Page 1

High-Speed Development Kit,

Stratix GX Edition

User Guide

101 Innovation Drive

San Jose, CA 95134

(408) 544-7000

http://www.altera.com

UG-STRATIXGX-1.0

P25-09565-00

Document Version: 1.0

Page 2

Copyright © 2003 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the trademarks and

service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights, and copyrights. Altera warrants

performance of its semiconductor products to current specifications in accordance with Altera's standard warranty, but reserves the right to make

changes to any products and services at any time without notice. Altera assumes no responsibility or liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing by Altera

Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published information and before placing orders for products or services.

Printed on recycled paper

ii Altera Corporation

Page 3

Contents

About this User Guide ............................................................................ vii

How to Find Information ...................................................................................................................... vii

How to Contact Altera ........................................................................................................................... vii

Typographic Conventions .................................................................................................................... viii

Section I. Introduction

Revision History ....................................................................................................................... Section I–i

Chapter 1. About this Kit

General Description ............................................................................................................................... 1–1

Features ................................................................................................................................................... 1–2

Documentation ....................................................................................................................................... 1–3

Section II. Getting Started

Revision History ...................................................................................................................... Section II–i

Chapter 2. Before You Begin

Development Kit Contents ................................................................................................................... 2–1

Inspect the Board ................................................................................................................................... 2–2

Software Requirements ......................................................................................................................... 2–2

Set Up Licensing .................................................................................................................................... 2–4

Next Steps ............................................................................................................................................... 2–4

Chapter 3. Board Setup

Required Hardware ............................................................................................................................... 3–3

Power Up the Board & View the XCVR Eye ..................................................................................... 3–3

Chapter 4. Run the Preloaded Diagnostic Tests

User I/O .................................................................................................................................................. 4–1

Required Hardware ......................................................................................................................... 4–2

Test Setup .......................................................................................................................................... 4–2

Run the User I/O Test ..................................................................................................................... 4–3

Stratix GX DDR SDRAM Interface ...................................................................................................... 4–5

Required Hardware & Software .................................................................................................... 4–5

Test Setup .......................................................................................................................................... 4–6

Run the Stratix GX DDR SDRAM Interface Test ......................................................................... 4–6

Altera Corporation iii

Page 4

Contents High-Speed Development Kit, Stratix GX Edition User Guide

Stratix GX HM-Zd SPI-4.2 Loopback .................................................................................................. 4–8

Required Hardware ......................................................................................................................... 4–8

Test Setup .......................................................................................................................................... 4–8

Run the Stratix GX HM-Zd SPI-4.2 Loopback Test ..................................................................... 4–9

Stratix GX HM-Zd XCVR Loopback ................................................................................................. 4–10

Required Hardware ....................................................................................................................... 4–10

Test Setup ........................................................................................................................................ 4–10

Run the Stratix GX HM-Zd XCVR Loopback Test .................................................................... 4–11

Stratix GX SFP XCVR Loopback ........................................................................................................ 4–12

Required Hardware & Software .................................................................................................. 4–12

Test Setup ........................................................................................................................................ 4–12

Run the Stratix GX SFP XCVR Loopback Test ........................................................................... 4–13

Stratix GX XCVR Eye Diagram .......................................................................................................... 4–14

Section III. Diagnostic Tests

Revision History ..................................................................................................................... Section III–i

Chapter 5. Perform the Production Diagnostic Tests

Required Hardware & Software .......................................................................................................... 5–1

Set Up the Board .................................................................................................................................... 5–1

Perform the Standard Tests ................................................................................................................ 5–10

User I/O ........................................................................................................................................... 5–10

Stratix GX-to-Stratix Bridge .......................................................................................................... 5–12

Source Synchronous HM-Zd Interface (Stratix GX HM-Zd SPI 4.2) ...................................... 5–14

Source Synchronous DPA SMA interface (Stratix GX SMA DPA) ......................................... 5–15

Gigabit Transceivers with SMA Interface (Stratix GX SMA XCVR) ....................................... 5–17

Gigabit Transceivers with HM-Zd Interface (Stratix GX HM-Zd XCVR) .............................. 5–18

Gigabit Transceivers with SFP Interface (Stratix GX SFP XCVR) ........................................... 5–19

Gigabit Transceivers with XPAK Interface (Stratix GX XPAK XCVR) ................................... 5–20

Gigabit Transceivers with HSSDC2 Interface (Stratix GX HSSDC2 XCVR) (GX40 Device Only)

............................................................................................................................................................5–21

Nios-Based Tests .................................................................................................................................. 5–22

DDR Interface (Stratix GX Nios DDR) ........................................................................................ 5–22

PMC Card Interface (Stratix Nios PMC) ..................................................................................... 5–23

Ethernet, On-Board Flash & EPC16 Flash Interface (Stratix Nios Ethernet) (Stratix Nios On-

Board Flash) (Stratix Nios EPC16 Flash) ..................................................................................... 5–25

10/100 Ethernet Network-Interface Card I/O Interface (Stratix Nios PROTO1 IO) ........... 5–29

Compact Flash Interface (Stratix Nios Compact Flash) ............................................................ 5–32

Finishing Test & Breakdown .............................................................................................................. 5–35

Chapter 6. Troubleshooting

Chapter 7. Diagnostic Test Details

Standard Tests ........................................................................................................................................ 7–1

User I/O ............................................................................................................................................. 7–1

iv Altera Corporation

Page 5

Contents Contents

Mictor & 20-Pin Header Logic Analyzer Interfaces .................................................................... 7–4

Stratix GX-to-Stratix Bridge ............................................................................................................ 7–6

Stratix GX HM-Zd (SPI-4.2) .......................................................................................................... 7–12

Stratix GX SMA DPA ..................................................................................................................... 7–15

Stratix GX SMA XCVR .................................................................................................................. 7–19

Stratix GX HM-Zd XCVR .............................................................................................................. 7–23

Stratix GX SFP XCVR ..................................................................................................................... 7–26

Stratix GX XPAK XCVR ................................................................................................................ 7–29

Stratix GX HSSDC2 XCVR ............................................................................................................ 7–32

Nios Designs ......................................................................................................................................... 7–35

Stratix GX Nios DDR Test ............................................................................................................. 7–36

Stratix Nios PMC Test ................................................................................................................... 7–38

Stratix Nios Ethernet, On-Board Flash & EPC16 Flash Test .................................................... 7–39

Stratix Nios 10/100 Ethernet Network-Interface Card I/O Test ............................................. 7–41

Stratix Nios Compact Flash Test .................................................................................................. 7–43

Section IV.

Demonstrations

Revision History ..................................................................................................................... Section IV–i

Chapter 8. Stratix GX SPI-4.2 Demonstration with 10-Port Gigabit Ethernet MAC

Chapter 9. 10-Gigabit Ethernet MAC Demonstration

Introduction ............................................................................................................................................ 9–1

Contact .................................................................................................................................................... 9–3

Altera Corporation v

Page 6

Contents High-Speed Development Kit, Stratix GX Edition User Guide

vi Altera Corporation

Page 7

About this User Guide

This user guide provides comprehensive information about the Altera®

High-Speed Development Kit, Stratix™ GX Edition.

How to Find Information

How to Contact Altera

Table 1–1. Contact Altera

Information Type USA & Canada All Other Locations

Technical support www.altera.com/mysupport/ altera.com/mysupport/

Product literature www.altera.com www.altera.com

Altera literature services lit_req@altera.com (1) lit_req@altera.com (1)

Non-technical customer

service

FTP site ftp.altera.com ftp.altera.com

Note to table:

(1) You can also contact your local Altera sales office or sales representative.

You can find more information in the following ways:

■ The Adobe Acrobat Find feature, which searches the text of a PDF

document. Click the binoculars toolbar icon to open the Find dialog

box.

■ Acrobat bookmarks, which serve as an additional table of contents in

PDF documents.

■ Thumbnail icons, which provide miniature previews of each page,

provide a link to the pages.

■ Numerous links, shown in green text, which allow you to jump to

related information.

For the most up-to-date information about Altera products, go to the

Altera world-wide web site at www.altera.com. For technical support on

this product, go to www.altera.com/mysupport. For additional

information about Altera products, consult the sources shown in

Table 1–1.

(800) 800-EPLD (3753)

(7:00 a.m. to 5:00 p.m. Pacific Time)

(800) 767-3753 (408) 544-7000

(408) 544-7000 (1)

(7:00 a.m. to 5:00 p.m. Pacific Time)

(7:30 a.m. to 5:30 p.m. Pacific Time)

Altera Corporation vii

Preliminary

Page 8

Typographic Conventions High-Speed Development Kit, Stratix GX Edition User Guide

Typographic

This document uses the typographic conventions shown in Table 1–2.

Conventions

Table 1–2. Typographic Conventions

Visual Cue Meaning

Bold Type with Initial

Capital Letters

bold type External timing parameters, directory names, project names, disk drive names,

Italic Type with Initial Capital

Letters

Italic type Internal timing parameters and variables are shown in italic type.

Initial Capital Letters Keyboard keys and menu names are shown with initial capital letters. Examples:

“Subheading Title” References to sections within a document and titles of on-line help topics are

Courier type Signal and port names are shown in lowercase Courier type. Examples: data1,

Command names, dialog box titles, checkbox options, and dialog box options are

shown in bold, initial capital letters. Example: Save As dialog box.

filenames, filename extensions, and software utility names are shown in bold

type. Examples: f

Document titles are shown in italic type with initial capital letters. Example: AN

75: High-Speed Board Design.

Examples: t

Variable names are enclosed in angle brackets (< >) and shown in italic type.

Example: <file name>, <project name>.pof file.

Delete key, the Options menu.

shown in quotation marks. Example: “Typographic Conventions.”

PIA

, \qdesigns directory, d: drive, chiptrip.gdf file.

MAX

, n + 1.

tdi, input. Active-low signals are denoted by suffix n, e.g., resetn.

Anything that must be typed exactly as it appears is shown in Courier type. For

example:

actual file, such as a Report File, references to parts of files (e.g., the AHDL

keyword

Courier.

1., 2., 3., and

a., b., c., etc.

● • Bullets are used in a list of items when the sequence of the items is not important.

■

v The checkmark indicates a procedure that consists of one step only.

1 The hand points to information that requires special attention.

r The angled arrow indicates you should press the Enter key.

f The feet direct you to more information on a particular topic.

viii Altera Corporation

Preliminary

Numbered steps are used in a list of items when the sequence of the items is

important, such as the steps listed in a procedure.

c:\qdesigns\tutorial\chiptrip.gdf. Also, sections of an

SUBDESIGN), as well as logic function names (e.g., TRI) are shown in

Page 9

Section I. Introduction

This section provides information about the High-Speed Development

Kit, Stratix GX Edition contents.

This section includes the following chapter:

■ Chapter 1. About this Kit

Revision History

The table below shows the revision history for Chapter 1.

Chapter(s) Date / Version Changes Made

1 July 2003 First publication.

Altera Corporation Section I–i

Preliminary

Page 10

Introduction High-Speed Development Kit, Stratix GX Edition User Guide

Section I–ii Altera Corporation

Preliminary

Page 11

1. About this Kit

General Description

Figure 1–1. Stratix GX Development Board

The High-Speed Development Kit, Stratix GX Edition is designed for the

development and rapid prototyping of applications that incorporate

single-channel or multi-channel transceiver interfaces up to 3.125 gigabits

per second (Gbps) and/or source-synchronous interfaces with dynamic

phase alignment (DPA) up to 1 Gbps per channel. Figure 1–1 shows the

development board included in the kit.

Altera Corporation Quartus II Version 3.0 1–1

July 2003

Page 12

Features High-Speed Development Kit, Stratix GX Edition User Guide

The development kit includes the following items:

■ Stratix GX Development Board—The development board has a variety

of connectors from the Stratix GX device to external sources that you

can use for a wide array of applications, including Gigabit Ethernet,

10 Gigabit Ethernet, OC-12/STM-4 and OC-48/STM-16

SONET/SDH, Fibre Channel (1 and 2 Gbps), System Packet Interface

– Level 4 Phase 2 (SPI-4.2) (also known as POS-PHY Level 4), PCI

Express, 8-bit RapidIO, and 1x/4x Serial RapidIO. You can use a

®

embedded processor to control the application, or you can

Nios

access an external processor via the PCI mezzanine card (PMC)

interface.

■ Board Design Files—The kit includes a complete package of schematic

and layout design files along with a viewer tool, which you can use

as reference to accelerate PCB design using the Stratix GX device.

■ Design Examples—The kit includes design examples that illustrate the

use of Stratix GX transceivers. You can use these design examples as

a reference when implementing your proprietary backplane

interface, accelerating the design, verification, and prototyping cycle.

■ Demonstrations—The kit includes two device programming files that

demonstrate a 10 Gigabit Ethernet MAC with a 10 Gigabit

attachment unit interface (XAUI) and a SPI-4.2 interface connected to

a 10-port multi-physical layer (PHY) device.

■ Loopback Connectors—The kit includes 2 cards with reciprocal source-

synchronous connectors wired for external loopback mode and 1

card for XCVR loopback. Additionally, the kit includes 4 loopback

cards for the SFP connectors.

■ Cables—The kit includes 4 SMA cables that you can use to connect to

an external oscilloscope or use for loopback testing of quad-channel

transceiver interfaces such as XAUI.

Features

1–2 Quartus II Version 3.0 Altera Corporation

■ Supports a wide array of applications, including:

● Gigabit and 10 Gigabit Ethernet

● 1 and 2 Gbps Fibre Channel

● OC-12/STM-4 and OC-48/STM-16 SONET/SDH

● SPI-4.2

● SDI

● PCI Express

● 8-bit RapidIO and 1x/4x Serial RapidIO

● PCI

● Proprietary backplane

July 2003

Page 13

About this Kit Documentation

■ Includes a broad array of external connectors, including:

● HM-Zd interconnect for SPI-4.2/DPA, compatible with Intel’s

10-Channel Gigabit Ethernet media access controller (MAC)

Evaluation Board (#IXD1110)

● SMA interconnect on two LVDS/DPA channels

● SMA interconnect on four transceiver channels

● HM-Zd interconnect on four transceiver channels, compatible

with Tyco’s XAUI HM-Zd Evaluation Backplane (#B024519-013)

● XPAK connector on four transceiver channels (optical module

not included)

● Four small form factor pluggable (SFP) optical connectors

(optics not included)

● Four high speed serial data connectors (HSSDC2)

● High-speed logic analyzer access, compatible with Agilent and

Tektronix connectorless probes

● 10/100 Ethernet MAC/PHY for remote device access

Documentation

The High-Speed Development Kit, Stratix GX Edition contains the

following documentation:

■ Stratix GX Development Board Data Sheet—Describes the

specifications for the board and explains how to use it. This

document is printed.

■ High-Speed Development Kit, Stratix GX Edition User Guide (this

document)—Describes how to use the kit, including setting up the

board, running the diagnostic tests, and describing the example

designs. This document is printed.

■ Stratix GX Board Design Guidelines—This document provides design

guidelines for the board. This document is printed.

■ Stratix GX Device Family Data Sheet—Provides the technical

specifications for Stratix GX devices.

■ AN 249: Implementing 10 Gigabit Ethernet XAUI in Stratix GX

Devices—Describes the fundamentals of 10 Gigabit Ethernet and

XAUI electrical specifications, and illustrates how to implement a

XAUI interface in a Stratix GX device.

■ POS-PHY Level 4 MegaCore Function User Guide—Provides the

specifications for the Altera POS-PHY Level 4 MegaCore

®

function

and explains how to use it.

■ 10 Gigabit Ethernet MAC Product Brief—Describes the features of the

10 Gigabit Ethernet MAC megafunction from AMPP

SM

partner

MorethanIP.

■ SONET/SDH Compiler User Guide—Provides the specifications of the

Altera SONET/SDH Framer and Overhead Processor MegaCore

function and explains how to use it.

Altera Corporation Quartus II Version 3.0 1–3

July 2003

Page 14

Documentation High-Speed Development Kit, Stratix GX Edition User Guide

■ PCI Compiler User Guide—Provides the specifications of the Altera

PCI MegaCore functions and explains how to use them.

■ DDR SDRAM Controller User Guide—Provides the specifications of

the Altera DDR SDRAM Controller MegaCore function and explains

how to use it.

1–4 Quartus II Version 3.0 Altera Corporation

July 2003

Page 15

Section II. Getting Started

This section describes how to get started with the board, including

describing the board components, explaining how to set up the board,

and describing how to perform the preloaded diagnostic tests.

This section includes the following chapters:

■ Chapter 2. Before You Begin

■ Chapter 3. Board Setup

■ Chapter 4. Run the Preloaded Diagnostic Tests

Revision History

The table below shows the revision history for these chapters.

Chapter(s) Date / Version Changes Made

2 - 4 July 2003 First publication.

Altera Corporation Quartus II Version 3.0 Section II–i

Preliminary

Page 16

Getting Started High-Speed Development Kit, Stratix GX Edition User Guide

Section II–ii Quartus II Version 3.0 Altera Corporation

Preliminary

Page 17

2. Before You Begin

Before using the kit or installing the software, be sure to check the

contents of the kit and inspect the board to verify that you received all of

the items. If any of these items are missing, contact Altera before you

proceed. You should also verify that your PC meets the software and

system requirements of the kit.

Development Kit Contents

The High-Speed Development Kit, Stratix GX Edition contains the

following items:

■ Stratix GX development board

■ ByteBlaster™ II cable

■ ATX power su p ply

■ 4 SMA cables

■ RS-232 cable

■ 3 mini-cards with reciprocal HM-Zd connectors wired for loopback

■ 4 mini-cards to loop back the SFP connectors

■ Stratix GX Reference Designs & Software CD-ROM

■ Quartus II Development Software CD-ROM (version 3.0)

■ High-Speed Development Kit, Stratix GX Edition User Guide (this

document)

■ Stratix GX Development Board Data Sheet

■ Stratix GX Board Design Guidelines

■ Introductory letter

The Stratix GX Reference Designs & Software CD-ROM contains all of the

supporting files and documentation, including:

■ Stratix GX development board schematic

■ Stratix GX development board layout file (Allegro format)

■ Stratix GX development board layout guidelines

■ Stratix GX development board test designs

■ Stratix GX development board example designs and demonstrations

■ 60-day evaluation versions of Altera MegaCore functions

■ Related documentation in Adobe PDF

Altera Corporation Quartus II Version 3.0 2–1

Page 18

Inspect the Board High-Speed Development Kit, Stratix GX Edition User Guide

Inspect the Board

f Refer to the Stratix GX Development Board Data Sheet for information on

Software Requirements

f Refer to “Set Up Licensing” for information on obtaining licenses for the

Place the board on an anti-static surface and inspect it to ensure that it has

not been damaged during shipment. Verify that all components are on

the board and appear intact.

1 The board can be damaged without proper anti-static handling.

Therefore, you should take anti-static precautions before

handling the board.

the board components and their locations.

You should install the following software before you begin using the kit.

■ Quartus

■ The software on the High-Speed Development Kit, Stratix GX Edition

CD-ROM.

software.

Figure 2–1 shows the development kit directory structure on the

Stratix GX Reference Designs & Software CD-ROM.

®

II software version 3.0 or higher.

2–2 Quartus II Version 3.0 Altera Corporation

Page 19

Before You Begin Software Requirements

g

Figure 2–1. Stratix GX Reference Designs & Software Directory Structure

<

path

>\Stratix_GX_kit

Demonstrations

Contains the files for the demonstrations provided with the kit.

SPI4

Contains a device programming file that demonstrates Stratix GX SPI-4.2 interoperability with

the Intel IXF1110 and PMC-Sierra S/UNI-10xGE 10-port Gigabit Ethernet MAC devices.

10GBEthernet

This demonstration application implements a 10-Gigabit Ethernet MAC connected to the

Stratix GX embedded SERDES device, providing an XAUI connection to an optional

Xenpak/XPAK optical transceiver module.

Supporting_docs

Contains the board schematics, layout files, layout guidelines, and documentation in Adobe PDF.

Test_designs

Contains the test designs described in the kit user guide.

Standard_test_designs

Contains the archived standard test designs.

Standard_sofs

Contains the SRAM Object Files (.sof) for the standard test designs.

Nios_tests_designs

Contains the archived Nios-based test designs.

Nios_sofs

Contains SOFs for the Nios test designs and run files.

Preloaded_test_files

Contains Pro

rammer Object Files (.pof) for the preloaded test designs.

Altera provides archived Quartus II projects for the designs included in

the kit. Before compiling an archived project, you must restore it. To

restore and compile, perform the following steps:

1. Choose Restore Archived Project (Project menu).

2. In the Archive name box, type the path and file name of the

Quartus II Archive File (.qar) you wish to restore, or select a QAR

File with Browse (...).

3. In the Destination folder box, type or select the path of the folder

into which you wish to restore the contents of the QAR File, or select

a folder with Browse (...).

4. Click Show log to view the Quartus II Archive Log File (.qarlog) for

the project you are restoring from the QAR File.

5. Click OK.

6. Compile the project.

Altera Corporation Quartus II Version 3.0 2–3

Page 20

Set Up Licensing High-Speed Development Kit, Stratix GX Edition User Guide

Set Up Licensing

You must have a valid license to use the Quartus II development software

and to compile and generate programming files for designs that include

Altera MegaCore functions. The kit includes a full, 1-year license for the

Quartus II development software and temporary 60-day evaluation

licenses for the Altera POS-PHY Level 4, SONET/SDH Framer and

Overhead Processor, PCI, and DDR SDRAM Controller MegaCore

functions. To purchase full licenses for the MegaCore functions, visit the

the Altera web site at www.altera.com or contact your local Altera sales

representative.

1 To design for Stratix GX devices using the Quartus II software,

you need a special FEATURE line. Therefore, you have to request

and install a license file before creating designs with the kit.

To obtain your Quartus II and temporary MegaCore licenses, perform the

following steps:

1. Point your web browser to the Altera web site at

www.altera.com/licensing.

2. Scroll to the Development Kit Licenses section of the Altera

Licensing Center page.

3. Click the High-Speed Development Kit, Stratix GX Edition link.

4. Follow the on-line instructions to request your license. A license file

is e-mailed to you.

5. To install your license, refer to “Specifying the License File” in the

Quartus II Installation & Licensing Manual for PCs, which is included

with the kit.

1 The 60-day period for MegaCore evaluation licenses starts from

the request date and cannot be renewed. After this period, you

will still be able to compile and simulate using these MegaCore

functions, but you will not be able to generate programming

files.

Next Steps

2–4 Quartus II Version 3.0 Altera Corporation

This user guide contains the following chapters to help you get started

working with the board:

■ “Board Setup” on page 3–1 explains how to setup and configure the

Stratix GX development board.

■ “Run the Preloaded Diagnostic Tests” on page 4–1 describes how to

set up and run each preloaded design and the required equipment.

■ “Perform the Production Diagnostic Tests” on page 5–1 explains

how to run the production tests.

Page 21

Before You Begin Next Steps

■ “Troubleshooting” on page 6–1 describes how to solve problems you

may encounter with the test designs or with setting up the board.

■ “Diagnostic Test Details” on page 7–1 explains each diagnostic test,

including board-level block diagrams, design-level block diagrams,

and simulations or screenshots of each test.

■ “Stratix GX SPI-4.2 Demonstration with 10-Port Gigabit Ethernet

MAC” on page 8–1 describes this provided demonstration.

■ “10-Gigabit Ethernet MAC Demonstration” on page 9–1 describes

this provided demonstration.

Altera Corporation Quartus II Version 3.0 2–5

Page 22

Next Steps High-Speed Development Kit, Stratix GX Edition User Guide

2–6 Quartus II Version 3.0 Altera Corporation

Page 23

The Stratix GX development board has a variety of interfaces and

features. See Figure 3–1 and Table 3–1.

Figure 3–1. Features of the Stratix GX Development Kit Board

3. Board Setup

Altera Corporation Quartus II Version 3.0 3–1

Page 24

High-Speed Development Kit, Stratix GX Edition User Guide

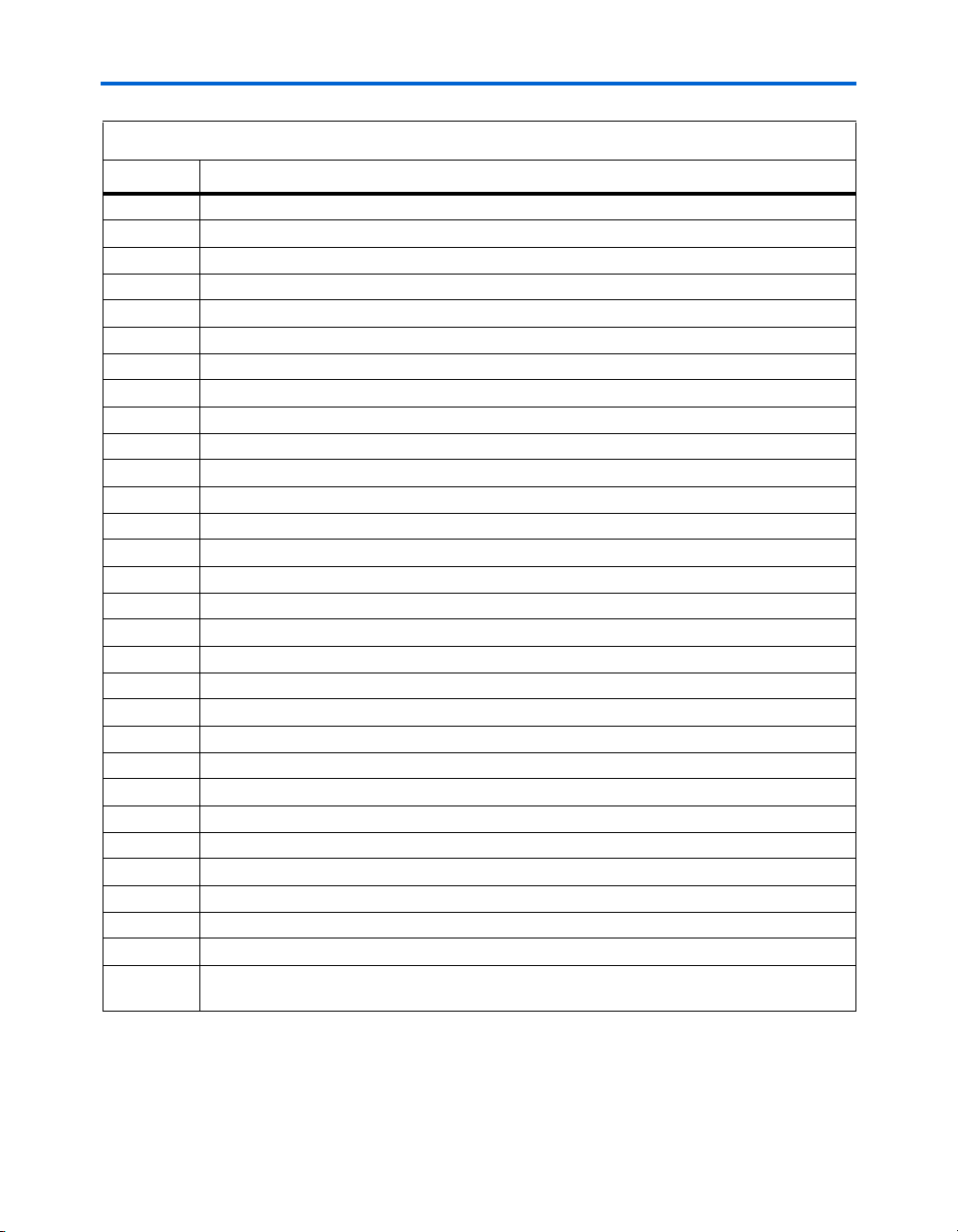

Table 3–1. Stratix GX Development Board Features

Feature Description

1 Power connector and circuitry

2 Configuration switches

3 Divide by 20 and divide by 2 clock circuitry

4 Stratix Mictor connector

5 Stratix 20-pin test header

6 10/100 Ethernet interface

7 Exansion prototype card (PROTO1) interface

8 On-board flash interface

9 RS-232 interface for Stratix and Stratix GX devices

10 General-purpose interface (user pushbutton switches, dipswitches, LEDs, and displays)

11 Configuration circuitry

12 Stratix device

13 Source synchronous HM-Zd SPI-4.2 interface

14 Clock source (crystal oscillators and clock input and output)

15 DPA SMA interface

16 Edge-launched XCVR SMA connectors

17 XPAK interface

18 Tektronix high-speed differential probe for Stratix GX/Stratix device bridge

19 MDIO interface for XPAK

20 Stratix GX 20-pin test header

21 Agilent high-speed differential probe for source synchronous (HM-Zd SPI-4.2) interface

22 SFP interface

23 Stratix GX device

24 Stratix GX Mictor connector

25 HSSDC2 interface

26 Vertical launched XCVR SMA connectors

27 DDR SDRAM interface

28 Recovered clock SMA connectors

29 XAUI HM-Zd interface

Not shown PMC interface (on the back of the board)

Compact flash interface (on the back of the board)

3–2 Quartus II Version 3.0 Altera Corporation

Page 25

Board Setup Required Hardware

Required Hardware

Table 3–2. Required Equipment

Hardware Manufacturer Part Number Quantity

Stratix GX Development Board Altera 1

ATX Power Supply Sparkle Power FSP250-60GTA 1

Programming Cable Altera ByteBlaster II 1

SMA DC Block (1) Any 2

SMA 20-dB 50-Ω Attenuator (1) Any 1

High-Speed Digital Sampling Oscillocope (1), (2) Tektronix CSA8000 1

3-Foot SMA Cable (1) Any 3

Note:

(1) This item is required to view the XCVR eye.

(2) You can also use other oscilloscopes.

Power Up the Board & View the XCVR Eye

To power up the Stratix GX development board, you need the hardware

listed in Table 3–2. See “Development Kit Contents” on page 2–1 for a list

of items provided in the kit.

Perform the following steps to power up the Stratix GX development

board. You will set switches on the board so that the Stratix GX device

displays the transceiver (XCVR) eye in an oscilloscope.

1 Before you attempt to power up the board, make sure that you

have the equipment listed in Table 3–2.

1. Set switch SW3 to off (middle position).

2. Connect one end of the ATX power supply to J31 and the other end

to a power outlet.

3. Set the Stratix GX device switches as shown in Table 3–3. These

settings display the XCVR eye.

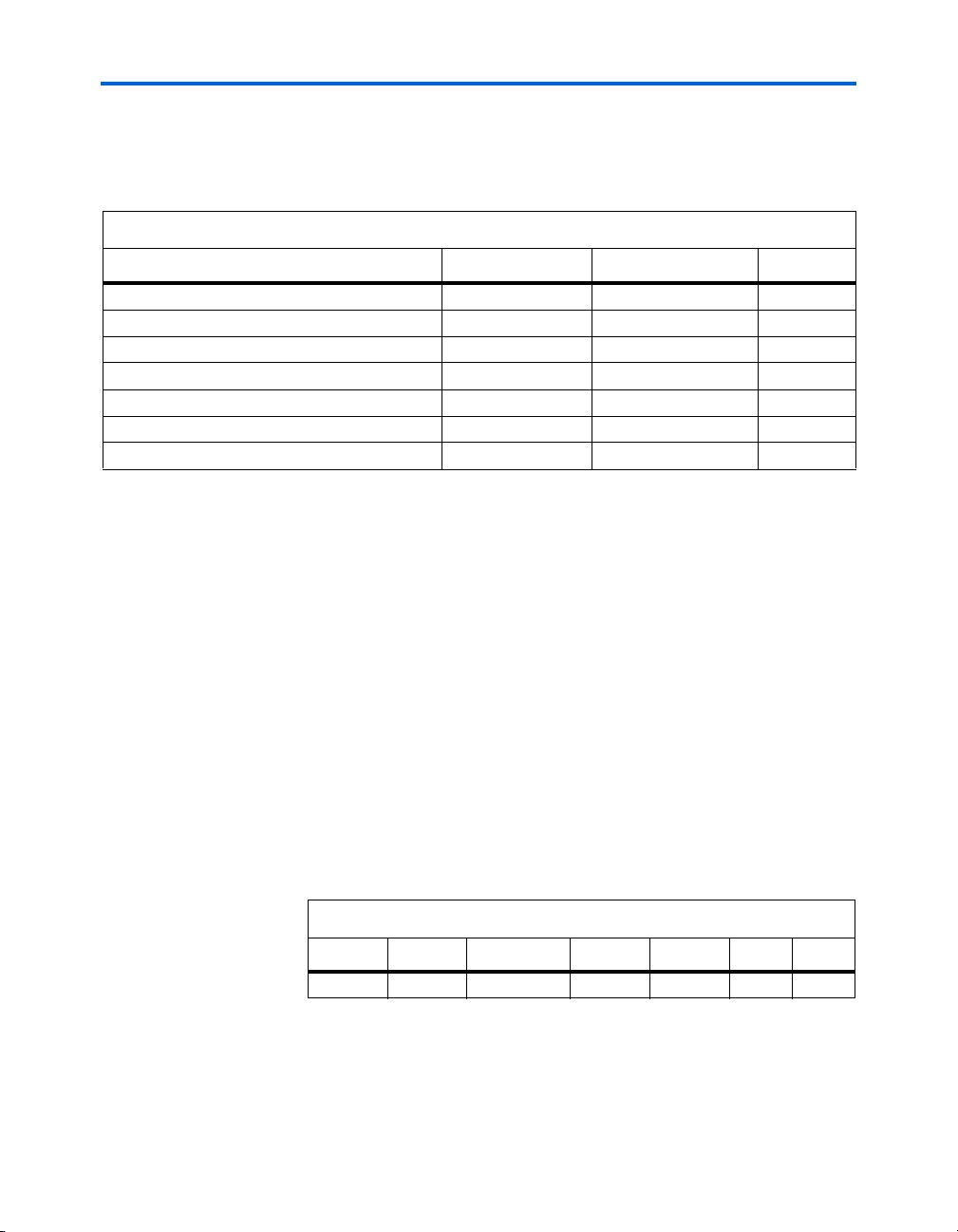

Table 3–3. Stratix GX XCVR Eye Switches Settings

SW1 SW2 SW4 SW5 SW8 J48 J90

YES NO EPC16 STD 000 X X

4. Set switch SW3 to the on position (all of the way up). All of the

board LEDs illuminate.

Altera Corporation Quartus II Version 3.0 3–3

Page 26

Power Up the Board & View the XCVR Eye High-Speed Development Kit, Stratix GX Edition User Guide

The Stratix GX development board is powered up. To view the Stratix GX

XCVR eye, perform the following steps:

1. Place a DC block on the signals TX_N3 (J25) and TX_P3 (J17).

2. Place the SMA attenuator on J97.

3. Connect one end of an SMA cable to the attenuator and connect the

other end to the trigger input of the oscilloscope.

4. Connect one end of an SMA cable to J25 and connect the other end

to an input channel of the oscilloscope.

5. Connect one end of an SMA cable to J17 and connect the other end

to an input channel of the oscilloscope.

6. Set the switch SW9 to select the crystal oscillator.

7. On the oscilloscope, set the vertical setting on each channel to

52 mV/div.

8. Set the oscilloscope’s horizontal setting to 100 ps/div.

9. On the oscilloscope’s trigger section, press the SET TO 50% button.

10. Turn on and set the math channel to C2-C1.

11. Turn off channels 1 and 2. The oscilloscope should capture an eye

pattern similar to the one shown in Figure 3–2.

3–4 Quartus II Version 3.0 Altera Corporation

Page 27

Board Setup Power Up the Board & View the XCVR Eye

Figure 3–2. Eye Pattern for CSA8000

12. Stratix GX devices can dynamically control the transceiver’s VOD

and pre-emphasis settings. To view this control, perform the

following steps.

a. Press the adjust pre-emphasis pushbutton (S4). You should see

the pre-emphasis change on the oscilloscope. There are 6 preemphasis settings: pressing S4 5 times in succession cycles

through the settings. Pressing S4 a sixth time sets the

transceiver back to the original setting. The value of the setting

is indicated by the left digit of the Stratix GX seven segment

display (D9).

b. Press the adjust VOD pushbutton (S5). You should see the VOD

change on the oscilloscope. There are 6 VOD settings: pressing

S5 5 times in succession cycles through the settings. Pressing S5

a sixth time sets the transceiver back to the original setting. The

value of the setting is indicated by the right digit of the Stratix

GX seven segment display (D9).

Altera Corporation Quartus II Version 3.0 3–5

Page 28

Power Up the Board & View the XCVR Eye High-Speed Development Kit, Stratix GX Edition User Guide

3–6 Quartus II Version 3.0 Altera Corporation

Page 29

4. Run the Preloaded Diagnostic Tests

Each interface on the Stratix GX development board has an associated

diagnostic test that exercises the interface at the supported I/O rates.

Although the tests are not exhaustive, they help you confirm that each

interface runs according to its intended design. A subset of the diagnostic

tests are loaded into the Stratix GX development board’s configuration

devices, making it easy for you to run any of the tests when you power

up the board. This chapter describes how to set up and perform these

preloaded diagnostic tests, including:

■ User I/O

■ Stratix GX Double Data Rate (DDR) SDRAM Interface

■ Stratix GX HM-Zd SPI-4.2 Loopback

■ Stratix GX HM-Zd XCVR Loopback

■ Stratix GX SFP XCVR Loopback

■ Stratix GX XCVR Eye Diagram

The following sections describe how to perfom each test, including the

equipment you need to perform each test, how to set up the board, and

the test procedure. Table 4–1 shows the switch settings you must make to

load the designs on power up. For more details on these designs, refer to

Chapter 7, Diagnostic Test Details.

Table 4–1. Factory-Default Switch Settings

Diagnostic Test SW1 SW2 SW4 SW5 SW7 SW8 (1) J48 J90

XCVR Eye Diagram YES NO EPC16 STD --- 000 X X

DDR YES NO EPC16 STD --- 011 X X

HM-Zd SPI-4.2 YES NO EPC16 STD --- 001 X X

HM-Zd XCVR Loopback YES NO EPC16 STD --- 001 X X

SFP XCVR Loopback YES NO EPC16 STD --- 001 X X

User I/O NO NO EPC16 STD 111 111 X X

Note:

(1) Slider 3 is the MSB and slider 1 is the LSB. A slider in the up position is 0 and a slider in the down position is 1.

User I/O

Altera Corporation Quartus II Version 3.0 4–1

The user I/O design tests all of the user LEDs, dipswitches, pushbuttons,

and 7-segment displays on the board (the Stratix and Stratix GX devices

each have a set). One pair of pushbuttons controls each device’s user

Page 30

User I/O High-Speed Development Kit, Stratix GX Edition User Guide

LEDs, while the other pair increments or decrements the counter shown

on the 7-segment display. The dipswitches enter numbers on each

device’s 7-segment display.

Required Hardware

In addition to the board, you need the Altera-provided ATX power

supply.

Test Se t up

Perform the following steps to set up the user I/O test.

1. Set the switches as shown in Table 4–1 for the user I/O test.

2. Connect the power supply to the board.

3. Confirm that the Stratix and Stratix GX devices have finished

configuration (the GX_CONF_DONE (D7) and S_CONF_DONE

(D6) LEDs illuminate as shown in Figure 4–1).

Figure 4–1. GX_CONF_DONE, S_CONF_DONE & User I/O LEDs

PB0

4–2 Quartus II Version 3.0 Altera Corporation

PB1

PB2

PB3

S_CONF_DONE

GX_CONF_DONE

Page 31

Run the Preloaded Diagnostic Tests User I/O

Run the User I/O Test

Perform the following steps to execute the test for the Stratix GX device

user I/O.

1. Set all of the Stratix GX user dipswitches (S11) to 0.

2. Press GX_CLR (S14) to reset the design. When the pushbutton is

pressed, the GX_CLR LED (D16) illuminates. When you release the

pushbutton, the 7-segment display (D9) shows 00.

3. Press the Stratix GX channel pushbutton switches, Stratix_GX_PB_0

(S2) for up and Stratix_GX_PB_1 (S3) for down. The channel

numbers on the Stratix GX 7-segment display (D9) increment and

decrement as you press S2 and S3, respectively.

4. Press S14 once.

5. Press S2 three times. D9 displays 03.

6. Press S3 four times. D9 displays 99.

7. Press the Stratix GX volume pushbutton switches, Stratix_GX_PB_2

(S4) for up and Stratix_GX _PB_3 (S5) for down. As you press S4

and S5, the number of Stratix_GX LEDs (D10-15) that are

illuminated should increment and decrement, respectively.

8. Press S14 once.

9. Press S4 six times. All of the Stratix_GX LEDs illuminate.

10. Press S5 six times. All of the Stratix_GX LEDs turn off.

11. Using the Stratix GX user dipswitches (S11), enter the binary

number 15.

a. Set dipswitches 4-1 to 1.

b. Set dipswitch 7 to the up position and then to the down

position to enter the value. D9 displays the number 15.

12. Enter the binary number 127.

a. Set dipswitches 7-1 to 1.

b. Set dipswitch 8 to the up position and then to the down

position to enter the value. D9 displays the number 99.

Altera Corporation Quartus II Version 3.0 4–3

Page 32

User I/O High-Speed Development Kit, Stratix GX Edition User Guide

You are finished testing the Stratix GX device user I/O. Perform the

following steps to execute the test for the Stratix device user I/O.

13. Set all of the Stratix user dipswitches (D6) to 0.

14. Press S_CLR (S12) to reset the design. The S_CLR LED (D24)

illuminates and the 7-segment display (D8) shows 00.

15. Press the Stratix channel pushbutton switches, Stratix_PB_0 (S8) for

up and Stratix_PB_1 (S9) for down. The channel numbers on the 7segment display (D8) increment and decrement.

16. Press S12 once.

17. Press S8 three times. D8 displays 03.

18. Press S9 four times. D8 displays 99.

19. Press the Stratix volume pushbutton switches, Stratix_PB_2 (S10) for

up and Stratix_PB_3 (S7) for down. The number of illuminated

Stratix LEDs increment and decrement.

20. Press S12 once.

21. Press S10 six times. All of the LEDs illuminate.

22. Press S7 six times. All of the LEDs turn off.

23. Enter the binary number 15.

a. Set dipswitches 4-1 to 1.

b. Set dipswitch 8 to the up position and then to the down

position to enter the value. D8 displays the number 15.

24. Enter the binary number 127.

a. Set dipswitches 7-1 to 1.

b. Set dipswitch 8 to the up position and then to the down

position to enter the value. D8 displays the number 99.

You have finished the user I/O test.

4–4 Quartus II Version 3.0 Altera Corporation

Page 33

Run the Preloaded Diagnostic Tests Stratix GX DDR SDRAM Interface

Stratix GX DDR SDRAM Interface

Figure 4–2. RS-232 Connector

Serial Port for

Stratix Device

Serial Port for

Stratix GX Device

The Stratix GX DDR SDRAM interface connects to a 184-pin, 200-MHz

Micron DDR DIMM module. To test this interface, you use a Nios

embedded processor-based test that you run from the SOPC Builder SDK

Shell. You observe the test output in the shell. An RS-232 cable connected

to your PC’s COM 1 port allows communication between the board and

the software running on the PC. The RS-232 connector serves the Stratix

GX device when the serial cable is attached to the bottom connector and

the Stratix device when the serial cable is attached to the top connector as

shown in Figure 4–2.

Required Hardware & Software

The Stratix GX DDR SDRAM test design uses the following equipment

and software:

■ DDR DIMM module

■ RS-232 cable

■ ATX power su p ply

■ Nios embedded processor version 2.0 or higher

Altera Corporation Quartus II Version 3.0 4–5

Page 34

Stratix GX DDR SDRAM Interface High-Speed Development Kit, Stratix GX Edition User Guide

Test Se t up

Perform the following steps to set up the test.

1. Remove power from the board.

2. Insert the DDR DIMM module in the location defined in Figure 4–3.

Figure 4–3. Inserting DDR DIMM

3. Attach one end of the RS-232 cable to your PC’s COM 1 port and the

other end to the bottom connector of the RS-232 serial port on the

board.

4. Set the board’s switches as shown in Table 4–1 for this test.

5. Supply power to the board.

6. Confirm that the Stratix GX device has finished configuration (the

GX_CONF_DONE (D7) LED illuminates).

Run the Stratix GX DDR SDRAM Interface Test

Perform the following steps to run the test.

1. Choose Programs > Altera > SOPC Builder <version> > SOPC

Builder SDK Shell (Windows Start menu).

1 This shell may be named Nios SDK Shell in older versions

of the Nios embedded processor.

2. Change to the Nios SOFs directory by typing the following

command:

cd /Stratix_GX_kit/Test_designs/Nios_test_designs/

Nios_sofs r

3. Type nr -t r to open a terminal window that connects to COM 1.

4–6 Quartus II Version 3.0 Altera Corporation

Page 35

Run the Preloaded Diagnostic Tests Stratix GX DDR SDRAM Interface

4. Press the Enter key twice in the terminal window. You should be at

a Nios prompt.

5. Confirm that you are connected to the Nios processor running on

the board by pressing the Enter key a few times in the terminal

window to display the processor’s memory contents.

6. Exit the terminal window by pressing the Ctrl + C keys.

7. Type nr DDR.srec r to start the DDR test. Observe the results to

see if any errors are reported. Figure 4–4 shows the text that should

display in the shell.

Figure 4–4. DDR Test Display in SOPC Builder SDK Shell

======================================================

= Altera GX Development Board DDR SDRAM Demonstration =

= - Nios v2.2 (66MHz) =

= - Altera DDR SDRAM Controller v1.1.0 (200MHz) =

= - Avalon test interface to DDR SDRAM Controller =

======================================================

Doing a sequence of 100 back-to-back writes (of 8) followed by 100 back-to-back

reads (of 8)

Repeating this test 20000 times

Testing... [####################]

Walking ones on the addresses test

Repeating this test 20000 times

Testing... [####################]

Burst length test (burst reads and writes of 2,4 and 8)

5 sequences of 4 write & read bursts

Repeating this test 20000 times

Testing... [####################]

Entire DIMM write and read test

Write the entire DIMM with the address of each location,

Then read each location to check that the address and data are the same.

Writing... [####################]

Finished writing.

Reading... [####################]

Read and checked 8388608 locations (128 Mb).

======================================================

= END OF TEST =

= Type "g0" and press Enter to restart the test =

Altera Corporation Quartus II Version 3.0 4–7

Page 36

Stratix GX HM-Zd SPI-4.2 Loopback High-Speed Development Kit, Stratix GX Edition User Guide

8. The test continues until you press the Ctrl + C keys. Press these keys

to stop the status display in the SOPC Builder SDK Shell.

9. Press S2 to stop the test.

Stratix GX HMZd SPI-4.2

Loopback

The Stratix GX HM-Zd SPI-4.2 loopback test design tests the SPI-4.2

source synchronous signals at up to 1 Gbps using the provided HM-ZD

SPI-4.2 loopback cards.

Required Hardware

This test requires the following hardware:

■ HM-Zd SPI-4.2 loopback cards (labeled J108 and J109)

■ ATX power su p ply

Test Se t up

Perform the following steps to set up the test.

1. Remove power from the board.

2. Install the HM-Zd SPI-4.2 loopback cards as shown in Figure 4–5.

3. Set the board’s switches as shown in Table 4–1 for this test.

4–8 Quartus II Version 3.0 Altera Corporation

Page 37

Run the Preloaded Diagnostic Tests Stratix GX HM-Zd SPI-4.2 Loopback

Figure 4–5. Install the HM-Zd SPI-4.2 Loopback Cards

4. Supply power to the board.

5. Confirm that the Stratix GX device has finished configuration (the

GX_CONF_DONE (D7) LED illuminates).

Run the Stratix GX HM-Zd SPI-4.2 Loopback Test

Perform the following steps to run the test.

1. Setthe Stratix GX dipswitch 5 to 1 (up position).

2. Press the reset pushbutton switch (GX_CLR).

3. Press the start pushbutton switch (Stratix_GX_PB_0). Several LEDs

illuminate.

● LED0 is the high-speed data match LED. If it illuminates, the test

is successful.

● LED1 indicates that the GX device has received the data.

Altera Corporation Quartus II Version 3.0 4–9

Page 38

Stratix GX HM-Zd XCVR Loopback High-Speed Development Kit, Stratix GX Edition User Guide

● LED2 indicates a per channel match. This LED is used for the per

channel feature.

● LED3 indicates that the test has started.

● LED4 is the match LED for the low-speed control signals.

● LED5 is the error indicator.

4. Press the stop pushbutton switch (GX PB1) to stop the device from

transmitting data.

5. Press the reset pushbutton switch (GX_CLR).

6. Press the Stratix_GX_PB_0.

7. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The

Stratix GX 7-segment display (D9) shows 01 and LED5 illuminates.

8. Inject two more errors by pressing S4 twice. D9 displays 03.

Stratix GX HMZd XCVR

Loopback

The Stratix GX HM-Zd XCVR loopback test design tests the HM-Zd

XCVR signals at up to 3.125 Gbps using the provided HM-Zd XCVR

loopback card.

Required Hardware

This test requires the following hardware:

■ HM-Zd XCVR loopback card (labeled J1)

■ ATX power su p ply

Test Se t up

Perform the following steps to set up the test.

1. Remove power from the board.

2. Install the HM-Zd XCVR loopback card as shown in Figure 4–6.

4–10 Quartus II Version 3.0 Altera Corporation

Page 39

Run the Preloaded Diagnostic Tests Stratix GX HM-Zd XCVR Loopback

Figure 4–6. Install the HM-Zd XCVR Loopback Card

3. Set the board’s switches as shown in Table 4–1 for this test.

4. Supply power to the board.

5. Confirm that the Stratix GX device has finished configuration (the

GX_CONF_DONE (D7) LED illuminates).

Run the Stratix GX HM-Zd XCVR Loopback Test

Perform the following steps to run the test.

1. Set Stratix GX user dipswitches 5 and 6 to the up position to set the

XCVR setting to HM-Zd.

2. Press the reset pushbutton switch (GX_DEV CLR) to initialize the

design. The GX_DEV_CLR LED illuminates.

3. Press the start pushbutton switch (GX PB0). Several LEDs

illuminate.

● LED0, LED1, LED2, and LED3 are the match lights on a per

channel basis. They illuminate if the test is successful.

● LED4 indicates that the test is running.

● LED5 is the error signal.

4. Press the stop pushbutton switch (GX PB1) to stop the device from

transmitting.

5. Press the reset pushbutton switch (GX_DEVCLR).

Altera Corporation Quartus II Version 3.0 4–11

Page 40

Stratix GX SFP XCVR Loopback High-Speed Development Kit, Stratix GX Edition User Guide

6. Press the start pushbutton switch (Stratix_GX_PB_0).

7. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The

Stratix GX 7-segment display (D9) shows 01 and Stratix GX LED5

illuminates.

8. Inject two more errors by pressing S4 twice. D9 displays 03.

Stratix GX SFP XCVR Loopback

The Stratix GX SFP XCVR loopback test design tests the SFP XCVR

signals at up to 2.488 Gbps using the provided SFP XCVR loopback cards.

Required Hardware & Software

This test requires the following hardware and software:

■ SFP XCVR loopback cards

■ ATX power su p ply

Test Se t up

To set up the test, perform the following steps.

1. Remove power from the board.

2. Insert the SFP loopback cards on the board as shown in Figure 4–6.

3. Attach the SFP loopback card (labeled J3 on the card) to the SFP

transceiver connectors at J54, J64, J45, and J38 as shown in

Figure 4–7.

4–12 Quartus II Version 3.0 Altera Corporation

Page 41

Run the Preloaded Diagnostic Tests Stratix GX SFP XCVR Loopback

Figure 4–7. Attach the XCVR SFP Loopback Cards

4. Set the board’s switches as shown in Table 4–1 for this test.

5. Supply power to the board.

6. Confirm that the Stratix GX device has finished configuration (the

GX_CONF_DONE (D7) LED illuminates).

Run the Stratix GX SFP XCVR Loopback Test

Perform the following steps to run the test.

1. Set Stratix GX user dipswitches 5 and 6 to the down position to set

the XCVR setting to SFP.

2. Press the reset pushbutton switch (GX_DEV CLR) to initialize the

design. The GX_DEV_CLR LED illuminates.

3. Press the start pushbutton switch (GX PB0). Several LEDs

illuminate.

● LED0, LED1, LED2, and LED3 are the match lights on a per

channel basis. They illuminate if the test is successful.

● LED4 indicates that the test is running.

● LED5 is the error signal.

4. Press the stop pushbutton switch (GX PB1) to stop the device from

transmitting.

Altera Corporation Quartus II Version 3.0 4–13

Page 42

Stratix GX XCVR Eye Diagram High-Speed Development Kit, Stratix GX Edition User Guide

5. Press the reset pushbutton switch (GX_DEVCLR).

6. Press the start pushbutton switch (Stratix_GX_PB_0).

7. Inject errors by pressing Stratix_GX_PB_2 (S4) once. The Stratix GX

7-segment display (D9) shows 01 or more and Stratix GX LED5

illuminates. Because this test runs all channels at once, the Stratix

GX 7-segment display (D9) may show more than one error when

you press Stratix_GX_PB_2 (S4).

8. Inject two more errors by pressing S4 twice. D9 displays 03 or more.

Stratix GX XCVR Eye Diagram

f To perform this test, refer to “Power Up the Board & View the XCVR

The Stratix GX XCVR eye test design produces an eye on an oscilloscope

at 3.125 Gbps using the on-board crystal oscillator and SMA cables. This

design also shows the dynamic control of the Stratix GX device for both

the pre-emphasis and VOD settings using the pushbutton switches S4

and S5. For this design, the Stratix GX transceiver block has the parameter

settings shown in Table 4–2.

Table 4–2. Transceiver Block Parameter Settings

Parameter Setting

Data Rate 3.125 GHz

Clock In 156.25 MHz

PLL Clock 156.25 MHz

PLL DC Coupling Disabled

PLL Bandwidth High

PPM Threshold 1000

8b/10b Encoder/Decoder Bypassed

Run Length Violation Bypassed

Rx Bandwidth Disabled

Word Alignment Mode Manual

Alignment Pattern 0101111100

Eye” on page 3–3.

4–14 Quartus II Version 3.0 Altera Corporation

Page 43

Section III. Diagnostic

Tests

Each interface on the Stratix GX development board has an associated

diagnostic test that exercises the interface at the supported I/O rates.

Although the tests are not exhaustive, they help you confirm that each

interface runs according to its intended design. The production tests

execute each diagnostic test. Altera executes the production tests on every

Stratix GX development board to confirm that all of the interfaces pass.

This section includes the following chapters:

■ Chapter 5. Perform the Production Diagnostic Tests

■ Chapter 6. Troubleshooting

■ Chapter 7. Diagnostic Test Details

Revision History

The table below shows the revision history for these chapters.

Chapter(s) Date / Version Changes Made

5 - 7 July 2003 First publication.

Altera Corporation Quartus II Version 3.0 Section III–i

Preliminary

Page 44

Diagnostic Tests High-Speed Development Kit, Stratix GX Edition User Guide

Section III–ii Quartus II Version 3.0 Altera Corporation

Preliminary

Page 45

5. Perform the Production Diagnostic Tests

Required Hardware & Software

Set Up the Board

The following list describes the hardware and software you need to run

the production diagnostic tests.

■ Windows-based PC

■ Quartus II software

■ Parallel port cable

■ Serial port cable

■ PMC card (part number 853-10010 PMC100TX)

■ 10/100-Mbit Ethernet network-interface daughter board (part

number NIOS-EDKX)

■ Six to ten short (1-foot) SMA cables

■ High-Speed Development Kit, Stratix GX Edition

● Stratix GX development board revision C

● ATX power su p ply

● ByteBlaster II cable

● Programming files

● Four long (3-foot) SMA cables

● HM-Zd loopback cards

● SFP loopback card

● Micron DDR DIMM

● Compact flash card

The following procedure describes how to set up the board, including

attaching the daughter cards and cables.

1. Install the PMC card on the back side of the board as shown in

Figure 5–1.

Altera Corporation Quartus II Version 3.0 5–1

Page 46

Set Up the Board High-Speed Development Kit, Stratix GX Edition User Guide

Figure 5–1. Attach the PMC Card

2. Attach the HM-Zd SPI-4.2 loopback card (labeled J108 on the card)

to the connector at J108, which is located on the bottom edge of the

board as shown in Figure 5–2.

3. If your version of the Stratix GX development board has an

EP1SGX40GF1020C5 device, you may also need to attach a second

HM-Zd loopback card (labeled J109 on the card) to the connector at

J109 for the optional differential status signals.

Figure 5–2. Attach the HM-Zd Loopback Card

5–2 Quartus II Version 3.0 Altera Corporation

Page 47

Perform the Production Diagnostic Tests Set Up the Board

4. Install six short SMA cables to the DPA SMA connectors:

● Connect DPA_CLKOUT (P & N) to DPA_CLKIN

● Connect DPA_TX0 (P & N) to DPA_RX0

● Connect DPA_TX1 (P & N) to DPA_RX1

See Figure 5–3.

1 Take care to connect the cables to the proper connectors and

ensure that the cables are completely seated.

Figure 5–3. Connect the Short SMA Cables for the SS DPA test

5. Install eight SMA cables to the transceiver SMA connectors as

shown in Figures 5–4 and 5–5. Do not overtighten the connectors

(using your fingers is good enough). Connect TX_P[3:0] to

RX_P[3:0] and TX_N[3:0] to RX_N[3:0].

1 Take care to connect the cables to the proper connectors

(there are 2 sets of connectors, 8 vertical launch and 8 edge

launch). Channels 0 and 1 are the edge launch and Channels

2 and 3 are the vertical launch connectors.

Altera Corporation Quartus II Version 3.0 5–3

Page 48

Set Up the Board High-Speed Development Kit, Stratix GX Edition User Guide

Figure 5–4. Connnect the Long SMA Cables to the Edge Launch Connectors

Figure 5–5. Attach Short SMA Cables to the Vertical Launch Connectors

6. Attach the HM-Zd XCVR loopback card (labeled J1 on the card) to

the HM-Zd transceiver connector as shown in Figure 5–6.

5–4 Quartus II Version 3.0 Altera Corporation

Page 49

Perform the Production Diagnostic Tests Set Up the Board

Figure 5–6. Attach the XCVR HM-Zd Loopback Card

7. Attach the SFP loopback card (labeled J3 on the card) to the SFP

transceiver connector at J54 as shown in Figure 5–7.

Figure 5–7. Attach the XCVR SFP Module

8. Attach the XPAK module to the XPAK transceiver connector at U27

as shown in Figure 5–8.

Altera Corporation Quartus II Version 3.0 5–5

Page 50

Set Up the Board High-Speed Development Kit, Stratix GX Edition User Guide

Figure 5–8. Attach the XCVR XPAK Module

9. Attach the HSSDC2 loopback cables to the HSSDC2 transceiver

connectors at J23 through J32 and J15 through J11 as shown in

Figure 5–9.

5–6 Quartus II Version 3.0 Altera Corporation

Page 51

Perform the Production Diagnostic Tests Set Up the Board

Figure 5–9. Attach the XCVR HSSDC2 Loopback Cables

10. Attach the DDR DIMM module to the DDR connector shown in

Figure 5–10.

Figure 5–10. Attach the DDR DIMM

11. Attach the 10/100-Mbit Ethernet network-interface daughter card to

the board as shown in Figure 5–11.

Figure 5–11. Attach the 10/100 Ethernet Network-Interface Card

Expansion Prototype

Card (PROTO1)

Connector

Altera Corporation Quartus II Version 3.0 5–7

Page 52

Set Up the Board High-Speed Development Kit, Stratix GX Edition User Guide

12. Attach the one end of the parallel cable to the PC’s parallel port if it

is not already attached.

13. Connect one end of the ByteBlaster II cable to the parallel cable.

14. Connect the other end of the ByteBlaster II cable to the JTAG header

(J87) on the Stratix GX development board, as shown in Figure 5–12.

Align the red edge of the cable with pin 1.

Figure 5–12. Attach the ByteBlaster II Cable

15. Move the power selection switch (SW3) to the middle position (off).

16. Attach the main power cable from the ATX supply to the power

connector (J31) on the board.

17. Set the Stratix bypass (SW1) and Stratix GX bypass (SW2) switches

to NO.

18. Set the configuration switch (SW4) to PS_HDR as shown in

Figure 5–13.

5–8 Quartus II Version 3.0 Altera Corporation

Page 53

Perform the Production Diagnostic Tests Set Up the Board

Figure 5–13. Power, Bypass & Configuration Switches

Power

Switch SW3

Configuration

Switch SW4

Stratix GX Device

Bypass Switch SW2

Stratix Device

Bypass Switch SW1

19. Set switches SW6 and SW9 to OSC, which is the up position.

20. Set the user dipswitches, S6 and S11, to zero, which is the down

position.

Figure 5–14 shows the board after you have attached all of the

daughter cards and cables, and set all of the switches.

Altera Corporation Quartus II Version 3.0 5–9

Page 54

Perform the Standard Tests High-Speed Development Kit, Stratix GX Edition User Guide

Figure 5–14. Board Completely Set Up

21. Power up the board by moving switch SW3 to the on position. The

board power ups with all of the user LEDs illuminated and the

7-segment displays turned on.

The board is now set up and you are ready to perform the tests.

Perform the Standard Tests

In this section you will perform all of the standard tests. For each test, you

will load a SOF onto the board. These SOFs are located in the

Stratix_GX_kit\test_designs\standard_test_designs\standard_sofs

directory.

1 Table 5–1 on page 5–36 is a worksheet for the tests. You should

have a printed copy of this worksheet when you perform the

tests so that you can note the test results in the appropriate

row/column in the worksheet.

User I/O

For this test, perform the following steps.

1. Run the Quartus II software. Keep the software open until you

finish all of the tests.

2. Choose Programmer (Tools menu). Leave the Programmer open

until you finish all of the tests.

5–10 Quartus II Version 3.0 Altera Corporation

Page 55

Perform the Production Diagnostic Tests Perform the Standard Tests

3. Click Auto-Detect. The Stratix, Stratix GX, and 2 EPC16 devices

display in the JTAG chain.

4. Change the programming file for the Stratix GX device:

a. Right-click the filename next to the Stratix GX device.

b. Browse to the standard SOFs directory.

c. Select the file GX40_User_IO.sof.

d. Click Open. Wait until the checksum field is updated.

5. Change the programming file for the Stratix device to

STX40_User_IO.sof using the steps described above. Wait until the

checksum field is updated.

6. Turn on the Program/Configure option for the Stratix and

Stratix GX devices. See Figure 5–15.

Figure 5–15. Quartus II Programmer for the User I/O Test

7. Click Start to configure both devices. When configuration is

complete for both devices, the GX_CONF_DONE (D7) and

S_CONF_DONE (D6) LEDs illuminate as shown in Figure 4–1 on

page 4–2.

8. Test the user I/O for the Stratix GX device by performing steps 1

through 12 in “Run the User I/O Test” on page 4–3.

Altera Corporation Quartus II Version 3.0 5–11

Page 56

Perform the Standard Tests High-Speed Development Kit, Stratix GX Edition User Guide

9. If all of the tests pass, write “PASS” in the column under Stratix GX

in the User I/O row in Table 5–1 on page 5–36.

10. Test the user I/O for the Stratix device by performing steps 13

through 24 in “Run the User I/O Test” on page 4–3.

11. If all of the tests pass, write “PASS” in the column under Stratix in

the User I/O row in the worksheet (Table 5–1 on page 5–36).

Stratix GX-to-Stratix Bridge

For this test, perform the following steps in the Programmer.

1. Change the programming file for the Stratix GX device to

GX40_Bridge.sof.

2. Change the programming file for the Stratix device to

STX40_Bridge.sof. Wait until the checksum field is updated.

3. Turn on the Program/Configure option for the Stratix and

Stratix GX devices.

Figure 5–16 shows the Programmer after you have done these steps.

Figure 5–16. Quartus II Programmer for the Stratix GX-to-Stratix Bridge Test

4. Click Start to configure both devices. When configuration is

complete for both devices, the GX_CONF_DONE (D7) and

S_CONF_DONE (D6) LEDs illuminate.

5–12 Quartus II Version 3.0 Altera Corporation

Page 57

Perform the Production Diagnostic Tests Perform the Standard Tests

5. Although this design uses both the Stratix and Stratix GX devices,

the Stratix GX device controls it. Set all of the Stratix GX user

dipswitches to 0.

6. Press GX_CLR (S14) to reset the design. The GX_CLR (D16) LED

illuminates and the Stratix GX LEDs 0 through 4 (D10, D11, D12,

D13, and D14) should be off. Additionally, the Stratix LEDs 0 and 1

(D18 and D19) illuminate while the rest are off.

7. Press the start pushbutton switch (Stratix_GX_PB_0). Several LEDs

illuminate.

● Stratix GX LED0 is the match LED. If it illuminates, the test is

successful.

● Stratix GX LED1 indicates the test has started.

● Stratix GX LED2 indicates that the GX device is transmitting to

the Stratix device.

● Stratix GX LED3 indicates that the GX device has received the

data from the Stratix device.

● Stratix GX LED5 illuminates if there is an error.

8. Press the stop pushbutton switch (Stratix_GX_PB_1) to stop the

device from transmitting.

9. Press the reset pushbutton switch (GX_CLR).

10. Press the start pushbutton switch (Stratix_GX_PB_0).

11. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The number

01 displays on the Stratix GX 7-segment display (D9) and Stratix GX

LED5 illuminates.

12. Inject two more errors by pressing S4 twice. 03 displays on the

Stratix GX 7-segment display (D9).

13. Press start and then reset three times to insure that the test is

working.

14. If all of these tests pass, write the word “PASS” in the column under

Stratix and Stratix GX in the row Stratix GX-to-Stratix Bridge in the

worksheet.

Altera Corporation Quartus II Version 3.0 5–13

Page 58

Perform the Standard Tests High-Speed Development Kit, Stratix GX Edition User Guide

Source Synchronous HM-Zd Interface (Stratix GX HM-Zd SPI 4.2)

For this test, perform the following steps in the Programmer.

1. Change the programming file for the Stratix GX device to

GX40_SS_HMZd.sof. Wait until the checksum field is updated.

2. Turn on the Program/Configure option for the Stratix GX device.

Figure 5–17 shows the Programmer after you have done these steps.

Figure 5–17. Quartus II Programmer for the Source-Synchronous HM-ZdTest

3. Click Start. When configuration is complete, the GX_CONF_DONE

(D7) LED illuminates.

4. Press the reset pushbutton switch (GX_CLR).

5. Press the start pushbutton switch (Stratix_GX_PB_0). Several LEDs

illuminate.

● LED0 is the high-speed data and control signal match LED. If it

illuminates, the test is successful.

● LED1 indicates that the GX device has received the data.

● LED2 indicates a per channel match. This LED is used for the per

channel feature.

● LED3 indicates that the test has started.

● LED4 is the match LED for the low-speed control signals.

● LED5 is the error indicator.

5–14 Quartus II Version 3.0 Altera Corporation

Page 59

Perform the Production Diagnostic Tests Perform the Standard Tests

6. Press the stop pushbutton switch (Stratix_GX_PB1) to stop the

device from transmitting.

7. Press the reset pushbutton switch (GX_CLR).

8. Press the start pushbutton switch (Stratix_GX_PB_0).

9. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The number

01 displays on the Stratix GX 7-segment display (D9) and Stratix GX

LED5 illuminates.

10. Inject two more errors by pressing Stratix_GX_PB_2 (S4) twice. 03

displays on the Stratix GX 7-segment display (D9).

11. Press start and then reset three times to insure that the test is

working.

12. If all of these tests pass, write the word “PASS” in the column under

Stratix GX in the row Stratix GX HM-Zd (SPI 4.2) in the worksheet.

Source Synchronous DPA SMA interface (Stratix GX SMA DPA)

For this test, perform the following steps in the Programmer.

1. Click Auto-Detect to display all of the devices in the JTAG chain.

2. Change the programming file for the Stratix GX device to

GX40_SS_DPA.sof. Wait until the checksum field is updated.

3. Turn on the Program/Configure option for the Stratix GX device.

Figure 5–18 shows the Programmer after you have done these steps.

Altera Corporation Quartus II Version 3.0 5–15

Page 60

Perform the Standard Tests High-Speed Development Kit, Stratix GX Edition User Guide

Figure 5–18. Quartus II Programmer for the Source-Synchronous DPA Test

4. Click Start. When configuration is complete, the GX_CONF_DONE

(D7) LED illuminates.

5. Press the reset pushbutton switch (GX_CLR) to initialize the design.

The GX_DEV_CLR LED illuminates.

6. Press the start pushbutton switch (GX PB0). Several LEDs

illuminate.

● LED0 is the match LED; it illuminates if the test is successful.

LED1 indicates that the test is running.

● LED2 indicates that the device has received the data through the

cables.

● LED3 is the per channel match. This LED is used for the per

channel feature.

● LED4 is turned off.

● LED5 is the error signal.

7. Press the stop pushbutton switch (Stratix_GX_PB1) to stop the

device from transmitting.

8. Press the reset pushbutton switch (GX_CLR).

9. Press the start pushbutton switch (Stratix_GX_PB_0).

10. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The number

01 displays on the Stratix GX 7-segment display (D9) and Stratix GX

LED5 illuminates.

5–16 Quartus II Version 3.0 Altera Corporation

Page 61

Perform the Production Diagnostic Tests Perform the Standard Tests

11. Inject two more errors by pressing Stratix_GX_PB_2 (S4) twice. 03

displays on the Stratix GX 7-segment display (D9).

12. Press start and then reset three times to insure that the test is

working.

13. If all of these tests pass, write the word “PASS” in the column under

Stratix GX in the row Stratix GX SMA DPA in the worksheet.

Gigabit Transceivers with SMA Interface (Stratix GX SMA XCVR)

For this test, perform the following steps in the Programmer.

1. Change the programming file for the Stratix GX device to

GX40_XCVRs.sof. Wait until the checksum field is updated.

2. Turn on the Program/Configure option for the Stratix GX device.

Figure 5–19 shows the Programmer after you have done these steps.

Figure 5–19. Quartus II Programmer for the Gigabit Transceiver Test

3. Click Start. When configuration is complete, the GX_CONF_DONE

(D7) LED illuminates.

4. Change the XCVR setting to SMA by setting the Stratix GX user

dipswitch 6 to the up position and dipswitch 5 to the down position.

5. Press the reset pushbutton switch (GX_DEV CLR) to initialize the

design. The GX_DEV_CLR LED illuminates.

Altera Corporation Quartus II Version 3.0 5–17

Page 62

Perform the Standard Tests High-Speed Development Kit, Stratix GX Edition User Guide

6. Press the start pushbutton switch (GX PB0). Several LEDs

illuminate.

● LED0, LED1, LED2, and LED3 are the match LEDs on a per

channel basis; they illuminate if the test is successful.

● LED4 indicates that the test is running.

● LED5 is the error signal.

7. Press the stop pushbutton switch (GX PB1) to stop the device from

transmitting.

8. Press the reset pushbutton switch (GX_CLR).

9. Press the start pushbutton switch (Stratix_GX_PB_0).

10. Inject an error by pressing Stratix_GX_PB_2 (S4) once. The number

01 displays on the Stratix GX 7-segment display (D9) and Stratix GX

LED5 illuminates.

11. Inject two more errors by pressing Stratix_GX_PB_2 (S4) twice. 03

displays on the Stratix GX 7-segment display (D9).

12. Press start and then reset three times to insure that the test is

working.

13. If all of these tests pass, write the word “PASS” in the column under

Stratix GX in the row Stratix GX SMA XCVR in the worksheet.

Gigabit Transceivers with HM-Zd Interface (Stratix GX HM-Zd XCVR)

For this test, perform the following steps.

1. Change the XCVR setting to HM-Zd by moving the Stratix GX user

dipswitch 6 to the up position and dipswitch 5 to the up position.

2. Press the reset pushbutton switch (GX_DEV CLR) to initialize the

design. The GX_DEV_CLR LED illuminates.

3. Press the start pushbutton switch (GX PB0). Several LEDs

illuminate.

● LED0, LED1, LED2, and LED3 are the match LEDs on a per

channel basis; they illuminate if the test is successful.

● LED4 indicates that the test is running.

● LED5 is the error signal.

5–18 Quartus II Version 3.0 Altera Corporation

Page 63

Perform the Production Diagnostic Tests Perform the Standard Tests