Page 1

Evaluation Kit for the

PRODUCT DESCRIPTION

This evaluation board allows the ADM1191/ADM1192 devices

to be easily evaluated. The ADM1191/ADM1192 are integrated

current sense amplifiers that offer digital current and voltage

monitoring via an on-chip analog-to-digital converter (ADC)

communicated through an I

sense amplifier senses voltage across the sense resistor in the

power path via the VCC and SENSE pins.

The ADC can measure the current seen in the sense resistor

and the supply voltage on the VCC pin. An industry standard

2

I

C interface allows a controller to read current and voltage data

from the ADC. Measurements can be initiated by an I

command. Alternatively, the ADC can run continuously, and

the latest conversion can be read whenever it is required.

The devices have a SETV pin. A voltage applied to this pin is

internally compared to the output voltage on the current sense

amplifier. The output of the SETV comparator asserts when the

current sense amplifier output exceeds the SETV voltage.

When this event occurs for the ADM1191, the ALERTB output

asserts; when the event occurs for the ADM1192, the ALERT

output asserts. This alert signal can be used as a flag to warn a

microcontroller or field programmable gate array (FPGA) of an

overcurrent condition. The alert output of multiple devices can

be tied together and used as a combined alert.

2

C interface. An internal current

2

C

C6

ADM1191/ADM1192

EVAL-ADM1191/ADM1192

EVALUATION BOARD DESCRIPTION

The ADM1191/ADM1192 digital power monitor evaluation

board can be controlled using the configuration tool, allowing

the device to be actively simulated through software. This

evaluation board provides an I

power supply of between 3.15 V and 26 V connected through

the J2 and J4 connectors. The latest version of the configuration

tool can be downloaded from the Analog Devices, Inc., website

www.analog.com/powermonitorsw.

Note that, when changing devices, the software should first be

shut down and the power supply to the board removed. J7 is an

2

I

C connector that connects the evaluation board to a PC via a

5-pin SMBus cable.

PACKAGE CONTENTS

ADM1191/ADM1192 evaluation board

5-pin SMBus cable

5-pin interconnection cable

ADM1191/ADM1192 device samples

R8

PIN 1 IDENTIFIER

2

C interface requiring a bench

ADM1191/ADM1192 DEVICESOCKET

Figure 1. Sample Device Placement

Rev. 0

Evaluation boards are only intended for device evaluation and not for production purposes.

Evaluation boards are supplied “as is” and without warranties of any kind, express, implied, or

statutory including, but not limited to, any implied warranty of merchantability or fitness for a

particular purpose. No license is granted by implication or otherwise under any patents or other

intellectual property by application or use of evaluation boards. Information furnished by Analog

Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog

Devices for its use, nor for any infringements of pate nts or other rights of third parties t hat may result

from its use. Analog Devices reserves the right to change devices or specifications at any time

without notice. Trademarks and registered trademarks are the property of their respective owners.

Evaluation boards are not authorized to be used in life support devices or systems.

6486-001

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Page 2

EVAL-ADM1191/ADM1192

TABLE OF CONTENTS

Product Description......................................................................... 1

Evaluation Board Description......................................................... 1

Package Contents.............................................................................. 1

Revision History ............................................................................... 2

Evaluation Board Hardware............................................................ 3

Hardware Components................................................................ 3

Switch Functions .......................................................................... 3

Jumper Functions......................................................................... 4

LED Functions.............................................................................. 4

Links and Connectors.................................................................. 5

Evaluation Board Software.............................................................. 6

Powering the Evaluation Board.................................................. 6

Communicating with the Evaluation Board............................. 6

Configuration Tool....................................................................... 6

Installing the Evaluation Software ............................................. 7

Uninstalling the Evaluation Software ........................................ 8

Manually Uninstalling the Evaluation Software....................... 8

USB–Communicating for the First Time.................................. 9

Starting the Evaluation Software.............................................. 10

Evaluation Software—Main Panel Tab ........................................ 11

Command Register Controls.................................................... 11

Alert Register Controls.............................................................. 11

Status Register Controls ............................................................ 12

Force Alert Off Control............................................................. 12

Overcurrent Output Flag........................................................... 12

Trace Data Display Controls..................................................... 12

Readback Update Rate Control ................................................ 13

Data Logger................................................................................. 13

Convert Pin Control .................................................................. 13

Communication Status Indicator............................................. 14

Real-Time Graphs of Voltage, Current, and Power ................... 15

Evaluating Multiple Devices in Parallel....................................... 16

Communicating with Interconnected ADM1191/ADM1192

Evaluation Boards ...................................................................... 16

Interconnecting a Combination of ADM1191 and ADM1192

Devices......................................................................................... 18

Evaluation Board Schematic......................................................... 19

Ordering Information.................................................................... 20

Bill of Materials........................................................................... 20

Ordering Guide .......................................................................... 21

ESD Caution................................................................................ 21

REVISION HISTORY

5/08—Revision 0: Initial Version

Rev. 0 | Page 2 of 24

Page 3

EVAL-ADM1191/ADM1192

EVALUATION BOARD HARDWARE

HARDWARE COMPONENTS

Main Evaluation Board

The evaluation board contains all of the circuitry necessary to

simulate power monitoring events, such as a control FET, a

sense resistor, and timing components. VR1 adjusts a variable

load; turning VR1 clockwise reduces the load resistance,

thereby increasing the load current to a maximum of 550 mA.

The load circuit is useful when evaluating the performance of the

device under varying load conditions.

5-Pin SMBus Cable

The 5-pin SMBus cable connects the main evaluation board to a

standard PC through connector J7.

SWITCH FUNCTIONS

Table 1.

Switch Description Default

S1 On Pin Setting Switch.

S1-1 Connects the resistor dividers R5B, R5A/R6B, R6A to the CONV/SETV pin of the device. Open

S1-2 Connects the resistor dividers R14B, R14A/R26B, R26A to the CONV/SETV pin of the device. Closed

S2 Timer Adjust Capacitor. Sets current limit on time.

S2-1 Connects the 4.7 nF capacitor (C1) to the SETV/TIMER pin. Open

S2-2 Connects the 47 nF capacitor (C2) to the SETV/TIMER pin. Closed

S2-3 Connects the 470 nF capacitor (C3) to the SETV/TIMER pin. Open

S2-4 Connects the user-defined capacitors (C4 and C5) to the SETV/TIMER pin. Open

S3 Additional Board Address Control Switch. Applies to the ADM1191.

S3-1 Connects the A1 pin of the board to 3.3 V. Open

S3-2 Pulls the A1 pin of the board to GND through a 150 k resistor. Open

S3-3 Pulls the A1 pin of the board to GND. Open

S3-4 N/C.

S4 Board Address Control Switch.

S4-1 Connects the A0/ADR pin of the board to 3.3 V. Open

S4-2 Pulls the A0/ADR pin to GND through a 150 k resistor. Open

S4-3 Pulls the A0/ADR pin to GND. Open

S4-4 N/C.

S5 Applies to the ADM1191 only; controls the CONV pin of the ADM1191. When depressed, the convert pin is high. Closed

S6

VR1

Applies to the ADM1192 only; controls the CLRB pin of the ADM1192 device. When depressed, the CLRB pin is

pulled low.

Adjusts a variable load; turning VR1 clockwise reduces the load resistance, thereby increasing the load current to

a maximum of 550 mA.

5-Pin Interconnection Cable

The interconnection cable is used for multiple evaluation board

parallel connection setup. Two or more boards can be connected in

parallel through the J1 and J5 connectors using the 5-pin

interconnection cable. Each device should be assigned to a

different address using an address pin. The maximum number

of devices that can be interconnected is four for the ADM1192

and 16 for the ADM1191.

Device Samples

Some loose samples of the device to be evaluated are included

in a samples box. A single device should be placed in the socket

before powering up the evaluation board. The device should be

oriented in the socket so that Pin 1 is in the top left corner, near

C6, as shown in

Figure 1.

Closed

N/A

Rev. 0 | Page 3 of 24

Page 4

EVAL-ADM1191/ADM1192

JUMPER FUNCTIONS

Table 2.

Jumper Description Default

JP1 In Position A, the ALERTB pin of the ADM1191 is connected to the D5 LED circuitry.

In Position B, the ALERTB pin of the ADM1191 is connected to J1-5, J5-5, and J7-5.

JP2 In Position A, the CONV pin of the ADM1191 is connected to S5.

In Position B, the CONV pin of the ADM1191 is connected to J5-4, J1-4, and J7-4.

JP3 In Position A, the ALERTB pin of the ADM1192 is connected to the gate of FET Q1.

In Position B, the ALERTB pin of the ADM1192 is connected to +3.3 V rail.

JP4 In Position A, the ADM1192 ALERT output controls LED D1 (note that JP3 must be set to Position B).

In Position B, the ADM1192 ALERT output is connected to J1-5, J5-5, and J7-5.

JP5 When inserted, the output LED D4 circuitry is active. Inserted

JP6 When inserted, the A1/CLRB pin is connected to S3 (ADM1191) or S6 (ADM1192). Inserted

JP7 When inserted, the A0/ADR pin is connected to S4. Inserted

J8 When in Position A, the SENSE pin of the device is connected to the source of FET Q1 (applies only to the ADM1192).

In Position B, the SENSE pin of the device is connected to J10.

J10 When in Position A, the drain of Q1 is connected to J3 (applies only to the ADM1192).

When in Position B, the variable load circuit is active.

LED FUNCTIONS

Table 3.

LED Name Description

D1 ALERT

D3 INPUT Indicates that the supply voltage is present.

D4 OUTPUT Indicates that the output voltage is present.

D5 ALERTB

Applies to the ADM1192. Indicates that an overcurrent condition has been detected; the level at which the

overcurrent condition is detected depends on the voltage on the SETV pin. This can also be programmed

digitally.

Applies to the ADM1191. Indicates that an overcurrent condition has been detected; the level at which the

overcurrent condition is detected depends on the voltage on the SETV pin. This can also be programmed

digitally.

A

B

A

B

B

B

Rev. 0 | Page 4 of 24

Page 5

EVAL-ADM1191/ADM1192

LINKS AND CONNECTORS

Solder pads SL1 to SL13 are preset on the EVAL-ADM1191EBZ and the EVAL-ADM1192EBZ, with different settings for the devices they

are designed to test. A board that is set up to test the ADM1191 device can be used later to test the ADM1192 device by changing the

connections on the solder pad.

Table 4. Configuration Links Used to Configure an Evaluation Board for a Specific Device

Link Description

SL1 Inserted for the ADM1191

SL2 Inserted for the ADM1192

SL3 Inserted for the ADM1191

SL4 Inserted for the ADM1192

SL5 Inserted for the ADM1192

SL6 Inserted for the ADM1191

SL7 Inserted with high current link

SL9 Inserted for the ADM1192

SL10 Inserted for the ADM1191

SL11 Inserted with high current link

SL12 Inserted for the ADM1191

SL13 Inserted for the ADM1192

Table 5. Connector Functions

Connector Description

J1 Minimolex Connector. Used for interconnecting devices.

J2 Red Banana Connector. Input Voltage Line.

J3 Red Banana Connector. Output Voltage Line.

J4 Black Banana Connector. Ground.

J5 Minimolex Connector. Used for interconnecting devices.

J7 5-Pin Header. I2C Connector.

J9 Black Banana Connector. Ground.

Rev. 0 | Page 5 of 24

Page 6

EVAL-ADM1191/ADM1192

EVALUATION BOARD SOFTWARE

For the ADM1191, measurements can be initiated by an I2C

command or via the convert (CONV) pin. The CONV pin is

especially useful for synchronizing reads on multiple ADM1191

devices. Up to 16 unique I

on the way the A0 and A1 pins are connected.

For the ADM1192, a CLRB pin is provided to clear fault

conditions, and a timer pin is provided to time overcurrent

conditions. Up to four unique I

depending on the way the ADR pin is connected.

2

C addresses can be created, depending

2

C addresses can be created,

VIN (J2)

GND (J4)

POWERING THE EVALUATION BOARD

The evaluation board is powered using a bench supply of

between 3.15 V and 26 V, connected to the J2 (VIN) and J4

(GND) connectors.

COMMUNICATING WITH THE EVALUATION BOARD

Communication with the ADM1191/ADM1192 devices is

facilitated by the graphical user interface (GUI) provided by

Analog Devices. The latest revision of this software is available

for download at

software is compatible with Windows® 2000 and Windows® XP.

Communication between a PC and the evaluation board is

achieved through the 5-pin header (J7), which should be

connected to the PC using the cable provided.

www.analog.com/powermonitorsw. The

5-PIN SMBus CABLE (J7)

Figure 2. ADM1191/ADM1192 Evaluation Board

06486-002

CONFIGURATION TOOL

The evaluation kit configuration tool allows you to program

and monitor the many features of the ADM1191/ADM1192

current sense amplifiers through an intuitive GUI-based

interface. With the evaluation kit, you can verify a configuration

before using the ADM1191/ADM1192 in system applications.

The following minimum system requirements apply:

• Windows 2000

• 500 MHz processor

• 80 MB free disc space

• 256 MB RAM

• Minimum monitor resolution: 800 × 600 high color

(16 bit).

The software interface is arranged in a tabbed format, each tab

enabling the control of a key feature of the device.

Rev. 0 | Page 6 of 24

Page 7

EVAL-ADM1191/ADM1192

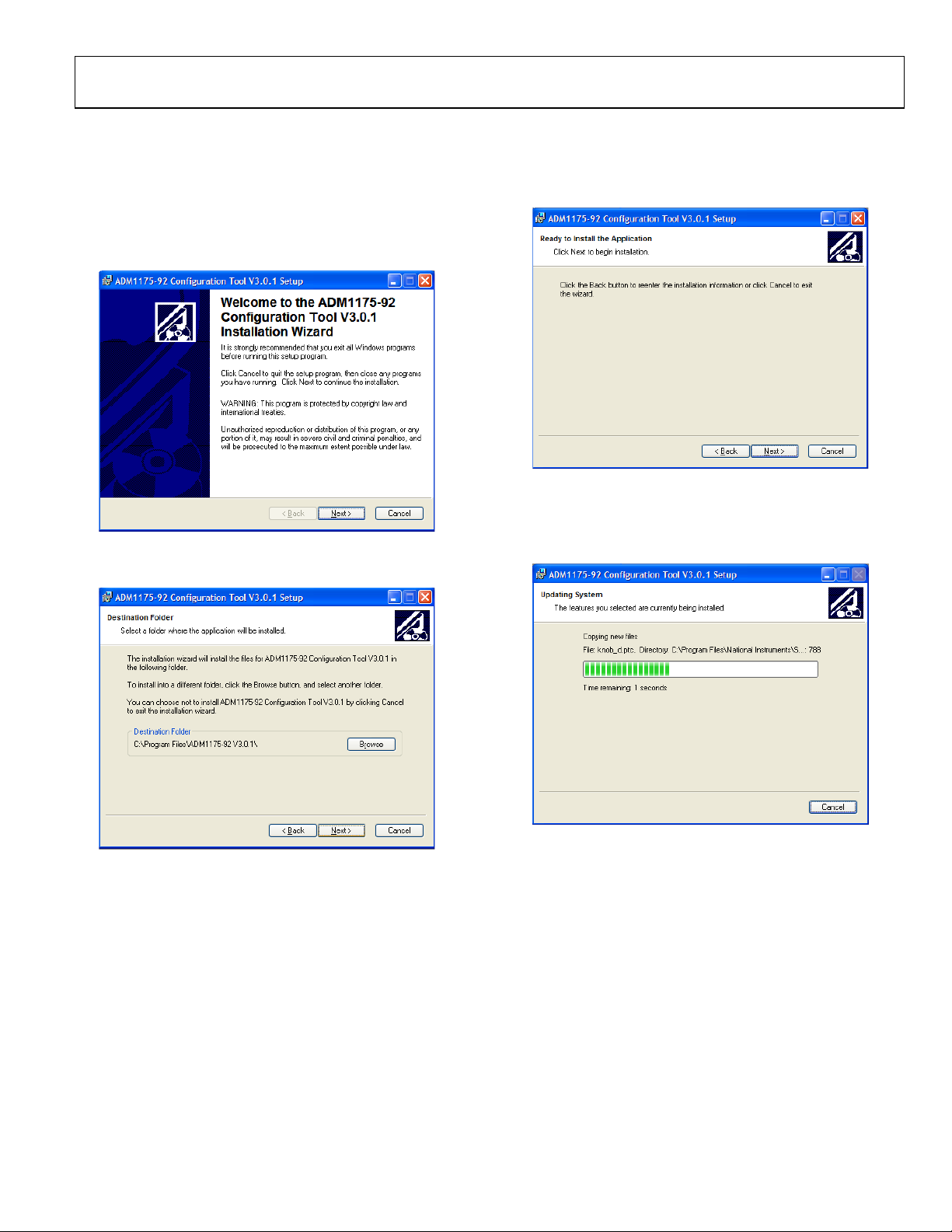

INSTALLING THE EVALUATION SOFTWARE

Install the ADM1191/ADM1192 software as follows:

1. Download the .zip file containing the software from

www.analog.com/powermonitorsw.

2. When the download is complete, extract the files from the

.zip file.

3. Double-click setup.exe. The setup window appears.

Figure 3. Evaluation Software Installation Wizard

4. Click Next to display the Destination Folder box.

06486-003

5. To create a new destination folder, click Browse. If the

default destination folder is acceptable, click Next. The

following box appears:

Figure 5. Installing the Evaluation Software

6. Choose to step back and reenter installation information,

stop installation, or begin installation. To begin installation,

click Next. The installation runs as shown in

Figure 6.

06486-005

Figure 4. Evaluation Software—Choosing a Destination Folder

06486-004

Rev. 0 | Page 7 of 24

Figure 6. Installation in Progress

06486-006

Page 8

EVAL-ADM1191/ADM1192

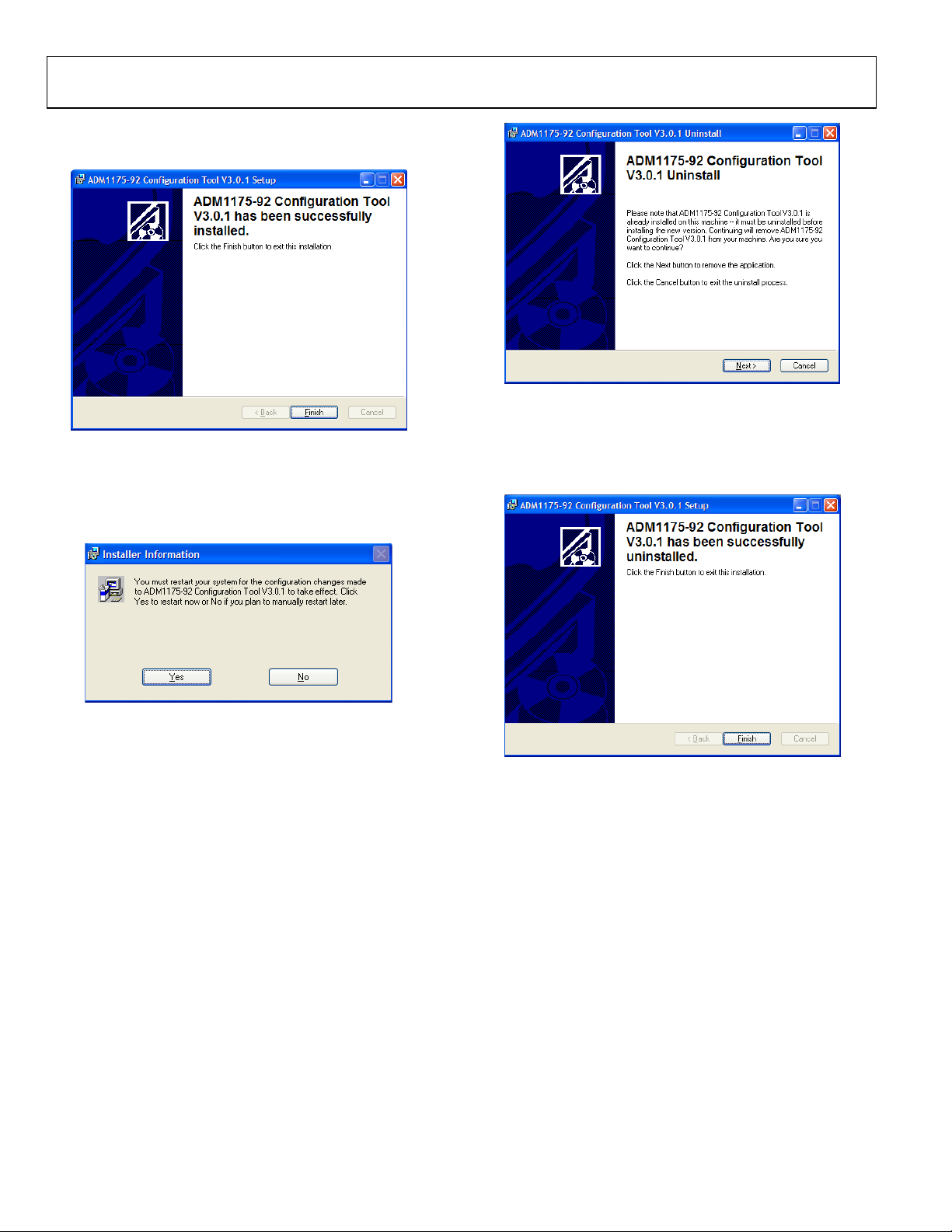

7. When installation is complete, the following message box

appears:

Figure 7. Evaluation Software—Installation Complete

8. Click Finish. The message shown in Figure 8 appears,

indicating that you must restart the system for the

configuration changes to take effect. Click Ye s to restart the

PC immediately; click No to manually restart later.

06486-009

Figure 9. Evaluation Software—Uninstalling

06486-007

When you click Next, the software uninstalls the software,

providing status as it does so, and displays the following

message to indicate that the previous version has successfully

uninstalled:

06486-008

Figure 8. Installation Restart Reminder

UNINSTALLING THE EVALUATION SOFTWARE

Before an updated version of the evaluation software is

installed, any previous version is uninstalled automatically after

the newly downloaded setup.exe is double-clicked (see Step 3).

The message shown in

previous version will be uninstalled.

Figure 9 appears, notifying you that the

Figure 10. Evaluation Software—Uninstalling Complete

MANUALLY UNINSTALLING THE EVALUATION SOFTWARE

If you want to manually uninstall the ADM1191/ADM1192

software (without upgrading it to a newer version), do the

following:

1. On the PC desktop, click Start.

2. Click Control Panel.

3. Click Add or Remove Programs.

4. Select the ADM1191 or ADM1192 program and click

Remove to uninstall it.

06486-010

Rev. 0 | Page 8 of 24

Page 9

EVAL-ADM1191/ADM1192

USB–COMMUNICATING FOR THE FIRST TIME

When the evaluation board is launched for the first time using a

USB connection, Windows does not recognize the external

board and begins installing drivers automatically. To identify

the USB converter to Windows, select the ADM1191/ADM1192

software and, when the box shown in

Install the software automatically (Recommended).

Figure 11. Automatically Installing Drivers for the Evaluation Board

In Windows XP, a warning is displayed indicating that the

hardware has not passed Windows logo testing, which verifies

compatibility with Windows XP. Because the evaluation board

has been tested and is compatible with Windows XP, you can

simply click Contine Anyway to install the necessary drivers as

shown in

Figure 12.

Figure 11 appears, select

06486-012

Figure 12. Windows XP Compatibility

After this process is complete, the message shown in Figure 13

appears. To close the installation wizard, click Finish. The

software can now be opened again and run normally.

06486-011

Rev. 0 | Page 9 of 24

Figure 13. Completing Installation

06486-013

Page 10

EVAL-ADM1191/ADM1192

STARTING THE EVALUATION SOFTWARE

1. Click Start> All Programs> ADM1175-92 Configuration

Tool 3.0.1> ADM1175-92 Configuration Tool 3.0.1 (note

that the actual folder name is version dependent).

2. When the software starts, the software agreement window

appears. Read the use conditions, select I Agree to agree

with the conditions, and click Continue.

06486-014

Figure 14. Software Agreement

If the evaluation board is powered up and an ADM1191/

ADM1192 device is in the socket, the window shown in

appears, displaying a green highlighted box that corresponds to

the device I

As shown in

2

C address.

Figure 15, there are four possible I2C addresses for

the ADM1175, ADM1177, ADM1178, and ADM1192, while

there are 16 possible I

ADM1191. In

2

C addresses for the ADM1176 and

Figure 15, an ADM1191 has responded with I2C

address 7Eh.

Figure 15

3. To c o n t inu e , cl i ck OK.

The window shown in

you are prompted to accept the sense resistor value R

(R8). The default value of the sense resistor, R

Figure 16 appears. In this example,

SENSE

, on the

SENSE

ADM1191/ADM1192 evaluation boards is 0.2 Ω.

06486-016

Figure 16. Sense Resistor Value Entry

4. Enter the value of the correct sense resistor and click OK to

continue.

Note that related information on interconnecting devices can be

found in the

Evaluating Multiple Devices in Parallel section.

06486-015

Figure 15. Device Address Detection Window

Rev. 0 | Page 10 of 24

Page 11

EVAL-ADM1191/ADM1192

EVALUATION SOFTWARE—MAIN PANEL TAB

The Main Panel tab of the evaluation software is shown in

Figure 17. It is divided into 10 control areas that you can use to

test and evaluate the ADM1191/ADM1192 devices.

Figure 17. Main Panel Tab on the User Interface

COMMAND REGISTER CONTROLS

06486-017

Alert Register controls consist of four buttons you can use to

enable or disable the various alerts generated by the device

being evaluated.

The four alert types are

• ADC OC1 (analog-to-digital converter overcurrent

Alert 1): When you enable this alert, a message box appears

prompting you to enter the current limit that triggers the

alert. When you set the sense resistor to the default value

0.2 Ω, the range is 0 to 0.529 A. If a lower value sense

resistor is used, the range increases; similarly, if a higher

value is used, the range is reduced.

Press Enter after entering the value to set it. The ADC

overcurrent alert is then triggered when a current greater

than the specified level is detected by a single ADC sample.

06486-018

Figure 18. Register Control Panel

Command Register controls allow you to manage the way in

which the device reads the data. There are five toggle buttons

with which to select the data reading method and voltage range.

The voltage range is set at 14:1 by default (7:2 if the Range

button is selected). You have the option of reading the current

and voltage just once or continuously. Once you have selected

the range and reading method, click Write D ata t o Co m ma n d

Register to pass the change to the register of the device.

Note that Read Current Once and Continuous Current Read

cannot be selected simultaneously; the same rule applies to the

voltage read buttons.

ALERT REGISTER CONTROLS

06486-019

Figure 19. Alerts Panel

06486-020

Figure 20. Analog to Digital Converter Overcurrent Alert 1

• ADC OC4 (analog-to-digital converter overcurrent

Alert 4): The ADC OC4 alert is similar to the ADC OC1

alert except that it triggers only if a current greater than the

specified level is detected for four consecutive ADC samples.

This prevents a single transient event from triggering an

ADC overcurrent condition.

• Over current Alert: This alert is enabled when an over-

current condition is present.

• OFF ALERT: This alert enables the Software Off Alert.

By default, the overcurrent alert is enabled when ADC OC1,

ADC OC4, and OFF ALERT are disabled. An enabled alert is

highlighted in yellow; a disabled alert is gray in color. To enable

or disable an alert, simply select the corresponding button in

the Alert Register.

Rev. 0 | Page 11 of 24

Page 12

EVAL-ADM1191/ADM1192

STATUS REGISTER CONTROLS

06486-021

Figure 21. Status Register

Status Register controls monitor the following alert types:

• ADC overcurrent alert

• Overcurrent alert

• Software off alert

The status register panel has six alert indicators. The upper row

shows the real-time alert status, while the lower row shows the

latched alert status. Each type of alert can be enabled or disabled

with Alert Register controls, as discussed in the

Controls

section.

To read the alert status, click Read Status Register. If the color

of an alert indicator turns from green to red, it indicates that the

alert has been triggered.

To clear latched alerts, click Clear Latched Alerts and then

click Read Status Register.

Alert Register

The Force Alert OFF control manually overrides the

ALERT/ALERTB output. The off status alert triggers when the

software turns off, and the OFF STATUS control turns from

green to red in the Status Register control panel.

OVERCURRENT OUTPUT FLAG

To the right of the Status Register controls, there is an indicator

called the Overcurrent Output Flag. For the ADM1191, it is

labeled ALERTB, while for the ADM1192, it is labeled ALERT.

This indicator updates in real time. If an overcurrent condition

is detected, the indicator changes from green to red.

06486-024

Figure 24. ADM1191 Overcurrent Output Flag

Figure 25. ADM1192 Overcurrent Output Flag

When the overcurrent condition is removed, the indicator

changes to green after Read Status Register in the Status

Register panel is selected.

Note that the positions of Jumper JP1 for the ADM1191 and

Jumper JP4 for the ADM1192 on the evaluation board affect the

status of this indicator. When the appropriate jumper is inserted

in Position A on the board, the Overcurrent Output Flag is

represented by the on-board LEDs, and the indicator in the

software is constantly green, even when an overcurrent event

occurs.

06486-025

06486-022

Figure 22. Status Register Showing Triggered Alerts

When the overcurrent alert is triggered, as shown in Figure 22,

the device goes into overcurrent protection mode. To restart the

board, cycle the power or toggle the ON pin of the device or the

software ON bit.

FORCE ALERT OFF CONTROL

06486-023

Figure 23. Software On/Off Switch

TRACE DATA DISPLAY CONTROLS

06486-026

Figure 26. Trace Data Display

The trace data display area displays the digitized current,

voltage, and power data. You have the option of changing the

name of the trace using the Trace n a m e box. The color box to

the right of the Power box indicates the color with which the

trace is plotted on the voltage, current, and power (V, I & P

graphs) tab.

When the software is supporting multiple board connections,

multiple traces appear. For more information, see the

Evaluating Multiple Devices in Parallel section.

Rev. 0 | Page 12 of 24

Page 13

EVAL-ADM1191/ADM1192

READBACK UPDATE RATE CONTROL

06486-027

Figure 27. Readback Update Rate Options

The readback update rate is set using the Readback update rate

control box shown in

Figure 27. You can choose from four

update options: every 100 ms, 200 ms, 500 ms, and 1000 ms.

Each option changes the rate at which the data in the trace data

display area is updated. The readback update rate also sets the

rate for data display in the Data Logger and the real-time

graphs on the V, I & P g r a ph s tab.

DATA LOGGER

06486-028

Figure 28. Data Logger Panel

Data Logger controls allow you to log the digitized data that is

collected to a Microsoft Excel® format file, giving you more

flexibility to monitor and compare data. You must set up the

data sampling rules. Enter the number of times to perform a

sample in the Set log limit box. If this value is zero, there is no

limit on the number of samples the data logger can log.

The sampling rate is set using one of the four options in the

Readback update rate box. In

100 samples, with 100 ms between each sample.

Figure 29, the data logger logs

CONVERT PIN CONTROL

06486-030

Figure 30. Convert Pin Control (ADM1191 Only)

The Convert Pin Control options apply to the ADM1191

device only. You can use these options to control the analog-todigital conversion of voltage and current.

Jumper JP2 should be in Position B to allow the evaluation

software to control the convert pin. If the jumper is in Position B,

the on-board switch S6 can be used to control the conversion.

The four options on the panel control the type of data conversion

carried out.

• Press to Stop Converting allows you to stop a continuous

conversion.

• Convert Once carries out a single conversion by issuing a

single pulse to the CONV pin. The result of the conversion

appears in the trace data display area at the top right of the

Main Panel tab.

• Continuously Converting begins a continuous conversion

by pulling the CONV pin high. The results of the continuous

conversion are displayed in the trace data display area.

• Pulse Convert line controls pulse frequency, as shown in

Figure 31. You can choose from one of four pulse frequencies:

100 ms, 200 ms, 500 ms, and 1000 ms.

06486-029

Figure 29. Data Logging

After you set up the data logger, click Log data to file. A file

browser box appears so that you can specify a file name and

location for storing the data. In the box, click Log to start

logging data to the file. The data is sampled at the chosen rate

and logged to the selected Excel file.

After the data begins logging, the total number of samples

logged is displayed at the bottom of the Data Logger area. This

number increases with the sampling rate. The log progress is

complete when it reaches the log limit value. Alternatively, you

can click Stop data log to file to terminate the process. After

the data is imported to the Excel file you specify, the data can be

easily evaluated.

Rev. 0 | Page 13 of 24

06486-031

Figure 31. Pulse Frequency Selection

Note that, if you set the pulse frequency for the ADM1191,

you will not be able to change the readback update rate.

Page 14

EVAL-ADM1191/ADM1192

COMMUNICATION STATUS INDICATOR

At the lower right corner of the Main Panel tab, there is a

communication status indicator that reports the status of the

connection between the software and the evaluation board.

There are three possible indicators, as shown in

Figure 32. Device Communication Indicator

Figure 32.

06486-032

The leftmost indicator reports normal communication. The

middle indicator spins to report a write data to register. The

third indicator reports that communication between the device

and the user interface has been lost. The software should be

restarted to reestablish communication with the device.

Rev. 0 | Page 14 of 24

Page 15

EVAL-ADM1191/ADM1192

REAL-TIME GRAPHS OF VOLTAGE, CURRENT, AND POWER

On the V, I & P g ra ph s tab, you can monitor data collected

through the evaluation board using the software generated

graphs. On the tab, there are three sets of controls and graphs

corresponding to voltage, current, and power. Voltage and

current graphs are displayed using actual voltage and current

data from the device. The values for the power graph are

calculated using P = V.I.

06486-033

Figure 33. Panel Selection Tabs

The Readback update rate control on the Main Panel tab sets

the rate at which the ADC samples are taken and, consequently,

the speed at which the graphs update.

format. The options are Strip Chart, Scope Chart, and Sweep

Chart. The default is Scope Chart.

06486-037

Figure 37. Pause Graph and Chart Type Selection

Figure 38 shows the result of varying the supply voltage. Note

that the power graph also changes.

06486-034

Figure 34. Voltage, Current, and Power Plot

The digitized values for voltage, current, and power are displayed at

the left in each set of controls and graphs.

06486-035

Figure 35. Trace Identifier

For ease of viewing, you can scale the y-axis of a plot.

06486-036

Figure 36. Scale Adjustment Bar

At the top right corner of the tab, there is a Pause button that

you can use to pause the graph from real-time plotting. There is

also a chart selection box that you can use to choose a graph

Figure 38. Plot with Voltage Variation

Figure 39 shows that the supply voltage is constant but that the

current is changing as a result of varying the load resistance by

turning switch VR1. Turning VR1 clockwise reduces the load

resistance, thereby increasing the current; turning VR1

counterclockwise has the opposite effect. Again, notice the

variation in the power graph as the current graph changes.

Figure 39. Plot with Current Variation

06486-038

06486-039

Rev. 0 | Page 15 of 24

Page 16

EVAL-ADM1191/ADM1192

EVALUATING MULTIPLE DEVICES IN PARALLEL

For the ADM1191, up to 16 unique I2C addresses can be created,

allowing you to interconnect up to 16 devices. For the ADM1192,

up to four I

connect up to four ADM1192 devices.

Each evaluation board is fitted with switches labeled A0 and A1.

A0 is used on an ADM1192 device to assign an address, via the

ADR pin, to that particular device. For the ADM1191, both A0

and A1 are used to assign up to 16 I

ensure that each device has a unique I

When interconnecting ADM1191/ADM1192 devices, you should

power each device using a bench supply of between 3.15 V and

26 V, connected to J2 (VIN) and J4 (GND).

The first evaluation board should be connected to the PC

parallel port using a 5-pin SMBus cable from the 5-pin header

labeled J7. Each board is fitted with two Minimolex connectors,

J1 and J5. To interconnect multiple boards, use the red 5-pin

Minimolex cables provided.

COMMUNICATING WITH INTERCONNECTED ADM1191/ADM1192 EVALUATION BOARDS

Figure 40 displays the result of the device address search when

two ADM1191s, one ADM1192, and one ADM1176 are

cascaded. Note that the I

highlighted in green.

2

C addresses can be created, allowing you to inter-

2

C addresses. You must

2

C address.

2

C addresses of the four devices are

Figure 41. Sense Resistor Value Input Panel for Multiple Devices

Click OK to proceed. The evaluation software Main Panel tab

appears.

06486-041

Figure 40. Device Address Search for Four Interconnected

ADM1191/ADM1192 Devices

After you click OK, the window shown in Figure 41 appears,

prompting you to enter the value of the current sense resistors.

The default value of the sense Resistor, R8, is 0.2 Ω.

06486-042

Figure 42. Main Panel for Multiple Devices

Note the Device selector drop-down box at the top of the tab.

06486-043

Figure 43. Multidevice Selector

06486-040

You can use this box to select each device and select the configuration settings for that device. After you select the range and

reading methods, click Write Data to Command Register in

the Command Register control panel to pass the changes to the

device register.

Rev. 0 | Page 16 of 24

Page 17

EVAL-ADM1191/ADM1192

You can view the voltage, current, and power graphs on the

V, I & P g r a p h s tab.

06486-046

06486-047

Figure 44. Voltage, Current, and Power Plot for Multiple Devices

The digitized values for voltage, current. and power are displayed at the left in each set of controls and graphs. You can

select the traces to view by clicking the box to the left of each

trace name. You can also scale the y-axis of the plots for easy

viewing.

Figure 45 depicts the result of altering the input voltage. Note

the corresponding change on the power graph.

Figure 46. Multidevice Plot with Current Variation

06486-044

If more than four boards are interconnected, there are

additional tabs for the voltage, current, and power graphs. As

shown in

Figure 47, four traces are displayed in each graph, up

to a maximum of 16 traces on four graph tabs when 16 ADM1191

devices are set up in parallel.

Figure 47. Multidevice Panel Selection Tab

06486-045

Figure 45. Plot with Voltage Variation for Multiple Devices

As shown in Figure 45, the supply voltage is constant and the

current associated with traces is varied. The current is changed

by changing the load resistance. Turning VR1 clockwise on each

evaluation board reduces the load resistance, thereby increasing

the current, and turning VR1 counterclockwise increases the

load resistance and, thus, reduces the current.

Rev. 0 | Page 17 of 24

Figure 48. Multidevice Plotting Screen for Device 1 Through Device 4

06486-048

Page 18

EVAL-ADM1191/ADM1192

INTERCONNECTING A COMBINATION OF ADM1191 AND ADM1192 DEVICES

ALERT/ALERTB output is not supported by the evaluation

tool when a combination of ADM1191 and ADM1192 devices

is interconnected. This is because the ADM1191 and ADM1192

have alert outputs with opposing polarity (ALERTB and

ALERT), and these output flags cannot be supported as a single

logic signal via J7 through J5 to the PC.

06486-049

Figure 49. Overcurrent Flag Indicator for Interconnected Devices with ALERT

and ALERTB Output

The Main Panel tab of the configuration tool has a different

appearance in this situation. To the right of Status Register,

there is no Overcurrent Output Flag for either the ADM1191

or the ADM1192 device.

Note that the Overcurrent Output Flag appears when

ADM1178 and ADM1191 devices are interconnected. The

reason is that both devices have the ALERTB type output.

Therefore, when interconnecting a combination of ADM1191

and ADM1192 devices, it is recommended that you use the

LEDs on the evaluation board that correspond to ALERT (D1)

and ALERTB (D5) to give a hardware alert. When an overcurrent condition is detected, the corresponding LED lights up.

To configure the evaluation board to give a hardware alert for

ALERT/ALERTB, position the jumpers as shown in

Tabl e 6.

Table 6. Jumper Positions for ALERT/ALERTB

Device Jumper

ADM1191 JP1 Position A

ADM1192 JP3 Position B

ADM1192 JP4 Position A

Note that, if an overcurrent condition occurs for the ADM1192,

you can press the on-board CLRB button to clear the alert after

the overcurrent condition is eliminated. This does not apply to

the ADM1191.

Rev. 0 | Page 18 of 24

Page 19

EVAL-ADM1191/ADM1192

EVALUATION BOARD SCHEMATIC

06486-050

Figure 50.

Rev. 0 | Page 19 of 24

Page 20

EVAL-ADM1191/ADM1192

ORDERING INFORMATION

BILL OF MATERIALS

Table 7.

Reference

Designator

Qty

1 C1

1 C2

1 C3

2 C4, C5 User-defined capacitor

5

C6, C10, C11, C12,

C17

1 C7

1 C9

1 C13

2 C15, C16 10 pF, 5%, 0603, multilayer ceramic capacitor Epcos B37930K5100J60 FEC 9753478

4 D1, D3, D4, D5 LED-0805, red SMD LED Avago HLMP-6000-E0011 FEC 1003354

1 D2 3.3 V, 5%, SOT23, Zener diode Philips BZX84-C3V3 T/R FEC 1081419

1 D6 10 V, DIODE-SMB, Zener diode Philips BZV55-C10 FEC 1081361

2 J1, J5

2 J2, J3 Red 4 mm banana Deltron 571-0500-01 FEC 1101127

1 J7 MOLEX, 5-way right angle header Molex 22-12-2054 FEC 3116890

2 J8, J10

2 J9, J4 Black 4 mm banana socket Deltron 571-0100-01 FEC 1101128

7

JP1, JP2, JP3, JP4,

JP5, JP6, JP7

1 P10 TO220 heat sink AAVID Thermalloy TV40 FEC 170074

1 Q1

4 Q2, Q3, Q4, Q7

1 Q5

2 Q6, Q8

1 R1 22 kΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 22K FEC 9332820

9

R2, R6A, R7, R9, R22,

R25, R27, R28, R29

2 R3, R4 2.2 kΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 2K2 FEC 9332812

1 R5 1 MΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 1M FEC 9332413

1 R5A 3.3 kΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 3K3 FEC 9333045

1 R8 0.2 Ω, 1%, 2512, current sense SMD resistor Welwyn LR2512-R20FW FEC 1100068

2 R10, R11 1.8 kΩ, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 1K8 FEC 9332715

2 R12, R13 150 kΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 150K FEC 9332626

Description Manufacturer

4.7 nF, 10%, 0805,

capacitor

47 nF, 10%, 0805,

capacitor

470 nF, 10%, 0805,

capacitor

0.1μF, 10%, 0805,

capacitor

10 μF, 10%, CAP\TAJ_D, 35 V Tantalum

capacitor

100 μF, 10%, CAP\TAJ_C, 10 V Tantalum

capacitor

10 μF, 10%, CAP\TAJ_A, 10 V Tantalum

capacitor

MOLEX53398-0671, 6-way SMD straight mini

header

PCB_SELECTOR_PLUGS_DIP4, 4-pin (2 x 2)

shorting and socket

LINK-3P, 3-pin (0.1" pitch) header and jumper

socket

IRFR_U3910_TRIPLE_FOOTPRINT, MOSFET, P,

D2-PAK

BC849BLT1G, SOT23, NPN small signal

transistor

TO-220_EXPOSED_PAD_HEATSINK, MOSFET,

N logic

SOT23, N-channel, enhancement mode,

TMOSFET

1 kΩ, %, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 1K FEC 9332383

multilayer ceramic

multilayer ceramic

multilayer ceramic

multilayer ceramic

Phycomp 2238 580 15632 FEC 3019913

Phycomp 2238 580 15645 FEC 718683

Multicomp B0805R474KCT FEC 9406336

Multicomp U0805R104KCT FEC 9406387

Kemet T495D106K035ATE300 FEC 9229248

AVX TAJC107K010R FEC 197180

AVX TPSA106K010R1800 FEC 1135105

Molex 533980671–Molex FEC 1125368

Harwin

Harwin

Vishay SUB65P06-20 FEC 9551395

On Semiconductor BC849BLT1G FEC 9558616

Fairchild FDP7030BL FEC 9845151

Fairchild NDS7002A FEC 9845437

Manufacturer

Number

D3086-98 & H316101/ D3086-98

M20-9990346/

M7566-05

Supplier

Number

FEC 149318/

149306

FEC 1022249/

150411

1

Rev. 0 | Page 20 of 24

Page 21

EVAL-ADM1191/ADM1192

Reference

Qty

Designator Description Manufacturer

1 R14A 2.4 kΩ, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 2K4 FEC 9332880

2 R15, R17 100 kΩ, 1%, 0805, SMD resistor Multicomp

1 R16 510 Ω 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 510R FEC 9333312

1 R18 100 Ω 1%, 0805, SMD resistor Multicomp

1 R19 3 kΩ,1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 3K FEC 9332995

1 R20 10 Ω, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 10R FEC 4762113

1 R21 1 Ω, 5, 0805, SMD resistor Phycomp 232276260108 FEC 9235833

1 R23 13.3 kΩ, 5, SMD resistor Yageo RC0805FR-0713K3L

1 R24 47 kΩ, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 47K FEC 9333274

1 R26A 3.3 Ω, 1%, 0805, SMD resistor Multicomp MC 0.1W 0805 1% 3K3 FEC 9333096

1 RL1 RELAY-IM02GR, SMD DPCO 4.5VDC, relay Tyco IM02GR FEC 4148344

1 S1

SW\2_DIP_SMD, DIP4_SMD, 2-way SMD

Omron A6S-2102 FEC 9901850

switch

3 S2, S3, S4 SW\4DIP, DIP8_SMD, 4-way SMD switch Omron A6S-4101 FEC 9901868

2 S5, S6

SW-PUSH-SMD, SW_PB_SMD_6MM, SMD

Omron B3S-1000 FEC 177807

push button switch (sealed)

13

DRAIN, GATE,

Red testpoint Vero 20-313137 FEC 8731144

SOURCE, TP1, TP2,

TP3, TP4, TP5, TP6,

TP7, TP8, TP11,

TP12

2 TP13, TP14 Black testpoint Vero 20-2137 FEC 8731128

1 U1 MSO10 Analog Devices ADM1191ARMZ/

1 U2 TO-92C, 3.3 V regulator STMicroelectronics LE33CZ FEC 9755349

1 U3 MSO10-SKT, 10-pin MSOP socket Wells 656-0102211

1 VR1 VRES_ROTARY, trimmer pot Vishay Spectrol 63M-T607-202 FEC 9608214

4

R5B, R6B, R14B,

User-defined resistor

R26B

4 Stick-on feet 3M FEC 148-922

1

FEC indicates the Farnell Electronic Components company.

ORDERING GUIDE

Model Description

EVAL-ADM1191EBZ

EVAL-ADM1192EBZ

CABLE-SMBUS-5PINZ

USB-5PSMBUS-CABLEZ

1

Z = RoHS Compliant Part.

1

1

1

ADM1191 Evaluation Board

ADM1192 Evaluation Board

5-Pin SMBus Cable (Parallel Port)

1

5-Pin SMBus Cable (USB Port)

ESD CAUTION

Manufacturer

Number

MC 0.1W 0805 1%

100K

MC 0.1W 0805 1%

100R

ADM1192ARMZ

Supplier

Number

1

FEC 9332405

FEC 9332375

Digikey 311-

13.3KCRCT-ND

Abrel Products

656-0102211

Rev. 0 | Page 21 of 24

Page 22

EVAL-ADM1191/ADM1192

NOTES

Rev. 0 | Page 22 of 24

Page 23

EVAL-ADM1191/ADM1192

NOTES

Rev. 0 | Page 23 of 24

Page 24

EVAL-ADM1191/ADM1192

NOTES

Purchase of licensed I2C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips Rights to

use these components in an I2C system, provided that the system conforms to the I2C Standard Specification as defined by Philips.

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

EB06486–0–5/08(0)

Rev. 0 | Page 24 of 24

Loading...

Loading...