a typical field wiring diagram for a single stage

boiler LINEAR-TEMP installation. The boiler may be controlled

by a main temperature controller as shown or may include outdoor

reset if desired.

The following fig’s. 11 thru 13 are shown as layouts for various

choices of controls often found in commercial heating. These

layouts are not intended to be wiring diagrams and only show the

relation of one device to another in the system.

Figure 11 is a typical layout of controls for two boilers with two

circulators and thermal balancers plus optional outdoor reset

control.

Figure 12 is shown as a typical control group for various multiple

boiler installations, and is not intended to imply that this is the

only arrangement to be considered. Commercial size installations

are always best when designed to individual building requirements.

If the primary pump is controlled by a manual switch or any other

controllers, the electric current supply to the boiler group should

be through the primary pump controller. The fast response of

A.O. Smith boilers eliminates any need to maintain boiler

temperature when the system is satisfied. Wiring should always

prevent firing of boiler(s) when there is no water flow in the mains.

Installation diagrams show safety flow switches in the outlet piping

from each boiler as good protection against any boiler being fired

when the boiler loop circulator is not in operation.

These safety flow switches will also provide some protection if

there is a loss of water.

LINEAR-TEMP multiple boiler installations are especially adapted

to the use of outdoor reset for main water temperatures. This

feature is not mandatory but offers smooth, efficient operation of

a modern system.

Outdoor reset systems should utilize an automatic shutdown

control if there is a continuous recirculating main and/or if the

entire building is not under control of space temperature

thermostats. A single bulb outdoor sensing control will serve this

requirement. This precaution will prevent overheating of halls,

stairways or other uncontrolled areas. There are occasions when

outdoor temperatures are temporarily too warm for even a

moderate amount of heating in these areas.

Space temperature controlling can be varied to meet the building

requirements. Either the single thermostat, as shown, or multiple

zone thermostats should control a common relay. This relay

controls electric power to the system primary circulator and to the

main water temperature controller. This provides for water

movement in the system before the main temperature controller

can start the secondary circulating pump or fire the boiler.

17

FIGURE 13

LINEAR-TEMP SPACE HEATING INSTALLA TIONS

A. New Installation

The A.O. Smith LINEAR-TEMP system has been designed to

provide efficient, trouble-free operation of these boilers with any

of the following conditions:

• unknown system flow rate.

• varying flow rates as with zoned systems and 3-way valve

system.

• multiple boiler installations.

Figure 14 shows piping and accessory arrangement for 1 or more

boilers pumped independently of the primary system mains. Pipe

sizing and boiler loop pump selection data, are shown in table 4 for

several different temperature rises across various boiler sizes.

Total heating requirements for the building can be supplied by a

series of boiler loops all connecting to a common pipe joining the

system supply and return mains. The supply and return branches

of each boiler loop must join the common pipe only a short nipple

length apart. The different sets of branches should be installed

reasonably close together, but not necessarily to the short nipple

length as required for the supply and return of each set. These

branches may be made with tees or with welded connections.

The installer is reminded that the total boiler flow rates do not

have to match the system flow rate. Flow rates through heat

Page 18

generator type boilers establish temperature rises. The deciding

factor in choice of boiler temperature rise relates to the boiler inlet

temperature. Boiler outlet, minus system temperature drop, is

boiler inlet temperature. THE BOILER TEMPERATURE RISE

SHOULD NOT RAISE THE OUTLET TEMPERATURE UP T O THE

MAXIMUM 250°F (115°C) SETTING OF THE LIMIT CONTROL.

If inlet temperature (plus temperature rise) of any boiler on the

group exceeds 240°F (115°C), that boiler and all downstream

boilers will shut down (cycle on and off).

B. Commercial Boiler Replacements

Application of LINEAR-TEMP to a commercial boiler replacement

with an old multiple pump installation is an excellent way to

modernize the system. The A. O. Smith boiler(s) should be

installed on a pipe loop with a separate circulating pump. Use

table 7 to determine pipe sizes and operating ranges.

The following illustration shows how the system headers should

be connected to pipe loop that is installed with the replacement

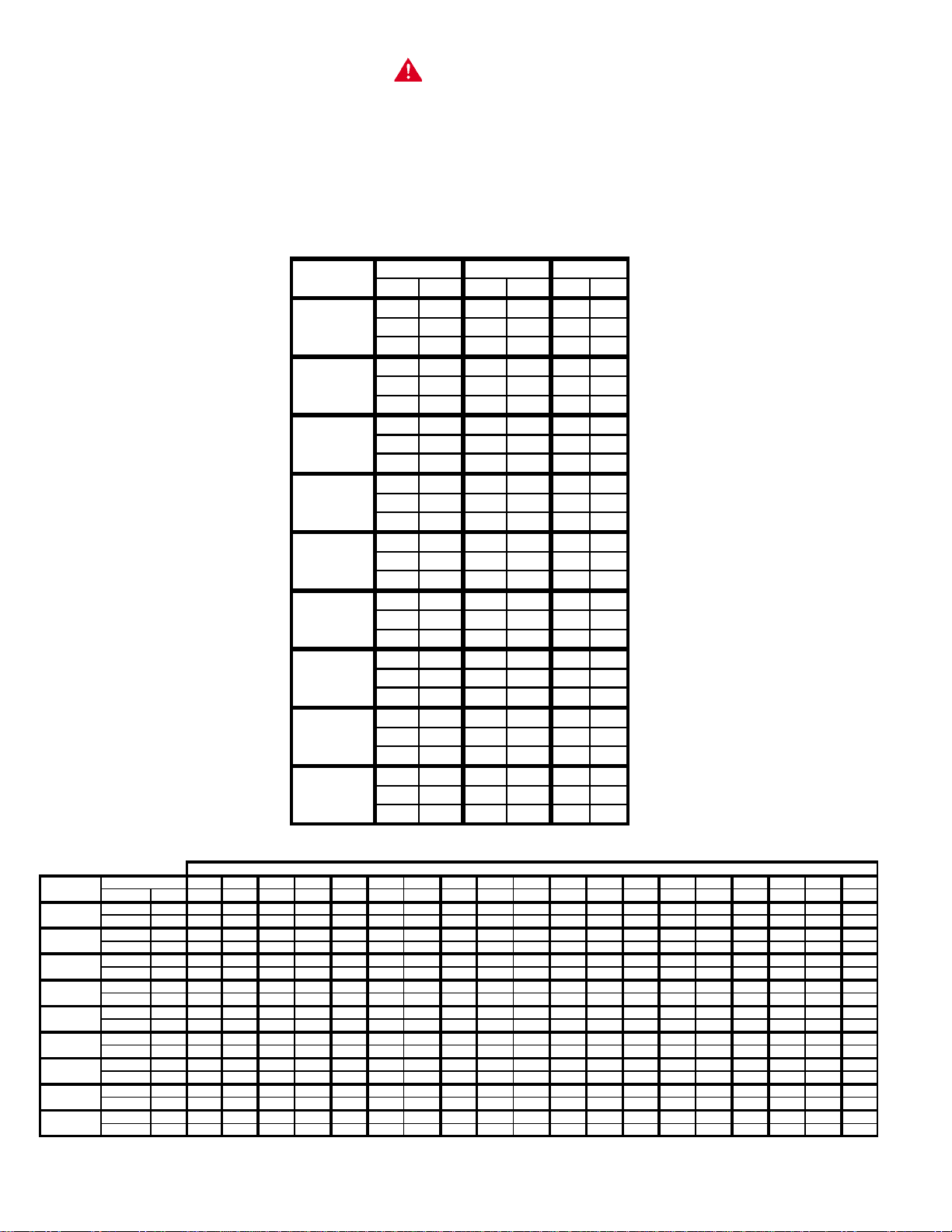

TABLE 7, DuraMax Pump Performance Requirements

Model

DW-720

DW-840

DW-960

DW-1080

DW-1210

DW-1350

DW-1480

DW-1610

DW-1810

* - Head loss includes the loss through 40 feet (12 m ) of pipe and normal f i t t in gs.

Water

Category

Soft

Normal

Hard

Hard

Soft

Normal

Hard

Hard

Soft

Normal

Normal

Hard

Soft

Normal

Normal

Hard

Soft

Normal

Hard

Soft

Normal

Hard

Soft

Normal

Hard

Hard

Soft

Normal

Hard

Hard

Soft

Normal

Hard

Hard

Temp Rise

FC

35 19.4 34 127 3.7 1.1 2" #0012 (1/7 HP)

25 13.9 47 178 6.2 1.9 2" #120 ( 1/6 HP)

18 10.0 65 248 12.6 3.8 2" #1935 (1/3 HP)

18 10.0 65 248 7.4 2.3 2 1/2" #121 (1/4 HP)

35 19.4 39 149 5.9 1.8 2" #0012 (1/7 HP)

25 13.9 55 208 8.9 2.7 2" #120 ( 1/6 HP)

18 10.0 76 289 15.1 4.6 2" #1935 (1/3 HP)

18 10.0 76 289 10.2 3.1 2 1/2" #1935 (1/3 HP)

35 19.4 45 170 6.6 2.0 2" #0012 (1/7 HP)

25 13.9 63 238 12.1 3.7 2" #1935 (1/3 HP)

25 13.9 63 238 7.6 2.3 2 1/2" #121 (1/4 HP)

18 10.0 87 330 12.9 3.9 2 1/2" #1935 (1/2 HP)

35 19.4 51 193 7.0 2.1 2" #120 ( 1/6 HP)

25 13.9 72 271 13.1 4.0 2" #1935 (1/3 HP)

25 13.9 72 271 7.1 2.2 2 1/2" #121 (1/4 HP)

19 10.6 94 356 11.3 3.4 2 1/2" #1935 (1/2 HP)

35 19.4 57 217 4.7 1.4 2 1/2" #120 (1/6 HP)

25 13.9 80 303 8.8 2.7 2 1/2" #121 (1/4 HP)

19 10.6 105 399 13.4 4.1 2 1/2" #1935 (1/2 HP)

35 19.4 64 242 6.0 1.8 2 1/2" #121 (1/4 HP)

25 13.9 89 339 10.5 3.2 2 1/2" #1935 (1/3 HP)

18 10.0 124 470 18.9 5.8 2 1/2" #1935 (3/4 HP)

35 19.4 68 259 6.3 1.9 2 1/2" #121 (1/4 HP)

25 13.9 96 362 12.7 3.9 2 1/2" #1935 (1/2 HP)

18 10.0 133 503 20.5 6.2 2 1/2" #1935 (3/4 HP)

18 10.0 133 503 12.2 3.7 3" #133 (3/4 HP)

35 19.4 74 281 8.0 2.4 2 1/2" #121 (1/4 HP)

25 13.9 104 394 13.6 4.1 2 1/2" #1935 (1/2 HP)

20 11.1 130 492 20.7 6.3 2 1/2" #1935 (3/4 HP)

20 11.1 130 492 12.4 3.8 3" #133 (3/4 HP)

38 21.1 77 291 8.2 2.5 2 1/2" #121 (1/4 HP)

28 15.6 104 395 13.8 4.2 2 1/2" #1935 (1/2 HP)

22 12.2 133 503 20.9 6.4 2 1/2" #1935 (3/4 HP)

22 12.2 133 503 12.6 3.8 3" #133 (3/4 HP)

Flow Rate HdLoss*

GPM LPM ft

boiler(s). Make-up water connections, and accessories are not

shown.

Supply and return headers of the old system should be connected

to the boiler loop with a pair of tees set close together. The boiler

loop pump and the boiler(s) should be wired to operate only when

any of the system pumps are in operation. The number of zone

pumps that may be in operation at any particular time will take

their required flow rate out from the first tee in the boiler piping.

This water will be circulated through the proper branches from the

supply header to the zones calling for heat. The water will be brought

back to the return header and then into the second tee in the boiler

pipe loop. There will be no conflict between the boiler pump and

the zone pumps when the two tees in the boiler loop are placed

close together.