Amana WS924D1STC, WS936D1, WS900GS, WS900DINTERNAL Installation Manual

PTAC WALL SLEEVE

INSTALLATION INSTRUCTIONS

The wall sleeve must be installed before the air conditioner or heat pump chassis can be set in place.

Read the instructions thoroughly before proceeding.

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This includes all safety precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special attention to all safety warnings. Often during installation or repair it is possible to place yourself in a position which is more hazardous than when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to instruct a customer in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of specific good safety practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices. However, if there is a direct conflict between existing practices and the content of this manual, the precautions listed here take precedence.

RECOGNIZE THIS SYMBOL AS A SAFETY

RECOGNIZE THIS SYMBOL AS A SAFETY

PRECAUTIONDESCRIPTON

When 230/208 volt units are to be installed, the power supply may be either cord connected or permanent wiring. Permanent wiring may be done through the hard wire junction box, or the accessory subbase.

When 265 volt units are to be installed, the power supply must be permanent wiring. Permanent wiring may be done through the accessory hard wire junction box, or the accessory subbase. An exposed cord connection on 265 volt units is not permitted.

The subbase accessory includes leveling legs. If added wall sleeve support is required and the subbase is not to be used an accessory leveling leg kit may be installed.

INDEX |

|

ATTENTION INSTALLING PERSONNEL ................................... |

1 |

KIT ACCESSORIES ................................................................. |

1 |

DRAIN KIT ..................................................................... |

1 |

SUBBASE, LEVELING LEGS, MAIN DUCT & HYDRONIC HEAT KITS ........ |

1 |

PRE-INSTALLATION CONSIDERATIONS .................................. |

3 |

OUTDOOR ENCLOSURE PANEL REMOVAL ................................... |

3 |

WALL SLEEVE INSTALLATION ............................................... |

4 |

KIT ACCESSORIES

DRAIN KIT

An indoor/outdoor drain kit is available as an accessory item. When a drain kit is to be installed, do so before installing the wall sleeve in the wall. See the drain kit for actual installation instructions.

SUBBASE, LEVELING LEGS, MAIN DUCT, AND HYDRONIC HEAT

KITS

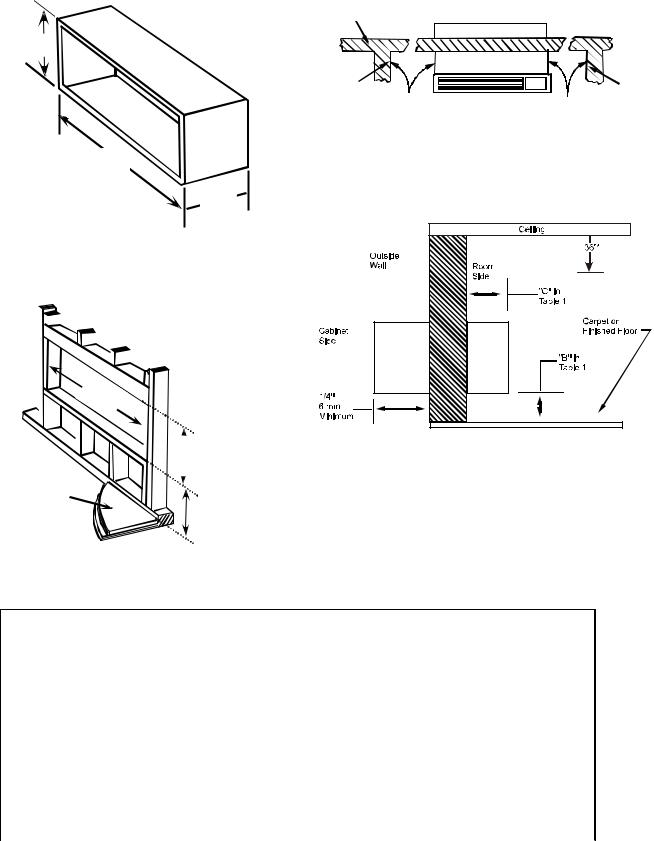

Installation of these kits requires drilling of mounting holes on both sides of the wall sleeve. The minimum required clearance distance between the wall sleeve and wall is shown in Table 1. If the distance between wall sleeve and wall will be at or near the minimum clearance distance, mount these kits on the sleeve before installing the sleeve in the wall. The kit installation instructions are included with the accessory kits.

is a registered trademark of Maytag Corporation or its related companies and is used under license to

is a registered trademark of Maytag Corporation or its related companies and is used under license to

Goodman Company, L.P., Houston, TX, USA. All rights reserved.

A3495105r4 |

5151 San Felipe, Suite 500 • |

Houston, TX 77056 • www.amana-ptac.com |

|

01 / 2017 |

|||

|

|

© 1996, 2000, 2004-2005, 2017 Goodman Company, L.P.

16 1/16" 410 mm

42" 1065 mm

14 1/8"

359 mm

359 mm

Wall Receptacle Within 58" From Bottom Right Side Corner on 208/230 VAC Units Only

Figure 1 - Wall Sleeve Dimensions

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

1 |

|

|

2 |

|

|

|

|

|

|

|

||||

|

|

|

|

1 |

|

|

|

|

|

|

|||||

|

|

|

|

|

0 |

|

|

/ |

|

|

|

|

|

||

|

|

|

|

|

|

7 |

4 |

|

|

|

|

|

|||

|

|

|

M |

|

|

5 |

m |

" |

|

|

|

|

|

||

|

|

|

|

|

|

||||||||||

|

|

|

|

i |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

i |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

m |

m |

|

|

|

|

||||

|

|

|

|

|

|

|

|

u |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m |

|

|

" m m |

|||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

u |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 m m |

|||

|

|

|

|

|

|

|

|

|

|

|

|

/ |

5 |

i |

|

|

|

|

|

|

|

|

|

|

|

6 |

|||||

|

|

|

|

|

|

|

|

|

|

|

n |

||||

|

|

|

|

|

|

|

|

|

|

1 |

1 i |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Finished Floor |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Dimension "B" |

|||||||

|

|

|

|

|

|

|

|

in Table 1 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2 - Minimum Wall Opening Dimensions

Outside

Wall

|

|

Top of Wall Sleeve |

|

|

Internal |

|

|

Internal |

|

|

|

|||

Adjacent |

|

|

||

|

|

Adjacent |

||

Wall |

"A" |

"A" |

||

Wall |

||||

|

Minimum |

Minimum |

||

|

|

Allow Front Clearance (See Table 1)

Figure 3 - Minimum Unit Clearances

* To ensure proper airflow and filter removal, it is recommended the wall sleeve be installed a minimum of 36” from the ceiling.

Figure 4 - Minimum Interior and Exterior

NOTE: To ensure proper airflow and filter removal, it is recommended installation of the wall sleeve be a minimum of 36” from the ceiling.

MINIMUM CLEARANCES AND PROJECTIONS

|

|

MINIMUM CLEARANCES |

|

MINIMUM PROJECTION |

||||

OPTION |

A (Figure 2) |

B (Figure 3) |

C (Figure 4) |

|||||

|

Inches |

|

mm |

Inches |

|

mm |

Inches |

mm |

|

|

|

|

|

|

|

|

|

Wall Sleeve Only |

3 |

|

75 |

0 |

|

0 |

0 |

0 |

Subbase Kit |

3 |

|

75 |

3 1/4 |

|

85 |

2 3/4 |

70 |

Leveling Legs Kit |

3 |

|

75 |

3 |

|

75 |

2 |

50 |

Duct Kit |

3 |

|

75 |

0 |

|

0 |

2 3/8 |

35 |

Hydronic Heat Kit "A Series" |

9 |

|

230 |

0 to 3 1/43 |

|

0 to 853 |

32 |

752 |

Hydronic Heat Kit "J Series" |

6 |

|

150 |

0 |

|

0 |

2 1/2 |

65 |

Drain Kit |

3 |

|

75 |

'01 |

|

'01 |

0 |

0 |

Hardwire Kit |

3 |

|

75 |

1 1/4 |

|

30 |

0 |

0 |

1If inside mounted then B = 1 1/2 inches (40 mm)

2To achieve a flush fit between the hydronic front and the finished wall, Dimension “C” must be between 3” and 3 1/8”. If this dimension is more than 3 1/8” there will be a gap between the front and the wall. This gap could permit occupant access to hydronic lines or other dangerous parts. For flush

mounts, internal drain kits or flashing are required to prevent leaking from external drains into space. See drain kit installation for details on sleeve positioning for internal drain kits.

3 This dimension can be from 0” to 3-1/4”, but cannot exceed 3-1/4”. If this dimension exceeds 3-1/4”, the skirt around the front will not reach the floor.

Table 1

2

Loading...

Loading...