Evaluation Board User Guide

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

UG-188

Evaluation Board for the ADP2119/ADP2120 Step-Down Regulator

GENERAL DESCRIPTION

The ADP2119/ADP2120 are synchronous, step-down, dc-to-dc

regulators in a compact 3 mm × 3 mm LFCSP_WD package.

The ADP2119/ADP2120 evaluation boards provide an easy way

to evaluate the device. This user guide describes how to quickly

set up the board to collect performance data. Full details on the

ADP2119/ADP2120 are available in the ADP2119/ADP2120

data sheet, which is available from Analog Devices, Inc., and

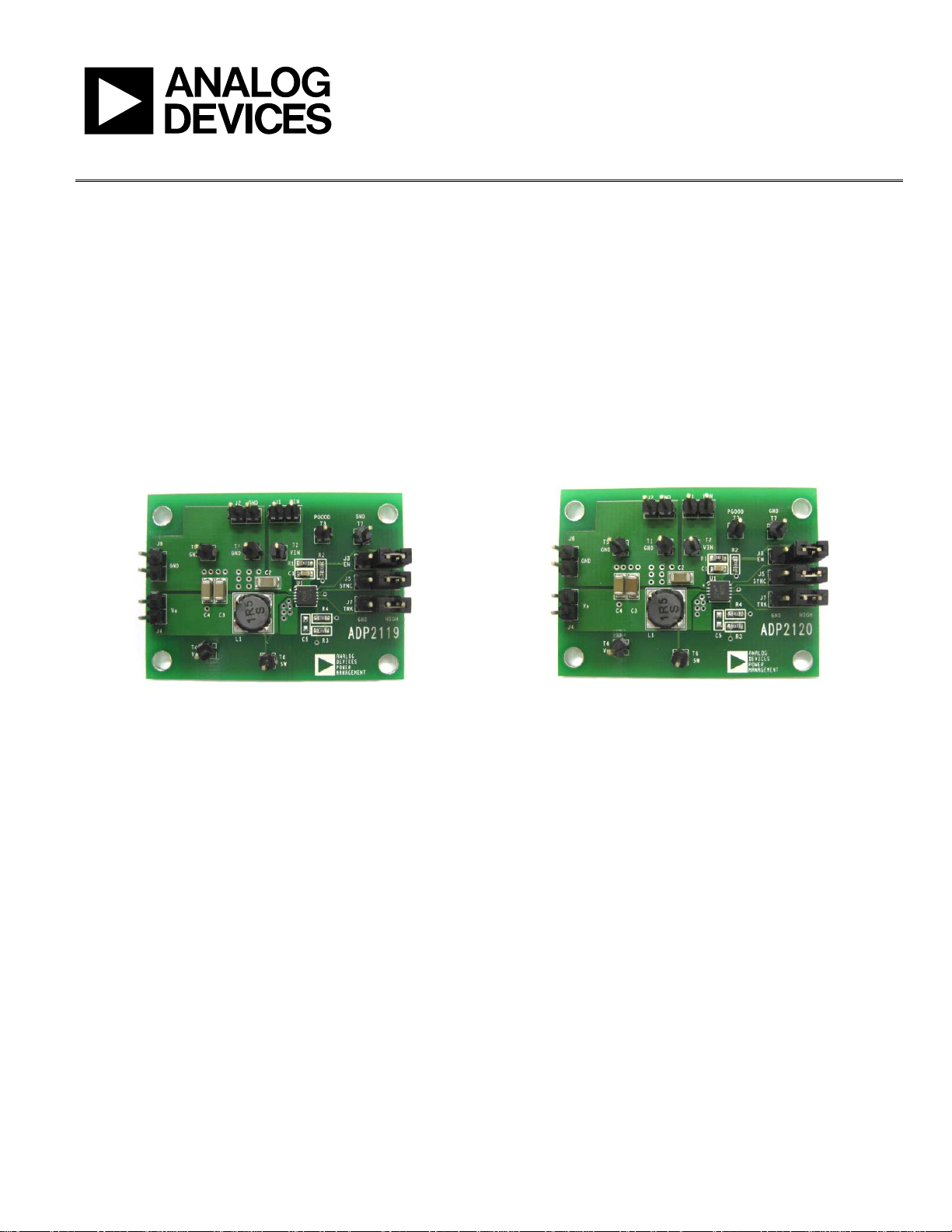

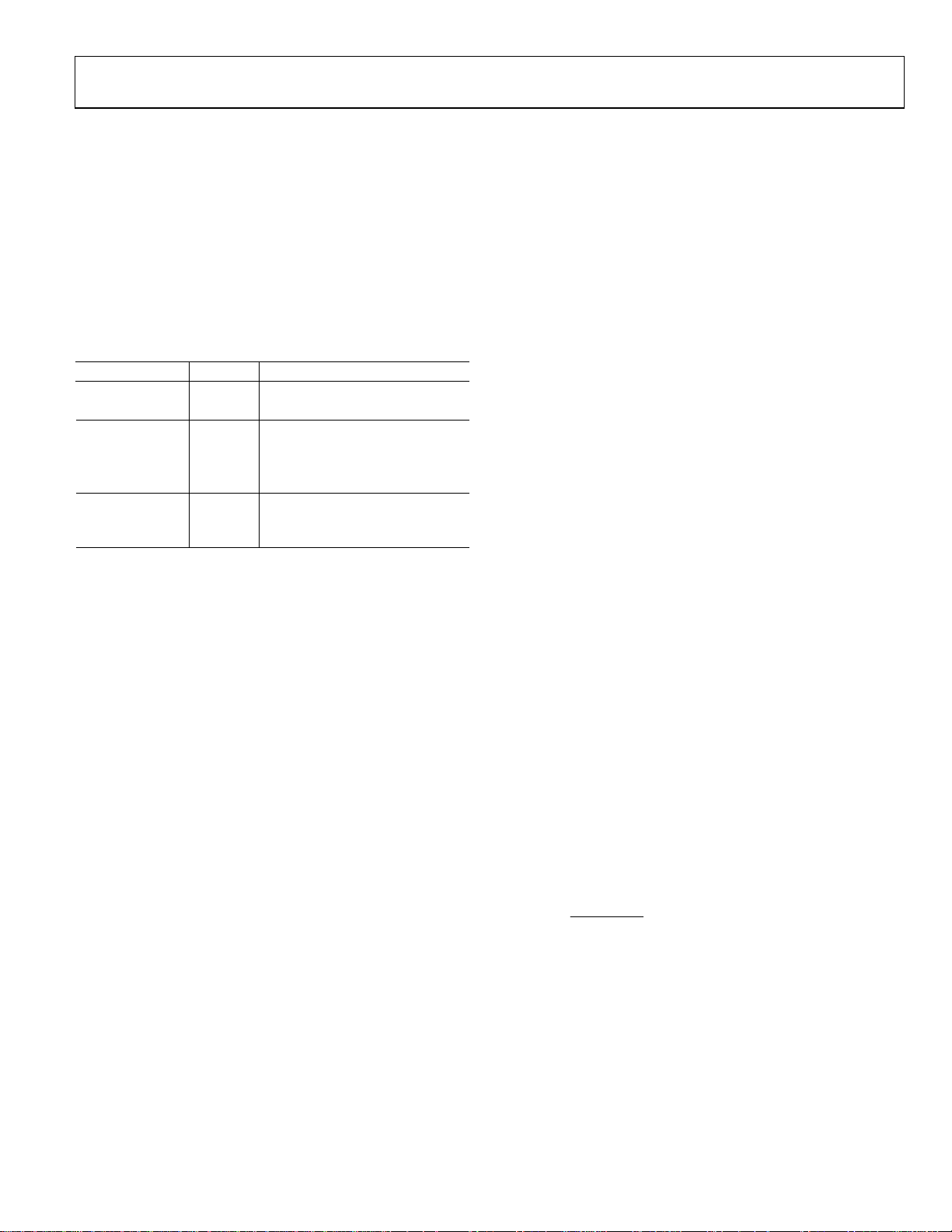

ADP2119/ADP2120 EVALUATION BOARDS

should be consulted in conjunction with this user guide when

using the evaluation boards.

The ADP2119/ADP2120 run from input voltages of 2.3 V to 5.5 V

and require minimal external components to provide a high

efficiency solution with integrated power switch, synchronous

rectifier, and internal compensation.

09314-001

Figure 1. ADP2119 Evaluation Board Figure 2. ADP2120 Evaluation Board

09314-002

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Rev. 0 | Page 1 of 8

UG-188 Evaluation Board User Guide

TABLE OF CONTENTS

General Description ......................................................................... 1

ADP2119/ADP2120 Evaluation Boards........................................ 1

Revision History ............................................................................... 2

Setting Up the Evaluation Board .................................................... 3

Powering up the Evaluation Board ............................................ 3

Measuring Evaluation Board Performance............................... 3

REVISION HISTORY

9/10—Revision 0: Initial Version

Typical Performance Characteristics ..............................................5

Evaluation Board Schematics and Artwork...................................6

Evaluation Board Layout ..................................................................7

Ordering Information.......................................................................8

Bill of Materials..............................................................................8

Rev. 0 | Page 2 of 8

Evaluation Board User Guide UG-188

×

SETTING UP THE EVALUATION BOARD

POWERING UP THE EVALUATION BOARD

The ADP2119/ADP2120 evaluation boards are fully assembled

and tested. Before applying power to the evaluation boards,

follow the setup procedures in this section.

Jumper Settings

Refer to Tabl e 1 for selecting the jumper positions.

Before selecting the jumper positions, make sure that the enable

input, EN, is high.

Table 1. Jumper Settings

Jumper States Function

High Enable V

Low Disable V

J5

(SYNC/MODE)

High Force PWM (FPWM)

Low Enable PFM

External

clock

High Tracking function not used J7 (TRK)

External

voltage

Synchronize to the external clock

Tracking with the external

voltage

Input Power Source Connection

Before connecting the power source to the ADP2119/ADP2120

evaluation boards, make sure that they are turned off. If the

input power source includes a current meter, use that meter to

monitor the input current.

Connect the positive terminal of the power source to the VIN

terminal (J1) on the evaluation boards, and the negative

terminal of the power source to the GND terminal (J2) of the

board. If the power source does not include a current meter,

connect a current meter in series with the input source voltage.

Connect the positive terminal of the power source to the ammeter

positive terminal (+), the negative terminal of the power source

to the GND terminal (J2) on the evaluation board, and the

negative terminal (−) of the ammeter to the VIN terminal (J1)

on the board.

Output Load Connection

Make sure that the board is turned off before connecting the

load. If the load includes an ammeter, or if the current is not

measured, connect the load directly to the evaluation board

with the positive (+) load connection to the VOUT terminal

(J4) and negative (−) load connection to the GND terminal (J6).

If an ammeter is used, connect it in series with the load;

connect the positive (+) ammeter terminal to the evaluation

board VOUT terminal (J4), the negative (−) ammeter terminal

to the positive (+) load terminal, and the negative (−) load

terminal to the evaluation board GND terminal (J6).

Input and Output Voltmeter Connections

Measure the input and output voltages with voltmeters. Make

sure that the voltmeters are connected to the appropriate test

OUT

OUT

J3 (EN)

Rev. 0 | Page 3 of 8

points on the board. If the voltmeters are not connected to the

right test point, the measured voltages may be incorrect due to

the voltage drop across the leads and/or connections between

the boards, the power source, and/or load.

Connect the positive (+) terminal of the input voltage

measuring voltmeter to Test Point T2 and the negative (−)

terminal to Test Point T1.

Connect the positive (+) terminal of the output voltage

measuring voltmeter to Test Point T4 and the negative (−)

terminal to Test Point T5.

Power On the Evaluation Board

When the power source and load are connected to the ADP2119/

ADP2120 evaluation board, it can be powered up for operation.

If the input power source is above 2.3 V, the output voltage rises

to 1.2 V as the default setting.

MEASURING EVALUATION BOARD PERFORMANCE

Measuring the Switching Waveform

To observe the switching waveform with an oscilloscope,

place the oscilloscope probe tip at Test Point T6 with the

probe ground connected to GND. Set the oscilloscope to a

dc coupling, 2 V/division, and 1 μs/division time base. The

switching waveform should alternate between 0 V and

approximately the input voltage.

Measuring Load Regulation

Load regulation should be tested by increasing the load at the

output and measuring the output voltage between the T4 and

T5 test points.

Measuring Line Regulation

Vary the input voltage and measure the output voltage at a fixed

output current. Input voltage can be measured between T2 and

T1. The output voltage is measured between T4 and T5.

Measuring Efficiency

The efficiency, η, is measured by comparing the input power

with the output power.

IV

OUTOUT

η

=

Measuring Inductor Current

The inductor current can be measured by removing one end of

the inductor from the pad on the board and using a wire connected between the pad and the inductor. Then, a current probe

can be used to measure the inductor current.

Measuring Output Voltage Ripple

To observe the output voltage ripple, place an oscilloscope

probe across the output capacitor (C4) with the probe ground

lead placed at the negative (−) capacitor terminal and the probe

tip placed at the positive (+) capacitor terminal. Set the oscillo-

×

IV

ININ

Loading...

Loading...