Alto-Shaam ECO SMART 1200-TH-III, ECO SMART 1000-TH-III, ECO SMART 500-TH-III, ECO SMART 750-TH-III User Manual

US A/C A NA DA

U.S.A . O NLY

Cooking & Holding Oven

Electronic Control

Model:

500-TH/III

750-TH/III

1000-TH/III

1200-TH/III

1200-TH/III

500-TH/III

1000-TH/III

•INSTALLATION

•OPERATION

•MAINTENANCE

750-TH/III

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

p ri n te d in u .s . a .

www.alto-shaam.com

FAX: 262.251.7067 • 800.329.8744

M N - 2 8 8 5 2 • 0 4 / 1 1

Delivery ............................................................................. 1

Unpacking ......................................................................... 1

Safety Procedures and Precautions ................................... 2

Sanitation

Sanitation/Food Safety ............................................... 23

Internal Food Product Temperatures .......................... 23

Installation

Installation Requirements ............................................. 3

Clearance Requirements .............................................. 3

Dimension Drawings, weights & capacities ................ 4-7

Options and Accessories .............................................. 8

Stacking Configurations ............................................... 9

Leveling ..................................................................... 10

Restraint Requirements - Mobile Equipment ............... 10

Drip Tray Installation .................................................. 11

Electrical Specifications......................................... 12-13

Operating Instructions

User Safety Information .............................................. 14

Start-up Operation ...................................................... 14

Audible Signals .......................................................... 14

Control Features ........................................................ 15

Operating Features & Functions ................................. 16

Cook/Hold Instructions ............................................... 17

To Cook/Hold Using Preset Menu Keys ...................... 17

Programming a Preset ................................................ 18

Erasing a Preset......................................................... 18

User Options .............................................................. 19

General Holding Guidelines ........................................ 20

Care and Cleaning

Cleaning and Preventative Maintenance ..................... 21

Protecting Stainless Steel Surfaces ............................ 21

Cleaning Agents ......................................................... 21

Cleaning Materials ..................................................... 21

Equipment Care ......................................................... 22

Clean Daily ................................................................ 22

Clean the Door Vents ................................................. 22

Check Overall Condition of Oven ................................ 22

Service

Trouble Shooting - Error Codes .................................. 24

Trouble Shooting Electrical Components .................... 25

Exterior Service View & Parts - 500, 750, 1000 ..... 26-27

Exterior Service View & Parts - 1200 ..................... 28-29

Cable Heating Kits ..................................................... 29

Bonnet Assembly View & Parts - all mod els .......... 30-31

Wire Diagrams

Always refer to the wire diagram(s) included with the unit

for most current version.

Warranty

Transportation Damage and Claims ............. Back Cover

Limited Warranty .......................................... Back Cover

DELIVERY

UNPACKING

This Alto-Shaam appliance has been

thoroughly tested and inspected to ensure only

the highest quality unit is provided. Upon

receipt, check for any possible shipping damage

and report it at once to the delivering carrier.

See Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered

in one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to ensure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood

by all people using or installing the equipment

model. Contact the Alto-Shaam Tech Team Service

Department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

1. Carefully remove the

appliance from the

carton or crate.

®

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

Tech Team Service Department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al pg . 1

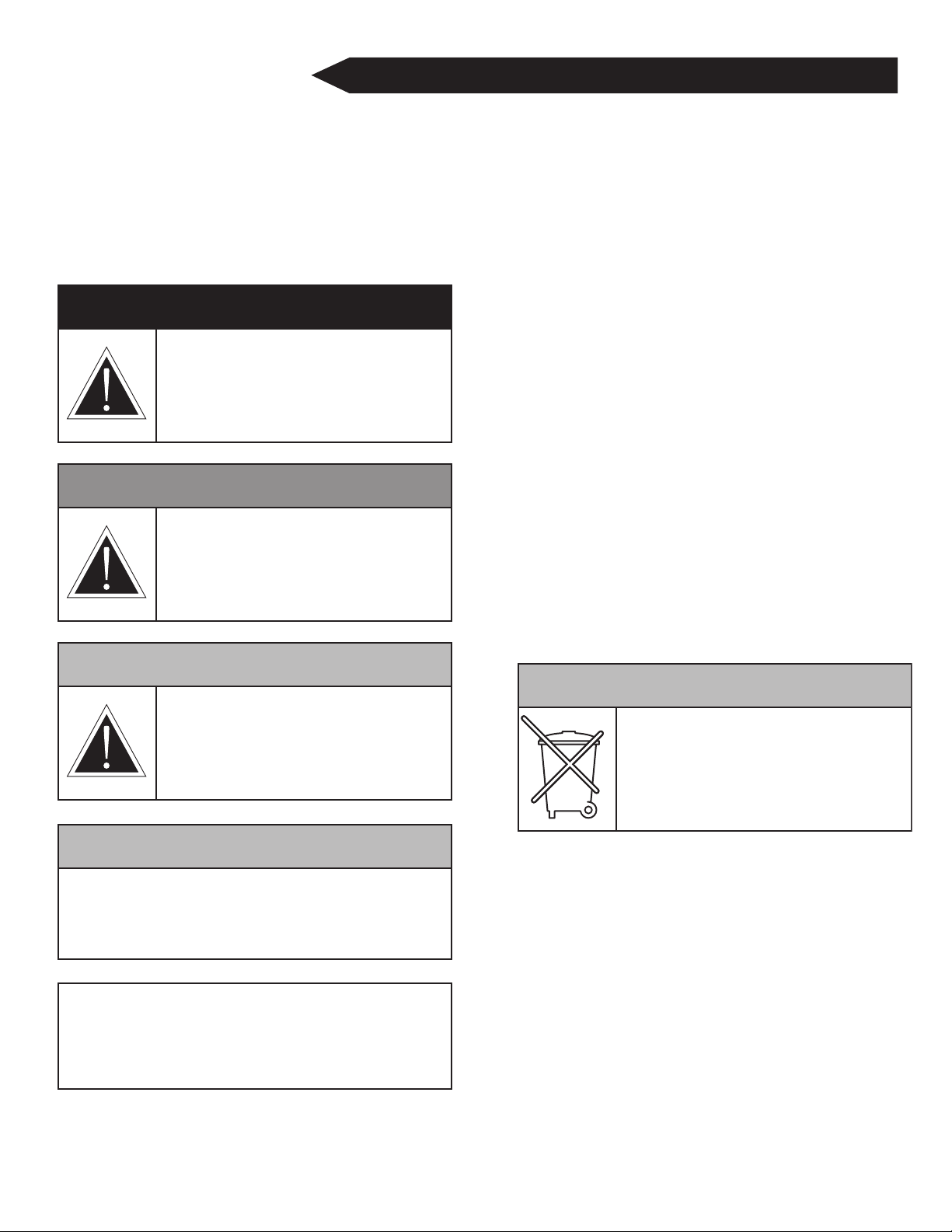

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

DANGER

Used to indicate the presence of

a hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of

a hazard that CAN cause personal

injury, possible death, or major

property damage if the warning

included with this symbol is ignored.

1. This appliance is intended to cook, hold

or process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are

familiar with the purpose, limitations, and

associated hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

CAUTION

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard that

can or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

NOTE: Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

NOTE

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

pg . 2 TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al

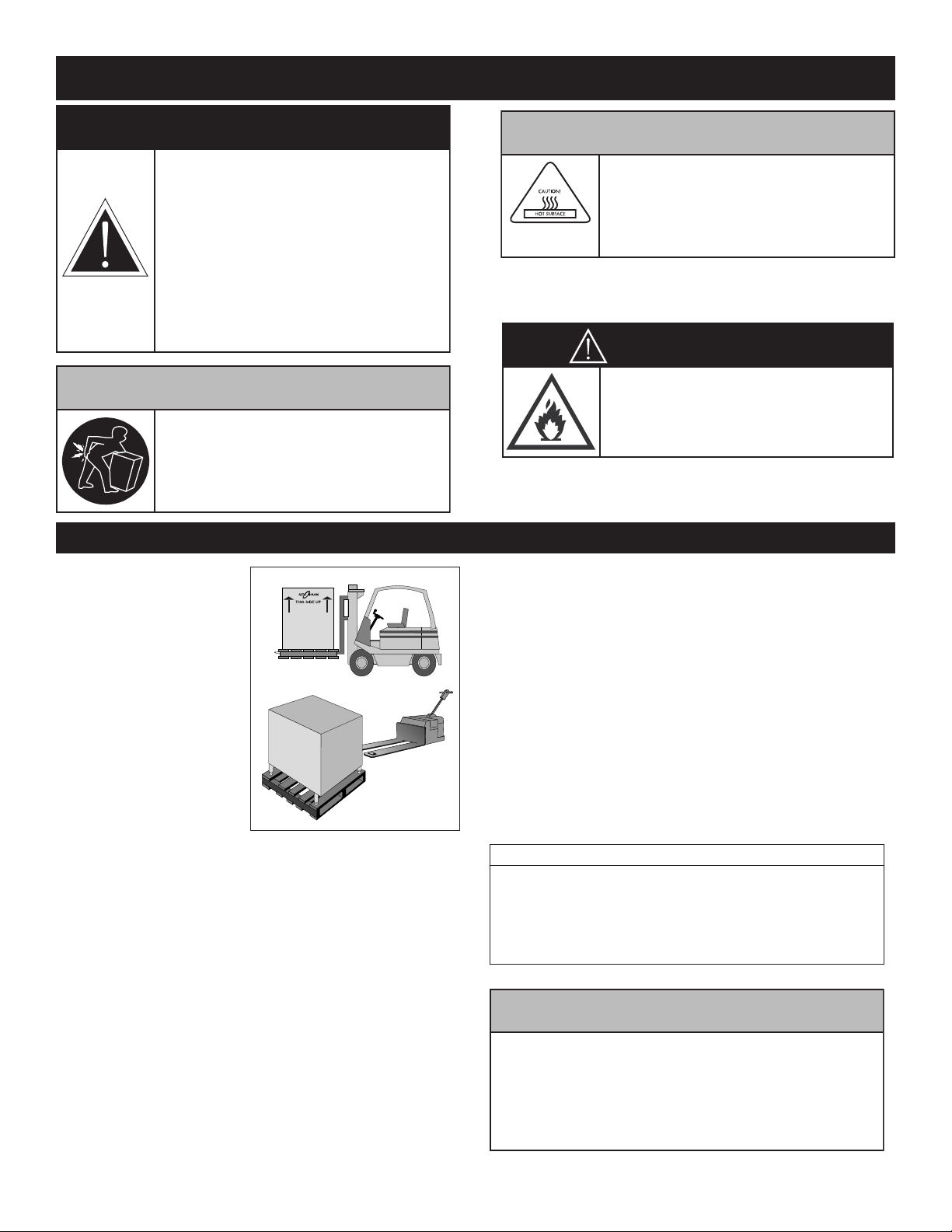

INSTALLATION

DANGER

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

CAUTION

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

The Alto-Shaam cook

and hold oven must be

installed in a location

that will permit the

oven to function

for its intended

purpose and to allow

adequate clearance

for ventilation,

proper cleaning, and

maintenance access.

CAUTION

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN

IN OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

DANGER

DO NOT store or use gasoline or other

fl ammable vapors or liquids in the

vicinity of this or any other appliance.

SITE INSTALLATION

®

Emissions testing conducted by Underwriters

Laboratories, Inc.® was found to be in compliance

with the applicable requirements of NFPA96:

2004 Edition, Par. 4.1.1.2. U.L emissions

sampling of grease laden vapor resulted in a total

of 0.55 milligrams per cubic meter with no visible

smoke and is considered representative of all

oven models in the line. Based on these results,

hood installation and/or outside venting should

not be a requirement in most areas. Verify local

codes for locations where more restrictive codes

are applicable.

1. The oven must be installed on a stable and

level surface.

2. DO NOT install this appliance in any area

where it may be affected by any adverse

conditions such as steam, grease, dripping

water, high temperatures, or any other severely

adverse conditions.

3. DO NOT store or use any flammable liquids or

allow flammable vapors in the vicinity of this

oven or any other appliance.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear

of any obstructions blocking access for

maintenance or service.

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al pg . 3

MINIMUM CLEARANCE REQUIREMENTS

18" (457mm) minimum clearance at the back from

heat producing equipment. To protect the electronic

control, maintain sufficient side clearance to prevent

the control area from reaching any temperature at or

above 140°F (60°C).

NOTE

If the appliance has been unplugged for an

extended period of time, the Real Time Clock may

require recharging. Turn main breaker to the unit

off for 10 seconds and then restore power.

For more information, see Error Code E-60 in

the Troubleshooting section of this manual.

SITE INSTALLATION

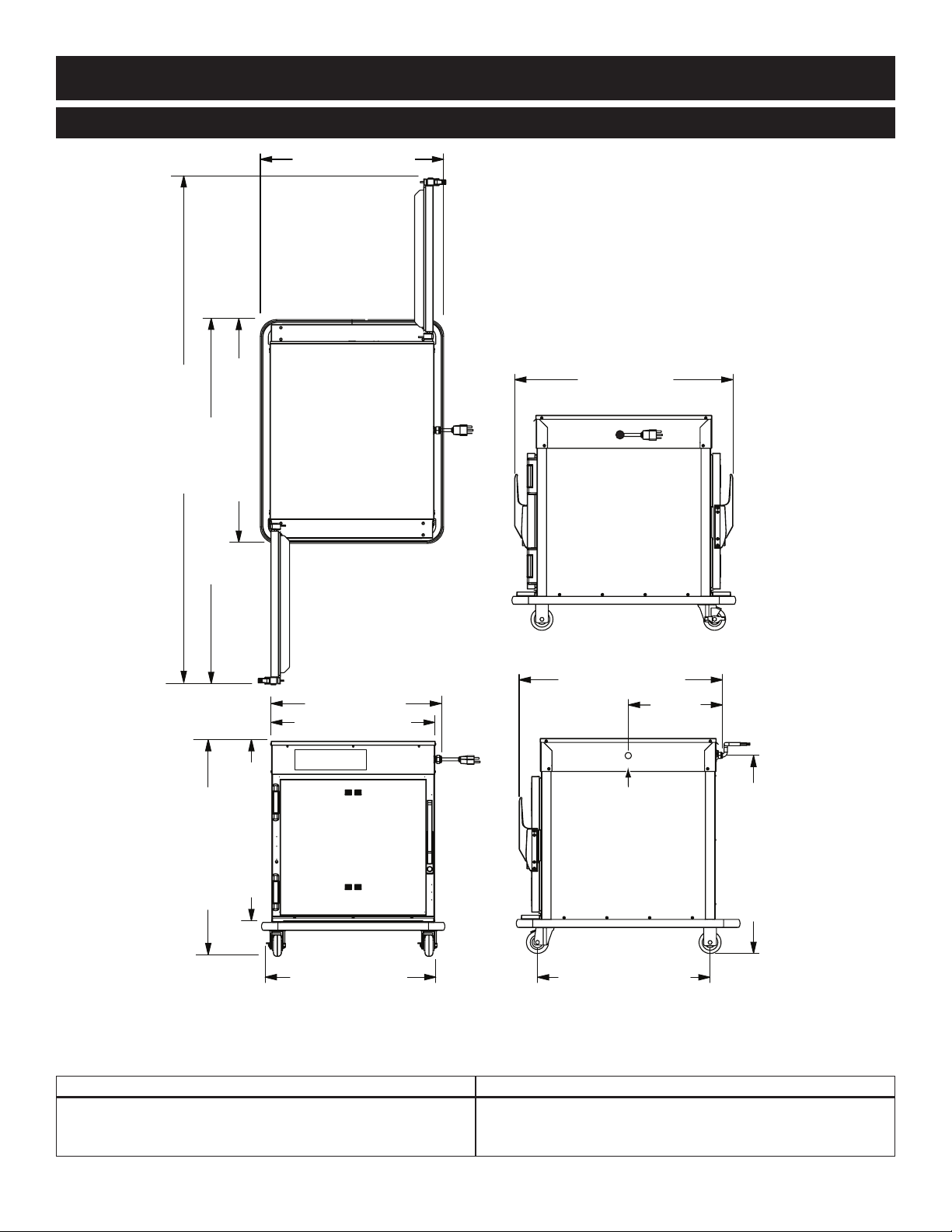

21" (532mm)

500-TH/III

44-1/16" (1118mm)

58-1/4" (1479mm)

INSTALLATION

Shown with

optional

bumper

29-7/8" (758mm)

with optional bumper

28-1/2" (724mm)

Pass-Through

Design

26-11/16" (678mm)

19-3/8" (492mm)

18-1/8" (460mm)

Connection

(Pass-Through)

28-1/4" (716mm)

33-1/2" (850mm)

with 3-1/2" (89mm) casters*

16" (406mm)

19" (482mm)

*31-13/16" (808mm) - with optional 2-1/2" casters

*35-1/4" (894mm) - with optional 5" casters

*34-7/16" (874mm) - with optional 6" legs

21-15/16"

(556mm)

12-3/16"

(310mm)

Electrical

Elec. Connection

30-13/16" (782mm)

WEIGHT

ne t: 125 lb (57 kg) es t.

sh ip : 150 lb (68 kg)

pg . 4 TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al

PRODUCT\PAN CAPACITY

40 lb (18 kg) ma xim u m

vo luM e M axi MuM : 30 q uar ts (38 l it ers )

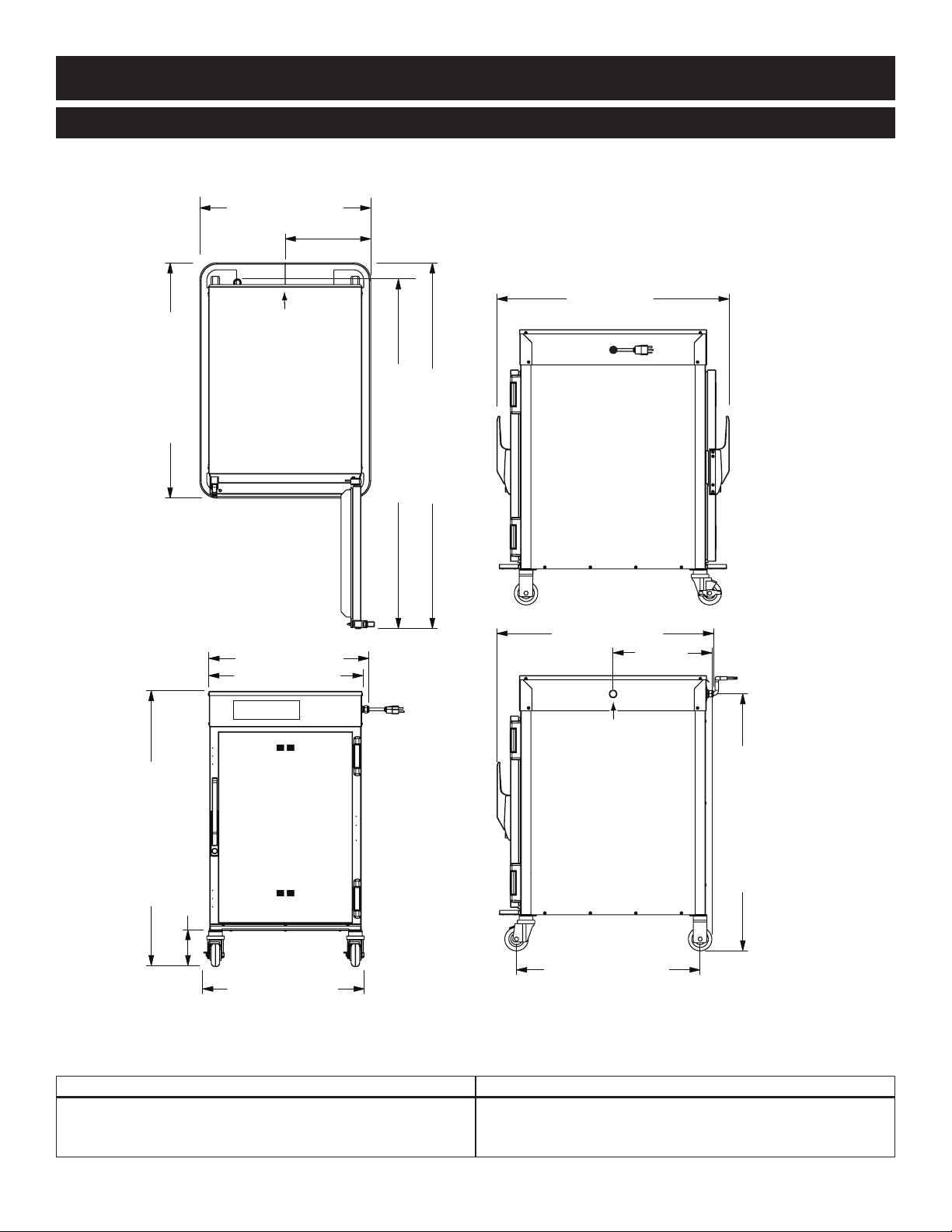

SITE INSTALLATION

28-5/8" (726mm)

750-TH/III

INSTALLATION

34" (864mm)

79" (2006mm)

34-7/8" (886mm)

Shown with

optional bumper

56-15/16" (1445mm)

25-3/4" (654mm)

28-1/4" (717mm)

33-1/2" (851mm)

with 3-1/2" casters*

27" (686mm)

Pass-Through

31-3/4" (805mm)

14-3/4"

(373mm)

Electrical

Connection

(Pass-Through)

30-7/8" (784mm)

(electrical connection)

26-5/8" (676mm)

26-15/16" (683mm)

*31-13/16" (807mm) - with optional 2-1/2" casters

*35-1/4" (894mm) - with optional 5" casters

*34-7/16" (874mm) - with optional 6" legs

WEIGHT

ne t: 192 lb (87 kg) es t.

sh ip : 258 lb (117 kg)

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al pg . 5

PRODUCT\PAN CAPACITY

100 lb (45 kg) ma xim u m

vo luM e M axi MuM : 75 q uar ts (95 l it ers )

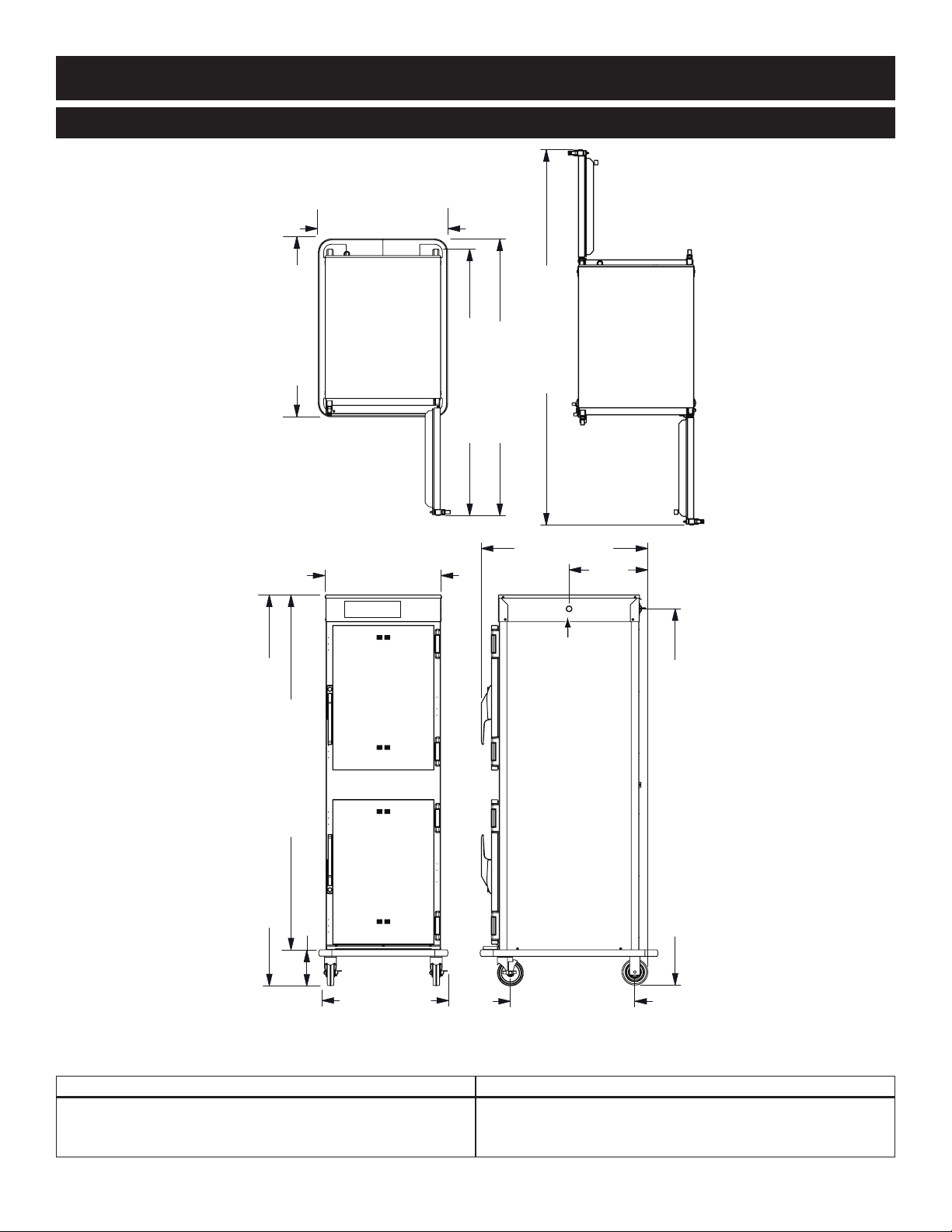

SITE INSTALLATION

1000-TH/III

25-1/16" (636mm)

Electrical

Connection

34-1/2" (876mm)

with optional bumper

12-9/16"

(318mm)

INSTALLATION

34" (864mm)

Pass-Through

Design

51-1/4" (1302mm)

53-5/8" (1361mm)

23-7/8" (606mm)

22-5/8" (574mm)

40-3/8" (1024mm)

5-5/16" (134mm)

with 3-1/2" (89mm) casters

23-1/2" (596mm)

*38-5/8" (980mm) - with optional 2-1/2" casters

*42" (1067mm) - with optional 5" casters

*41-1/4" (1046mm) - with optional 6" legs

31-3/4" (805mm)

14-1/2"

(367mm)

Electrical

Connection

(Pass-Through)

26-15/16" (683mm)

Elec. Connection

37-11/16" (957mm)

WEIGHT

ne t: 225 lb (102 kg) es t.

sh ip : 275 lb (125 kg)

pg . 6 TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al

PRODUCT\PAN CAPACITY

120 lb (54 kg) ma xim u m

vo luM e M axi MuM : 60 q uar ts (76 l it ers )

SITE INSTALLATION

1200-TH/III

INSTALLATION

25-1/16" (636mm)

with optional bumper

34-1/2" (876mm)

with optional bumper

Pass-Through

Design

72-3/4" (1847mm)

51-5/8" (1310mm)

53-5/8" (1361mm)

with optional bumper

22-9/16" (573mm)

68-13/16" (1747mm)

75-3/4" (1924mm) with 5" (127mm) Casters*

7" (177mm)

32-1/4" (819mm)

15-1/4"

(387mm)

Electrical

Connection

(Pass-Through)

72-15/16" (1852mm) to Electrical Connection

24-1/8" (613mm)

120 lb (54 kg) ma xim u m

vo luM e M axi MuM : 60 q uar ts (76 l it ers )

*74-3/8" (1889mm) - with optional 3-1/2" (89mm) casters

*75-3/4" (1924mm) approx. - with optional 6" (152mm) legs

WEIGHT

ne t: 402 lb (182 kg) es t.

sh ip : 432 lb (196 kg)

23-1/2" (596mm)

PRODUCT\PAN CAPACITY ( p er c oM p ar tM eN t)

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al pg . 7

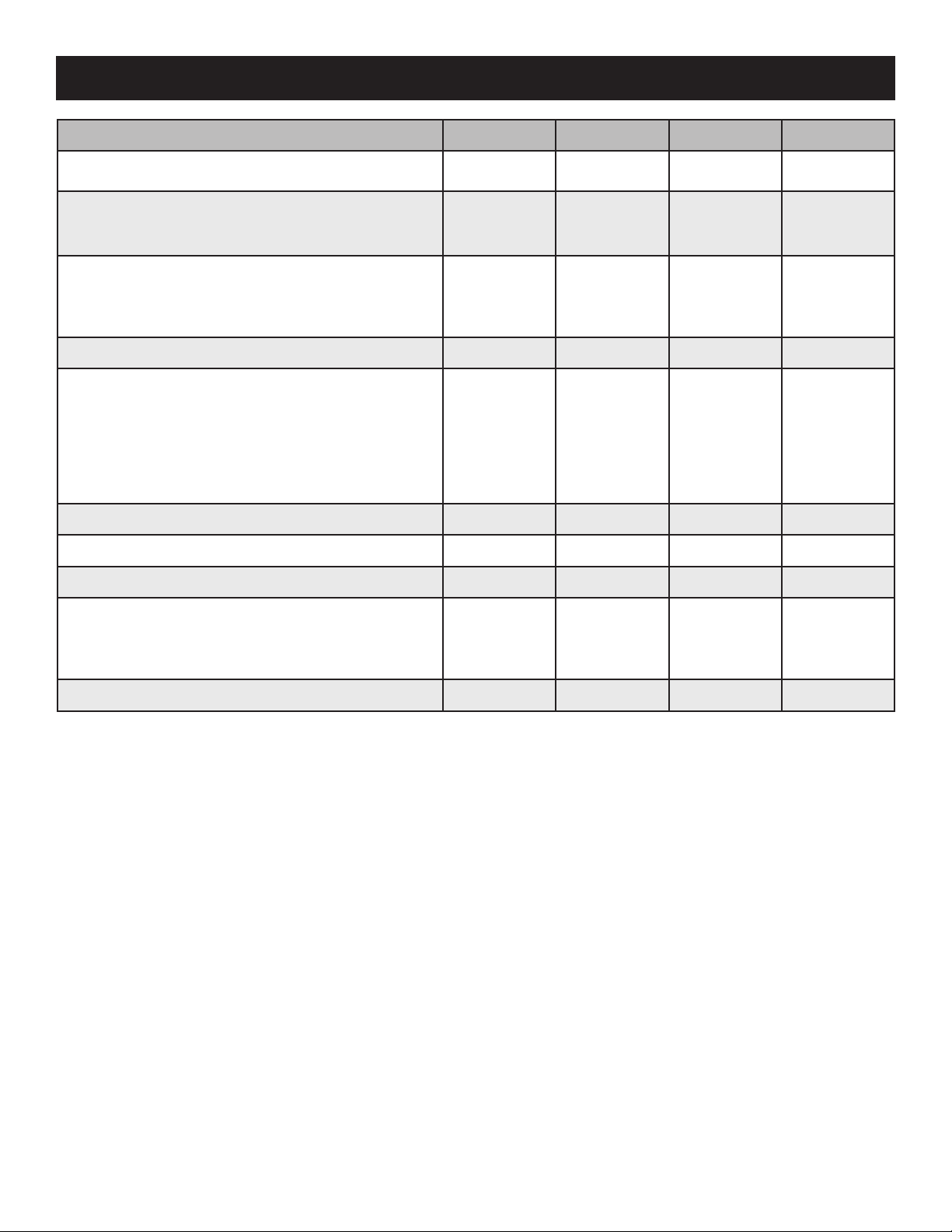

INSTALLATION

OPTI ONS AN D ACCESSORIES 500-TH/III 750-TH/III 1000-TH/III 1200-TH/III

Bumper, Full Perimeter

(N ot ava ilabl e wi th 2 -1/2" c aste rs)

5011161 5010371 5009767 5009767

Carving Holder

pr iM e rib

st ea Mship ( c af ete ri a) ro uN d

HL-2635

4459

HL-2635

4459

HL-2635

4459

HL-2635

4459

Casters - 2 ri gid, 2 s wivel w/brake

5" (127mm)

3-1/2" (89mm)

2-1/2" (64mm)

5004 862

st an dar d

5008 022

5004 862

st an dar d

5008 022

5004 862

st an dar d

5008 022

5004 862

st an dar d

—

Door Lock with Key LK-22567 LK-22567 LK-22567 LK-22567

Drip Pan

st aN dard wi th dr aiN 1-7/16 " (37mm)

st aN dard wi th dr aiN 1-11/1 6" (43mm)

st aN dard wi th dr aiN 1-7/8" (48mm)

wi th out d ra iN, 1-7/16" (37mm)

wi th out d ra iN, 1-7/8" (48mm)

ex tr a dee p, 4" (102 mm)

14813

—

—

11898

—

—

—

14831

—

—

—

—

—

—

5005616

—

11906

15929

—

—

5005616

—

11906

15929

Legs, 6" (152mm), Stemmed (se t o f f ou r) 5011149 5011149 5011149 5011149

Pan Grid, Wire - 1 8" x 26" pa N i Ns ert — PN-2115 PN-2115 PN-2115

Security Panel with key lock 5006787 5004750 5005776 5011592

Shelf, Stainless Steel

fl at wire , r ea ch-iN

fl at wire , p as s-t hr ough

ri b r ac k

SH-2326

SH-2326

—

SH-2324

SH-2327

SH-2743

SH-2325

SH-2346

SH-29474

SH-2325

SH-2346

SH-29474

Stacking Hardware 5004864 5004864 5004864 —

pg . 8 TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al

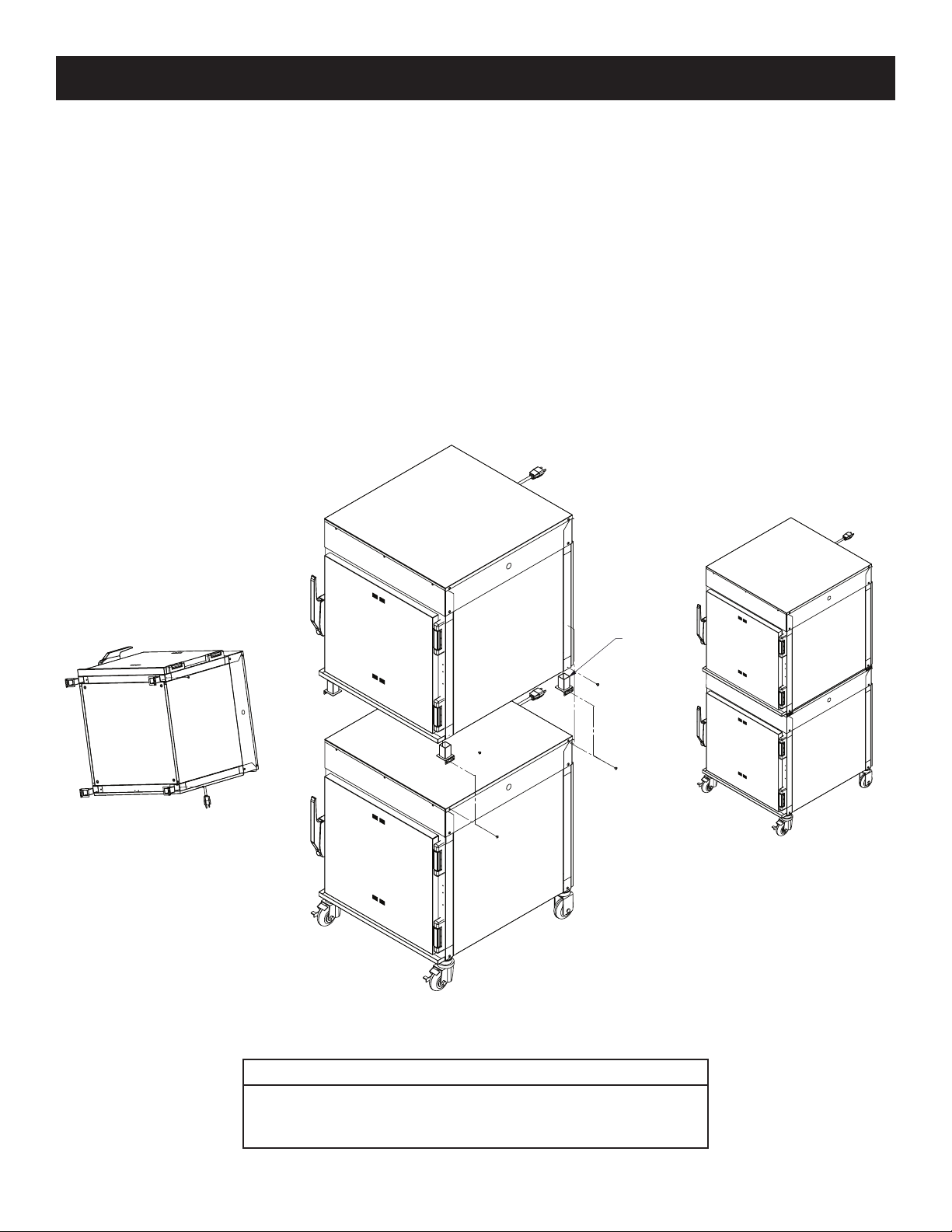

STACKING INSTRUCTIONS

1) If the two appliances were shipped together from the factory, the top unit will have the casters

already removed. A stacking kit will be included with the shipment.

If casters need to be removed: lay the unit on its back, and remove the set screw on each caster. Pull the casters

out of the unit.

2) While appliance is laid on its back, insert one stacking post in each of the four corners of the

upper unit. Secure the stacking posts using one screw and two fl at washers that come with the

stacking kit.

Note: The ange on the stacking posts must face the outside of the unit.

3) Remove the four top mounting screws from the lower unit. Place the upper appliance, which has

the stacking posts installed, on top of the bottom unit. Center the top unit from front to back.

Re-install the four screws through the fl ange of the four stacking posts.

INSTALLATION

STACKING

POSTS

CASTER SET SCREW

TOP

MOUNTING

SCREWS

TOP

MOUNTING

SCREWS

Stacking Configurations

1000-TH/III with 1000-TH/III, 1000-SK/III, 1000-SK/II or 1000-S

750-TH/III with 750-TH/III, 750-TH-II, 750-S, 767-SK or 767-SK/III

500-TH/III with 500-TH/III, 500-TH-II or 500-S

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al pg . 9

SITE INSTALLATION

INSTALLATION

A number of adjustments are associated with

initial installation and start-up. It is important

that these adjustments be conducted by a qualified

service technician. Installation and start-up

adjustments are the responsibility of the dealer

or user. These adjustments include but are not

limited to thermostat calibration, door adjustment,

leveling, electrical hook-up and installation of

optional casters or legs.

LEVELING

Level the oven

from side-to-side and

front-to-back with the use of a spirit level.

For ovens installed with casters, it is important

that the installation surface be level due to the

probability of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted nor the oven moved.

NOTE: Failure to properly level this oven can

cause improper function and will result

in the uneven baking with products

consisting of semi-liquid batter.

RESTRAINT REQUIREMENTS

—MOBILE EQUIPMENT

WARNING

RISK OF ELECTRIC SHOCK.

Appliance must be secured

to building structure.

Any appliance that is not furnished with a power

supply cord but that includes a set of casters

must be installed with a tether. Adequate means

must be provided to limit the movement of this

appliance without depending on or transmitting

stress to the electrical conduit. The following

requirements apply:

1. Maximum height of casters is 6" (152mm).

2. Two of the casters must of be the locking type.

3. Such mobile appliances or appliances on mobile

stands must be installed with the use of a flexible

connector secured to the building structure.

A mounting connector for a restraining device is

located on the upper back flange of the appliance.

A flexible connector is not supplied by nor is it

available from the factory.

pg . 10 TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al

INSTALLATION

WILL RESULT IN A LEAKAGE HAZARD

SITE INSTALLATION

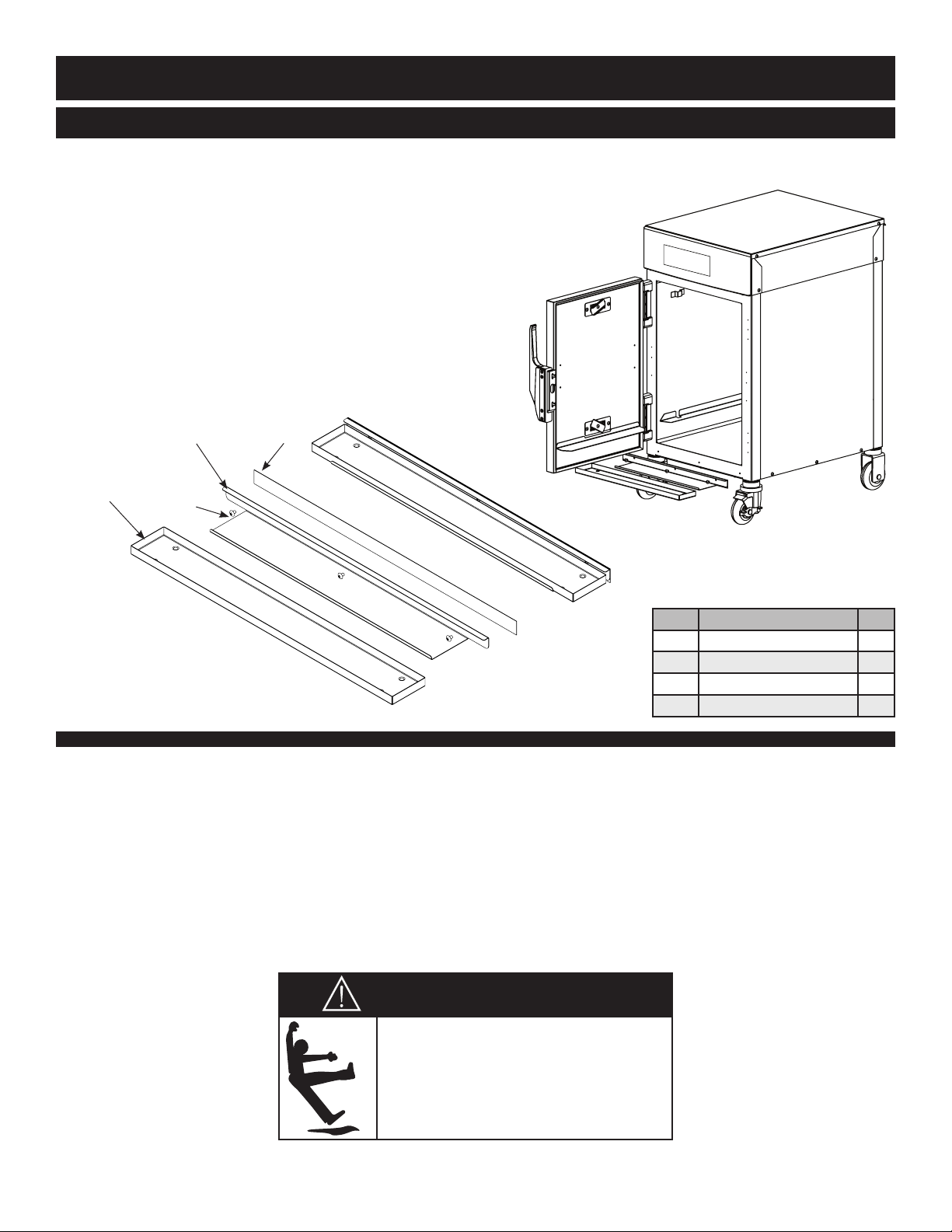

DRIP TRAY INSTALLATION INSTRUCTIONS

b

d

1. Poke holes through double-sided tape a which is attached to the back of drip tray holder b.

2. Remove backing on double-sided tape a.

3. Put screws c through holes and attach drip tray holder b to unit.

4. Optional, but strongly recommended - apply a line of food-grade silicone caulk along top edge

of drip tray holder b to seal.

5. Place drip tray d in drip tray holder b.

c

a

Item Description Qty

1 Double-Sided Tape 1

2 Drip Tray Holder 1

3 8-32 x 1/4” Phil Screw 3

4 Drip Tray 1

WARNING

FAILURE TO PROPERLY INSTALL

THE DRIP TRAY CAN OR WILL CAUSE

MAJOR EQUIPMENT DAMAGE AND

THAT CAN CAUSE PERSONAL

INJURY.

TH /I II I ns Ta l la T Io n/ o pe r aT Io n /s e rv Ic e m a nu al p g. 1 1

Loading...

Loading...