Page 1

AT-MCF2000

Multi-channel

Media Converter

Series

Fast and Gigabit Ethernet

Media Converter Modules:

AT-MCF2012LC

AT-MCF2012LC/1

AT-MCF2032SP

Enclosures:

AT-MCF2000

◆

Installation Guide

AT-MCF2300

613-001052 Rev. A

Page 2

Copyright © 2008 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names, company names, logos or

other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for any

incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related to this

manual or the information contained herein, even if Allied Telesis, Inc. has been advised of, known, or should have known, the possibility of

such damages.

Page 3

Electrical Safety and Emissions

Standards

This product meets the following standards.

U.S. Federal Communications Commission

Radiated Energy

Note: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15

of FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved of by the manufacturer or the FCC, can void your right to operate

this equipment.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

RFI Emissions FCC Class A, EN55022 Class A, EN61000-3-2, EN61000-3-3, VCCI Class A,

C-TICK, CE

Warning: In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

EMC Immunity EN55024

Electrical Safety EN60950-1 (TUV), UL 60950-1 (

Laser Safety EN60825

CULUS

)

3

Page 4

Electrical Safety and Emissions Standards

Translated Safety Statements

Important: The symbol indicates that a translation of the safety statement is available in the PDF document titled “Translated Safety

Statements” (613-000990) posted on the Allied Telesis website at www.alliedtelesis.com. This document is also included on

the documentation CD that is shipped with the product.

4

Page 5

Contents

Preface ............................................................................................................................................................ 13

How this Guide is Organized ............................................................................................................................ 14

Where to Find Web-based Guides ................................................................................................................... 16

Contacting Allied Telesis .................................................................................................................................. 17

Online Support ........................................................................................................................................... 17

Email and Telephone Support.................................................................................................................... 17

Returning Products .................................................................................................................................... 17

Sales and Corporate Information ............................................................................................................... 17

Warranty..................................................................................................................................................... 17

Management Software Updates................................................................................................................. 17

Section I: Features .....................................................................................................19

Chapter 1: AT-MCF2000 Multi-channel Media Converter Series ............................................................... 21

Hardware Components..................................................................................................................................... 22

Management Software Components ................................................................................................................ 25

Chapter 2: AT-MCF2000 and AT-MCF2300 Chassis ................................................................................... 27

Chapter 3: AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules ......................................... 31

Overview........................................................................................................................................................... 32

Front Panels ..................................................................................................................................................... 33

Media Converter Channels............................................................................................................................... 34

Twisted Pair Ports ............................................................................................................................................ 35

Fiber Optic Ports............................................................................................................................................... 36

Channel Operating Modes................................................................................................................................ 37

Link Test Mode........................................................................................................................................... 37

MissingLink Mode ...................................................................................................................................... 37

Smart MissingLink Mode............................................................................................................................ 39

Guidelines to Using the Channel Operating Modes ................................................................................... 40

Port and Channel LEDs.................................................................................................................................... 41

“A” Activity LED .......................................................................................................................................... 41

“L” Link LEDs ............................................................................................................................................. 42

CDC and FDC Duplex Mode and Collision LEDs ......................................................................................46

LT, ML, and SML Channel Operating Mode LEDs.....................................................................................48

RDY/FLT LED ............................................................................................................................................ 49

HBI and HBO Heartbeat LEDs................................................................................................................... 50

Channel LEDs ............................................................................................................................................ 50

Mode Button ..................................................................................................................................................... 51

Guidelines to Using the Media Converter Modules .......................................................................................... 53

Chapter 4: AT-MCF2000M Management Module ........................................................................................ 55

Overview........................................................................................................................................................... 56

Front Panel ....................................................................................................................................................... 58

10/100/1000Base-T Management Port ............................................................................................................ 59

RS-232 Terminal Port....................................................................................................................................... 61

5

Page 6

Contents

Stack Port .........................................................................................................................................................62

Reset Button .....................................................................................................................................................63

SD Slot .............................................................................................................................................................. 65

Chassis ID Jumper............................................................................................................................................ 66

LEDs .................................................................................................................................................................67

General Status LEDs.................................................................................................................................. 67

RS-232 Terminal Port LED......................................................................................................................... 68

10/100/1000Base-T Management Port LEDs............................................................................................. 69

ID LEDs ......................................................................................................................................................70

Stack Port LED ...........................................................................................................................................70

Secure Digital Memory Card Slot LED .......................................................................................................71

Chapter 5: AT-MCF2000S Stacking Module ................................................................................................. 73

Overview ........................................................................................................................................................... 74

Topology ........................................................................................................................................................... 75

Maximum Number of Media Converter Modules in a Stack.............................................................................. 76

Cabling the Stack Ports ....................................................................................................................................77

Chassis ID Numbers ......................................................................................................................................... 79

LEDs .................................................................................................................................................................81

Chassis ID LEDs ...............................................................................................................................................82

Guidelines to Building a Stack .......................................................................................................................... 83

Section II: Installation ...............................................................................................85

Chapter 6: Reviewing the Safety Precautions ............................................................................................. 87

Chapter 7: Selecting a Location ...................................................................................................................91

Chapter 8: Unpacking the AT-MCF2000 or AT-MCF2300 Chassis .............................................................93

Chapter 9: Removing the Rubber Feet .........................................................................................................97

Chapter 10: Installing the AT-MCF2000AC or AT-MCF2300AC Power Supply Module ........................... 99

Chapter 11: Installing the AT-MCF2KFAN Module .................................................................................... 103

Chapter 12: Installing a Media Converter Module ..................................................................................... 107

Chapter 13: Installing the AT-MCF2000M Management Module ..............................................................111

Chapter 14: Installing the AT-MCF2000S Stacking Module .....................................................................115

Chapter 15: Installing the Chassis in an Equipment Rack .......................................................................119

Chapter 16: Grounding the AT-MCF2300 Chassis ....................................................................................123

Chapter 17: Installing the SFP Modules in the AT-MCF2032SP Module .................................................125

Chapter 18: Cabling the Ports on the Media Converter Module .............................................................. 129

Chapter 19: Cabling the AT-MCF2000M and AT-MCF2000S Modules .....................................................131

Chapter 20: Powering on the Chassis ........................................................................................................135

Chapter 21: Verifying the Installation ......................................................................................................... 139

AT-MCF2000AC and AT-MCF2300AC Power Supply Module .......................................................................140

AT-MCF2KFAN and AT-MCF2300FAN Modules............................................................................................ 140

AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Media Converter Modules ..................................141

AT-MCF2000M Management Module.............................................................................................................142

AT-MCF2000S Stacking Module ....................................................................................................................142

6

Page 7

AT-MCF2000 Media Converter Series Installation Guide

Chapter 22: Starting a Local Management Session ................................................................................. 143

Chapter 23: Troubleshooting the Modules ............................................................................................... 145

AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Media Converter Modules.................................. 146

AT-MCF2000AC and AT-MCF2300AC Power Supply Modules..................................................................... 150

AT-MCF2KFAN and AT-MCF2300FAN Modules ........................................................................................... 151

AT-MCF2000M Management Module ............................................................................................................ 153

AT-MCF2000S Stacking Module .................................................................................................................... 155

Chapter 24: Replacing the Modules ........................................................................................................... 157

Replacing a Media Converter Module ............................................................................................................ 158

Replacing the AT-MCF2000M or AT-MCF2000S Module .............................................................................. 161

Replacing the AT-MCF2000AC or AT-MCF2300AC Power Supply ............................................................... 164

Replacing the AT-MCF2300FAN Module ....................................................................................................... 168

Appendix A: Technical Specifications ...................................................................................................... 171

Environmental Specifications ......................................................................................................................... 171

Standards ....................................................................................................................................................... 171

Safety and Electromagnetic Emissions Certifications .................................................................................... 172

AT-MCF2000 Chassis .................................................................................................................................... 172

AT-MCF2300 Chassis .................................................................................................................................... 172

AT-MCF2000AC Power Supply Module ......................................................................................................... 173

AT-MCF2300AC Power Supply Module ......................................................................................................... 173

AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Media Converter Modules.................................. 174

Specifications ........................................................................................................................................... 174

Twisted Pair Port Pinouts......................................................................................................................... 174

100Base-FX Fiber Optic Ports ................................................................................................................. 175

AT-MCF2000M Management Module ............................................................................................................ 176

Specifications ........................................................................................................................................... 176

10/100/1000Base-T Port Pin-outs............................................................................................................ 176

RS-232 Terminal Port Pinouts ................................................................................................................. 177

AT-MCF2000S Stacking Module .................................................................................................................... 178

AT-MCF2KFAN Module.................................................................................................................................. 178

AT-MCF2300FAN Module .............................................................................................................................. 178

Appendix B: DIP Switch Settings for the AT-MCF2000S Stacking Module ............................................ 179

Appendix C: Cleaning Fiber Optic Connectors ........................................................................................ 181

Using a Cartridge-Type Cleaner..................................................................................................................... 182

Using a Swab ................................................................................................................................................. 184

Index ............................................................................................................................................................. 187

7

Page 8

Contents

8

Page 9

Figures

Figure 1: AT-MCF2000 and AT-MCF2300 Chassis..............................................................................................................27

Figure 2: AT-MCF2000 Chassis Slots ..................................................................................................................................28

Figure 3: AT-MCF2300 Chassis Sots ...................................................................................................................................29

Figure 4: AT-MCF2000 Series Media Converter Module .....................................................................................................32

Figure 5: Front Panel of the AT-MCF2012LC Module..........................................................................................................33

Figure 6: Front Panel of the AT-MCF2012LC/1 Module.......................................................................................................33

Figure 7: Front Panel of the AT-MCF2032SP Module..........................................................................................................33

Figure 8: Channel 1 on the Media Converter Module...........................................................................................................34

Figure 9: Activity LED for a Twisted Pair Port.......................................................................................................................41

Figure 10: Activity LED for a Fiber Optic Port on the AT-MCF2012LC and AT-MCF2012LC/1 Modules.............................41

Figure 11: Activity LEDs for the Fiber Optic Ports on the AT-MCF2032SP Module.............................................................42

Figure 12: Link LED for a Twisted Pair Port .........................................................................................................................42

Figure 13: Link LED for a Fiber Optic Port on the AT-MCF2012LC and AT-MCF2012LC/1 Modules..................................43

Figure 14: Link LEDs for the Fiber Optic Ports on the AT-MCF2032SP Module..................................................................43

Figure 15: Duplex Mode and Collision LEDs on the AT-MCF2012LC and AT-MCF2012LC/1 Modules.............................. 47

Figure 16: Duplex Mode and Collision LEDs on the AT-MCF2032SP Module .....................................................................47

Figure 17: Channel Operating Mode LEDs on the AT-MCF2012LC and AT-MCF2012LC/1 Modules.................................48

Figure 18: Channel Operating Mode LEDs on the AT-MCF2032SP Module .......................................................................49

Figure 19: RDY/FLT LED on the AT-MCF2032SP Module ..................................................................................................49

Figure 20: HBI and HBO Heartbeat LEDs on the AT-MCF2032SP Module.........................................................................50

Figure 21: Mode Button .........................................................................................................

Figure 22: “CH” Channel LEDs on the AT-MCF2012LC and AT-MCF2012LC/1 Modules ...................................................51

Figure 23: Channel LEDs on the AT-MCF2032SP Module ..................................................................................................52

Figure 24: AT-MCF2000M Management Module .................................................................................................................56

Figure 25: Front Panel of the AT-MCF2000M Management Module....................................................................................58

Figure 26: Pressing the Reset Button...................................................................................................................................64

Figure 27: Chassis ID Jumper ..............................................................................................................................................66

Figure 28: General Status LEDs...........................................................................................................................................67

Figure 29: Link/Activity LED on the RS-232 Terminal Port...................................................................................................68

Figure 30: Link/Activity and Duplex-mode LEDs on the Management Port..........................................................................69

Figure 31: Chassis ID Number LEDs....................................................................................................................................70

Figure 32: Link/Activity LED on the Stack Port.....................................................................................................................70

Figure 33: SD Slot LED ........................................................................................................................................................71

Figure 34: AT-MCF2000S Stacking Module .........................................................................................................................74

Figure 35: Example Stack of Four Media Converter Chassis...............................................................................................75

Figure 36: Maximum Length of a Stacking Cable.................................................................................................................75

Figure 37: Cabling the AT-MCF2000M Management Module to the AT-MCF2000S Stacking Module ...............................77

Figure 38: Cabling Two AT-MCF2000S Stacking Modules ..................................................................................................78

Figure 39: Chassis ID Jumper on the AT-MCF2000M Management Module .......................................................................79

Figure 40: Chassis ID DIP Switches on the AT-MCF2000S Stacking Module .....................................................................80

Figure 41: Chassis ID Numbers............................................................................................................................................80

Figure 42: Removing the Chassis Feet ................................................................................................................................97

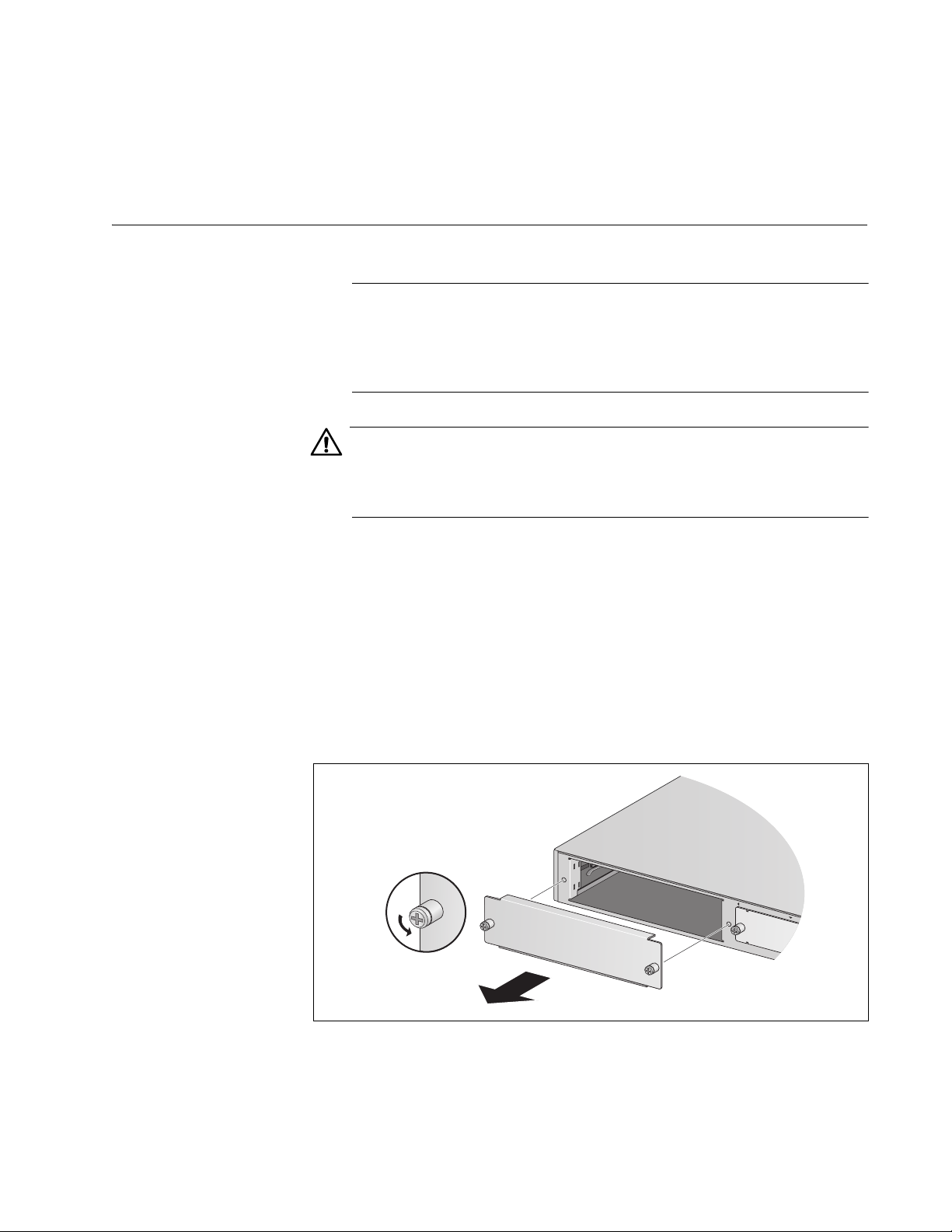

Figure 43: Removing the Blank Panel from a Power Supply Slot.........................................................................................99

Figure 44: Installing the AT-MCF2000AC Power Supply Module.....................................................................

Figure 45: Securing the AT-MCF2000AC Power Supply Module.......................................................................................101

Figure 46: Installing a Retaining Clip ..................................................................................................................................102

Figure 47: Removing the Cover from a Power Supply Slot ................................................................................................103

Figure 48: Installing the AT-MCF2KFAN Fan Module ........................................................................................................105

Figure 49: Securing the AT-MCF2KFAN Fan Module ........................................................................................................105

...............................................51

..................101

9

Page 10

Figures

Figure 50: Removing a Blank Cover from a Media Converter Slot .....................................................................................107

Figure 51: Removing the Battery Insulator .........................................................................................................................108

Figure 52: Installing a Media Converter Module .................................................................................................................109

Figure 53: Securing a Media Converter Module .................................................................................................................109

Figure 54: Removing the Blank Panel from the Management Slot.....................................................................................111

Figure 55: Setting the Chassis ID Jumper on the AT-MCF2000M Management Module...................................................113

Figure 56: Removing the Battery Insulator .........................................................................................................................113

Figure 57: Installing the Management Module....................................................................................................................114

Figure 58: Securing the Management Module....................................................................................................................114

Figure 59: Removing the Blank Panel from the Management Slot.....................................................................................115

Figure 60: Setting the Chassis ID DIP Switches.................................................................................................................117

Figure 61: Installing the AT-MCF2000S Stacking Module ..................................................................................................117

Figure 62: Securing the AT-MCF2000S Stacking Module ..................................................................................................118

Figure 63: Labelling the AT-MCF2000S Stacking Module with the Chassis ID Number ....................................................118

Figure 64: Attaching a Rack-mount Bracket to the AT-MCF2000 Chassis.........................................................................119

Figure 65: Attaching a Rack-mount Bracket to the AT-MCF2300 Chassis.........................................................................119

Figure 66: Rack-mount Bracket Positions on the AT-MCF2300 Chassis ...........................................................................120

Figure 67: Invalid Rack-mount Bracket Positions on the AT-MCF2300 Chassis................................................................121

Figure 68: Stripping the Grounding Wire ............................................................................................................................123

Figure 69: Attaching the Grounding Wire to the Grounding Lug .........................................................................................123

Figure 70: Removing the Grounding Lug Screws ...................................................................................

Figure 71: Attaching the Grounding Lug .............................................................................................................................124

Figure 72: Removing a Dust Cover from an SFP Slot ........................................................................................................125

Figure 73: Installing an SFP Module...................................................................................................................................126

Figure 74: Positioning the SFP Handle...............................................................................................................................126

Figure 75: Connecting an Enhanced Category 5 Network Cable to the 10/100/1000Base-T Management Port...............131

Figure 76: Cabling the AT-MCF2000M Management Module to the AT-MCF2000S Stacking Module..............................132

Figure 77: Cabling Two AT-MCF2000S Stacking Modules ................................................................................................133

Figure 78: Setting the ON/OFF Switch to the OFF Position ...............................................................................................135

Figure 79: Raising the Retaining Clip .................................................................................................................................135

Figure 80: Connecting the AC Power Cord.........................................................................................................................136

Figure 81: Positioning the Power Cord Retaining Clip ........................................................................................................136

Figure 82: Connecting the RS-232 Serial Management Cable to the RS-232 Terminal Port .............................................143

Figure 83: Command Line Prompt......................................................................................................................................144

Figure 84: Covering a Broken Fan on the AT-MCF2300FAN Module ................................................................................152

Figure 85: Labelling and Removing the Twisted Pair Cables and the Fiber Optic Cables .................................................158

Figure 86: Installing the Dust Covers on the Fiber Optic Ports...........................................................................................158

Figure 87: Removing the SFP Modules from the AT-MCF2032SP Module........................................................................159

Figure 88: Removing the Media Converter Module ............................................................................................................159

Figure 89: Installing the AT-MCF2KPNL1 Slot Cover over a Media Converter Slot ...........................................................160

Figure 90: Disconnecting the Cables from the AT-MCF2000M and AT-MCF2000S Modules............................................161

Figure 91: Removing the AT-MCF2000M Management Module or the AT-MCF2000S Stacking Module .........................162

Figure 92: Installing the AT-MCF2KPNL3 Slot Cover on the Management Slot.......................................................

Figure 93: Setting the ON/OFF Switch to the OFF Position ...............................................................................................164

Figure 94: Removing the Power Cord.................................................................................................................................165

Figure 95: Removing the AT-MCF2000AC or AT-MCF2300AC Power Supply Module .....................................................166

Figure 96: Installing the AT-MCF2KPNL2 Slot Cover over the Power Supply Slot ............................................................167

Figure 97: Removing the Fan Cover...................................................................................................................................168

Figure 98: Removing the AT-MCF2300FAN Module ..........................................................................................................169

Figure 99: Installing a New AT-MCF2300FAN Module.......................................................................................................170

Figure 100: RJ-45 Connector and Port Pin Assignments ...................................................................................................176

Figure 101: RS-232 Terminal Port Pinouts.........................................................................................................................177

Figure 102: Chassis ID DIP Switches on the AT-MCF2000S Stacking Module .................................................................179

Figure 103: Ferrule in an SC Connector Plug.....................................................................................................................181

Figure 104: Unclean and Clean Ferrule..............................................................................................................................181

Figure 105: Cartridge Cleaner ............................................................................................................................................182

Figure 106: Rubbing the Ferrule Tip on the Cleaning Surface ...........................................................................................183

Figure 107: Lint-Free and Alcohol-Free Swabs ..................................................................................................................184

Figure 108: Cleaning a Recessed Ferrule ..........................................................................................................................184

............................124

..........163

10

Page 11

Tab le s

Table 1: Hardware Components ..........................................................................................................................................22

Table 2: Management Software ..........................................................................................................................................25

Table 3: AT-MCF2000 Chassis Slots ..................................................................................................................................28

Table 4: AT-MCF2300 Chassis Slots ..................................................................................................................................29

Table 5: Twisted Pair Cabling and Distances ......................................................................................................................35

Table 6: Fiber Optic Ports ....................................................................................................................................................36

Table 7: “A” Activity LED ......................................................................................................................................................42

Table 8: Link LEDs in the Link Test Mode ...........................................................................................................................44

Table 9: “L” Link LEDs in the MissingLink Mode .................................................................................................................45

Table 10: “L” Link LEDs in the Smart MissingLink Mode .....................................................................................................45

Table 11: CDC and FDC Duplex Mode and Collisions LEDs ..............................................................................................48

Table 12: RDY/FLT LED ......................................................................................................................................................49

Table 13: Cable Requirements for the 10/100/1000Base-T Management Port ...................................................................59

Table 14: General Status LEDs ...........................................................................................................................................67

Table 15: Link/Activity LED on the RS-232 Terminal Port ...................................................................................................68

Table 16: Link/Activity LED on the Management Port .........................................................................................................69

Table 17: Duplex-mode/Collisions LED on the Management Port ......................................................................................69

Table 18: Link/Activity LED on the Management Port .........................................................................................................71

Table 19: SD Slot LED ........................................................................................................................................................71

Table 20: Cable Requirements for the Stack Ports .............................................................................................................77

Table 21: LEDs on the AT-MCF2000S Stacking Module ....................................................................................................81

Table 22: AT-MCF2000 Chassis Items ................................................................................................................................93

Table 23: AT-MCF2300 Chassis Items ................................................................................................................................94

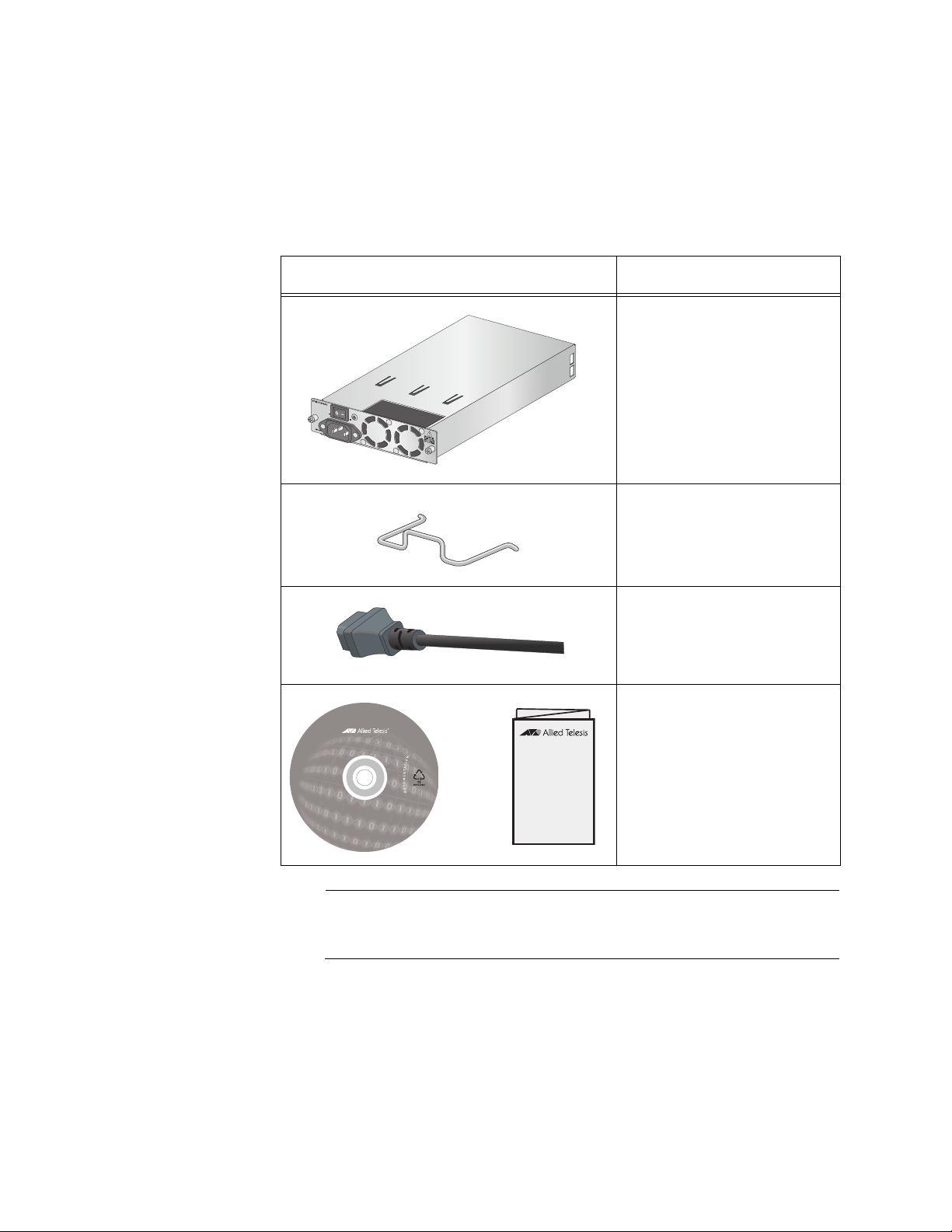

Table 24: AT-MCF2000AC or AT-MCF2300AC Power Supply Module Items ...................................................................100

Table 25: AT-MCF2KFAN Module Items ...........................................................................................................................104

Table 26: AT-MCF2000 Media Converter Module Items ...................................................................................................108

Table 27: AT-MCF2000M Management Module ...............................................................................................................112

Table 28: AT-MCF2000S Module Items ............................................................................................................................116

Table 29: 10/100Base-TX Port Pinouts ..........................................................................................

Table 30: Fiber Optic Port Specifications for the AT-MFC2012LC Module .......................................................................175

Table 31: Fiber Optic Port Specifications for the AT-MFC2012LC/1 Module ....................................................................175

Table 32: 10/100/1000Base-T Management Port Pinouts at 10 or 100 Mbps ...................................................................176

Table 33: 10/100/1000Base-T Management Port Pinouts at 1000 Mbps ..........................................................................176

Table 34: RS-232 Terminal Port ........................................................................................................................................177

Table 35: SW2 DIP Switch Settings (ID Numbers 1 to 15) for the AT-MCF2000S Stacking Module ................................179

Table 36: SW2 DIP Switch Settings (ID Numbers 16 to 30) for the AT-MCF2000S Stacking Module ..............................180

...................................174

11

Page 12

Tables

12

Page 13

Preface

This is the installation guide for the AT-MCF2000 Series of multi-channel,

Fast and Gigabit Ethernet media converter products. In this guide you’ll

learn about the features of the product and how to install the components.

This preface contains the following sections:

“How this Guide is Organized” on page 14

“Where to Find Web-based Guides” on page 16

“Contacting Allied Telesis” on page 17

13

Page 14

Preface

How this Guide is Organized

The chapters in this guide are divided into two sections. The chapters in

the first section describe the features and components of the product. If

you are installing your first system, you will find the installation easier to do

and will be less likely to assemble or cable the product incorrectly if you

first familiarize yourself with the basics of the product by reviewing the

material in these chapters.

The chapters in the second section contain the installation instructions. If

you are installing a new system, Allied Telesis recommends that you

perform the chapters as they are presented in the section, skipping any

chapters that are not relevant to your installation. To upgrade or expand

an existing system, go straight to the appropriate chapters.

Here are the sections, chapters, and appendices in this guide:

Section I, Features

Chapter 1, “AT-MCF2000 Multi-channel Media Converter Series” on

page 21

Chapter 2, “AT-MCF2000 and AT-MCF2300 Chassis” on page 27

Chapter 3, “AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP

Modules” on page 31

Chapter 4, “AT-MCF2000M Management Module” on page 55

Chapter 5, “AT-MCF2000S Stacking Module” on page 73

Section II, Installation

Chapter 6, “Reviewing the Safety Precautions” on page 87

Chapter 7, “Selecting a Location” on page 91

Chapter 8, “Unpacking the AT-MCF2000 or AT-MCF2300 Chassis” on

page 93

Chapter 9, “Removing the Rubber Feet” on page 97

Chapter 10, “Installing the AT-MCF2000AC or AT-MCF2300AC Power

Supply Module” on page 99

14

Chapter 11, “Installing the AT-MCF2KFAN Module” on page 103

Chapter 12, “Installing a Media Converter Module” on page 107

Chapter 13, “Installing the AT-MCF2000M Management Module” on

page 111

Page 15

AT-MCF2000 Media Converter Series Installation Guide

Chapter 14, “Installing the AT-MCF2000S Stacking Module” on page

115

Chapter 15, “Installing the Chassis in an Equipment Rack” on page

119

Chapter 16, “Grounding the AT-MCF2300 Chassis” on page 123

Chapter 17, “Installing the SFP Modules in the AT-MCF2032SP

Module” on page 125

Chapter 18, “Cabling the Ports on the Media Converter Module” on

page 129

Chapter 19, “Cabling the AT-MCF2000M and AT-MCF2000S Modules”

on page 131

Chapter 20, “Powering on the Chassis” on page 135

Chapter 21, “Verifying the Installation” on page 139

Chapter 22, “Starting a Local Management Session” on page 143

Chapter 23, “Troubleshooting the Modules” on page 145

Chapter 24, “Replacing the Modules” on page 157

Appendix A, “Technical Specifications” on page 171

Appendix B, “DIP Switch Settings for the AT-MCF2000S Stacking

Module” on page 179

Appendix C, “Cleaning Fiber Optic Connectors” on page 181

15

Page 16

Preface

Where to Find Web-based Guides

The installation and user guides for all of the Allied Telesis products are

available for viewing in portable document format (PDF) from our web site

at www.alliedtelesis.com.

16

Page 17

AT-MCF2000 Media Converter Series Installation Guide

Contacting Allied Telesis

This section provides Allied Telesis contact information for technical

support and for sales and corporate information.

Online Support You can request technical support online from the Allied Telesis

Knowledge Base at www.alliedtelesis.com/support/kb.aspx. You can

submit questions to our technical support staff from the Knowledge Base

and review answers to previously asked questions.

Email and

Telephone

Support

Returning

Products

Sales and

Corporate

Information

Warranty All the products in the AT-MCF2000 Media Converter Series have a 2

Management

Software Updates

For Technical Support via email or telephone, refer to the Allied Telesis

web site at www.alliedtelesis.com. Select your country from the list on

the web site and then select the appropriate tab.

Products for return or repair must be assigned Return Materials

Authorization (RMA) numbers. A product sent to Allied Telesis without an

RMA number will be returned to the sender at the sender’s expense.

To obtain an RMA number, contact the Allied Telesis Technical Support

group at www.alliedtelesis.com/support/rma.aspx.

You can contact Allied Telesis for sales or corporate information at our

web site at www.alliedtelesis.com.

Year Warranty. All Allied Telesis warranties are subject to the terms and

conditions set out in the Allied Telesis Limited Warranties on our web site

at www.alliedtelesis.com/warranty.

New releases of the management software for our managed products are

available from the following Internet sites:

Allied Telesis web site: www.alliedtelesis.com

Allied Telesis FTP server: ftp://ftp.alliedtelesis.com

If the FTP server prompts you to log on, enter “anonymous” as the user

name and your email address as the password.

17

Page 18

Preface

18

Page 19

Section I

Features

The chapters in this section are listed here:

Chapter 1, “AT-MCF2000 Multi-channel Media Converter Series” on

page 21

Chapter 2, “AT-MCF2000 and AT-MCF2300 Chassis” on page 27

Chapter 3, “AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP

Modules” on page 31

Chapter 4, “AT-MCF2000M Management Module” on page 55

Chapter 5, ”AT-MCF2000S Stacking Module” on page 73

Section I: Features 19

Page 20

20 Section I: Features

Page 21

Chapter 1

AT-MCF2000 Multi-channel Media Converter Series

The multi-channel media converters in the AT-MCF2000 Series are a

simple and reliable method for consolidating large numbers of

geographically separated Fast Ethernet or Gigabit Ethernet networks into

a central location over fiber optic cable.

The main components of the product are three high-density, 12-channel

media converter modules. Each channel on the modules functions as an

independent media converter for transferring local and remote network

traffic between a twisted pair port and a fiber optic port.

This product can be installed on a table or in a standard 19-inch equipment

rack and can be used in a managed or unmanaged network environment.

Section I: Features 21

Page 22

Chapter 1: AT-MCF2000 Multi-channel Media Converter Series

Hardware Components

Table 1 lists the hardware components that comprise the AT-MCF2000

Media Converter Series.

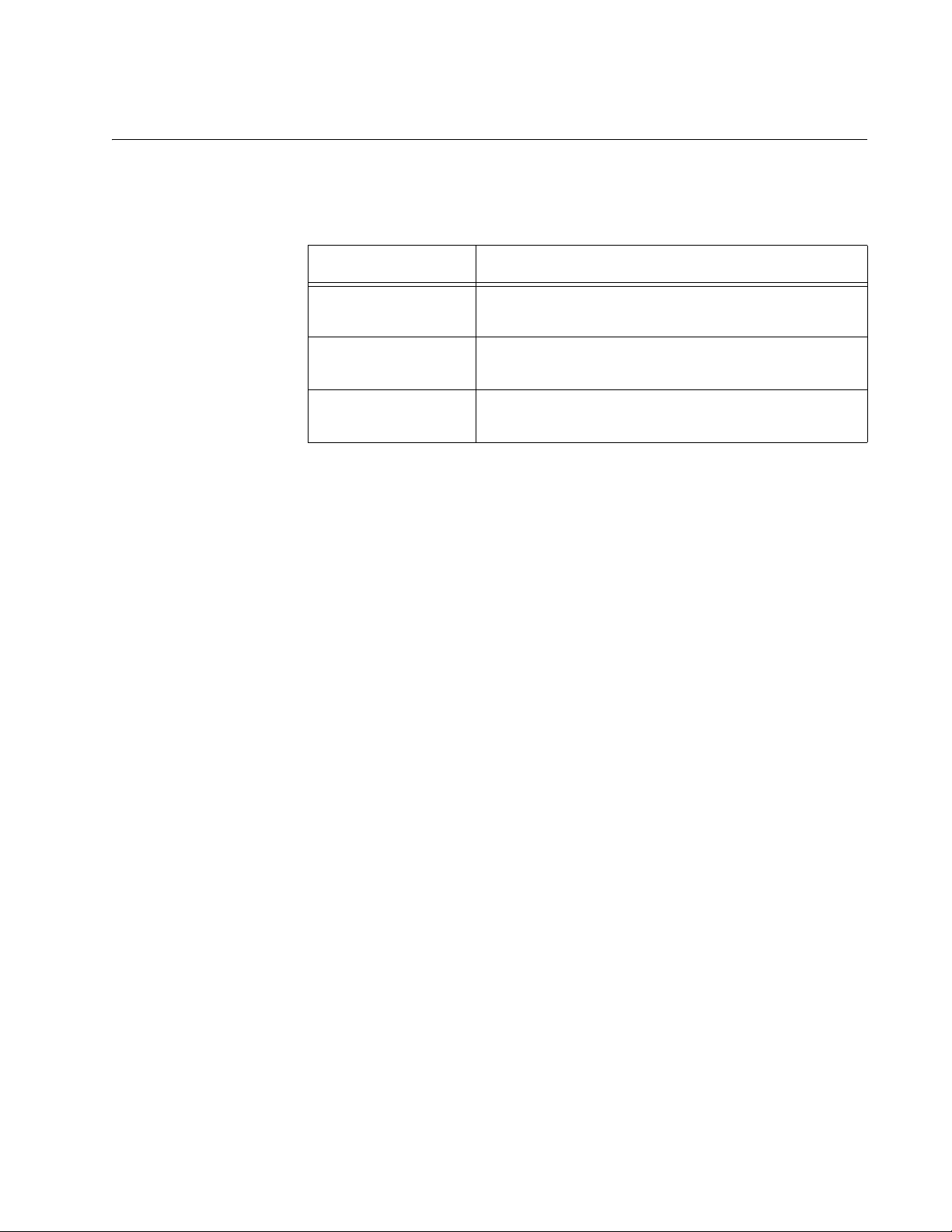

Table 1. Hardware Components

Component Description

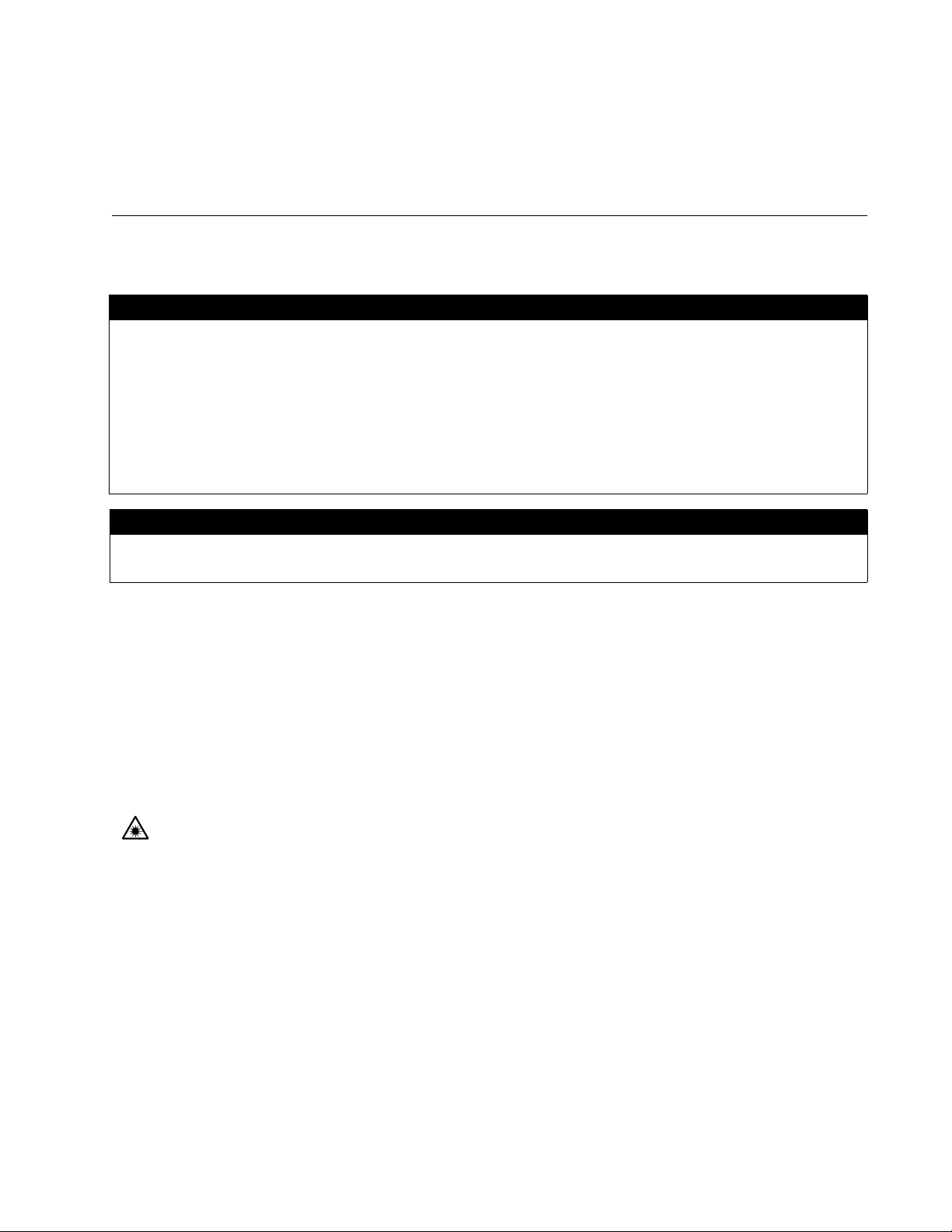

AT-MCF2012LC This is a Fast Ethernet media converter module. It

1390

has twelve independent channels that transfer

network traffic between twisted pair cables and fiber

optic cables. Each channel has one 10/100Base-TX

twisted pair port and one 10/100Base-FX fiber optic

port. The fiber optic ports have a maximum

operating distance of 2 km (1.24 mi.) in full-duplex

mode, feature duplex LC connectors, and use 50/

125 µm or 62.5/125 µm (core/cladding) multimode

fiber optic cable.

AT-MCF2012LC/1 This is also a Fast Ethernet media converter

module. It has twelve independent channels that

feature 10/100Base-TX twisted pair ports and

100Base-FX fiber optic ports. The fiber optic ports

on this module have a greater operating distance, up

to 20 kilometers (12.4 mi.) in full-duplex mode, than

the ports on the AT-MCF2012LC Module and use

1390

9/125 µm single-mode fiber optic cable.

AT-MCF2032SP This is a Fast and Gigabit media converter module.

Each of the twelve channels on this module has a

10/100/1000Base-T twisted pair port and an SFP

slot that supports either a 100Base or a 1000Base

fiber optic SFP module. The SFP slots let you

customize the channels for different operating

distances. For the list of supported SFP modules,

1389

contact your Allied Telesis sales representative.

AT-MCF2000 This 1U chassis has slots for two 12-channel media

converter modules, primary and redundant power

supplies, and the optional management or stacking

module.

A

T

-M

A

C

T

M

F

C

2

F

0

2

0

K

0

P

N

L

1

AT-

M

C

F

2

K

P

N

L

1

1

AT-MCF2000

2

1415

22 Section I: Features

Page 23

AT-MCF2000 Media Converter Series Installation Guide

Table 1. Hardware Components

Component Description

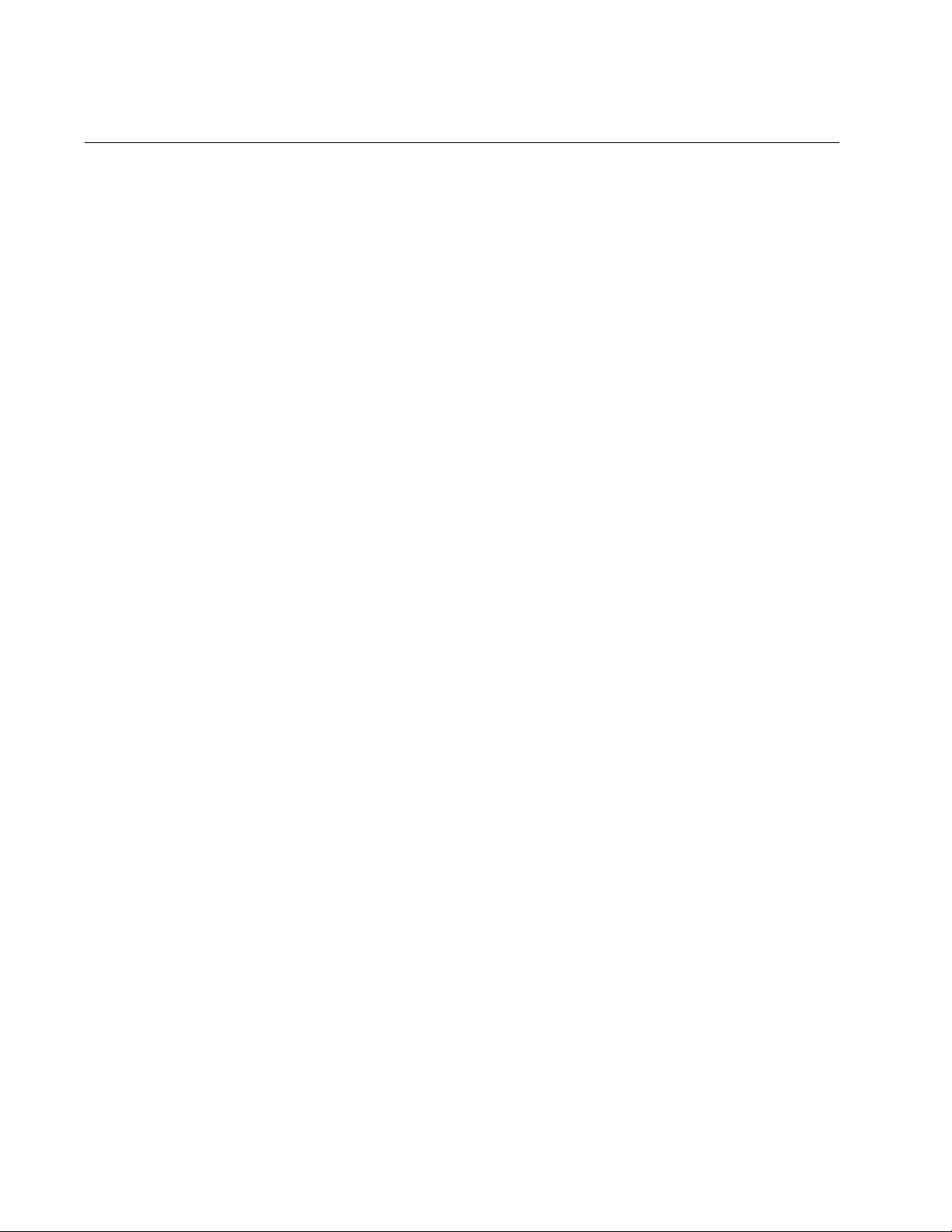

AT-MCF2300 This 3U chassis can accommodate up to four 12-

channel media converter modules, primary and

redundant power supplies, and the optional

management or stacking module.

A

T

M

A

T

C

-M

F

C

2

F

0

2

K

0

P

0

N

L

1

A

T

-M

C

F

2

K

P

N

L

1

A

T

M

C

F

2

K

P

N

L

2

A

T

-M

C

F

2

K

P

N

L

1

1

A

T

-M

C

F

2

K

P

N

L

1

A

3

M

A

NA

A

T

G

-M

E

M

C

F

E

2

N

K

T

P

N

L

3

B

A

T

M

C

F

2

K

P

N

L

AT-MCF200

2

2

4

1388

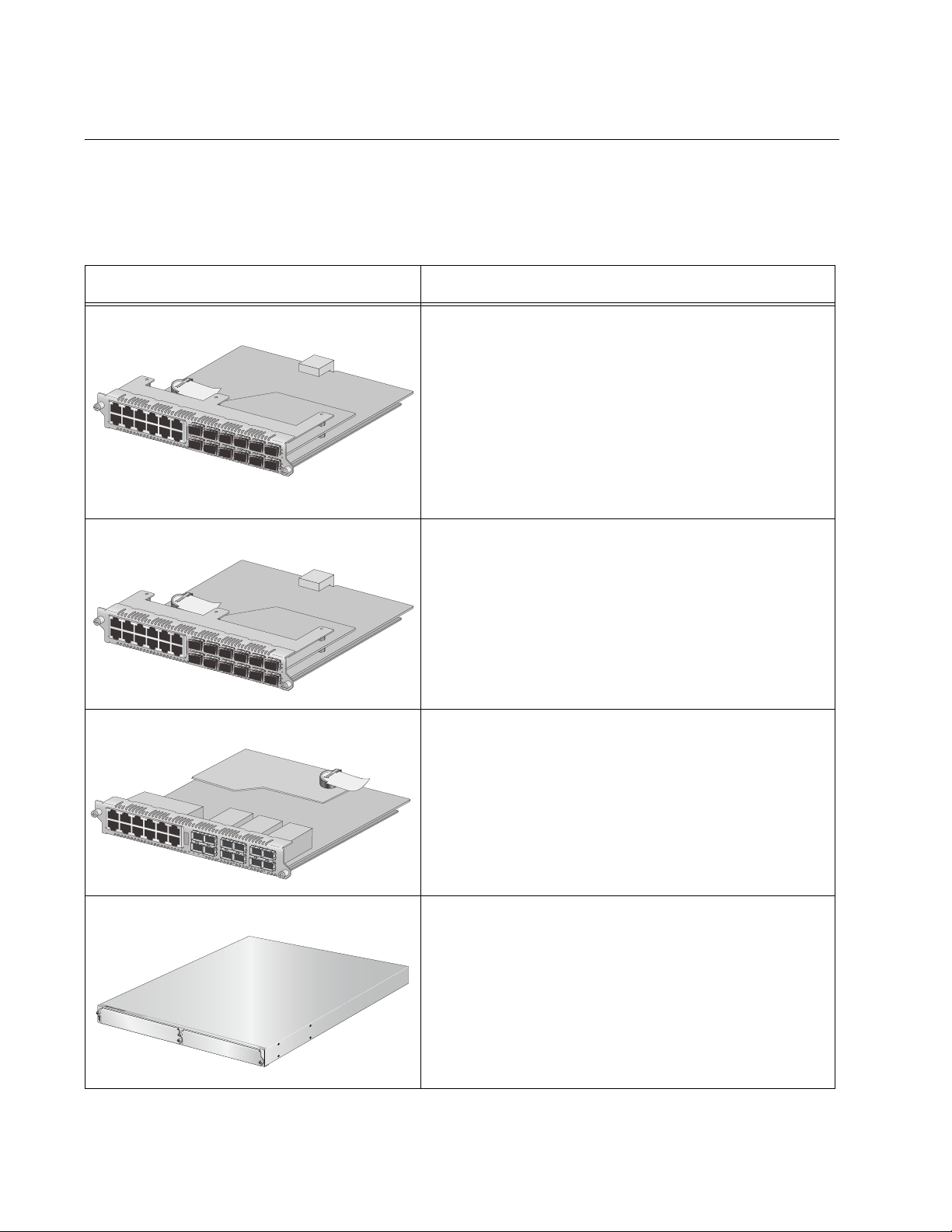

AT-MCF2000M This is an optional management module for

monitoring the states of the media converter

modules and configuring the parameters on the

ports. The module supports local management

through its RS-232 Terminal Port and remote

management from Telnet clients or Secure Shell

AT

-MCF2000M

ST

AC

K

L

I

N

K

AC

T

M

A

NAG

E

M

1

E

0

N

0

0

T

L

I

N

K

AC

T

1

0

/

T

1

0

E

0

R

L

M

I

N

I

N

K

A

L

AC

0

ID

3

1

T

F

PO

D

X

R

T A

H

D

CTIVITY

X

C

O

L

R

10

E

/100/100

S

E

T

BO

0B

O

A

T

SE

-T

R

D

Y

FA

U

L

T

R

S

-2

32

SD

1391

M

R

D

A

Y

S

T

E

R

B

US

Y

P

OW

E

R

clients on your network.

A

T-MCF2000

AT-MCF2000S This optional management stacking module lets you

daisy-chain the media converter units together so

that you can manage them simultaneously from one

AT-MCF2000M Management Card.

S

ST

A

C

K

1

L

I

N

KA

P

O

C

RT

T

AC

T

IV

IT

S

Y

T

A

C

K

2

C

H

A

S

S

IS

ID

1264

AT-MCF2000AC This is the power supply module for the

AT-MCF2000 Chassis. You can install two power

supply modules in the unit for power redundancy.

1110

Section I: Features 23

Page 24

Chapter 1: AT-MCF2000 Multi-channel Media Converter Series

Table 1. Hardware Components

Component Description

AT-MCF2300AC This is the power supply module for the

A

T

M

C

F

2

3

0

0A

C

1392

AT-MCF2KFAN This is the cooling module for the AT-MCF2000

AT-MCF2300 Chassis. The chassis can

accommodate two power modules for redundancy.

Chassis. This module is required if the chassis has

just one AT-MCF2000AC Power Supply Module.

AT-MCF2000FAN

1123

AT-MCF2300FAN This is the cooling module for the AT-MCF2300

Chassis. It comes preinstalled in the unit.

FAN 1

FAN 2

FAN 3

1393

24 Section I: Features

Page 25

Management Software Components

Table 2 lists the management software programs of the AT-MCF2000

Media Converter Series.

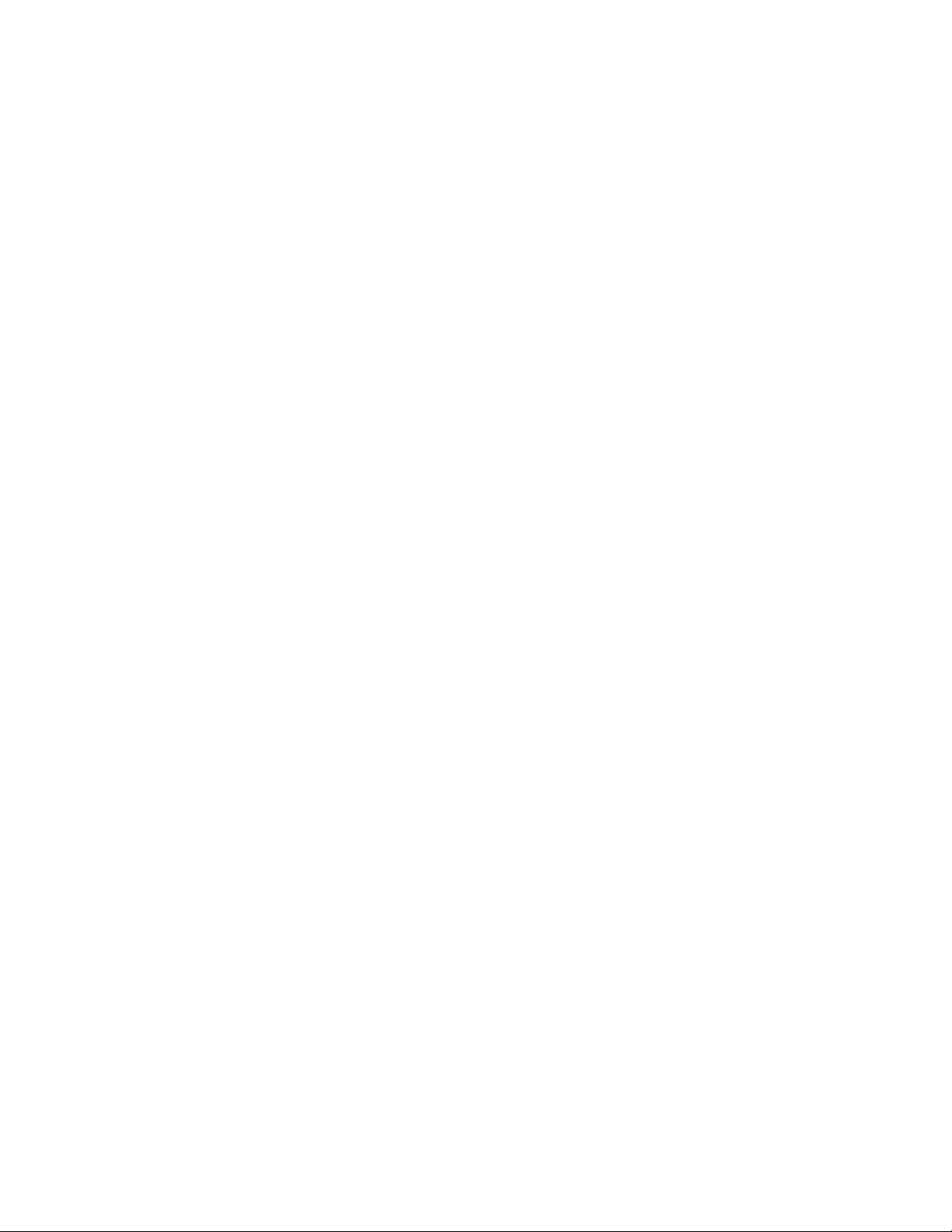

Table 2. Management Software

Management Software Description

AT-S85 This is the management software for the

AT-S97 This is the management software for the

AT-MCF2000 Media Converter Series Installation Guide

AT-MCF2012LC, AT-MCF2012LC/1 and

AT-MCF2032SP Media Converter

Modules. It comes preinstalled on the

modules and is upgradable with the

optional AT-MCF2000M Management

Module.

optional AT-MCF2000M Management

Module.

Note

The optional AT-MCF2000S Stacking Module does not have

management software.

Section I: Features 25

Page 26

Chapter 1: AT-MCF2000 Multi-channel Media Converter Series

26 Section I: Features

Page 27

Chapter 2

AT-MCF2000 and AT-MCF2300 Chassis

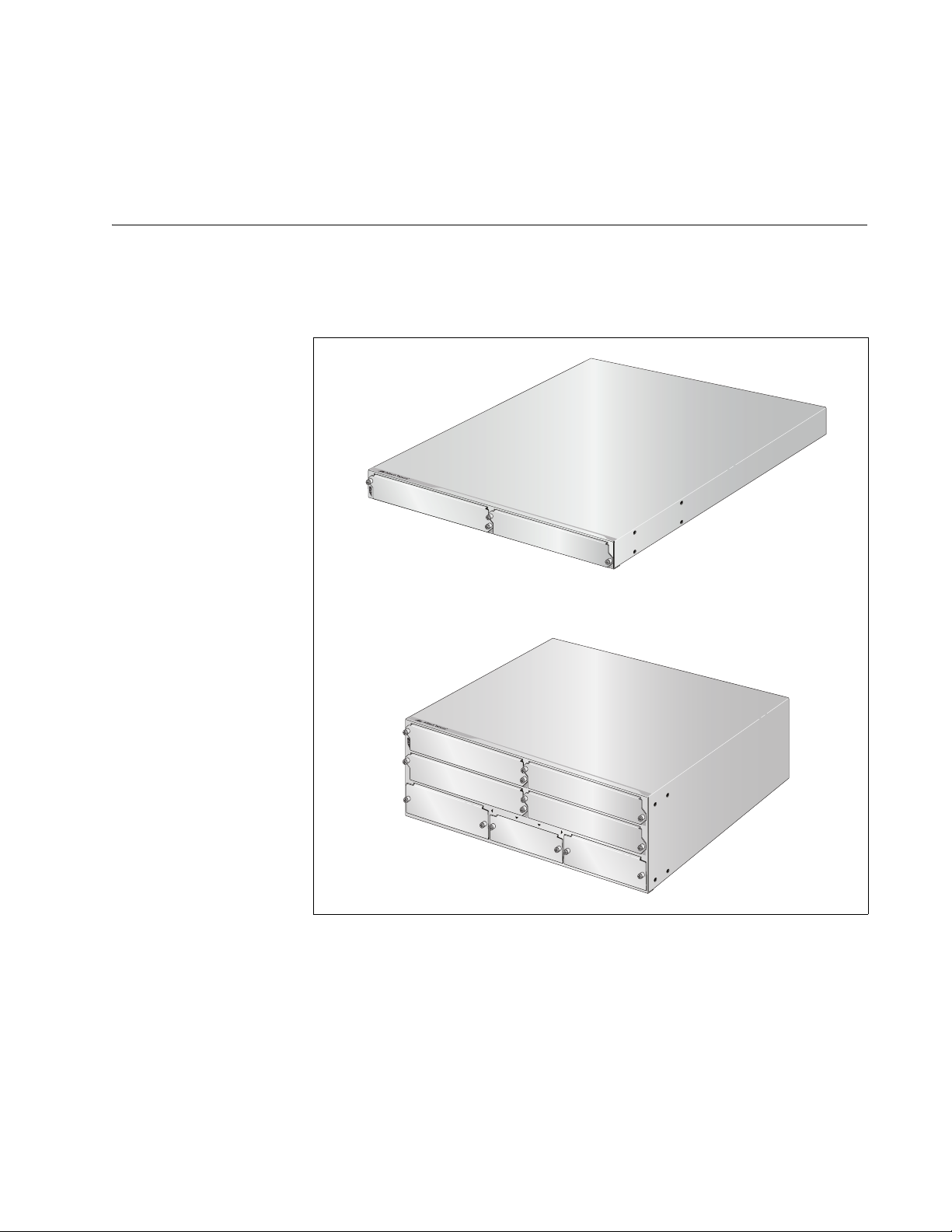

The AT-MCF2000 Chassis and the AT-MCF2300 Chassis are illustrated in

Figure 1.

AT-MCF2000

A

T

-MCF2000

A

T

-M

C

F

2K

P

N

L

1

AT

-M

C

F2

KP

N

L1

1

AT-MCF2000

2

1415

AT-MCF2300

A

T

-M

A

T

C

-MCF2K

F

2

00

PNL1

0

A

T

-M

CF2K

PNL1

A

T

-MCF2K

PNL2

A

T

-MCF2K

PNL1

1

A

T

-M

C

F2K

A

A

PNL1

3

MAN

A

T

GEM

-MC

F2K

EN

T

PN

L3

B

AT

-M

CF2K

PNL2

AT-MCF200

2

4

1388

Figure 1. AT-MCF2000 and AT-MCF2300 Chassis

Section I: Features 27

Page 28

Chapter 2: AT-MCF2000 and AT-MCF2300 Chassis

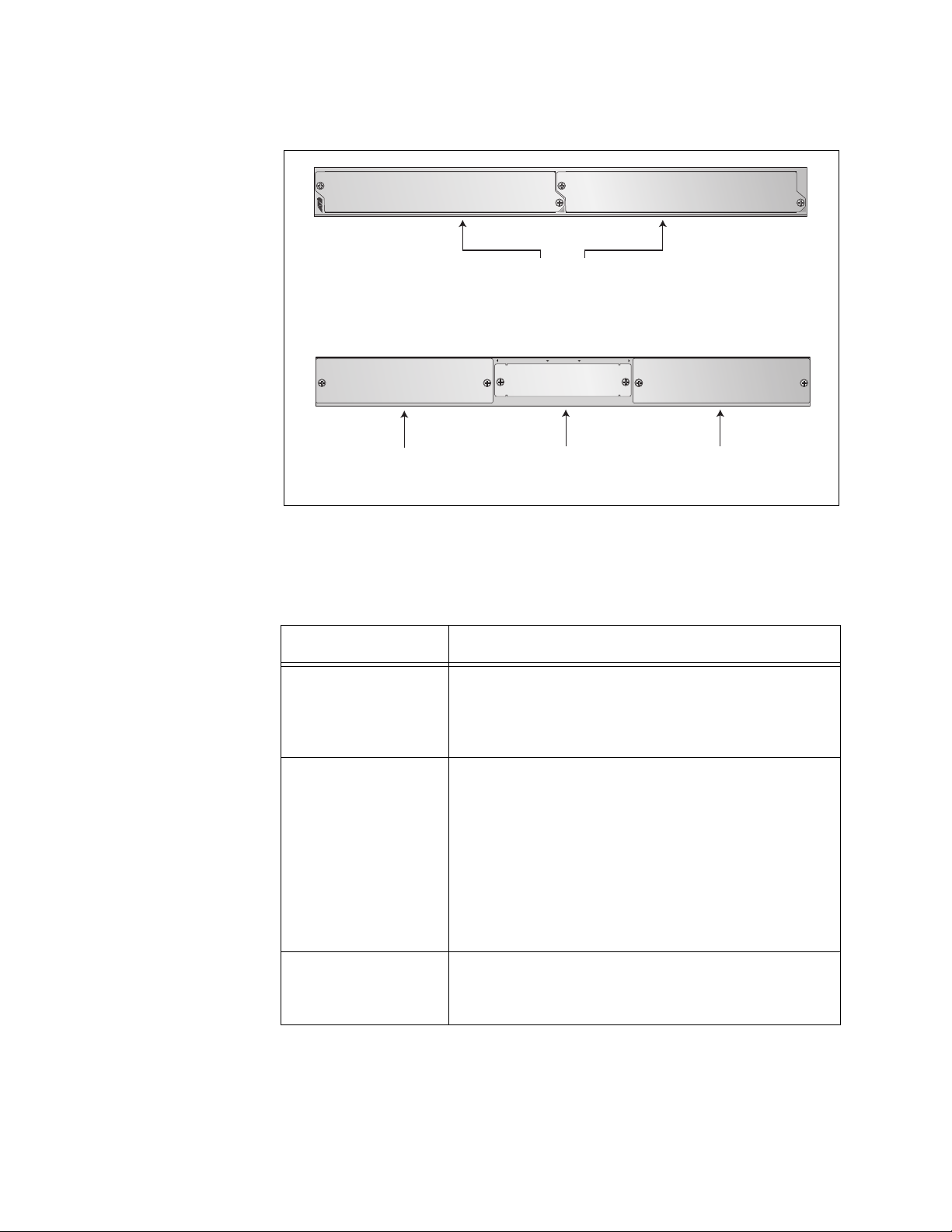

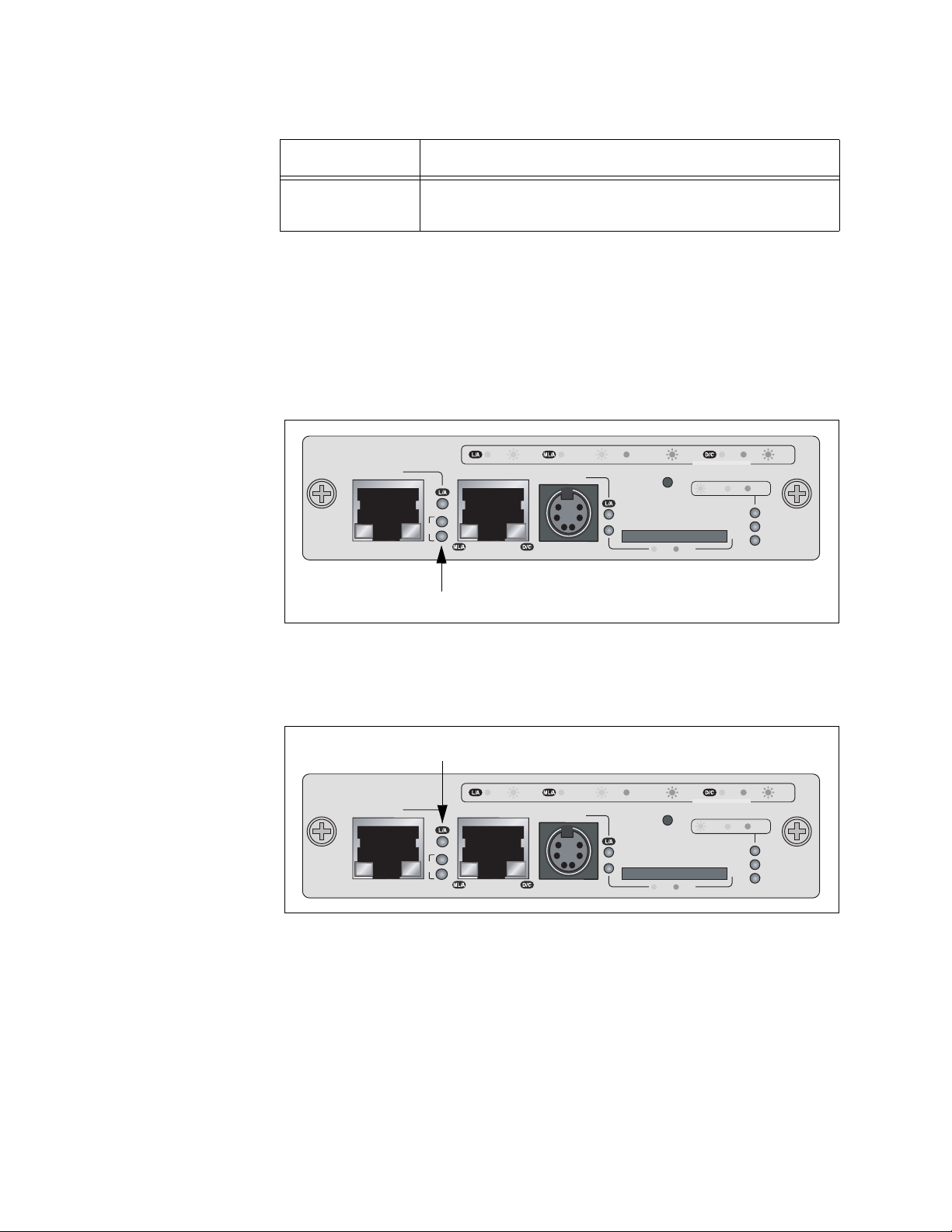

Figure 2 shows the front and back panels of the AT-MCF2000 Chassis.

AT-MCF2KPNL1 AT-MCF2KPNL1

1

Slots 1 and 2

AT-MCF2KPNL2 AT-MCF2KPNL2

A

Slot A

MANAGEMENT

AT-MCF2KPNL3

Management

Slot

Figure 2. AT-MCF2000 Chassis Slots

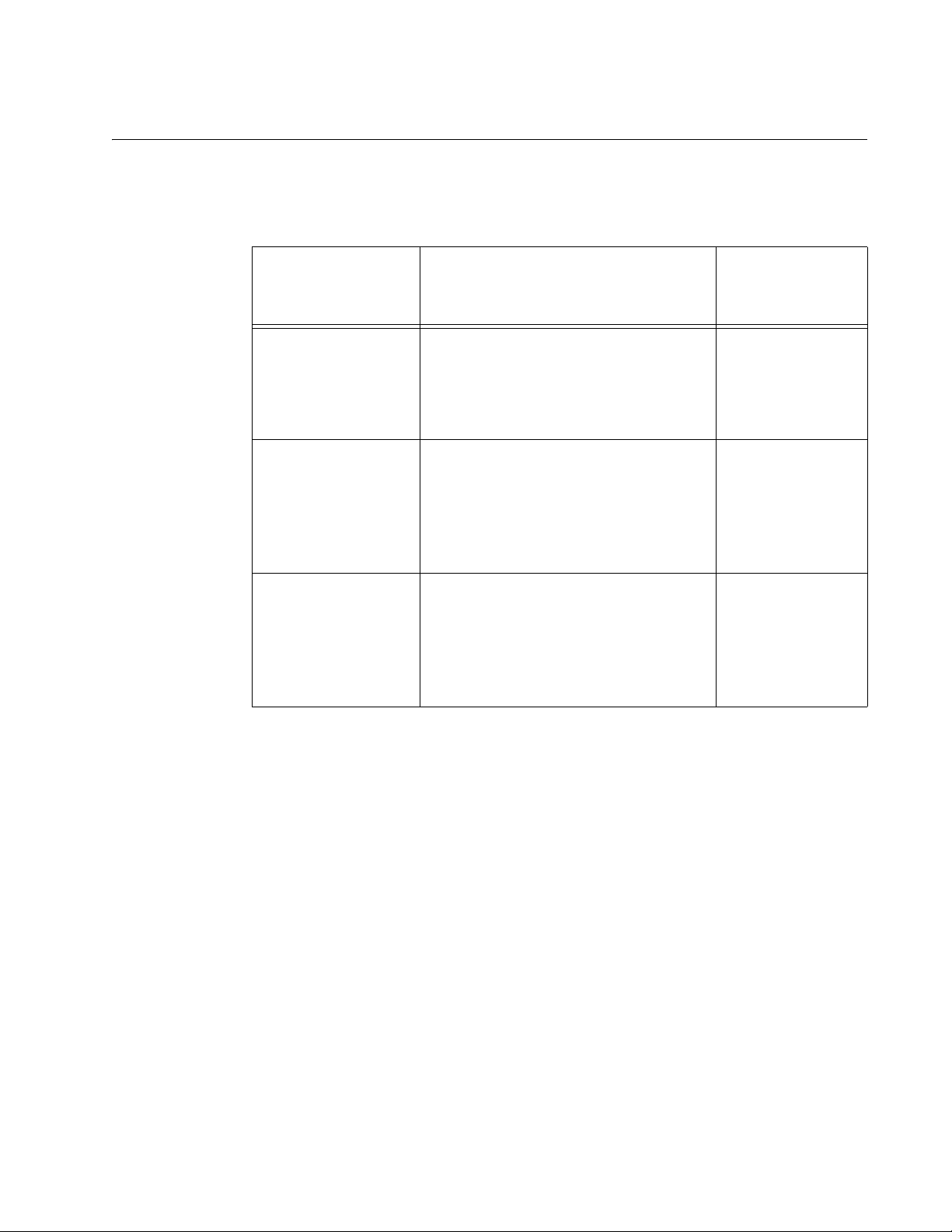

Table 3 lists the slots in the unit.

Table 3. AT-MCF2000 Chassis Slots

AT-MCF2000

2

1107-a

B

1108-a

Slot B

Slot Module

1 and 2 These slots are for the multi-channel

AT-MCF2012LC, AT-MCF2012LC/1 and

AT-MCF2032SP Media Converter Modules. Each

slot can accommodate one module.

A and B These slots are for the AT-MCF2000AC Power

Supply Module and the AT-MCF2KFAN Module.

The power requirements of the chassis can be

met with a single power supply module. A second

power supply module can be installed for power

redundancy. If the chassis has just one power

supply module, the AT-MCF2KFAN Module, a

cooling and ventilation module, must be installed

in one of these slots.

Management This slot is for the optional AT-MCF2000M

Management Module or the AT-MCF2000S

Stacking Module.

28 Section I: Features

Page 29

AT-MCF2000 Media Converter Series Installation Guide

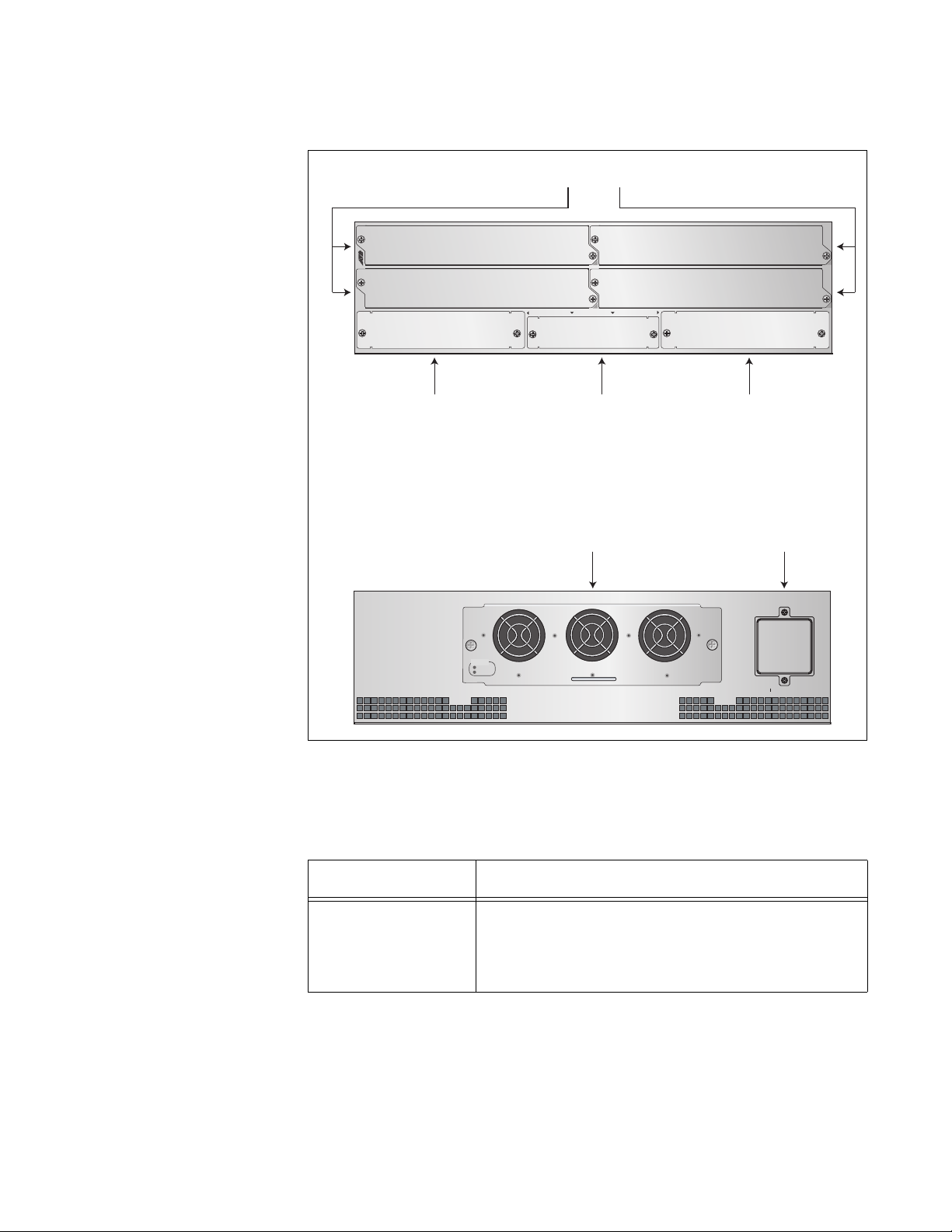

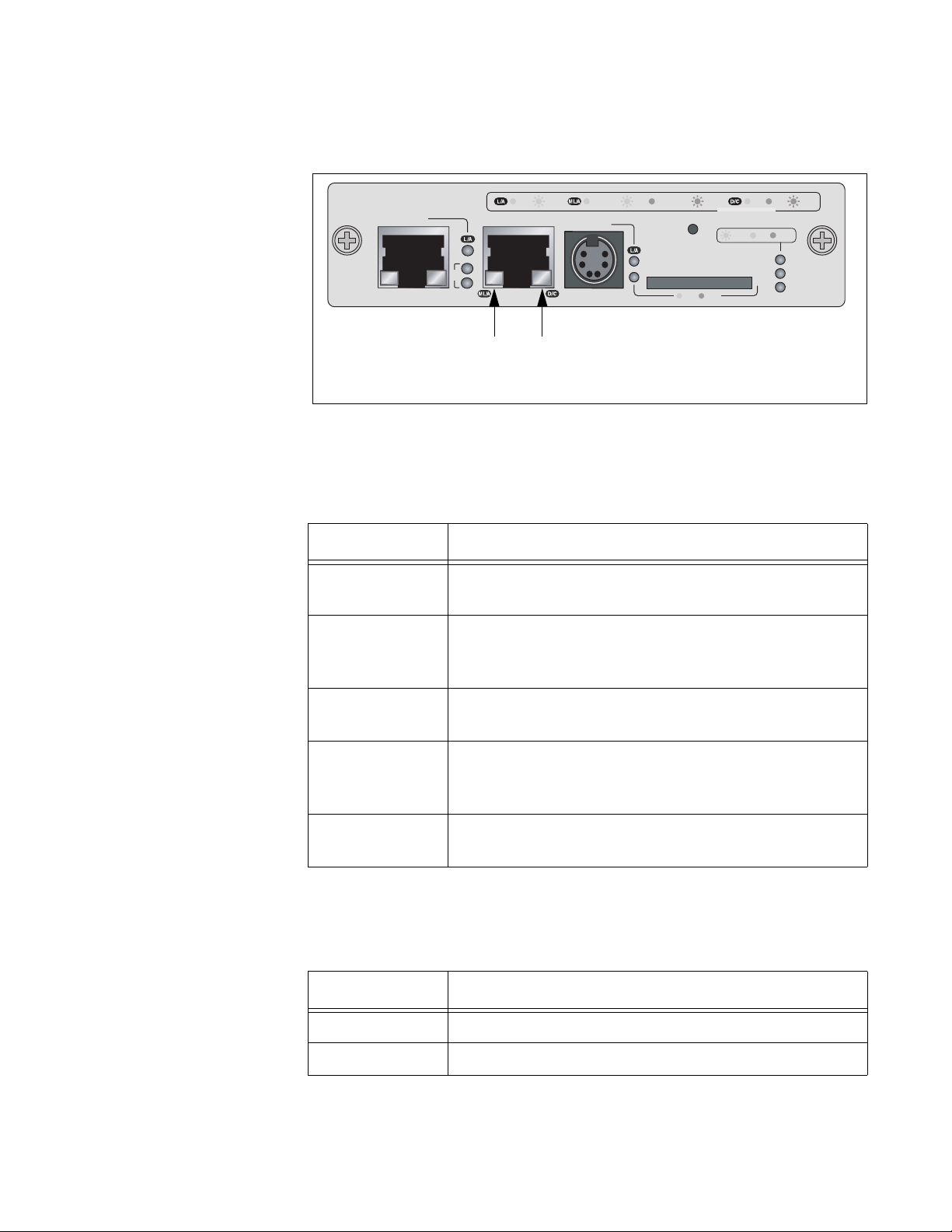

Figure 3 illustrates the front and back panels of the AT-MCF2300 Chassis.

Slots 1 to 4

AT-MCF2KPNL1 AT-MCF2KPNL1

AT-MCF2KPNL1 AT-MCF2KPNL1

AT-MCF2KPNL2

A

AT-MCF2KPNL3

Slot A

1

3

MANAGEMENT

Management

Slot

AT-MCF2300FAN

Module Fan Cover

AT-MCF2300FAN

STATUS

NORMAL

FAN 1 FAN 2 FAN 3

FAULT

B

AT-MCF2000

2

4

AT-MCF2KPNL2

Slot B

Figure 3. AT-MCF2300 Chassis Sots

Table 4 lists the slots in the chassis.

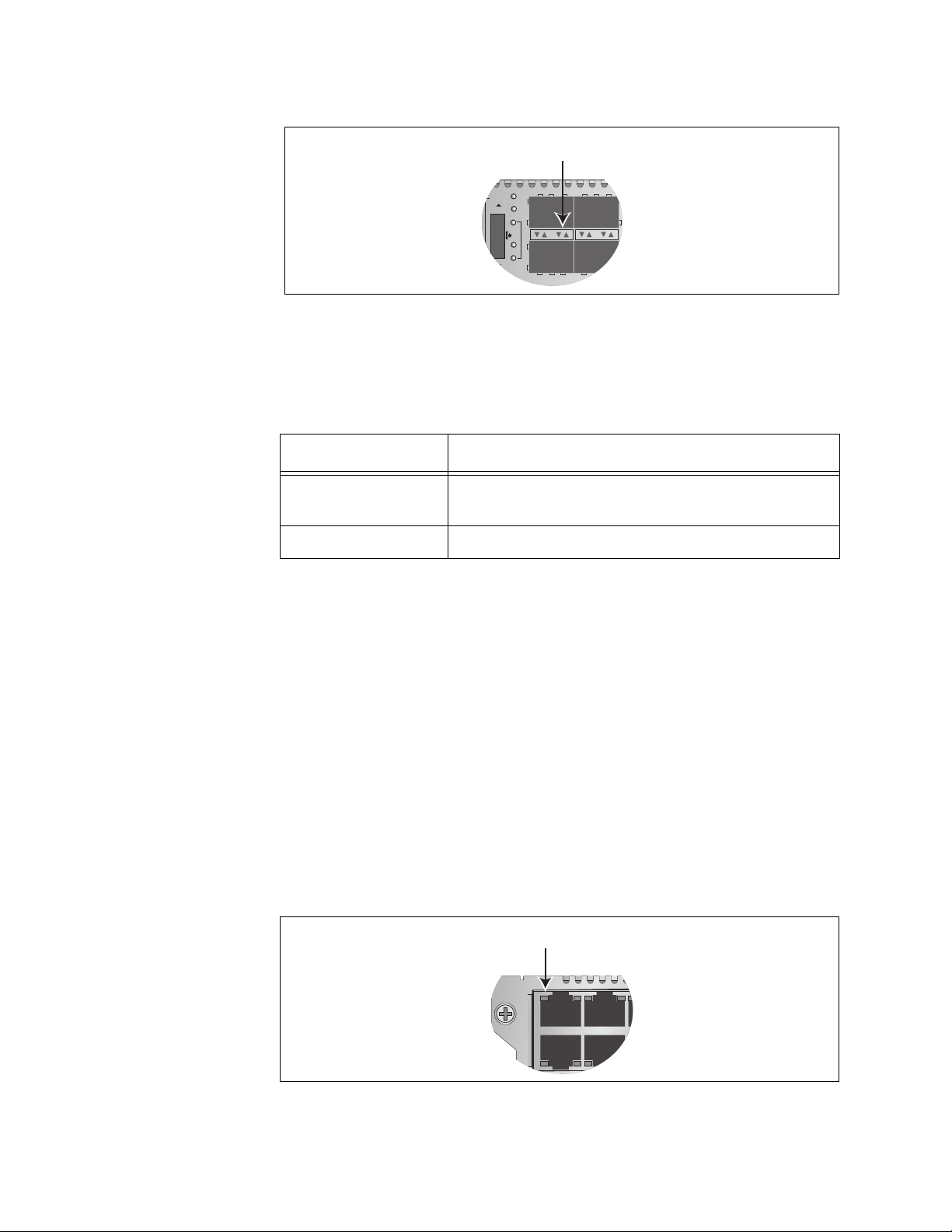

Table 4. AT-MCF2300 Chassis Slots

Slot/Module Module

1 to 4 These slots are for the multi-channel

AT-MCF2012LC, AT-MCF2012LC/1 and

AT-MCF2032SP Media Converter Modules. Each

slot can accommodate one module.

Section I: Features 29

Page 30

Chapter 2: AT-MCF2000 and AT-MCF2300 Chassis

Slot/Module Module

A and B These slots are for the AT-MCF2300AC Power

Management This slot is for the optional AT-MCF2000M

AT-MCF2300FAN This is a preinstalled cooling module. Also

Table 4. AT-MCF2300 Chassis Slots

Supply Module. The chassis requires only one

power supply module, but a second module can

be installed for power redundancy. If there are

two power supply modules in the unit, they loadshare the power requirements of the chassis.

Management Module or the AT-MCF2000S

Stacking Module.

included is a fan cover to use in the event a fan in

the module fails. The remaining operational fans

are better able to maintain adequate airflow and

ventilation in the chassis if a broken fan is

covered.

30 Section I: Features

Page 31

Chapter 3

AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules

This chapter contains the following sections:

❒ “Overview” on page 32

❒ “Front Panels” on page 33

❒ “Media Converter Channels” on page 34

❒ “Twisted Pair Ports” on page 35

❒ “Fiber Optic Ports” on page 36

❒ “Channel Operating Modes” on page 37

❒ “Port and Channel LEDs” on page 41

❒ “Mode Button” on page 51

❒ “Guidelines to Using the Media Converter Modules” on page 53

Section I: Features 31

Page 32

Chapter 3: AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules

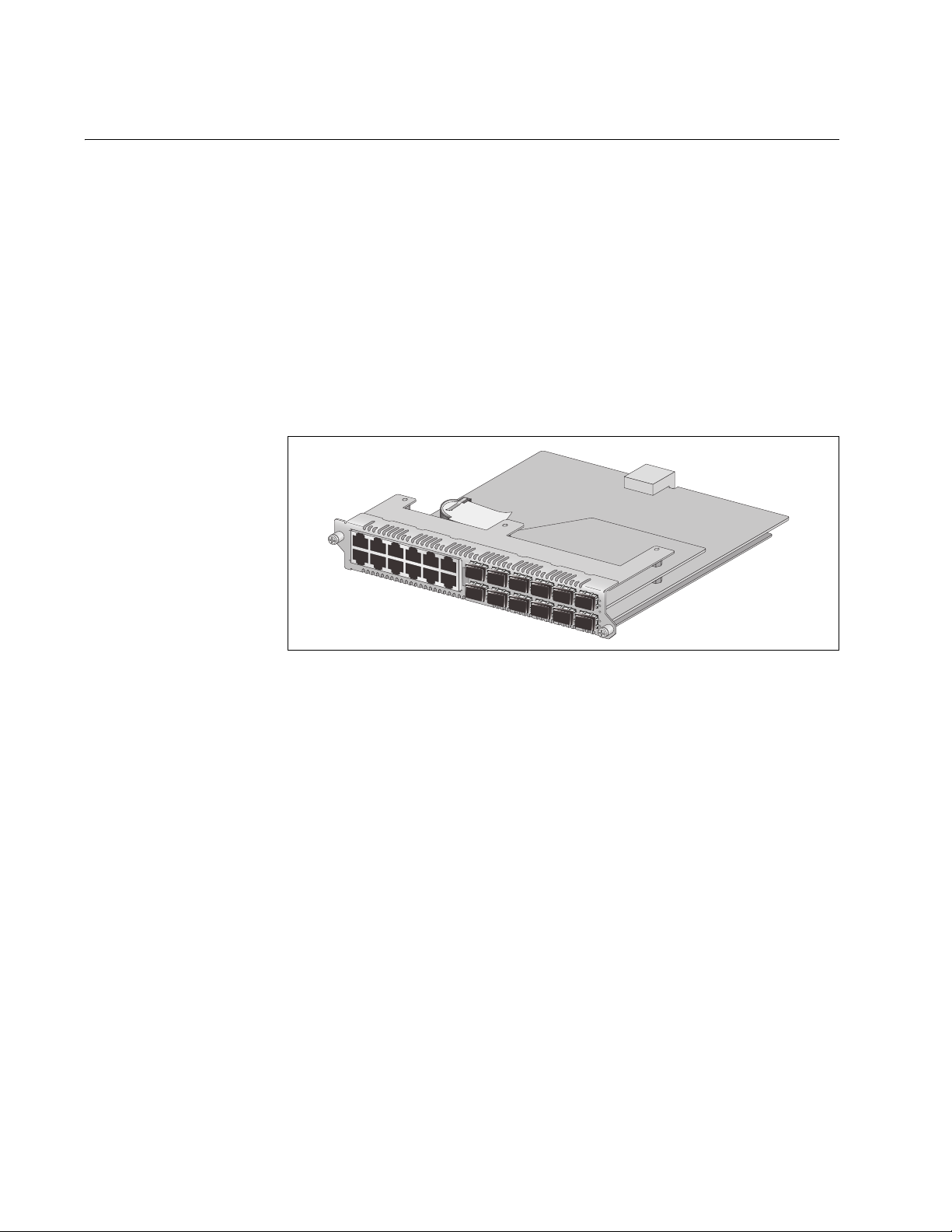

Overview

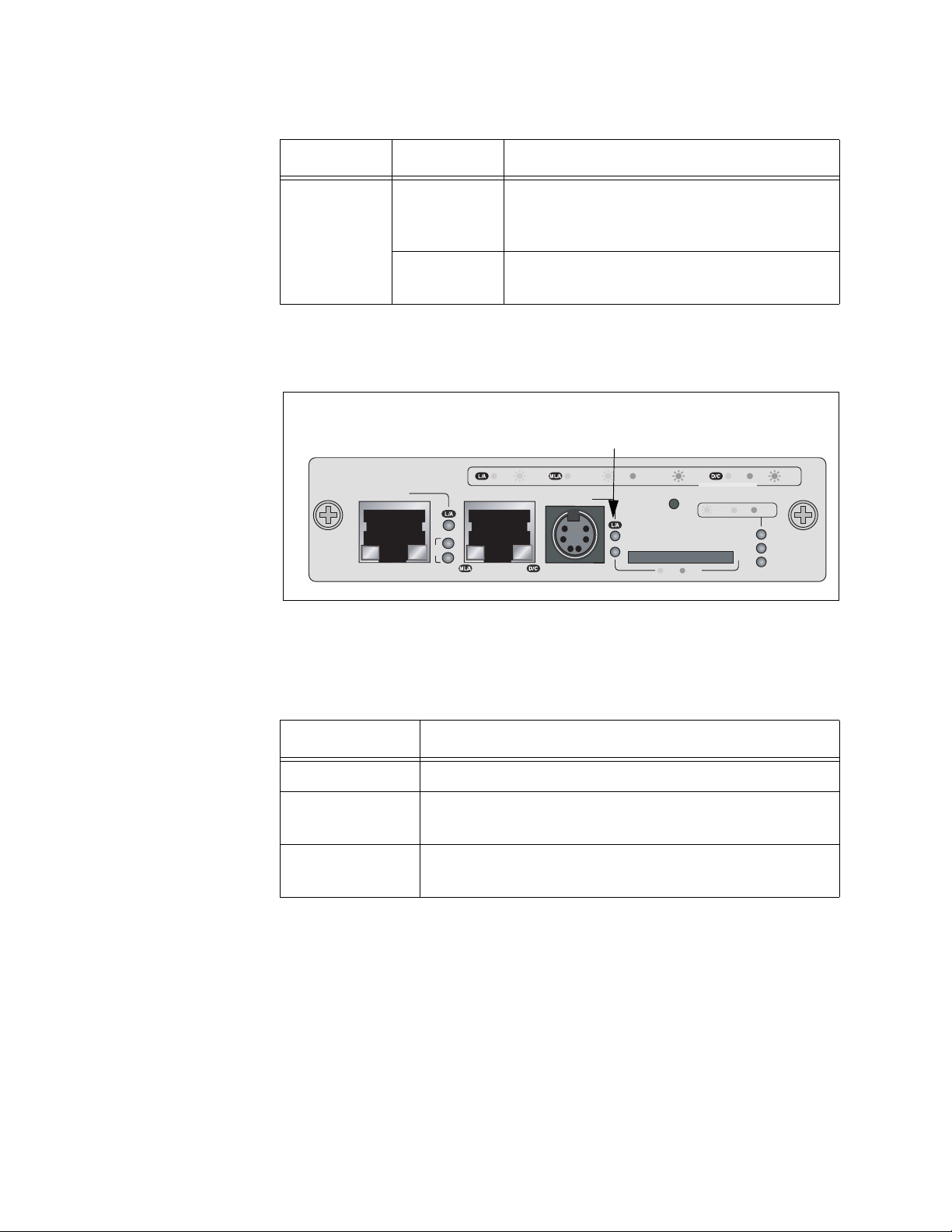

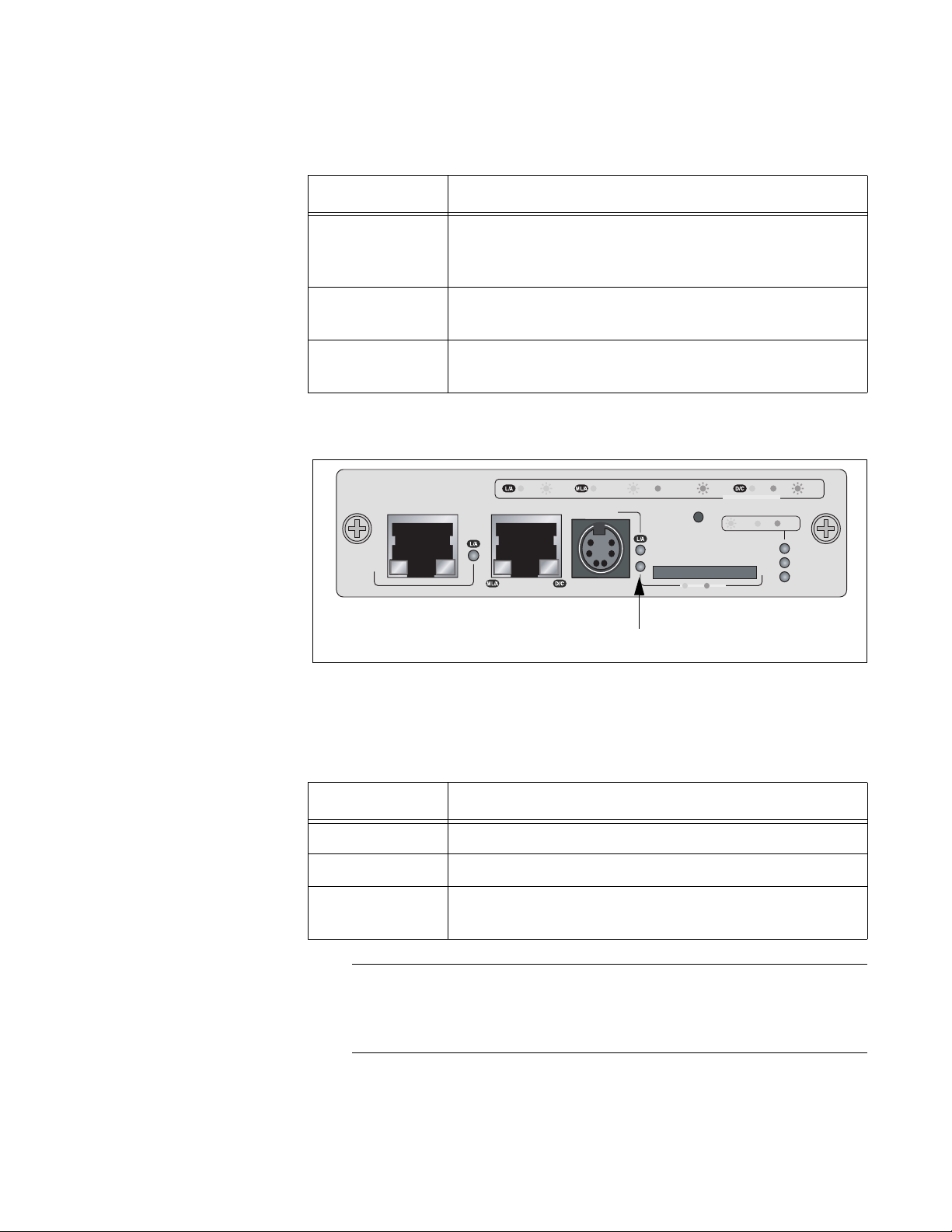

The AT-MCF2012LC, AT-MCF2012LC/1, and AT-MCF2032SP Modules

are high-density media converter modules that are used to connect Fast

Ethernet or Gigabit Ethernet networks over large geographical distances.

The modules have twelve channels. Each channel functions as an

independent media converter that transfers network traffic between a

twisted pair port and a fiber optic port or an SFP slot.

The modules feature low latency to minimize the impact on network

performance along with cyclic redundancy check (CRC) detection to

prevent the propagation of incomplete or fragmented packets on your

network.

1390

Figure 4. AT-MCF2000 Series Media Converter Module

The standards and features of the modules are listed here:

❒ IEEE 802.3 10Base-T

❒ IEEE 802.3u 100Base-TX

❒ IEEE 802.3u 100Base-TX

❒ IEEE 802.3u 100Base-FX compliant

❒ IEEE 802.3ab 1000Base-T (AT-MCF2032SP Module)

❒ IEEE 802.3u Auto-Negotiation on the twisted pair ports

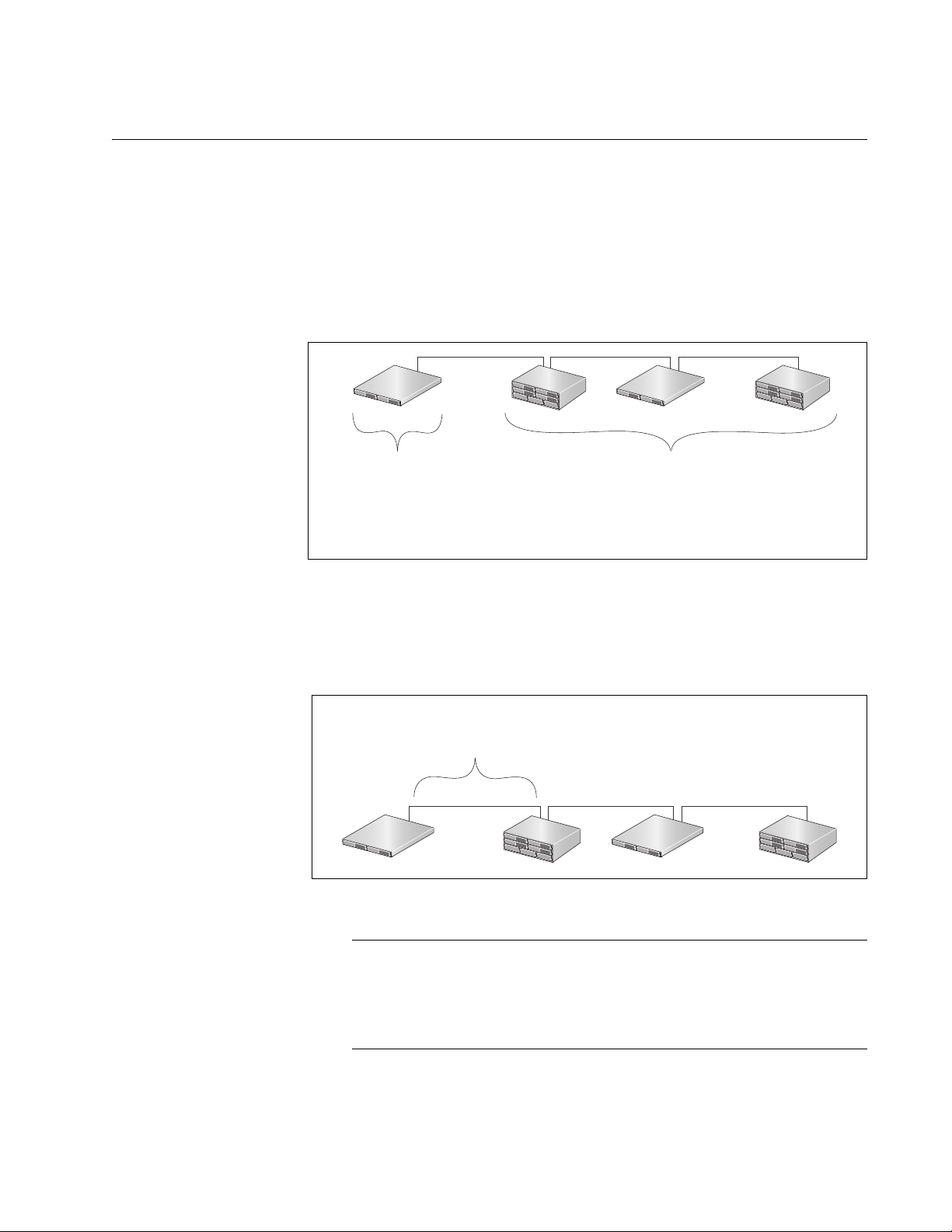

❒ Hot-swapping so the modules can be installed while a chassis is

powered on.

❒ AT-MCF2012LC Module — maximum operating distance of 2 km (1.24

mi.) using 50/125 µm or 62.5/125 µm (core/cladding) multimode cable

❒ AT-MCF2012LC/1 Module — maximum operating distance of 20 km

(12.4 mi.) using 9/125 µm single-mode cable

❒ Link Test, MissingLink™, and Smart MissingLink operating modes

❒ Store and forward packet processing with cyclic redundancy check

(CRC)

32 Section I: Features

Page 33

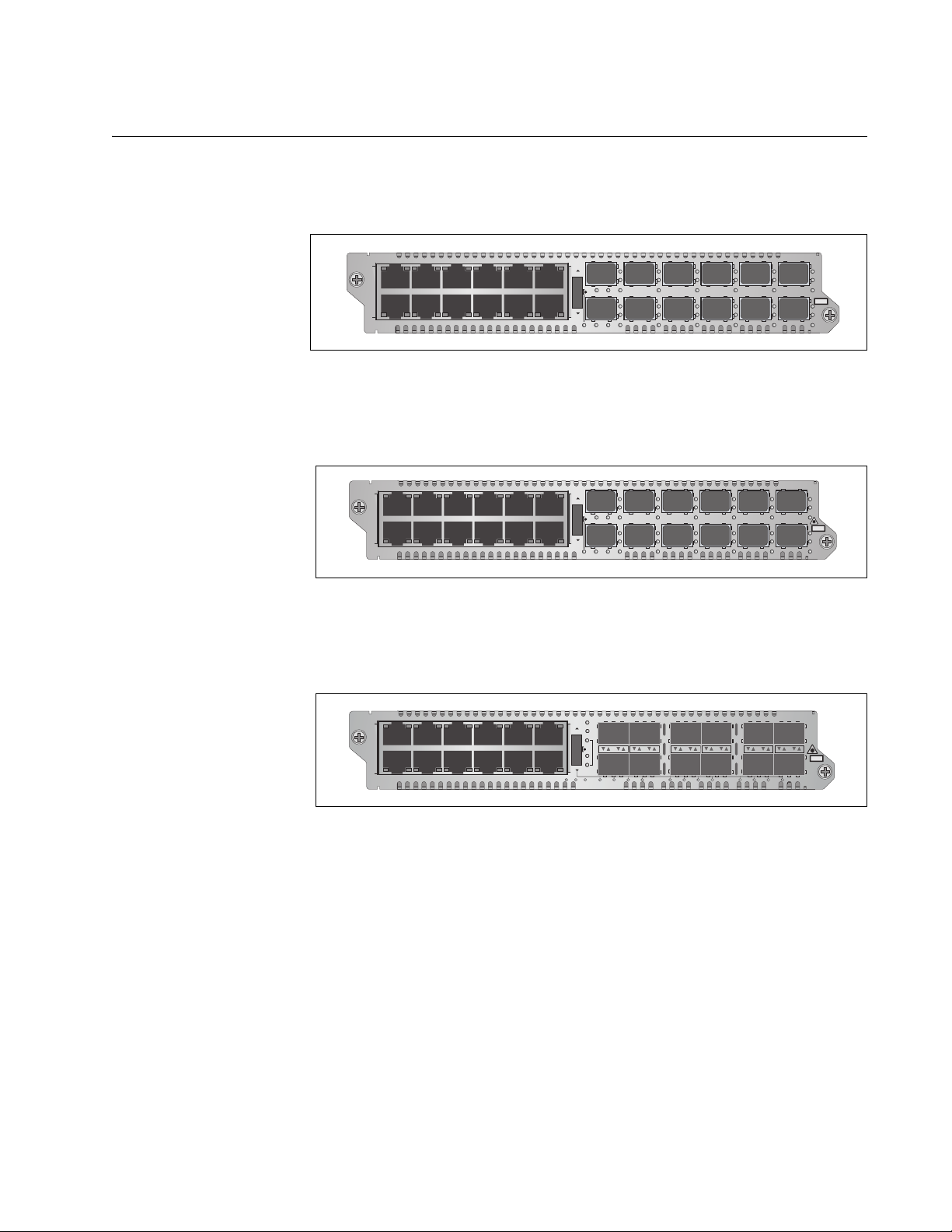

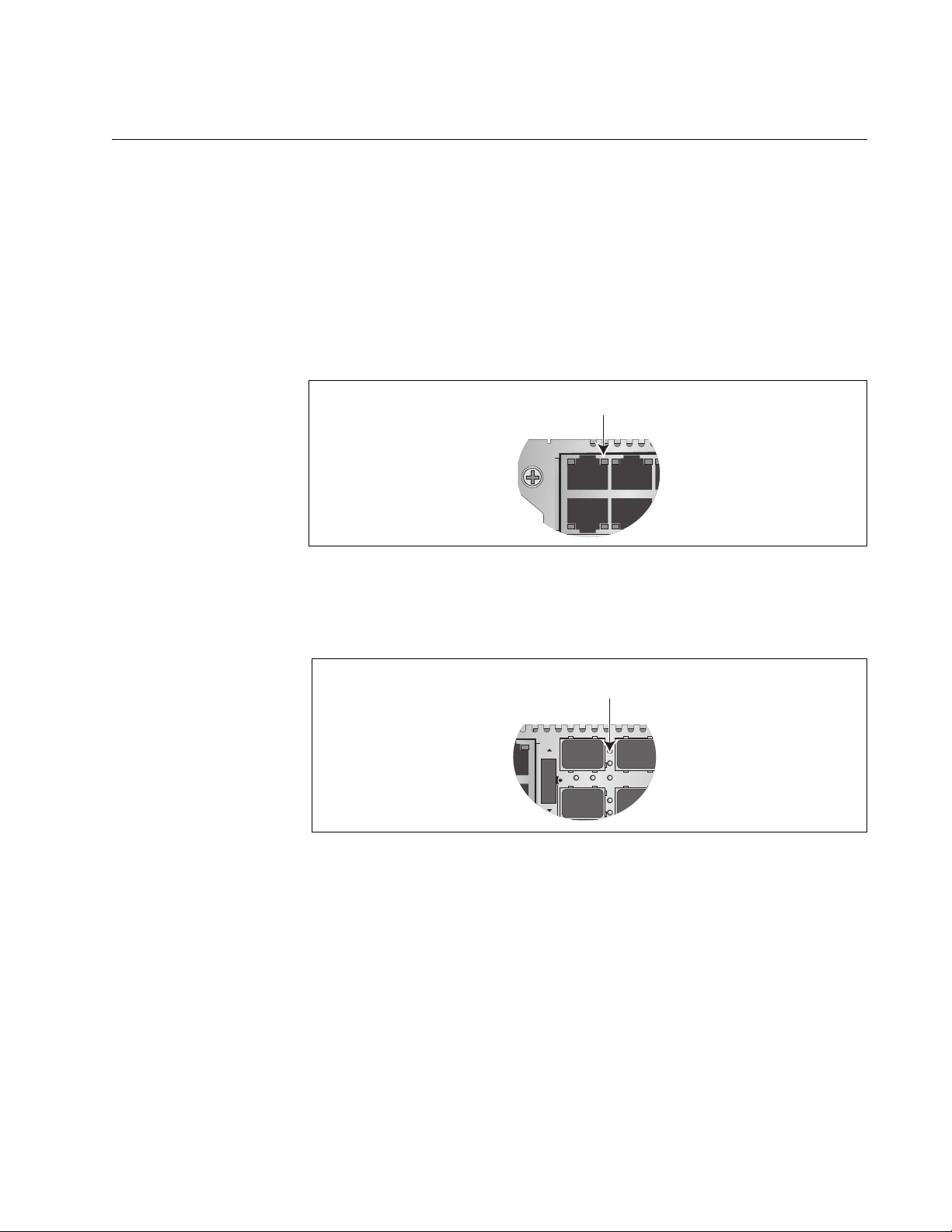

Front Panels

AT-MCF2000 Media Converter Series Installation Guide

The model names can be found on the left side of the faceplates. Figure 5

shows the front panel of the AT-MCF2012LC Media Converter Module.

1

3

5

7

9

LA1

AT-MCF2012LC

LA23456789101112

LA

CH

CH

LA

TX RX

CDC FDC

TX RX

LT ML SML

L

L

L

A

A

CH1

CH3

4

L

A

CH2

6

L

A

CH4

L

A

A

CH5

CH7

8

L

L

A

A

CH6

CH8

11

TX RX

L

L

A

A

CH9

CH11

TX RX2

10

12

CLASS 1

LED PRODUCT

L

L

A

A

CH10

CH12

1119

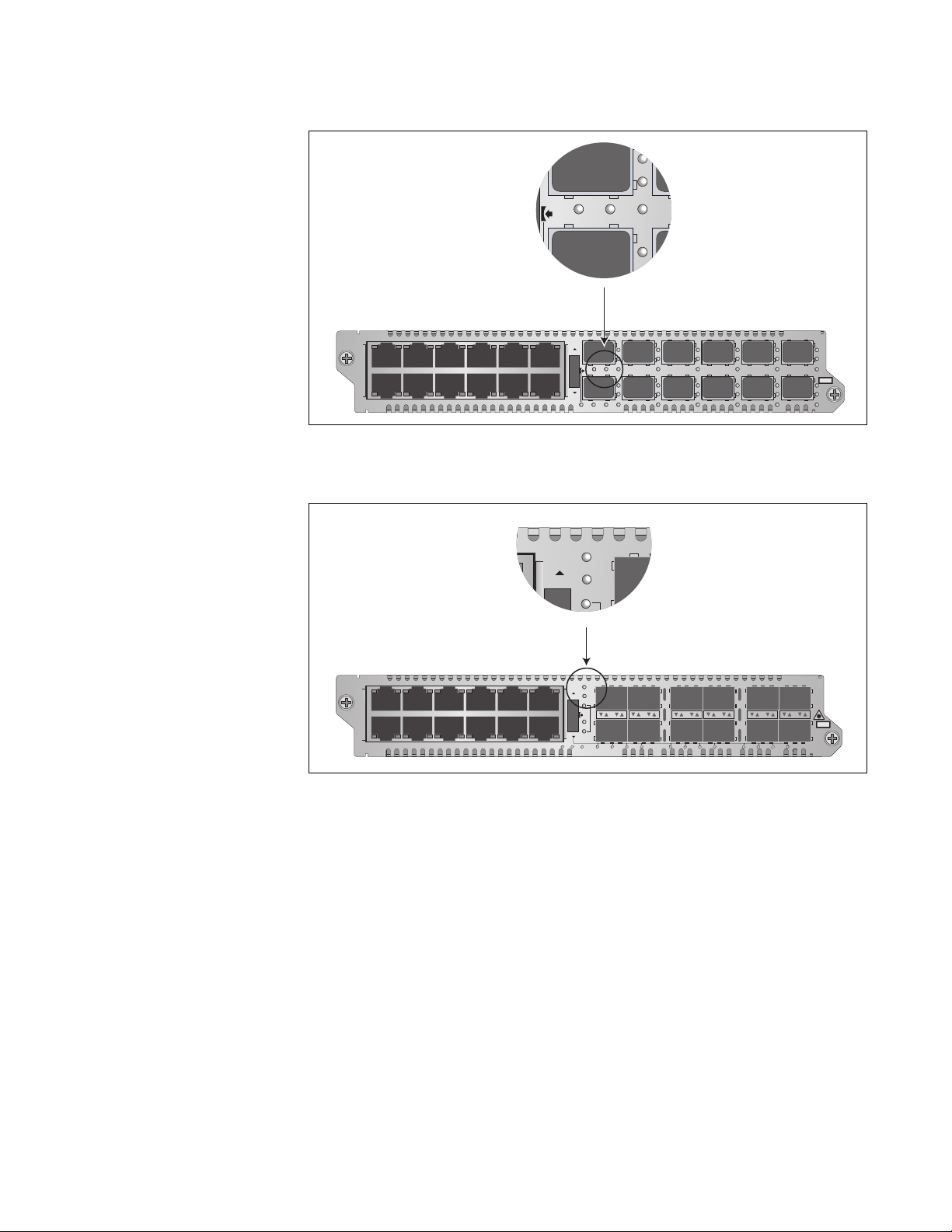

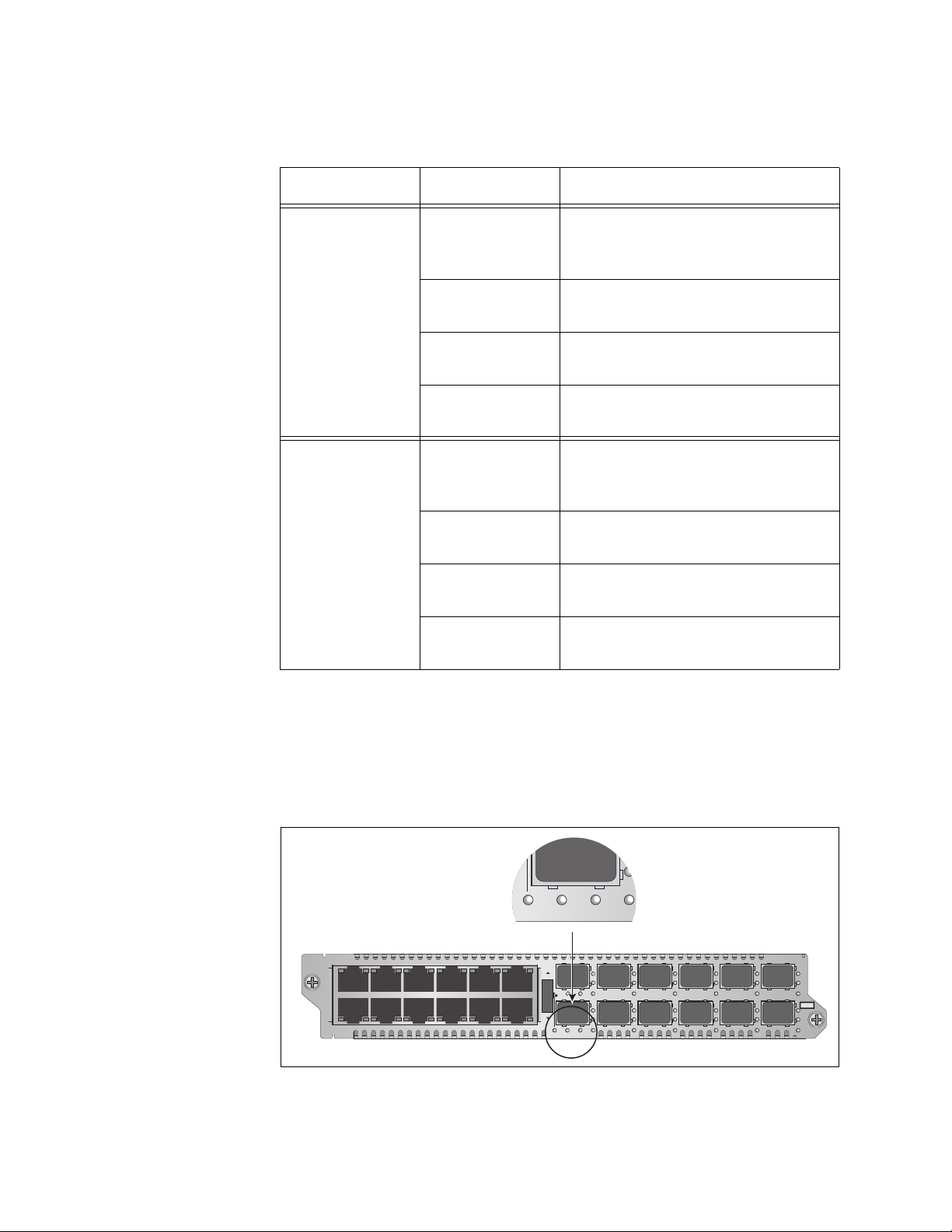

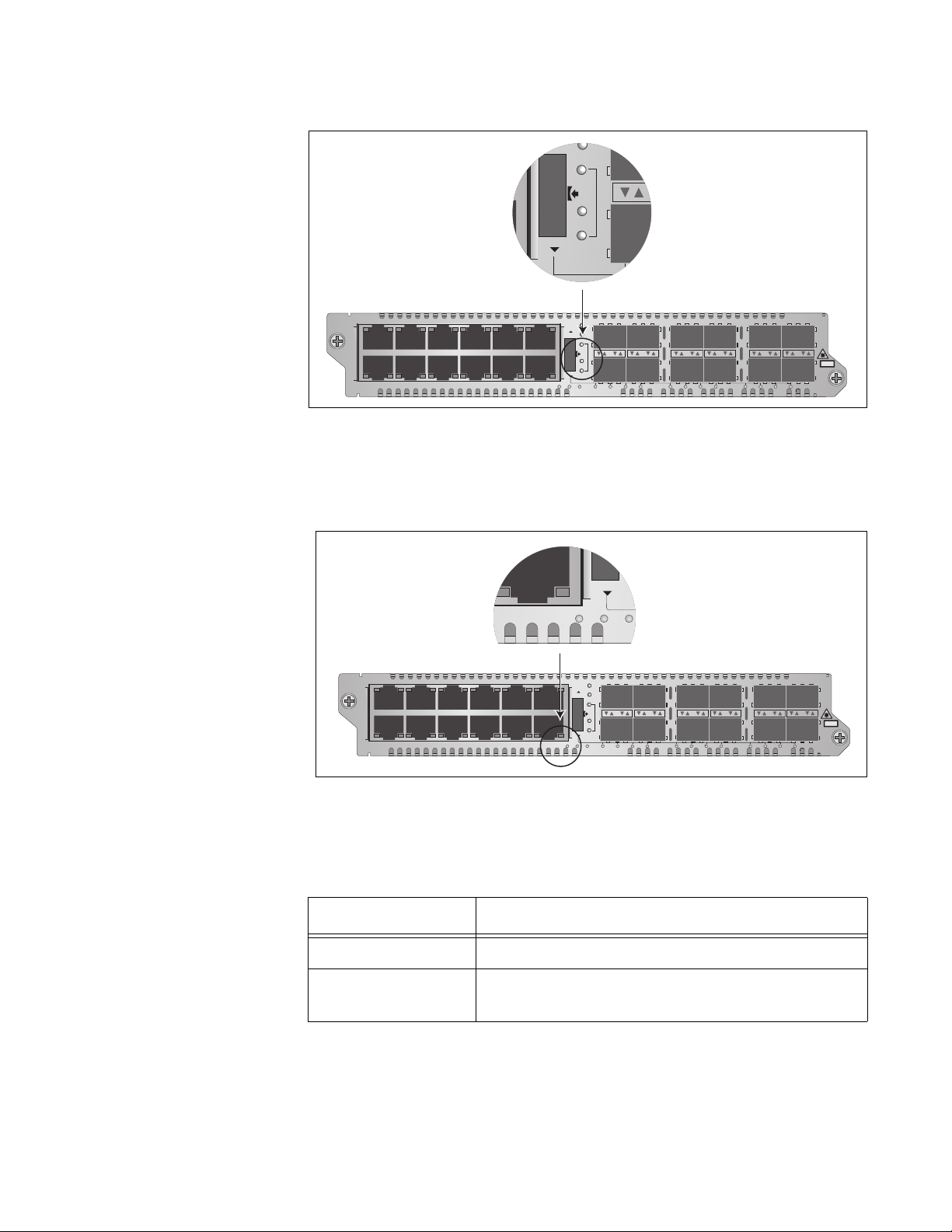

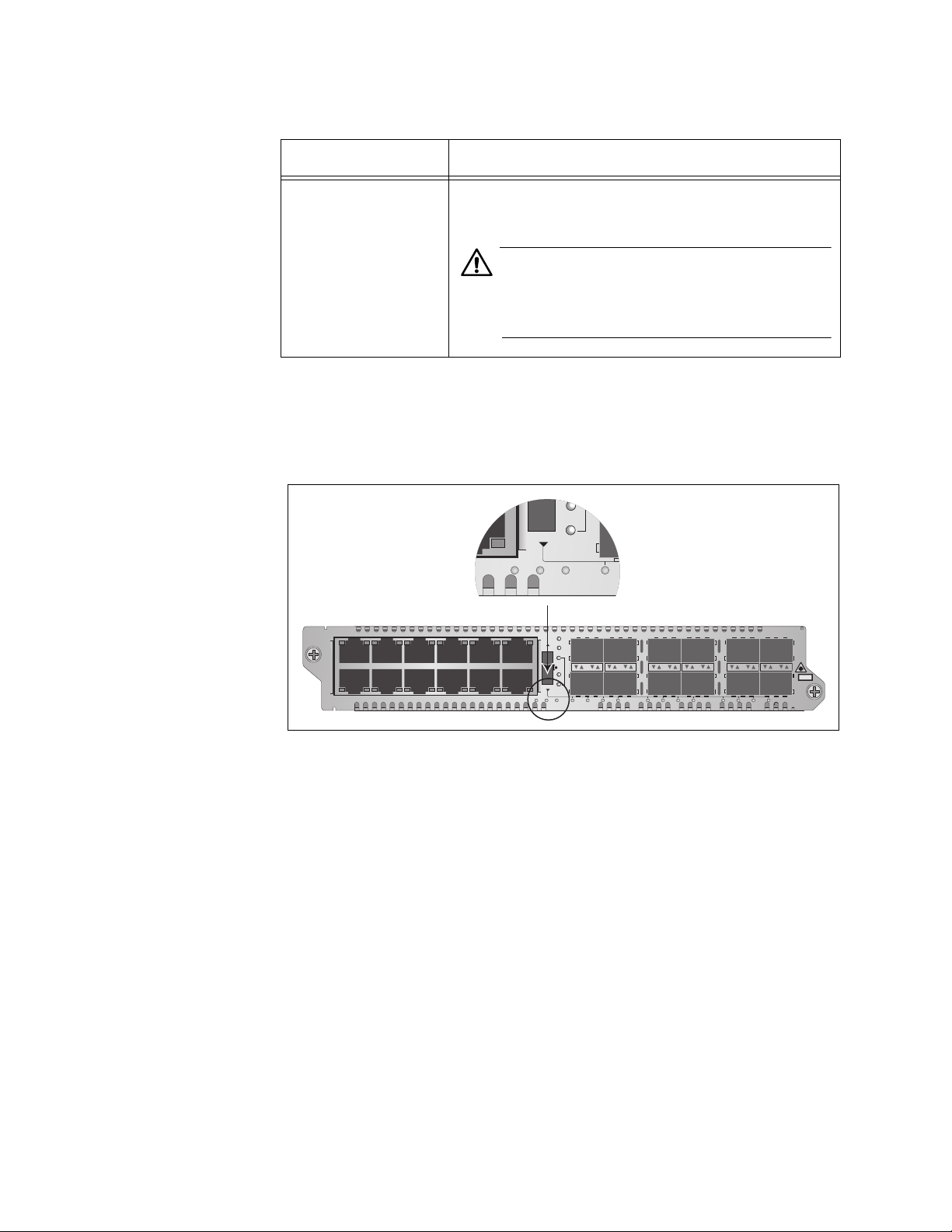

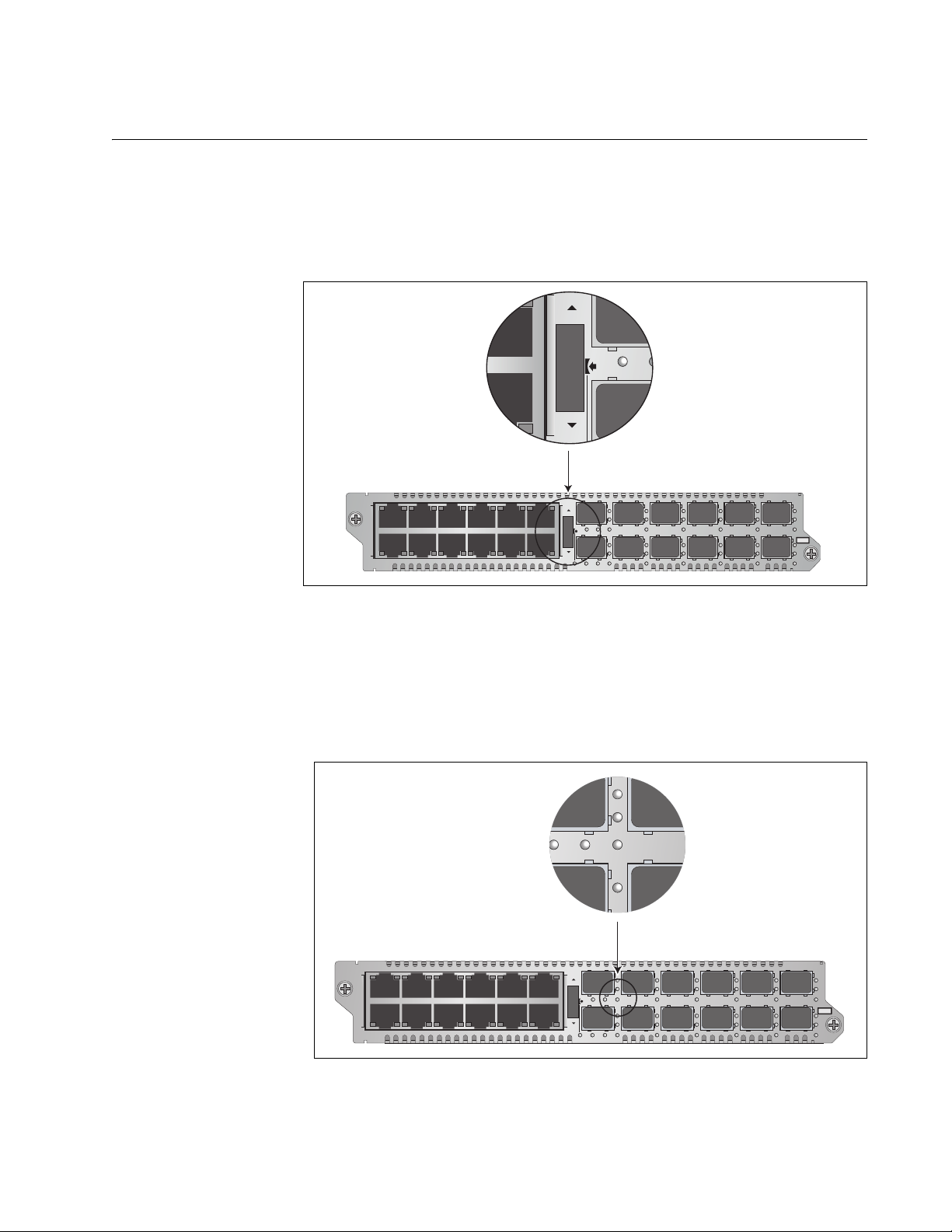

Figure 5. Front Panel of the AT-MCF2012LC Module

Figure 6 illustrates the front panel of the AT-MCF2012LC/1 Media

Converter Module.

1

3

5

7

9

LA1

AT-MCF2012LC/1

LA23456789101112

LA

CH

CH

LA

TX RX

CDC FDC

TX RX

LT ML SML

L

L

L

A

A

CH1

CH3

4

L

A

CH2

6

L

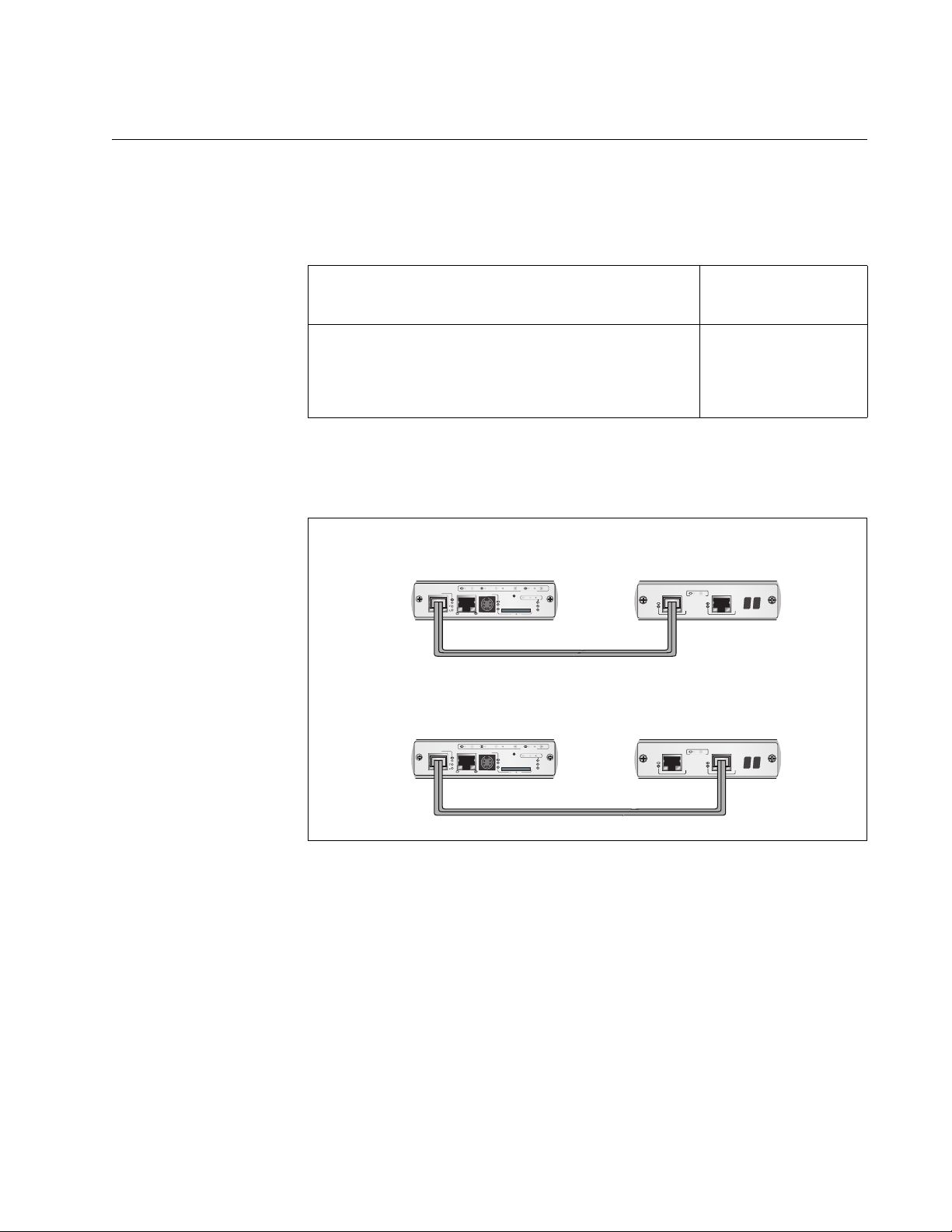

A

CH4

L

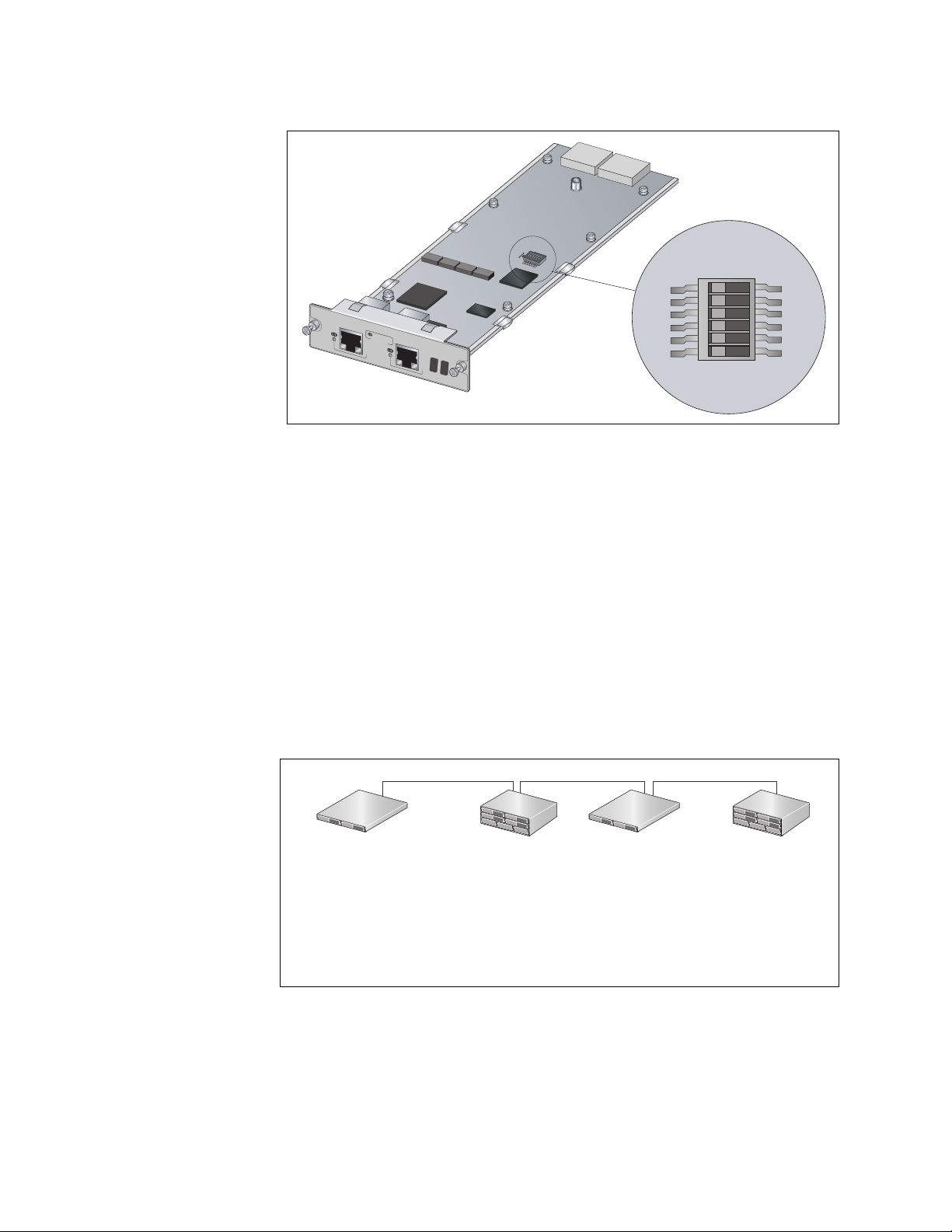

A

A

CH5

CH7

8

L

L

A

A

CH6

CH8

11

TX RX

L

L

A

A

CH9

CH11

TX RX2

10

12

CLASS 1

LASER PRODUCT

L

L

A

A

CH10

CH12

Figure 6. Front Panel of the AT-MCF2012LC/1 Module

Figure 7 illustrates the front panel of the AT-MCF2032SP Media Converter

Module.

LA1

AT-MCF2032SP

LA23456789101112

LA

CH

CH

LA

RDY/FLT HBI HBO

CDC

FDC

LT

ML

SML

123 45678 9101112

CLASS 1

LASER PRODUCT

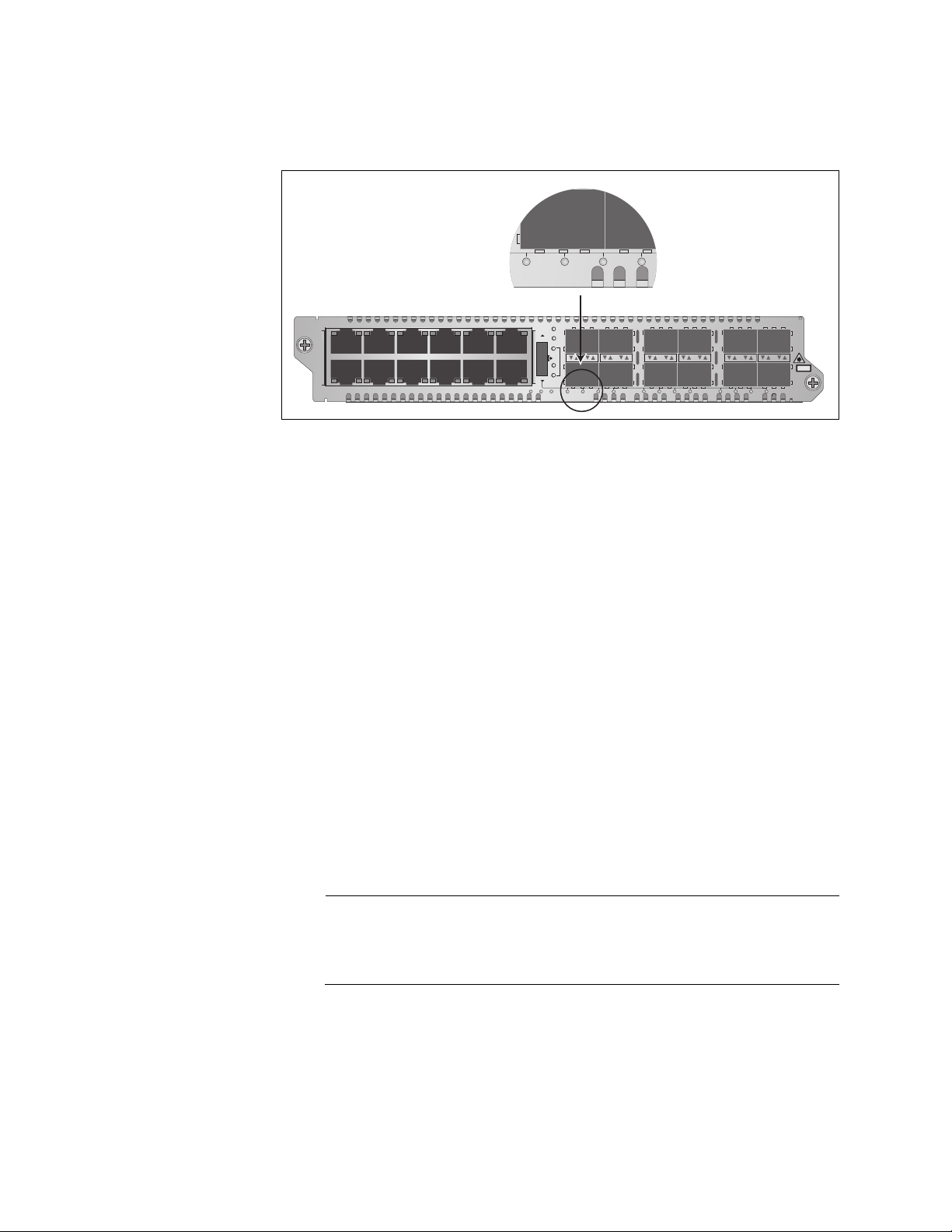

Figure 7. Front Panel of the AT-MCF2032SP Module

Section I: Features 33

Page 34

Chapter 3: AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules

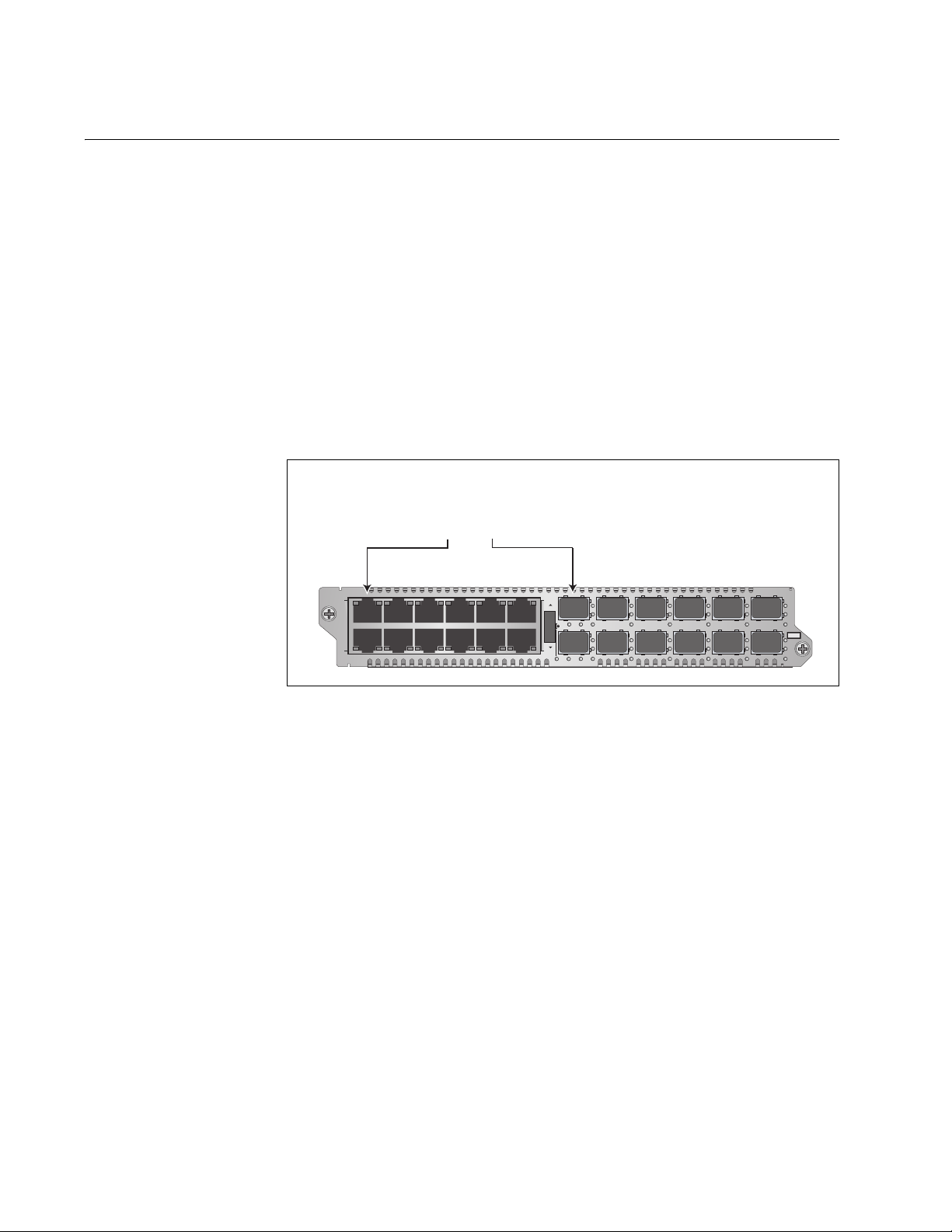

Media Converter Channels

The media converter modules have twelve independent media converter

channels that forward Fast or Gigabit Ethernet network traffic. Each

channel has one twisted pair port and one fiber optic port. The channels

on the AT-MCF2012LC and AT-MCF2012LC/1 Media Converter Modules

have 10/100Base-TX twisted pair ports and 100Base-FX fiber optic ports.

In contrast, the channels on the AT-MCF2032SP Media Converter Module

have 10/100/1000Base-T twisted pair ports and SFP slots for either 100

Mbps or 1000 Mbps fiber optic SFP modules.

The ports of the channels are predefined. Channel 1 consists of twisted

pair port 1 and fiber optic port 1 (as shown in Figure 8), channel 2 has

twisted pair port 2 and fiber optic port 2, and so forth. You are not allowed

to alter the port assignments of the channels.

Channel 1

Twisted Pair Port 1 and

Fiber Optic Port 1

1

3

5

7

9

LA1

AT-MCF2012LC

LA23456789101112

LA

CH

CH

LA

TX RX

CDC FDC

TX RX

LT ML SML

L

L

L

A

A

CH1

CH3

4

L

A

CH2

6

L

A

CH4

L

A

A

CH5

CH7

8

L

L

A

A

CH6

CH8

11

TX RX

L

L

A

A

CH9

CH11

TX RX2

10

12

CLASS 1

LED PRODUCT

L

L

A

A

CH10

CH12

1119

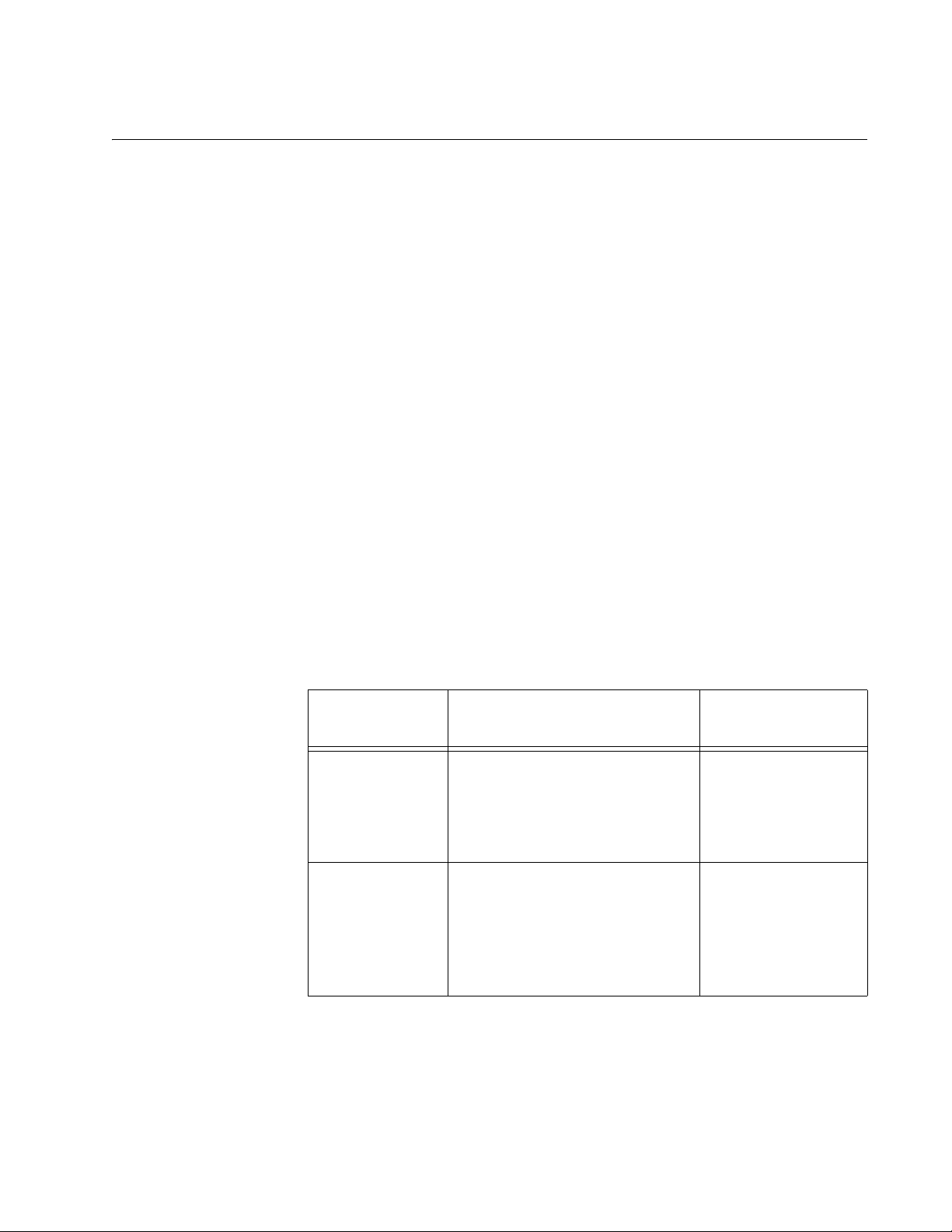

Figure 8. Channel 1 on the Media Converter Module

Each channel acts as an independent media converter. The traffic on one

channel cannot crossover to another channel. As such, local and remote

network devices that need to forward traffic to each other through the

media converter module have to be connected to ports in the same

channel. For example, for a local Fast Ethernet switch to communicate

with a remote switch, the twisted pair cable from the local switch and the

fiber optic cable from the remote switch have to be connected to ports in

the same channel, such as twisted pair port 4 and fiber optic port 4.

Devices that are connected to ports in different channels cannot

communicate with each other through the media converter module.

The ports of a channel use “store and forward” to forward traffic. A packet

is forwarded to the egress port of a channel after it has been fully received

and buffered on the ingress port and checked for CRC errors. Packets

without a CRC error are forwarded to the egress port where CRC is

regenerated prior to the transmission of the packet, while packets with

CRC errors are discarded to prevent their propagation on the network.

34 Section I: Features

Page 35

Twisted Pair Ports

AT-MCF2000 Media Converter Series Installation Guide

Table 5 lists the cable specifications for the twisted pair ports.

Table 5. Twisted Pair Cabling and Distances

Maximum

Speed Cable Type

Operating

Distance

10 Mbps Standard TIA/EIA 568-B-compliant

Category 3 or better shielded or

unshielded cabling with 100 ohm

impedance and a frequency of 16

MHz.

100 Mbps Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5 (Cat

5e) shielded or unshielded cabling

with 100 ohm impedance and a

frequency of 100 MHz.

1000 Mbps

(AT-MCF2032SP

only)

The twisted pair ports feature standard RJ-45 8-pin connectors. For the

port pinouts, refer to “Twisted Pair Port Pinouts” on page 174.

The ports are IEEE 802.3u. compliant and use Auto-Negotiation to

automatically set their speeds and duplex modes. To adjust the ports

manually, you have to use the optional management module.

Standard TIA/EIA 568-A-compliant

Category 5 or TIA/EIA 568-Bcompliant Enhanced Category 5 (Cat

5e) shielded or unshielded cabling

with 100 ohm impedance and a

frequency of 100 MHz.

100 m (328 ft)

100 m (328 ft)

100 m (328 ft)

The twisted pair ports also have auto-MDI/MDI-X, which enables them to

automatically adjust their wiring configuration to MDI or MDI-X, depending

on the wiring configuration of the end nodes. This allows you to use a

straight-through twisted pair cable regardless of the wiring configuration of

the ports on the network devices.

The auto-MDI/MDI-X feature is only available when the twisted pair ports

are using Auto-Negotiation, the default setting. If you disable AutoNegotiation on a port and set the speed and duplex mode manually, this

feature is also disabled and the port defaults to the MDI-X setting.

Section I: Features 35

Page 36

Chapter 3: AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules

Fiber Optic Ports

Table 6 lists the specifications for the fiber optic cabling for the

AT-MCF2012LC and AT-MCF2012LC/1 Media Converter Modules.

Table 6. Fiber Optic Ports

Media Converter

Module

AT-MCF2012LC Duplex LC 2 km (1.24 mi.) 50/125 µm or 62.5/125 µm

AT-MCF2012LC/1 Duplex LC 20 km (12.4 mi.) 9/125 µm single-mode fiber

Connector

Note

The maximum operating distances in the table assume full-duplex

operation. The maximum operating distance of a fiber optic port

operating in half-duplex mode will be significantly less.

For the operating specifications of the fiber optic ports on the

AT-MCF2012LC and AT-MCF2012LC/1 Modules, refer to “100Base-FX

Fiber Optic Ports” on page 175.

For the fiber optic cabling specifications for the AT-MCF2032SP Module,

refer to the instructions that come with the SFP modules.

Maximum

Operating

Distance

Fiber Optic Cable

(core/cladding) multimode

fiber optic cable

optic cable

36 Section I: Features

Page 37

AT-MCF2000 Media Converter Series Installation Guide

Channel Operating Modes

The media converter channels support these operating modes:

❒ Link Test mode

❒ MissingLink mode

❒ Smart MissingLink mode

The operating modes of the channels are set with the Mode button on the

front panel of the module explained in “Mode Button” on page 51, or with

the optional management module. These operating modes, which, during

normal network operations, do not interfere with the flow of traffic through

the ports of the channels, can be used to alert you when a port loses its

link to a network device or to troubleshoot a network problem.

Link Test Mode Contrary to its name, the Link Test operating mode is not a diagnostic

utility. Rather, it simply displays on the Link LEDs the states of the links of

the two ports in a channel. When a channel is operating in this mode, a

Link LED will be on when a port has established a link to its network

device, and it will be off when a port does not have a link. (Refer to Table 8

on page 44.)

MissingLink

Mode

This mode, as with all of the operating modes, does not interfere with the

flow of traffic between the two ports of a channel during normal network

operations. It is typically used when the network devices connected to a

channel cannot take advantage of the features of the MissingLink mode,

or when you want to use the Link LEDs to troubleshoot a link problem.

This operating mode is also useful after you have installed a media

converter module and want to verify whether the ports of the channels

have successfully established links with the local and remote network

devices. This is explained in “AT-MCF2012LC, AT-MCF2012LC/1 and

AT-MCF2032SP Media Converter Modules” on page 141 in Chapter 21,

“Verifying the Installation”.

The MissingLink mode enables the twisted pair port and the fiber optic port

of a channel to pass the “Link” status of their connections to each other.

This ensures that both ports of a channel and, consequently, the network

devices connected to the ports, are aware of any changes to the state of

the link on the companion port.

When a channel in the MissingLink mode detects the loss of a link on one

of the ports, it disables the transmitter on the companion port to notify the

network device connected to it of the loss of the link on the other channel

port. Without the MissingLink mode, a network device connected to a port

on the media converter would not be aware of a loss of a link on a

companion port in the channel, because its link to the media converter

would be unaffected.

Section I: Features 37

Page 38

Chapter 3: AT-MCF2012LC, AT-MCF2012LC/1 and AT-MCF2032SP Modules

When the link is reestablished on a port of a channel, the MissingLink

mode automatically reactivates the transmitter on the companion port so

that the two network devices can again forward traffic to each other

through the two ports of the media converter channel.

The value to this type of fault notification is that some network devices,

such as managed Fast Ethernet switches, can respond to the loss of a link

on a port by performing a specific action. For example, the network device

might send a trap to a network management station, and so alert the

network administrator of the problem. Or, if the device is running a

spanning tree protocol, it might seek a redundant path to a disconnected

node.

Here is an example of how the MissingLink mode works. Assume that the

two ports of a channel are connected to two Fast Ethernet switches, one

local and the other remote. Switch A, the local switch, is connected to the

twisted pair port of the channel, while Switch B, the remote device, is

connected to the fiber optic port. If the link to Switch A is lost on the twisted

pair cable, the media converter disables the transmitter on the fiber optic

port in the same channel to signal Switch B of the loss of the link to Switch

A. This notifies Switch B of the problem so that it too, along with Switch A,

can take remedial action, such as activating a redundant path if it is

running a spanning tree protocol or sending an SNMP trap to a

management workstation if it is using SNMP. Without the MissingLink

mode, Switch B would assume that it still had a valid link to the remote

device on the other side of the media converter channel since its link to the

port on the channel is still valid, even though no remote traffic is received.

In the example, the initial loss of a link in a channel occurred on the

twisted pair port. But the mode operates in the same fashion when the

initial loss of a link is on the fiber optic port. Here, the mode disables the

transmitter on the twisted pair port to notify the node connected to that port

of the loss of the link on the fiber optic port.

The Link LEDs of the ports in a channel that are running in this mode

always operate in tandem, as shown in Table 9 on page 45. They are both

on or off. Both Link LEDs of the ports of a channel remain off until both

ports can establish links with their network devices.

This operating mode is primarily used on a channel when the network