Measure what you see.

A5-A1 / A-T / U-Z6 / Z7-Z10

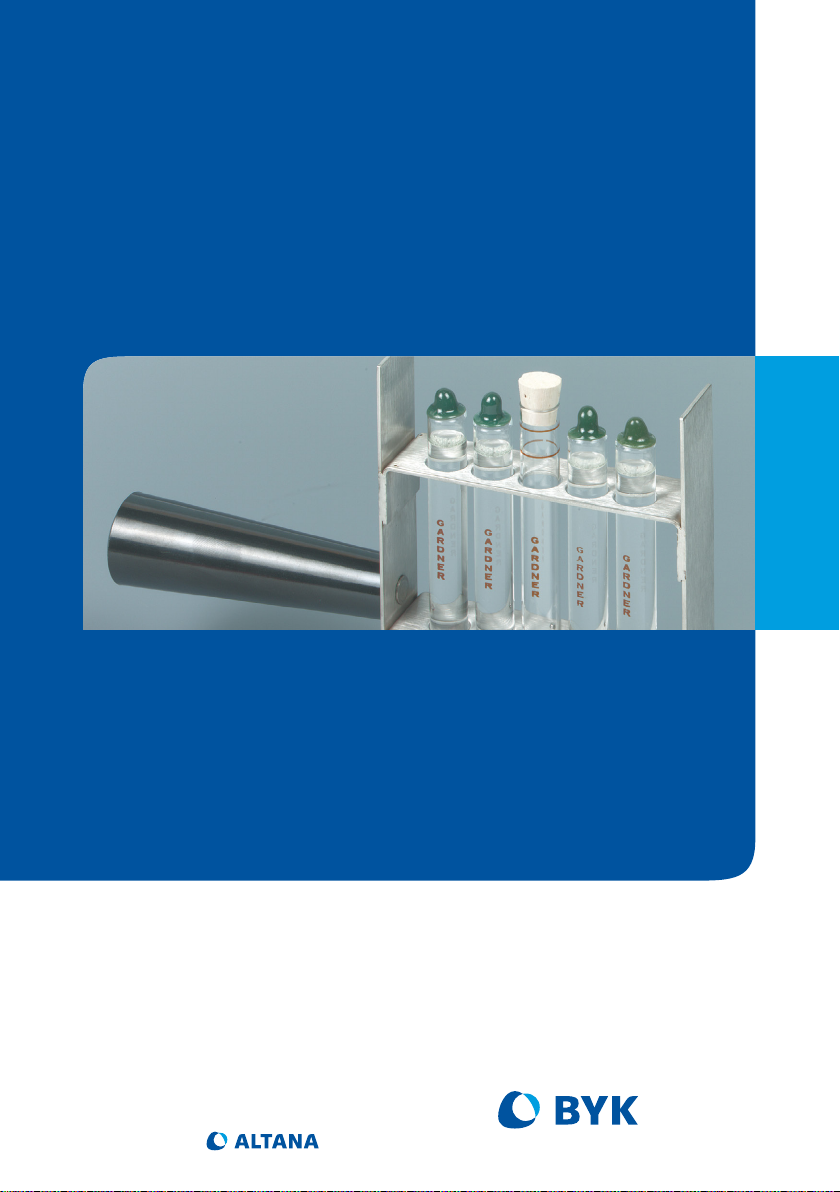

Bubble Viscometers

A member of

Manual

Additives & Instruments

Bubble Viscometers

A5-A1 / A-T /

U-Z6 / Z7-Z10

Manual

English

PV-0500 Series

PV-0600 Series

BYK - Gardner USA

9104 Guilford Road

Columbia, MD 21046

USA

Phone 800-343-7721

301-483-6500

Fax 800-394-8215

301-483-6555

www.byk.com/instruments

BYK-Gardner GmbH

Lausitzer Str. 8

D-82538 Geretsried

Germany

Tel. 0-800-gardner

(0-800-4273637)

+49-8171-3493-0

Fax +49-8171-3493-140

Directions for Using the Gardner Bubble Viscometer

DIRECTIONS FOR USING THE

GARDNER BUBBLE VISCOMETER A-5 to A-1

CAT. NO. PV-0500

This instrument is based on the principle that the

viscosity is directly proportional to the bubble

speed. The viscosity of a sample of varnish or

other transparent liquid is therefore determined

by reference to the standard tubes in which an air

bubble rises with the same speed as it does in a

tube of the sample being tested. For this purpose

two carefully calibrated empty tubes are furnished

with each set.

The bubble size of the sample is rst adjusted as

nearly as possible to that in the standard tubes.

The tubes are then brought to a temperature of

25ºC (77ºF). This is essential due to the difference

in the temperature coefcient of viscosity of

mineral oils and varnishes. It is suggested that

a water bath be used, which quickly brings the

tubes to the proper temperature and insures

greater accuracy.

The bubble should be started from the at end

of the tube held in a true vertical position. The

bottom meniscus of the bubble should be used

for comparing the samples. It is only necessary

that they start together. Owing to unavoidable

differences in bubble sizes and in the shapes of

the ends of the tubes, it may be necessary to raise

one of the tubes so that the points of comparison

will be on the same level. The observation is made

after the bubbles are completely formes and

moving upwards along a true vertical line. This

takes place about 1½ to 2 cm from the bottom of

the tube.

The standard empty grade “A” tubes have been

carefully selected to and I.D. of 10.65 ± 0.0025

mm. and should be used for exact determinations.

However, this close tolerance is relatively

expensive, and for the sake of economy, tubes

2

Directions for Using the Gardner Bubble Viscometer

having the same approximate diameter with a

tolerance of ± 0.150 mm. Grade “B” are used by

many manufacturer for general factory control

tests.

This viscometer meets the requirements of ASTM

D 154, D 555, D 1131, D 1545, D 1725, FTMS

14la-Method 4271, and AOCS Method Ka6.

Approximate Viscosity in Stokes at 25º C (77º F)

A5 0.051

A4 0.071

A3 0.140

A2 0.213

A1 0.310

3

Directions for Using the Gardner Bubble Viscometer

DIRECTIONS FOR USING THE

GARDNER BUBBLE VISCOMETER A to T

CAT. NO. PV-0510

This instrument is based on the principle that the

viscosity is directly proportional to the bubble

speed. The viscosity of a sample of varnish or

other transparent liquid is therefore determined

by reference to the standard tubes in which an air

bubble rises with the same speed as it does in a

tube of the sample being tested. For this purpose

two carefully calibrated empty tubes are furnished

with each set.

The bubble size of the sample is rst adjusted as

nearly as possible to that in the standard tubes.

The tubes are then brought to a temperature of

25ºC (77ºF). This is essential due to the difference

in the temperature coefcient of viscosity of mineral oils and varnishes. It is suggested that a water

bath be used, which quickly brings the tubes to

the proper temperature and insures greater accuracy.

The bubble should be started from the at end

of the tube held in a true vertical position. The

bottom meniscus of the bubble should be used

for comparing the samples. It is only necessary

that they start together. Owing to unavoidable

differences in bubble sizes and in the shapes of

the ends of the tubes, it may be necessary to raise

one of the tubes so that the points of comparison will be on the same level. The observation is

made after the bubbles are completely formes and

moving upwards along a true vertical line. This

takes place about 1½ to 2 cm from the bottom of

the tube.

The standard empty grade “A” tubes have been

carefully selected to and I.D. of 10.65 ± 0.0025

mm. and should be used for exact determinations.

4

Directions for Using the Gardner Bubble Viscometer

However, this close tolerance is relatively expensive,

and for the sake of economy, tubes having the

same approximate diameter with a tolerance of

± 0.150 mm. Grade “B” are used by many

manufacturer for general factory control tests.

This viscometer meets the requirements of ASTM

D 154, D 555, D 1131, D 1545, D 1725, FTMS

14la-Method 4271, and AOCS Method Ka6.

Approximate Viscosity in Stokes at 25º C (77º F)

A 0.54

B 0.69

C 0.93

D 1.03

E 1.23

F 1.52

G 1.60

H 2.11

I 2.24

J 2.68

K 2.88

L 3.02

M 3.35

N 3.45

O 3.78

P 4.09

Q 4.42

R 4.67

S 5.18

T 5.47

5

Directions for Using the Gardner Bubble Viscometer

DIRECTIONS FOR USING THE

GARDNER BUBBLE VISCOMETER „U“ to „Z-6“

CAT. NO. PV-0540

This instrument is based on the principle that the

viscosity is directly proportional to the bubble

speed. The viscosity of a sample of varnish or

other transparent liquid is therefore determined

by reference to the standard tubes in which an air

bubble rises with the same speed as it does in a

tube of the sample being tested. For this purpose

two carefully calibrated empty tubes are furnished

with each set.

The bubble size of the sample is rst adjusted as

nearly as possible to that in the standard tubes.

The tubes are then brought to a temperature of

25ºC (77ºF). This is essential due to the difference

in the temperature coefcient of viscosity of mineral oils and varnishes. It is suggested that a water

bath be used, which quickly brings the tubes to

the proper temperature and insures greater

accuracy.

The bubble should be started from the at end

of the tube held in a true vertical position. The

bottom meniscus of the bubble should be used

for comparing the samples. It is only necessary

that they start together. Owing to unavoidable

differences in bubble sizes and in the shapes of

the ends of the tubes, it may be necessary to raise

one of the tubes so that the points of comparison will be on the same level. The observation is

made after the bubbles are completely formes and

moving upwards along a true vertical line. This

takes place about 1½ to 2 cm from the bottom of

the tube.

The standard empty grade “A” tubes have been

carefully selected to and I.D. of 10.65 ± 0.0025

6

Directions for Using the Gardner Bubble Viscometer

mm. and should be used for exact determinations.

However, this close tolerance is relatively expensive,

and for the sake of economy, tubes having the

same approximate diameter with a tolerance of

± 0.150 mm. Grade “B” are used by many

manufacturer for general factory control tests.

This viscometer meets the requirements of ASTM

D 154, D 555, D 1131, D 1545, D 1725, FTMS

14la-Method 4271, and AOCS Method Ka6.

Approximate Viscosity in Stokes at 25º C (77º F)

U 6.66

V 8.89

W 10.7

X 12.0

Y 17.4

Z 22.9

Z-1 29.1

Z-2 40.6

Z-3 48.4

Z-4 72.4

Z-5 99.2

Z-6 150.8

7

Directions for Using the Gardner Bubble Viscometer

DIRECTIONS FOR USING THE

GARDNER BUBBLE VISCOMETER Z-7 to Z-10

CAT. NO. PV-0560

This instrument is based on the principle that the

viscosity is directly proportional to the bubble

speed. The viscosity of a sample of varnish or

other transparent liquid is therefore determined

by reference to the standard tubes in which an air

bubble rises with the same speed as it does in a

tube of the sample being tested. For this purpose

two carefully calibrated empty tubes are furnished

with each set.

The bubble size of the sample is rst adjusted as

nearly as possible to that in the standard tubes.

The tubes are then brought to a temperature of

25ºC (77ºF). This is essential due to the difference

in the temperature coefcient of viscosity of

mineral oils and varnishes. It is suggested that

a water bath be used, which quickly brings the

tubes to the proper temperature and insures

greater accuracy.

The bubble should be started from the at end

of the tube held in a true vertical position. The

bottom meniscus of the bubble should be used

for comparing the samples. It is only necessary

that they start together. Owing to unavoidable

differences in bubble sizes and in the shapes of

the ends of the tubes, it may be necessary to raise

one of the tubes so that the points of comparison

will be on the same level. The observation is made

after the bubbles are completely formes and

moving upwards along a true vertical line. This

takes place about 1½ to 2 cm from the bottom of

the tube.

The standard empty grade “A” tubes have been

carefully selected to and I.D. of 10.65 ± 0.0025

mm. and should be used for exact determinations.

However, this close tolerance is relatively

expensive, and for the sake of economy, tubes

having the same approximate diameter with a

8

Directions for Using the Gardner Bubble Viscometer

tolerance of ± 0.150 mm. Grade “B” are used by

many manufacturer for general factory control

tests.

This viscometer meets the requirements of ASTM

D 154, D 555, D 1131, D 1545, D 1725, FTMS

14la-Method 4271, and AOCS Method Ka6.

Approximate Viscosity in Stokes at 25º C (77º F)

Z-7 407

Z-8 733

Z-9 915

Z-10 1190

9

253 017 659 EDFIS 0408 Europe

Loading...

Loading...