查询EVAL-ADM1030供应商查询EVAL-ADM1030供应商

Evaluation Board for ACPI Temperature

a

Preliminary T echnical Data

FEATURES

Optimized for Pentium III

Guardbanding

Programmable (ACPI) and Automatic Fan Speed Control

Automatic Fan Speed Control allows control Independant

of CPU Intervention after initial setup.

Control Loop minimizes Acoustic Noise and Battery

Consumption

RPM Feedback mode to maintain constant fan speed

Remote Temperature measurement accurate to 1°C using

Remote Diode (2 channels for ADM1031, 1 for ADM1030)

0.125°C Resolution on External Temperature Channels

Local Temperature Sensor with 0.25°C resolution

Pulse Width Modulation Fan Control (PWM) (two fans for

ADM1031, one fan for ADM1030)

Programmable PWM Frequency

Programmable PWM Duty Cycle

Tach Fan Speed Measurement (One Channel for

ADM1030, Two for ADM1031 )

Analog Inputs to measure Fan Speed of 2-wire fans (using

Sense Resistor)

2-Wire Serial System Management Bus(SMBus) with ARA

Over-Temperature

Programmable

Configurable Offsets for Temperature Channels

3V to 5.5V Supply Range

Shutdown Mode to Minimize Power Consumption

Limit Comparisons of all Monitored Values

APPLICATIONS

Notebook PC’s, Network Computers and Personal

Computers

Microprocessor Based Office Equipment.

INTRODUCTION

The ADM1030/31 evaluation board allows the

ADM1030/31 PC Temperature Monitor and PWM Fan

Controller to be quickly and easily evaluated using a

personal computer. Using the evaluation board and the

accompanying software the ADM1030/31 can be

interfaced to any personal computer running Windows

95 or Windows 98 via the computer’s parallel port.

The evaluation board allows the input and output

functions of the ADM1030/31 to be exercised without the

need for external components. The software allows control

and monitoring of the ADM1030/31’s internal registers.

INTINT

INT Output Pin

INTINT

:- Allows Reduced

THERMTHERM

THERM Output Pin

THERMTHERM

PRELIMINARY

TECHNICAL

DATA

Monitor and PWM Fan Controller

EV AL-ADM1030/31

THE ADM1030/31

The following is a brief description of the ADM1030/31

and a system overview. Further information can be found

on the ADM1030 and ADM1031 datasheet.

The ADM1030 and ADM1031 function in a very similar

manner. The main difference is that the ADM1031 is dual

channel and the ADM1030 is single channel i.e. the

ADM1031 has a second remote temperature measurement

channel, a second fan speed measurement channel and a

second PWM fan speed control channel.

The ADM1030/31 is an ACPI compliant two/three

channel digital thermometer and under/over temperature

alarm, for use in personal computers. A PWM Fan

Control Output controls the speed of cooling fans. The

speed of these fans may be monitored using the Tach

Inputs. A dedicated Fan Speed Control Loop provides

control even without CPU Intervention.

The device has a programmable INT output to indicate

error conditions. The THERM pin is a failsafe output for

over temperatire conditions.

EVALUATION SYSTEM PACKAGE CONTENTS

The evaluation system contains the following items

1. The ADM1030/31 Evaluation Board

2. Centronics Cable

3. CD containing this application note, datasheet and the

ADM1030/31 evaluation software.

EVALUATION BOARD HARDWARE

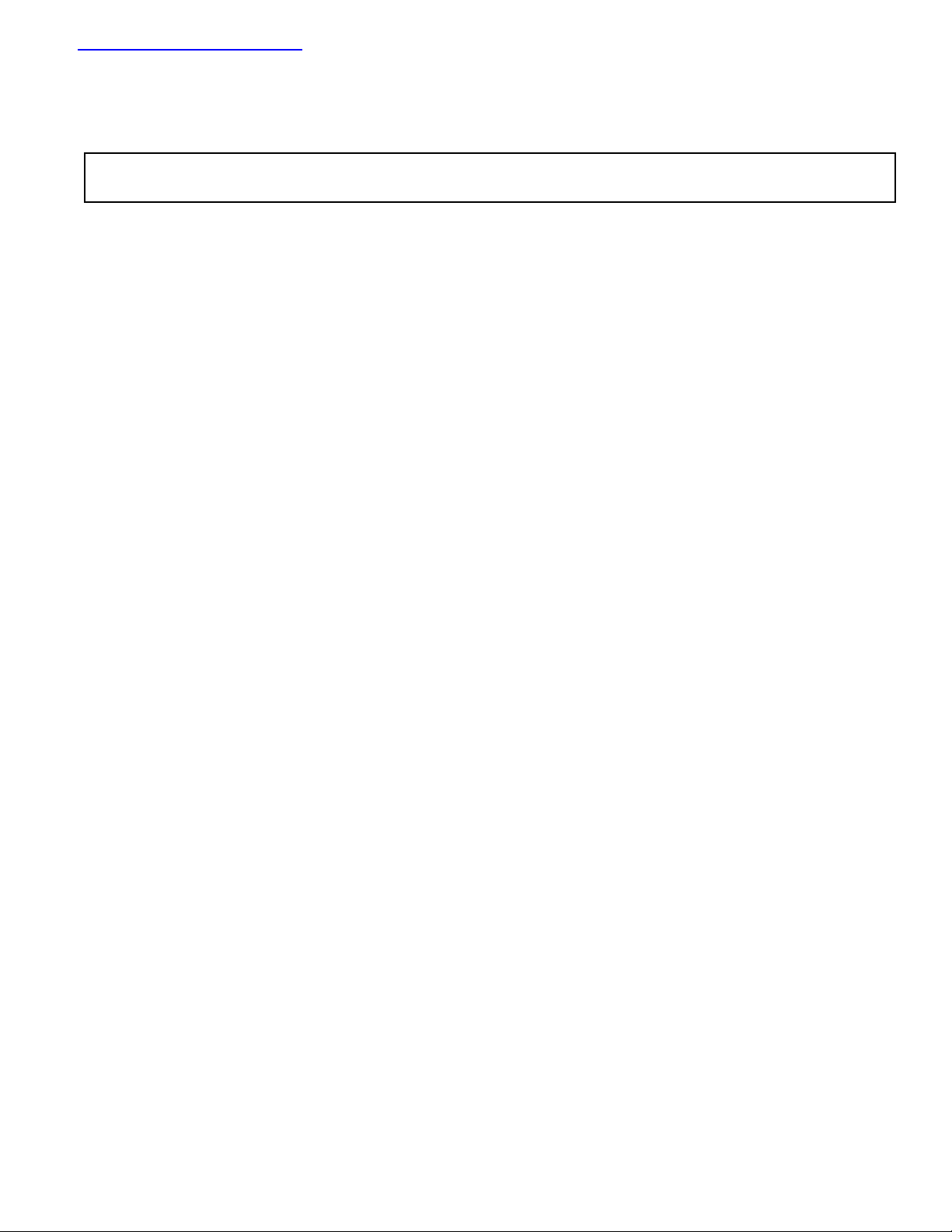

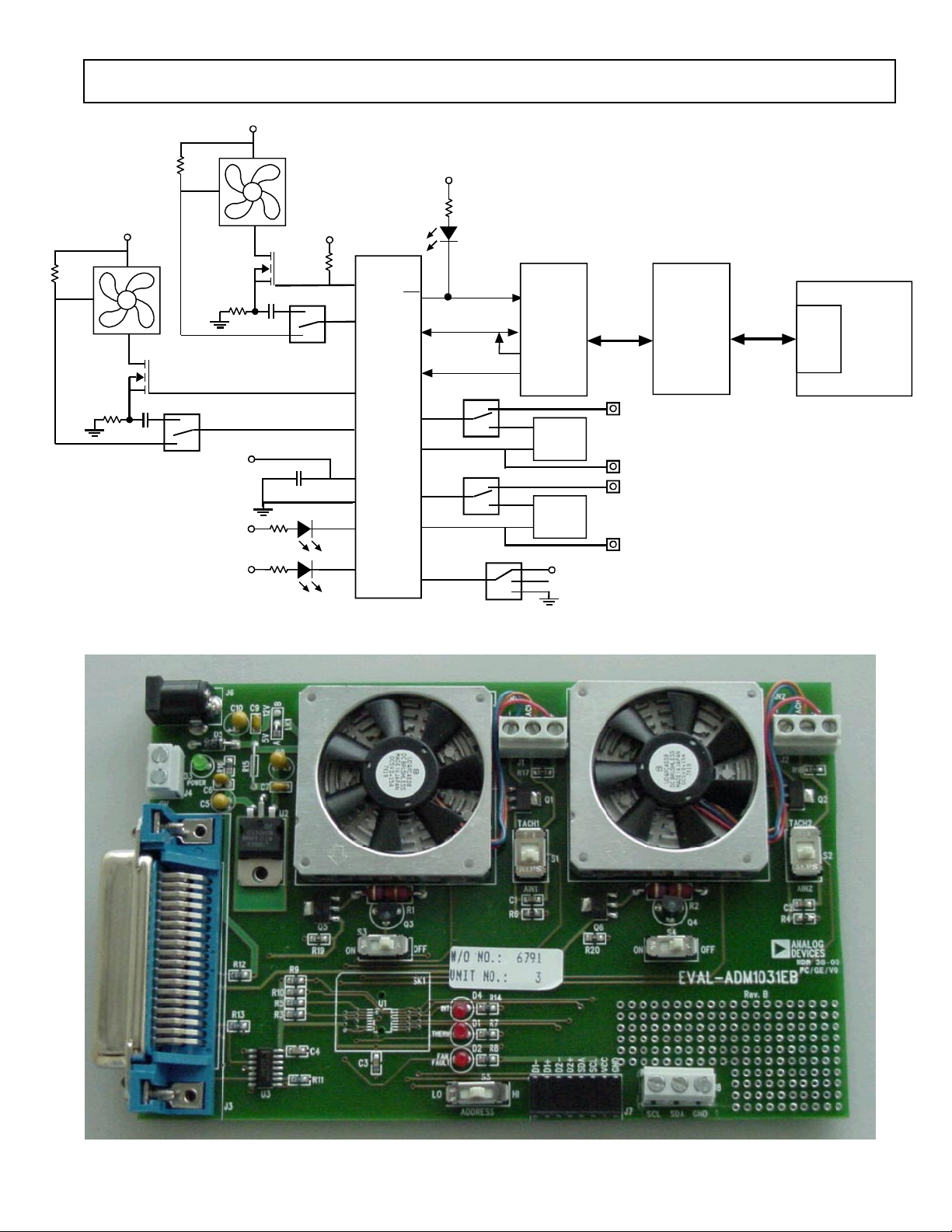

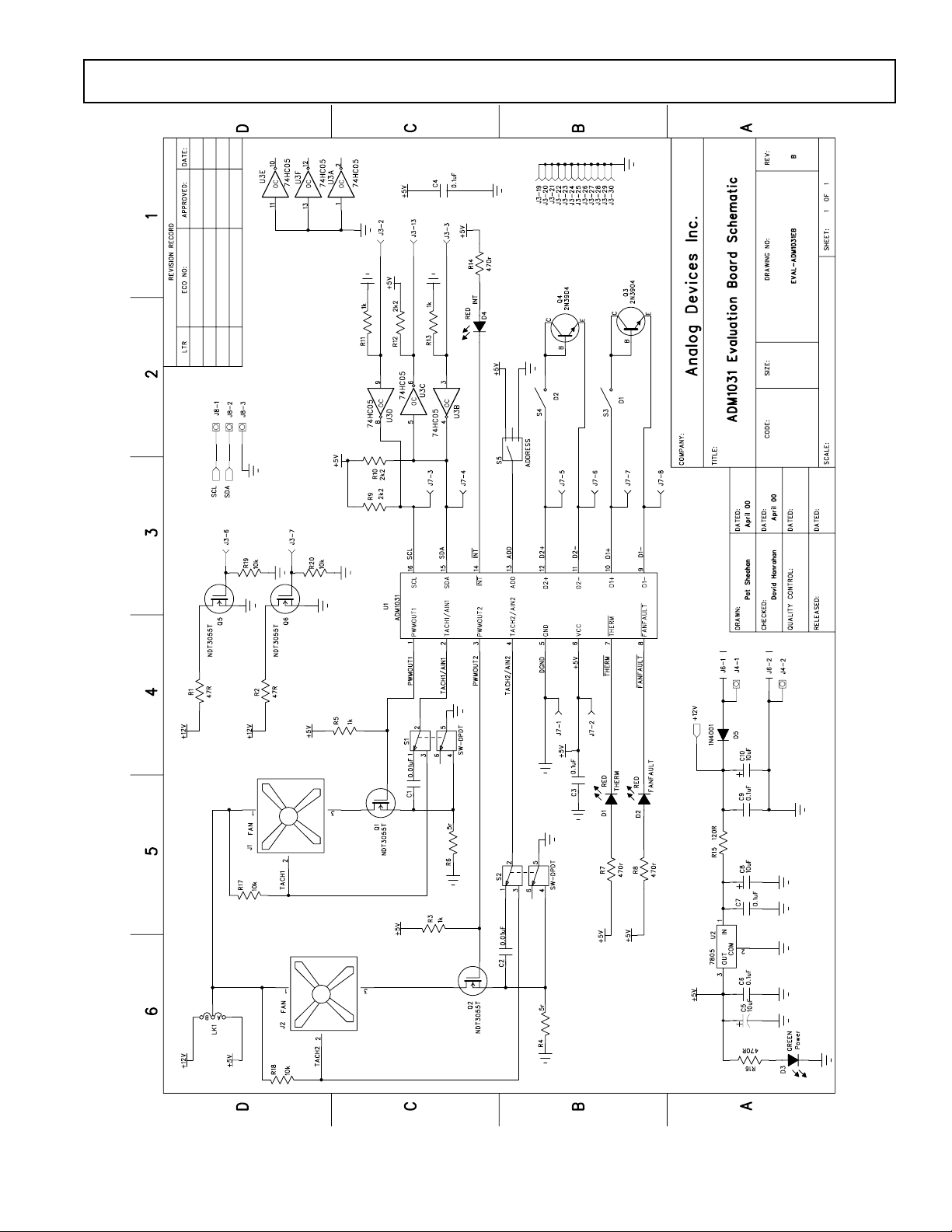

The ADM1030/31 evaluation board contains the

following main components which can be identified from

the block diagram, printed circuit board silk screen and

schematic diagram of Figures1, 2 and 3 overleaf.

1. ADM1030 or ADM1031 IC

2. 1 or 2 NPN sensor transistors (depending on whether

ADM1030 or ADM1031 IC is used)

3. LED indicators

4. Interface Buffers

5. Connector for parallel interface.

6. Test Connector for connecting to remote thermal

sensor (J7)

7. Fan (1 or 2 depending on IC).

REV. PrA 10/200 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One T ec hnology Wa y, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 Wor ld Wide Web Site: http://www .analog.com

Fax: 781/326-8703 Analog Devices, Inc., 2000

EVAL-ADM1030/31

V

DD

TACH

Preliminary T echnical Data

V

DD

Q2

NDT3055L

D

D

V

D

D

V

D

D

V

V

DD

PWMOUT

S2

D1

RED

THERM

D2

RED

FAN_FAULT

Figure1. ADM1030 Evaluation Board Block Diagram

PRELIMINARY

SDATA

TACH / AIN

ADM10 30

SCLK

V

CC

GND

THERM

ADD

FAN_FAULT

INT

D1+

D1-

D4

RED

INT

BUFFERS

S3

NPN

SENSOR

S5

V

DD

TECHNICAL

DATA

36-WAY

CENTRONICS

CONNECTOR

(J2)*

J5-10

TEST CONNECTOR FOR

CONNECTING O FF BO ARD

REMOTE SENSOR

J5-9

EL

LL

RA

PA

T

R

PO

PC

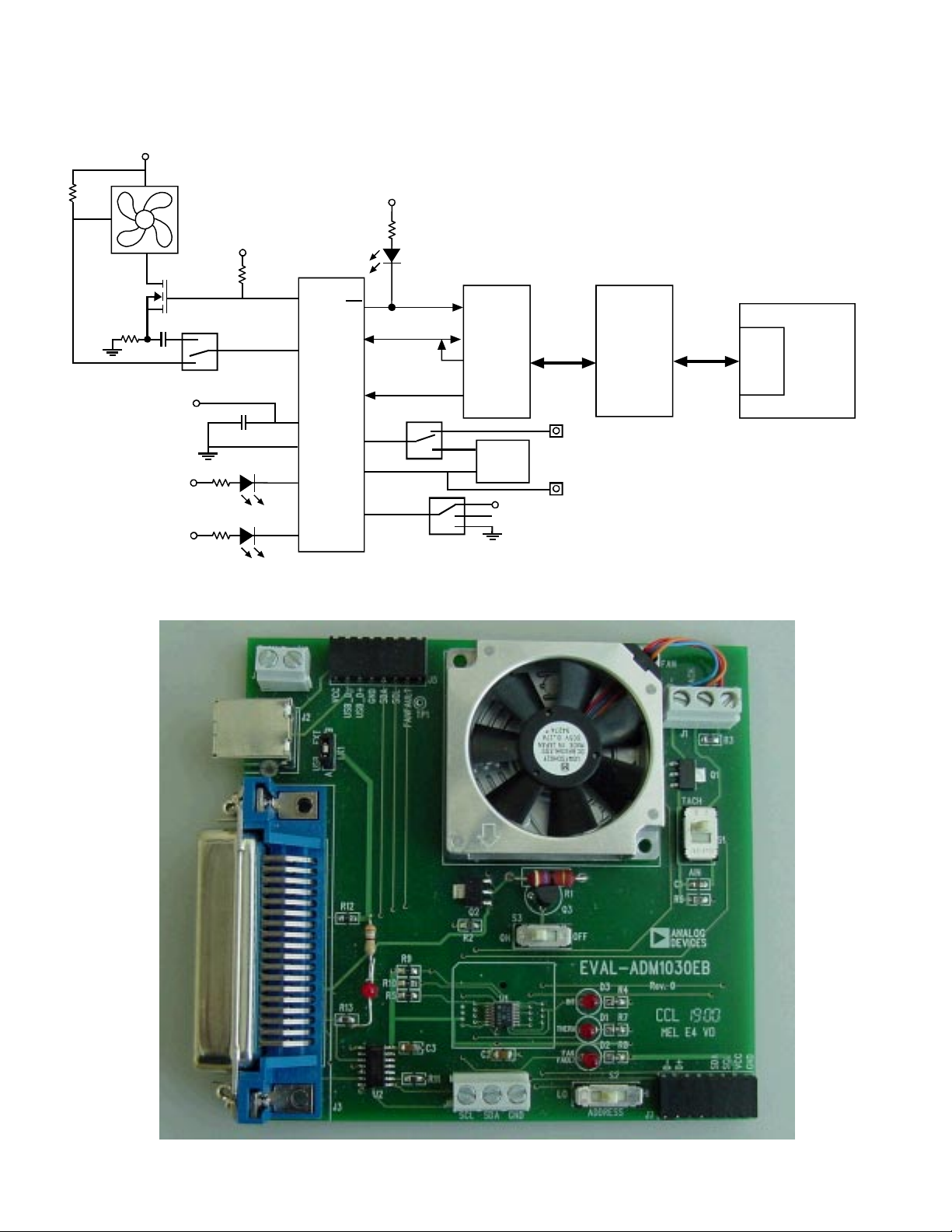

Figure2. ADM1030 Evaluation Board Picture

–2– REV. PrA

Preliminary T echnical Data

V

DD

TACH

EVAL-ADM1030/31

V

DD

TACH

NDT3055L

Q3

V

DD

Q2

NDT3055L

V

DD

S2

TACH2 / AIN

PWM2OUT

SDATA

INT

ADM10 31

SCLK

PWM1OUT

S1

D

D

V

D

D

V

D

D

V

D1

RED

THERM

D2

RED

FAN_FAULT

PRELIMINARY

TACH1 / AIN

V

CC

GND

THERM

FAN_FAULT

ADD

D1+

D1-

D2+

D2-

D4

RED

INT

36-WAY

BUFF E R S

S3

NPN

SENSOR

S4

NPN

SENSOR

S5

TEST CONNECTOR FOR

BOARD REMOTE SENSOR

TEST CONNECTOR FOR

BOARD REMOTE SENSOR

V

DD

CENTRONICS

CONNECTOR

(J2)*

J7-12

CONNECTING O FF

J7-11

J7-10

CONNECTING O FF

J7-9

EL

LL

RA

PA

T

R

PO

PC

Figure1. ADM1031 Evaluation Board Block Diagram

TECHNICAL

DATA

Figure2. ADM1031 Evaluation Board Picture

–3–REV. PrA

EVAL-ADM1030/31

Preliminary T echnical Data

PRELIMINARY

TECHNICAL

DATA

Figure3. ADM1030/31 Evaluation Board Schematic

–4– REV. PrA

Preliminary T echnical Data

EVAL-ADM1030/31

PRELIMINARY

TECHNICAL

DATA

Figure3. ADM1030/31 Evaluation Board Schematic

–5–REV. PrA

EVAL-ADM1030/31

Preliminary T echnical Data

CONNECTORS AND SWITCHES AND INDICATORS

The function of the various connectors, switches and

indicators on the evaluation board are explained below.

CENTRONICS CONNECTOR (J3)

The evaluation board may be connected to the personal

computer via the parallel printer port using the centronics

cable provided.

POWER CONNECTORS (J4 & J6)

Power is supplied to the board via J6 using a 15V Power

Supply mains adaptor. This adaptor is not included in the

evaluation kit. Alternatively power may be supplied to the

board via J4 thus allowing a desktop power supply to be

used.

TEST CONNECTOR (J7)

J7 is provided as a test connector on the ADM1030/31

evaluation board. The remote thermal diode pins, SMBus

and Power pins are all connected to here. This allows the

user easy access to ADM1030/31 signals.

An off board thermal sensor may be connected as the

external sensor via the remote thermal diode pins of the

test connector.

ADDRESS SELECT SWITCH (S5)

The ADM1030/31 has an SMBus Address pin (ADD).

This is a tri-state logic input which sets the lower 2 bits of

the SMBus address.

TABLE1. ADD PIN TRUTH TABLE

ADD Pin A1 A0 SW5

Gnd 0 0 Lo

No Connect 1 0 Center

Vcc 0 1 Hi

THERM LED (D1)

This LED illuminates whenever a measured temperature

exceeds a pre-programmed THERM Limit.

FAN_FAULT LED (D2)

This LED will illuminate whenever a fan fault is detected.

If there is a second fan connected then this should spin up

to full speed.

POWER LED (D3)

This LED illuminates whenever power is supplied to the

board.

PRELIMINARY

FAN CONNECTORS (J1 AND J2)

The fans which are to be controlled by the ADM1030/31

are connected to the board using these connectors.

SMBUS CONNECTOR (J8)

This connector allows the user easy access to the SMBus

signals and may be used if the user wishes to communicate

with the ADM1030/31 in a different way other than using

the Centronics connector.

TACH\AIN SWITCH (S1 AND S2)

This essentially allows the user to switch between a fan

with a Tach Signal and one without. In this case switching

off the Tach signal will automatically switch in the Rsense

circuit which is used to determine the fan speed without

the Tach signal. Details of this method of fan speed

measurement are provided on the datasheet.

REMOTE DIODE SWITCH (S3 AND S4)

This switch allows the user to choose between the onboard remote temperature sensors (Q3 and Q4) and ones

that can be connected to the test connector J7. When the

switch is in the on position the on-board sensors are

selected. When it is in the off position the off-board sensor

is selected.

TECHNICAL

INT LED (D4)

This LED illuminates whenever the ADM1030/31 issues

an interrupt signal (eg. when an out of limit measurement

is made). For more information on the various conditions

DATA

which cause INT to be pulled low please see the datasheet.

–6– REV. PrA

Preliminary T echnical Data

THE SOFTWARE

The software allows the ADM1030/31’s functions to be

controlled from the PC via an easy to use interface

operating under the Windows environment. The

contents of the device’s internal registers can easily be

read or altered through a user-friendly graphics interface,

while the control center window allows the graphing of the

temperature readings.

INSTALLING THE SOFTWARE

To install the software insert the Analog Devices

ADM1030/31 CD-ROM into the CD-ROM Drive. The

CD-ROM should autorun and start installing the software.

If this does not occur then the user should click on the

Start Icon and then on Run Icon and type X:setup.exe as

the file name, where X is the drive letter of the CD-ROM

drive. To finish installing the software follow the

on-screen instructions.

USING THE SOFTWARE

When using the software, first ensure that the evaluation

board is connected to the Parallel Printer Port and that the

power supply is plugged into the board.

To start the Software, select Start-Programs-Analog

Devices- ADM1030/31 Evaluation Software.

When the program is selected the Software Initialisation

Wizard will appear first.

PRELIMINARY

EVAL-ADM1030/31

Once the Communications medium has been selected,

click on “Next” to go to the next screen. When you are

ready for the evaluation software to begin searching for the

device on the chosen medium, click on “Next”.

TECHNICAL

DATA

Click on “Next” to go to the next screen, which will

allow the user to choose between connecting the

evaluation board via the printer port, via the SMBus or via

USB. However the USB option is not available on this

revision of the evaluation board and so should not be

selected.

The software will search for the ADM1030 or ADM1031

and if it finds it the following screen will appear.

Click on “Yes” if this is the ADM1030 or ADM1031 you

wish to use. The next screen should then appear.

–7–REV. PrA

EVAL-ADM1030/31

Preliminary T echnical Data

If the ADM1030 or ADM1031 was not found on the

chosen medium the following screen will appear.

PRELIMINARY

TECHNICAL

In this case check the connections to the board and the

power supply. Then click on “Back” and try again. If this

does not work then try re-booting the PC and re-running

the software.

USING THE SOFTWARE

The index type display which appears on the screen when

the software starts to run has four tabs.

MAIN TAB

The main tab shows the software version and allows the

user to quit the program by clicking on

DATA

Figure4. ADM1030/31 Evaluation Software Main Tab

–8– REV. PrA

Preliminary T echnical Data

EVAL-ADM1030/31

READ/WRITE

This tab displays information about the ADM1030/31’s

internal registers and allows their contents to be read and/

or altered. Each register has a button associated with it.

Clicking on a button will display the contents of the

selected register in the register contents box and the name

of each register bit.

Clicking on a register button causes its contents to be read

once if continuous reading is off. If continuous reading is

on, the register will be updated continuously. Click on the

button to toggle between

and

The type of register selected and its hexadecimal address

is displayed on the right hand side of the screen.

Data may be written to all registers that are Read/Write,

(refer to data sheet for more information). When the Read/

Write tab is first selected, none of the registers have been

written to, and they contain their default values.

Registers may be written to in two ways. Clicking on a bit in

the Read/Write display will toggle its value between 0 and 1.

This is useful where a function is controlled by setting or

clearing individual bits in a register, for example setting or

clearing the Int_Enable bit in the configuration register.

The entire contents of a register may be changed by typing a

Hex or decimal value in the text boxes of the Write display.

The button will change from green to red and the new value

can be written to the register by clicking on the red button.

This is useful where a register contains a numeric value such

as a temperature limit.

PRELIMINARY

TECHNICAL

DATA

Figure5 . ADM1030/31 Read/Write Program Tab

–9–REV. PrA

EVAL-ADM1030/31

Preliminary T echnical Data

VISUAL DISPLAY

The visual display tab allows readings to be displayed

graphically on bargraphs or line graphs.

When the visual display is selected for the first time the

value displayed on the bargraph is the value of local

temperature. To display one of the other values e.g. remote

temperature or fan speed click on the relevant bar graph

button.

EASY SETUP

The line and bargraphs can also be started by clicking on

the

both local and remote temperature. When you click “Easy

Setup” the software prompts the user to ensure that S1 and

S2 are switched to AIN. This is because Esay Setup sets up

the ADM1030/31 for a 2-wire fan. Easy Setup also places

the ADM1030/31 under simple software control.

button. This also sets limits for

FAN SPEED CONTROL

The user may also control fan speed using the PWM duty

cycle select method in the visual display window. This may

be done by adjusting the position of the fan speed control

slider to the required PWM. The duty cycle is displayed as

a percentage at the bottom of the slider. The value written

to the Fan Speed Config Register is displayed on the slider

button.

PRELIMINARY

TECHNICAL

DATA

Figure6. ADM1030/31 Visual Display Program Tab

–10– REV. PrA

Preliminary T echnical Data

EVAL-ADM1030/31

ADM1030/31 MODES OF OPERATION

The ADM1030/31 has four modes of operation. They are

as follows

1. Automatic Fan Speed Control Mode

2. Filtered Automatic Fan Speed Control Mode

3. PWM Duty Cycle Select Mode

4. RPM Feedback Mode

The ADM1030/31 software allows the user to choose which

mode of operation they require. It will then prompt the user

to provide the information required by that particular mode

of operation.

AUTOMATIC FAN SPEED CONTROL MODE.

Click on “Automatic Fan Speed Control” in the “Mode

Select” window in the Control Tab. This causes the

“Automatic Fan Speed Control” window to be displayed.

1. First choose which Control Operation is required, i.e.

which temperature channel controls the fan.

2. Choose the necessary Tmin’s and Trange’s for the

chosen Control Operation.

3. Choose the spin up times for Fan1 and if you are using

the ADM1031 for Fan2 also.

4. Click on “Enable Control”

5. Automatic Fan Speed Control is enabled using the user

defined parameters.

PRELIMINARY

FILTERED AUTOMATIC FAN SPEED CONTROL

MODE.

This mode is almost identical to the Automatic Fan

Speed Control Mode. The main difference is the rate at

which fan speed is ramped up after a temperature

increase. Filtering is implemented by two different

means, selecting the sampling rate of the ADC and

ramping the fan speed to the desired speed (In Automatic Fan Speed Control Mode the fan speed is jumped

immediately to the newly calculated speed). To implement Filtered Automatic Fan Speed Control click on

“Filtered Automatic Control” in the “Mode Select”

window of the Control Tab. This causes the “Filter

Mode” window to be displayed.

1. Choose an “Increment Rate” and an “ADC Sample

Rate”. See the datasheet for more information on these

parameters.

2. The user may also choose to enable or disable “Fan

Spin Up”

3. Finally the user is prompted to choose Automatic

Fan Speed Control Parameters. This should be completed if these Parameters have not already been chosen.

4. Click on “Enable Fan Filter” to implement Filtered

Automatic Fan Speed Control. (Enable Fan1 for the

ADM1030 and Fan1 and Fan2 for the ADM1031)

TECHNICAL

DATA

–11–REV. PrA

EVAL-ADM1030/31

RPM CONTROL MODE

In this method of control the user programs the required RPM

values to the ADM1030/31. Click on the “RPM Feedback

Mode” in the “Mode Select” window of the Control Tab.

1. Enter the required RPM Value in the window.

2. Choose which fan you wish to run at that RPM value.

3. Enter the fan divisor value for that fan.

4. Click on Calculate. The software will calculate Count. This

is the value that has to be written to the ADM1030/31 Tach

High Limit Register to maintain the required speed. See the

datasheet for an explanation of the formulas.

5. Click on “Enable RPM Mode” to place the ADM1030/31 in

RPM Feedback mode.

6. Sometimes after you place a value in the “Enter RPM Mode”

window and click “Calculate” the “Enable RPM Mode” button

does not become active. This is because the Count value is

outside the particular fan’s RPM range. The fan’s RPM range is

determined by the “Fan Divisor Value”.

PWM DUTY CYCLE

In this method the ADM1030/31 is placed under software

control. Fan speed is controlled by programming PWM values

in to the ADM1030/31. Click on “PWM Duty Cycle Select”

in the “Mode Select” window of the Control Tab.

Preliminary T echnical Data

1. Each fan can be programmed with a duty cycle value of

between 0% and 100%.

2. Choose the required PWM value for each fan, the value

chosen must be on the list in the drop down window as the

ADM1030/31 can only be programmed in 6% increments.

3. Click on “Enable PWM Mode”

4. The fan/s should then either spin up or down to the

programmed value.

TEMPERATURE CONTROL

Temperature control allows the user to heat up the remote

thermal diodes on the ADM1030/31 Evaluation Board. First

choose which diode is to be monitored. Then Click on “Enable

Control”. This causes a current to be switched through the two

large heating resistors behind the remote thermal diodes which

in turn causes the remote thermal diodes to heat up. These

resistors can become very hot so care is required. Do not touch

when there is a current flowing through them. Use the slider to

vary the PWM duty cycle applied to the heating resistors.

Adjusting the slider allows limited control of the temperature of

the heating resistors.

PRELIMINARY

TECHNICAL

DATA

–12– REV. PrA

Preliminary T echnical Data

SAVING TO FILE

This window allows the user to save all the ADM1030/31

data to an Microsoft Excel File. The following data is

saved

1.Local Temperature

2.Remote Temperature, channel 1

3.Fan Speed, channel 1, in RPM

4.Channel 1, PWM Duty Cycle

5.Remote Temperature, channel 2

6.Fan Speed, channel 2, in RPM

7.Channel 2, PWM Duty Cycle

To begin saving this data to an Excel file first click on

“Make New Log”. A Windows “Open File” window

should open. Choose a name for the log and then click

“Open”. The software will then begin saving the above

values to the Excel file. The user can also control how often

these values are stored to the Excel file by changing the

value written in the “Delay(Sec)” window. This value

represents the time in seconds between successive saves. To

stop saving to the Excel file the user should click on the

“Logging to file” button.

SAVE/RECALL

This window allows the user to save all the current values in

the device to a .txt file. Click on “Save Register Values”.

This causes the Register Contents Window to be displayed.

Click on “Set File Path” command. The Windows “Open”

Window is then displayed. Choose a filename and Click

“Open”. Then Click on “Save” in the “Register Contents

Window”. This allows a register dump for easy writing of

BIOS Software.

This window also allows the user to program all the

registers with a previously saved set of values. This is

achieved using the “Recall Previous Setup” Command.

Click on “Recall Previous Setup” and choose the .txt

filename of a previous set of register values. Then Click on

“Open”. These previous values are written to the registers.

PRELIMINARY

TECHNICAL

DATA

EVAL-ADM1030/31

–13–REV. PrA

EVAL-ADM1030/31

APPENDIX A. COMPONENT LIST

Capacitors

C1-2, 0.01µF

C3-4, C6, C7, C9 0.1µF

C5, C8, C10 10 µF

Diodes

D1, D2, D4 Red LED

D3 Green LED

D5 IN4001 Diode

Connectors

J1, J2, J8 3-pin Terminal Block

J3 Centronics Connector

J4 2-pin Ter minal Block

J6 DC Barrell Connector

J7 CON\16 Header

Resistors

R1, R2 47 Ω

R3, R5, R11, R13 1 kΩ

R4, R6 5 Ω

R7, R8, R14, R16 47 0Ω

R9, R10, R12 2.2kΩ

R15 Wire Link

R17, R18, R19, R20 10 kΩ

Preliminary T echnical Data

Switches

S1, S2 DPDT Slide Switch

S3, S4 SPDT Slide Switch

S5 SP3T Slide Switch

Semiconductors

Q1, Q2,Q5,Q6 NDT3055L

Q3, Q4 2N3904

U1 ADM1030/31ARQ

U2 74HC05

U3 CD74AC05M

Fans

LK1-A Wire Link

Fan1, Fan2 Panasonic

PRELIMINARY

TECHNICAL

UDQFSDH12F

DATA

–14– REV. PrA

Loading...

Loading...