SERIES

683XXC

SYNTHESIZED HIGH PERFORMANCE

SIGNAL GENERATOR

GPIB PROGRAMMING MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10338

REVISION: A

PRINTED: JANUARY 1999

COPYRIGHT 1999 ANRITSU CO.

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the

warranty period.Buyers shall prepay transportation charges for equipment returned to Anritsu for

warranty repairs. Obligation islimited to the originalpurchaser. Anritsuis not liable forconsequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also, the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer,unauthorizedmodification or misuse, oroperationoutside of the environmentalspecifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment

and computor programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifications, and informationis prohibited; theyshall not bereproduced, copied, or used in whole orin part

as the basis for manufacture or sale of the equipment or software programs without the prior writtten consent of Anritsu Company.

MANUAL CHANGES

0$18$/

7LWOH Series 683XXC Synthesized High Performance Signal Generator GPIB Programming Manual

3DUW1XPEHU 10370-10338

5HY/WU'DWH A / January 1999

&+$1*(3$&.(7

3DUW1XPEHU 10900-00285

,16758&7,216

1. Make the manual changes listed below. The changes are listed in numerical order by page number.

Effectivity is all 683XXC models with Firmware Version 1.01 and above.

2. The replacement pages provided are for technical changes to the manual. The black bar or bars in the

replacement page margins shows the area in which the changes were made.

&+$1*( 0D\

Page 2-5

Replace with enclosed pages 2-5 and 2-6, Changed: May 1999.

Pages 2-52

Replace with enclosed pages 2-51 thru 2-58, Changed: May 1999.

Page 2-51A

Insert enclosed page 2-51A/2-52A after page 2-52, Changed: May 1999.

Page A- 1 5

Replace with enclosed pages A-15 and A-16, Changed: May 1999.

ECN: MI001082

683XXC PM C-1

Table of Contents

Chapter 1 - General GPIB Information

1-1 SCOPE OF MANUAL.................1-3

Electronic Manual ..................1-3

1-2 INTRODUCTION ...................1-3

1-3 IEEE-488 INTERFACE BUS DESCRIPTION ...1-5

Functional Elements.................1-6

Bus Structure.....................1-7

Data Bus Description ................1-7

Data Byte Transfer Control Bus Description ....1-8

General Interface Management Bus Description. . 1-9

Device Interface Function Capability .......1-10

Message Types ...................1-11

1-4 683XXC GPIB OPERATION.............1-13

Setting GPIB Operating Parameters .......1-13

Selecting the Interface Language .........1-13

Response to GPIB Interface Function Messages . 1-13

Chapter 2 - Programming with GPIB Commands

2-1 INTRODUCTION ...................2-3

2-2 COMMAND CODES .................2-3

2-3 DATA INPUT RESTRICTIONS............2-6

2-4 PARAMETER AND DATA ENTRY COMMANDS . . 2-7

Opening a Parameter ................2-7

Data Entry ......................2-7

Using the SYZ Command..............2-15

2-5 CW FREQUENCY COMMANDS ..........2-16

2-6 ANALOG AND STEP SWEEP COMMANDS....2-17

Sweep Range ....................2-17

Alternate Sweep ..................2-18

Sweep Triggering ..................2-18

Analog/Step Sweep Select .............2-20

Special Step Sweep .................2-22

2-7 FREQUENCY MARKER COMMANDS ......2-22

2-8 OUTPUT POWER LEVELING COMMANDS . . . 2-24

683XXC PM i

Table of Contents (Continued)

Linear or Logarithmic Power Level Selection . . . 2-24

RF Output Power Level Selection .........2-24

Alternate Sweep RF Output Power Level Selection2-24

Output Power Leveling ...............2-24

ALC Power Slope ..................2-27

Attenuator Decoupling ...............2-27

2-9 MODULATION COMMANDS............2-28

Amplitude Modulation ...............2-28

Frequency Modulation ...............2-29

Phase Modulation..................2-30

Pulse Modulation ..................2-31

2-10 MEASURE FUNCTION COMMANDS .......2-39

2-11 OUTPUT COMMANDS ...............2-40

2-12 STORED SETUP COMMANDS...........2-45

2-13 SRQ AND STATUS BYTE COMMANDS ......2-47

Status Bytes.....................2-47

SRQ Generation...................2-47

2-14 CONFIGURATION COMMANDS..........2-52

2-15 GROUP EXECUTE TRIGGER COMMANDS . . . 2-53

2-16 LIST SWEEP COMMANDS.............2-54

Accessing and Editing a List ............2-54

List Sweep Triggering ...............2-56

Generating a List Sweep ..............2-56

2-17 FAST-FREQUENCY-SWITCHING COMMANDS . 2-58

Loading the Frequency Table ...........2-58

2-18 POWER-OFFSET-TABLE COMMANDS ......2-62

Loading the Power-Offset Table ..........2-62

2-19 USER LEVEL CALIBRATION COMMANDS . . . 2-65

Editing the Table Data ...............2-69

2-20 MASTER-SLAVE OPERATION COMMANDS . . . 2-73

2-21 SELF TEST COMMAND ..............2-74

2-22 MISCELLANEOUS COMMANDS .........2-76

2-23 PROGRAM ERRORS ................2-77

Invalid Parameter .................2-77

Syntax ........................2-77

ii 683XXC PM

Table of Contents (Continued)

2-24 RESET PROGRAMMING AND DEFAULT

CONDITIONS ...................2-78

2-25 PROGRAMMING EXAMPLES ...........2-79

Appendix A - Index of GPIB Commands

A-1 INTRODUCTION...................A-1

683XXC PM iii/iv

Chapter 1

General GPIB Information

Table of Contents

1-1 SCOPE OF MANUAL.................1-3

Electronic Manual ..................1-3

1-2 INTRODUCTION ...................1-3

1-3 IEEE-488 INTERFACE BUS DESCRIPTION ...1-5

Functional Elements.................1-6

Bus Structure.....................1-7

Data Bus Description ................1-7

Data Byte Transfer Control Bus Description ....1-8

General Interface Management Bus Description. . 1-9

Device Interface Function Capability .......1-10

Message Types ...................1-11

1-4 683XXC GPIB OPERATION.............1-13

Setting GPIB Operating Parameters .......1-13

Selecting the Interface Language .........1-13

Response to GPIB Interface Function Messages . 1-13

Chapter 1

General GPIB Information

1-1

SCOPE OF MANUAL

This manual provides information for remote operation of the Series

683XXC Synthesized High Performance Signal Generator using commands sent from an external controller via the IEEE-488 General Purpose Interface Bus (GPIB). It includes the following:

A general description of the GPIB and the bus data transfer and

q

control functions.

A listing of the IEEE-488 Interface Function Messages recog-

q

nized by the signal generator with a description of its response.

A complete listing and description of all 683XXC GPIB com-

q

mands (i.e., Product Specific Commands) that can be used to control signal generator operation with programming examples.

This manual is intended to be used in conjunction with the Series

683XXC Synthesized High Performance Signal Generator Operation

Manual, P/N 10370-10337. Refer to that manual for general information about the 683XXC, including equipment set up and front panel

(manual mode) operating instructions.

Electronic

Manual

This manual is available on CD ROM as an Adobe

Acrobat Portable Document Format (*.pdf) file. The

file can be viewed using Acrobat Reader, a free program that is also included on the CD ROM. The file

is “linked” such that the viewer can choose a topic to

view from the displayed “bookmark” list and “jump”

to the manual page on which the topic resides. The

text can also be word-searched. Contact Anritsu

Customer Service for price and availability.

1-2

INTRODUCTION

This chapter provides a general description of the GPIB and the bus

data transfer and control functions. It also contains a listing of the

683XXC’s GPIB interface function subset capability and response to

IEEE-488 interface function messages.

The GPIB information presented in this chapter is general in nature.

For complete and specific information, refer to the following documents: ANSI/IEEE Std 488.1-1987 IEEE Standard Digital Interface

for Programmable Instrumentation and ANSI/IEEE Std 488.2-1987

IEEE Standard Codes, Formats, Protocols and Common Commands.

These documents precisely define the total specification of the mechanical and electrical interface, and of the data transfer and control

protocols.

683XXC PM 1-3

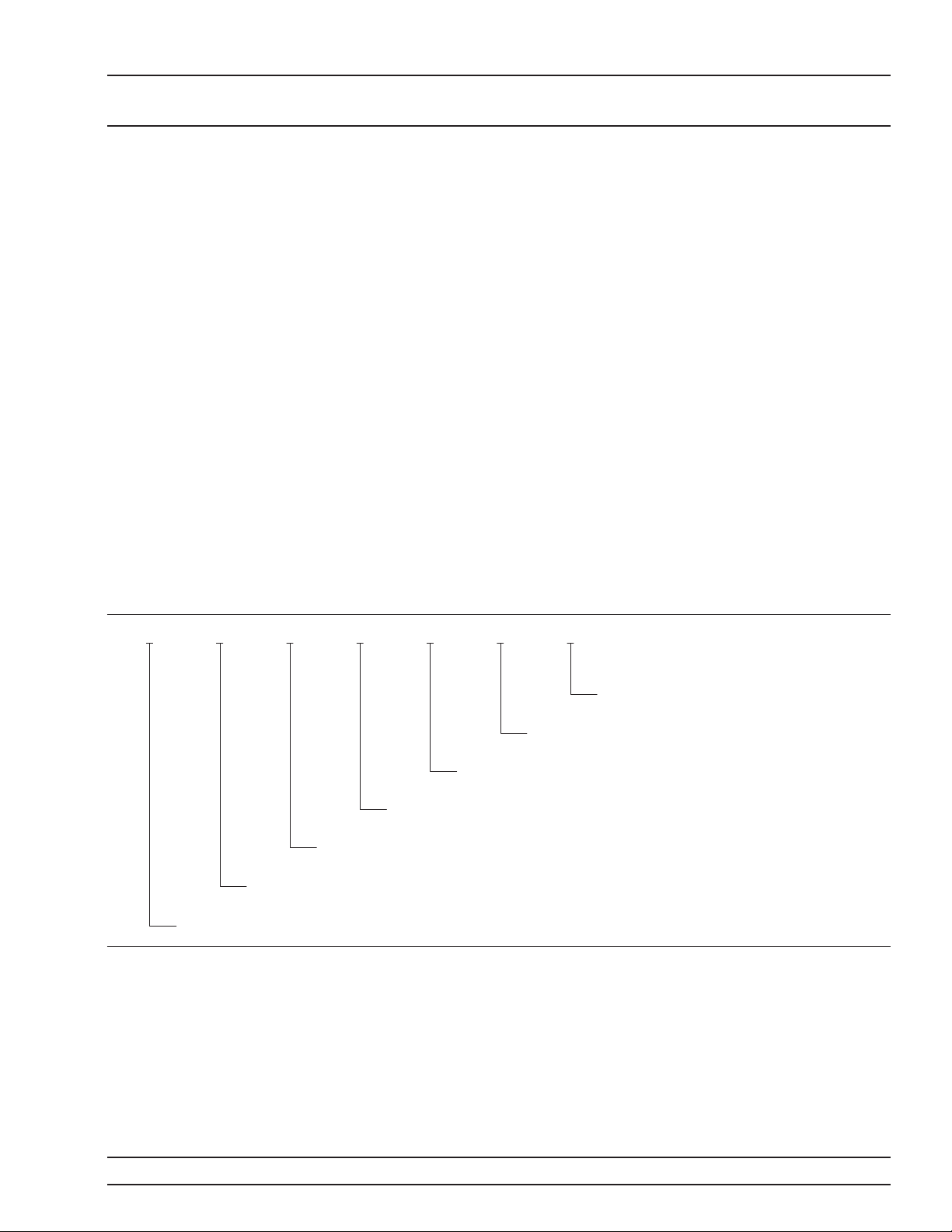

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

IE EE -488 B U S (16 L ines)

DEVICE A

A b le to ta lk , lis te n ,

and control

(e.g. CO M PUTER)

DEVICE B

A b le to ta lk a n d lis te n

(e.g. 683X XC

SIGNAL

GENERATOR)

DEVICE C

D a ta B u s

(8 signal lines)

D a ta B y te T ra n s fe r

Control Bus

(3 signal lines)

DATA LINES

HANDSHAKE Lines

O n ly a b le to lis te n

(e.g. O THER

IN STR UM ENT**)

DEVICE D

O n ly a b le to ta lk

(e.g. O THER

IN STR UM ENT**)

G eneral Interface

M anagem ent B us

(5 signal lines)

DATA INPUT/OUTPUT,

DIO 1 thru DIO 8

DAV - DATA VALID

NRFD - NOT READY FOR DATA*

NDAC - NO T DATA ACCEPTED*

IFC - INTERFACE CLEAR

ATN - ATTENTION

SRQ - SERVICE REQ UEST

REN - REMO TE ENABLE

E O I - E N D O R ID E N T IF Y

* NEG ATION IS REPRESENTED B Y

LOW STATE ON THESE TW O LINES

** IF U S E D

Figure 1-1. Interface Connections and GPIB Bus Structure

M anagem ent

C O N TR O L Lines

1-4 683XXC PM

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

1-3

IEEE-488 INTERFACE

BUS DESCRIPTION

The IEEE-488 General Purpose Interface Bus (GPIB) is an instrumentation interface for integrating instruments, computers, printers, plotters, and other measurement devices into systems. The GPIB uses 16

signal lines to effect transfer of information between all devices connected on the bus.

The following requirements and restrictions apply to the GPIB.

No more than 15 devices can be interconnected by one contiguous

q

bus; however, an instrumentation system may contain more than

one interface bus.

The maximum total cumulative cable length for one interface bus

q

may not exceed twice the number of devices connected (in meters), or 20 meters—whichever is less.

A maximum data rate of 1 Mb/s across the interface on any sig-

q

nal line.

Each device on the interface bus must have a unique address,

q

ranging from 00 to 30.

The devices on the GPIB are connected in parallel, as shown in Figure

1-1. The interface consists of 16 signal lines and 8 ground lines in a

shielded cable. Eight of the signal lines are the data lines, DIO 1 thru

DIO 8. These data lines carry messages (data and commands), one

byte at a time, among the GPIB devices. Three of the remaining lines

are the handshake lines that control the transfer of message bytes between devices. The five remaining signal lines are referred to as interface management lines.

The following paragraphs provide an overview of the GPIB including a

description of the functional elements, bus structure, bus data transfer

process, interface management bus, device interface function requirements, and message types.

683XXC PM 1-5

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

Functional

Elements

Effective communications between devices on the

GPIB requires three functional elements; a talker,a

listener, and a controller. Each device on the GPIB is

categorized as one of these elements depending on

its current interface function and capabilities.

Talker

A talker is a device capable of sending devicedependent data to another device on the bus when

addressed to talk. Only one GPIB device at a time

can be an active talker.

Listener

A listener is a device capable of receiving devicedependent data from another device on the bus

when addressed to listen. Any number of GPIB devices can be listeners simultaneously.

Controller

A controller is a device, usually a computer, capable

of managing the operation of the GPIB. Only one

GPIB device at a time can be an active controller.

The active controller manages the transfer of

device-dependent data between GPIB devices by

designating who will talk and who will listen.

System Controller

The system controller is the device that always retains ultimate control of the GPIB. When the system is first powered-up, the system controller is the

active controller and manages the GPIB. The system controller can pass control to a device, making

it the new active controller. The new active controller, in turn, may pass control on to yet another device. Even if it is not the active controller, the

system controller maintains control of the Interface

Clear (IFC) and Remote Enable (REN) interface

management lines and can thus take control of the

GPIB at anytime.

1-6 683XXC PM

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

Bus

Structure

The GPIB uses 16 signal lines to carry data and

commands between the devices connected to the

bus. The interface signal lines are organized into

three functional groups.

Data Bus (8 lines)

q

Data Byte Transfer Control Bus (3 lines)

q

General Interface Management Bus (5 lines)

q

The signal lines in each of the three groups are designated according to function. Table 1-1 lists these

designations.

Table 1-1. Interface Bus Signal Line Designations

Bus Type

Data Bus DIO1–DIO8 Data Input/Output, 1 thru 8

Data Byte

Transfer

Control Bus

General

Interface

Management

Bus

Signal Line

DAV

NRFD

NDAC

ATN

IFC

SRQ

REN

EOI

Name

Data Available

Not Ready For Data

Not Data Accepted

Attention

Interface Clear

Service Request

Remote Enable

End Or Identify

Function

Data Bus

Description

The data bus is the conduit for the transfer of data

and commands between the devices on the GPIB. It

contains eight bi-directional, active-low signal lines

—DIO 1 thru DIO 8. Data and commands are transferred over the data bus in byte-serial, bit-parallel

form. This means that one byte of data (eight bits) is

transferred over the bus at a time. DIO 1 represents

the least-significant bit (LSB) in this byte and

DIO 8 represents the most-significant bit (MSB).

Bytes of data are normally formatted in seven-bit

ASCII (American Standard Code for Information Interchange) code. The eighth (parity) bit is not used.

Each byte placed on the data bus represents either a

command or a data byte. If the Attention (ATN) interface management line is TRUE while the data is

transferred, then the data bus is carrying a bus

command which is to be received by every GPIB device. If ATN is FALSE, then a data byte is being

transferred and only the active listeners will receive

that byte.

683XXC PM 1-7

GENERAL GPIB IEEE-488 INTERFACE

1st Data Byte 2nd Data Byte

Valid

Not

Valid

Valid

Not

Valid

All

Ready

None

Ready

All

Ready

None

Ready

All

Accept

None

Accept

None

Accept

All

Accept

DIO1-DIO8

(composite)

DAV

NRFD

NDAC

INFORMATION BUS DESCRIPTION

Figure 1-2. Typical GPIB Handshake Operation

Data Byte

Transfer

Control Bus

Description

Control of the transfer of each byte of data on the

data bus is accomplished by a technique called the

“three-wire handshake”, which involves the three

signal lines of the Data Byte Transfer Control Bus.

This technique forces data transfers at the speed of

the slowest listener, which ensures data integrity in

multiple listener transfers. One line (DAV) is controlled by the talker, while the other two (NRFD and

NDAC) are wired-OR lines shared by all active listeners. The handshake lines, like the other GPIB

lines, are active low. The technique is described

briefly in the following paragraphs and is depicted

in Figure 1-2. For further information, refer to

ANSI/IEEE Std 488.1.

DAV (Data Valid)

This line is controlled by the active talker. Before

sending any data, the talker verifies that NDAC is

TRUE (active low) which indicates that all listeners

have accepted the previous data byte. The talker

then places a byte on the data lines and waits until

NRFD is FALSE (high) which indicates that all addressed listeners are ready to accept the information. When both NRFD and NDAC are in the proper

state, the talker sets the DAV line TRUE (active

low) to indicate that the data on the bus is valid

(stable).

1-8 683XXC PM

NRFD (Not Ready For Data)

This line is used by the listeners to inform the

talker when they are ready to accept new data. The

talker must wait for each listener to set the NRFD

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

line FALSE (high) which they will do at their own

rate. This assures that all devices that are to accept

the data are ready to receive it.

NDAC (Not Data Accepted)

This line is also controlled by the listeners and is

used to inform the talker that each device addressed

to listen has accepted the data. Each device releases

NDAC at its own rate, but NDAC will not go FALSE

(high) until the slowest listener has accepted the

data byte.

General

Interface

Management

Bus

Description

The general interface management bus is a group of

five signal lines used to manage the flow of information across the GPIB. A description of the function of

each of the individual control lines is provided below.

ATN (Attention)

The active controller uses the ATN line to define

whether the information on the data bus is a command or is data. When ATN is TRUE (low), the bus

is in the command mode and the data lines carry

bus commands. When ATN is FALSE (high), the bus

is in the data mode and the data lines carry devicedependent instructions or data.

EOI (End or Identify)

The EOI line is used to indicate the last byte of a

multibyte data transfer. The talker sets the EOI line

TRUE during the last data byte.

The active controller also uses the EOI line in conjunction with the ATN line to initiate a parallel poll

sequence.

IFC (Interface Clear)

Only the system controller uses this line. When IFC

is TRUE (low), all devices on the bus are placed in a

known, quiescent state (unaddressed to talk, unaddressed to listen, and service request idle).

REN (Remote Enable)

Only the system controller uses this line. When

REN is set TRUE (low), the bus is in the remote

mode and devices are addressed either to listen or to

talk. When the bus is in remote and a device is addressed, it receives instructions from the GPIB

rather than from its front panel. When REN is set

FALSE (high), the bus and all devices return to local

operation.

683XXC PM 1-9

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

SRQ (Service Request)

The SRQ line is set TRUE (low) by any device requesting service by the active controller.

Device

Interface

Function

Capability

An interface function is the GPIB system element

which provides the basic operational facility through

which a device can receive, process, and send messages. Each specific interface function may only

send or receive a limited set of messages within particular classes of messages. As a result, a set of interface functions is necessary to achieve complete

communications among devices on the GPIB.

ANSI/IEEE Std 488.1 defines each of the interface

functions along with its specific protocol.

ANSI/IEEE Std 488.2 specifies the minimum set of

IEEE 488.1 interface capabilities that each GPIB

device must have. This minimum set of interface

functions assures that the device is able to send and

receive data, request service, and repond to a device

clear message. Table 1-2 lists the interface function

capability of the series 683XXC signal generators.

Table 1-2. 683XXC Interface Function Capability

Function

Identifier

AH1 Acceptor Handshake Complete Capability

SH1 Source Handshake Complete Capability

Function 683XXC Capability

T6 Talker No Talk Only (TON)

L4 Listener No Listen Only (LON)

SR1 Service Request Complete Capability

RL1 Remote/Local Complete Capability

PP1 Parallel Poll Complete Capability

DC1 Device Clear Complete Capability

DT1 Device Trigger Complete Capability

C0, C1, C2,

C3, C28

E2 Tri-StateDrivers Three-state bus drivers

Controller Capability

Options

C0, No Capability;

C1, System Controller;

C2, Send IFC and Take Charge;

C3, Send REN;

C28, Send IF Messages

1-10 683XXC PM

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

Message

Types

There are three types of information transmitted

over the GPIB—interface function messages,

device-specific commands, and data and instrument

status messages.

Interface Function Messages

The controller manages the flow of information on

the GPIB using interface function messages, usually

called commands or command messages. Interface

function messages perform such functions as initializing the bus, addressing and unaddressing devices,

and setting device modes for remote or local operation.

There are two types of commands—multiline and

uniline. Multiline commands are bytes sent by the

active controller over the data bus (DIO1-DIO8)

with ATN set TRUE. Uniline commands are signals

carried by the individual interface management

lines.

The user generally has control over these commands; however, the extent of user control depends

on the implementation and varies with the specific

GPIB interface hardware and software used with

the external controller.

Device-Specific Commands

These commands are keywords or mnemonic codes

sent by the external controller to control the setup

and operation of the addressed device or instrument. The commands are normally unique to a particular instrument or class of instruments and are

described in its documentation.

Device-specific commands are transmitted over the

data bus of the GPIB to the device in the form of ASCII strings containing one or more keywords or

codes.They are decoded by the device’s internal con-

troller and cause the various instrument functions

to be performed.

Data and Instrument Status Messages

These messages are sent by the device to the external controller via the GPIB. They contain measurement results, instrument status, or data files that

the device transmits over the data bus in response

to specific requests from the external controller. The

contents of these messages are instrument specific

and may be in the form of ASCII strings or binary

data.

683XXC PM 1-11

GENERAL GPIB IEEE-488 INTERFACE

INFORMATION BUS DESCRIPTION

In some cases data messages will be transmitted

from the external controller to the device. For example, messages to load calibration data.

An SRQ (service request) is an interface function

message sent from the device to the external controller to request service from the controller, usually

due to some predetermined status condition or error.

To send this message, the device sets the SRQ line

of the General Interface Management Bus true,

then sends a status byte on the data bus lines.

An SRQ interface function message is also sent by

the device in response to a serial poll message from

the controller, or upon receiving an Output Status

Byte(s) command from the controller. The protocols

associated with the SRQ functions are defined in the

ANSI/IEEE Std 488.2 document.

The manner in which interface function messages

and device-specific commands are invoked in programs is implementation specific for the GPIB interface used with the external controller. Even though

both message types are represented by mnemonics,

they are implemented and used in different ways.

Normally, the interface function messages are sent

automatically by the GPIB driver software in response to invocation of a software function. For example, to send the IFC (Interface Clear) interface

fuction message, one would call the ibsic function of

the National Instruments software driver. On the

other hand, the command *RST (Reset) is sent in a

command string to the addressed device. In the case

of the National Instruments example, this would be

done by using the ibwrt function call.

1-12 683XXC PM

GENERAL GPIB 683XXC

INFORMATION GPIB OPERATION

1-4

683XXC GPIB

OPERATION

All Series 683XXC Synthesized High Performance Signal Generator

functions, settings, and operating modes (except for power on/standby)

are controllable using commands sent from an external controller via

the GPIB. When in the remote (GPIB) mode, the signal generator

functions both as a listener and a talker. The GPIB interface function

capability of the 683XXC is listed in Table 1-2 (page 1-10).

Setting GPIB

Operating

Parameters

Selecting the

Interface

Language

The 683XXC leaves the factory with the GPIB address value set to 5 and the data delimiting terminator set to carriage return and line feed (CR/LF). A

different address value can be entered from the

front panel using the Configure GPIB menu. Using

this same menu, the data delimiting terminator can

be changed to carriage return (CR) only. Refer to

Chapter 2 of the Series 683XXC Synthesized High

Performance Signal Generator Operation Manual

for the procedure.

Series 683XXC Synthesized High Performance Signal Generators with Option 19 can be remotely operated using one of two external interface languages

—Native or SCPI. The Native interface language

uses a set of 683XXC GPIB Product-Specific commands to control the instrument; the SCPI interface

language uses a set of the Standard Commands for

Programmable Instruments commands to control

the unit. Selecting which of these external interface

languages is to be used can be done from the front

panel using the Configure GPIB menu. Refer to

Chapter 2 of the Series 683XXC Synthesized High

Performance Signal Generator Operation Manual

for the procedure.

Response to

GPIB

Interface

Function

Messages

Table 1-3 (page 1-14) lists the GPIB Interface Function Messages that the 683XXC will recognize and

respond to. With the exception of the Device Clear

and Selected Device Clear messages, these messages affect only the operation of the 683XXC GPIB

interface. The signal generator's response for each

message is indicated.

Interface function messages are transmitted on the

GPIB data lines and interface management lines as

either unaddressed or addressed commands. The

manner in which these messages are invoked in programs is implementation dependent. For programming information, refer to the documentation

included with the GPIB Interface for the external

controller used.

683XXC PM 1-13

GENERAL GPIB 683XXC

INFORMATION GPIB OPERATION

Table 1-3. 683XXC Response to GPIB Interface Function Messages

Interface Function Message

Addressed

Command

683XXC Response

Device Clear (DCL)

Selected Device Clear

(SDC)

Go To Local (GTL) Yes Returnsthe 683XXC to local (front

Group Execute Trigger

(GET)

Interface Clear (IFC) No Stops the683XXC GPIB interface

Local Lockout (LLO) No Disables the frontpanel menu

Remote Enable (REN) No Places the 683XXC under remote

Serial-Poll Enable (SPE) No Outputs the serial-poll status byte.

Serial-Poll Disable (SPD) No Disables the serial-poll function.

Parallel-Poll Configure (PPC) Yes Respondsto a parallel-poll message

Parallel-Poll Unconfigure

(PPU)

No

Yes

Yes Executesa string of commands, if

No Disables the parallel-poll function.

Resets the 683XXC to itsdefault

state. (Equivalent to sending the

*

RST command.)

panel) control.

programmed.

from listening or talking. (Thefront

panel controls are not cleared.)

RETURN TO LOCALsoft-key.

(GPIB) control when it hasbeen addressed to listen.

(PPOLL) by setting assigned data

bus line to the logicalstate (1,0) that

indicates its correct SRQ status.

1-14 683XXC PM

Chapter 2

Programming with

GPIB Commands

Table of Contents

2-1 INTRODUCTION ...................2-3

2-2 COMMAND CODES .................2-3

2-3 DATA INPUT RESTRICTIONS............2-6

2-4 PARAMETER AND DATA ENTRY COMMANDS . . 2-7

Opening a Parameter ................2-7

Data Entry ......................2-7

Using the SYZ Command..............2-15

2-5 CW FREQUENCY COMMANDS ..........2-16

2-6 ANALOG AND STEP SWEEP COMMANDS....2-17

Sweep Range ....................2-17

Alternate Sweep ..................2-18

Sweep Triggering ..................2-18

Analog/Step Sweep Select .............2-20

Special Step Sweep .................2-22

2-7 FREQUENCY MARKER COMMANDS ......2-22

2-8 OUTPUT POWER LEVELING COMMANDS . . . 2-24

Linear or Logarithmic Power Level Operation . . 2-24

RF Output Power Level Selection .........2-24

Alternate Sweep RF Output Power Level

Selection ......................2-24

Output Power Leveling ...............2-24

ALC Power Slope ..................2-27

Attenuator Decoupling ...............2-27

Table of Contents (Continued)

2-9 MODULATION COMMANDS............2-28

Amplitude Modulation ...............2-28

Frequency Modulation ...............2-29

Phase Modulation..................2-30

Pulse Modulation ..................2-31

2-10 MEASURE FUNCTION COMMANDS .......2-39

2-11 OUTPUT COMMANDS ...............2-40

2-12 STORED SETUP COMMANDS...........2-45

2-13 SRQ AND STATUS BYTE COMMANDS ......2-47

Status Bytes.....................2-47

SRQ Generation...................2-47

2-14 CONFIGURATION COMMANDS..........2-52

2-15 GROUP EXECUTE TRIGGER COMMANDS . . . 2-53

2-16 LIST SWEEP COMMANDS.............2-54

Accessing and Editing a List ............2-54

List Sweep Triggering ...............2-56

Generating a List Sweep ..............2-56

2-17 FAST-FREQUENCY-SWITCHING COMMANDS . 2-58

Loading the Frequency Table ...........2-58

2-18 POWER-OFFSET-TABLE COMMANDS ......2-62

Loading the Power-Offset Table ..........2-62

2-19 USER LEVEL CALIBRATION COMMANDS . . . 2-65

Editing the Table Data ...............2-69

2-20 MASTER-SLAVE OPERATION COMMANDS . . . 2-73

2-21 SELF TEST COMMAND ..............2-74

2-22 MISCELLANEOUS COMMANDS .........2-76

2-23 PROGRAM ERRORS ................2-77

Invalid-Parameter .................2-77

Syntax ........................2-77

2-24 RESET PROGRAMMING AND DEFAULT

CONDITIONS ...................2-78

2-25 PROGRAMMING EXAMPLES ...........2-79

2-2 683XXC PM

Chapter 2

Programming with

GPIB Commands

2-1

2-2

INTRODUCTION

COMMAND CODES

This chapter provides information for remote operation of the Series

683XXC Synthesized High Performance Signal Generators via the

GPIB using 683XXC GPIB commands. All GPIB Product-Specific commands that are accepted and implemented by the 683XXC are listed

and described by function. Sample programs showing usage of the

commands are also included.

There are over four hundred and fifty GPIB Product-Specific commands that are accepted and implemented by the 683XXC. These

GPIB commands allow the user to program all front panel and menu

functions (except for power on/standby). Each GPIB command is a

two- or three-character mnemonic code that represents an instrument

command or parameter; for example: RST (reset).

Table 2-1, beginning on page 2-4, is a listing of all 683XXC GPIB command mnemonic codes grouped into functional categories. The listing

for each category includes references to the paragraph and page

number in this chapter where a complete description of that group of

commands can be found.

NOTE

Aquick way to determine the function ofany of the GPIB command codes listed inTable 2-1 istolook up the commandcode

of interest inAppendix A of thismanual. Appendix Ais analphabetical index of all 683XXC GPIB command mnemonic

codes. Abrief description of the function of each command is

also included.

683XXC PM 2-3

PROGRAMMING WITH COMMAND

GPIB COMMANDS CODES

Table 2-1. 683XXC GPIB Command Codes Listed by Function (1 of 3)

GPIB Command

Group Function

Parameter Entry

Commands

Data Entry/

DataTerminator

Commands

CW Frequency

Commands

Command Codes Para. Page

F0, F1, F2, F3, F4,F5, F6, F7, F8, F9, M0,

M1, M2, M3, M4, M5,M6, M7, M8, M9,

XL0, XL1, XL2, XL3, XL4,XL5, XL6, XL7,

XL8, XL9, DLF, DFF, DFM, SLF0, SLF1,

SLF2, SLF3, SLF4, SLF5, SLF6,SLF7,

SLF8, SLF9, SLM0, SLM1, SLM2,SLM3,

SLM4, SLM5, SLM6, SLM7, SLM8,SLM9,

SLDF, SDT, SNS, SWT, LOS, PDT, PNS,

ADP1, ADP2, AMR, AMS, ASD,FDV,

FMR, FMS, PHD, PHR, PHS,PER, PR,

PW, W1, W2, W3, W4, PDY, D1, D2, D3,

D4, PVT, SDD, SDE, SDL, SDS,SLP, SOF,

SLV, SLL1, SLL2, EGI,ADD, FRS, LDT,

SYZ, UP,DN, CLO

0 thru 9, –, .,ADR, CLR, DB, DM, GH, MH,

KH, HZ, SEC, MS, US,NS, PCT, RD, GV,

MV, KV, DV, PCV,RV, SPS, TMS, VT

CF0, CF1, CF2, CF3, CF4,CF5, CF6,

CF7, CF8, CF9, CM0, CM1,CM2, CM3,

CM4, CM5, CM6, CM7, CM8,CM9, SQF,

SQU, SQD, ACW

2-4 2-7

2-4 2-13,

2-14

2-5 2-16

Analog and Step

Sweep Commands

Frequency Marker

Commands

Output Power

Leveling

Commands

Modulation

Commands

SF1, SF3, FUL, DF0, DF1,DF5, DF6,

AFU, AF1, AF3, AD1, AD5,AD6, AUT,

HWT, EXT, TRG, TRS, RSS, SWP, SSP,

LIS, LGS, MAN, DU1, DU0,TSS, SP1,

SP0

ME1, ME0, MK0, IM1, VM1 2-7 2-22

LOG, LIN, L0, L1, L2,L3, L4, L5, L6, L7,

L8, L9, AL0, AL1, AL2,AL3, AL4, AL5,

AL6, AL7, AL8, AL9, RF1,RF0, LO1, LO0,

IL1, DL1, PL1, ELF, ELR, LV0, LSP, AT0,

AT1,ATT(xx), SL0, SL1, EGO

AM0, AM1, AM2, AM3, AM4,AM5, AM6,

AM7, AM8, AMW(x), FM0, FM1,FM2,

FM3, FM4, FM5, FM6, FM7,FM8, FM9,

FMN, FMW, FML, FMU, FWV(x), PH0,

PH1, PH2, PH3, PH4, PH5,PH6, PH7,

PH8, PHN, PHW, PHV(x), P0, IP, XP, P3,

P4, PC1, PC4, PMD(x), PTG(x),PTR, PTF,

GP, DPT, SD0, SD1, SQP, SW0, SW1,

SW2, SW3, SW4, SW5, SW6,SC0, SC1

2-6 2-17

2-8 2-24

2-9 2-28

2-4 683XXC PM

PROGRAMMING WITH COMMAND

GPIB COMMANDS CODES

Table 2-1. 683XXC GPIB Command Codes Listed by Function (2 of 3)

GPIB Command

Group Function

Measure Function

Commands

Output Commands*IDN?, OI, OFL, OFH, OF0,OF1, OF2,

Stored Setup

Commands

Service Request

and Status Byte

Commands

AMI, FMD, MOM, PM1, PM0 2-10 2-39

OF3, OF4, OF5, OF6, OF7,OF8, OF9,

OM0, OM1, OM2, OM3, OM4,OM5, OM6,

OM7, OM8, OM9, OL0, OL1,OL2, OL3,

OL4, OL5, OL6, OL7, OL8,OL9, OLO,

ODF, OPD, OPS, OSD, OSS, OST, OAD1,

OAD2, OAR, OAW, OAS, OAB, OAI, OAE,

OFD, OFR, OFW, OFK, OFS, OFI,OFE,

OPR, OPP,OPW,OW1, OW2, OW3, OW4,

ODP, OD1, OD2, OD3, OD4, ODD, ODE,

ODL, ODS, OMD, OPC, OPT, OP5, OP3,

OMM, OPHD, OPHR, OPHW, OPHM,

OPHS, OPHI, OPHE, OPM, OVN,OWT,

OSE, OEM, OES, OSB,OSM, OSR

SAF, SAM, SM, SSN(M

RSN(M

ES1, ES0, FB1, FB0, LE1,LE0, MB0,

MB1, MB2, PE1, PE0, SB1,SB0, SE1,

SE0, SQ1, SQ0, UL1, UL0,LS1, LS0, LA1,

LA0, EL1, EL0, II1, II0,CSB

Command Codes Para. Page

), RCF, RCM,

1-9

1-9

)

2-11 2-40

2-12 2-45

2-13 2-47

Configuration

Commands

Group Execute

Trigger (GET)

Commands

List Sweep

Commands

Fast-FrequencySwitching

Commands

Power-OffsetTable Commands

User Level

Calibration

Commands

BPN, BPP,EP0, EP1, FRS, PPO, PPC,

RC0, RC1, RT0, RT1, RO0, RO1, TR0,

TR1

GTC, GTD, GTF, GTL, GTO, GTS,GTT,

GTU, Y

LST, ELI(xxxx), ELN(x), LF, LP, LIB(xxxx),

LIE(xxxx), AUT, HWT, EXT, TRG, MNT, UP,

DN, LEA, CTL

000-999

), ZEL, ZS(X

ZL(X

ZPN(bbbb),

ZTL(bbbbnnnnD8D8D8.....D8)

PT0, PT1, PTC, PTL 2-18 2-62

LU0, LU1, LU2, LU3, LU4,LU5, LUS, LUR 2-19 2-65

000-999

),

2-14 2-52

2-15 2-53

2-16 2-54

2-17 2-58

683XXC PM 2-5

Changed: May 1999

PROGRAMMING WITH DATA INPUT

GPIB COMMANDS RESTRICTIONS

Table 2-1. 683XXC GPIB Command Codes Listed by Function (3 of 3)

2-3

DATA INPUT

RESTRICTIONS

GPIB Command

Group Function

Master-Slave

Operation

Commands

Self Test

Command

Miscellaneous

Commands

S0, S1 2-20 2-73

TST 2-21 2-74

ADD, CS0, CS1, DS0, DS1,RL, RST, SNR 2-22 2-76

Command Codes Para. Page

The 683XXC signal generator does not accept parameter or data entries in an exponential or scientific notation format. The accepted data

formats are as follows:

A decimal or integer format for entering parameters and data.

q

A binary-byte format for entering the status byte mask com-

q

mands (paragraph 2-13), the RCF and RCM stored-setup commands (paragraph 2-12), the ZTL fast-frequency-switching command (paragraph 2-17), the power-offset-table commands

(paragraph 2-18), and the LUR user level calibration command

(paragraph 2-19).

Programming Note: The signal generator only recognizes the following 65 characters:

q

The 52 upper- and lower-case alphabetic characters. (The

682XXC/

683XXC accepts both upper- and lower-case characters without

distinguishing between the cases).

q

The minus sign (–).

q

The comma (,).

q

The decimal point (.).

q

The numerals between 0 and 9.

All characters other than the 65 listed above are ignored and can be

interspersed between meaningful characters without ill effect. This

use of other characters can improve readability. For example, the two

command strings below are valid and interchangable.

“F12.754GHF27.792GHSF1SWPMK0L12DM”

“F1=2.754 GH, F2=7.792 GH, SF1, SWP, MK0, L1=2 DM”

2-6 683XXC PM

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

2-4

PARAMETER AND DATA

ENTRY COMMANDS

Table 2-2 lists the command mnemonic codes that open parameters for

data entry. The table also provides the range of values permitted for

each parameter and the data terminator mnemonic codes for each.

Tables 2-3 and 2-4 (pages 2-13 and 2-14) list the data entry and data

terminator command mnemonic codes.

Opening a

Parameter

Data Entry When a parameter is open for data entry, its value

All of the commands listed in Table 2-2 open a parameter for data entry. Once opened, a parameter

remains open until one of the following occurs:

Another parameter is opened.

q

A function other than video markers, intensity

q

markers, or output power leveling is commanded.

The CLO (close open parameter) command is

q

received.

can be changed as follows:

q

By sending a numeric value followed by the appropriate terminator code.

q

By incrementing or decrementing its value using an associated step size.

NOTE

An appropriate data terminator must be

usedtoterminate anumeric-parameterentry, and itmust immediately followthenumeric value. If it doesnot, a parameter entry error will result.

The parameter and data entry commands do not affect the signal generator’s output unless the parameter being changed is also the current

output parameter. The commands, therefore, may be used to change

the preset values of parameters without altering the 683XXC output.

Example: Assume that the 683XXC is executing an F3-F4 sweep from

3 GHz to 10 GHz. Changing the value of F1 to 3 GHz with the command string “F13GH” does not affect the current output of the signal

generator. However, changing the value of F4 with the command

string “F4 16.01 GH” alters the output of the 683XXC because it

changes the end point of the F3-F4 sweep to 16.01 GHz.

683XXC PM 2-7

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-2. Parameter Entry Commands (1 of 5)

MNEMONIC

CODE

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

M0

M1

M2

M3

M4

M5

M6

M7

M8

M9

XL0

XL1

XL2

XL3

XL4

XL5

XL6

XL7

XL8

XL9

PARAMETER VALUES

Opens the F0 parameter

Opens the F1 parameter

Opens the F2 parameter

Opens the F3 parameter

Opens the F4 parameter

Opens the F5 parameter

Opens the F6 parameter

Opens the F7 parameter

Opens the F8 parameter

Opens the F9 parameter

Opens the M0 parameter

Opens the M1 parameter

Opens the M2 parameter

Opens the M3 parameter

Opens the M4 parameter

Opens the M5 parameter

Opens the M6 parameter

Opens the M7 parameter

Opens the M8 parameter

Opens the M9 parameter

Opens the L0 parameter

Opens the L1 parameter

Opens the L2 parameter

Opens the L3 parameter

Opens the L4 parameter

Opens the L5 parameter

Opens the L6 parameter

Opens the L7 parameter

Opens the L8 parameter

Opens the L9 parameter

Dependent on the

frequency range of

the instrument

Dependent on the

frequency range of

the instrument

Dependent on the

power level range of

the instrument

TERMINA-

TOR

GH

MH

KH

HZ

GH

MH

KH

HZ

DM

(Logarithmic)

VT

(Linear)

DLF

DFF

DFM

Opens theDF parameter

Opens theDF parameter

Opens theDF parameter

Dependent on the

frequency range of

the instrument

GH

MH

KH

HZ

Slave Unit Frequencies

SLF0

SLF1

SLF2

SLF3

SLF4

SLF5

SLF6

SLF7

SLF8

SLF9

Opens the F0 parameter

Opens the F1 parameter

Opens the F2 parameter

Opens the F3 parameter

Opens the F4 parameter

Opens the F5 parameter

Opens the F6 parameter

Opens the F7 parameter

Opens the F8 parameter

Opens the F9 parameter

Dependent on the

frequency range of

the instrument

GH

MH

KH

HZ

2-8 683XXC PM

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-2. Parameter Entry Commands (2 of 5)

MNEMONIC

CODE

PARAMETER VALUES TERMINATOR

Slave Unit Frequencies

SLM0

SLM1

SLM2

SLM3

SLM4

SLM5

SLM6

SLM7

SLM8

SLM9

SLDF Opens theDF parameter for

SDT Opens the step sweep

SNS Opens the step sweep

SWT Opens the analogsweep,

Opens the M0 parameter

Opens the M1 parameter

Opens the M2 parameter

Opens the M3 parameter

Opens the M4 parameter

Opens the M5 parameter

Opens the M6 parameter

Opens the M7 parameter

Opens the M8 parameter

Opens the M9 parameter

the slave unit

dwell time parameter

number of steps parameter

step sweep, and CW ramp

time parameter

Dependent on the

frequency range of

the instrument

Dependent on the

frequency range of

the instrument

1msto99s MS

1 to 10,000 SPS

30 ms to 99s MS

GH

MH

KH

HZ

GH

MH

KH

HZ

SEC

SEC

LOS Opens the level offset

parameter

PDT Opens the power sweep

dwell time parameter

PNS Opens the power sweep

number of steps parameter

ADP1 Opens the internal AM %

depth parameter

ADP2 Opens the internal AM dB

depth parameter

AMR Opens the internalAM rate

parameter

+100 dB to –100 dB DB

1msto99sec MS

SEC

1 to 10,000 SPS

0% to 100% PCT

0dBto25dB DB

0.1 Hz to 1 MHzfor

sine wave;

0.1 Hz to 100 kHzfor

square, triangle, and

ramp waveforms

MH

KH

HZ

683XXC PM 2-9

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-2. Parameter Entry Commands (3 of 5)

MNEMONIC

CODE

AMS Opens the external AM %/V

ASD Opens the external AM

FDV Opens the internal FM

FMR Opens the internal FM rate

FMS Opens the external FM sen-

PARAMETER VALUES TERMINATOR

sensitivity parameter

dB/V sensitivity parameter

deviation parameter

parameter

sitivity parameter

0 %/V to 100 %/V PCV

0 dB/V to 25 dB/V DV

10 kHz to 20 MHzin

Locked, Locked LowNoise, and Unlocked

Narrow FM; 100 kHz

to 100 MHz in

Unlocked Wide FM

0.1 Hz to 1 MHzfor

sine wave;

0.1 Hz to 100 kHzfor

square, triangle, and

ramp waveforms

±

10 kHz/V to

±

20 MHz/V in Locked,

Locked Low-Noise,

and Unlocked Narrow

FM;±100 kHz/V to

±

100 MHz/V in

Unlocked Wide FM

MH

KH

MH

KH

HZ

KV

MV

PHD Opens the internalFM

deviation parameter

PHR Opens the internalFM rate

parameter

PHS Opens the externalFM

sensitivity parameter

PER Opens the internal pulse

period parameter

0.0025 to 5 radians in

F

M Narrow mode;

0.25 to 500 radians in

F

M Wide mode

0.1 Hz to 1 MHzfor

sine wave;

0.1 Hz to 100 kHzfor

square, triangle, and

ramp waveforms

±

0.0025 radians/V to

±

5 radians/V inFM

Narrow mode;

±

0.25 radians/V to

±

500 radians/V inFM

Wide mode

250 ns to 419 msat

40 MHz pulse clock

rate; 600 ns to 1.6sat

10 MHz pulse clock

rate

RD

MH

KH

HZ

RV

SEC

MS

US

NS

2-10 683XXC PM

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-2. Parameter Entry Commands (4 of 5)

MNEMONIC

CODE

PR Opens the internal pulse

PW, W1

W2

W3

W4

PDY, D1 Opens the internal pulse

D2

D3

D4

PARAMETER VALUES TERMINATOR

frequency parameter

Opens the internal pulse

width 1 parameter

Opens the internal pulse

width 2 parameter

Opens the internal pulse

width 3 parameter

Opens the internal pulse

width 4 parameter

delay 1 parameter

Opens the internal pulse

delay 2 parameter

Opens the internal pulse

delay 3 parameter

Opens the internal pulse

delay 4 parameter

2.385 Hz to 4 MHzat

40 MHz pulse clock

rate;

0.597 Hz to 1.66 MHz

at 10 MHz pulse clock

rate

25 ns to 419 msat

40 MHz pulse clock

rate; 100 ns to 1.6sat

10 MHz pulse clock

rate

0 to 419 ms at

40 MHz pulse clock

rate; 0 to 1.6 sat

10 MHz pulse clock

rate

100 ns to 419 msat

40 MHz pulse clock

rate; 300 ns to 1.6sat

10 MHz pulse clock

rate

MH

KH

HZ

SEC

MS

US

NS

SEC

MS

US

NS

SEC

MS

US

NS

SDD Opens the internal pulse

stepped delay mode step

size parameter

SDE Opens the internal pulse

stepped delay mode delay

1 stop parameter

SDL Opens the internal pulse

stepped delay mode dwelltime-per-step parameter

SDS Opens the internal pulse

stepped delay mode delay

1 start parameter

0 to 419 ms at

40 MHz pulse clock

rate; 0 to 1.6 sat

10 MHz pulse clock

rate

0 to 419 ms at

40 MHz pulse clock

rate; 0 to 1.6 sat

10 MHz pulse clock

rate

100ms to 10s SEC

0 to 419 ms at

40 MHz pulse clock

rate; 0 to 1.6 sat

10 MHz pulse clock

rate

SEC

MS

US

NS

SEC

MS

US

NS

MS

US

SEC

MS

US

NS

683XXC PM 2-11

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-2. Parameter Entry Commands (5 of 5)

MNEMONIC

CODE

PVT Opens the ALC power

SLP Opens the ALC power

SOF Opens the frequency

SLV, SLL1 Opens the main power level

SLL2 Opens the alternate sweep

EGI Opens the Reference Level

PARAMETER VALUES TERMINATOR

slope pivot point frequency

parameter

slope value parameter

offset parameter for the

slave unit (in a 360BVNA

configuration)

parameter (L1) for the slave

unit

power level parameter (L2)

for the slave unit

DAC setting parameter (in

external power leveling

mode)

Dependent on the frequency range of the

instrument

0 to 255 SPS

Dependent on the

frequency range of

the instrument

Dependent on the

power level range of

the instrument

Dependent on the

power level range of

the instrument

0 to 255 SPS

GH

MH

KH

HZ

GH

MH

KH

HZ

DM (Log)

VT (Linear)

DM (Log)

VT (Linear)

ADD Opens the GPIB address

parameter.

FRS Opens the frequency

scaling reference multiplier

parameter

LDT Opens the list sweep dwell

time parameter

SYZ Opens the step-size

parameter for updating

UP Increments the open

parameter by the step size

DN Decrements the open

parameter by the step size

CLO Closes the previously

opened parameter

1to30 ADR

0.1 to 14 TMS

1msto99s MS

SEC

Dependent on the

open parameter

N/A N/A

N/A N/A

N/A N/A

N/A

2-12 683XXC PM

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-3. Data Entry Commands

MNEMONIC

CODE

0, 1, 2, 3, 4,

5, 6, 7, 8, 9

– Change sign of input

. Decimal point

CLR Clear data entry

Numerals for parameter value entries

DESCRIPTION

683XXC PM 2-13

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Table 2-4. Data Terminator Codes

MNEMONIC

CODE

ADR GPIBAddress

DB Decibels (dB)

DM dBm

GH GHz

MH MHz

KH kHz

HZ Hertz (Hz)

SEC Seconds

MS Milliseconds (ms)

US Microseconds (ms)

NS Nanoseconds (ns)

PCT Percent (%)

DESCRIPTION

RD Radians

GV GHz per volt (GHz/V)

MV MHz per volt(MHz/V)

KV kHz per volt (kHz/V)

DV Decibel pervolt (dB/V)

PCV Percent per volt(%/V)

RV Radians per volt (rad/V)

SPS Steps

TMS Times

VT Volts

2-14 683XXC PM

PROGRAMMING WITH PARAMETER AND DATA

GPIB COMMANDS ENTRY COMMANDS

Using the

SYZ

Command

Each 683XXC parameter has an associated step size

that can be used to increment or decrement its

value. Parameters that have common units share a

common step size. For example, the frequency parameters (F0-F9, M0-M9, and DF) have a common

step size as do the power level parameters (XL0XL9, L0-L9, and Level Offset). Other parameters,

such as analog sweep time, have individual step

sizes.

To set the step size for a parameter, first send the

command code to open the parameter, then send the

SYZ command. Now set the step size by sending a

numeric string with the proper terminator. When

the terminator is received, the step size is accepted

and the original parameter is again open for entry.

Figure 2-1 shows how the SYZ command can be

used to increment a parameter. In this example, the

F1 frequency parameter is set to 4 GHz, the step

size is set to 10 MHz, and F1 frequency is incremented three times by the value of the step size.

F1 4 GH SYZ 10 MH UP UP UP

Sets a step size of 10 MHz, ends the step-size entry,

and reopens the F1 parameter.

Opens the step-size parameter for F1.

Sets the F1 Parameter to 4 GHz.

Selects the F1 Parameter and opens it for entry.

Figure 2-1. Using the SYZ (Step Size) Command

Increments F1 from 4.02 GHz to 4.03 GHz.

Increments F1 from 4.01 GHz to 4.02 GHz.

Increments F1 from 4.00 GHz to 4.01 GHz.

683XXC PM 2-15

PROGRAMMING WITH CW FREQUENCY

GPIB COMMANDS COMMANDS

2-5

CW FREQUENCY

COMMANDS

Table 2-5 lists the CW frequency command mnemonic codes. These

commands call up each of the 20 preset (or previously set) CW frequencies. Each command causes its associated CW frequency to be

output and opens that frequency’s parameter for data entry.

The command, SQF, accesses the preset frequencies in sequential or-

der—that is, F0 to F9 and M0 to M9.

Table 2-5. CW Frequency Commands

MNEMONIC

CODE

CF0

CF1

CF2

CF3

CF4

CF5

CF6

CF7

CF8

CF9

CM0

CM1

CM2

CM3

CM4

CM5

CM6

CM7

CM8

CM9

Set CW mode at F0

Set CW mode at F1

Set CW mode at F2

Set CW mode at F3

Set CW mode at F4

Set CW mode at F5

Set CW mode at F6

Set CW mode at F7

Set CW mode at F8

Set CW mode at F9

Set CW mode at M0

Set CW mode at M1

Set CW mode at M2

Set CW mode at M3

Set CW mode at M4

Set CW mode at M5

Set CW mode at M6

Set CW mode at M7

Set CW mode at M8

Set CW mode at M9

FUNCTION OPENS FOR ENTRY

F0 parameter

F1 parameter

F2 parameter

F3 parameter

F4 parameter

F5 parameter

F6 parameter

F7 parameter

F8 parameter

F9 parameter

M0 parameter

M1 parameter

M2 parameter

M3 parameter

M4 parameter

M5 parameter

M6 parameter

M7 parameter

M8 parameter

M9 parameter

SQF Scan to the next higherpreset

CW frequency.

SQU Scan up to the next higher preset

CW frequency.

SQD Scan down to the next lower pre-

set CW frequency.

ACW Activates the currently scanned

frequency as CW.

CW frequency parameter

then selected

CW frequency parameter

then selected

CW frequency parameter

then selected

CW frequency parameter

then selected

2-16 683XXC PM

PROGRAMMING WITH ANALOG AND STEP

GPIB COMMANDS SWEEP COMMANDS

Programming Note: Signal generator response to a SQF command

depends on the state that the instrument is in at the time the command is received. For example, if the 683XXC is in a CW mode of operation with the current output frequency open for entry, the SQF

command (1) causes the output to change to the next sequential frequency and (2) opens that frequency’s parameter for data entry. However, if the instrument is in any other mode of operation, the SQF command causes it to switch to the last CW frequency that was output

and opens that parameter for data entry.

Figure 2-2 is an example of a CW frequency command string.

CF1 CF6 7 GH SQF

C loses the F6 param eter. P laces the 683XX C at the

preset (or previously set) C W F 7 param eter and opens

the F7 param eter for data entry.

2-6

ANALOG AND STEP

SWEEP COMMANDS

C loses the F1 param eter. P laces the 683XX C at the preset

(or previously set) C W F6 frequency and opens the F6

param eter for data entry. S ets the F6 frequency to 7 G H z.

Places the 683X X C at the preset (or previously set) C W

F1 frequency and opens the F1 param eter for data entry.

Figure 2-2. Example of a CW Frequency Command String

Table 2-6 (page 2-19) lists the analog and step sweep command mnemonic codes. These commands are divided into five subclasses and are

described in the following paragraphs.

Sweep Range Seven sweep ranges are available. The SF1 and SF3

commands select the sweep ranges of F1-F2 and

F3-F4 respectively; the FUL command selects a full

band sweep from the signal generator’s low frequency limit to its high frequency limit.

The DF0, DF1, DF5, and DF6 commands each select

a symmetrical frequency sweep around F0, F1, F5,

and F6 respectively. The width of the sweep is determined by the DF frequency parameter.

683XXC PM 2-17

PROGRAMMING WITH ANALOG AND STEP

GPIB COMMANDS SWEEP COMMANDS

Programming Examples:

Programming “F12GHF28GHSF1” sets F1 to

2 GHz, F2 to 8 GHz, and implements a F1-F2 frequency sweep.

Programming “DLF6GHF57GHDF5” sets DFto

6 GHz, F5 to 7 GHz, and implements a F5-DF frequency sweep.

Programming Note:

If the commanded sweep range is invalid, a parameter error (paragraph 2-23) will be generated, and the

output of the signal generator will not be altered.

A sweep range is invalid if (1) the analog sweep

start frequency is greater than the stop frequency,

or (2) the DF frequency parameter results in a sweep

that is outside the range of the instrument.

Alternate

Sweep

Sweep

Triggering

Six alternate sweep commands are available. If the

683XXC is sweeping when the alternate sweep command is received, the signal generator’s output will

alternate between the commanded sweep and the

sweep then being executed.

Programming Example:

Assume that the 683XXC had been previously programmed and was then executing an F1-F2 sweep.

Programming “AF3” would then activate the F3-F4

sweep and cause it to alternate with the F1-F2

sweep.

Programming Note:

An alternate sweep command will only be recognized when the 683XXC has been programmed to

sweep. It will be ignored at all other times.

Two modes of sweep triggering are available over

the bus—Automatic, External, and Single. The AUT

command selects automatic sweep triggering; the

HWT command selects external triggering; the EXT

command selects single sweep triggering.

When automatic sweep triggering is selected, the

sweep continually sweeps from its start frequency

(or power level) to its stop frequency (or power level)

with optimal retrace time.

2-18 683XXC PM

PROGRAMMING WITH ANALOG AND STEP

GPIB COMMANDS SWEEP COMMANDS

When external sweep triggering is selected, a single

sweep occurs when triggered by an external TTLcompatible clock pulse to the rear panel AUX I/O

connector.

When single sweep triggering is selected, a single

sweep starts when the TRG or TRS command is received. The RSS command resets the sweep to its

start frequency (or power level), whenever the command is received while a single sweep is in progress.

Table 2-6. Analog and Step Sweep Commands

MNEMONIC

CODE

SF1

SF3

FUL

DF0

DF1

DF5

DF6

AFU

AF1

AF3

AD1

AD5

AD6

AUT

HWT

EXT

TRG

TRS

RSS

FUNCTION

Sweep Range

Selects the F1-F2 sweep mode

Selects the F3-F4 sweep mode

Selects the Full Range sweepmode

Selects the F0-DF sweep mode

Selects the F1-DF sweep mode

Selects the F5-DF sweep mode

Selects the F6-DF sweep mode

Alternate Sweep

Selects Full Range alternate sweep

Selects F1-F2 alternate sweep

Selects F3-F4 alternate sweep

Selects F1-DF alternate sweep

Selects F5-DF alternate sweep

Selects F6-DF alternate sweep

Sweep Triggering

Selects Auto Trigger

Selects External Trigger

Selects Single Trigger

Triggers a Single Sweep

Triggers a Single Sweep

Resets a Sweep if inprogress

OPENS FOR

ENTRY

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

Analog/Step Sweep Select

SWP

SSP

LIS

LGS

MAN

DU1

DU0

TSS

SP1

SP0

Selects Analog Sweep

Selects Step Sweep (Linear)

Selects Linear Step Sweep (DefaultMode)

Selects Logarithmic Step Sweep

Selects Manual (Step) Sweep

Selects Dual Step Sweep mode

Deselects Dual Step Sweep mode

Steps to next point inDU1 mode

Special Step Sweep (Steps Not Equally Spaced)

Selects non-equally spaced step sweep

Deselects non-equally spaced step sweep

None

None

None

None

None

None

None

None

None

None

683XXC PM 2-19

PROGRAMMING WITH ANALOG AND STEP

GPIB COMMANDS SWEEP COMMANDS

Analog/Step

Sweep Select

Five commands are available—SWP selects an analog sweep, SSP and LIS select a linear step sweep,

LGS selects a logarithmic step sweep, and MAN selects a manual (step) sweep. The selected sweep

mode applies to all sweep ranges. Figure 2-3 shows

an example of a sweep command string.

Programming Notes:

Commanding either SWP or SSP does not, by itself,

provide a swept-frequency output. It only determines whether the swept-frequency output will be

an analog or step sweep. If, on the other hand, a

frequency sweep is being output by the signal generator when one of these commands is received, that

sweep will assume the commanded sweep mode.

The MAN command only provides for setting up the

683XXC for a manual sweep. It must be accompanied by the RL command to return the instrument to

local (front panel) control in order for the operator to

perform the manual sweep.

AUT SWP EXT TRS SSP TRSSF1

Selects analog sweep.

Selects Auto triggering.

Selects the F1-F2 sweep range.

Figure 2-3. Example of a Sweep Command String

Triggers a single sweep.

Selects linear step sweep.

Triggers a single sweep.

Selects the Single triggering mode.

2-20 683XXC PM

PROGRAMMING WITH ANALOG AND STEP

GPIB COMMANDS SWEEP COMMANDS

Dual Step Sweep Mode

The dual step sweep mode provides for generating

synchronized, step sweep outputs from two

683XXCs at a frequency offset. Figure 2-4 shows an

example of dual step sweep programming.

10 ! “DUAL”

20 CLEAR

30 DISP “ENTER # OF STEPS”

40 INPUT S

50 DISP “ENTER WAIT TIME [mS]

60 INPUT W

70 WAIT 100

80 DISP “ENTER ‘LO’ START FREQ [GHz]”

90 INPUT F1

100 DISP “ENTER ‘LO’ STOP FREQ [GHz]

110 INPUT F2

120 DISP “ENTER OFFSET [GHz]

130 INPUT F3

140 !

150 ! Initialize both 683XXC’s

160 !

170 OUTPUT 705 ;"CF1F1";F1;"GHF2";F2;

“GHSNS”;S;"SPSSSPEXTCLO"

180 OUTPUT 706 ;"CF1F1";F1+F3;"GHF2";

F2+F3;"GHSNS";S;"SPSSSPEXTCLO"

190 WAIT 1000

200 !

210 ! Set both to dual mode and enable

GET to end DWELL

220 !

230 SEND 7 ; CMD “%&” DATA “GTLDU1SF1"

EOL

240 WAIT 100

250 ! Trigger the sweep and wait for

retrace to finish

260 SEND 7 ; CMD “%&” DATA “TRS” EOL

270 WAIT 100

280 ! Listen address both 683XXC’s

290 SEND 7 ; CMD “%&”

300 FOR C+1 TO S+1

310 WAIT W

320 ! Trigger both to next point

330 TRIGGER 7

340 NEXT C

350 GOTO 260

Figure 2-4. Dual Step Sweep Programming Example

683XXC PM 2-21

PROGRAMMING WITH FREQUENCY

GPIB COMMANDS MARKER COMMANDS

Special Step

Sweep

For this example, assume afrequency sweep of 3 GHz to 10 GHz, with steps at 3,

6, 8, 9, and 10GHz.

Sample Coding in BASIC

10 OUTPUT 705; “ZL000 3GH 6GH 8GH 9GH 10GH ZEL”

20 OUTPUT 705; “F1 3GH F2 10GH SNS 4SPS”

30 OUTPUT 705; “SP1 SSP SF1"

This special step sweep provides for a step sweep

that has non-equally spaced steps. It can be used in

any of the available sweep ranges (F1-F2, F3-F4,

Full, F0-DF, F1-DF, F5-DF, and F6-DF). The start frequency in this sweep must be equal to the first frequency programmed with the ZL(X

(Table 2-17). The intermediate steps can be programmed to be any frequency within the range of

the programmed sweep.

Programming Note:

The SP1 command can be used with the dual step

sweep mode.

Figure 2-5 shows an example of special step sweep

programming.

000-999

) command

2-7

FREQUENCY MARKER

COMMANDS

Explanation of Code

Line 10 sets up thestep frequencies.

Line 20 sets start andstop frequencies and number of steps (frequency points – 1).

Line 30 set the signalgenerator to SP1, Step Sweep, and F1-F2 sweep range.

Figure 2-5. Special Step Sweep Programming Example

Table 2-7 lists the frequency marker command mnemonic codes. These

commands provide for (1) selecting a CW frequency as a potential

marker, (2) selecting a potential marker as an active marker, and (3)

individually turning markers on and off.

The ME1 command will enable a marker at the current frequency that

is open for update; the ME0 command will disable the same marker. If

a frequency parameter is not open, no action will be taken. The IM1

and VM1 commands will turn on their respective intensity and video

markers. The MK0 command will turn all markers off.

2-22 683XXC PM

PROGRAMMING WITH FREQUENCY

GPIB COMMANDS MARKER COMMANDS

Figure 2-6 shows an example of a frequency marker command string.

Table 2-7. Frequency Marker Commands

MNEMONIC

CODE

ME1 Enables a marker at theactive frequency

ME0 Disables the marker at theactive frequency None

MK0 Turns off markers. Enabled markers remain

IM1 Turns on the intensitymarker mode None

VM1 Turns on the video marker mode None

Programming Note: Only one marker mode can be active. Consequently, if the intensity marker mode is active and the video marker

mode is programmed, the displayed markers will change to video

markers. Either mode can be turned off with the MK0 command.

VM1 F1 ME0 F7 ME1 F4 ME1 MK0

FUNCTION

(F0-F9 or M0-M9)

enabled, but are not active

Turns both m arkers off, but leaves the F7 and F4 m arkers

enabled. T herefore, w hen V M 1 is next program m ed, tw o

frequency m arkers w ill reappear on the display provided

their frequencies are w ithin the 683X X C 's sw eep range.

OPENS FOR

ENTRY

None

None

Enables the F4 frequency m arker.

Enables the F7 frequency m arker.

D isables the F1 frequency m arker.

Turns on the video-m arker m ode.

Figure 2-6. Example of a Frequency Marker Command String

683XXC PM 2-23

PROGRAMMING WITH OUTPUT POWER

GPIB COMMANDS LEVELING COMMANDS

2-8

OUTPUT POWER

LEVELING COMMANDS

Table 2-8 lists the output power leveling command mnemonic codes.

These commands provide for (1) selecting linear or logarithmic power

level operation, (2) selecting an RF output power level, (3) leveling the

output power, and (4) turning the output power leveling off. In addition, commands are provided for the level offset, power level sweep,

ALC power slope, and step attenuator decoupling functions. Figure 2-7

(page 2-27) shows an example of an output power level command

string.

Linear or

Logarithmic

Power Level

Selection

RF Output

Power Level

Selection

Power level operations can be linear or logarithmic.

The command, LOG, selects logarithmic power level

operation. In logarithmic mode, power level entries

and outputs are in dBm and power level sweeps are

logarithmic. This is the default mode.

The command, LIN, selects linear power level operation. In linear mode, power level entries and outputs are in mV and power level sweeps are linear.

The commands, L0 thru L9, call up each of the preset (or previously set) output power levels. Each

command causes its associated RF power level to be

output and opens that power level’s parameter for

data entry. Each command will also deselect any

other previously programmed power level and will

turn off a power level sweep, if active.

Alternate

Sweep RF

Output

Power Level

Selection

Output

Power

Leveling

In the alternate sweep mode, the commands, AL0

thru AL9, call up each of the preset (or previously

set) L0 to L9 output power levels. Each command

causes its associated RF power level to be output

during the alternate sweep. Each command will also

deselect any other previously programmed alternate

sweep power level. The commands do not open the

L1 to L9 power level parameters for data entry. Use

the parameter entry commands, XL0 thru XL9 or L0

thru L9, to enter new power level values.

There are three output power leveling modes of operation—internal, external (detector or power meter), and fixed gain (leveling off). The IL1 command

selects the internal leveling mode. In this mode, a

signal from an internal level detector is used to level

the output power. This is the default mode.

The DL1 command selects the external (detector)

leveling mode; the PL1 command selects the external (power meter) leveling mode. In this mode, the

output power is leveled using a signal from an

2-24 683XXC PM

PROGRAMMING WITH OUTPUT POWER

GPIB COMMANDS LEVELING COMMANDS

external detector (power meter) connected to the

EXTERNAL ALC IN connector. In the external power

leveling mode, the parameter entry command EGI

provides for entering a setting for the Reference

Level DAC to control the ALC gain. The LV0 command selects the fixed gain (leveling off) mode. Each

command will also deselect any other previously

programmed output power leveling mode.

Programming Example:

Programming “PL1 EGI 140 SPS” selects external

leveling of the output power using a signal from an

external power meter and sets the Reference Level

DAC to 140.

Table 2-8. Power Leveling Commands (1 of 2)

MNEMONIC

CODE

LOG Selects logarithmic power level operation.

(This is the default mode.)

LIN Selects linear power level operation. None

L0

L1

L2

L3

L4

L5

L6

L7

L8

L9

AL0

AL1

AL2

AL3

AL4

AL5

AL6

AL7

AL8

AL9

Set RF output power levelto L0

Set RF output power levelto L1

Set RF output power levelto L2

Set RF output power levelto L3

Set RF output power levelto L4

Set RF output power levelto L5

Set RF output power levelto L6

Set RF output power levelto L7

Set RF output power levelto L8

Set RF output power levelto L9

Set alternate sweep RF outputlevel to L0

Set alternate sweep RF outputlevel to L1

Set alternate sweep RF outputlevel to L2

Set alternate sweep RF outputlevel to L3

Set alternate sweep RF outputlevel to L4

Set alternate sweep RF outputlevel to L5

Set alternate sweep RF outputlevel to L6

Set alternate sweep RF outputlevel to L7

Set alternate sweep RF outputlevel to L8

Set alternate sweep RF outputlevel to L9

FUNCTION

OPENS FOR

ENTRY

None

L0

L1

L2

L3

L4

L5

L6

L7

L8

L9

None

None

None

None

None

None

None

None

None

None

RF1 Turns on the RF output. (This is the default

mode.)

RF0 Turns off the RF output. None

None

683XXC PM 2-25

PROGRAMMING WITH OUTPUT POWER

GPIB COMMANDS LEVELING COMMANDS

Table 2-8. Power Leveling Commands (2 of 2)

MNEMONIC

CODE

LO1 Turns on the Level Offset function. The value of

the Level Offset parameter is added to the level

measured by the internal levelingloop. The

resultant power level value isdisplayed.

LO0 Turns off the Level Offset function. None

IL1 Selects internal leveling of the output power.

(This is the default mode.)

Deselects the DL1 or PL1leveling modes, if

previously programmed.

DL1 Selects external leveling of the output power,

using a signal from anexternal detector connected to the EXTERNAL ALC IN connector.

Deselects the IL1 or PL1leveling modes, if previously programmed.

PL1 Selects external leveling of theoutput power us-

ing a signal from anexternal power meter connected to the EXTERNAL ALC IN connector.

Deselects the IL1 and DL1levelingmodes, if

previously programmed.

FUNCTION

OPENS FOR

ENTRY

None

None

None

None

ELF Selects front panel external leveling input. None

ELR Selects rear panel external leveling input. None

LV0 Turns off leveling of the output power. None

LSP Selects thePower Sweep mode. The power

level will sweep as determinedby the preset (or

previously set) dwell-time and number-of-steps

parameters.

AT1 Selects ALC step attenuator decoupling. None

AT0 Deselects ALC step attenuator decoupling. None

ATT(xx) Sets step attenuator value to xx (´10 dB) in the

ALC step attenuator decouple mode.xx is an

unsigned integer between 00 (0dB attenuation)

and 11 (110 dB attenuation).

SL1 Turns on the ALC power slope function. None

SL0 Turns off the ALC power slopefunction. None