Amana PGA60C0902*, PGB24C0452, PGB24C0702, PGB24C0902, PGB30C0702 Service Instructions Manual

...

Service

Instructions

PHB**C, PHD**C PACKAGE HEAT PUMPS

PGA**C, PGB**C, PGD**C P ACKAGE GAS

& PCC**C P ACKAGE COOLERS

Models listed on

Page 6

®

to Goodman Company, L.P. All rights reserved. Copyright © 1999-2007 Goodman Company, L.P.

is a trademark of Maytag Corporation and is used under license

This manual is to be used by qualified, professionally trained HVAC

technicians only. Goodman does not assume any responsibility for

property damage or personal injury due to improper service

procedures or services performed by an unqualified person.

RS6300003 Rev. 1

January 2007

INDEX

IMPORT ANT INFORMA TION ........................................................................................................ 4

PRODUCT IDENTIFICATION ........................................................................................................ 6

ACCESSORIES............................................................................................................................. 9

LIGHTING INSTRUCTIONS ........................................................................................................ 13

PRODUCT DESIGN .................................................................................................................... 19

ELECTRICAL WIRING ................................................................................................................ 20

LINE VOL TAGE WIRING ............................................................................................................ .20

GAS SUPPLY AND PIPING......................................................................................................... 21

SYSTEM OPERATION ................................................................................................................24

SCHEDULED MAINTENANCE ................................................................................................... 30

SERVICING ................................................................................................................................. 31

S-1 CHECKING VOLTAGE..............................................................................................................35

S-2 CHECKING WIRING.................................................................................................................35

S-3 CHECKING THERMOSTAT, WIRING, AND ANTICIPATOR .................................................... 35

S-3A Thermostat and Wiring ............................................................................................................35

S-3B Cooling Anticipator...................................................................................................................35

S-4 CHECKING TRANSFORMER AND CONTROL CIRCUIT......................................................36

S-6 CHECKING TIME DELAY RELAY ............................................................................................ 37

S-7 CHECKING CONTACTOR AND/OR RELAYS ......................................................................... 37

S-8 CHECKING CONTACTOR CONTACTS..................................................................................37

S-9 CHECKING FAN RELAY CONTACTS ..................................................................................... 37

S-15 CHECKING CAPACITOR .........................................................................................................37

S-15A Resistance Check ....................................................................................................................38

S-15B Capacitance Check ..................................................................................................................38

S-16 CHECKING FAN AND BLOWER MOTOR............................................................................... 38

S-16B ECM/ICM Motors ......................................................................................................................39

S-16E Testing Interface Board ..........................................................................................................41

S-17 CHECKING COMPRESSOR WINDINGS ................................................................................45

S-17A Resistance Test .......................................................................................................................45

S-17B Ground Test..............................................................................................................................45

S-17D Operation Test .........................................................................................................................46

S-18 TESTING CRANKCASE HEATER ........................................................................................... 46

S-21 CHECKING REVERSING VALVE AND SOLENOID ................................................................47

S-22 REVERSING VALVE REPLACEMENT .....................................................................................47

S-24 TESTING DEFROST BOARD ..................................................................................................47

S-25 TESTING DEFROST CONTROL (30°/60°) .............................................................................49

S-50 CHECKING HEATER LIMIT CONTROL(S) ............................................................................49

S-52 CHECKING HEATER ELEMENTS ..........................................................................................49

S-53 OUTDOOR TEMPERATURE CONTROL ...............................................................................50

S-100 REFRIGERATION REPAIR PRACTICE ................................................................................... 50

S-101 LEAK TESTING ........................................................................................................................50

S-102 EVACUATION ............................................................................................................................50

S-103 CHARGING................................................................................................................................51

S-104 CHECKING COMPRESSOR EFFICIENCY .............................................................................52

S-105 THERMOSTATIC EXPANSION VALVE ....................................................................................52

2

INDEX

S-106 OVERFEEDING.........................................................................................................................52

S-107 UNDERFEEDING......................................................................................................................52

S-108 SUPERHEAT .............................................................................................................................53

S-109 CHECKING SUBCOOLING .....................................................................................................54

S-110 CHECKING EXPANSION VALVE OPERATION .......................................................................54

S-111 FIXED ORIFICE RESTRICTION DEVICES .............................................................................55

S-112 CHECKING RESTRICTED LIQUID LINE ................................................................................55

S-113 OVERCHARGE OF REFRIGERANT ........................................................................................55

S-114 NON-CONDENSABLES ...........................................................................................................55

S-115 COMPRESSOR BURNOUT ....................................................................................................55

S-200 CHECKING EXTERNAL STATIC PRESSURE ........................................................................56

S-301 TESTING AUXILIARY LIMIT.....................................................................................................57

S-302 CHECKING FLAME ROLLOUT SWITCH ................................................................................ 57

S-304 TESTING GAS VALVE...............................................................................................................58

S-306 CHECKING ORIFICES .............................................................................................................60

S-307 CHECKING GAS PRESSURE .................................................................................................. 60

S-308 CHECKING FOR DELAYED IGNITION ................................................................................... 61

S-309 CHECKING FOR FLASHBACK................................................................................................ 61

S-310 CHECKING PRESSURE CONTROL ......................................................................................61

S-311 HIGH ALTITUDE APPLICATION...............................................................................................66

S-313 TESTING IGNITION CONTROL MODULE ............................................................................66

S-314 CHECKING FLAME SENSOR .................................................................................................. 68

S-315 CHECKING HOT SURFACE IGNITER ....................................................................................70

WIRING DIAGRAMS.................................................................................................................... 71

3

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE

SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES FOR CONSUMERS AND SERVICERS

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

WARNING

T

O PREVENT THE RISK OF PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH,

DO NOT STORE COMBUSTIBLE MATE RIALS OR USE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY OF THIS APPLIANCE.

WARNING

G

OODMAN WILL NOT BE RESPONSIBLE FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR SERVICE PROCEDURES.

I

F YOU INSTALL OR PERFORM SERVICE ON THIS UNIT, YOU ASSUME RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY DAMAGE WHICH

MAY RESU LT.

M

ANY JURISDICTIONS REQU IRE A LICENSE TO INSTALL OR SERVICE HEATING AND AIR CONDITIONING EQUIPMEN T.

WARNING

HIGH VOLTAGE

ISCONNECT

D

INSTALLING THIS UNIT.

BE PRES ENT.

DAMAG E, PERS ONAL INJ URY OR DEATH.

POWER BEFORE SERVICING OR

ALL

MULTIPLE POWER SOURCES MAY

AILURE TO DO SO MAY CAUSE PROPERTY

F

To locate an authorized servicer, please consult your telephone book or the dealer

from whom you purchased this product. For further assistance, please contact:

CONSUMER INFORMATION LINE - AMANA® BRAND PRODUCTS TOLL FREE

1-877-254-4729 (U.S. only)

email us at: hac.consumer.affairs@amanahvac.com

fax us at: (931) 438- 4362

(Not a technical assistance line for dealers.)

(Not a technical assistance line for dealers.)

Your telephone company will bill you for the call.

4

Outside the U.S., call 1-931-433-6101.

IMPORTANT INFORMATION

SAFE REFRIGERANT HANDLING

While these items will not cover every conceivable situation, they should serve as a useful guide.

WARNING

REFRIGERANTS ARE HEAVIER THAN AIR. THEY CAN "PUSH OUT" THE

OXYGEN IN YOUR LUNGS OR IN ANY ENCLOSED SPACE.

POSSIBLE DI FFICULTY IN BREATHING OR DEATH:

•

EVER PURGE REFRIGERANT INTO AN ENCLOSED ROOM OR SPACE. BY

N

LAW, ALL REFRIGERANTS MUST BE RECLAI MED.

•

F AN INDOOR LEAK IS SUSPECTED, THOROUGHLY VENTILATE THE AREA

I

BEFORE BEGINNI NG WORK .

•

LIQUID REFRIGERANT CAN BE VERY COLD. TO AVOID POS SIBLE FROST-

BITE OR BLINDNESS, AVOID CONTACT WITH REFRIGERANT AND WEAR

GLOVES AND GOGGLES.

SKIN OR EYES, SEEK MEDI CAL HELP IMMEDIATELY.

A

•

LWAYS FOLLOW

AS POISONOUS GAS WILL BE PRODUCED.

I

F LIQUID REFRIGERANT DOES CONTAC T YOUR

EPA

REGULATIONS. NEVER BURN REFRIGERAN T,

TO AVOID

WARNING

TO AVOID POSSIBLE EXPLOSION:

EVER APPLY FLAME OR ST EAM TO A REFRIGERANT CY LINDER. IF YOU

•

N

MUST HEAT A CYLINDE R FOR FASTER CHARGING , PARTIALLY IMMERSE

IT IN WARM WATER.

NEVER FILL A CYLINDE R MORE THAN 80% FULL OF LIQ UID REFRIGERANT.

•

NEVER ADD ANYTHING OTHER THAN R-22 TO AN R-22 CYLINDER OR

•

R-410A TO AN R-410A CYLINDER . THE SERVICE EQUIPMENT USED MUST

BE LISTED OR CERTIF IED FOR THE TYPE OF REF RIGERANT USED.

TORE CYLINDERS IN A CO OL, DRY PLACE. NEVER USE A CYLIND ER

•

S

AS A PLATFORM OR A ROLLER.

WARNING

TO AVOID POSSIBLE EXPLOSION, USE ONLY RETURNABLE (NOT DISPOSABLE)

SERVICE CYLINDERS WHEN REMOVING REFRIGERANT FROM A SYSTEM.

ENSURE THE CYLINDER IS FREE OF DAMAGE WHICH COULD LEAD TO A

•

LEAK OR EX PLOS ION.

ENSURE THE HYDROST ATIC TEST DATE DOES NO T EXCEED 5 YEARS.

•

ENSURE THE PRESSURE RATING MEETS OR EXCEEDS 400 LBS.

•

WHEN IN DOUBT, DO NOT USE CYLINDER.

WARNING

WARNING

SYSTEM CONTAMINANTS, IMPROPER SERVICE PROCEDURE AND/OR PHYSICAL

ABUSE AFFECTING HERMETIC COMPRESSOR ELE CTRICAL TERMINALS MAY

CAUSE DANGEROUS SYSTEM VENTING.

The successful development of hermetically sealed refrigeration compressors has completely sealed the compressor's

moving parts and electric motor inside a common housing,

minimizing refrigerant leaks and the hazards sometimes associated with moving belts, pulleys or couplings.

Fundamental to the design of hermetic compressors is a

method whereby electrical current is transmitted to the compressor motor through terminal conductors which pass

through the compressor housing wall. These terminals are

sealed in a dielectric material which insulates them from the

housing and maintains the pressure tight integrity of the hermetic compressor. The terminals and their dielectric embedment are strongly constructed, but are vulnerable to careless compressor installation or maintenance procedures and

equally vulnerable to internal electrical short circuits caused

by excessive system contaminants.

T

O AVOID POSSIBLE INJURY, EXPLOSION OR DEATH, PRACTICE SAFE

HANDLING OF REFRIGERANTS.

In either of these instances, an electrical short between the

terminal and the compressor housing may result in the loss

of integrity between the terminal and its dielectric embedment. This loss may cause the terminals to be expelled,

thereby venting the vaporous and liquid contents of the compressor housing and system.

A venting compressor terminal normally presents no danger

to anyone, providing the terminal protective cover is properly

in place.

If, however, the terminal protective cover is not properly in

place, a venting terminal may discharge a combination of

(a ) hot lubricating oil and refrigerant

(b ) flammable mixture (if system is contaminated

with air)

in a stream of spray which may be dangerous to anyone in

the vicinity. Death or serious bodily injury could occur.

Under no circumstances is a hermetic compressor to be electrically energized and/or operated without having the terminal

protective cover properly in place.

See Service Section S-17 for proper servicing.

5

PRODUCT IDENTIFICATION

P G B 24 C 045 2 D

Product Type

Single Package

Cooling/Heating

Product Family

G - Gas/Electric

H - Heat Pump

C - Cooling

Product Series

A: 10 SEER Line

B: 11 SEER Line

C: 12 SEER Line

D: 13 SEER Line

Nominal Capacity

24: 24000 BTUH

30: 30000 BTUH

36: 36000 BTUH

42: 42000 BTUH

48: 48000 BTUH

60: 60000 BTUH

Engineering Revision

Voltage

2: 230V/60Hz/1ph

Heating Input

HEAT PUMPS

0: No heat installed

C: 10 kw heat installed

PACKAGE GAS

045: 45000 BTUH

070: 70000 BTUH

090: 90000 BTUH

115: 115000 BTUH

140: 140000 BTUH

Design Sequence

PGA60C0902*

PGA60C1152*

PGB24C0452*

PGB24C0702*

PGB24C0902*

PGB30C0702*

PGB30C0902*

PGB36C0702*

PGB36C0902*

PGB42C0902*

PGB42C1152*

PGB48C0902*

PGB48C1152*

PGB48C1402*

PGB60C0902*

PGB60C1152*

PGB60C1402*

PGD24C0452*

PGD24C0702*

PGD24C0902*

PGD30C0702*

PGD30C0902*

PGD36C0702*

PGD36C0902*

PGD42C0902*

PGD42C1152*

PGD48C0902*

PGD48C1152*

PGD48C1402*

PGD60C0902*

PGD60C1152*

PGD60C1402*

6

PHB24C02*

PHB30C02*

PHB36C02*

PHB42C02*

PHB48C02*

PHB60C02*

PHD24C02*

PHD30C02*

PHD36C02*

PHD42C02*

PHD48C02*

PHD60C02*

PHB24CC2*

PHB30CC2*

PHB36CC2*

PHD24CC2*

PHD30CC2*

PHD36CC2*

PCC24C02*

PCC30C02*

PCC36C02*

PCC42C02*

PCC48C02*

PCC60C02*

PRODUCT IDENTIFICATION

Package Gas Units

Model # Manufacturing # Description

ackage Gas (A) 10 Seer gas/elec tric units. New chass i s design with

PGA60C0902D

PGA60C1152D

PGA60C0902D

PGA60C1152D

PGA60C0902E

PGA60C1152E

PGA**C***2F

PGB**C***2D

P1217301C-P1217302C

P1220301C-1220302C

P1236201C-P1236202C

P1231901C-P1231902C

P1236309C-P1236313C

P1236408C-P1236411C

P1213601C-P1213608C

P1217201C-P1217207C

P

smaller footprint. PGA models have stronger blower perf ormance for down

shot applications .

P

ackage Gas (A) 10 Seer gas/e l ectric units. Changed from 26" fan blade to

22" fan blade to improve operating sound. PGA models have stronger blower

performance for down shot applications.

P

ackage Gas (A) 10 Seer gas/e l ectric units. Changed from Smart Valve

system to "DSI " direct spark ignition systems. PGA mode ls have stronger

blower performance for down shot applications.

P

ackage Gas (A) 10 Seer gas/el ectric units. Revised features include

alternate vendor for DSI ignition control, deletion of low voltage terminal

board (pigtail low voltage wire connections), alternate ID blower, and

alternate condenser fan/motor.

ackage Gas (B) 11 Seer gas/electri c uni ts. Ne w ch assis de si gn w ith

P

smaller footprint.

Gas Units

PGB**C***2D

PGB**C***2E

PGB**C***2E

PGD**C***2D P1204301C-P1204308C

PGD**C***2D

PGD**C***2E

PGD**C***2G

PGD**C***2G P1236522C-P1236529C

PGD**C***2X P1236530C-P1236533C

P1220201C-P1220207C

P1222201C-P1222208C

P1231701C-P1231708C

P1231801C-P1231807C

P1236401C-P1236407C

P1236301C-P1236308C

P1222301C-P1222308C

P1231402C-P1231407C

P1232001C-P1232008C

P1232101C-P1232107C

P1236501C-P1236513C

P1236514C-P1236521C

P1236608C-P1236613C

P

ackage Gas (B) 11 Seer gas/electric units. Changed from 26" fan blade to

22" fan blade to improv e operating sound.

P

ackage Gas (B) 11 Seer gas/electric units. Changed from Smart Valve

system to "DSI" direct spark ignition systems.

P

ackage Gas (B) 11 Seer gas/electric units. Upgraded with burner bracket

used on 90% gas furnaces.

P

ackage Gas (D) 13 Seer gas/electric units. New chassi s desi gn w i th

smaller footprint.

P

ackage Gas (D) 13 Seer gas/electric units. Changed from 26" fan blade to

22" fan blade to improv e operating sound.

P

ackage Gas (D) 13 Seer gas/electric units. Changed from Smart Valve

system to "DSI" direct spark ignition systems.

P

ackage Gas (D) 13 Seer gas/electr ic units. Changed from tan to new

architectrual gray/executive gray color.

P

ackage Gas (D) 13 Seer gas/electric units. Changed from TXV to Flowrator

on 2 - 3 1/2 ton models.

P

ackage Gas (D) 13 Seer gas/electric units. Introduce TXV equipped PGD

"2X" models 2 - 3 1/2 ton.

7

PRODUCT IDENTIFICATION

Model # Manufacturing # Description

ackage Heat Pump (B) 11 Seer heat pump units. New chassis design with smaller

PHB**C02D P1214402C-P1214404C

PHB**C02E P1204501C-P1214404C

PHB**C02E P1220101C-P1220106C

PHB**CC2E P1228101C-P1228103C

PHB**CC2E P1235801C-P1235803C

PHB**C02E P1235601C-P1235606C

PHB**C02E1 P1239207C-P1239212C

PHB**CC2E1 P1239904C-P1239906C

PHB**C02E1 P1239214C-P1239219C

P

footprint.

P

ackage Heat Pump (B) 11 Seer heat pump units. New chassis design with smaller

footprint. Improved heating capacity

P

ackage Heat Pump (B) 11 Seer heat pump units. Changed from 26" fan blade to

22" fan blade to improve operating sound.

P

ackage Heat Pump (B) 11 Seer heat pump units. New chassis design with smaller

footprint. With 10 K.W. factory installed heat strips.

P

ackage Heat Pump (B) 11 Seer heat pump units. Changed to Ranco Defrost

Board. Moved low pressure switch to suction side.

P

ackage Heat Pump (B) 11 Seer heat pump units. Changed to Ranco Defrost

Board. Moved low pressure switch to suction side.

P

ackage Heat Pump (B) 11 Seer heat pump units. Tubing redesigned to improve

serviceability and reduce the potential for distributor tubes rubbing and leaking.

P

ackage Heat Pump (B) 11 Seer heat pump units. Tubing redesigned to improve

serviceability and reduce the potential for distributor tubes rubbing and leaking.

P

ackage Heat Pump (B) 11 Seer heat pump units. Change to UTEC Defrost Board.

Moved low pressure switch to liquid line and changed pressure setting from 5 PSIG

to 15 PSIG. Moved ECM interface board to return air section.

Heat Pumps and Coolers

PHB**CC2E1

PHB**C02F1 P1239220C-P1239225C

HEA T PUMPS

PHB**CC2F1 P1239911C-P1239913C

PHD**C02E P1224301C-P1224305C

PHD**C02E P1235701C-P1235705C

PHD**CC2E P1228201C-P1228203C

PHD**CC2E P1235901C-P1235903C

PHD**C02E1 P1239706C-P1239710C

PHD**CC2E1 P1240004C-P1240006C

PHD**C02E1 P1239711C P

PHD**CC2E1 P1240007C

PHD**C02F1 P1239718C-P1239723C

PHD**CC2F1 P1240011C-P1240013C

P1239908C-P1239910C

P1240008C-P1240010C

P

ackage Heat Pump (B) 11 Seer heat pump units. Change to UTEC Defrost Board.

Moved low pressure switch to liquid line and changed pressure setting from 5 PSIG

to 15 PSIG. Moved ECM interface board to return air section.

P

ackage Heat Pump (B) 11 Seer heat pump units. Changed from tan to new

corporate colors.

P

ackage Heat Pump (B) 11 Seer heat pump units. Changed from tan to new

corporate colors.

P

ackage Heat Pump (D) 13 Seer heat pump units. New chassis design with smaller

footprint.

P

ackage Heat Pump (D) 13 Seer heat pump units. Changed to Ranco Defrost

Board. Moved low pressure switch to suction side.

P

ackage Heat Pump (D) 13 Seer heat pump units. New chassis design with smaller

footprint. With 10 K.W. factory installed heat strips.

P

ackage Heat Pump (D) 13 Seer heat pump units. Changed to Ranco Defrost

Board. Moved low pressure switch to suction side.

P

ackage Heat Pump (D) 13 Seer heat pump units. Tubing redesigned to improve

serviceability and reduce the potential for distributor tubes rubbing and leaking.

P

ackage Heat Pump (D) 13 Seer heat pump units. Tubing redesigned to improve

serviceability and reduce the potential for distributor tubes rubbing and leaking.

ackage Heat Pump (D) 13 Seer heat pump units. Scroll compressor.

ackage Heat Pump (D) 13 Seer heat pump units. Scroll compressor.

P

P

ackage Heat Pump (D) 13 Seer heat pump units. Changed from tan to new

corporate colors.

P

ackage Heat Pump (D) 13 Seer heat pump units. Changed from tan to new

corporate colors.

Model # Manufacturing # Description

PCC**C02E P1231101C-P1231106C

PCC**C02F P1231107-P1231112C

PCA**C02E P1234801C-P1234806C

COOLERS

PCA**C02F P1234807C-P1234811C

8

P

ackage Cooling (C) 12 Seer electric heat electric cooling units. New chassis design

with smaller footprint.

P

ackage Cooling (C) 12 Seer electric heat electric cooling units. Changed from tan

to new corporate colors.

P

ackage Cooling (A) 10 Seer electric heat electric cooling units. Changed from tan

to new corporate colors.

ackage Cooling (A) 10 Seer electric heat electric cooling units. New condenser

P

fan/motor.

ACCESSORIES

Additional Amana® brand accessories, as described below, can be purchased to fit specific application needs. Accessories

can be ordered by the following part numbers and each accessory includes its own separate instructions.

ACCESSORY PART NUMBER DESCRIPTION

Duct Transition Round RSDK01A (24-60)

Converts existing round duct connections to rectangular. Used to install

the ho rizont al duct cover kit on

heat pump units

.

Duct Transition

Over/Under

Roof Curbs

Horizontal Du ct Co ver

Kits

50°F Compressor

Lockout

Ambient Thermostat Kit ATK01

Compressor Sound

Blankets

Propane Gas Conversion

Kit

Electric He ater Kits

Single Point Wiring Kits

PDTR0U4A (Sm Chassis)

PDTR0U6A (LG Chassis)

PRC06A1

PRC07A1

PRC08A1

CHK001A

CHK002A

CHK601A (6 PACK)

LOK501A

CSB04A

CSB07A

CSB08A

CSB09A

LPTK07A

LPTK09

PHCB05C1

PHCB10C1

PHCB15C1

PHCB20C1

SPK04A

SPK05A

SPK06A

SPK07A

SPK08A

SPK09A

Converts existing side by side duct connections to over & under

ductwork. (F o r replacemen t p u r poses). Some Amana preceding unit s

had over & under ductwork. For use on

Roof top mounting/support system for package units. Must be used when

unit is installed in downflow applications. PRC06A fits

pump and coolers

is a combo roof curb adaptable to either footprint.

Block s off horizontal dis c h arge. Used for downflow ap p l ications. For use

on

all Amana® brand Packa ge Units.

Prevents mechanical cooling at ambients below 50°F. For use on

Amana® brand Package Units.

This kit controls the staging of electric heat and allows supplemental

heat to be energized only when a set outdoor temperature is reached.

This will allow the system's heat output to more closely match the

building's load. For use on

Compressor sound blankets reduce the ambient noise level of the

package units. Used in installations where extra quite operation is

desired. For use on

Converts

4.8KW 1ph - 30 Amp Circuit Breaker

9.6KW 1ph - 50 Amp Circuit Breaker

14.4KW 1ph - 30 & 50 Amp Circuit Breakers

19.2KW 1ph - 2-50 Amp Circuit Breakers

For use on

Single point wiring kit allows one electrical supply connection to power

both heater kit and package unit. For use on

package units

packa ge gas units

heat pum p and cooling package units

. PRC07A1 fits Package gas/electric units. PRC08A1

.

.

heat pump and cooling package units

all Amana® brand Package Units.

from natural gas to propane gas operation

.

all Amana

®

brand Package Units.

Package heat

all

.

.

.

heat pu m p and cool ing

9

ACCESSORIES

Accessories

PHCB**C1

SPK**A

PRC06A1

PRC07A1

PRC07A1

PDTROU4A

PDTROU6A

P1219401C-P1219406C

P1219408C-P1219412C

P1221701C-P1221706C

P1221708C-P1221712C

P1219801C-P1219803C

P9850603C-P9850604C

ackage Heat kit with Circuit Breakers. Electric heat kits include breakers

P

for electric heat only.

ingle Point power connection Kit. Kit allows for one circuit to provide

S

power supply for package heat pumps (PHB/PHD**C) and coolers

(PCC**C). Kit includes circuit breaker for compressor.

ackage Roof Curb Kit. Accessory roof curb for roof top/down discharge

P

installations. PRC06A1 is designed for package heat pumps and coolers.

PRC07A1 is designed for package gas units. PRC07A1 is a combo curb

and will adapt to either footprint.

ackage Duct TRansition Over-Under kit. Transition converts side by side

P

to over-under duct connections. Early model Amana units (EPCG, EPHO,

EP, and PHK) had over-under duct connections.

THERMOSTATS

THSMEC1H2BA Manual changeover - 2 Stage Heat

THSADC1H2BA Auto changeover - 2 Stage Hea t

THSMDC1H2BA Manual changeover - 2 Stage Heat

THSMDC1H3BA Auto changeover - 3 Stage Hea t

1213401 Electronic programmable - 1 Stage Heat, 1 Stage Cool

1213403 Electronic non-programmable - 2 Stage Heat, 1 Stage Cool

1213404 Electronic non-programmable - 2 Stage Heat, 1 Stage Cool

1213405 Electronic programmable - 2 Stage Heat, 1 Stage Cool

1213701 Electronic programmable - 1 Stage Heat, 1 Stage Cool

1214901 Electronic programmable - 2 Stage Heat, 2 Stage Cool

C5200607 Manual changeover - 1 Stage Heat, 1 Stage Cool

M0380101 Manual changeover - 1 Stage Heat, 1 Stage Cool

D6853512 Auto changeover - 1 Stage Heat, 1 Stage Cool

D6853510 Auto changeover - 2 Stage Heat, 1 Stage Cool

D9945801 Manual changeover - 2 Stage Heat, 1 Stage Cool

D9807604 Electronic programmable - 1 Stage Heat, 1 Stage Cool

1213402 Manual Changeover - Nonprogrammable Digital - 1 Stage Heat, 1 Stage Cool

1213406 Manual/Auto Changeover - 5 + 2 Programming Digital - 3 Stage Heat, 2 Stage Cool

1213407 Manual Changeover - 5 + 2 Programming Digital - 2 Stage Heat, 2 Stage Cool

1213408 Manual/Auto Changeover -7 Day Programming Digital - 1 Stage Heat, 1 Stage Cool

1213410 Manual Changeover - 5 + 2 Programming Digital - 2 Stage Heat, 1 Stage Cool

1213411 Manual Changeover - Nonprogrammable Digital - 2 Stage Heat, 2 Stage Cool

1213412 Manual/Auto Changeover - 7 Day Programming Digital - 3 Stage Heat, 2 Stage Cool

1213431 Manual/Auto Changeover - 7 Day Programming Digital - 3 Stage Heat, 2 Stage Cool

10

ACCESSORIES

5

3

1

"

42

-

3/8

"

"

19

SUPPLY

-

3/

1

6"

1

9

-3

/

1

6"

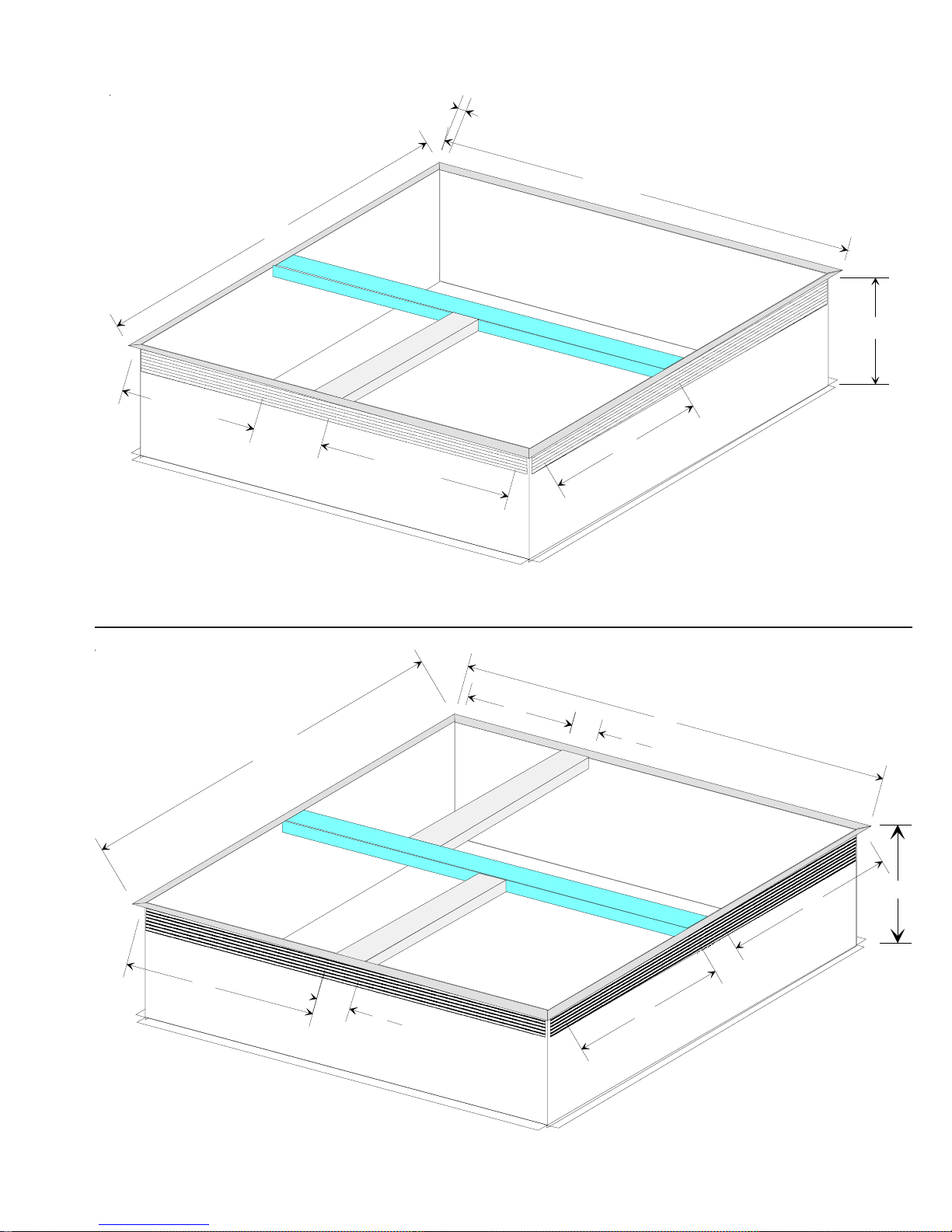

PRC06A1 ROOF CURB

"

8

/

3

-

2

4

SUPPLY

RETURN

1

2

"

"

9

1

4

7

"

2

"

14"

RETURN

2

5

"

"

5

2

"

2

"

PRC07A1 ROOF CURB

2

1

14"

11

ACCESSORIES

A

®

A

1

12

UNIT SUPPORT

47

14

42 3/8

24 3/8

2

RETURN

SUPPLY

14

14

35

INSULATED PLATFORM

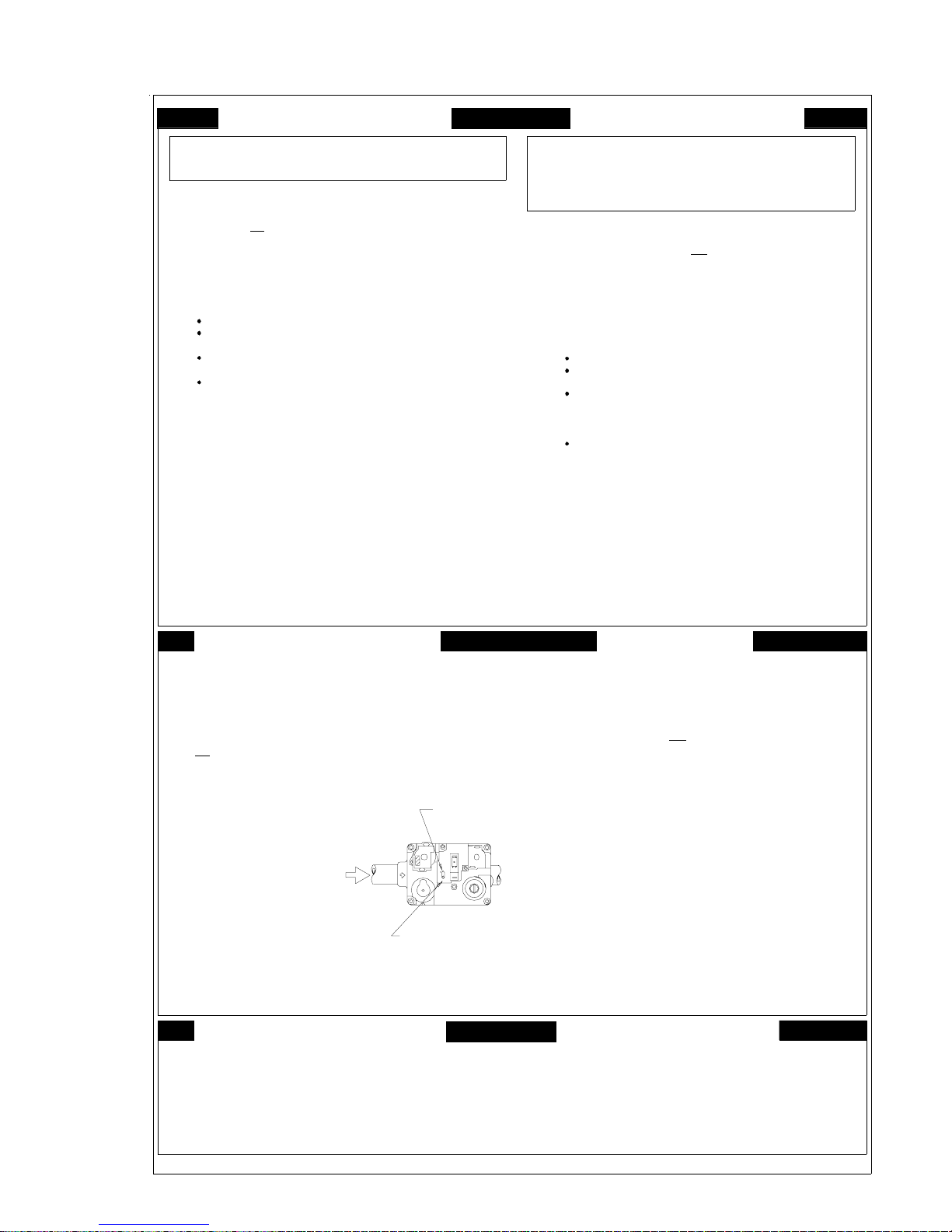

PRC08A ROOF CURB

J

H

B

D

A

G

F

E

1.00"

C

OVER/UNDER DUCT TRANSITION

AMAN

BRAND

MODEL

"A" DIM "B" DIM "C" DIM "D" DIM "E" DIM "F" DIM "G" DIM "H" DIM "J" DIM

PDTROU4A 42" 26 7/16" 12" 26 1/4" 15" 6 7/8" 20 11/16" 9/16" 9/16"

PDTROU6

42" 32" 12" 39 1/2" 15" 10" 20 11/16" 1" 9/16"

Duct Transition

Over/Under

PDTROU4A

PDTROU6A

12

Converts existing side by side duct connections to over/under ductwork.

(For replacement purposes. The Amana® brand's preceding units had

over/under ducts.)

LIGHTING INSTRUCTIONS

F

O

Y

O

R

R

E

B

A

E

D

F

If you do not follow these instructions

WARNING

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

is

T

h

A

.

w

ic

h

lig

o

t

B

.

B

E

F

a

a

e

r

c

e

b

t

t

e

s

H

A

T

W

D

D

D

m

I

h

p

f

I

a

c

C

U

.

n

o

e

s

N

e

v

e

r

,

d

n

a

h

ic

n

h

c

e

t

p

x

e

r

o

D

D

.

n

o

o

m

I

m

d

e

a

e

h

t

p

ys

m

s

e

t

li

p

p

a

n

a

o

t

u

a

h

e

h

t

t

h

O

R

E

a

g

r

o

f

so

e

s

u

a

o

le

h

t

n

D

T

O

O

tr

t

o

n

o

to

t

o

n

o

s

u

t

o

n

o

m

ia

d

e

.

e

n

o

F

a

c

u

o

y

ir

ll

f

th

e

r

u

o

y

ly

o

o

t

e

s

u

n

o

d

y

r

'

t

t

ia

F

.

n

o

lo

io

s

.

n

th

e

s

u

t

ia

te

c

ly

lia

p

e

c

n

a

a

d

n

ip

u

q

e

p

is

e

c

m

a

lig

ic

lly

a

t

y

b

ilo

p

t

h

d

n

a

O

P

E

R

N

A

T

I

o

t

e

r

u

B

s

.

e

s

is

s

h

a

g

m

e

.

lo

r

o

f

e

Y

O

S

U

F

I

lig

o

t

h

y

a

n

t

le

e

y

n

a

h

c

u

e

e

t

ll

o

n

e

h

ls

to

c

r

is

a

a

y

n

n

o

h

p

y

n

a

ll

a

c

u

o

y

ly

a

g

e

h

t

w

o

h

c

a

e

r

t

o

n

p

e

d

m

e

t

r

a

p

o

t

d

n

a

u

o

n

k

e

h

t

f

I

.

,

it

ir

a

p

e

r

te

m

t

a

r

o

e

p

p

a

lia

e

c

n

ll

lif

a

u

q

i

a

e

la

p

e

r

o

t

d

n

r

t

n

o

c

s

a

g

S

U

A

R

F

E

T

O

O

R

E

a

w

h

it

d

e

n

ilo

p

e

h

t

s

t

h

.

m

s

ll

e

a

G

m

s

ll

e

x

e

n

v

a

e

n

a

h

t

ie

r

G

M

A

E

L

L

lia

p

p

a

c

n

y

ic

s

r

h

w

c

it

t

c

e

r

u

o

y

in

s

a

g

r

lie

p

p

s

lie

p

p

u

s

s

's

r

s

s

a

g

r

u

o

y

.

t

n

n

in

r

u

h

s

t

r

o

b

w

ill n

p

t

o

ll

a

c

a

lif

a

u

q

a

p

e

r

d

e

t

p

ir

r

a

p

y

n

a

if

t

ic

v

e

s

d

r

e

e

c

r

a

p

y

n

a

w

l

ic

o

h

a

h

h

Y

P

E

N

R

A

T

I

G

ic

v

e

e

d

ig

io

it

n

n

.

t

t

o

n

D

o

y

r

t

p

p

a

e

h

ll a

t

d

n

u

o

r

lo

r

o

f

e

h

t

o

t

t

w

a

ill

ir

a

d

n

S

.

e

;

ild

u

b

in

.

g

i

e

n

a

m

fr

o

r

r

in

t

s

p

lie

p

r

g

e

h

t

in

h

s

u

ie

s

d

m

y

a

b

s

a

h

t

ic

n

h

c

e

h

t

f

o

t

e

e

b

s

b

h

g

io

.

s

n

t

c

u

,

c

s

a

l

tr

o

n

o

n

r

u

t

r

o

y

b

ic

v

e

r

e

lt

u

a

s

e

in

r

r

e

d

n

u

n

e

e

o

t

ia

n

in

p

s

tr

o

n

o

c

e

l

w

u

n

a

r

e

d

n

A

R

V

E

I

L

A

M

E

N

AVERTISSEMENT:

N

M

D

E

E

T

A

R

T

T

R

E

C

H

R

E

E

I

L

Ouiconque ne respcte pas `a

la lettre les instructions dans le present manuel risque

de declencher un incendie ou une explosion entrainant

des dommages materiels, des lesions corporelles ou la

perte de vies humaines.

m

il

e

t

s

e

r

a

p

p

a

C

t

e

A

.

i a

u

q

llu

li

e

c

n

a

's

r

o

.

b

o

n

k

e

ir

f

.

r

e

w

t

a

t

c

e

e

t

.

r

e

t

t

n

A

B

.

n

e

r

e

n

u

r

e

c

u

e

p

Q

U

C

N

.

e

q

u

S

i

p

e

r

t

n

e

d

e

N

e

D

.

d

a

c

e

t

m

e

r

to

u

to

u

a

m

m

e

'a

d

llu

d

N

m

e

d

n

a

l'e

la

c

la

m

r

e

D

N

E

T

t

u

o

t

r

n

N

A

S

u

u

o

a

t

u

e

d

r

u

e

a

g

s

z

a

g

n

o

s

s

m

'a

c

t

c

u

R

E

F

A

I

e

n

e

t

s

a

p

u

o

t

e

r

e

h

c

ilis

'u

n

t

r

e

u

a

le

e

p

p

im

r

m

e

lo

p

n

e

y

r

e

t

c

e

R

p

s

e

is

u

n

e

s

r

u

o

f

p

i

n

n

o

s

r

e

in

d

n

e

c

ie

.

s

r

e

s

s

o

t

u

o

m

ne

in

a

;

s

e

r

e

tt

e

n

a

le

e

p

p

a

r

;

r

la

r

e

c

r

o

f

e

e

e

n

u

r

e

h

c

v

r

e

s

e

s

s

u

a

m

o

c

,

u

ic

q

ie

n

a

t

u

o

t

r

e

c

m

o

m

d

n

a

r

e

V

A

le

if

o

in

a

t

e

v

E

p

o

la

'a

la

r

a

e

t

c

le

p

s

n

n

h

p

e

t

d

'u

d

i

n

u

n

iq

t

a

m

e

t

n

e

ille

e

v

s

m

e

R

F

A

I

E

L

l'a

a

e

d

p

p

r

R

le

.

if

z

n

e

r

t

d

lo

r

u

lu

p

s

le

r

iv

n

a

e

a

Y

L

S

'I

A

'a

d

llu

te

r

m

e

in

t

n

u

c

u

a

le

e

t

n

u

h

p

c

m

e

m

e

ia

d

e

t

le

t

n

a

le

e

t

p

a

r

t

le

la

t

e

.

z

a

g

d

e

r

n

o

p

e

r

n

e

e

m

la

r

e

n

r

u

ja

m

m

e

is

a

t

in

o

e

e

c

c

e

n

u

ic

n

h

c

e

t

m

t

e

n

a

o

e

t

lo

p

x

io

s

n

o

c

e

d

t

e

ir

m

e

le

p

n

e

t

in

r

u

o

lif

p

ie

a

p

u

d

ie

t

r

u

q

e

i o

t

n

'a

d

ll

if

is

it

s

o

p

e

v

la

u

n

a

E

ie

l

r

s

e

r

p

u

q

s

d

u

u

U

N

l'a

r

u

r

r

e

e

n

o

le

t

n

n

o

h

le

s

a

,

d

e

n

a

lo

p

e

e

n

,

ie

q

n

d

u

u

u

p

a

p

o

t

p

s

s

y

s

e

t

e

m

u

e

g

a

N

ille

e

.

e

s

u

lle

e

m

F

O

N

o

p

r

u

u

d

l'a

e

l.

o

s

O

E

p

a

p

u

e

t

p

r

n

a

d

u

o

f

u

d

e

u

r

in

t

s

p

le

e

p

d

e

t

t

'o

d

r

s

a

p

lif

a

ie

r

la

e

in

c

n

il

e

r

a

e

u

n

e

t

c

e

m

e

t

lo

p

s

a

p

.

t

n

e

O

C

N

T

I

N

E

R

le

e

c

e

d

l

p

e

h

c

n

a

t

e

ir

D

E

U

ie

l.

r

iq

r

le

e

t

c

s

a

b

le

is

n

e

s

r

u

is

o

v

in

n

io

s

n

t

c

er

s

le

r

'a

m

d

is

s

i

t

u

e

c

a

l

e

t

n

e

t

r

Q

.

ic

u

r

e

r

a

p

e

ie

d

n

e

.

e

'il

s

a

tie

r

a

p

r

l'a

p

p

c

e

d

e

o

d

s

e

g

n

,

r

ca

,

r

r

R

G

D

A

E

Z

;

e

u

im

t

t.

n

e

z

a

g

e

d

r

.

u

d

s

e

d

ic

v

e

z

a

g

u

d

io

n

.

t

e

f

f

e

t

la

e

d

o

e

u

q

n

u

e

p

t

lo

p

g

n

e

t

e

A

l

e

p

p

n

.

a

a

u

r

e

il

e

t

e

r

t

n

t

e

le

o

r

s

n

l

'e

.

u

a

O

P

E

R

A

.

1

S

T

O

P

R

.

d

a

S

.

2

T

.

3

T

.

4

e

d

D

o

T

.

5

"

O

W

.

6

m

s

e

h

t

in

y

if

e

n

T

.

7

u

o

c

R

.

8

T

.

9

o

p

S

.

0

1

1

1

I

.

fo

O

s

.

1

S

T

.

2

if

T

.

3

"

4

R

.

e

la

l.

e

is

b

h

t

e

u

h

u

o

f

e

u

w

f

ll

ff

e

s

O

m

s

o

r

e

h

t

e

h

t

t

n

o

r

ll

a

f

le

e

t

c

f

li

p

p

a

is

ic

v

e

n

o

t

n

r

F

F

a

f

it

ll

e

f

m

s

n

m

r

d

u

o

s

t

x

g

n

r

n

u

e

t

la

p

o

n

r

r

e

t

t

e

e

h

t

w

o

G

a

ic

v

r

T

h

t

t

e

r

u

n

v

r

e

n

r

u

F

la

p

e

is

e

c

n

a

w

ic

h

h

t

u

a

t

lig

o

h

t

y

r

t

o

c

s

a

g

e

h

io

it

.

s

n

o

p

"

m

in

)

5

(

iv

e

o

in

,

s

a

g

c

r

ll

e

,

s

a

g

S

b

a

io

n

t

a

v

o

m

s

ll

e

't

n

o

.

p

e

t

l

o

r

t

n

o

c

s

a

lo

w

c

k

is

c

e

r

e

c

s

s

e

c

c

a

ll

a

n

le

e

t

c

p

p

a

e

h

t

o

t

t

a

m

t

s

o

r

e

h

lia

p

p

a

e

c

n

t

c

r

in

t

s

e

h

t

s

A

lia

p

p

T

o

e

t

e

ch

ic

n

ia

T

U

O

R

N

m

o

r

e

h

t

e

ll

a

f

le

e

f

o

ic

o

t

is

e

g

e

h

t

c

s

a

io

it

s

o

p

F

"

r

c

e

c

t

n

o

N

S

T

N

G

T

I

f

a

s

e

h

t

lo

o

t

t

a

t

ic

p

r

w

o

ip

u

q

e

ic

m

o

t

a

p

e

h

t

t

o

r

t

n

n

k

l

D

o

o

n

t

o

t

s

e

lu

in

d

g

T

O

P

.

h

n

o

t

e

g

,

s

a

g

b

o

n

k

o

t

l.

e

n

a

p

ic

l

a

r

lia

e

c

n

d

o

t

s

e

w

ill

n

T

"

io

s

n

"

e

c

n

g

r

o

n

O

F

t

ta

s

t

tr

ic

c

a

e

p

e

b

o

r

t

n

o

D

.

n

o

c

a

l

o

c

R

I

U

in

y

t

e

w

s

e

o

t

r

e

d

e

p

lly

a

lig

ilo

b

t

c

b

o

c

r

o

f

t

le

c

r

a

r

a

e

n

llo

F

o

la

is

o

t

o

O

N

"

.

s

d

e

ir

o

p

o

t

T

o

u

d

n

a

o

c

s

a

G

F

lo

o

w

w

o

p

l

m

r

o

f

r

o

n

k

l

t

o

n

s

s

e

C

O

N

T

I

S

.

1

A

R

R

E

T

f

io

m

t

r

a

o

in

.

g

t

t

e

s

t

lia

p

p

a

e

h

t

w

ith

a

ig

n

e

h

t

s

t

h

.

d

n

a

h

y

lo

w

k

is

c

e

.

e

g

y

n

a

o

t

h

t

lo

f

e

r

o

w

in

B

"

"

l.

e

b

.

"

in

.

g

t

t

e

,

e

t

a

r

e

n

r

a

c

ll

r

u

o

y

m

n

a

p

.

y

T

O

A

S

t

t

e

s

t

s

e

h

t

o

t

r

e

.

d

e

lo

c

c

b

w

k

f

.

e

c

r

o

l.

e

n

a

p

n

o

e

v

o

b

a

n

.

e

c

n

io

it

n

n

ilo

p

.

t

o

t

n

e

T

h

.

s

a

u

o

y

f

I

.

y

t

e

f

a

s

e

h

t

R

O

M

A

"

ON

A

P

P

in

e

is

A

I

L

.

g

lia

p

p

a

e

c

n

o

t

e

G

A

A

N

E

T

B

I

P

E

O

N

N

U

E

,

L

O

M

N

A

/

R

C

H

E

OFF

M

K

I

N

C

N

I

A

R

R

D

U

A

N

G

U

A

L

N

O

B

S

H

O

P

O

N

"

"

N

O

E

la

.

2

R

C

o

.

3

C

e

.

4

llu

a

'a

d

T

o

.

5

'u

d

N

A

t

.

6

a

g

la

p

A

Z

S

"

G

A

S

E

L

T

V

E

E

I

G

A

Z

A

S

N

W

S

u

s

S

T

o

.

7

ig

a

R

e

.

8

M

.

9

R

.

0

1

1

S

.

1

i

in

e

d

u

q

.

1

R

e

C

.

2

fa

T

o

.

3

'u

d

N

.

4

R

e

E

p

u

s

io

n

t

r

o

p

r

e

h

t

le

le

g

e

r

u

l'a

r

e

p

lim

e

p

a

t

il e

e

r

a

p

t

u

a

m

e

m

o

v

llu

la

m

r

e

in

b

o

r

le

r

e

n

r

e

e

t

z

R

r

'il

u

e

e

l'a

s

a

e

r

m

t

n

o

e

n

e

c

fo

r

s

a

p

in

c

q

e

r

d

n

R

e

.

ifle

n

r

o

p

,

r

e

h

c

n

u

R

E

T

E

R

.

!

io

n

t

r

o

p

la

as

p

a

'y

n

b

o

r

le

r

e

n

r

ille

u

'u

d

n

s

e

r

t

m

t

e

p

n

e

l'a

e

p

p

r

t

t

a

r

e

h

t

le

le

g

r

il

e

n

r

a

p

p

in

io

s

n

t

u

c

r

t

a

g

l'a

e

d

p

z

lifie

o

le

u

P

O

U

e

h

t

le

le

g

r

o

l'a

lim

r

e

p

u

r

p

t

u

e

m

e

d

e

c

o

r

e

n

r

u

r

le

m

e

n

tr

n

o

e

c

fo

r

s

a

p

e

e

n

r

tt

e

E

S

M

E

I

L

.

R

!

le

u

r

e

m

ta

s

o

tio

a

t

n

m

u

t

s

iq

e

u

t

a

ille

e

u

t

e

a

.

r

m

)

5

(

a

t

u

o

t

c

e

d

r

s

P

s

a

e

p

u

s

'o

d

e

d

a

in

t

e

m

n

o

e

la

e

c

il

e

o

s

r

m

o

a

t

s

m

e

s

e

le

u

it

t

il

e

r

a

p

n

r

u

o

f

C

R

G

D

E

m

s

o

r

a

t

n

e

d

a

r

in

b

o

e

e

.

r

la

p

c

e

M

N

A

R

C

H

E

io

n

t

u

c

r

in

t

s

le

s

is

z

e

r

d

e

a

t

e

n

d

i

n

m

e

m

e

s

z

a

g

e

in

t

u

u

o

t

u

le

e

r

r

e

a

r

ie

u

d

r

u

a

g

e

r

t

p

le

s

u

t

a

t

e

s

e

t

e

is

e

s

O

A

a

t

t

tio

s

e

a

t

n

e

le

iq

u

t

e

e

et

c

t

e

t

a

m

e

r

e

p

t

la

le

t

c

e

d

iq

e

u

r

is

d

'u

n

it

s

o

p

t

n

ille

e

v

la

u

lle

e

u

n

a

m

e

l

s

n

a

d

s

e

n

e

i

s

o

p

n

io

n

t

O

"

p

s

e

la

is

s

r

u

o

l'a

e

d

p

r

u

l'

e

r

g

e

z

n

a

e

t

la

a

p

C

a

r

u

U

Z

a

n

p

o

g

p

p

r

a

p

d

r

u

e

d

o

e

n

d

B

e

p

a

t

e

e

e

t

t

e

c

e

d

s

s

a

p

,

z

a

d

e

s

le

s

n

a

e

s

o

p

n

d

u

a

e

n

'a

c

io

s

n

.

n

te

t

a

m

r

e

p

m

e

s

r

a

n

o

c

m

m

t

n

e

e

p

p

n

u

le

r

z

a

g

e

d

.

P

L

E

R

L

D

E

'A

m

e

e

p

t

la

e

iq

e

u

r

le

t

c

i

t

a

r

e

s

n

o

n

a

d

z

a

le

s

io

it

s

n

o

"

d

u

a

e

n

n

a

e

s

e

d

s

te

.

t

e

lu

p

la

s

e

r

u

l'a

il.

e

r

a

p

p

'a

d

llu

if

m

a

s

a

p

N

e

.

e

s

.

t

n

e

d

s

ig

a

u

s

A

R

R

F

F

/

ec

p

p

a

h

r

e

m

o

c

p

y

il,

e

S

i

.

z

a

g

e

t

c

u

in

s

r

e

t

s

e

t

iq

t

e

u

t

.

l'e

e

p

a

a

t

r

e

in

er

v

e

s

n

s

O

M

N

"

A

/

.

s

e

c

d

e

r

u

e

ir

s

e

iv

u

s

,

e

h

c

e

r

l'a

m

d

r

e

p

u

o

i

n

h

c

e

t

ie

c

n

'A

D

S

M

I

P

P

A

R

la

e

r

u

t

a

r

l'a

e

d

p

p

tie

e

r

'e

d

t

n

e

d

s

n

e

s

A

O

R

F

F

/

s

e

'a

c

c

.

r

u

s

e

it

r

u

c

.

e

s

s

a

b

i

u

q

e

g

r

e

t

n

e

t

ille

s

E

T

"

to

r

e

le

t

u

s

e

r

p

is

r

u

d

le

'e

c

t

s

c

,

s

a

e

it

s

r

e

u

d

u

c

e

io

s

n

.

e

s

lv

u

t

n

a

e

d

s

R

C

H

.

E

"

.

e

le

s

is

io

s

n

O

S

I

N

L

E

I

lu

p

e

r

a

.

n

s

R

.

e

s

s

a

b

s

il

'il

s

ig

a

ille

u

s

E

.

T

"

0

7

2

7

0

1

1

5

13

LIGHTING INSTRUCTIONS

F

O

R

Y

O

S

U

A

F

R

E

T

R

B

E

A

D

E

F

O

O

R

E

If you do not follow these instructions

WARNING

exactly, a fire or explosion may result causing propert y

damage, personal injury or loss of life.

T

h

is

A

.

w

h

ic

lig

o

t

B

.

B

E

F

e

a

a

r

b

e

c

t

e

t

s

H

A

T

W

D

D

D

m

I

p

f

I

a

c

C

.

o

U

e

s

N

e

r

e

v

a

h

d

n

d

,

e

t

h

n

ic

c

r

o

p

x

e

D

o

D

.

n

o

m

m

I

e

d

a

e

h

t

p

e

t

s

y

s

m

lia

a

p

p

c

n

is

e

a

a

u

to

m

h

tic

a

p

ilo

h

e

t

t

h

t

b

O

O

R

P

E

E

R

B

.

s

g

a

r

o

f

a

u

le

T

o

o

o

m

h

o

y

ll t

n

ly

u

ia

lo

u

t

ia

p

e

e

o

m

s

e

s

g

a

h

e

f

t

o

n

lo

o

r

D

O

O

F

I

Y

lig

o

t

y

r

t

n

o

t

o

lia

a

h

o

u

c

t

n

o

t

a

n

y

u

e

s

n

o

t

c

ly

e

e

d

ia

t

F

o

llo

w

n

e

.

r

t

a

n

n

o

c

o

u

p

d

e

e

ir

f

h

e

h

y

u

r

o

a

n

d

t

f

o

ls

o

I

.

t

e

s

s

a

e

r

o

t

y

r

t

n

't

o

e

c

F

o

r

n

.

io

.

n

a

p

p

h

is

t

e

s

t

q

a

ll

c

a

e

ly

t

a

n

d

e

c

n

g

a

s

n

d

a

n

y

w

q

u

e

lly

h

y

A

u

r

s

s

.

O

U

t

h

n

y

p

a

ll

h

e

t

a

e

a

r

o

t

h

e

p

a

a

r

lia

n

u

a

e

r

o

c

h

ip

a

T

e

is

a

e

h

y

c

m

t

p

k

ir

e

t

t

c

lif

p

o

a

it

d

e

p

lig

n

I

t

h

S

n

le

o

o

a

g

h

e

u

n

it

m

e

ie

la

t

n

n

h

e

p

ilo

t

s

h

t

d

.

e

ll

m

s

N

G

m

s

e

ll

o

n

e

x

h

a

n

t

ie

e

a

v

r

G

M

A

E

L

L

p

p

lia

a

n

c

y

w

h

s

c

it

ic

r

t

c

n

u

s

o

,

r

o

u

r

y

in

e

s

s

g

a

p

lie

p

r

u

p

p

lie

s

's

r

s

s

s

g

a

r

o

u

y

.

t

n

u

r

t

o

r

in

h

p

w

ill

b

t

n

o

a

ll a

c

lif

q

u

a

e

d

r

a

ir

e

p

p

t

t

p

a

r

a

if

n

y

d

t

ic

v

e

e

r

s

e

c

p

a

r

n

y

a

l

o

w

h

a

h

ic

h

Y

P

E

R

A

N

G

T

I

ig

io

n

it

n

d

ic

e

v

D

.

t

a

ll

a

o

t

t

t

a

i

r

S

e

.

;

b

u

ild

r

f

r

in

s

p

p

lie

u

h

e

t

n

h

u

s

ie

d

m

a

a

s

h

h

n

e

c

t

o

f

t

b

s

e

e

o

y

r

t

n

o

t

t

o

u

n

d

r

h

a

in

o

r

t

in

s

y

b

ic

h

e

p

p

a

h

e

flo

e

r

o

w

ill

n

d

g

.

a

m

ig

b

o

h

n

e

t

u

c

io

.

n

s

,

r

g

a

s

k

o

n

tr

o

l

c

o

r

b

y

n

u

r

t

ic

v

e

r

e

lt

u

s

e

r

e

e

ia

e

n

ir

f

a

in

u

n

n

w

r

d

e

i

o

t

n

e

p

s

n

o

r

t

o

n

c

l

u

r

n

d

e

w

a

t

A

R

V

E

I

L

A

M

E

N

AVERTISSEMENT:

N

M

D

E

E

T

T

A

R

C

T

R

E

R

H

E

E

I

L

Ouiconque ne respcte pas `a

la lettre les instructions dans le present manuel risque

de declencher un incendie ou une explosion entrainant

des dommages materiels, des lesions corporelles ou la

perte de vies humaines.

e

il

e

s

p

p

a

r

a

C

e

t

A

.

u

q

lia

e

n

c

's

r

b

.

n

o

e

.

r

e

a

t

t

c

.

e

r

n

e

t

A

B

.

e

r

u

c

e

p

Q

N

C

.

q

S

r

e

t

d

N

D

.

d

e

t

e

r

to

u

a

a

llu

i

e

m

d

'a

llu

e

r

m

t

V

A

N

T

t

o

u

t

le

if

n

r

d

d

e

u

r

o

n

e

a

z

g

a

in

s

t

r

e

'a

s

e

n

t

u

v

F

U

A

I

E

p

N

e

o

t

N

e

ilis

n

'u

t

A

e

p

p

e

m

e

n

R

p

e

s

n

r

o

u

f

S

p

e

i

in

e

n

c

e

s

p

o

u

s

e

in

a

m

a

l

u

'a

i

la

t

a

n

e

m

e

a

p

;

e

r

p

a

r

r

o

f

d

e

e

n

t

e

c

le

h

e

r

n

c

e

e

s

s

a

p

s

n

a

l'e

u

a

h

c

ic

n

ie

n

m

la

p

r

e

c

c

e

t

u

m

o

m

d

'u

n

i

u

n

m

t

o

t

e

r

D

E

a

u

t

e

g

o

s

m

c

c

R

E

a

s

c

u

r

e

le

r

lo

p

t

e

c

is

s

o

s

r

ie

d

o

u

r

n

;

r

e

t

le

p

e

e

r

c

u

n

e

s

o

c

,

u

q

u

o

t

a

n

e

iq

m

e

m

a

t

e

ille

v

la

o

a

n

e

t

h

im

e

e

n

s

e

e

e

r

a

n

e

s

F

A

I

E

L

u

l'a

d

r

e

p

p

z

R

le

e

n

if

.

t

lo

lu

p

u

s

le

u

n

iv

e

a

r

S

A

Y

L

'I

d

'a

e

r

n

t

llu

a

u

e

r