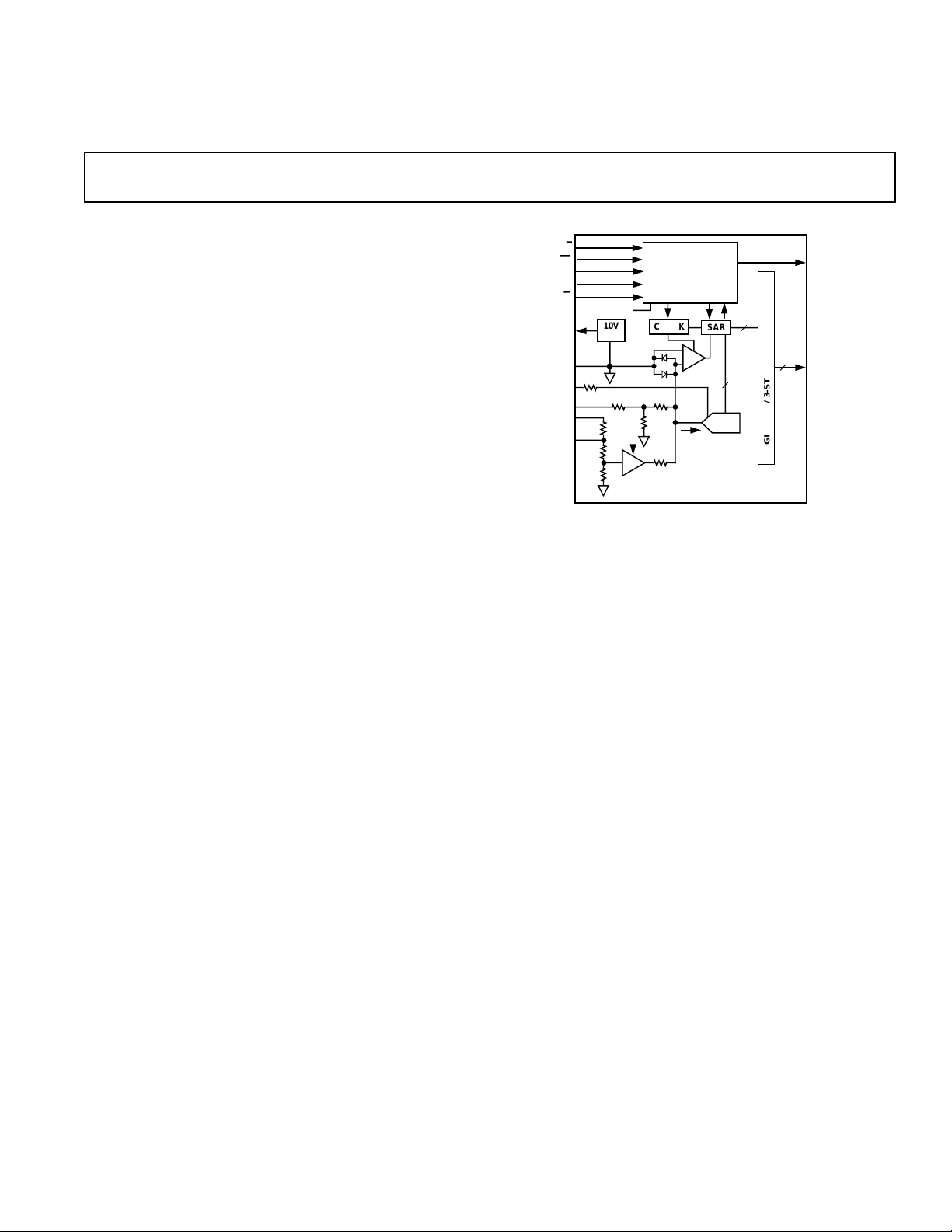

REF OUT

SHA

COMP

20k

10k

5k

2.5k

2.5k

5k

12

12

AD1674

AGND

BIP OFF

REF IN

20V

IN

10V

IN

IDAC

12

CONTROL

CE

12/8

CS

R/C

A

0

5k

10k

SAR

CLOCK

A

10V

REF

REGISTERS / 3-STATE OUTPUT BUFFERS

DAC

STS

DB11 (MSB)

DB0 (LSB)

12-Bit 100 kSPS

a

FEATURES

Complete Monolithic 12-Bit 10 ms Sampling ADC

On-Board Sample-and-Hold Amplifier

Industry Standard Pinout

8- and 16-Bit Microprocessor Interface

AC and DC Specified and Tested

Unipolar and Bipolar Inputs

65 V, 610 V, 0 V–10 V, 0 V–20 V Input Ranges

Commercial, Industrial and Military Temperature

Range Grades

MIL-STD-883 and SMD Compliant Versions Available

PRODUCT DESCRIPTION

The AD1674 is a complete, multipurpose, 12-bit analog-todigital converter, consisting of a user-transparent onboard

sample-and-hold amplifier (SHA), 10 volt reference, clock and

three-state output buffers for microprocessor interface.

The AD1674 is pin compatible with the industry standard

AD574A and AD674A, but includes a sampling function while

delivering a faster conversion rate. The on-chip SHA has a wide

input bandwidth supporting 12-bit accuracy over the full

Nyquist bandwidth of the converter.

The AD1674 is fully specified for ac parameters (such as S/(N+D)

ratio, THD, and IMD) and dc parameters (offset, full-scale

error, etc.). With both ac and dc specifications, the AD1674 is

ideal for use in signal processing and traditional dc measurement applications.

The AD1674 design is implemented using Analog Devices’

BiMOS II process allowing high performance bipolar analog circuitry to be combined on the same die with digital CMOS logic.

Five different temperature grades are available. The AD1674J

and K grades are specified for operation over the 0°C to +70°C

temperature range. The A and B grades are specified from

–40°C to +85°C; the AD1674T grade is specified from –55°C

to +125°C. The J and K grades are available in both 28-lead

plastic DIP and SOIC. The A and B grade devices are available

in 28-lead hermetically sealed ceramic DIP and 28-lead SOIC.

The T grade is available in 28-lead hermetically sealed ceramic

DIP.

*Protected by U. S. Patent Nos. 4,962,325; 4,250,445; 4,808,908; RE30586.

A/D Converter

AD1674*

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Industry Standard Pinout: The AD1674 utilizes the pinout

established by the industry standard AD574A and AD674A.

2. Integrated SHA: The AD1674 has an integrated SHA which

supports the full Nyquist bandwidth of the converter. The

SHA function is transparent to the user; no wait-states are

needed for SHA acquisition.

3. DC and AC Specified: In addition to traditional dc specifications, the AD1674 is also fully specified for frequency domain ac parameters such as total harmonic distortion,

signal-to-noise ratio and input bandwidth. These parameters

can be tested and guaranteed as a result of the onboard

SHA.

4. Analog Operation: The precision, laser-trimmed scaling and

bipolar offset resistors provide four calibrated ranges:

0 V to +10 V and 0 V to +20 V unipolar, –5 V to +5 V and

–10 V to +10 V bipolar. The AD1674 operates on +5 V and

±12 V or ±15 V power supplies.

5. Flexible Digital Interface: On-chip multiple-mode

three-state output buffers and interface logic allow direct

connection to most microprocessors.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

AD1674–SPECIFICA TIONS

(T

to T

, VCC = +15 V 6 10% or +12 V 6 5%, V

MAX

DC SPECIFICATIONS

MIN

–12 V 6 5% unless otherwise noted)

AD1674J AD1674K

Parameter Min Typ Max Min Typ Max Unit

RESOLUTION 12 12 Bits

INTEGRAL NONLINEARITY (INL) ±1 ±1/2 LSB

DIFFERENTIAL NONLINEARITY (DNL)

(No Missing Codes) 12 12 Bits

UNIPOLAR OFFSET1 @ +25°C ±3 ±2 LSB

BIPOLAR OFFSET1 @ +25°C ±6 ±4 LSB

FULL-SCALE ERROR

1, 2

@ +25°C

(with Fixed 50 Ω Resistor from REF OUT to REF IN) 0.1 0.25 0.1 0.25 % of FSR

TEMPERATURE RANGE 0 +70 0 +70 °C

TEMPERATURE DRIFT

Unipolar Offset

Bipolar Offset

Full-Scale Error

2

2

2

3

POWER SUPPLY REJECTION

VCC = 15 V ± 1.5 V or 12 V ± 0.6 V ±2 ±1 LSB

V

= 5 V ± 0.5 V ±1/2 ±1/2 LSB

LOGIC

VEE = –15 V ± 1.5 V or –12 V ± 0.6 V ±2 ±1 LSB

= +5 V 6 10%, VEE = –15 V 6 10% or

LOGIC

±2 ±1 LSB

±2 ±1 LSB

±6 ±3 LSB

ANALOG INPUT

Input Ranges

Bipolar –5 +5 –5 +5 Volts

–10 +10 –10 +10 Volts

Unipolar 0 +10 0 +10 Volts

0 +20 0 +20 Volts

Input Impedance

10 Volt Span 357357 kΩ

20 Volt Span 6 10 14 6 10 14 kΩ

POWER SUPPLIES

Operating Voltages

V

LOGIC

V

CC

V

EE

+4.5 +5.5 +4.5 +5.5 Volts

+11.4 +16.5 +11.4 +16.5 Volts

–16.5 –11.4 –16.5 –11.4 Volts

Operating Current

I

LOGIC

I

CC

I

EE

58 58 mA

10 14 10 14 mA

14 18 14 18 mA

POWER DISSIPATION 385 575 385 575 mW

INTERNAL REFERENCE VOLTAGE 9.9 10.0 10.1 9.9 10.0 10.1 Volts

Output Current (Available for External Loads)

4

2.0 2.0 mA

(External Load Should Not Change During Conversion

NOTES

1

Adjustable to zero.

2

Includes internal voltage reference error.

3

Maximum change from 25°C value to the value at T

4

Reference should be buffered for ±12 V operation.

All min and max specifications are guaranteed.

Specifications subject to change without notice.

MIN

or T

MAX

.

–2–

REV. C

AD1674

AD1674A AD1674B AD1674T

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

RESOLUTION 12 12 12 Bits

INTEGRAL NONLINEARITY (INL) ±1 ±1/2 ±1/2 LSB

±1 ±1/2 ±1 LSB

DIFFERENTIAL NONLINEARITY (DNL)

(No Missing Codes) 12 12 12 Bits

UNIPOLAR OFFSET1 @ +25°C ±2 ±2 ±2 LSB

BIPOLAR OFFSET1 @ +25°C ±6 ±3 ±3 LSB

FULL-SCALE ERROR

(with Fixed 50 Ω Resistor from REF OUT to REF IN) 0.1 0.25 0.1 0.125 0.1 0.125 % of FSR

TEMPERATURE RANGE –40 +85 –40 +85 –55 +125 °C

TEMPERATURE DRIFT

Unipolar Offset

Bipolar Offset

Full-Scale Error

POWER SUPPLY REJECTION

VCC = 15 V ± 1.5 V or 12 V ± 0.6 V ±2 ±1 ±1 LSB

= 5 V ± 0.5 V ±1/2 ±1/2 ±1/2 LSB

V

LOGIC

VEE = –15 V ± 1.5 V or –12 V ± 0.6 V ±2 ±1 ±1 LSB

1, 2

@ +25°C

3

2

2

2

±2 ±1 ±1 LSB

±2 ±1 ±2 LSB

±8 ±5 ±7 LSB

ANALOG INPUT

Input Ranges

Bipolar –5 +5 –5 +5 –5 +5 Volts

–10 +10 –10 +10 –10 +10 Volts

Unipolar 0 +10 0 +10 0 +10 Volts

0 +20 0 +20 0 +20 Volts

Input Impedance

10 Volt Span 357357357 kΩ

20 Volt Span 6 10 14 6 10 14 6 10 14 kΩ

POWER SUPPLIES

Operating Voltages

V

LOGIC

V

CC

V

EE

+4.5 +5.5 +4.5 +5.5 +4.5 +5.5 Volts

+11.4 +16.5 +11.4 +16.5 +11.4 +16.5 Volts

–16.5 –11.4 –16.5 –11.4 –16.5 –11.4 Volts

Operating Current

I

LOGIC

I

CC

I

EE

58 58 58 mA

10 14 10 14 10 14 mA

14 18 14 18 14 18 mA

POWER DISSIPATION 385 575 385 575 385 575 mW

INTERNAL REFERENCE VOLTAGE 9.9 10.0 10.1 9.9 10.0 10.1 9.9 10.0 10.1 Volts

Output Current (Available for External Loads)

4

2.0 2.0 2.0 mA

(External Load Should Not Change During Conversion

REV. C

–3–

AD1674–SPECIFICATIONS

(T

to T

, with VCC = +15 V 6 10% or +12 V 6 5%, V

MAX

= 100 kSPS, fIN = 10 kHz, stand-alone mode unless otherwise noted)

SAMPLE

AC SPECIFICATIONS

MIN

–12 V 6 5%, f

AD1674J/A AD1674K/B/T

Parameter Min Typ Max Min Typ Max Units

Signal to Noise and Distortion (S/N+D) Ratio

Total Harmonic Distortion (THD)

4

2, 3

69 70 70 71 dB

–90 –82 –90 –82 dB

Peak Spurious or Peak Harmonic Component –92 –82 –92 –82 dB

Full Power Bandwidth 1 1 MHz

Full Linear Bandwidth 500 500 kHz

Intermodulation Distortion (IMD)

5

Second Order Products –90 –80 –90 –80 dB

Third Order Products –90 –80 –90 –80 dB

SHA (Specifications are Included in Overall Timing Specifications)

Aperture Delay 50 50 ns

Aperture Jitter 250 250 ps

Acquisition Time 1 1 µs

= +5 V 6 10%, VEE = –15 V 610% or

LOGIC

1

0.008 0.008 %

DIGITAL SPECIFICATIONS

(for all grades T

VEE = –15 V 6 10% or –12 V 6 5%)

MIN

to T

, with VCC = +15 V 6 10% or +12 V 6 5%, V

MAX

= +5 V 6 10%,

LOGIC

Parameter Test Conditions Min Max Units

LOGIC INPUTS

V

IH

V

IL

I

IH

I

IL

C

IN

High Level Input Voltage +2.0 V

+0.5 V V

LOGIC

Low Level Input Voltage –0.5 +0.8 V

High Level Input Current (VIN = 5 V) VIN = V

LOGIC

–10 +10 µA

Low Level Input Current (VIN = 0 V) VIN = 0 V –10 +10 µA

Input Capacitance 10 pF

LOGIC OUTPUTS

V

OH

V

OL

I

OZ

C

OZ

NOTES

1

fIN amplitude = –0.5 dB (9.44 V p-p) 10 V bipolar mode unless otherwise noted. All measurements referred to –0 dB (9.997 V p-p) input signal unless

otherwise noted.

2

Specified at worst case temperatures and supplies after one minute warm-up.

3

See Figures 12 and 13 for other input frequencies and amplitudes.

4

See Figure 11.

5

fa = 9.08 kHz, fb = 9.58 kHz with f

All min and max specifications are guaranteed.

Specifications subject to change without notice.

High Level Output Voltage IOH = 0.5 mA +2.4 V

Low Level Output Voltage IOL = 1.6 mA +0.4 V

High-Z Leakage Current VIN = 0 to V

LOGIC

–10 +10 µA

High-Z Output Capacitance 10 pF

= 100 kHz. See Definition of Specifications section and Figure 15.

SAMPLE

–4–

REV. C

AD1674

HIGH

IMPEDANCE

CE

STS

DB11 – DB0

A

0

CS

__

R/C

_

t

HSR

t

SSRtHRR

t

SAR

t

HAR

t

DD

t

HL

HIGH

IMP.

DATA

VALID

t

HD

t

HS

t

SSR

V

CP

D

OUT

C

OUT

I

OH

I

OL

SWITCHING SPECIFICATIONS

(for all grades T

V

= +5 V 610%, VEE = –15 V 6 10% or –12 V 6 5%; VIL = 0.4 V,

LOGIC

VIH = 2.4 V unless otherwise noted)

MIN

to T

CONVERTER START TIMING (Figure 1)

Parameter Symbol Min Typ Max Min Typ Max Units

Conversion Time

8-Bit Cycle t

12-Bit Cycle t

STS Delay from CE t

CE Pulse Width t

CS to CE Setup t

CS Low During CE High t

R/C to CE Setup t

R/C Low During CE High t

A0 to CE Setup t

A

Valid During CE High t

0

J, K, A, B, Grades T Grade

C

C

DSC

HEC

SSC

HSC

SRC

HRC

SAC

HAC

78 78µs

910 910µs

200 225 ns

50 50 ns

50 50 ns

50 50 ns

50 50 ns

50 50 ns

00ns

50 50 ns

READ TIMING—FULL CONTROL MODE (Figure 2)

J, K, A, B, Grades T Grade

Parameter Symbol Min Typ Max Min Typ Max Units

Access Time t

Data Valid After CE Low t

Output Float Delay t

CS to CE Setup t

R/C to CE Setup t

A

to CE Setup t

0

CS Valid After CE Low t

R/C High After CE Low t

A

Valid After CE Low t

0

NOTES

1

tDD is measured with the load circuit of Figure 3 and is defined as the time

required for an output to cross 0.4 V or 2.4 V.

2

0°C to T

3

At –40°C.

4

At –55°C.

5

tHL is defined as the time required for the data lines to change 0.5 V when

MAX

.

DD

HD

HL

SSR

SRR

SAR

HSR

HRR

HAR

1

5

75 150 75 150 ns

25

20

2

3

25

15

2

4

ns

ns

150 150 ns

50 50 ns

00ns

50 50 ns

00ns

00ns

50 50 ns

loaded with the circuit of Figure 3.

All min and max specifications are guaranteed.

Specifications subject to change without notice.

Test V

CP

C

OUT

Access Time High Z to Logic Low 5 V 100 pF

Float Time Logic High to High Z 0 V 10 pF

Access Time High Z to Logic High 0 V 100 pF

Float Time Logic Low to High Z 5 V 10 pF

with VCC = +15 V 6 10% or +12 V 6 5%,

MAX

CE

R/C

STS

DB11 – DB0

__

CS

_

t

A

SAC

0

t

SSC

t

SRCtHRC

t

HSC

t

Figure 1. Converter Start Timing

Figure 2. Read Timing

DSC

t

HEC

t

HAC

t

C

HIGH IMPEDANCE

REV. C

Figure 3. Load Circuit for Bus Timing Specifications

–5–

AD1674

DATA

VALID

HIGH-Z

HIGH-Z

STS

DB11 – DB0

R/C

_

t

HRH

t

DS

t

C

t

DDRtHDR

t

HL

TIMING—STAND-ALONE MODE (Figures 4a and 4b)

J, K, A, B Grades T Grade

Parameter Symbol Min Typ Max Min Typ Max Units

Data Access Time t

Low R/

C Pulse Width t

STS Delay from R/

Data Valid After R/

C t

C Low t

STS Delay After Data Valid t

High R/C Pulse Width t

NOTE

All min and max specifications are guaranteed.

Specifications subject to change without notice.

t

HRL

_

R/C

t

DS

STS

t

HDR

DB11 – DB0

DATA

VALID

Figure 4a. Stand-Alone Mode Timing Low Pulse for R/

DDR

HRL

DS

HDR

HS

HRH

t

C

HIGH-Z

50 50 ns

25 25 ns

0.6 0.8 1.2 0.6 0.8 1.2 µs

150 150 ns

t

HS

DATA VALID

C

ABSOLUTE MAXIMUM RATINGS*

VCC to Digital Common . . . . . . . . . . . . . . . . . . . 0 to + 16.5 V

V

to Digital Common . . . . . . . . . . . . . . . . . . . . . 0 to –16.5 V

EE

V

to Digital Common . . . . . . . . . . . . . . . . . . 0 V to +7 V

LOGIC

Analog Common to Digital Common . . . . . . . . . . . . . . . ±1 V

Digital Inputs to Digital Common . . . –0.5 V to V

Analog Inputs to Analog Common . . . . . . . . . . . . V

LOGIC

EE

+0.5 V

to V

CC

20 VIN to Analog Common . . . . . . . . . . . . . . . . . VEE to +24 V

REF OUT . . . . . . . . . . . . . . . . . Indefinite Short to Common

150 150 ns

200 225 ns

Figure 4b. Stand-Alone Mode Timing High Pulse for R/

. . . . . . . . . . . . . . . . . . . . . . . . . . . Momentary Short to V

C

CC

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +175°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . .825 mW

Lead Temperature, Soldering (10 sec) . . . . . . . +300°C, 10 sec

Storage Temperature . . . . . . . . . . . . . . . . . . .–65°C to +150°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

WARNING!

the AD1674 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

ESD SENSITIVE DEVICE

ORDERING GUIDE

INL S/(N+D) Package Package

MIN

to T

)(T

MAX

MIN

to T

) Description Option

MAX

Model

1

Temperature Range (T

AD1674JN 0°C to +70°C ±1 LSB 69 dB Plastic DIP N-28

AD1674KN 0°C to +70°C ± 1/2 LSB 70 dB Plastic DIP N-28

AD1674JR 0°C to +70°C ±1 LSB 69 dB Plastic SOIC R-28

AD1674KR 0°C to +70°C ±1/2 LSB 70 dB Plastic SOIC R-28

AD1674AR –40°C to +85°C ±1 LSB 69 dB Plastic SOIC R-28

AD1674BR –40°C to +85°C ±1/2 LSB 70 dB Plastic SOIC R-28

AD1674AD –40°C to +85°C ±1 LSB 69 dB Ceramic DIP D-28

AD1674BD –40°C to +85°C ±1/2 LSB 70 dB Ceramic DIP D-28

AD1674TD –55°C to +125°C ±1 LSB 70 dB Ceramic DIP D-28

NOTES

1

For details on grade and package offerings screened in accordance with MIL-STD-883, refer to the Analog Devices Military Products Databook or current

AD1674/883B data sheet. SMD is also available.

2

N = Plastic DIP; D = Hermetic Ceramic DIP; R = Plastic SOIC.

–6–

REV. C

2

AD1674

A

A

A

A

A

TOP VIEW

(Not to Scale)

AD1674

18

28

27

24

23

22

26

25

21

20

19

17

16

15

13

1

2

5

6

7

3

4

8

9

10

12

14

V

LOGIC

CE

V

CC

A

0

REF OUT

AGND

REF IN

V

EE

BIP OFF

10V

IN

20V

IN

CS

12/8

R/C

STS

DB11(MSB)

DB8

DB7

DB6

DB10

DB9

DB5

DB4

DB3

DB2

DB1

DB0(LSB)

DGND

11

PIN DESCRIPTION

Symbol Pin No. Type Name and Function

AGND 9 P Analog Ground (Common).

A

0

BIP OFF 12 AI Bipolar Offset. Connect through a 50 Ω resistor to REF OUT for bipolar operation or to Analog

CE 6 DI Chip Enable. Chip Enable is Active HIGH and is used to initiate a convert or read operation.

CS 3 DI Chip Select. Chip Select is Active LOW.

DB11–DB8 27–24 DO Data Bits 11 through 8. In the 12-bit format (see 12/

DB7–DB4 23–20 DO Data Bits 7 through 4. In the 12-bit format these pins provide the middle 4 bits of data. In the

DB3–DB0 19–16 DO Data Bits 3 through 0. In the 12-bit format these pins provide the lower 4 bits of data. In the

DGND 15 P Digital Ground (Common).

REF OUT 8 AO +10 V Reference Output.

R/

C 5 DI Read/Convert. In the full control mode R/C is Active HIGH for a read operation and Active LOW

REF IN 10 AI Reference Input is connected through a 50 Ω resistor to +10 V Reference for normal operation.

STS 28 DO Status is Active HIGH when a conversion is in progress and goes LOW when the conversion is

V

CC

V

EE

V

LOGIC

10 V

IN

20 V

IN

12/

8 2 DI The 12/8 pin determines whether the digital output data is to be organized as two 8-bit words

TYPE: AI = Analog Input

4 DI Byte Address/Short Cycle. If a conversion is started with A0 Active LOW, a full 12-bit conversion

cycle is initiated. If A

results. During Read (R/

(DB4–DB11), and A

is Active HIGH during a convert start, a shorter 8-bit conversion cycle

0

C = 1) with 12/8 LOW, A0 = LOW enables the 8 most significant bits

= HIGH enables DB3–DB0 and sets DB7–DB4 = 0.

0

Common for unipolar operation.

8 and A0 pins), these pins provide the up-

per 4 bits of data. In the 8-bit format, they provide the upper 4 bits when A

disabled when A

is HIGH.

0

8-bit format they provide the middle 4 bits when Ao is LOW and all zeroes when A

8-bit format these pins provide the lower 4 bits of data when A

when A

is LOW.

0

is HIGH, they are disabled

0

for a convert operation. In the stand-alone mode, the falling edge of R/

is LOW and are

0

is HIGH.

0

C initiates a conversion.

completed.

7 P +12 V/+15 V Analog Supply.

11 P –12 V/–15 V Analog Supply.

1 P +5 V Logic Supply.

13 AI 10 V Span Input, 0 V to +10 V unipolar mode or –5 V to +5 V bipolar mode. When using the

AD1674 in the 20 V Span 10 V

should not be connected.

IN

14 AI 20 V Span Input, 0 V to +20 V unipolar mode or –10 V to +10 V bipolar mode. When using

the AD1674 in the 10 V Span 20 V

should not be connected.

IN

(12/8 LOW) or a single 12-bit word (12/8 HIGH).

AO = Analog Output

DI = Digital Input

DO = Digital Output

P = Power

FUNCTIONAL BLOCK DIAGRAM

12/8

CS

A

CE

R/C

0

CONTROL

PIN CONFIGURATION

STS

REV. C

REF OUT

AGND

REF IN

BIP OFF

20V

10V

10V

REF

20k

IN

5k

IN

2.5k

2.5k

CLOCK

5k

10k

10k

5k

SHA

COMP

IDAC

SAR

12

DAC

AD1674

12

DB11 (MSB)

DB0 (LSB)

12

REGISTERS / 3-STATE OUTPUT BUFFERS

–7–

AD1674

DEFINITION OF SPECIFICATIONS

INTEGRAL NONLINEARITY (INL)

The ideal transfer function for an ADC is a straight line drawn

between “zero” and “full scale.” The point used as “zero”

occurs 1/2 LSB before the first code transition. “Full scale” is

defined as a level 1 1/2 LSB beyond the last code transition.

Integral nonlinearity is the worst-case deviation of a code from

the straight line. The deviation of each code is measured from

the middle of that code.

DIFFERENTIAL NONLINEARITY (DNL)

A specification which guarantees no missing codes requires that

every code combination appear in a monotonic increasing

sequence as the analog input level is increased. Thus every code

must have a finite width. The AD1674 guarantees no missing

codes to 12-bit resolution; all 4096 codes are present over the

entire operating range.

UNIPOLAR OFFSET

The first transition should occur at a level 1/2 LSB above analog common. Unipolar offset is defined as the deviation of the

actual transition from that point at 25°C. This offset can be

adjusted as shown in Figure 11.

BIPOLAR OFFSET

In the bipolar mode the major carry transition (0111 1111 1111

to 1000 0000 0000) should occur for an analog value 1/2 LSB

below analog common. The bipolar offset error specifies the

deviation of the actual transition from that point at 25°C. This

offset can be adjusted as shown in Figure 12.

FULL-SCALE ERROR

The last transition (from 1111 1111 1110 to 1111 1111 1111)

should occur for an analog value 1 1/2 LSB below the nominal

full scale (9.9963 volts for 10 volts full scale). The full-scale

error is the deviation of the actual level of the last transition

from the ideal level at 25°C. The full-scale error can be adjusted

to zero as shown in Figures 11 and 12.

TEMPERATURE DRIFT

The temperature drifts for full-scale error, unipolar offset and

bipolar offset specify the maximum change from the initial

(25°C) value to the value at T

POWER SUPPLY REJECTION

MIN

or T

MAX

.

The effect of power supply error on the performance of the

device will be a small change in full scale. The specifications

show the maximum full-scale change from the initial value with

the supplies at various limits.

FREQUENCY-DOMAIN TESTING

The AD1674 is tested dynamically using a sine wave input and

a 2048 point Fast Fourier Transform (FFT) to analyze the

resulting output. Coherent sampling is used, wherein the ADC

sampling frequency and the analog input frequency are related

to each other by a ratio of integers. This ensures that an integral

multiple of input cycles is captured, allowing direct FFT processing without windowing or digital filtering which could mask

some of the dynamic characteristics of the device. In addition,

the frequencies are chosen to he “relatively prime” (no common

factors) to maximize the number of different ADC codes that

are present in a sample sequence. The result, called Prime

Coherent Sampling, is a highly accurate and repeatable measure

of the actual frequency-domain response of the converter.

NYQUIST FREQUENCY

An implication of the Nyquist sampling theorem, the “Nyquist

Frequency” of a converter is that input frequency which is onehalf the sampling frequency of the converter.

SIGNAL-TO-NOISE AND DISTORTION (S/N+D) RATIO

S/(N+D) is the ratio of the rms value of the measured input signal to the rms sum of all other spectral components below the

Nyquist frequency, including harmonics but excluding dc. The

value for S/(N+D) is expressed in decibels.

TOTAL HARMONIC DISTORTION (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of a full-scale input signal and is expressed as a percentage or in decibels. For input signals or

harmonics that are above the Nyquist frequency, the aliased

component is used.

INTERMODULATION DISTORTION (IMD)

With inputs consisting of sine waves at two frequencies, fa and

fb, any device with nonlinearities will create distortion products,

of order (m+n), at sum and difference frequencies of mfa ± nfb,

where m, n = 0, 1, 2, 3. . . . Intermodulation terms are those for

which m or n is not equal to zero. For example, the second

order terms are (fa + fb) and (fa – fb) and the third order terms

are (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb). The IMD

products are expressed as the decibel ratio of the rms sum of the

measured input signals to the rms sum of the distortion terms.

The two signals are of equal amplitude and the peak value of

their sums is –0.5 dB from full scale. The IMD products are

normalized to a 0 dB input signal.

FULL-POWER BANDWIDTH

The full-power bandwidth is that input frequency at which the

amplitude of the reconstructed fundamental is reduced by 3 dB

for a full-scale input.

FULL-LINEAR BANDWIDTH

The full-linear bandwidth is the input frequency at which the

slew rate limit of the sample-hold-amplifier (SHA) is reached.

At this point, the amplitude of the reconstructed fundamental

has degraded by less than –0.1 dB. Beyond this frequency, distortion of the sampled input signal increases significantly.

APERTURE DELAY

Aperture delay is a measure of the SHA’s performance and is

measured from the falling edge of Read/Convert (R/

C) to when

the input signal is held for conversion.

APERTURE JITTER

Aperture jitter is the variation in aperture delay for successive

samples and is manifested as noise on the input to the A/D.

–8–

REV. C

T ypical Dynamic Performance–AD1674

f

= 100kSPS

SAMPLE

FULL-SCALE = +10V

0

–20

–40

–60

–80

AMPLITUDE – dB

–100

–120

101

INPUT FREQUENCY – kHz

THD

HARMONIC

2NDHARMONIC

100

1000

RD

3

10000

Figure 5. Harmonic Distortion vs.

Input Frequency

0

–20

–40

–60

–80

AMPLITUDE – dB

–100

–120

–140

5

0

FREQUENCY – kHz

Figure 8. Nonaveraged 2048 Point FFT

at 100 kSPS, f

= 25.049 kHz

IN

80

70

60

50

40

S/(N+D) – dB

30

20

10

0

0dB INPUT

–20dB INPUT

–60dB INPUT

100

101

INPUT FREQUENCY – kHz

Figure 6. S/(N+D) vs. Input Frequency

and Amplitude

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

AMPLITUDE – dB

–100

–110

–120

–130

50

4540353025201510

5

0

Figure 9. IMD Plot for fIN = 9.08 kHz (fa), 9.58 kHz (fb)

GENERAL CIRCUIT OPERATION

The AD1674 is a complete 12-bit, 10 µs sampling analog-to-

digital converter. A block diagram of the AD1674 is shown on

page 7.

When the control section is commanded to initiate a conversion

(as described later), it places the sample-and-hold amplifier

(SHA) in the hold mode, enables the clock, and resets the successive approximation register (SAR). Once a conversion cycle

has begun, it cannot be stopped or restarted and data is not

available from the output buffers. The SAR, timed by the internal clock, will sequence through the conversion cycle and return

an end-of-convert flag to the control section when the conversion has been completed. The control section will then disable

the clock, switch the SHA to sample mode, and delay the STS

LOW going edge to allow for acquisition to 12-bit accuracy.

The control section will allow data read functions by external

command anytime during the SHA acquisition interval.

During the conversion cycle, the internal 12-bit, 1 mA full-scale

current output DAC is sequenced by the SAR from the most

significant bit (MSB) to the least significant bit (LSB) to provide an output that accurately balances the current through the

5 kΩ resistor from the input signal voltage held by the SHA.

The SHA’s input scaling resistors divide the input voltage by 2

for the 10 V input span and by 4 V for the 20 V input span,

maintaining a 1 mA full-scale output current through the 5 kΩ

resistor for both ranges. The comparator determines whether

the addition of each successively weighted bit current causes the

10000

1000

Figure 7. S/(N+D) vs. Input Amplitude

50

20 25 40

FREQUENCY – kHz

4535301510

DAC current sum to be greater than or less than the input current. If the sum is less, the bit is left on; if more, the bit is

turned off. After testing all the bits, the SAR contains a 12-bit

binary code which accurately represents the input signal to

within ±1/2 LSB.

CONTROL LOGIC

The AD1674 may be operated in one of two modes, the fullcontrol mode and the stand-alone mode. The full-control mode

utilizes all the AD1674 control signals and is useful in systems

that address decode multiple devices on a single data bus. The

stand-alone mode is useful in systems with dedicated input ports

available and thus not requiring full bus interface capability.

Table I is a truth table for the AD1674, and Figure 10 illustrates the internal logic circuitry.

Table I. AD1674A Truth Table

CE CS R/C 12/8 A0Operation

0 X X X X None

X 1 X X X None

1 0 0 X 0 Initiate 12-Bit Conversion

1 0 0 X 1 Initiate 8-Bit Conversion

1 0 1 1 X Enable 12-Bit Parallel Output

1 0 1 0 0 Enable 8 Most Significant Bits

1 0 1 0 1 Enable 4 LSBs +4 Trailing Zeroes

REV. C

–9–

AD1674

D

READ

EN

Q

QB

–10–

Q

D

EN

R

Q

S

CE

CS

R/C

A

0

12/8

Figure 10. Equivalent Internal Logic Circuitry

FULL-CONTROL MODE

Chip Enable (CE), Chip Select (

CS) and Read/ Convert (R/C)

are used to control Convert or Read modes of operation. Either

CE or

CS may be used to initiate a conversion. The state of R/C

when CE and

Read (R/

should be LOW before both CE and

CS are both asserted determines whether a data

C = 1) or a Convert (R/C = 0) is in progress. R/C

CS are asserted; if R/C is

HIGH, a Read operation will momentarily occur, possibly

resulting in system bus contention.

STAND-ALONE MODE

The AD1674 can be used in a “stand-alone” mode, which is

useful in systems with dedicated input ports available and thus

not requiring full bus interface capability. Stand-alone mode

applications are generally able to issue conversion start commands more precisely than full-control mode. This improves ac

performance by reducing the amount of control-induced aperture jitter.

In stand-alone mode, the control interface for the AD1674 and

AD674A are identical. CE and 12/

A

are wired LOW, and conversion is controlled by R/C. The

0

three-state buffers are enabled when R/

version starts when R/

C goes LOW. This gives rise to two pos-

8 are wired HIGH, CS and

C is HIGH and a con-

sible control signals—a high pulse or a low pulse. Operation

with a low pulse is shown in Figure 4a. In this case, the outputs

are forced into the high impedance state in response to the falling edge of R/

C and return to valid logic levels after the conversion cycle is completed. The STS line goes HIGH 200 ns after

R/

C goes LOW and returns low 1 µs after data is valid.

If conversion is initiated by a high pulse as shown in Figure 4b,

the data lines are enabled during the time when R/

The falling edge of R/

C starts the next conversion and the data

C is HIGH.

lines return to three-state (and remain three-state) until the next

high pulse of R/

C.

CONVERSION TIMING

Once a conversion is started, the STS line goes HIGH. Convert

start commands will be ignored until the conversion cycle is

complete. The output data buffers will be enabled a minimum

of 0.6 µs prior to STS going LOW. The STS line will return

LOW at the end of the conversion cycle.

VALUE OF A0 AT LAST

CONVERT COMMAND

EOC 12

EOC 8

S

R

The register control inputs, A

length and data format. If a conversion is started with A

a full 12-bit conversion cycle is initiated. If A

SAR RESET

Q

QB

NYBBLE A

NYBBLE B

NYBBLE C

NYBBLE B = 0

1µs DELAY-HOLD SETTLING

1µs DELAY-ACQUISITION

TO OUTPUT

BUFFERS

and 12/8, control conversion

0

CLK ENABLE

STATUS

HOLD/SAMPLE

is HIGH during a

0

LOW,

0

convert start, a shorter 8-bit conversion cycle results.

During data read operations, A

state buffers containing the 8 MSBs of the conversion result (A

determines whether the three-

0

0

= 0) or the 4 LSBs (A0 = 1) are enabled. The 12/8 pin determines whether the output data is to be organized as two 8-bit

words (12/

HIGH). In the 8-bit mode, the byte addressed when A

8 tied LOW) or a single 12-bit word (12/8 tied

is high

0

contains the 4 LSBs from the conversion followed by four trailing zeroes. This organization allows the data lines to be overlapped for direct interface to 8-bit buses without the need for

external three-state buffers.

INPUT CONNECTIONS AND CALIBRATION

The 10 V p-p and 20 V p-p full-scale input ranges of the

AD1674 accept the majority of signal voltages without the need

for external voltage divider networks which could deteriorate the

accuracy of the ADC.

The AD1674 is factory trimmed to minimize offset, linearity,

and full-scale errors. In many applications, no calibration trimming will be required and the AD1674 will exhibit the accuracy

limits listed in the specification tables.

In some applications, offset and full-scale errors need to be

trimmed out completely. The following sections describe the

correct procedure for these various situations.

UNIPOLAR RANGE INPUTS

Figure 11 illustrates the external connections for the AD1674 in

unipolar-input mode. The first output-code transition (from

0000 0000 0000 to 0000 0000 0001) should nominally occur

for an input level of +1/2 LSB (1.22 mV above ground for a 10 V

range; 2.44 mV for a 20 V range). To trim unipolar offset to this

nominal value, apply a +1/2 LSB signal between Pin 13 and

ground (10 V range) or Pin 14 and ground (20 V range) and adjust R1 until the first transition is located. If the offset trim is

not required, Pin 12 can be connected directly to Pin 9; the two

resistors and trimmer for Pin 12 are then not needed.

REV. C

AD1674

–15V

100k

100Ω

0 TO +10V

ANALOG

INPUTS

0 TO +20V

R1

100k

+15V

R2

100Ω

2 12/8

3 CS

4 A

0

5 R/C

6 CE

10 REF IN

8 REF OUT

12 BIP OFF

13 10V

14 20V

9 ANA COM

AD1674

IN

IN

STS 28

HIGH BITS

24-27

MIDDLE BITS

20-23

LOW BITS

16-19

+5V 1

+15V 7

–15V 11

DIG COM 15

Figure 11. Unipolar Input Connections with Gain and

Offset Trims

The full-scale trim is done by applying a signal 1 1/2 LSB below

the nominal full scale (9.9963 V for a 10 V range) and adjusting

R2 until the last transition is located (1111 1111 1110 to 1111

1111 1111). If full-scale adjustment is not required, R2 should

be replaced with a fixed 50 Ω ±1% metal film resistor. If REF

OUT is connected directly to REF IN, the additional full-scale

error will be approximately 1%.

BIPOLAR RANGE INPUTS

The connections for the bipolar-input mode are shown in Figure

12. Either or both of the trimming potentiometers can be

replaced with 50 Ω ± 1% fixed resistors if the specified AD1674

accuracy limits are sufficient for the application. If the pins are

shorted together, the additional offset and gain errors will be

approximately 1%.

To trim bipolar offset to its nominal value, apply a signal 1/2

LSB below midrange (–1.22 mV for a ± 5 V range) and adjust

R1 until the major carry transition is located (0111 1111 1111

to 1000 0000 0000). To trim the full-scale error, apply a signal

1 1/2 LSB below full scale (+4.9963 V for a ± 5 V range) and

adjust R2 to give the last positive transition (1111 1111 1110 to

1111 1111 1111). These trims are interactive so several iterations may be necessary for convergence.

A single-pass calibration can be done by substituting a negative

full-scale trim for the bipolar offset trim (error at midscale),

using the same circuit. First, apply a signal 1/2 LSB above minus

full scale (–4.9988 V for a ±5 V range) and adjust R1 until the

minus full-scale transition is located (0000 0000 0001 to 0000

0000 0000). Then perform the gain error trim as outlined above.

ANALOG

INPUTS

±5V

±10V

R2

100Ω

100Ω

R1

2 12/8

3 CS

4 A

0

5 R/C

6 CE

10 REF IN

8 REF OUT

12 BIP OFF

13 10V

14 20V

9 ANA COM

AD1674

IN

IN

STS 28

HIGH BITS

24-27

MIDDLE BITS

20-23

LOW BITS

16-19

+5V 1

+15V 7

–15V 11

DIG COM 15

Figure 12. Bipolar Input Connections with Gain and Offset

Trims

REFERENCE DECOUPLING

It is recommended that a 10 µF tantalum capacitor be con-

nected between REF IN (Pin 10) and ground. This has the

effect of improving the S/(N+D) ratio through filtering possible

broad-band noise contributions from the voltage reference.

BOARD LAYOUT

Designing with high resolution data converters requires careful

attention to board layout. Trace impedance is a significant issue.

At the 12-bit level, a 5 mA current through a 0.5 Ω trace will

develop a voltage drop of 2.5 mV, which is 1 LSB for a 10 V

full-scale range. In addition to ground drops, inductive and capacitive coupling need to be considered, especially when high

accuracy analog signals share the same board with digital signals. Finally, power supplies should be decoupled in order to

filter out ac noise.

The AD1674 has a wide bandwidth sampling front end. This

means that the AD1674 will “see” high frequency noise at the

input, which nonsampling (or limited-bandwidth sampling)

ADCs would ignore. Therefore, it’s important to make an effort

to eliminate such high frequency noise through decoupling or by

using an anti-aliasing filter at the analog input of the AD1674.

Analog and digital signals should not share a common path.

Each signal should have an appropriate analog or digital return

routed close to it. Using this approach, signal loops enclose a

small area, minimizing the inductive coupling of noise. Wide PC

tracks, large gauge wire, and ground planes are highly recommended to provide low impedance signal paths. Separate analog

and digital ground planes are also desirable, with a single interconnection point to minimize ground loops. Analog signals

should be routed as far as possible from digital signals and

should cross them (if necessary) only at right angles.

The AD1674 incorporates several features to help the user’s layout. Analog pins are adjacent to help isolate analog from digital

signals. Ground currents have been minimized by careful circuit

architecture. Current through AGND is 2.2 mA, with little

code-dependent variation. The current through DGND is dominated by the return current for DB11–DB0.

SUPPLY DECOUPLING

The AD1674 power supplies should be well filtered, well regulated, and free from high frequency noise. Switching power supplies are not recommended due to their tendency to generate

spikes which can induce noise in the analog system.

Decoupling capacitors should be used in very close layout proximity between all power supply pins and ground. A 10 µF tanta-

lum capacitor in parallel with a 0.1 µF disc ceramic capacitor

provides adequate decoupling over a wide range of frequencies.

An effort should be made to minimize the trace length between

the capacitor leads and the respective converter power supply

and common pins. The circuit layout should attempt to locate

the AD1674, associated analog input circuitry, and interconnections as far as possible from logic circuitry. A solid analog

ground plane around the AD1674 will isolate large switching

ground currents. For these reasons, the use of wire-wrap circuit

construction is not recommended; careful printed-circuit construction is preferred.

REV. C

–11–

AD1674

0.050 ±0.010

(1.27 ±0.254)

SEATING

PLANE

1.42 (36.07)

1.40 (35.56)

0.047 ±0.007

(1.19 ±0.178)

0.1 (2.54)

0.017 ±0.003

(0.43 ±0.076)

0.145 ±0.02

(3.68 ±0.51)

0.125

(3.17)

MIN

0.6 (15.24)

0.010 ±0.002

(0.254 ±0.05)

0.095

(2.41)

0.085

(2.16)

0.59 ±0.01

(14.98 ±0.254)

14

15

PIN 1

1

28

0.505 (12.83)

PIN 1

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

1

28

15

14

0.0125 (0.32)

0.0091 (0.23)

0.0500 (1.27)

0.0157 (0.40)

8°

0°

0.0291 (0.74)

0.0098 (0.25)

x 45°

0.0192 (0.49)

0.0138 (0.35)

0.0500 (1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.7125 (18.10)

0.6969 (17.70)

0.0118 (0.30)

0.0040 (0.10)

GROUNDING

If a single AD1674 is used with separate analog and digital

ground planes, connect the analog ground plane to AGND and

the digital ground plane to DGND keeping lead lengths as short

as possible. Then connect AGND and DGND together at the

AD1674. If multiple AD1674s are used or the AD1674 shares

analog supplies with other components, connect the analog and

digital returns together once at the power supplies rather than at

each chip. This prevents large ground loops which inductively

couple noise and allow digital currents to flow through the analog system.

GENERAL MICROPROCESSOR INTERFACE CONSIDERATIONS

A typical A/D converter interface routine involves several operations. First, a write to the ADC address initiates a conversion.

The processor must then wait for the conversion cycle to complete, since most ADCs take longer than one instruction cycle to

complete a conversion. Valid data can, of course, only be read

after the conversion is complete. The AD1674 provides an output signal (STS) which indicates when a conversion is in

progress. This signal can be polled by the processor by reading

it through an external three-state buffer (or other input port).

The STS signal can also be used to generate an interrupt upon

completion of a conversion, if the system timing requirements

are critical (bear in mind that the maximum conversion time of

the AD1674 is only 10 microseconds) and the processor has

other tasks to perform during the ADC conversion cycle. Another possible time-out method is to assume that the ADC will

take 10 microseconds to convert, and insert a sufficient number

of “no-op” instructions to ensure that 10 microseconds of processor time is consumed.

Once it is established that the conversion is finished, the data

can be read. In the case of an ADC of 8-bit resolution (or less),

a single data read operation is sufficient. In the case of converters with more data bits than are available on the bus, a choice of

data formats is required, and multiple read operations are

needed. The AD1674 includes internal logic to permit direct interface to 8-bit or 16-bit data buses, selected by the 12/

In 16-bit bus applications (12/

8 HIGH) the data lines (DB11

8 input.

through DB0) may be connected to either the 12 most significant or 12 least significant hits of the data bus. The remaining

four bits should be masked in software. The interface to an 8-bit

data bus (12/

DB4). The odd address (A

8 LOW) contains the 8 MSBs (DB11 through

HIGH) contains the 4 LSBs (DB3

0

through DB0) in the upper half of the byte, followed by four

trailing zeroes, thus eliminating bit masking instructions.

PIN 1

0.200

(5.080)

MAX

0.175 (4.45)

0.120 (3.05)

PACKAGE INFORMATION

Dimensions shown in inches and (mm).

28-Pin Ceramic DIP Package (D-28)

28-Lead Plastic DIP Package (N-28)

28

1

0.020 (0.508)

0.015 (0.381)

1.450 (38.83)

1.440 (35.576)

0.105 (2.67)

0.095 (2.41)

15

14

0.065 (1.65)

0.045 (1.14)

0.550 (13.97)

0.530 (13.462)

0.160 (4.06)

0.140 (3.56)

SEATING

PLANE

0.606 (15.39)

0.594 (15.09)

15

°

0

°

28-Lead Wide-Body SO Package (R-28)

0.012 (0.305)

0.008 (0.203)

C1425b–10–3/94

AD1674 Data Format for 8-Bit Bus

–12–

PRINTED IN U.S.A.

REV. C

Loading...

Loading...