Page 1

th

Allison 4

Generation Controls

Troubleshooting

Manual

1000 and 2000

Product Families

TS3977EN

Page 2

Troubleshooting

Manual

TS3977EN 200707

1000 AND 2000 PRODUCT FAMILIES

ALLISON 4

TH

GENERATION CONTROLS

Page 3

2007 FEBRUARY

Troubleshooting

REV. 1 2007 JULY

Manual

TS3977EN

Allison Transmission

ALLISON 4

1000 and 2000 Product Families

TH

GENERATION CONTROLS

Allison Transmission, Inc.

P.O. Box 894 Indianapolis, Indiana 46206-0894

www.allisontransmission.com

Printed in USA

Copyright © 2007 Allison Transmission, Inc.

Page 4

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

FOREWORD — How to Use This Manual

This manual provides troubleshooting information for Allison Transmission 1000 and 2000 Product Families

transmissions. Service Manual SM4006EN, Mechanics Tips MT4007EN, and Parts Catalog PC3062EN may be

used in conjunction with this manual.

This manual includes:

•

Description of the electronic control system.

•

Description of the electronic control system components.

•

Description of diagnostic codes, system responses to faults, and troubleshooting.

•

Wire, terminal, and connector repair information.

Specific instructions for using many of the available or required service tools and equipment are not included in

this manual. The service tool manufacturer will furnish instructions for using the tools or equipment.

Additional information may be published from time to time in Service Information Letters (SIL) and will be

included in future revisions of this and other manuals. Please use these SILs to obtain up-to-date information

concerning Allison Transmission products.

This publication is revised periodically to include improvements, new models, special tools, and procedures. A

revision is indicated by a new date on the title page and rear cover. Check with your Allison Transmission service

outlet for the currently applicable publication. Additional copies of this publication may be purchased from

authorized Allison Transmission service outlets. Look in your telephone directory under the heading of

Transmissions—Truck, Tractor, etc.

Take time to review the Table of Contents and the manual. Reviewing the Table of Contents will aid you in quickly

locating information.

NOTE: Allison Transmission is providing service of wiring harnesses and wiring harness components as

follows:

•

Repair parts for the internal wiring harness will be available through the Allison Transmission

Parts Distribution Center (PDC). Use the P/N from your appropriate parts catalog or from

Appendix E in this manual. Allison Transmission is responsible for warranty on these parts.

•

Repair parts for the external harnesses and external harness components must be obtained from

the vehicle OEM or the OEM is responsible for warranty on these parts.

ii Copyright© 2007 Allison Transmission, Inc.

Page 5

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

IMPORTANT SAFETY NOTICE

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and cautions used in this

manual. These warnings and cautions advise against using specific service procedures that can result in

personal injury, equipment damage, or cause the equipment to become unsafe. These warnings and

cautions are not exhaustive. Allison Transmission could not possibly know, evaluate, or advise the

service trade of all conceivable procedures by which service might be performed or of the possible

hazardous consequences of each procedure. Consequently, Allison Transmission has not undertaken any

such broad evaluation. Accordingly, ANYONE WHO USES A SERVICE PROCEDURE OR TOOL

WHICH IS NOT RECOMMENDED BY ALLISON TRANSMISSION MUST first be thoroughly

satisfied that neither personal safety nor equipment safety will be jeopardized by the service procedures

used.

Also, be sure to review and observe WARNINGS, CAUTIONS, and NOTES provided by the vehicle

manufacturer and/or body builder before servicing the Allison transmission in that vehicle.

Proper service and repair is important to the safe and reliable operation of the equipment. The service

procedures recommended by Allison Transmission and described in this manual are effective methods for

performing troubleshooting operations. Some procedures require using specially designed tools. Use

special tools when and in the manner recommended.

The WARNINGS, CAUTIONS, and NOTES in this manual apply only to the Allison transmission and not to

other vehicle systems which may interact with the transmission. Be sure to review and observe any vehicle

system information provided by the vehicle manufacturer and/or body builder at all times the Allison

transmission is being serviced.

WARNINGS, CAUTIONS, AND NOTES

Three types of headings are used in this manual to attract your attention:

WARNING!

CAUTION:

Is used when an operating procedure, practice, etc., which, if not correctly followed,

could result in injury or loss of life.

Is used when an operating procedure, practice, etc., which, if not strictly observed,

could result in damage to or destruction of equipment.

NOTE: Is used when an operating procedure, practice, etc., is essential to highlight.

Copyright© 2007 Allison Transmission, Inc. iii

Page 6

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

TRADEMARKS USED IN THIS MANUAL

The following trademarks are the property of the companies indicated:

•

•

•

•

•

•

®

Adobe

Acrobat

Allison DOC™ For PC—Service Tool is a trademark of General Motors Corporation.

®

LPS

Cleaner is a registered trademark of LPS Laboratories.

Loctite

Teflon

Windows

®

is a registered trademark of the Loctite Corporation.

®

is a registered trademark of the DuPont Corporation.

®

®

Reader

95, Windows

®

are registered trademarks of Adobe Systems Incorporated.

®

98, Windows

®

XP, and Windows NT

®

are trademarks of Microsoft Corporation.

SERVICE LITERATURE

This service literature provides fully illustrated instructions for operation, maintenance, service, overhaul, and parts

support for your transmission. For maximum performance and service life from you unit, you may order

publications from:

SGI, Inc.

Attn: Allison Literature Fulfillment Desk

8350 Allison Avenue

Indianapolis, IN 46268

TOLL FREE: 888-666-5799

INTERNATIONAL: 317-471-4995

1000 and 2000 Product Families Service Literature

Publication Name Publication No.

Allison DOC™ For PC–Service Tool User Guide GN3433EN

Automatic Transmission Fluid Technician’s Guide GN2055EN

*Mechanic’s Tips MT4007EN

*In-Chassis Maintenance GN4008EN

*Emergency Vehicle Series Operator’s Manual OM3761EN

*Highway Series Operator’s Manual OM3757EN

*Rugged Duty Series Operator’s Manual OM3759EN

*Motorhome Series Operator’s Manual OM3364EN

*Pupil Transport/Shuttle Series Operator’s Manual OM3758EN

*Bus Series Operator’s Manual OM3765EN

*1000, 2000, 2400 Operator’s Manual OM3063EN

*Owner’s Manual (2000MH) OM3364EN

*Parts Catalog PC3062EN

Parts Catalog On CD-ROM CD3062EN

Principles Of Operation PO4009EN

Service Manual SM4006EN

th

Troubleshooting Manual—Allison 4

Also Available On The Internet At www.allisontransmission.com

*

Generation Controls TS3977EN

iv Copyright© 2007 Allison Transmission, Inc.

Page 7

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

TABLE OF CONTENTS

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

SAFETY INFORMATION

Important Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Trademarks Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Service Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

SECTION 1. GENERAL DESCRIPTION

1–1. TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–1

1–2. TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

1–3. SHIFT SELECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

A. Shift Selector Range Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

B. Manual Selector Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

C. Internal Mode Switch (IMS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

1–4. THROTTLE POSITION SENSOR (TPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

1–5. SPEED SENSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

A. Input (Engine) Speed Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

B. Turbine Speed Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

C. Output Speed Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

1–6. CONTROL VALVE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–7

A. Main Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–8

1–7. WIRING HARNESSES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–8

A. External Wiring Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–8

B. Internal Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–10

1–8. SPECIAL ELECTRONIC/ELECTRICAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–11

Page

SECTION 2. DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–1

2–2. RANGE INHIBIT RESPONSES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–1

2–3. ALLISON DOC™ FOR PC–SERVICE TOOL INHIBITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–1

2–4. ALLISON DOC™ FOR PC–SERVICE TOOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–4

2–5. ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–5

SECTION 3. BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

3–2. USING THE TROUBLESHOOTING MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

3–3. SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS. . . . . . . . . . . . . . . . .3–2

3–5. BASIC TROUBLESHOOTING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–3

3–6. TCM DIAGNOSTIC PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–9

3–7. RESETTING OF TCM PARAMETERS TO SUPPORT ENGINE UPDATE. . . . . . . . . . . . . . . . . .3–9

3–8. RESETTING TCM SEM AUTOSELECT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–10

Copyright© 2007 Allison Transmission, Inc. v

Page 8

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

TABLE OF CONTENTS

(cont’d)

th

GENERATION CONTROLS

SECTION 4. WIRE CHECK PROCEDURES

4–1. CHECKING OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . . . 4–1

4–2. CHECKING AT TRANSMISSION CONNECTOR AND THE INTERNAL HARNESS

FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND. . . . . . . . . . . . . . . . 4–2

SECTION 5. DIAGNOSTIC TROUBLE CODES (DTC)

5–1. DTC MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2. FAILURE RECORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–3. DTC READING AND DTC CLEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

A. Clearing DTCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

B. Clearing Active Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–4. BEGINNING THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

A. Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

B. Solenoid Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

C. Wire/Terminal Numbering Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

D. Available Diagnostic Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5–5. DIAGNOSTIC TROUBLE CODES (DTCs—Includes Index) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–10

Page

SECTION 6. INPUT AND OUTPUT FUNCTIONS

6–1. SPECIAL INPUT AND OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

A. Input Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

B. Output Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

SECTION 7. GENERAL TROUBLESHOOTING OF PERFORMANCE COMPLAINTS . . . . . . . . . . 7–1

APPENDICES

A. DIAGNOSING INTERMITTENT DTCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

B. MAIN PRESSURE CHECK PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C. SOLENOID AND CLUTCH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

D. WIRE/CONNECTOR TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

E. CONNECTOR REPAIR INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–1

F. THROTTLE POSITION SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

G. WELDING ON VEHICLE/VEHICLE INTERFACE MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . G–1

H. HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H–1

J. WIRING SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .J–1

K. RESISTANCE vs. TEMPERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K–1

L. ELECTRONIC INTERFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L–1

M. Allison DOC™ FOR PC–SERVICE TOOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M–1

N. INPUT/OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N–1

P. J1939 AND J2284 HARDWARE AND TCM CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . P–1

R. FLUID CHECK PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R–1

vi Copyright© 2007 Allison Transmission, Inc.

Page 9

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

ECTION

S

1—GENERAL DESCRIPTION

th

GENERATION CONTROLS

1–1. TRANSMISSION

The 1000 and 2000 Product Families Allison 4

provide superior shift quality over a wide range of operating conditions. The 1000 and 2000 Product Families

configurations can be programmed to provide up to six forward speeds, neutral, and reverse. The fifth and sixth

ranges are overdrive gear ratios. The 1000 and 2000 Product Families incorporates a variety of standard and

optional design features.

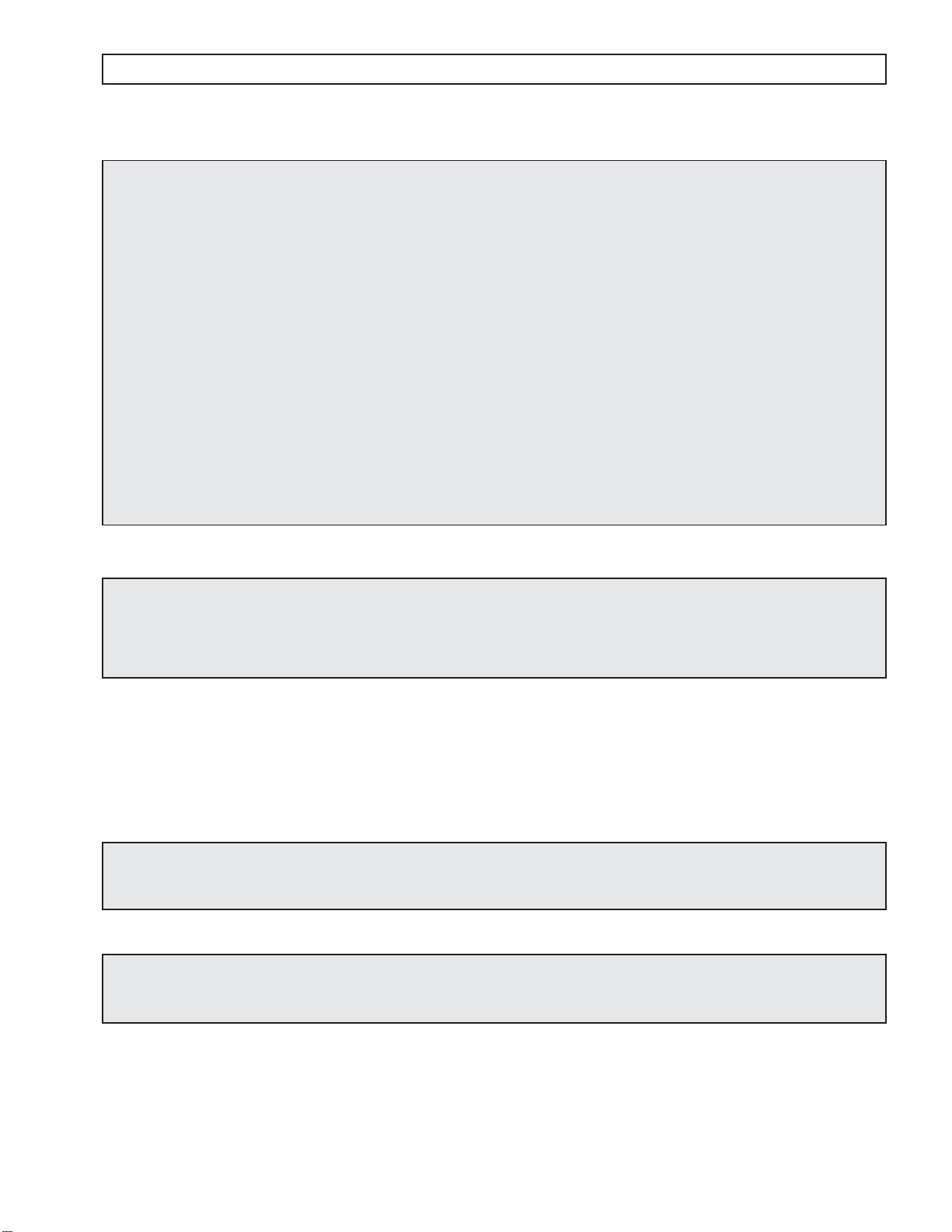

Figure 1–1 is a block diagram of the basic system inputs and outputs.

PRESSURE SWITCH MANIFOLD

SPEED SENSORS

THROTTLE POSITION SENSOR

VEHICLE/ENGINE

COMMUNICATION LINKS

th

Generation Controls system features closed-loop clutch control to

INTERNAL MODE SWITCH

SOLENOIDS

(VBS, ON/OFF)

TCM

TEMPERATURE SENSOR

(SUMP/ENGINE)

INPUTS

OUTPUTS

Figure 1–1. Transmission Control Module Block Diagram

Figure 1–2 shows the electronic control components.

Electronic Controls consist of the following elements:

•

Remote 12V or 24V Transmission Control Module (TCM)

•

Throttle Position Sensor (TPS), electronic engine throttle data, or PWM signal

•

Speed Sensors—Input (Engine), Turbine, and Output

•

Control Valve Assembly (Electro-Hydraulic Valve Body)

•

Internal Mode Switch (IMS)

•

Pressure Switch Manifold (PSM)

•

Wiring Harnesses

NOTE: All external harnesses are OEM-supplied.

V05726.00.01

Copyright© 2007 Allison Transmission, Inc. 1–1

Page 10

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

GENERAL DESCRIPTION

TRANSMISSION

CONTROL

MODULE

(TCM)

TRANSMISSION

HARNESS

80-WAY

CONNECTOR

J1939

CONNECTOR

OEM SUPPLIED

INTERFACE HARNESS

th

GENERATION CONTROLS

ENGINE

SPEED SENSOR

CONNECTOR

TURBINE

SPEED SENSOR

CONNECTOR

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

(OPTIONAL)

THROTTLE

POSITION

SENSOR (TPS)

NOTE: Illustration is not to scale. Actual harness

configuration may differ from this illustration.

OUTPUT

SPEED SENSOR

CONNECTOR

24-WAY MAIN

TRANSMISSION

CONNECTOR

20-WAY

CONNECTOR

(OPTIONAL)

.

Figure 1–2. Electronic Control Components

1–2 Copyright© 2007 Allison Transmission, Inc.

V06475.03.00

Page 11

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

GENERAL DESCRIPTION

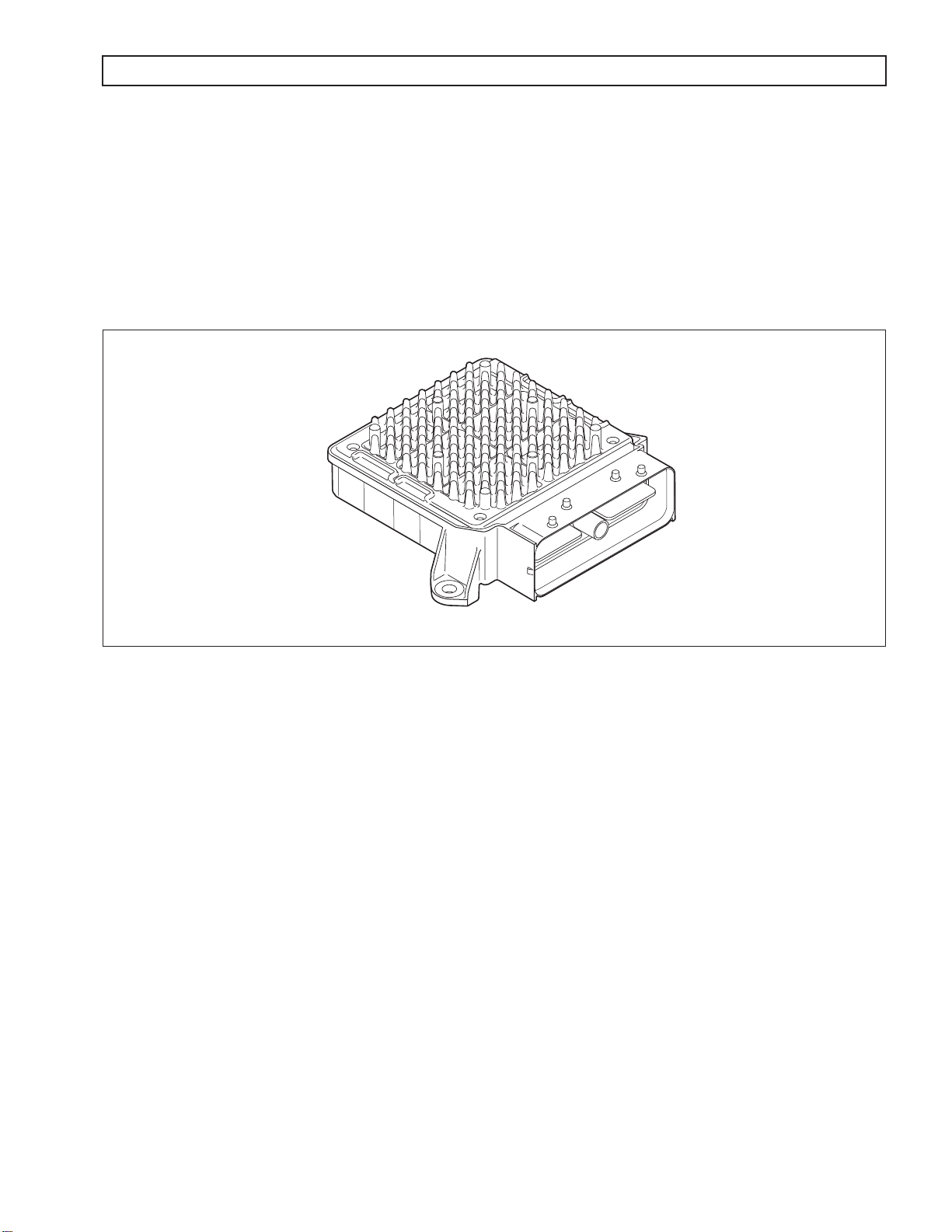

1–2. TRANSMISSION CONTROL MODULE (TCM)

The electronic control of the transmission is performed by a microcomputer. The microcomputer is an independent

controller and is referred to as a Transmission Control Module (TCM). TCMs are available in both 12V and 24V

configurations to match the configuration of the vehicle electrical system.

The TCM (refer to Figure 1–3) receives and processes signals from various switches and sensors. The TCM

determines shift sequences, shift timing, and clutch apply and release pressures. The TCM uses the information to

control transmission solenoids and valves, supply system status, and provide diagnostic information.

V09005.00.00

Figure 1–3. Transmission Control Module (TCM)

1–3. SHIFT SELECTOR

The vehicle is equipped with a lever-type shift selector (refer to Figure 1–4). In addition to the lever assembly

provided for the operator, other components associated with the shift selector are the manual selector valve in the

main control valve body and an Internal Mode Switch (IMS) mounted on the selector shaft inside the transmission

oil pan. Shift selector components (with the exception of the transmission selector shaft) are customer-supplied.

A. Shift Selector Range Positions

The operator chooses the transmission range by moving the selector lever to the appropriate gate

position (refer to Figure 1–4). When properly adjusted, the shifter gates prevent inadvertent shifting

between ranges and correspond to the internal transmission detent positions. A positive detent is

provided in the transmission to maintain the selector shaft in the selected position.

Copyright© 2007 Allison Transmission, Inc. 1–3

Page 12

P

R

N

OD

D , 2 , 1

M

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

GENERAL DESCRIPTION

SHIFT SELECTOR

Figure 1–4. Typical Lever-Type Shift Selector

th

GENERATION CONTROLS

P

R

N

OD

D

2

1

TOP VIEW

V06476.01.00

The TCM shift calibration determines the available forward ranges for each selector position.

Although specific installations vary, typical selector positions for the 1000 and 2000 Product Families

are:

—Park. Parking pawl or parking brake is engaged, if available. This position is not available on all

shift selectors.

—Reverse.

—Neutral. May be used when starting the engine and for stationary operations.

—Overdrive. The highest forward range used for normal driving. The transmission shifts to first

range for starting, then automatically upshifts through the ranges (as operating conditions permit)

until the highest range is attained.

—Forward Range. The transmission shifts to first range for starting. The range selected on the

shift selector is the highest range which will be attained during automatic shifting (on GM truck

applications, a position

is used for Tap Up/Tap Down functionality).

B. Manual Selector Valve

The manual shift selector shaft is attached to the manual selector valve within the transmission main

control valve body. The selector valve has three positions: reverse, neutral, and forward.

NOTE: For transmissions equipped with a P (Park) position, the selector valve remains in

the neutral position when the selector is moved to P (Park).

The neutral and reverse selector valve positions (refer to Appendix H—Hydraulic Schematics)

exhaust the C1 and C2 rotating clutches. By exhausting C1 and C2 clutches, forward range is

inhibited. This provides the capability for the operator to override the electronically commanded

ranges if neutral is required.

1–4 Copyright© 2007 Allison Transmission, Inc.

Page 13

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

GENERAL DESCRIPTION

C. Internal Mode Switch (IMS)

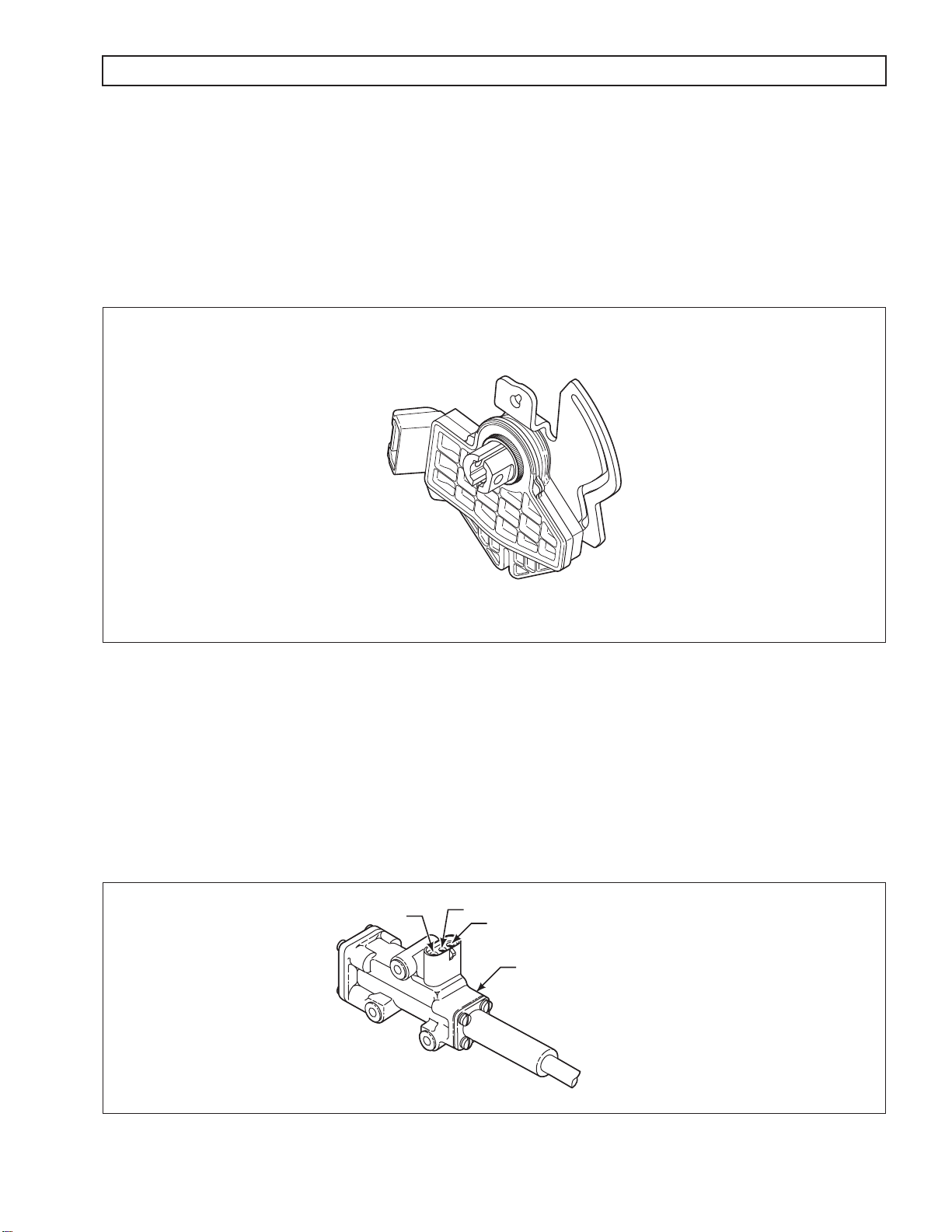

An internally-mounted switch, commonly called an Internal Mode Switch or IMS (refer to Figure 1–5),

mounts inside the transmission oil pan at the shift selector shaft. The IMS detects the angular position of

the shift selector shaft. This position is communicated to the TCM so that certain vehicle control

functions can be coordinated with the position of the shift controls. The neutral signal output of the IMS

is typically used as confirmation that the transmission is in neutral before the engine starter is engaged.

th

GENERATION CONTROLS

V09076.00.00

Figure 1–5. Internal Mode Sensor (IMS)

1–4. THROTTLE POSITION SENSOR (TPS)

The Throttle Position Sensor (TPS) can be mounted to the engine, chassis, or transmission. The TPS (refer to

Figure 1–6) contains a pull actuation cable and a potentiometer. One end of the cable is attached to the engine fuel

lever and the other, inside a protective housing, to the TPS potentiometer. Output voltage from the TPS is directed

to the TCM through the external harness. The voltage signal indicates the throttle position and, in combination with

other input data, determines shift timing.

A

B

C

THROTTLE POSITION

SENSOR (TPS)

V00628.01

Figure 1–6. Throttle Position Sensor (TPS)

Copyright© 2007 Allison Transmission, Inc. 1–5

Page 14

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4

th

GENERATION CONTROLS

GENERAL DESCRIPTION

1–5. SPEED SENSORS

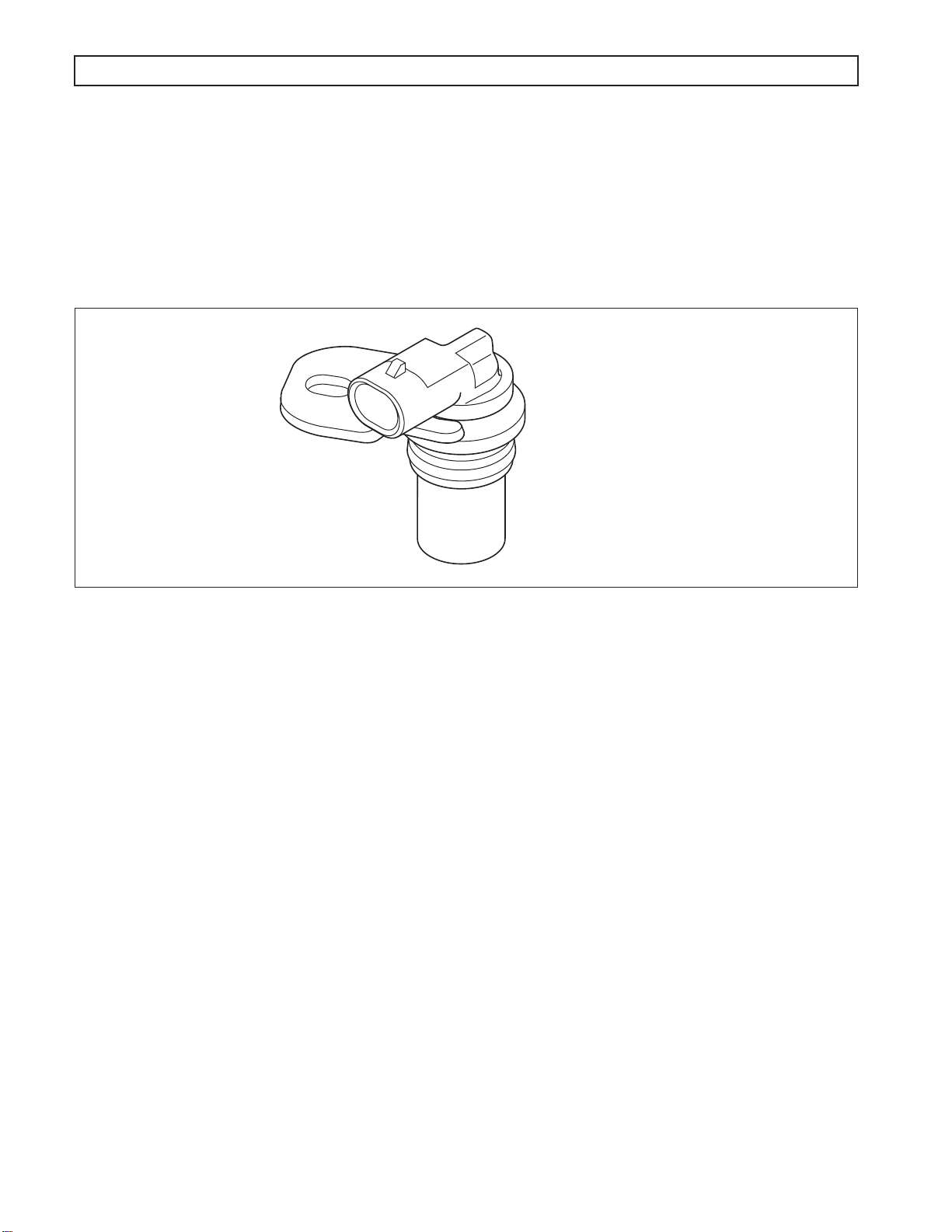

There are three speed sensors available for use with 1000 and 2000 Product Families transmissions: the input

(engine) speed sensor, the turbine speed sensor, and the output speed sensor (refer to Figure 1–7). The speed

sensors provide rpm information to the TCM. The speed ratios between the various sensors allow the TCM to

determine the transmission operating range. Speed sensor information is also used to control the timing of clutch

apply pressures, resulting in the best possible shift quality.

V04736

Figure 1–7. Typical Speed Sensor

The speed sensors are variable reluctance devices which convert mechanical motion to an AC voltage. Each sensor

consists of a wire coil wrapped around a pole piece that is adjacent to a permanent magnet. These elements are

contained in a housing which is mounted adjacent to a rotating ferrous member (such as a gear tooth). Two signal

wires extend from one end of the housing and an exposed end of the pole piece is at the opposite end of the

housing. The permanent magnet produces lines of flux around the pole piece. As a ferrous object (such as a gear

tooth) approaches and passes through the gap at the end of the pole piece, an AC voltage pulse is induced in the

wire coil. The TCM calculates the frequency of these AC pulses and converts it to a speed value. The AC voltage

generated varies from 150mV at low speed to 15V at high speed. The signal wires from the sensor are formed as

twisted pairs to cancel magnetically induced fields. The cable is also shielded to protect from voltage-related fields.

Noise from other sources is eliminated by using two-wire differential inputs at the TCM.

NOTE: Do not rotate the speed sensor in the retaining bracket. Orientation is fixed, and if changed, may cause

improper operation.

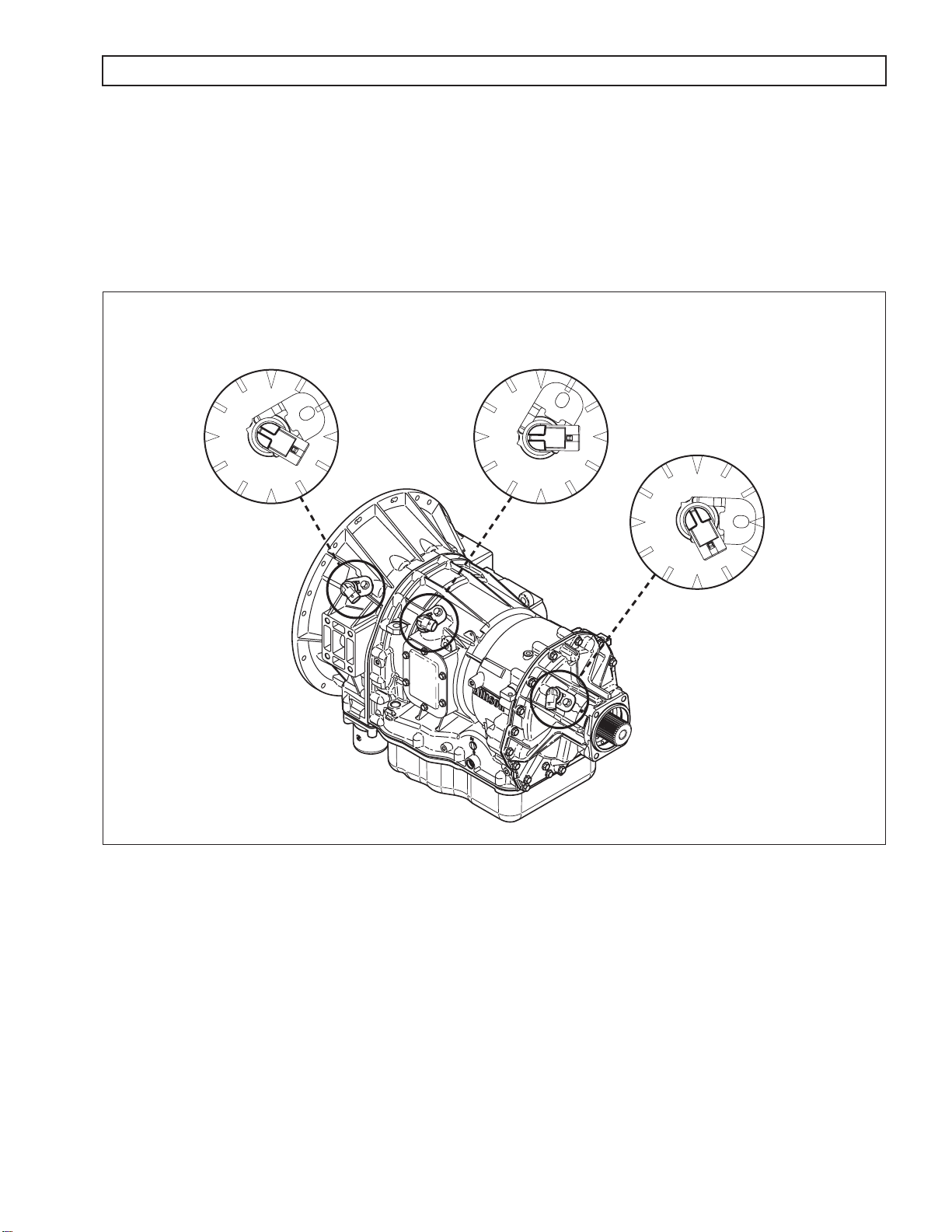

A. Input (Engine) Speed Sensor

The input speed sensor is externally mounted in the torque converter housing directed at the ribs

protruding from the torque converter. The input speed sensor connector should be positioned at

approximately four o’clock, as viewed from the left side of the transmission (refer to Figure 1–8).

B. Turbine Speed Sensor

The turbine speed sensor is externally mounted in the main housing directed at the tone wheel or PTO

drive gear attached to the rotating clutch module. The turbine speed sensor connector should be

positioned at approximately three o’clock, as viewed from the left side of the transmission (refer to

Figure 1–8).

1–6 Copyright© 2007 Allison Transmission, Inc.

Page 15

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

C. Output Speed Sensor

The output speed sensor is externally mounted in the rear cover and directed at the teeth of a tone

wheel splined to and rotating with the output shaft. The output speed sensor connector should be

positioned at approximately five o’clock, as viewed from the left side of the transmission (refer to

Figure 1–8).

ENGINE SPEED

SENSOR CONNECTOR

ORIENTATION = 4 o'clock

TURBINE SPEED

SENSOR CONNECTOR

ORIENTATION = 3 o'clock

OUTPUT SPEED

SENSOR CONNECTOR

ORIENTATION = 5 o'clock

V06457.01.00

Figure 1–8. Speed Sensor Connector Orientation

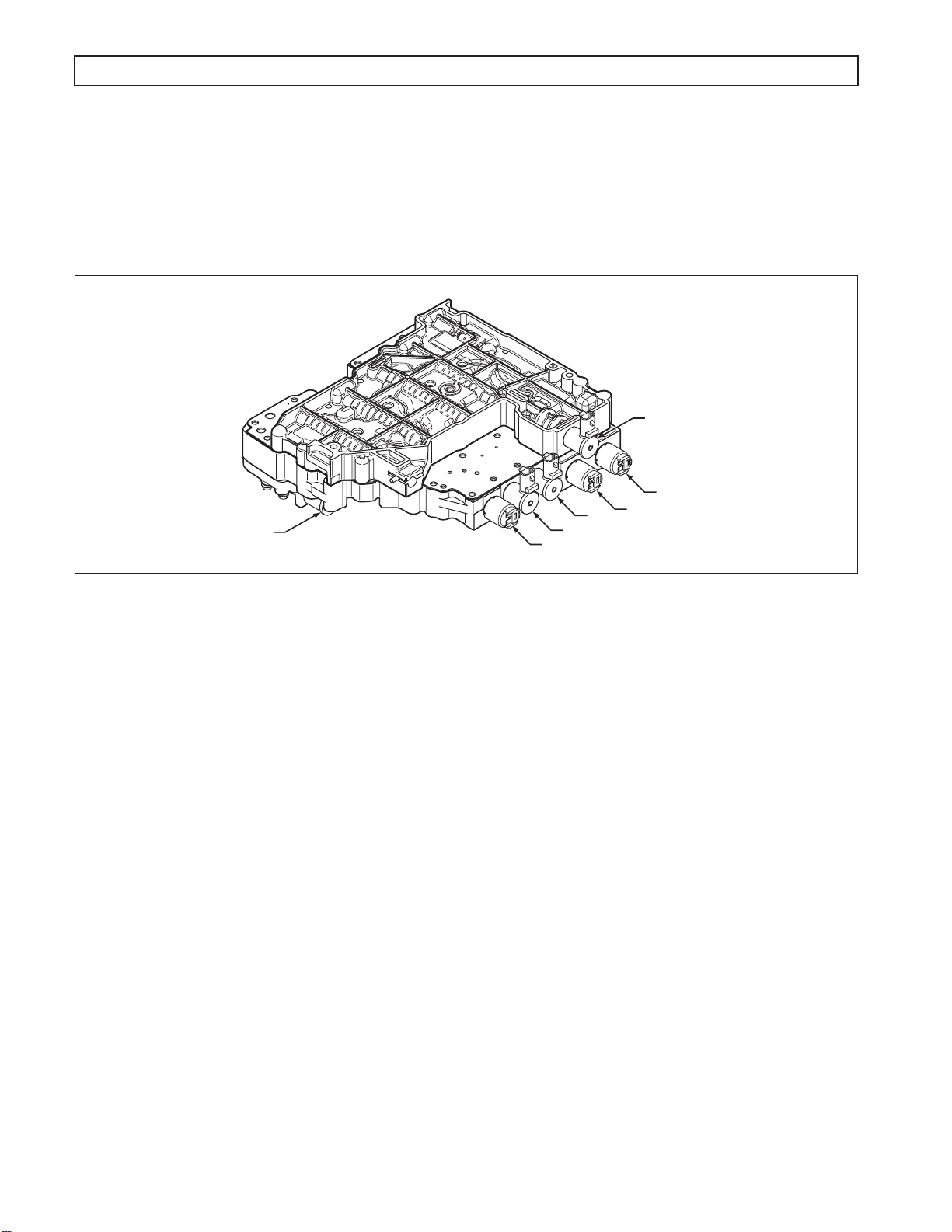

1–6. CONTROL VALVE ASSEMBLY

The hydraulic control valve assembly (Figure 1–9) governs fluid flow to the clutches (including the torque

converter clutch). Solenoids, actuated by the TCM, control valve movement.

The control valve assembly consists of two components, the main valve body and the control valve body. The main

valve body contains the pressure control valves (PCV), the TCC valve, the exhaust backfill valve, and the control

main relief valve. The shift valve body contains the shift valves, the control main pressure valve, and the manual

selector valve. The control valve assembly attaches to the bottom of the gearbox module and is enclosed by the oil

pan. An internal wiring harness connects the solenoids and Pressure Switch Manifold (PSM) to the main

transmission connector and external wiring harness.

Copyright© 2007 Allison Transmission, Inc. 1–7

Page 16

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

A. Main Modulation

Main pressure is reduced by utilizing an on/off Main Mod solenoid that is located in the control valve

body assembly. The Main Mod solenoid body is bolted to the main valve body. Main pressure will be

reduced under various conditions such as low throttle, low torque, low engine speeds, and low output

speeds. The primary benefit of modulating main pressure is to increase cooler flow at low engine speeds.

SS1

PCS1

PCS2

SS3

MAIN MOD

TCC

SS2

V07476.02.01

Figure 1–9. Control Valve Assembly

1–7. WIRING HARNESS

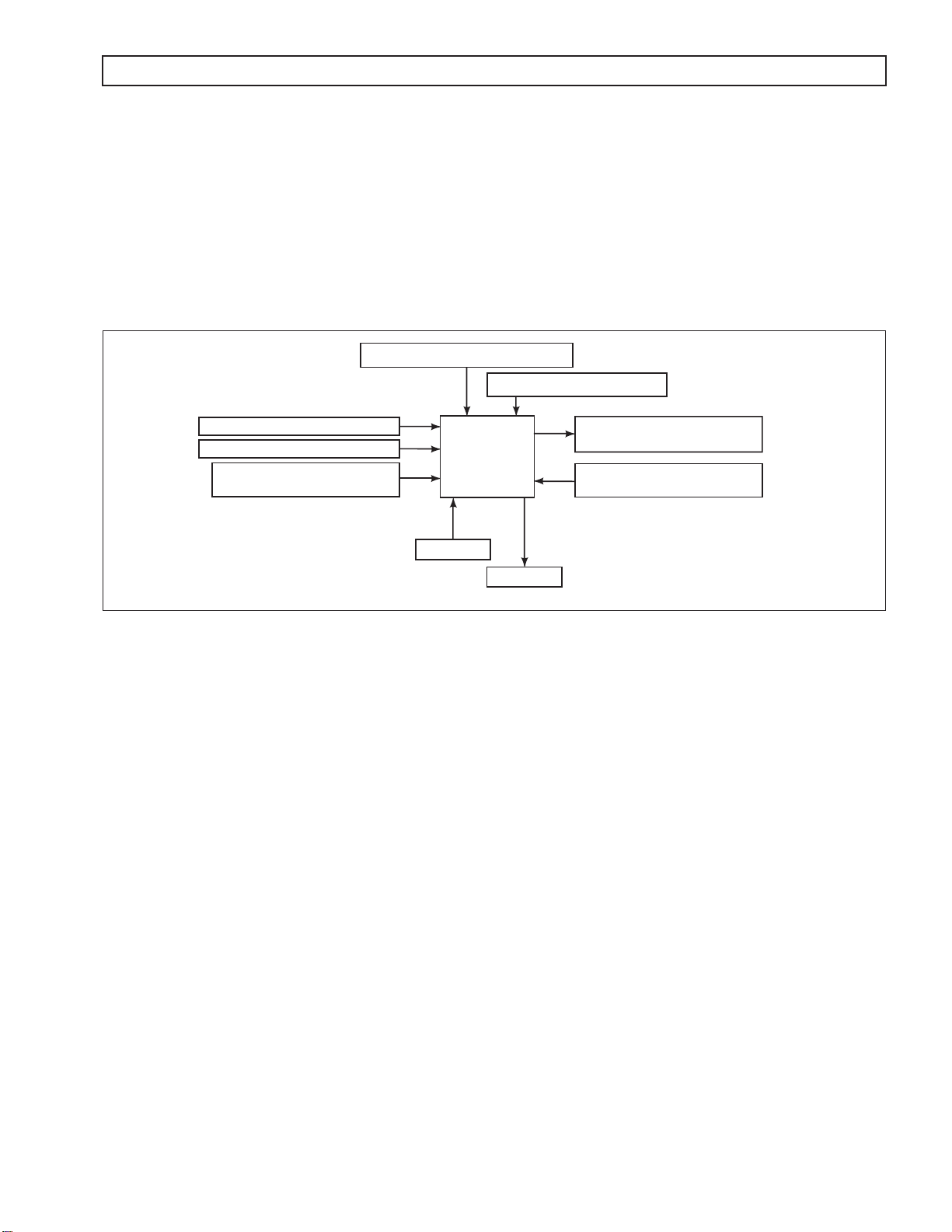

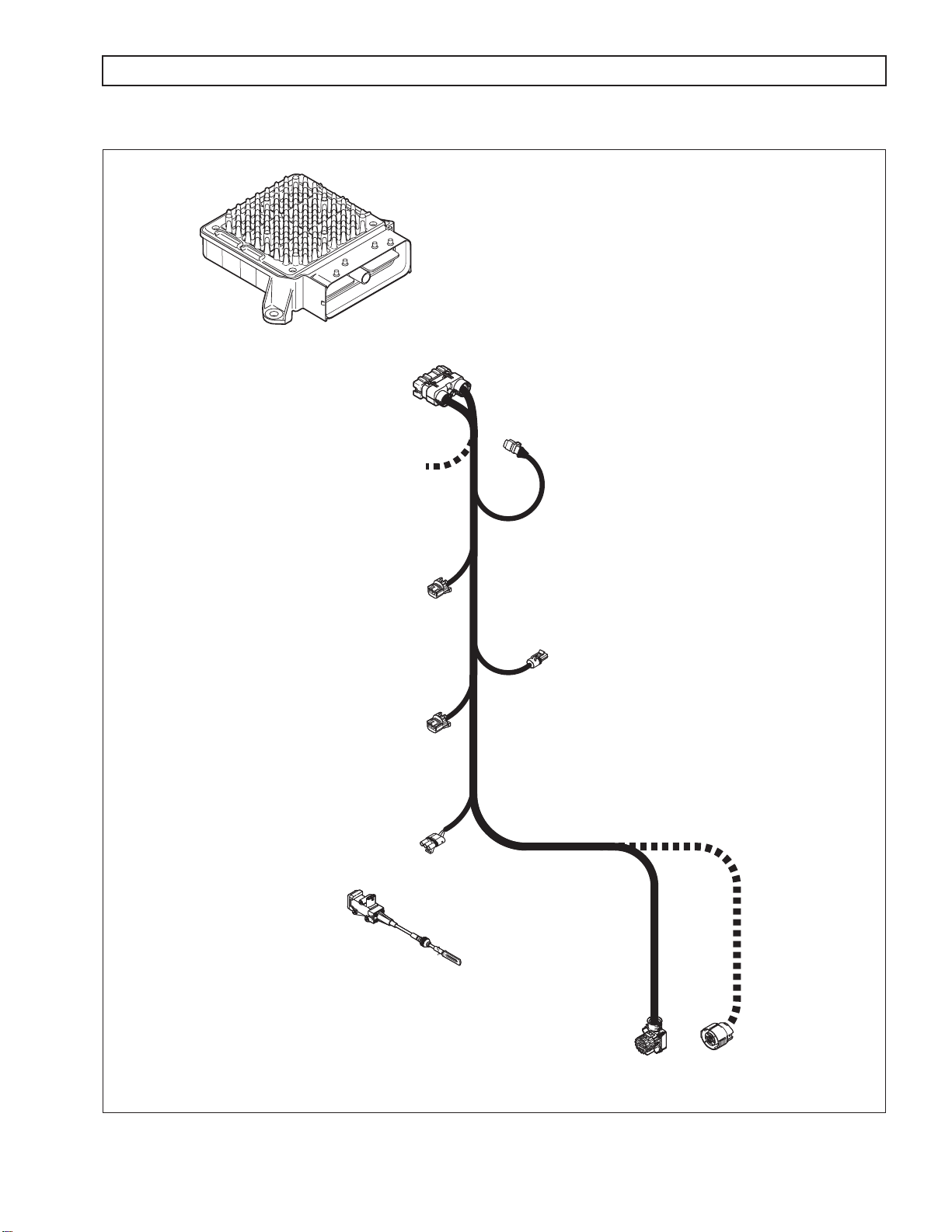

A. External Wiring Harness

The external wiring harness (refer to Figure 1–10) requirements are typically met through the use of a

single harness with one branch connecting the TCM to the transmission, throttle position sensor, IMS,

and speed sensors; another branch connecting the TCM to Allison DOC™ For PC–Service Tool and

other vehicle interfaces. All wiring harnesses and mating connectors are OEM-supplied.

NOTE: Repair parts for the external harness and external harness components must be obtained through the

vehicle OEM. The OEM is responsible for warranty on these parts.

1–8 Copyright© 2007 Allison Transmission, Inc.

Page 17

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

TRANSMISSION

CONTROL

MODULE

(TCM)

TRANSMISSION

HARNESS

80-WAY

CONNECTOR

J1939

CONNECTOR

OEM SUPPLIED

INTERFACE HARNESS

ENGINE

SPEED SENSOR

CONNECTOR

TURBINE

SPEED SENSOR

CONNECTOR

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

(OPTIONAL)

THROTTLE

POSITION

SENSOR (TPS)

NOTE: Illustration is not to scale. Actual harness

configuration may differ from this illustration.

OUTPUT

SPEED SENSOR

CONNECTOR

24-WAY MAIN

TRANSMISSION

CONNECTOR

20-WAY

CONNECTOR

(OPTIONAL)

V06475.03.00

Figure 1–10. Typical External Wiring Harnesses

Copyright© 2007 Allison Transmission, Inc. 1–9

Page 18

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

GENERAL DESCRIPTION

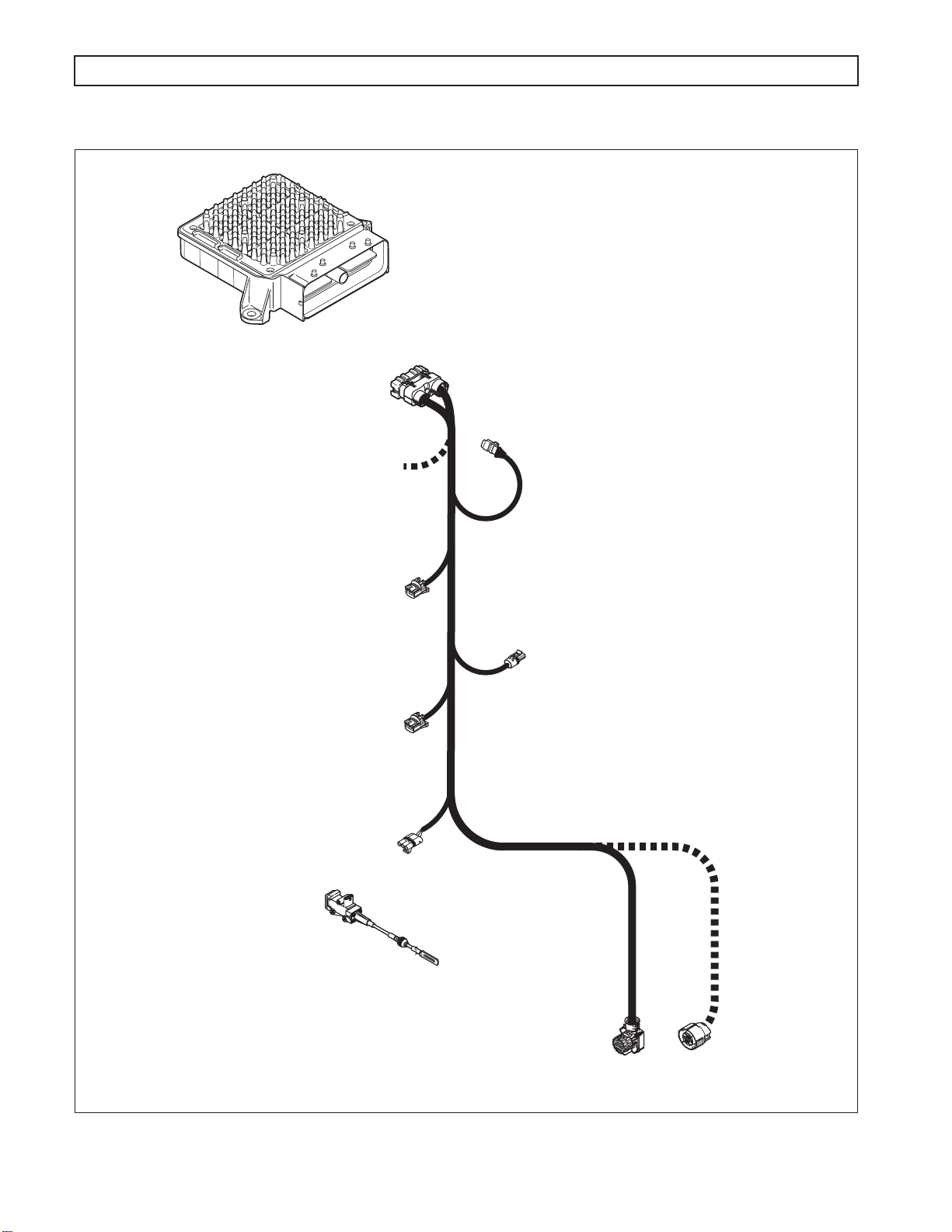

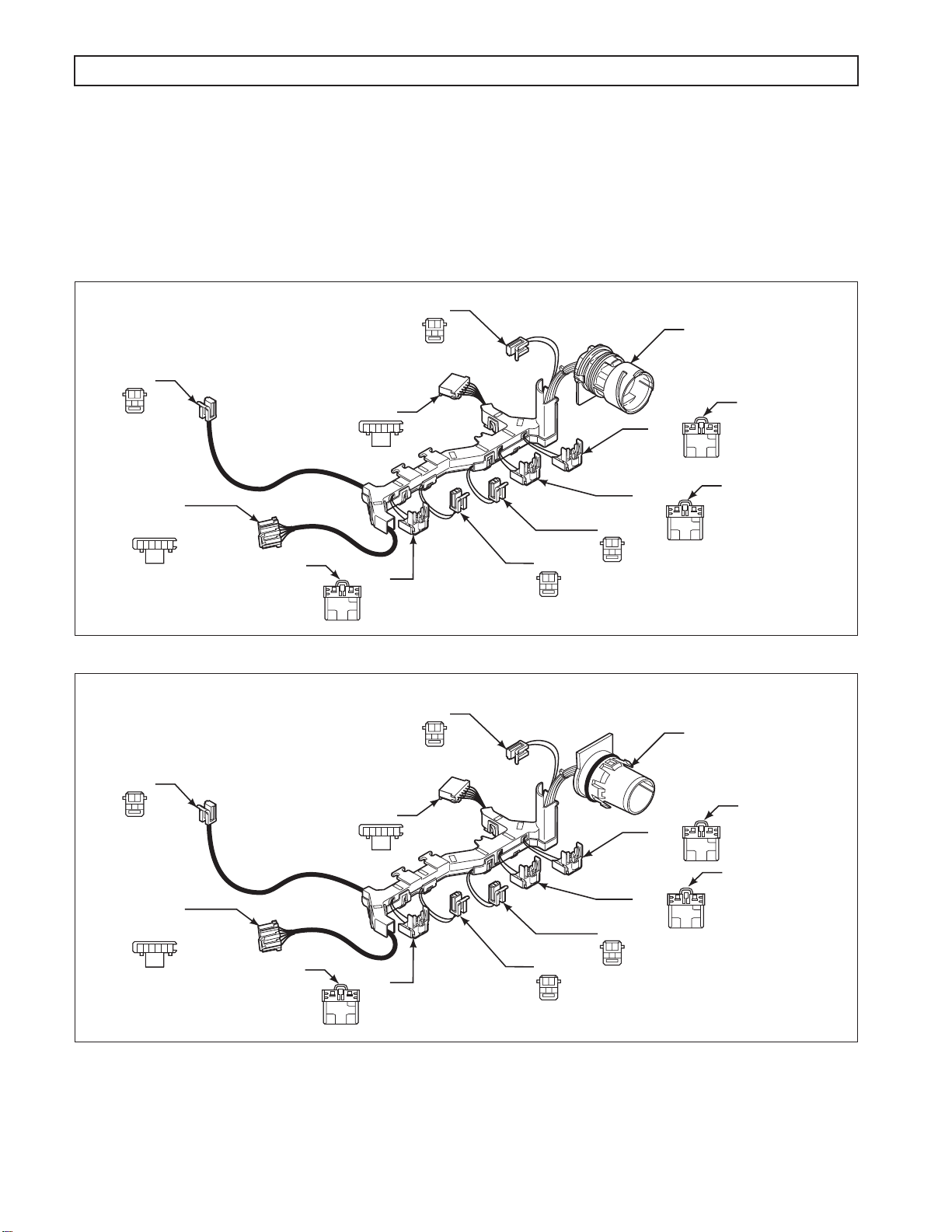

B. Internal Wiring Harness

An internal wiring harness (refer to Figure 1–11 and Figure 1–12) connects the shift solenoids (SS1,

SS2, SS3), pressure control solenoids (PCS1, PCS2), torque converter clutch solenoid (TCC), internal

mode switch (IMS), pressure switch manifold (PSM), and temperature sensor to the external harness

leading to the TCM.

MAIN

MOD

AB

GRAY

IMS

INTERNAL

MODE

SWITCH

A B C D E F

MAIN

MOD

AB

GRAY

SS1

AB

GRAY

PSM

A B C D E F

PCS1

PCS2

SS3

AB

LOCKARM

TCC

21

SS2

AB

GRAY

GRAY

Figure 1–11. Typical Internal Wiring Harness (24-Way Connector)

SS1

AB

GRAY

PSM

A B C D E F

PCS1

MAIN

TRANSMISSION

CONNECTOR

LOCKARM

21

LOCKARM

21

V08975.00.00

MAIN

TRANSMISSION

CONNECTOR

LOCKARM

21

IMS

INTERNAL

MODE

SWITCH

A B C D E F

LOCKARM

TCC

21

SS2

AB

GRAY

Figure 1–12. Typical Internal Wiring Harness (20-Way Connector for GM Applications Only)

1–10 Copyright© 2007 Allison Transmission, Inc.

SS3

AB

GRAY

PCS2

LOCKARM

21

V08974.00.00

Page 19

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

J 47275

J 47276

J 47277

J 47278

GENERAL DESCRIPTION

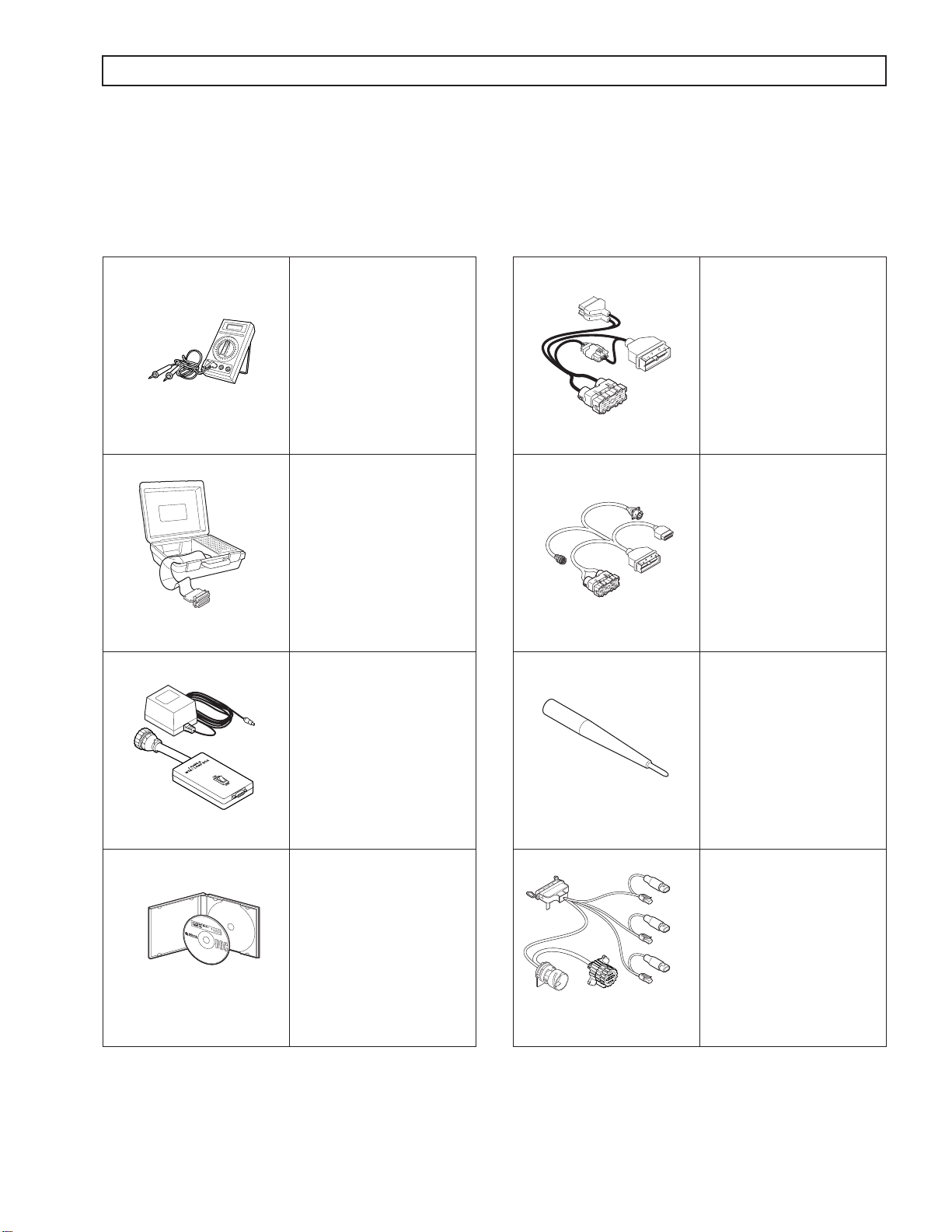

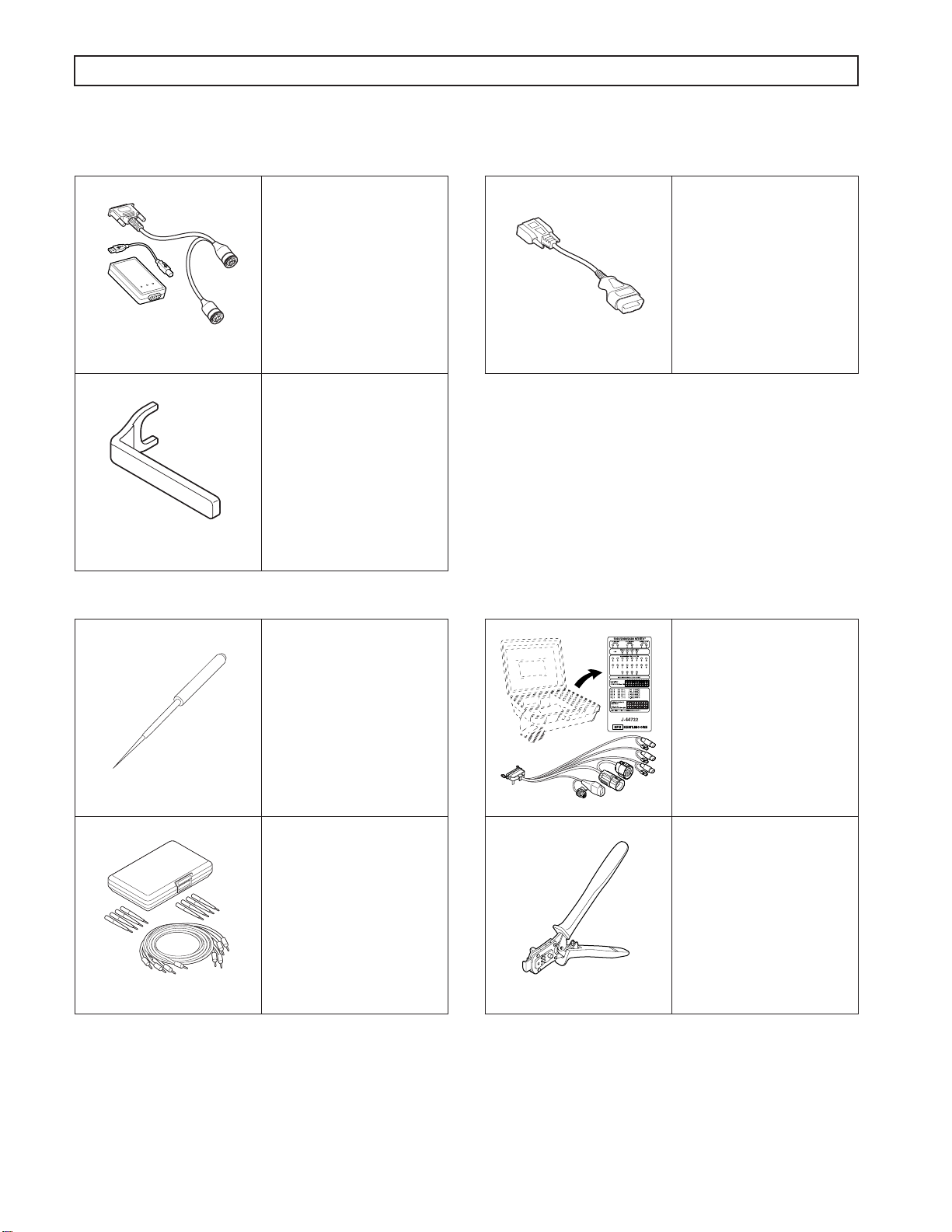

1–8. SPECIAL ELECTRONIC/ELECTRICAL TOOLS

All tools listed are essential for overhaul, maintenance, and/or recalibration of the 1000 and 2000 Product Families

electronic and electrical systems. The tools listed below are available for purchase from SPX/Kent-Moore.

Table 1–1. Essential Tools

3 4 of 9 D I G I T A L M U L T I M E T E R

40

50

100

500

200

300

300

900

400

600

2

5

7

200

500

300

600

400

500

500

700

600

x

COM

abcde

A

xyz ab

10 A

abcde

xyz ab

m

ultim

eter

J 34520-A

Digital

Volt/Ohmmeter

J 47275

TCM Breakout

Harness Adapter

J 39700

J 42455-A

J 39700

Univeral Breakout Box

J 42455-A

Load Box

J 44950

Allison DOC™ For

PC–Service Tool

J 47276

“T” Breakout and TCM

Reflashing Harness

J 47277

Terminal Probe

NOTE: J 47277 is now

included in the J 39197-A

Kit.

J 47278

1000 and 2000 Product

Families Breakout Harness

J 44950

Copyright© 2007 Allison Transmission, Inc. 1–11

Page 20

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

J 47949

J 47139

GENERAL DESCRIPTION

Table 1–1. Essential Tools (cont’d)

J 47943

J 47944

J 47943

DPA4 USB

Translator Device

J 47944

1000 and 2000 Product

Families Main

Transmission Connector

Removal Tool

Table 1–2. Available Tools

J 38125-12A

Terminal Remover

(80-way connector)

GM P/N: 12094429

J 47949

GMLAN Cable

J 44722-3 Overlay

J 44722-3 Cable

NOTE: J-44722-3 overlay

is for pick-up truck use

only.

J 38125-12A

J 39197-A

Jumper Kit

J 39197-A

1–12 Copyright© 2007 Allison Transmission, Inc.

J 47139

Crimper

Page 21

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

SECTION 2—DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT

The electronic control system is programmed to inform the operator of a problem with the transmission system and

automatically take action to protect the operator, vehicle, and transmission. To do this, the TCM turns on the

CHECK TRANS light on the instrument panel, which notifies the operator that a Diagnostic Trouble Code (DTC)

has been stored.

Each time the engine is started, the TCM will illuminate the CHECK TRANS light, then turn it off after a few

seconds. This is a circuit check to verify that the lamp and wiring are in proper working order. Illumination of the

CHECK TRANS light at any time after start-up indicates that the TCM has set a DTC. Allison DOC™ For PC–

Service Tool is used to verify that the TCM has set a DTC (refer to Section 2–2). While the CHECK TRANS light

is on, upshifts and downshifts may be restricted and direction changes (D–R, R–D) may not occur. The torque

converter clutch is inhibited when transmission shifting is restricted or during any critical transmission

malfunction.

The 1000 and 2000 Product Families transmissions DTCs are latching DTCs. When a failure condition is detected,

the DTC set by the TCM remains active for the entire time the ignition is on. When the ignition is turned off and

then on again, the transmission DTCs will reset and the TCM will recheck for the failure condition. If the failure

condition is not present, the previously set DTC will remain in history; the CHECK TRANS light will turn off

after the circuit check, and the transmission will function normally unless another failure occurs. This feature

allows the vehicle to be driven to a service outlet.

2–2. RANGE INHIBIT RESPONSES

The range inhibit feature is a function of the TCM logic. The TCM senses when certain input variables are

exceeded and takes action to prevent transmission damage. The TCM inhibits neutral-to-range shifts and

illuminates a light on the dash when the inhibit is active.

Listed below are three variables that, when exceeded, cause inhibited shifts (with thresholds listed).

• Engine speed above 1000 rpm

• Throttle setting above 40 percent

• Output speed above 225 rpm

There are two levels of the special logic inhibits.

• Self-clearing inhibit—This inhibit clears itself if one of the above conditions is not present after a

calibrated time. This is three seconds in the case of medium-duty vehicles. If the shift inhibit is active,

but not latched, the bulb will stay lit until self-cleared.

• Latching inhibit — This inhibit latches when one of the conditions listed above is still present after a

calibrated time. This is above three seconds for medium duty vehicles. To clear a latching inhibit, move

the selector into any other position than the one originally selected.

2–3. ALLISON DOC™ FOR PC–SERVICE TOOL INHIBITS

If an inhibit has occurred since the last DTC was cleared, the inhibit state will indicate ON and will stay ON until

the next manual DTC clear with Allison DOC™ For PC–Service Tool. These latched inhibits do not turn OFF

after a specified number ignition cycles.

Copyright© 2007 Allison Transmission, Inc. 2–1

Page 22

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

The range inhibit light will illuminate and/or an inhibited state will be shown on Allison DOC™ For PC–Service

Tool when the transmission is inhibited to Neutral for the following reasons:

• Low Main Pressure

If the transmission pressure switches do not indicate transmission pressurized at start-up, shifts-to-range

may be inhibited and the range inhibit light will illuminate. Allison DOC™ For PC–Service Tool will

indicate an active inhibit.

Common causes are transmission low on fluid, transmission filter has just been changed, or pan has

been removed and fluid recently drained.

May produce DTC P0701.

• Transfer Case Neutral

If the transfer case is shifted into neutral while the transmission is in drive or reverse at a speed above

idle, the transmission will continue to command range until the output speed is reduced to a point where

neutral range is commanded. The range inhibit light will illuminate and Allison DOC™ For PC–Service

Tool will indicate an active inhibit.

• Diagnostic Active

This indicates that an active diagnostic code was set and the driver attempted a range selection that was

inhibited. In some failure modes, reverse cannot and will not be commanded. If reverse is selected

during these failure modes a range inhibit light will illuminate in reverse.

During diagnostic responses, Neutral-to-Range Inhibits and Direction Change Inhibits continue to

operate, but they may latch under certain conditions. In these cases, shutting down ignition and waiting

for at least 5 seconds before restarting will clear the inhibit condition. Allison DOC™ For PC–Service

Tool will indicate an active inhibit.

• Auto Neutral for PTO

Neutral-to-Drive and Neutral-to-Reverse shifts will be inhibited to neutral and Allison DOC™ For

PC–Service Tool will show an inhibited state when TCM detects that auto neutral function input is

active.

• Reverse Enable

Neutral-to-Reverse shifts will be inhibited to neutral and Allison DOC™ For PC–Service Tool will

show an inhibited state when no input is detected from dash or floor mounted reverse enable switch

when selecting reverse range. Allison DOC™ For PC–Service Tool will indicate an active inhibit.

This function is only used in European transit and tour buses applications.

• Refuse Packer Step Switch

Transmission operation is limited to only 1st range. Neutral-to-reverse shifts will be inhibited to neutral

and Allison DOC™ For PC–Service Tool will show an inhibited state when input is detected from a step

switch indicating that personnel is present on rear step platform.

• Auxiliary Function Range Inhibit

Neutral-to-Drive and Neutral-to-Reverse shifts will be inhibited to neutral and Allison DOC™ For

PC–Service Tool will show an inhibited state when input is detected from an auxiliary switch or device.

This inhibit will remain active until the auxiliary switch input is shut off and range is reselected.

2–2 Copyright© 2007 Allison Transmission, Inc.

Page 23

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

• PTO Neutral Lockup

Allison DOC™ For PC–Service Tool will show an inhibited state when Neutral Lockup is active and

range shifts are being inhibited to neutral. When the selector is moved, lockup is released and the inhibit

clears.

• Engine Speed

Neutral-to-Drive and Neutral-to-Reverse shifts will be inhibited to neutral and the range inhibit light

will illuminate if the Engine Speed is greater than a calibrated value (1400 rpm for medium duty

non-emergency vehicles). Allison DOC™ For PC–Service Tool will indicate an active inhibit.

• Output Speed

Reverse-to-Drive, Drive-to-Reverse, and Neutral-to-Reverse shifts initiated above 300 rpm of output

speed will be inhibited to neutral and the range inhibit light will illuminate. Allison DOC™ For PC–

Service Tool will indicate an active inhibit.

• Throttle

Reverse-to-Drive, Drive-to-Reverse, Neutral-to-Drive, and Neutral-to-Reverse shifts where throttle

position is greater then 25 percent will be inhibited to neutral and the range inhibit light will illuminate.

Allison DOC™ For PC–Service Tool will indicate an active inhibit.

• IMS Function or Alignment

Reverse-to-Drive, Drive-to-Reverse, Neutral-to-Drive, and Neutral-to-Reverse shifts will be inhibited to

neutral and the range inhibit light will illuminate when an IMS failure or misalignment is detected. A

common cause would be an error in the four-bit IMS input signal that is sent to the TCM.

Allison DOC™ For PC–Service Tool will indicate an active inhibit.

• IMS PS4 Disagree

Reverse-to-Drive, Drive-to-Reverse, Neutral-to-Drive, and Neutral-to-Reverse shifts will be inhibited to

neutral and the range inhibit light will illuminate when the Pressure Switch 4 (PS4) status is in the

incorrect state when compared to the IMS state. Allison DOC™ For PC–Service Tool will indicate an

active inhibit. This inhibit may be caused by a defective IMS, PSM, or valve body concerns.

• MSV Mis-Alignment/Unable to detect ratio after shift to range

If the range verification test fails to detect turbine speed pull-down or valid gear ratio when the Manual

Selector Valve (MSV) shifts to either forward or reverse range from neutral, the transmission will shift

back to a neutral condition and the range inhibit light will illuminate.

Conditions that may cause this include: Attempts to shift the transmission from Neutral-to-Drive or

Neutral-to-Reverse with the transfer case in neutral; transmission low on fluid; misadjustment in the

IMS or Selector Linkage; turbine or output speed sensor failure that may prevent the pull down test/ratio

test from passing; solenoid A or B hydraulically failures; and possibly failed range clutch (C1 or C5 for

1st, C3 or C5 for Reverse).

Allison DOC™ For PC–Service Tool will indicate an active inhibit response.

• Wheel Spin or Lock

When the TCM detects that wheel lock or spin is occurring, the TCC is disengaged and a lock-to-range

response is commanded for 6 seconds. Allison DOC™ For PC–Service Tool will indicate an active

inhibit response.

Copyright© 2007 Allison Transmission, Inc. 2–3

Page 24

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

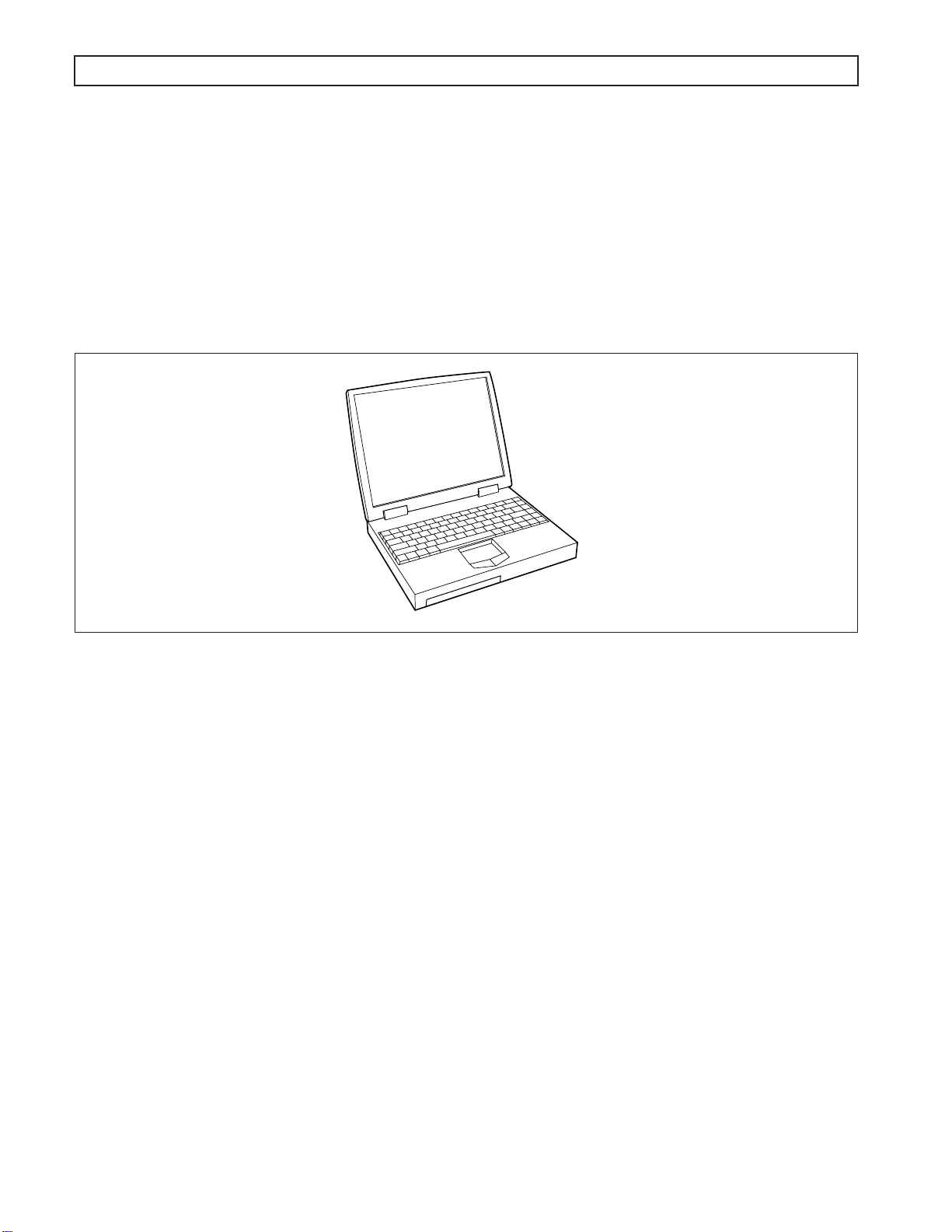

2–4. ALLISON DOC™ FOR PC–SERVICE TOOL

Allison DOC™ For PC–Service Tool v5.0.0 (or later) is available through Kent-Moore Heavy-Duty Division.

®

When installed on a Windows

receives data to and from the TCM via the vehicle data communications link, processes the data, and displays

appropriate information. Use Allison DOC™ For PC–Service Tool during installation checkout and

troubleshooting.

For more details on Allison DOC™ For PC–Service Tool features, refer to the User Guide for Allison DOC™ For

PC–Service Tool Version 5.0.0, GN3433EN.

PC, the Allison DOC™ For PC–Service Tool (refer to Figure 2–1) transmits and

V05490

Figure 2–1. Allison DOC™ For PC–Service Tool

2–4 Copyright© 2007 Allison Transmission, Inc.

Page 25

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

2–5. ABBREVIATIONS

A/N Assembly Number

ABS Anti-lock Brake System—OEM-provided means to detect and prevent wheel stoppage to

enhance vehicle handling. Retarder and engine brakes will not apply when ABS is active.

Amp Ampere—Unit of electrical current

CAN Controller Area Network—A network for all SAE J1939 communications in a vehicle

(engine, transmission, diagnostics, ABS, etc.)

CC Calibration Compatibility—First two digits of the CIN

CIN Calibration Identification Number—Used to identify transmission controls software level

CMC Customer Modifiable Constants

CT Closed Throttle

DNA Does Not Adapt—Adaptive shift control is disabled.

DNS DO NOT SHIFT—Refers to the DO NOT SHIFT diagnostic response during which the

CHECK TRANS light is illuminated and the transmission will not shift and will not

respond to the Shift Selector.

DTC Diagnostic Trouble Code

DVOM Digital volt/ohmmeter

ECM Engine Controller Module—Available on electronically-controlled engines—provides

some relevant data to TCM.

EMI ElectroMagnetic Interference

GPI General Purpose

condition.

GPO General Purpose Output—Output signal from the TCM to control vehicle components

(such as PTOs, backup lights, etc.) or allow a special operating mode or condition.

IMS Internal Mode Switch

IPC Instrument Panel Controller

J 1939 High-speed vehicle serial data communications standard.

LED Light-Emitting Diode—Electronic device used for illumination.

LRTP Low-Range Torque Protection—A feature limiting engine torque in lower ranges and

reverse to protect the transmission from damage.

NVL Neutral Very Low—The TCM has sensed turbine speed below 150 rpm. This is usually

caused by a dragging C1 or C3 clutch or a failed turbine speed sensor. When attained, the

C4 and C5 clutches are applied to lock the transmission output.

OBD II On Board Diagnostics Second generation. EPA mandated specification for vehicle

diagnostics.

Input—Input signal to the TCM to request a special operating mode or

OEM Original Equipment Manufacturer—Maker of vehicle or equipment.

Ohm Unit of electrical resistance.

PC Personal Computer

PCCS Production Calibration Configuration System

Copyright© 2007 Allison Transmission, Inc. 2–5

Page 26

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

DEFINITIONS AND ABBREVIATIONS

2–5. ABBREVIATIONS (cont’d)

PCM Powertrain Controller Module—Electronic device used on some vehicles.

PCS Pressure Control Solenoid

PCV Pressure Control Valve

PDM Parallel Data Module

PPC Pressure Proportional to Current solenoid. Solenoid control of clutch pressure is

proportional to the current being supplied to the solenoid.

PROM Programmable Read Only Memory

PS Pressure Switch

PSM Pressure Switch Manifold—Part of transmission control system located inside the oil pan.

PTO Power Takeoff

PWM Pulse Width Modulation

RFI Radio Frequency Interference

RPR Return to Previous Range—Diagnostic response in which the transmission is commanded

to return to previously commanded range.

SEM Shift Energy Management—Allows the TCM to request torque reduction from the ECM

during upshifts for increased clutch life.

SOL OFF All SOLenoids OFF

SS Shift

SV Shift Valve

TBC Truck Body Controller

TCC Torque Converter Clutch

TCM Transmission Control Module (also commonly referred to as the “computer”)

TFT Transmission Fluid Temperature—Data provided by thermistor that is part of the PSM.

TPS Throttle Position Sensor—Potentiometer for signaling the position of the engine fuel

V Version—Abbreviation used in describing TCM software levels.

VBS Variable Bleed Solenoid—Another name for Pressure Proportional to Current (PPC)

VDC Volts Direct Current (DC)

VIW Vehicle Interface Wiring—Interfaces TCM programmed input and output functions with

Volt Unit of electrical force

Solenoid

control lever.

solenoid. Solenoid control of clutch pressure is proportional to the current being supplied

to the solenoid.

the vehicle wiring.

VOM Volt/ohmmeter

WOT Wide Open Throttle

∞ Infinity—Condition of a circuit with higher resistance than can be measured; effectively an

open circuit.

2–6 Copyright© 2007 Allison Transmission, Inc.

Page 27

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

SECTION 3—BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED

To service 1000 and 2000 Product Families Allison 4th Generation Controls, the technician must understand basic

electrical concepts. Technicians need to know how to use a digital volt/ohmmeter (DVOM) to make resistance and

continuity checks. Most troubleshooting checks consist of checking resistance and continuity, and checking for

shorts between wires and to ground. The technician should be able to use jumper wires and breakout harnesses and

connectors. Technicians unsure of making the required checks should ask questions of experienced personnel or

find instruction.

The technician should also have the mechanical aptitude required to connect pressure gauges or transducers to

identified pressure ports used in the troubleshooting process. Pressure tap locations and pressure values are shown

in Appendix B—Main Pressure Check Procedure.

Input power, ground, neutral start circuitry, etc., can cause problems with electronic controls or vehicle functioning

th

and may not generate a DTC. A working knowledge of 1000 and 2000 Product Families Allison 4

Controls vehicle installation is necessary in troubleshooting installation-related problems.

Refer to Section 7 for information concerning performance complaints (non-DTC) troubleshooting. A complete

wiring schematic is shown in Appendix J. Refer to the 1000 and 2000 Product Family Tech Data for information

concerning electronic controls installation and the Installation Checklist. Reliable transmission operation and

performance depend upon a correctly installed transmission. For proper installation, review the Installation

Checklist in the 1000 and 2000 Product Family Tech Data, available on the extranet under Engineering at

www.allisontransmission.com.

Generation

3–2. USING THE TROUBLESHOOTING MANUAL

Use this manual as an aid to troubleshooting the 1000 and 2000 Product Families Allison 4th Generation Controls.

Every possible problem and its solution cannot be encompassed by any manual. However, this manual does

provide a starting point from which most problems can be resolved.

Once a problem solution is discovered in the manual do not look further for other solutions. It is necessary to

determine

why a problem occurred. The root cause of a problem as well as the symptom must be corrected to

ensure trouble free operation. For example, taping a wire that has been rubbing on a frame rail will not correct the

problem unless the rubbing contact is eliminated.

3–3. SYSTEM OVERVIEW

1000 and 2000 Product Families Allison 4th Generation Control functions are controlled by the TCM. The TCM

reads shift selector range selection, output speed, and throttle position to determine when to command a shift.

When a shift occurs, the TCM monitors turbine speed, output speed, and throttle position to control the oncoming

and off-going clutches during the shift.

When the TCM detects an electrical fault, it logs a DTC indicating the faulty circuit and may alter the transmission

operation to prevent or reduce damage.

When the TCM detects a non-electrical problem while trying to make a shift, the TCM may try that shift a second

or third time before setting a DTC. Once that shift has been retried, and a fault is still detected, the TCM sets a

DTC and holds the transmission in a fail-to-range mode of operation.

Copyright© 2007 Allison Transmission, Inc. 3–1

Page 28

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

The 1000 and 2000 Product Families transmission utilizes “clutch to clutch” shift control to achieve range

changes. In every case (except shifts to or from neutral), one clutch is exhausted and another applied to make a

range shift. The “handoff” between exhausting and applying clutches is very precisely controlled by use of two

Variable-Bleed Solenoids (VBS), commonly known as Pressure Proportional to Current (PPC) solenoids. These

solenoids are labelled PCS1 and PCS2 in the transmission, and are referred to as “pressure control” solenoids. For

example, to make a 1–2 shift, PCS1 is used to trim pressure off C5 clutch, and PCS2 is used to trim pressure on C4

clutch.

The TCM (transmission control module) modulates the current to both PCS1 and PCS2, which translates to a

proportional level of pressure to the clutch. In order to make a shift, the TCM uses software and calibration settings

of several program parameters to determine the level of current sent to the respective pressure control solenoids.

These parameters are referred to as “adaptive values.” With a new transmission and TCM calibration, the adaptive

values are set to “base calibration” level. The transmission uses the base calibration to perform the first of each

type of shift. However, once it has performed a shift, the TCM evaluates the actual shift and compares it to an

“ideal” shift in the TCM’s memory. Based on that comparison, the TCM changes the settings of the adaptive values

to a level that it believes will result in a shift closer to the “ideal” shift the next time it makes that type of shift. This

is referred to as “adaptive shifting.”

When the transmission/TCM calibration is new, the TCM is in “fast adaptive” mode. In other words, the TCM is

allowed to make relatively large changes in the adaptive values after each shift. Once the TCM determines that a

given shift is close to its ideal level it switches to “slow adaptive” mode. In slow adaptive the TCM still is

evaluating shifts and changing adaptive values, but is only allowed to do so in smaller increments.

The TCM is programmed to try to switch from fast to slow adaptive mode within approximately five shifts. It is

important to understand that there are many different distinct shifts recognized by the TCM, and each of these

shifts has its own adaptive values. For example, there are upshift and downshifts to and from each range, as well as

unique adaptive values for several different throttle regions for each upshift and downshift. The point is, it may take

a significant amount of time before most of the shifts converge from fast to slow adaptive, and thus it is not

unusual to experience somewhat harsh or unpleasant shift quality until these shifts are adapted.

TCC engagement is accomplished by a separate PPC (pressure proportional to current) TCC solenoid. There are

adaptive values for this as well, and thus it will also require some driving for TCC engagement to adapt.

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS

Before beginning the troubleshooting process, read and understand the following:

• Allison recommended wire numbers (i.e. 112) are a combination of the first digit indicating the TCM 80-way

connector number and the last two digits indicating the pin-out information (i.e. 12).

• Shut off the engine and ignition before any harness connectors are disconnected or connected.

• Remember to do the following when checking for shorts and opens:

— Minimize movement of wiring harnesses when looking for shorts. Shorts involve wire-to-wire or wire-to-

ground contacts and moving the harnesses may eliminate the problem.

— Wiggle connectors, harnesses, and splices when looking for opens. This simulates vehicle movements

which occur during actual operation.

• When disconnecting a harness connector, be sure that pulling force is applied to the connector itself and not

the wires extending from the connector.

• Resistance checks involving the wiring between the TCM connectors and other components adds about

one Ohm of resistance to the component resistance shown.

3–2 Copyright© 2007 Allison Transmission, Inc.

Page 29

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

• Inspect all connector terminals for damage. Terminals may have bent or lost the necessary tension to maintain

firm contact.

• Clean dirty terminals or connectors with isopropyl alcohol and a cotton swab, or a good quality, non-residue,

non-lubricating, cleaning solvent such as LPS Electro Contact Cleaner® or LPS NoFlash Electro Contact

Cleaner®.

The cleaning solvent must not be chlorine based, contain petroleum distillates, or

conduct electricity. The cleaning solvent should evaporate quickly to prevent the

CAUTION:

possibility of condensation within the connectors. Always blow or shake any excess

cleaner from the connector before assembling it to its mating connector or hardware.

Cleaner trapped in the connector can affect the connector seal. (Refer to

SIL 17-TR-94 for detailed information on the recommended cleaners.)

CAUTION:

• DTCs displayed after system power is turned on while a harness connector is disconnected can be ignored and

cleared from memory. Refer to Section 5, DTCs, for the DTC clearing procedure.

Care should be taken when welding on a vehicle equipped with electronic controls.

Refer to Appendix G.

3–5. BASIC TROUBLESHOOTING INFORMATION

1. Begin troubleshooting by checking the transmission fluid level and ignition voltage. Remember that some

problems may be temperature related. Do troubleshooting, including the fluid level and ignition voltage

checks, at the temperature level where the problem occurs.

NOTE: Fluid level and igniton voltage MUST be checked before any troubleshooting is performed.

NOTE: If you are experiencing harsh shifts, it is important to use Allison DOC™ For PC–Service Tool to

verify whether that particular shift is adapted. If it is not, the TCM is still “learning” how to adapt that

shift and simply needs to be driven further while performing more of that particular type of shift.

If a particular shift is in slow adapt but still objectionable, it’s good troubleshooting practice to reset the

adaptive values for that shift back to “base cal” level. This will automatically reset the TCM to fast

adaptive mode. The vehicle should then be driven to allow the TCM to “re-learn” the shift. Many times

this will correct the problem. It is possible to reset individual shifts without affecting the other shifts.

CAUTION:

Whenever a transmission is overhauled, exchanged, or has undergone repairs, the

Transmission Control Module (TCM) must be “RESET TO UNADAPTED

SHIFTS.” This will cause the TCM to erase previous adaptive information and begin

to adapt in Fast Adaptive Mode from the base calibration. Failure to follow this

procedure may cause premature failure of the overhauled, repaired, or replaced

transmission.

Copyright© 2007 Allison Transmission, Inc. 3–3

Page 30

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

2. If a transmission has been overhauled, exchanged, or repaired, use Allison DOC™ For PC–Service Tool

to “RESET ADAPTIVE SHIFT PARAMETERS.”

To reset Adaptive Shift Parameters:

• Select the Action Request drop-down menu.

• Click on the Reset Adaptive Shift Parameters menu item—the Reset Adaptive Parameters window

displays.

• The Reset Adaptive Shift Parameters window contains 10 tabs; one for each upshift and downshift

region, garage shifts and a reset tab for All regions.

— To reset all adaptive shift parameters, select the ALL tab.

— The adaptive shift parameters are reset when you click on the RESET ADAPTIVE SHIFT

PARAMETERS button—the Reset Adaptive Shift Parameters Successful window displays.

Click the OK button.

3. For proper operation of Allison DOC™ For PC–Service Tool v5.0.0 or later, check the following:

• The desktop or laptop computer must meet the minimum system requirements (see Allison DOC™

For PC–Service Tool Version 5.0.0 User Guide, GN3433EN):

— Microsoft Windows® 2000 Professional (SP4 or later) or Windows® XP Professional

— 600 MB free hard drive space

— 20 GB hard drive (40 GB preferred)

— 128 MB of RAM (256 MB preferred)

— Intel® Pentium® III or IV processor

— Available USB 1.1 or 2.0 port

— 1024 x 768 screen resolution

— 256-color palette

— Small fonts

— Internet connection (Internet Explorer 5.0 or greater)

— A media player program (Windows Media Player® is provided on the Allison DOC™ For

PC–Service Tool For PC CD)

— Adobe® Acrobat® Reader® (provided on the Allison DOC™ For PC–Service Tool CD)

— CD-ROM 16x minimum (48x preferred)

NOTE: Refer to the CD Readme.txt file for more information.

• The proper driver (electronic file) is installed for the Computer Interface Module.

• Power at the Deutsch 9-pin diagnostic connector (pin A is negative, pin B is positive).

• The proper connections exist for communicating with Allison DOC™ For PC–Service Tool (Figure 3–1

and Figure 3–2).

Presently there are two communication standards for Allison DOC™ For PC–Service Tool diagnostic

software: J1939 and GMLAN J2284. Both standards are supported by Allison DOC™ For PC–

Service Tool (versions 5.0).

3–4 Copyright© 2007 Allison Transmission, Inc.

Page 31

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

ALLISON DOC™

FOR PC–SERVICE TOOL

J 47943-3 USB

CONNECTOR

(PART OF J 47943 KIT)

DG

Dearborn Group

http:/ww

w.dgtech.com

J 47943-1

TRANSLATOR

DEVICE

(PART OF J 47943 KIT)

J 47943-2

(PART OF J 47943 KIT)

DB15

CONNNECTOR

OR

DB15

CONNECTOR

SPX P/N: J 47949

GMLAN CABLE

(AVAILABLE FROM

SPX/KENT-MOORE)

(NOT PART OF J 47943 KIT)

9-PIN

CONNNECTOR

6-PIN CONNNECTOR

(NOT USED FOR

1000 AND 2000

PRODUCT FAMILIES

APPLICATIONS)

OBDII/16-PIN

CONNECTOR

J 1962/B

GMLAN

ALLISON 4TH GENERATION CONTROLS

1000 AND 2000 PRODUCT FAMILIES

(PRE-ALLISON 4TH GENERATION CONTROLS)

J1939

MEDIUM DUTY

ALLISON 4TH GENERATION CONTROLS

MEDIUM DUTY

V09232.01.00

Figure 3–1. Proper Allison DOC™ For PC–Service Tool Connections

4. Check DTCs by using Allison DOC™ For PC–Service Tool.

TCM/Load Box Setup

For “TCM/Load Box” setup (no connection to vehicle) use the J 47276 “T” Breakout and

TCM Reflashing Harness. This harness is required for bench-type reflashing of Allison 4

th

Generation

Controls TCMs. Use one of the following methods for TCM reflashing (Figure 3–2).

• J1939-13 connector (for J1939 communication) in combination with J 42455-A Load Box/Power

Supply

• J1962 connector (for GMLAN “high-speed CAN” communications) in combination with

J 42455-A Load Box/TCM

The Dearborn DPA4 USB Translator Device Kit (P/N: J 47943) is required to establish connection

between the PC and the TCM.

NOTE: To use the J1962 connector, an additional cable (J 47949) is required. J 47949 is available for purchase

from SPX/Kent-Moore.

Copyright© 2007 Allison Transmission, Inc. 3–5

Page 32

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

J 47943-3 USB CABLE

(PART OF J 47943 KIT)

SPX P/N: J 47949

GMLAN CABLE

(AVAILABLE FROM

DG

Dearborn Group

htt

p:/ww

w.dgtech.com

SPX/KENT-MOORE)

(NOT PART OF J 47943 KIT)

OBDII/16-PIN

CONNECTOR

J 1962/B

ALLISON DOC™

FOR PC–SERVICE TOOL

TRANSLATOR DEVICE

(PART OF J 47943 KIT)

37-PIN

CONNECTOR

J 42455-A

LOAD BOX

LOAD BOX

POWER SUPPLY

NOTE:

Use Load Box (J 42455-A) when no connnection

is made from J 47276 to the vehicle harness.

J 47943-1

J1939-13 (9-PIN)

CONNECTOR

(250 Kbps CAN)

J 47276 HARNESS

OR

9-PIN

CONNNECTOR

J 47943-2

(PART OF J 47943 KIT)

6-PIN CONNNECTOR

(NOT USED)

J1962 (16-PIN)

GMLAN CONNECTOR

(500 Kbps CAN

“HIGH-SPEED CAN”)

80-WAY (M)

CONNECTOR

80-WAY (F)

CONNECTOR

TO TCM

EXISTING VEHICLE

HARNESS 80-WAY

CONNECTOR (F)

(NOT USED)

4TH GENERATION TCM

Figure 3–2. TCM/Load Box Setup

3–6 Copyright© 2007 Allison Transmission, Inc.

V09233.04.00

Page 33

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

TCM/Vehicle Harness Setup

On the vehicle, use the J 47276 “T” Breakout and TCM Reflashing Harness to connect the Allison

DOC™ For PC–Service Tool directly to the TCM to bypass the Diagnostic Tool Connector.

Use the Dearborn DPA4 USB Translator Device Kit (P/N: J 47943) to establish connection between the

PC and the TCM.

Example: When communications are not available at the Diagnostic Tool Connector on the vehicle,

DTCs can be read directly from the TCM using the Diagnostic Tool Connectors on the J 47276

“T” Breakout and TCM Reflashing Harness.

Use one of the following Diagnostic Tool Connectors on the harness to establish a diagnostic connection

between the TCM and the Service Tool (refer to Figure 3–3):

• J1939-13 connector (for J1939 communication)

• J1962 connector (for GMLAN “high-speed CAN” communications)

NOTE: To use the J1962 connector, an additional cable (J 47949) is required. J 47949 is available for

purchase from SPX/Kent-Moore.

5. When a problem exists but a DTC is not indicated, refer to the General Troubleshooting Section

(Section 7) for a listing of various electrical and hydraulic problems, their causes, and remedies.

6. If a DTC is found in the TCM memory, save all available DTC and failure record information before

clearing the active indicator (refer to Section 5).

7. When certain DTCs are active, a range selection into reverse or forward may not be possible. To deter-

mine if a failure is electrical or hydraulic, perform the following “limp home” test.

Never remove electronic control connectors while the engine is running. Always

WARNING!

Limp Home Test

With the ignition in the OFF position (engine not running), the selector in N (Neutral), and the parking

brake set, remove the 80-way connector at the TCM.

It will be necessary to provide battery power at pin 41 of the 80-way connector in order to energize the

neutral start relay. This can be accomplished by using a jumper wire between pin 10 and 41 at the 80-way

connector.

When the engine is restarted, the transmission will default to a “limp home” capability. In this state,

PCS1 (de-energized) allows C3 clutch to be applied. If the selector valve is moved to the reverse range

position, main pressure will be routed to C5 clutch, allowing reverse operation. If the selector valve is

moved to the drive range position, main pressure will be routed to C1 clutch, allowing third range

operation. This allows a technician to use “limp home” capability to determine if a hydraulic or an

electrical problem exists. If reverse and third ranges are available in “limp home,” an electrical failure

may be indicated. If only one of the two ranges or neither was obtainable, this may indicate an internal

hydraulic failure (failed clutch, stuck valve, or solenoid failure). The clutches that could possibly have an

indicated failure in “limp home” are C1, C3, and C5.

turn off the ignition, set parking brakes and chock the wheels. Failure to follow this

procedure may result in unexpected vehicle movement.

Copyright© 2007 Allison Transmission, Inc. 3–7

Page 34

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

J 47943-3 USB CABLE

(PART OF J 47943 KIT)

SPX P/N: J 47949

GMLAN CABLE

(AVAILABLE FROM

DG

Dearborn Group

http:/www.dgtech.com

SPX/KENT-MOORE)

(NOT PART OF J 47943 KIT)

OBDII/16-PIN

CONNECTOR

J 1962/B

ALLISON DOC™

FOR PC–SERVICE TOOL

37-PIN

CONNECTOR

NOTE:

37-Pin Connector is not used

when J 47276 is connected to

the vehicle harness.

TRANSLATOR DEVICE

J 47943-1

(PART OF J 47943 KIT)

J1939-13 (9-PIN)

J 47276 HARNESS

CONNECTOR

(250 Kbps CAN)

CONNECTOR

(PART OF J 47943 KIT)

80-WAY (F)

TO TCM

OR

9-PIN

CONNNECTOR

J 47943-2

6-PIN CONNNECTOR

(NOT USED)

J1962 (16-PIN)

GMLAN CONNECTOR

(500 Kbps CAN

“HIGH-SPEED CAN”)

80-WAY (M)

CONNECTOR

EXISTING VEHICLE

HARNESS 80-WAY (F)

CONNECTOR

4TH GENERATION TCM

Figure 3–3. TCM/Vehicle Harness Setup

3–8 Copyright© 2007 Allison Transmission, Inc.

TO

VEHICLE

V09234.06.00

Page 35

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

NOTE: Removing the 80-way connector may induce several DTCs. Make sure all codes are cleared before

proceeding with further troubleshooting.

8. Test drive the vehicle to confirm a DTC or performance complaint.

• If the DTC reappears, refer to the DTC section (refer to Section 5) and the appropriate DTC table.

The DTC section lists diagnostic codes and their description. Locate the appropriate

troubleshooting table and follow the instructions.

• If the DTC does not reappear and the test has passed, it may be an intermittent problem. Use

Allison DOC™ For PC–Service Tool and the DTC (refer to Section 5). The DTC display

procedure will identify possible causes of the problem.

• Appendix A deals with the identification of potential circuit problems. Refer to Appendix A if a

circuit problem is suspected.

NOTE: Information concerning specific items is contained in the appendices located in the back of this

manual. The appendices are referred to throughout the manual.

3–6. TCM DIAGNOSTIC PROCEDURE

• Using Allison DOC™ For PC–Service Tool, verify the current calibration information number (CIN)

and record or print a report of the current customer modifiable constants (CMC) information for later

reference.

• Remove the 80-way connector from the suspect TCM; inspect the 80-way connector for damaged or

bent pins.

• Replace TCM with a new or known good TCM from a similar vehicle.

• If the replacement TCM corrects the original complaint, reinstall the original TCM to verify the

complaint returns. If original complaint is confirmed, reinstall a new TCM.

• If the complaint does not return, leave the original TCM installed.

• Clear any DTCs that may be present and test drive the vehicle to confirm the repair.

NOTE: All 1000 and 2000 Product Families TCMs are designed to be isolated from the vehicle chassis ground.

Be sure that the TCM case is not contacting the vehicle frame or any other point that might provide a

ground connection.

3–7. RESETTING OF TCM PARAMETERS TO SUPPORT ENGINE UPDATE

Shift Energy Management (SEM) Autoselect feature may be used on certain transmissions. Autoselect is

deactivated following the first 20 engine starts where engine and transmission communication are present.

If during the first 20 engine starts the TCM recognizes an engine to be on its list of certified engines, it will

lock to the SEM active state. If the engine is not supported, the TCM will lock to a non-SEM state.

NOTE: Most engine upgrades are same type/rating; under normal circumstances there should be no reason to

reset the TCM Autoselect.

However, there may be a small chance that transmission performance, shift quality, or codes may result

from the use of different engine models within the same engine family or when a recalibration of engine

software has taken place. If a vehicle receives upgraded engine hardware or software it may become

necessary to reactivate the Autoselect feature to redetect the engines current SEM status.

NOTE: Once TCM Autoselect locks, the only way to reactivate is to perform a reset procedure (refer to

paragraph 3–8).

Copyright© 2007 Allison Transmission, Inc. 3–9

Page 36

1000 AND 2000 PRODUCT FAMILIES TROUBLESHOOTING MANUAL—ALLISON 4th GENERATION CONTROLS

BASIC KNOWLEDGE

3–8. RESETTING TCM SEM AUTOSELECT

Verify a new engine rating by checking the engine data tag. The engine must be compatible with the

transmission rating. If the engine rating is not compatible, the vehicle must be returned to the OEM for

engine recalibration. If the rating is correct for the transmission, perform the following steps.

Allison DOC™ For PC–Service Tool is used to reset Autoselect function.

• Click on the action requested button.

• On the drop down select Reset SEM Autoselect.

The TCM is now reset to Autoselect and will start looking for supporting engine software. Drive the

vehicle; confirm DTCs have not returned.

NOTE: Transmission shifts will now be in the unadaptive (base) state, so it will be necessary to drive the

vehicle to allow shifts to adapt.

3–10 Copyright© 2007 Allison Transmission, Inc.

Page 37