Evaluation Board User Guide

One Technology Way • P. O . Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel : 781.329.4700 • Fax : 781.461.3113 • www.analog.com

UG-179

Evaluation Board for the 1.2 A, 20 V Nonsynchronous Step-Down Regulators

FEATURES

1.2 A maximum load current

±2% output accuracy over temperature range

Wide input voltage range: 3.0 V to 20 V

Output voltage from 0.8 V to 0.85 × V

700 kHz (ADP2300) or 1.4 MHz (ADP2301) switching

frequency options

Automatic PFM/PWM mode switching

Precision enable pin with hysteresis

Integrated high-side MOSFET

Integrated bootstrap diode

ADIsimPower™ online design tool

Available in ultrasmall, 6-lead TSOT package

IN

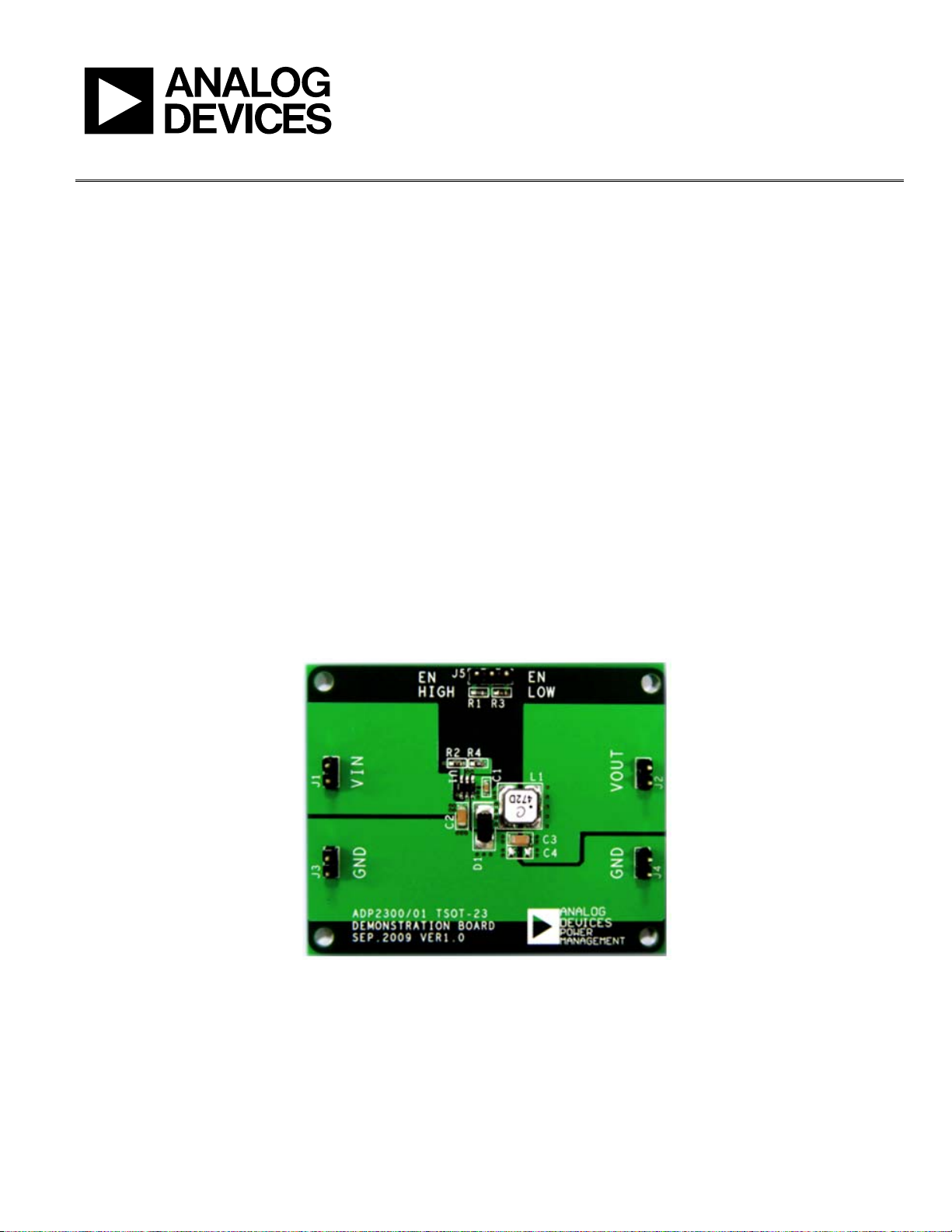

DEMONSTRATION BOARD

GENERAL DESCRIPTION

The ADP2300/ADP2301 are compact, constant-frequency, currentmode, step-down dc-to-dc regulators with an integrated power

MOSFET. The ADP2300/ADP2301 evaluation boards are complete

solutions that allow the user to evaluate the performance of the

regulators. There are two frequency options available: the ADP2300

runs at 700 kHz, and the ADP2301 runs at 1.4 MHz. These options

allow the user to make design decisions based on the trade-off

between efficiency and the size of the total solution.

The ADP2300/ADP2301 provide accurate (±2%) output regulation

for load currents up to 1.2 A. Current-mode control provides fast

and stable line and load transient performance. The precision,

EN pin, threshold voltage allows the ADP2300/ADP2301 to be

sequenced from other input/output supplies. The EN pin can also

be used as a programmable UVLO input by using a resistive divider.

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Figure 1.

Rev. 0 | Page 1 of 12

09232-001

UG-179 Evaluation Board User Guide

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description ......................................................................... 1

Demonstration Board ...................................................................... 1

Revision History ............................................................................... 2

Using the Evaluation Board ............................................................. 3

Jumper Setting .............................................................................. 3

Input Power Source Connection ................................................ 3

Output Load Connection ............................................................ 3

REVISION HISTORY

8/10—Revision 0: Initial Version

Input and Output Voltmeter Connections.................................3

Power On the Evaluation Board ..................................................3

Measuring Evaluation Board Performance ...................................3

Typical Performance Characteristics ..............................................5

Demonstration Board Schematics and Bill of Materials ..............7

ADP2300 Schematic and Bill of Materials .................................7

ADP2301 Schematic and Bill of Materials .................................8

Demonstration Board Layout ..........................................................9

Rev. 0 | Page 2 of 12

Evaluation Board User Guide UG-179

USING THE EVALUATION BOARD

The ADP2300/ADP2301 evaluation boards are fully assembled

and tested. Before applying power to the evaluation boards, follow

the procedures in this section.

JUMPER SETTING

Jumper J5 enables the part. Connect a jumper between Position 1

and Position 2 to enable the part. Connect a jumper between

Position 2 and Position 3 to disable the part. Leave Jumper J5

open to obtain an approximately 7.8 V V

Table 1. Jumper J5 (EN) Setting

State Function

High Enable the part

Low Disable the part

Open Program the VIN start-up voltage to be about 7.8 V

start-up voltage.

IN

INPUT POWER SOURCE CONNECTION

Before connecting the power source to the ADP2300/ADP2301

evaluation board, make sure that the evaluation board is turned off.

If the input power source includes a current meter, use that

meter to monitor the input current. Connect the positive terminal

of the power source to the VIN terminal (J1) on the evaluation

board, and the negative terminal of the power source to the

GND terminal (J3) of the board. If the power source does not

include a current meter, connect a current meter in series with

the input source voltage. Connect the positive terminal of the

power source to the current meter’s positive lead (+), the negative

terminal of the power source to the GND terminal (J3) on the

evaluation board, and the negative lead (−) of the current meter

to the VIN terminal (J1) on the board.

OUTPUT LOAD CONNECTION

Make sure that the board is turned off before connecting the load.

If the load includes a current meter, or if the current is not

measured, connect the load directly to the demonstration board

with the positive (+) load connection to the VOUT terminal (J2)

and negative (−) load connection to the GND terminal (J4). If a

current meter is used, connect it in series with the load; connect

the positive (+) current meter terminal to the evaluation board

VOUT terminal (J2), the negative (−) current meter terminal to

the positive (+) load terminal, and the negative (−) load terminal to

the evaluation board GND terminal (J4).

INPUT AND OUTPUT VOLTMETER CONNECTIONS

Measure the input and output voltages with voltmeters. Make

sure that the voltmeters are connected to the appropriate test

point on the board. If the voltmeters are not connected to the

right test point, the measured voltages will be incorrect due to

the voltage drop across the leads and/or connections between

the board, the power source, and/or the load.

Rev. 0 | Page 3 of 12

Connect the input voltage measuring the voltmeter’s positive

terminal (+) to the input capacitor (C2) positive terminal and the

negative (−) terminal to the input capacitor (C2) negative

terminal.

Connect the output voltage measuring the voltmeter’s positive (+)

terminal to the output capacitor (C3 or C4) positive terminal

and the negative (−) terminal to the output capacitor (C3 or C4)

negative terminal.

POWER ON THE EVALUATION BOARD

When the power source and load are connected to the ADP2300/

ADP2301 evaluation board, they can be powered up for operation.

If the input power source voltage goes higher than 7.8 V with

Jumper J5 open, the output voltage goes up to 3.3 V.

MEASURING EVALUATION BOARD PERFORMANCE

Measuring the Switching Waveform

To observe the switching waveform with an oscilloscope, place

the oscilloscope probe tip at the end of inductor connected to

the SW pin with the probe ground at GND. Set the scope to dc,

5 V/division, and 1 μs/division time base. The switching waveform

should alternate between 0 V and approximately the input voltage.

Measuring Load Regulation

Load regulation should be tested by increasing the load current

at the output and measuring the output voltage across the output

capacitor (C3 or C4).

Measuring Line Regulation

Vary the input voltage and measure the output voltage at a fixed

output current. The input voltage can be measured across the

input capacitor (C2), and the output voltage can be measured

across the output capacitor (C3 or C4).

Measuring Efficiency

The efficiency, η, is measured by comparing the input power

with the output power.

×

OUTOUT

=η

Measuring Inductor Current

The inductor current is measured by removing one end of the

inductor from the pad on the board and using a wire connected

between the pad and the inductor. Then a current probe is used

to measure the inductor current.

IVIV×

ININ

UG-179 Evaluation Board User Guide

Measuring Output Voltage Ripple

To observe the output voltage ripple, place an oscilloscope probe

across the output capacitor (C3 or C4) with the probe ground

lead at the negative (−) capacitor terminal and the probe tip at

the positive (+) capacitor terminal. Set the oscilloscope to ac,

1 mV/division, and 1 μs/division time base, 20 MHz bandwidth.

The standard oscilloscope probe has a long wire ground clip.

For high frequency measurements, this ground clip picks up

high frequency noise and injects it into the measured output

ripple. Make sure to keep the ground lengths on the

oscilloscope probe as short as possible to get a clean voltage

ripple measurement.

Varying the Output voltage

The ADP2300/ADP2301 demonstration board output is preset

to 3.3 V; however, the output voltage can be adjusted to other

output voltages using the following equation:

⎛

⎞

R

2

⎜

⎟

V

OUT

+×=

1V800.0

⎜

⎝

⎟

R

4

⎠

Rev. 0 | Page 4 of 12

Loading...

Loading...