High Speed ADC USB FIFO Evaluation Kit

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

FEATURES

Buffer memory board for capturing digital data

Used with high speed ADC evaluation boards

32 kB FIFO Depth at 133 MSPS (upgradeable to 256 kB)

Simplifies evaluation of high speed ADCs

Measures performance with ADC Analyzer™

Real-time FFT and time domain analysis

Analyze SNR, SINAD, SFDR, and harmonics

Import raw text data for analysis

Virtual ADC eval board support using ADIsimADC™

Simple USB port interface

nd

Compatible with Windows® 98 (2

Ed), Windows 2000,

Windows Me, or Windows XP

EQUIPMENT NEEDED

3.3 V power supply

Analog signal source and anti-aliasing filter

Low jitter clock source

High speed ADC evaluation board and ADC data sheet

nd

PC running Windows 98 (2

Ed), Windows 2000,

Windows Me, or Windows XP

USB 2.0 port recommended (USB 1.1 compatible)

Available ADIsimADC product model files

PRODUCT DESCRIPTION

The high speed ADC FIFO evaluation kit includes the latest

version of ADC Analyzer and a memory board to capture

blocks of digital data from Analog Devices’ high speed analogto-digital converter (ADC) evaluation boards. This FIFO board

can be connected to a PC through a USB port and used with

ADC Analyzer to evaluate the performance of high speed ADCs

quickly. Users can view an FFT for a specific analog input and

encode rate and analyze SNR, SINAD, SFDR, and harmonic

information.

The evaluation kit is easy to set up. Additional equipment

needed includes an Analog Devices’ high speed ADC evaluation

board, a power supply, a signal source, and a clock source. Once

the kit is connected and powered, the evaluation is enabled

instantly on the PC.

Two versions of the FIFO are available. The HSC-ADC-EVALADC is used with dual ADCs and converters with demultiplexed

digital outputs. The HSC-ADC-EVALA-SC evaluation board is

used with single-channel ADCs. See Table 1, to choose the FIFO

appropriate for your high speed ADC evaluation board.

FILTERED

ANALOG

INPUT

PRODUCT HIGHLIGHTS

1. Easy to set up—Connect the power supplies and signal

2. ADIsimADC – The software supports virtual ADC

3. USB Port Connection to PC—PC interface is a USB 2.0

4. 32 kB FIFO(s)—This FIFO(s) stores data from the ADC(s)

5. Up to 133 MSPS encode rate on each channel—Single-

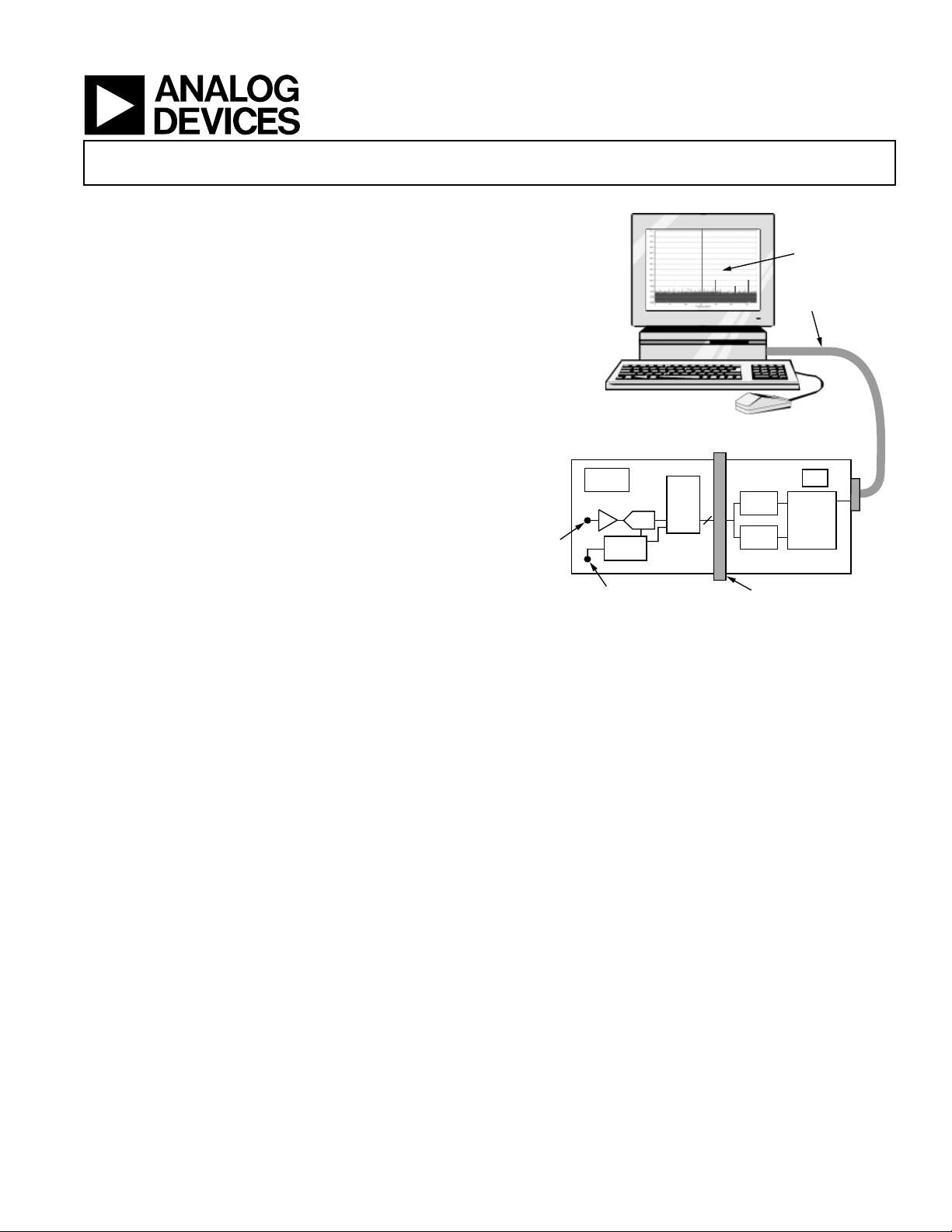

FUNCTIONAL BLOCK DIAGRAM

ADC ANALYZER

USB CABLE

SINGLE OR DUAL

HIGH SPEED ADC

EVALUATION BOARD

POWER

SUPPLY

LOGIC

ADC

CLOCK

CIRCUIT

CLOCK INPUT

Figure 1. Functional Block Diagram (Simplified)

n

HSC-ADC-EVALA-SC

OR

HSC-ADC-EVALA-DC

FIFO2

32K

TIMING

FIFO1

CIRCUIT

32K

80-PIN CONNECTOR

sources to the two evaluation boards. Then connect to the

PC and evaluate the performance instantly.

evaluation using ADI proprietary behavioral modeling

technology. This allows rapid comparison between multiple

ADCs, with or without hardware evaluation boards.

connection (1.1 compatible) to PC. A USB cable is

provided in the kit.

for processing. A pin compatible FIFO family is used for

easy upgrading.

channel ADCs with encode rates up to 133 MSPS can be

used with the FIFO board. Dual and demultiplexed output

ADCs also can be used with the FIFO board (with clock

rates up to 133 MSPS on each output channel).

TM

3.3V

04750-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Anal og Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

TABLE OF CONTENTS

FIFO Evaluation Board Quick Start............................................... 4

Requirements ................................................................................ 4

Quick Start Steps ...................................................................... 4

Virtual Evaluation Board Quick Start With ADIsimADC.......... 5

Requirements ................................................................................ 5

Quick Start Steps ...................................................................... 5

FIFO 4 Data Capture Board............................................................ 6

FIFO 4 Supported ADC Evaluation Boards.............................. 6

Te r m in o l o g y ...................................................................................... 8

Single Tone FFT............................................................................ 8

Two-Tone FFT .............................................................................. 9

Theory of Operation ...................................................................... 10

Clocking Description................................................................. 10

Clocking with Interleaved Data................................................ 10

Installing ADC Analyzer................................................................11

Average FFT................................................................................ 17

Continuous Average FFT .......................................................... 17

Two Tone ..................................................................................... 18

Continuous Two Tone ............................................................... 18

Average Two Tone...................................................................... 18

Stop............................................................................................... 18

Zooming and Exporting Data .................................................. 18

Importing Data ........................................................................... 19

.csv and ASCII files ................................................................ 19

Printing ........................................................................................ 20

Saving Files.................................................................................. 21

Additional Functions (Virtual ADC only) .............................. 21

Amplitude Sweep (Virtual ADC only) .................................... 21

Analog Frequency Sweep (Virtual ADC only)....................... 22

Troubleshooting.............................................................................. 23

Installation................................................................................... 11

Configuration File ...................................................................... 11

Configuring an Evaluation Board ............................................ 11

Additional Configuration Options .......................................... 14

Windowing ..............................................................................14

Power Supply........................................................................... 14

Y- Ax i s .......................................................................................14

Installing ADC Analyzer With ADIsimADC.............................. 15

Installation................................................................................... 15

Configuration File ...................................................................... 15

Configuring a Model.................................................................. 15

ADC Analyzer Functions .............................................................. 17

Time Domain .............................................................................. 17

Continuous Time Domain........................................................ 17

FFT ...............................................................................................17

Flat Line Signal Displayed......................................................... 23

Displayed Signal Unlike Analog Input .................................... 23

FFT Noise Floor Higher Than Expected................................. 24

Large Spur In FFT (Image Problem) ....................................... 24

MSBs Missing From Time Domain ......................................... 25

Upgrading FIFO Memor y ......................................................... 25

Jumpers ............................................................................................ 26

Default Settings........................................................................... 26

FIFO Schematices and PCB Layout ............................................. 28

FIFO Connector ......................................................................... 28

PCB Schematic............................................................................ 29

Assembly—Primary Side........................................................... 35

Assembly—Secondary Side....................................................... 36

Layer 1— Primary Side.............................................................. 37

Layer 2—Ground Plane............................................................. 38

Continuous FFT .........................................................................17

Rev. 0 | Page 2 of 44

Layer 3—Power Plane................................................................ 39

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

Layer 4—Secondary Side............................................................40

Windowing Functions................................................................43

ESD Caution ................................................................................40

Bill of Materials................................................................................41

Appendix: Sampling and FFT Fundamentals..............................43

Coherent Sampling .....................................................................43

REVISION HISTORY

5/04—Revision 0: Initial Version

FFT Calculations.........................................................................43

Ordering Guide ...........................................................................44

Rev. 0 | Page 3 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

FIFO EVALUATION BOARD QUICK START

Install ADC Analyzer from the CD provided in the FIFO

evaluation kit. See the Installing ADC Analyzer section for more

details. For the latest updates to the software, check the Analog

Devices website at

REQUIREMENTS

Requirements include

• FIFO evaluation board, ADC Analyzer, and USB cable

• High speed ADC evaluation board and ADC data sheet

• 3.3 V power supply for FIFO evaluation board

• Power supply for ADC evaluation board

• Analog signal source and appropriate filtering

• Low jitter clock source applicable for specific ADC

evaluation, typically < 1 ps rms

• PC running Windows 98 (2nd Ed), Windows 2000,

Windows Me, or Windows XP

• PC with a USB 2.0 port recommended (USB 1.1

compatible)

Quick Start Steps

1. Connect the FIFO evaluation board to the ADC evaluation

board. If an adapter is required, insert the adapter between

the ADC evaluation board and the FIFO board. If using the

HSC-ADC-EVALA-SC model, connect the evaluation

board to the bottom half of the 80-pin connector (closest

to the installed IDT FIFO chip).

2. Connect the provided USB cable to the FIFO evaluation

board and to an available USB port on the computer.

3. Refer to Table 4 for any jumper changes. Most evaluation

boards can be used with the default settings.

4. After verification, connect the appropriate power supplies

to the FIFO and ADC evaluation boards. The FIFO

evaluation board requires a single 3.3 V power supply with

1 A current capability. Refer to the instructions included in

the ADC data sheet for more information about the ADC

evaluation board setup.

www.analog.com/hsc-FIFO.

5. Once the cable is connected to both the computer and

FIFO and power is supplied, the USB drivers start to install.

To complete the total installation of the FIFO drivers, you

need to complete the new hardware sequence two times.

The first Found New Hardware Wizard opens with the text

message This wizard helps you install software for…Pre-

FIFO 4. Click the recommended install, and go to the next

screen. A Hardware Installation warning window should

then be displayed. Click Continue Anyway. The next

window that opens should finish the Pre-FIFO 4

installation. Click Finish to complete. Your computer

should go through a second Found New Hardware Wizard,

and the text message, This wizard helps you install

software for…Analog Devices FIFO 4, should be

displayed Continue as you did in the previous installation

and click Continue Anyway, then click Finish on the next

two windows. This should complete the installation.

6. (Optional) Verify in the device manager that “Analog

Devices, FIFO4” is listed under the USB hardware.

7. Apply power to the evaluation board and check the voltage

levels at the board level.

8. Connect the appropriate analog input (which should be

filtered with a band-pass filter) and low jitter clock signal.

Make sure the evaluation boards are powered before

connecting the analog input and clock.

9. Start ADC Analyzer (see the Installation section for

installing the software).

10. Choose a configuration file for the ADC evaluation board

used or create one (see the Configuring an Evaluation

Board section for more information).

11. Click Time Domain (left-most button under the pull-

down menus). A reconstruction of the analog input is

displayed. If the expected signal does not appear, or if there

is only a flat red line, refer to the Troubleshooting section

for more information.

Rev. 0 | Page 4 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

VIRTUAL EVALUATION BOARD QUICK START WITH ADIsimADC

REQUIREMENTS

Requirements include

• Completed installation of ADC Analyzer version 4.5.0 or

later.

• ADIsimADC product model files for the desired converter.

Models are not installed with the software, but may be

downloaded from the website at no charge. Go to

www.analog.com/ADIsimADC or look under Design

To o l s for the product of interest.

• No hardware is required. However, if you wish to compare

results of a real evaluation board and the model, you may

switch easily between the two, as outlined below.

Quick Start Steps

1. To obtain ADC model files, go to

www.analog.com/ADIsimADC or look under Design

To o l s for the product of interest. Download the files of

interest to a local drive. The default location is c:\program

files\adc_analyzer\models.

5. On the ADC Modeling form, select the Device tab and

click the

file browser and displays all of the models found in the

default directory: c:\program files\adc_analyzer\models. If

no model files are found, follow the on-screen directions or

see Step 1 to install available models. If you have saved the

models somewhere other than the default location, use the

browser to navigate to that location and select the file of

interest.

6. From the menu choose Config > FFT. In the FFT

Configuration form, ensure that the Encode Frequency is

set for a valid rate for the simulated device under test. If set

too low or too high, the model will not run.

7. Once a model has been selected, information about the

model displays on the Device tab. After ensuring that you

have selected the right model, select the Input tab. This lets

you configure the input to the model. From the drop down

menu, select either Sine Wave or Two Tone for the input

signal.

… button, adjacent to the dialog box. This opens a

2. Start ADC Analyzer (see the Installation section for

installing the software).

3. From the menu choose Config > Buffer and select Model

from the drop down menu as the buffer memory. In effect,

the model functions in place of the ADC and data capture

hardware.

4. After selecting the Model, a small button, Model, is

displayed next to the Stop button. Click Model to select

and configure which converter will be modeled. This places

a small form in the workspace where you can select and

configure how the model will behave.

8. Click Time Domain (left-most button under the pull-

down menus). A reconstruction of the analog input is

displayed. The model may now be used just as a standard

evaluation board would be.

9. The model supports additional features not found when

testing a standard evaluation board. When using the

modeling capabilities, it is possible to sweep either the

analog amplitude or the analog frequency. See the

Installing ADC Analyzer With ADISIMADC section for

additional features.

Rev. 0 | Page 5 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

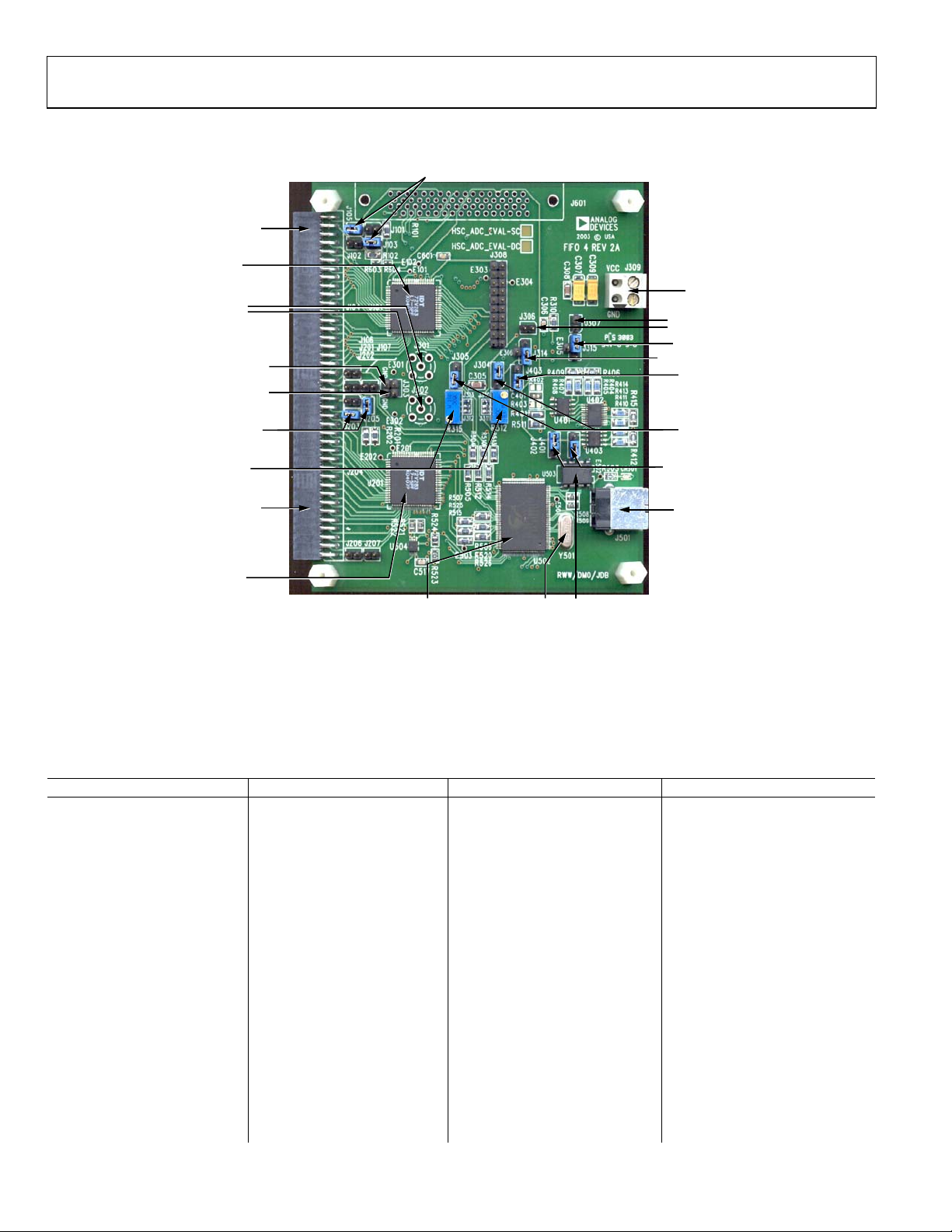

FIFO 4 DATA CAPTURE BOARD

JUMPERS UNUSED

PINS TO GROUND

ADC EVALUATION

BOARD CONNECTION:

40 PIN INTERFACE FOR

DATA AND CLOCK INPUT

FOR TOP CHANNEL

IDT72V283 32K

×

16-BIT FIFO

OPTIONAL SMA

CLOCK INPUTS

JUMPERS TIE TOP

AND BOTTOM CLOCK

INPUTS TOGETHER =

IN FOR SINGLE

CHANNEL OPTION,

OUT FOR DUAL

CHANNEL OPTION

JUMPERS UNUSED

PINS TO GROUND

OPTIONAL FINE

TUNING ADJUST

ADC EVALUATION

BOARD CONNECTION:

40 PIN INTERFACE

FOR DATA AND

CLOCK INPUT FOR

BOTTOM CHANNEL

IDT72V283 32K

×

16- BIT FIFO

×

CYPRESS F

SPEED USB 2.0

MICROCONTROLLER

2 HIGH

Figure 2. FIFO Components Description

MICROCONTROLLER

CRYSTAL CLOCK =

24MHz. OFF DURING

DATA CAPTURE

EEPROM TO LOAD

USB FIRMWARE

+3.3V POWER

CONNECTION

INVERT WRITE

CLOCK OPTIONS

ADDITIONAL

TIMING DELAYS

FOR WRITE CLOCK

WRITE CLOCK

SELECT TO

GENERATE WEN

SIGNAL

INVERT WRITE

CLOCK OPTIONS

SET WEN TIMING

FOR INTERLEAVE

MODES

USB CONNECTION

TO COMPUTER

04750-0-002

FIFO 4 SUPPORTED ADC EVALUATION BOARDS

The evaluation boards in Table 1 can be used with the high speed ADC FIFO Evaluation Kit1. Some evaluation boards require an adapter

between the ADC evaluation board connector and the FIFO connector. If an adapter is needed, send an email to

highspeed.converters@analog.com with the part number of the adapter and a mailing address.

Table 1 HSC-ADC-EVALA-DC: and HSC-ADC-EVALA-SC Compatible Evaluation Boards

Evaluation Board Model Description of ADC FIFO Board Version Comments

AD6640ST/PCB 12-Bit, 65 MSPS ADC SC Requires AD664xFFA

AD6644ST/PCB 14-Bit, 65 MSPS ADC SC Rev. C Requires AD664xFFA

AD6645/PCB 14-Bit, 80 MSPS ADC SC Rev. C Requires AD664xFFA

AD9051/PCB 10-Bit, 60 MSPS ADC SC Requires AD9051FFA

AD9057/PCB 8-Bit, 80 MSPS ADC SC Requires AD9283FFA

AD9059/PCB Dual 8-Bit, 60 MSPS ADC DC Requires AD9059FFA

AD9071/PCB 10-Bit, 100 MSPS ADC SC Requires AD9071FFA

AD9200SSOP-EVAL 10-Bit, 20 MSPS ADC SC Requires AD922xFFA

AD9200TQFP-EVAL 10-Bit, 20 MSPS ADC SC Requires AD922xFFA

AD9201-EVAL Dual 10-Bit, 20 MSPS ADC

4

SC Requires AD922xFFA

AD9203-EB 10-Bit, 40 MSPS ADC SC Requires AD922xFFA

AD9214-65PCB 10-Bit, 65 MSPS ADC SC

AD9214-105PCB 10-Bit, 105 MSPS ADC SC

AD9215BCP-65EB 10-Bit, 65 MSPS ADC SC

AD9215BCP-80EB 10-Bit, 80 MSPS ADC SC

AD9215BCP-105EB 10-Bit, 105 MSPS ADC SC

AD9215BRU-65EB 10-Bit, 65 MSPS ADC SC

AD9215BRU-80EB 10-Bit, 80 MSPS ADC SC

AD9215BRU-105EB 10-Bit, 105 MSPS ADC SC

2

3

Rev. 0 | Page 6 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

Evaluation Board Model Description of ADC FIFO Board Version Comments

AD9218-65PCB Dual 10-Bit, 65 MSPS ADC DC

AD9218-105PCB Dual 10-Bit, 105 MSPS ADC DC

AD9220-EB 12-Bit, 10 MSPS ADC SC Requires AD922xFFA

AD9221-EB 12-Bit, 1.25 MSPS ADC SC Requires AD922xFFA

AD9223-EB 12-Bit, 3 MSPS ADC SC Requires AD922xFFA

AD9224-EB 12-Bit, 40 MSPS ADC SC Requires AD922xFFA

AD9225-EB 12-Bit, 25 MSPS ADC SC Requires AD922xFFA

AD9226-EB 12-Bit, 65 MSPS ADC SC Requires AD922xFFA

AD9226QFP-EB 12-Bit, 65 MSPS ADC SC Requires AD922xFFA

AD9235BRU-20EB 12-Bit, 20 MSPS ADC SC

AD9235BRU-40EB 12-Bit, 40 MSPS ADC SC

AD9235BRU-65EB 12-Bit, 65 MSPS ADC SC

AD9235BCP-20EB 12-Bit, 20 MSPS ADC SC

AD9235BCP-40EB 12-Bit, 40 MSPS ADC SC

AD9235BCP-65EB 12-Bit, 65 MSPS ADC SC

AD9235-20PCB 12-Bit, 20 MSPS ADC SC

AD9235-40PCB 12-Bit, 40 MSPS ADC SC

AD9235-65PCB 12-Bit, 65 MSPS ADC SC

AD9236BCP-80EB 12-Bit, 80 MSPS ADC SC

AD9236BRU-80EB 12-Bit, 80 MSPS ADC SC

AD9236BCP-80EB 12-Bit, 80 MSPS ADC SC

AD9238-20PCB Dual 12-Bit, 20 MSPS ADC DC

AD9238-40PCB Dual 12-Bit, 40 MSPS ADC DC

AD9238-65PCB Dual 12-Bit, 65 MSPS ADC DC

AD9240-EB 14-Bit, 40 MSPS ADC SC Requires AD922xFFA

AD9241-EB 14-Bit, 1.25 MSPS ADC SC Requires AD922xFFA

AD9243-EB 14-Bit, 3 MSPS ADC SC Requires AD922xFFA

AD9244-40PCB 14-Bit, 40 MSPS ADC SC

AD9244-65PCB 14-Bit, 65 MSPS ADC SC

AD9245BCP-80EB 14-Bit, 80 MSPS ADC SC

AD9260-EB 16-Bit, 2.5 MSPS ADC SC Requires AD922xFFA

AD9280-EB 8-Bit, 32 MSPS ADC SC Requires AD922xFFA

AD9281-EB Dual 8-Bit, 28 MSPS ADC4 SC Requires AD922xFFA

AD9283/PCB 8-Bit, 100 MSPS ADC SC Requires AD9283FFA

AD9289BBC-65EB Quad 8-Bit, 65 MSPS ADC

AD9410/PCB 10-Bit, 210 MSPS ADC DC

AD9430-CMOS/PCB 12-Bit, 210 MSPS ADC DC

AD9432/PCB 12-Bit, 105 MSPS ADC SC Rev. 0 Requires AD9432FFA

AD9433/PCB 12-Bit, 125 MSPS ADC SC

AD9480BSU-250EB 8-Bit, 250 MSPS ADC DC

AD10200/PCB Dual 12-Bit, 105 MSPS ADC DC Requires LG-0204A

AD10201/PCB Dual 12-Bit, 105 MSPS ADC DC Requires LG-0204A

AD10226/PCB Dual 12-Bit, 125 MSPS ADC DC Requires LG-0204A

AD10235/PCB Dual 12-Bit, 215 MSPS ADC DC Requires LG-0204A

AD10265/PCB Dual 12-Bit, 65 MSPS ADC DC Requires LG-0204A

AD10401/PCB Dual 14-Bit, 105 MSPS ADC DC Requires LG-0204A

AD10465/PCB Dual 14-Bit, 65 MSPS ADC DC Requires LG-0204A

1

Send an email to highspeed.converters@analog.com for information on evaluating the AD9288 with the High Speed ADC FIFO Evaluation Kit.

2

Connector pin numbers and/or labeling on some evaluation boards (AD9214, AD9410, AD9430, AD9433, AD9235, and AD9244) may not match the FIFO connector

numbering; however, the physical connections are correct.

3

The AD6640 evaluation board has a 40-pin output connector that should be left (MSB) justified when connected to the 50-pin AD664x FIFO adapter.

4

The AD9281 and AD9201 have a single output bus

5

The High Speed ADC FIFO Evaluation Kit can be used to evaluate two channels of the AD9289 at a time.

5

DC

Rev. 0 | Page 7 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

TERMINOLOGY

SINGLE TONE FFT

Signal-to-Noise Ratio (SNR)

The ratio of the rms signal amplitude to the rms value of the

sum of all other spectral components, excluding the first five

harmonics and dc. It is reported in dBc.

Harmonic Distortion, Image

The ratio of the rms signal amplitude to the rms value of the

nonharmonic component generated from the clocking phase

difference of two ADCs, reported in dBc. Note: This measurement

result is valid only when analyzing demultiplexed ADCs.

Signal-to-Noise Ratio Full Scale (SNRFS)

The ratio of the rms signal amplitude related to full scale (0 dB)

to the rms value of the sum of all other spectral components,

excluding the first five harmonics and dc. It is reported in dBFS.

User Defined Signal-to-Noise Ratio (UDSNR)

The ratio of the rms signal amplitude to the rms value of the

sum of all other spectral components within a specified band

set by the user, excluding harmonics and dc. It is reported in dB.

Noise Figure (NF)

The noise figure is the ratio of the noise power at the output of

a device to the noise power at the input to the device, where the

input noise temperature is equal to the reference temperature

(273 K). The noise figure is expressed in dB.

1

Signal-to-Noise-and-Distortion (SINAD)

The ratio of the rms signal amplitude to the rms value of the

sum of all other spectral components, including harmonics but

excluding dc. It is reported in dB.

Harmonic Distortion, Second (2nd)–Sixth (6th)

The ratio of the rms signal amplitude to the rms value of the

fundamental related harmonic component, reported in dBc.

Worst Other Spur (WoSpur)

The ratio of the rms signal amplitude to the rms value of the

worst spurious component (excluding all harmonically related

components) reported in dBc.

Total Harmonic Distortion (THD)

The rms value of the sum of all spectral harmonics specified by

the user. It is reported in dBc.

Spurious-Free Dynamic Range (SFDR)

The ratio of the rms signal amplitude to the rms value of the

peak spurious spectral component. The peak spurious

component may or may not be a harmonic. It is reported in dBc.

Noise Floor

The rms value of the sum of all other spectral components,

excluding the fundamental, its harmonics, and dc referenced to

full-scale and reported in dBFS.

1

For Noise Figure for an ADC, the equation is

2

log10FigureNoise

×=

k= Boltzman’s Constant = 1.38 x 10

T = Temperature in Kelvin = 273 K

B = Bandwidth = 1 Hz

Encode Frequency = ADC Clock Rate

V

= RMS Fullscale Input Voltage

rms

= Input Impedance

Z

IN

SNRFS= FullScale ADC SNR

⎛

⎜

⎜

⎝

-23

/ZV

rms

0.001

in

⎞

⎟

⎟

⎠

⎛

log10SNRFS

×−−

⎜

⎝

Rev. 0 | Page 8 of 44

FrequencyEncode

2

⎞

⎟

⎠

⎛

×−

log10

⎜

⎝

××

0.001

BTk

⎞

⎟

⎠

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

TWO-TONE FFT

Two-Tone, Second Order Intermodulation

Distortion Products (F1 + F2)

The resulting rms second order distortion value reported by the

mixing of two analog input signals. The peak spurious

component is considered an IMD product. It is reported in dBc.

Two-Tone, Second Order Intermodulation

Distortion Products (F2–F1)

The resulting rms second order distortion value reported by the

mixing of two analog input signals. The peak spurious

component is considered an IMD product. It is reported in dBc.

Two-Tone, Third Order Intermodulation

Distortion Products (2F1

The resulting rms third order distortion value reported by the

mixing of two analog input signals. The peak spurious

component is considered an IMD product. It is reported in dBc.

+ F2)

Two-Tone, Third Order Intermodulation

Distortion Products (2F2

+ F1)

Two-Tone, Worst Other Spur (WoSpur)

The resulting rms distortion value, reported by the mixing of

two analog input signals that is not related to the second or

third order distortion products. The peak spurious component

is not considered an IMD product. It is reported in dBc.

Two-Tone, Second Order Input Intercept Point

(IIP2)

The measure of full-scale input signal power of the converter

minus half the IMD second order products. It is reported in dBm.

Two-Tone, Third Order Input Intercept Point (IIP3)

The measure of full-scale input signal power of the converter

minus half the IMD third order products. It is reported in dBm

Two-Tone, SFDR

The ratio of the rms value of either input tone to the rms value

of the peak spurious component. The peak spurious component

is not an IMD product. It is reported in dBc.

.

The resulting rms third order distortion value reported by the

mixing of two analog input signals. The peak spurious

component is considered an IMD product. It is reported in dBc.

Rev. 0 | Page 9 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

THEORY OF OPERATION

The FIFO evaluation board can be divided into several circuits,

each of which plays an important part in acquiring digital data

from the ADC and allows the PC to upload and process that

data. The evaluation kit is based around the IDT72V283 FIFO

chip from IDT. The system can acquire digital data at speeds up

to 133 MSPS and data record lengths up to 32 kB using the

HSC-ADC-EVALA-SC FIFO evaluation kit. The HSC-ADCEVALA-DC, which has two FIFO chips, is available to evaluate

dual ADCs or demultiplexed data from ADCs sampling faster

than 133 MSPS. A USB 2.0 microcontroller communicating

with ADC Analyzer allows for easy interfacing to newer

computers using the USB 2.0 (USB 1.1 compatible) interface.

The process of filling the FIFO chip(s) and reading the data

back requires several steps. First, ADC Analyzer initiates the

FIFO chip(s) fill process. The FIFO chip(s) are reset using a

master reset signal (MRS). The USB Microcontroller then is

suspended, which turns off the USB oscillator, ensuring that it

does not add noise to the ADC input. After the FIFO chip(s)

completely fill, the full flags from the FIFO chip(s) send a signal

to the USB microcontroller to wake up the microcontroller

from suspend. ADC Analyzer waits for approximately 30 ms

and begins the readback process.

During the readback process, the acquisition of data from

FIFO 1 (U201) or FIFO 2 (U101) is controlled via the signals

OEA and OEB. Because the data outputs of both FIFO chips

drive the same 16-bit data bus, the USB microcontroller

controls the OEA and OEB signals to read data from the correct

FIFO chip. From an application standpoint, ADC Analyzer

sends commands to the USB microcontroller to initiate a read

from the correct FIFO chip, or both FIFO chips in dual or

interleaved mode.

CLOCKING DESCRIPTION

Each channel of the buffer memory requires a clock signal to

capture data. These clock signals are normally provided by the

ADC evaluation board and are passed along with the data

through Connector J104/204 (Pin 37 for both Channel 1 and

Channel 2). If only a single clock is passed for both channels,

they can be connected together by Jumper J303.

Jumpers J304 and J305 at the output of the LVDS receiver allow

the output clock to be inverted by the LVDS receiver. By default,

the clock outputs are inverted by the LVDS receiver.

The single-ended clock signal from each data channel is

buffered and converted to a differential CMOS signal by two

gates of a low voltage differential signal (LVDS) receiver, U301.

This allows the clock source for each channel to be CMOS, TTL,

or ECL. The clock signals are ac-coupled by 0.1 µF capacitors.

Potentiometers R312 and R315 allow for fine tuning the

threshold of the LVDS gates. In applications where fine-tuning

the threshold is critical, these potentiometers may be replaced

with a higher resistance value to increase the adjustment range.

Resistors R303, R304, R307, R308, R311, R313, R314, and R316

set the static input to each of the differential gates to a dc

voltage of approximately 1.5 V.

At assembly, solder Jumpers J310–J313 are set to bypass the

potentiometer. For fine adjustment using the pot, the solder

jumpers must be removed.

U302, an XOR gate array, is included in the design to let users

add gate delays to the FIFO memory chips clock paths. They are

not required under normal conditions and are bypassed at

assembly by Jumpers J314 and J315. Jumpers J306 and J307

allow the clock signals to be inverted through an XOR gate. In

the default setting, the clocks are not inverted by the XOR gate.

The clock paths described above determine the WRT_CLK1

and WRT_CLK2 signals at each FIFO memory chip (U101 and

U201, Pin 80). The timing options above should let you choose

a clock signal that meets the setup and hold time requirements

to capture valid data.

A clock generator can be applied directly to S1 and/or S3. This

clock generator should be the same unit that provides the clock

for the ADC. These clock paths are ac-coupled, so that a sine

wave generator can be used. DC bias can be adjusted by

R301/R302 and R305/R306. Note that J301 and J302 (SMA

connectors) and R301, R302, R305, and R306 are not installed at

the factory and must be installed by the user.

The DS90LV048A differential line receiver is used to square the

clock signal levels applied externally to the FIFO evaluation

board. The output of this clock receiver can either directly drive

the write clock of the IDT72V283 FIFO(s), or first pass through

the XOR gate timing circuitry described above.

CLOCKING WITH INTERLEAVED DATA

ADCs with very high data rates may exceed the capability of a

single buffer memory channel (~133 MSPS). These converters

often demultiplex the data into two channels to reduce the rate

required to capture the data. In these applications, ADC

Analyzer must interleave the data from both channels to

process it as a single channel. The user can configure the

software to process the first sample from Channel 1, the second

from Channel 2, and so on, or vice versa, (see the

Troubleshooting section for more information). The

synchronization circuit included in the buffer memory forces a

small delay between the write enable signals (WENA and

WENB) to the FIFO memory chips (Pin 1, U101 and U201),

ensuring that the data is captured in one FIFO before the other.

Jumpers J401 and J402 determine which FIFO receives WENA

and which FIFO receives WENB

Rev. 0 | Page 10 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

INSTALLING ADC ANALYZER

ADC Analyzer is designed to evaluate the performance of an

Analog Devices analog-to-digital converter quickly and easily.

INSTALLATION

A copy of ADC Analyzer is included on the CD that comes with

the FIFO Evaluation Kit. Check the Analog Devices website for

updates to the software at

1. Copy the AnalyzerSetup.exe file to the hard drive.

2. Run the setup file and follow the instructions given in the

installation wizard. Note that administrator privileges are

required to install the software on Windows

2000/Windows Me/Windows XP machines.

www.analog.com/hsc-FIFO.

Step 1

3. Once the software is installed, run the executable file (the

default location is in c:\program files\

ADC_Analyzer\ADC_Analyzer.exe).

CONFIGURATION FILE

A configuration file can be created for each high speed ADC

evaluation board used with ADC Analyzer. A configuration file

provides the software with important information about the

data sent from the ADC evaluation board to the FIFO

evaluation board, such as the number of bits, speed of the clock,

and format of the data bits (binary or twos complement).

Configuration files for some of the evaluation boards are

included with the ADC Analyzer files. Each time ADC Analyzer

is launched, a window opens where a configuration file can be

specified. Click Ye s to specify a configuration file and choose

the file corresponding to the ADC being used.

The default configuration files can be modified or a new

configuration file can be created using the instructions in the

Configuring An Evaluation Board section.

CONFIGURING AN EVALUATION BOARD

Follow Steps 1 through 5 to configure the software with the

ADC evaluation board:

04750-0-003

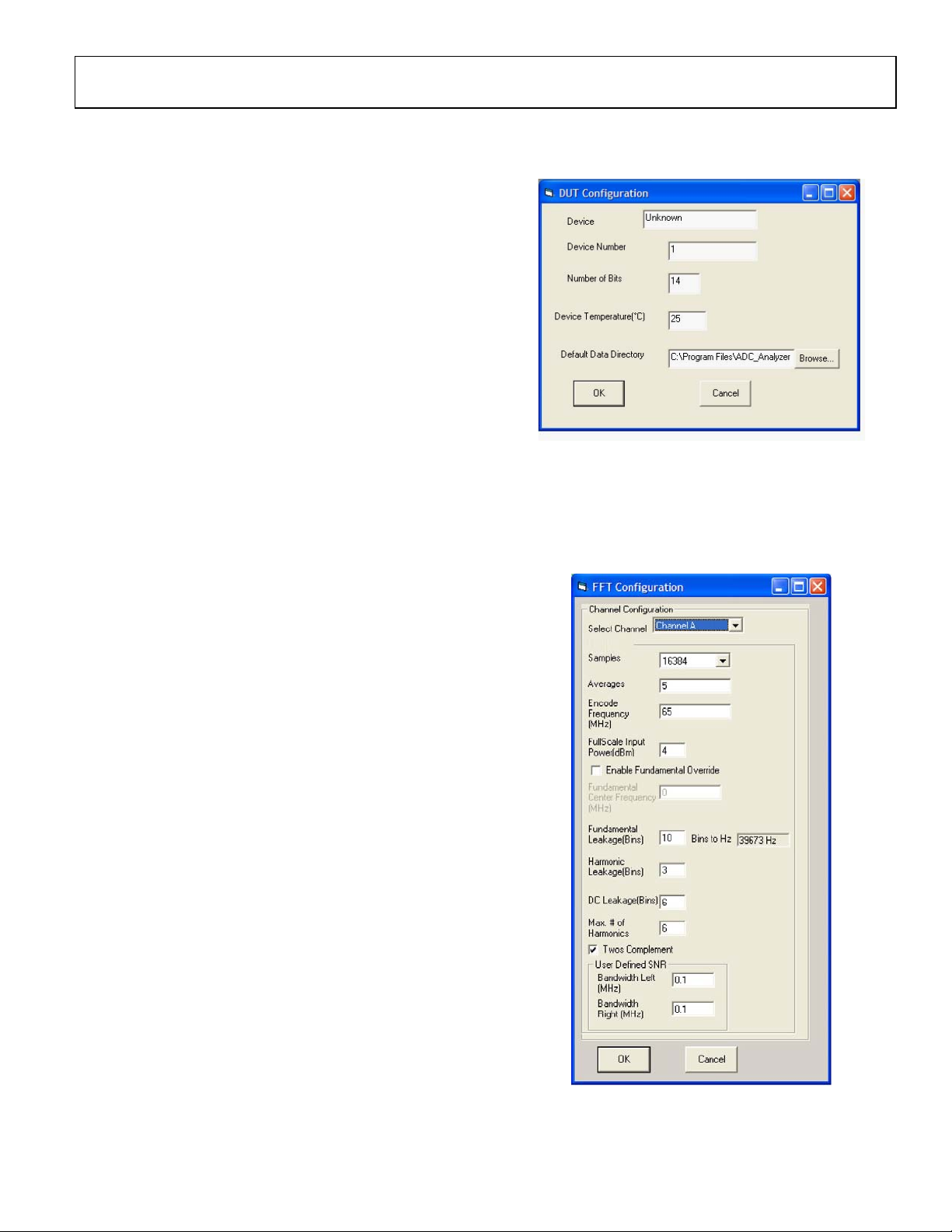

2. Choose Config > FFT from the pull-down menus or right-

click any of the analysis buttons to open the FFT

Configuration screen. Use this menu to configure the Fast

Fourier Transform plot. If needed, modify the options

under Channel A to select the appropriate channel.

Step 2

1. From the pull-down menus in the upper left hand corner,

choose Config > DUT. The screen, DUT Configuration

opens. Enter the name of the ADC being evaluated in the

Device dialog box and the number of bits (resolution of

the ADC) in the Number of Bits dialog box. (Note: This

information is used for display purposes only.) To specify a

directory different than the default to store the

configuration file, enter a new location in the Default Data

Directory dialog box, and click OK.

Rev. 0 | Page 11 of 44

04750-0-004

Note that Channel A in the software corresponds to Channel 1

on the FIFO schematics and the bottom FIFO on the evaluation

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

board. Channel B corresponds to Channel 2 on the FIFO

schematics and the top FIFO on the evaluation board (closest to

the Analog Devices logo). See the Jumpers section for more

information.

Configuring FFT— Defining Available Options

in the Max # of Harmonics’ box. Typically, this can be left at the

default value of 3.

DC Leakage: The number of bins (at dc) that are not used in

calculating SNR and SINAD. Typically, this can be left at the

default value of 6.

Samples: Choose the number of samples taken to calculate an

FFT. The default is 16 kB samples. Users can choose more or

fewer samples, depending on the application. The maximum

number of samples that can be selected in the software is 64 kB.

However, the FIFO evaluation boards are configured with 32 kB

FIFOs. For single ADCs evaluated with the HSC-ADC-EVALASC model, the maximum number of samples selected should

match the FIFO memory on the evaluation board. For dual

ADCs evaluated with the HSC-ADC-EVALA-DC model, the

maximum number of samples should match the FIFO memory

of each channel (a different number of samples can be selected

for each channel). ADCs with demultiplexed outputs (such as

the AD9430) can be used with a sample value of twice the FIFO

memory. See the Upgrading FIFO Memory section.

Ave rage s: Specify the number of averages taken for the average

FFT functions. See the ADC Analyzer Functions section for

more information.

Encode Frequency (MHz): Enter the speed of the sampling

clock to the ADC. If evaluating a dual ADC, two different clock

rates can be entered. Note: If the value is wrong, the analog

fundamental frequency displayed will be wrong.

FullScale Input Power (dBm): This feature lets the user enter

the amount of power (in dBm) needed on the input to

determine the output fullscale. It applies only in noise figure

and IIP2/IIP3 calculations.

Maximum Number of Harmonics: The number of harmonics

displayed by ADC Analyzer. The default value is 6 and the

maximum number of harmonics that can be displayed is 12.

Two s C ompl e ment: Check this box if the data from the ADC

evaluation board is in twos complement format. Refer to the

ADC data sheet to determine if the ADC outputs are configured

for twos complement or offset binary. If the Twos Comp l ement

option is not checked, ADC Analyzer will expect the data

outputs from the ADC to be in offset binary format.

User Defined SNR Left (MHz): This is the amount of

frequency specified to the left of the fundamental by the user to

analyze SNR. The resulting value is called UDSNR and will

show up after an FFT plot is captured.

User Defined SNR Right (MHz): This is the amount of

frequency specified to the right of the fundamental by the user

to analyze SNR. The resulting value is called UDSNR and will

show up after an FFT plot is captured.

After configuring the options for the Fast Fourier Transform

plot in this window, click OK.

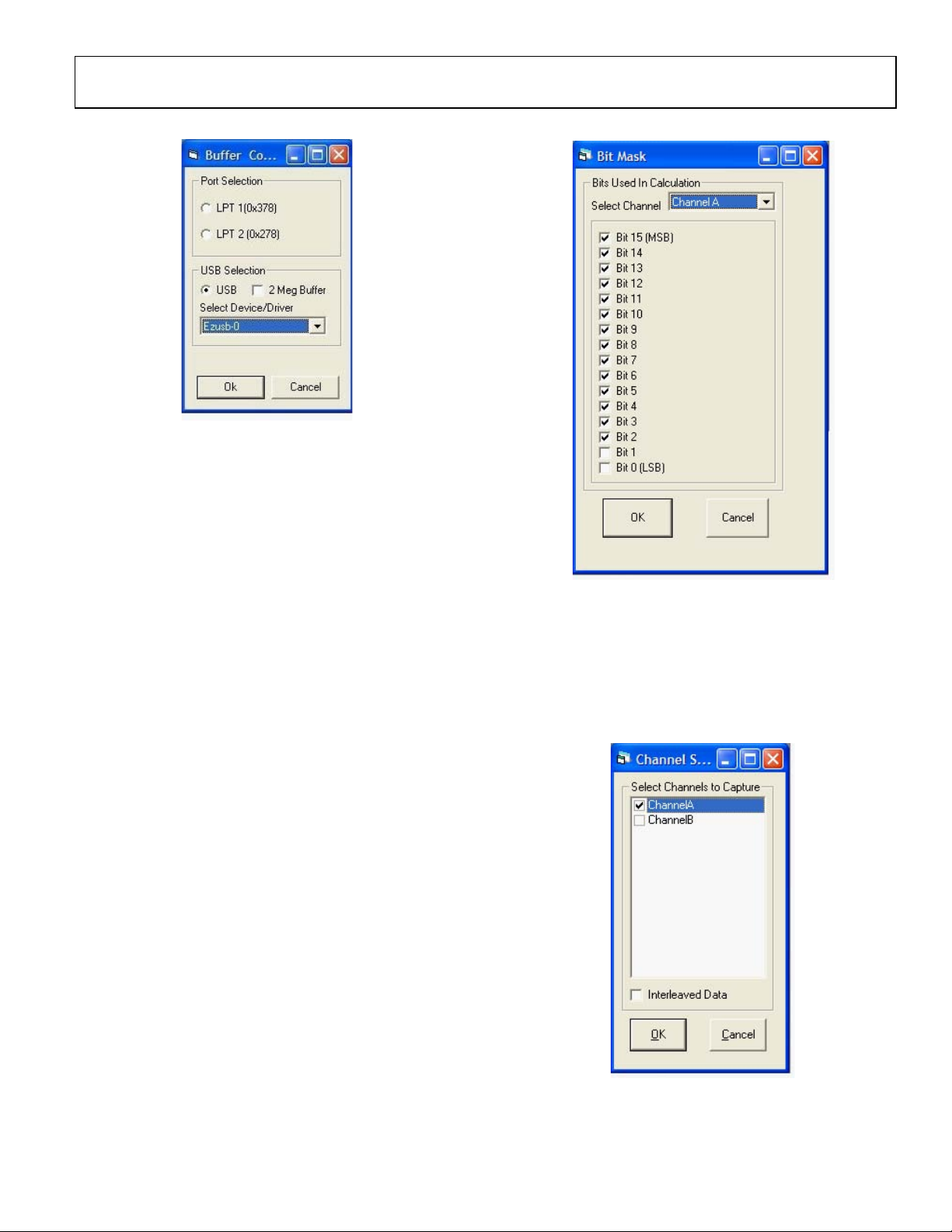

3. Choose Config > Buffer. HSC-ADC-EVAL(A), opening the

Buffer Memory screen.

Step 3

Enable Fundamental Override: ADC Analyzer automatically

defaults the highest spur as the fundamental frequency of

interest. However, in some applications, the user may have a

very small analog input signal that could be equal to or below

another spurious harmonic. This option lets the user specify the

small analog input signal needed for evaluation. If Enable

Fundamental Override is checked, the Fundamental

Frequency (MHz) box is enabled for the user to specify.

Fundamental Leakage: The number of bins that are neglected

on either side of the fundamental signal when calculating the

SNR and SINAD results. For example, if an encode rate is

defined at 80 MSPS with 16384 samples, then

80M/21/(16384/21) = 4883 Hz/Bin is specified. The type of

windowing selected determines the default value of the

fundamental leakage. See the Windowing section for more

information. The default values are 25, 10, and 1 for Hanning,

Blackman Harris, and no windowing, respectively.

Harmonic Leakage: The number of bins that are neglected on

either side of each harmonic of the fundamental signal defined

Rev. 0 | Page 12 of 44

04750-0-005

Click OK, and the Buffer Configuration window opens. ADC

Analyzer automatically seeks a USB connection. If a USB

connection is not found, it will assume that you want to use an

older version FIFO board which has a parallel connection. If so,

choose the appropriate parallel connection made to the

computer and click OK.

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

Step 3a

04750-0-006

4. Choose Config > Bits > Data Bits to open the Bit Mask

screen. Configure the number and location of the data bits

used to calculate the FFTs.

Make sure that the number of bits matches the resolution of the

converter. All of the supported evaluation boards are MSB

justified, so check the number of bits for the converter starting

with Bit 15 (MSB). Exceptions to this are the AD9280, AD9281,

AD9200, and AD9201. For these four ADCs, check the number

of bits starting with Bit 13.

If a single ADC is being evaluated, check only Channel A and

the appropriate bits under Channel A. If a dual ADC is being

evaluated, check Channel A and Channel B on the Channel

Select screen. (Config > Channel Select).

Step 4

04750-0-007

If evaluating a demultiplexed ADC, go to Config > Channel

Select, opening the Channel Select pop-up menu, and check the

Interleaved Data box. This automatically selects both Channel

A and Channel B. When using a dual ADC, select only the

appropriate channel that corresponds to the ADC that is being

evaluated. Channel A is the default selected channel at startup.

Step 4a

04750-0-008

Note that Channel A in the software corresponds to Channel 1

on the FIFO schematics and the bottom FIFO (U201) on the

Rev. 0 | Page 13 of 44

HSC-ADC-EVALA-SC/HSC-ADC-EVALA-DC

evaluation board. Channel B corresponds to Channel 2 on the

FIFO schematics and the top FIFO (U101) on the evaluation

board (closest to the Analog Devices logo). See the Jumpers

section for more information. Click OK. (For more information

about the channel selection process, see the Troubleshooting

section.)

5. As a last step, choose File > Configuration File > Save

Configuration from the pull-down menu to save the

configuration for future use. Choose a file name and a

location to save the file.

ADDITIONAL CONFIGURATION OPTIONS

Other options under the configuration pull-down menu include

Windowing, Power Supply, and Y-Axis.

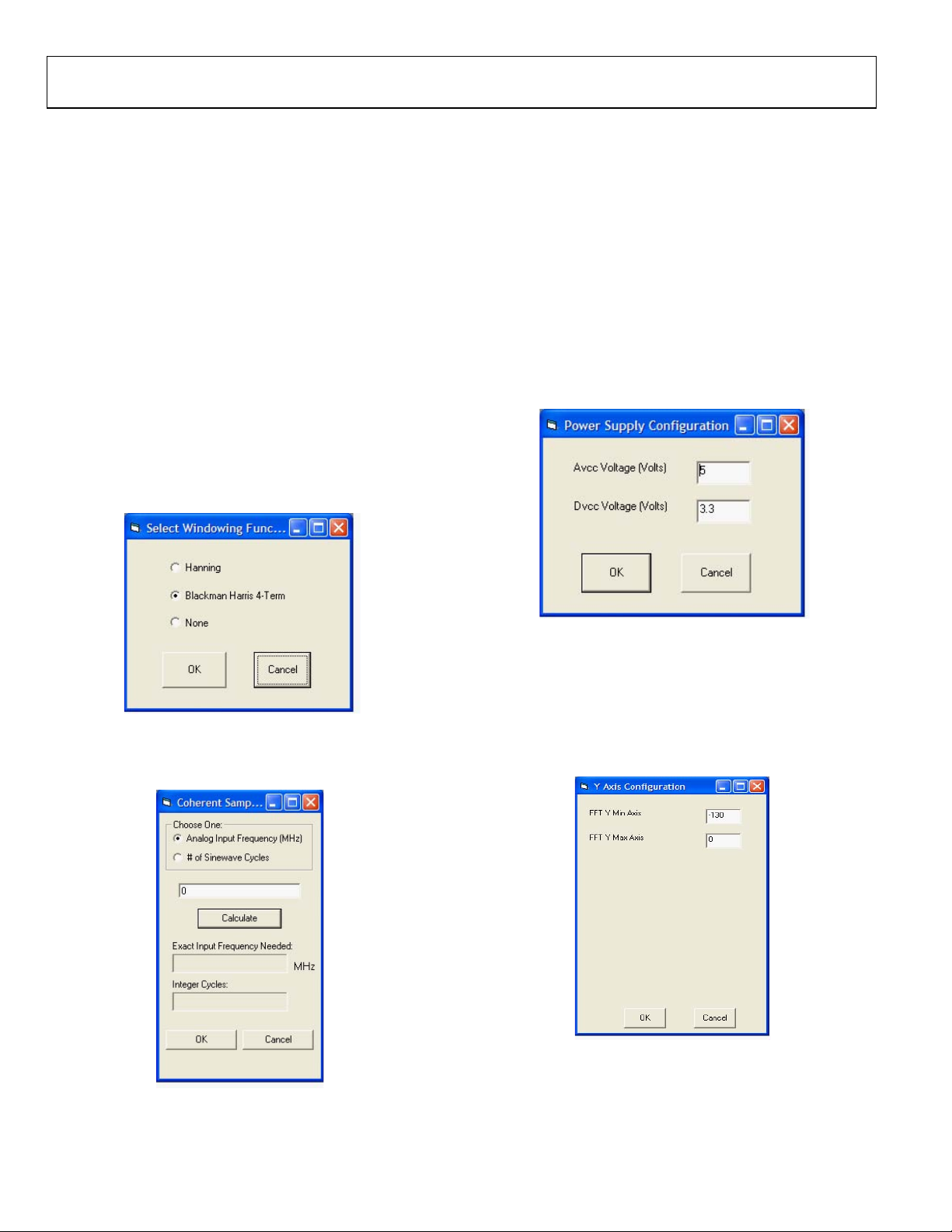

Windowing

Choose either the Hanning or Blackman Harris (default)

windowing functions or turn windowing off. See the

Windowing Functions section for a description of Hanning and

Blackman Harris windowing. Click OK.

For the calculator to work properly, the correct sampling

frequency must be entered under Config > FFT. Select either the

desired approximate Analog Input Frequency or the # of Sine

Wave Cyc l es . Enter the value in the dialog box (not labeled) and

click Calculate to view the Coherent Frequency. The Coherent

Frequency and Number of Integer Cycles will display in the

gray boxes. Click OK to exit the Coherent Sampling Calculator.

Power Supply

This option opens under Config > Power Supply, and users can

enter the value of the ADC analog and digital voltage supplies

(see Figure 5). Note this for user documentation only. No

external control is provided. ADC Analyzer displays this

information when data is captured. See the ADC Analyzer

Functions section for more information.

04750-0-009

Figure 3. Select Windowing Function

If you choose None, the Coherent Sampling Calculator window

opens (see Figure 4).

04750-0-011

Figure 5. Power Supply Configuration

Y-Axis

Use the Y Axis screen to configure the display of the FFT

Y-Axis. Go to Config > YAxis to change the default value of –

130, which is a typical setting for the noise floor of a 14-bit

ADC with 16,384 samples in the FFT calculation.

04750-0-012

Figure 6. Y Axis Configuration

04750-0-010

Figure 4. Coherent Sampling Calculator

Rev. 0 | Page 14 of 44

Loading...

Loading...