Page 1

OmniSwitch

Getting Started Guide

®

6600 Family

060178-10, Rev. E

March 2005

Page 2

Warning. Only personnel knowledgeable in basic electrical and mechanical procedures should install or maintain this

equipment.

Lithium Batteries Caution. There is a danger of explosion if the Lithium battery in your chassis is incorrectly replaced.

Replace the battery only with the same or equivalent type of battery recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions. The manufacturer’s instructions are as follows:

Return the module with the Lithium battery to Alcatel. The Lithium battery will

be replaced at Alcatel’s factory.

The features and specifications described in this guide are subject to change without notice.

Copyright © 2005 by Alcatel Internetworking, Inc. All rights reserved. This document may not be reproduced in whole or in

part without the express written permission of Alcatel Internetworking, Inc.

®

Alcatel

Alcatel OmniVista

OmniAccess™, Omni Switch/Router™, PolicyView™, RouterView™, SwitchManager™, VoiceView™, WebView™,

X-Cell™, X-Vision™, and the Xylan logo are trademarks of Alcatel Internetworking, Inc.

This OmniSwitch product contains components which may be covered by one or more of the following U.S. Patents:

and the Alcatel logo are registered trademarks of Alcatel. Xylan®, OmniSwitch®, OmniStack®, and

®

are registered trademarks of Alcatel Internetworking, Inc.

• U.S. Patent No. 6,339,830

• U.S. Patent No. 6,070,243

• U.S. Patent No. 6,061,368

• U.S. Patent No. 5,394,402

• U.S. Patent No. 6,047,024

• U.S. Patent No. 6,314,106

• U.S. Patent No. 6,542,507

(818) 880-3500 FAX (818) 880-3505

Alcatel Internetworking

26801 West Agoura Road

Calabasas, CA 91301

US Customer Support: (800) 995-2696

International Customer Support: (818) 878-4507

Internet: http://eservice.ind.alcatel.com

Page 3

Table of Contents

OmniSwitch 6600 Family. . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Stand-Alone and Stacked

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Stand-Alone . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Stacked Configurations . . . . . . . . . . . . . . . . . . . . 2

Availability Features . . . . . . . . . . . . . . . . . . . . . . . . 2

Chassis Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OmniSwitch 6624 (OS6624) . . . . . . . . . . . . . . . 3

OmniSwitch 6648 (OS6648) . . . . . . . . . . . . . . . 3

OmniSwitch 6600-U24 (OS6600-U24) . . . . . . . 4

OmniSwitch 6600-P24 (OS6600-P24) . . . . . . . . 4

OmniSwitch 6602-24 (OS6602-24) . . . . . . . . . . 5

OmniSwitch 6602-48 (OS6602-48) . . . . . . . . . . 5

Setting Up the Hardware. . . . . . . . . . . . . . 6

Items Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Environmental Requirements . . . . . . . . . . . . . . . 6

Electrical Requirements . . . . . . . . . . . . . . . . . . . 6

Weight Considerations . . . . . . . . . . . . . . . . . . . . 7

OS6624 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OS6648 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OS6600-U24 . . . . . . . . . . . . . . . . . . . . . . . . 7

OS6600-P24 . . . . . . . . . . . . . . . . . . . . . . . . . 7

OS6602-24 . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OS6602-48 . . . . . . . . . . . . . . . . . . . . . . . . . .7

Items Included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unpacking and Initial Setup . . . . . . . . . . . . . . . . . . . 8

Unpacking the Chassis . . . . . . . . . . . . . . . . . . . .8

Recommendations . . . . . . . . . . . . . . . . . . . .8

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . .9

Setting Up the Switch . . . . . . . . . . . . . . . . . . . . . . . . 9

Airflow Considerations . . . . . . . . . . . . . . . . . . . .9

Installing the Switch on a Tabletop or Bench . . 10

Rack-Mounting the Switch . . . . . . . . . . . . . . . .11

Rack Mounting Stacked Configurations . . . . . .13

Installing a Back Up Power Supply

(OS6624, OS6648, OS6600-U24) . . . . . . . . . . . . . 14

Installing Uplink and Stacking Modules . . . . . . . . . 16

Installing MiniGBIC Connectors . . . . . . . . . . . . . . 18

Installing SFP Connectors

(OS6600-U24 Only) . . . . . . . . . . . . . . . . . . . . . . . . 20

Blank Cover Plates . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connections and Cabling . . . . . . . . . . . . . 22

Connecting the Serial Cable to the Console Port . . 22

Serial Connection Default Settings . . . . . . . . . .22

The Next Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

March 2005 iii

Page 4

Completing a Stacked

Configuration

Slot Assignment Guidelines . . . . . . . . . . . . . . . 24

Assigning Slot Numbers . . . . . . . . . . . . . . . . . . . . . . . . 25

Slot Numbering Example . . . . . . . . . . . . . . . . . . . . 26

Connecting Cables

to Stacking Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Booting the Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Booting Stand-Alone Switches . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Verifying LED Status. . . . . . . . . . . . . . . . . . . . 30

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Verifying Primary and Secondary Status . . . . . 30

PRI LED . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SEC LED . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Idle Status . . . . . . . . . . . . . . . . . . . . . . . . . 31

Your First Login Session. . . . . . . . . . . . . . . 32

Logging In to the Switch . . . . . . . . . . . . . . . . . . . . 32

Assigning an IP Address to the Switch or Stack . . 33

Assigning IP Addresses to Switches in a

Stacked Configuration . . . . . . . . . . . . . . . . . . . 34

Unlocking Session Types . . . . . . . . . . . . . . . . . . . . 34

Unlocking All Session Types . . . . . . . . . . . . . . 34

Unlocking Specified Session Types . . . . . . . . . 35

How many sessions are allowed? . . . . . . . . . . . 35

Changing the Login Password . . . . . . . . . . . . . . . . 35

Setting the System Time Zone . . . . . . . . . . . . . . . . 36

Setting the Date and Time . . . . . . . . . . . . . . . . . . . 36

Setting Optional System Information . . . . . . . . . . . 37

Specifying an Administrative Contact . . . . . . .37

Specifying a System Name . . . . . . . . . . . . . . . .37

Specifying the Switch’s Location . . . . . . . . . . .37

Viewing Your Changes . . . . . . . . . . . . . . . . . . . . . . 38

Saving Your Changes . . . . . . . . . . . . . . . . . . . . . . . 38

Modifying the Serial Connection Settings . . . . . . . 38

CLI Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CLI Assistance Features . . . . . . . . . . . . . . . . . . . . . 41

Syntax Checking . . . . . . . . . . . . . . . . . . . . . . . .41

Command Line (?) Help . . . . . . . . . . . . . . . . . .42

Partial Keyword Completion . . . . . . . . . . . . . . .42

Deleting Characters . . . . . . . . . . . . . . . . . . . . . .42

Inserting Characters . . . . . . . . . . . . . . . . . . . . .43

Previous Command Recall . . . . . . . . . . . . . . . .43

Prefix Recognition . . . . . . . . . . . . . . . . . . . . . .43

Prefix Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Command History . . . . . . . . . . . . . . . . . . . . . . .44

Command Logging . . . . . . . . . . . . . . . . . . . . . .45

Enabling Command Logging . . . . . . . . . . .45

Common CLI Commands . . . . . . . . . . . . . . . . . . . . 46

Offline Configuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Syntax Checking . . . . . . . . . . . . . . . . . . . . . . . .47

Scheduling a Configuration File to be Applied

at a Later Time . . . . . . . . . . . . . . . . . . . . . . . . .47

Generating Snapshots of the

Current Configuration . . . . . . . . . . . . . . . . . . . . . . . 47

iv March 2005

Page 5

Files and Directories. . . . . . . . . . . . . . . . . . . . 48

Boot and Image Files . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

boot.params File . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

boot.cfg File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

boot.slot.cfg File . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Image Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Working and Certified Directories . . . . . . . . . . . . . . . . 51

Working Directory . . . . . . . . . . . . . . . . . . . . . . 51

Certified Directory . . . . . . . . . . . . . . . . . . . . . . 51

How can I tell which directory the switch

is currently using? . . . . . . . . . . . . . . . . . . . 52

Can I save changes to the Certified

directory? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

What happens when the switch boots? . . . . . . . 52

Working and Certified Are Identical . . . . . . . . 52

Working and Certified Are Different . . . . . . . . 53

My Working and Certified directories are

different. Can I force a reboot from the

Working directory? . . . . . . . . . . . . . . . . . . 53

Loading Software . . . . . . . . . . . . . . . . . . . . . . . 54

Stand-Alone Configurations . . . . . . . . . . . . . . . . . . 54

Stacked Configurations . . . . . . . . . . . . . . . . . . . . . 55

Certifying Your New Software . . . . . . . . . . . . . 56

Online Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Additional Information . . . . . . . . . . . . . . . . . . . . . . 60

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

The WebView login screen does not

display. . . . . . . . . . . . . . . . . . . . . . . . . . . .60

The login screen displays, but my login

attempt fails. . . . . . . . . . . . . . . . . . . . . . . .60

Hardware Basics . . . . . . . . . . . . . . . . . . . . . . . . 61

OmniSwitch 6624 Front Panel . . . . . . . . . . . . . . . . 61

OmniSwitch 6600-U24 Front Panel . . . . . . . . . . . . 62

OmniSwitch 6648 Front Panel . . . . . . . . . . . . . . . . 63

OmniSwitch 6600-P24 Front Panel . . . . . . . . . . . . 64

OmniSwitch 6602-24 Front Panel . . . . . . . . . . . . . . 65

OmniSwitch 6602-48 Front Panel . . . . . . . . . . . . . . 66

OmniSwitch 6600 Status LEDs . . . . . . . . . . . . . . . 67

Using WebView . . . . . . . . . . . . . . . . . . . . . . . . . 57

Browser Compatibility . . . . . . . . . . . . . . . . . . . . . . 57

Required Image Files . . . . . . . . . . . . . . . . . . . . . . . 57

Logging In to WebView . . . . . . . . . . . . . . . . . . . . . 58

Navigating WebView . . . . . . . . . . . . . . . . . . . . . . . 58

March 2005 v

Page 6

vi March 2005

Page 7

OmniSwitch 6600 Family

Features

The OmniSwitch 6600 Family (OS6624, OS6600-U24,

OS6648, OS6600-P24, OS6602-24, and OS6602-48) are next

generation enterprise edge/workgroup switches. These

switches are based on the same software architecture as

OmniSwitch 7000 and 8000 series switches (i.e., OS7700,

OS7800, and OS8800). These switches are designed to meet

the most stringent network requirements for mission-critical

networks.

OmniSwitch 6600 Family switches are optimized for voice

and data integration and provide non-blocking multi-Gigabit

Ethernet capacity. Additional features include Carrier-class

intelligence, best of breed QoS, Carrier-class resiliency,

network management, and advanced policy-based VLANs and

security. OmniSwitch 6600 Family switches also support wirespeed Layer 2 and Layer 3 switching, industry-based standards, and a full array of reliability, redundancy and resiliency

capabilities.

Stand-Alone and Stacked Configurations

Stand-Alone

A stand-alone OmniSwitch 6600 Family switch is ideal for

small and medium-sized network edge applications, offering

24 10/100 ports (OS6624 and OS6602-24), 24 Power over

Ethernet (PoE) ports (OS6600-P24), 48 10/100 (OS6648 and

OS6602-48) ports, and 24 100 SFP ports (OS6600-U24).

These switches provide support for enterprise-based devices,

such as computer workstations or IP telephones.

A single OmniSwitch 6600 Family also supports two Gigabit

Ethernet uplinks for high-bandwidth connections to a backbone or server.

March 2005 OmniSwitch 6600 Family 1

Page 8

Stacked Configurations

Availability Features

In addition to working as individual, stand-alone switches,

OmniSwitch 6600 Family switches can also be linked together

to form a single, high-density virtual chassis known as a stack.

Stacking switches provides scalability by allowing users to

quickly and easily expand 10/100 port density. Twenty-four

10/100 ports are added for each OS6624 brought into the

stack; twenty-four 100 SFP ports are added for each OS6600U24; forty-eight 10/100 ports are added for each OS6648.

Up to eight switches can be stacked. OmniSwitch 6600 Family

switches can be mixed and matched in any combination within

the stack. This provides a virtual chassis with a 10/100 or 100

capacity of up to 384 ports.

As with the stand-alone configuration, a stacked virtual chassis configuration provides Gigabit Ethernet uplinks to a backbone or server.

Note. For basic information on stacking OmniSwitch 6600

Family switches into a virtual chassis, refer to

“Completing a Stacked Configuration” on page 24.

For additional information, refer to the OmniSwitch

6600 Family Hardware Users Guide.

The OmniSwitch 6600 Family provides a broad variety of

Availability features. Availability features are hardware- and

software-based safeguards that help prevent the loss of data

flow in the event of a subsystem failure.

In addition, some Availability features allow you to maintain

or replace hardware components without powering off your

switch or interrupting switch operations.

Combined, these features provide added resiliency and help

ensure that your switch is consistently available for your dayto-day network operations.

Hardware-related Availability features include:

• Smart Continuous Switching

• Software Rollback

• Hot Swapping

• Hardware Monitoring

For information on these Availability features, refer to the

OmniSwitch 6600 Family Hardware Users Guide.

2 OmniSwitch 6600 Family March 2005

Page 9

Chassis Types

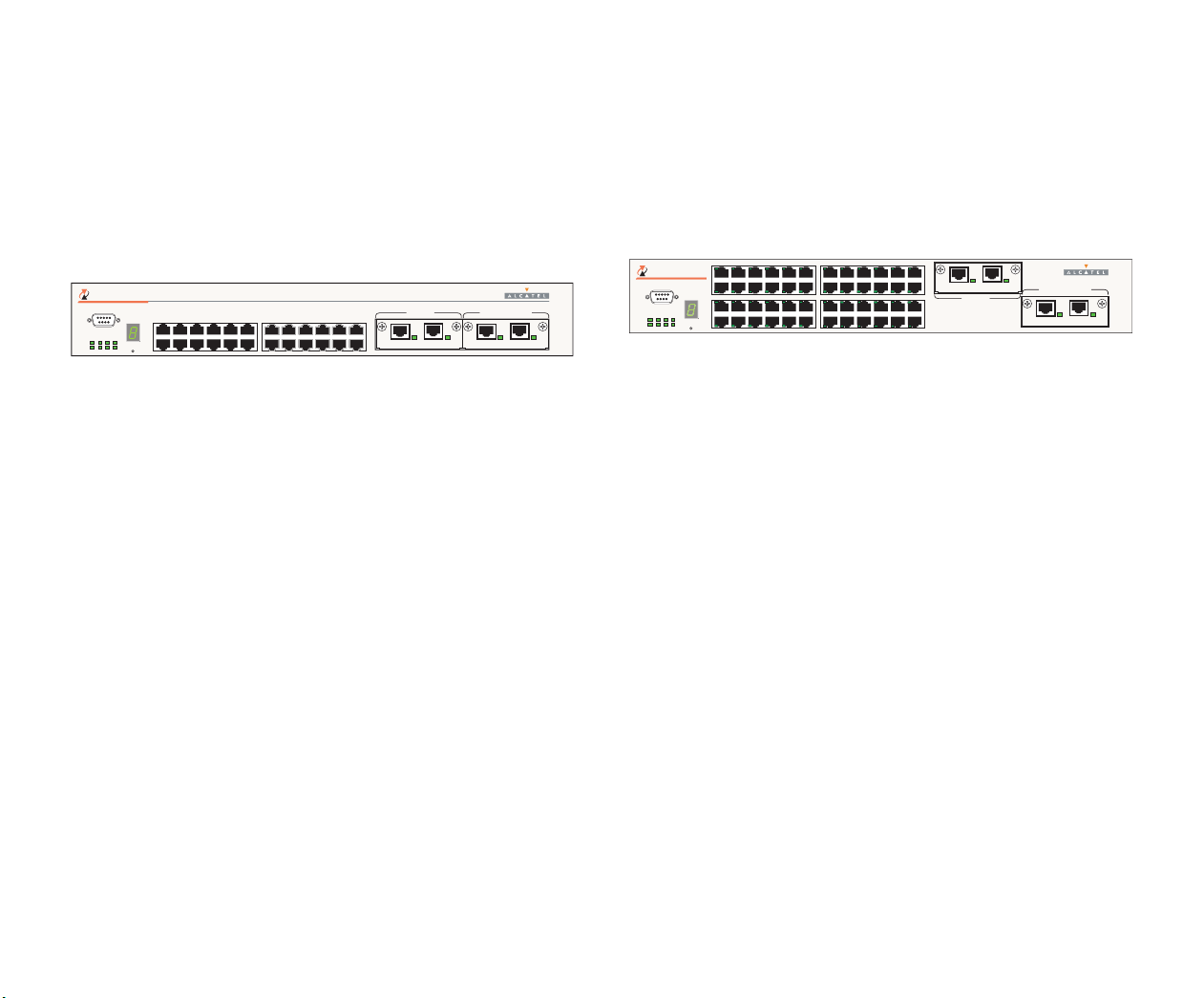

OmniSwitch 6624 (OS6624)

The OS6624 is a stackable edge/workgroup switch offering

24 10/100 Ethernet ports. The OS6624 can also be equipped

with up to four Gigabit Ethernet ports for connections to a

high speed backbone or server.

OmniSwitch 6624

TM

CONSOLE

OK1

PS1

PRI

TEMP

OK2

PS2

SEC

FAN SEL

34567891011

1

2

1314151617181920212223

12

25 26 27 28

LINK/ACT

24

The OS6624 chassis contains the following components:

• Console port (DB-9)

• Stack indicator and status LEDs

• 24 10/100 Ethernet ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-

C2 (copper) Gigabit Ethernet uplink module

• One slot for a Gigabit Ethernet uplink module as

described above or a stacking module

• Factory-installed power supply

• Bay for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

LINK/ACT

OmniSwitch 6648 (OS6648)

The OS6648 is a stackable edge/workgroup switch offering

48 10/100 Ethernet ports. The OS6648 can also be equipped

with up to four Gigabit Ethernet ports for connections to a

high speed backbone or server.

272829303132333435

OmniSwitch 6648

TM

CONSOLE

OK1

PS1

PRI

OK2

PS2

SEC

25

26

34567891011

1

TEMP

FAN

SEL

2

The OS6648 chassis contains the following components:

• Console port (DB-9)

• Stack indicator and status LEDs

• 48 10/100 Ethernet ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-

C2 (copper) Gigabit Ethernet uplink module

• One slot for a Gigabit Ethernet uplink module as

described above or a stacking module

• Factory-installed power supply

• Bay for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

3738394041424344454647

36

1314151617181920212223

12

LINK/ACT

49 50 51 52

48

EXPANSION

24

LINK/ACT

EXPANSION/STACKING

LINK/ACT

LINK/ACT

March 2005 OmniSwitch 6600 Family 3

Page 10

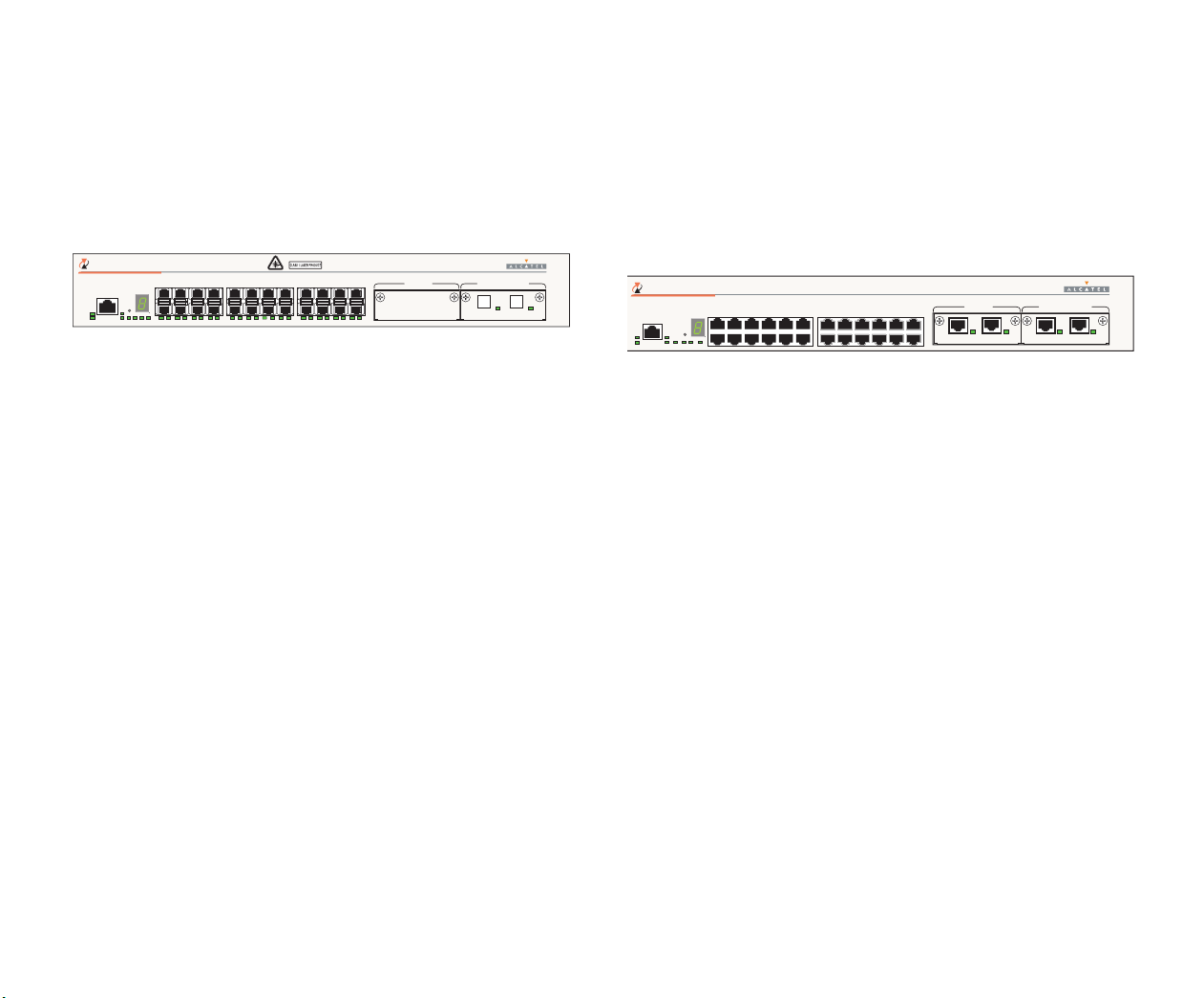

OmniSwitch 6600-U24 (OS6600-U24)

OmniSwitch 6600-P24 (OS6600-P24)

The OS6600-U24 is a stackable edge/workgroup switch offering 24 100 SFP Ethernet ports. The OS6600-U24 can also be

equipped with up to four Gigabit Ethernet ports for connections to a high speed backbone or server.

OmniSwitch 6600-U24

TM

CONSOLE

OK1

PS1

OK2

PS2 PRI SEC TEMPFAN

357 911

1

SEL

2 24

2143658710912111413

13 15 17 19 21 23

1615 1817 2019 2221 2423

25 26 27 28

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

The OS6600-U24 chassis contains the following components:

• Console port (RJ-45)

• Stack indicator and status LEDs

• 24 100 Ethernet SFP ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-

C2 (copper) Gigabit Ethernet uplink module

• One slot for a Gigabit Ethernet uplink module as

described above or a stacking module

• Factory-installed power supply

• Bay for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

The OS6600-U24 is a stackable edge/workgroup switch offering 24 Power over Ethernet (PoE) 10/100 Ethernet ports. The

OS6600-P24 can also be equipped with up to four Gigabit

Ethernet ports for connections to a high speed backbone or

server.

OmniSwitch 6600-P24

TM

34567891011

CONSOLE

OK1

OK2

1

SEL

PS1

PS2

TEMP

SEC

FAN

PRI

2

1314151617181920212223

12

25 26 27 28

LINK/ACT

24

EXPANSION/STACKINGEXPANSION

LINK/ACT

LINK/ACT

LINK/ACT

The OS6600-U24 chassis contains the following components:

• Console port (RJ-45)

• Stack indicator and status LEDs

• 24 10/100 PoE ports

• One slot for OS6600-GNI-U2 (fiber) or OS6600-GNI-

C2 (copper) Gigabit Ethernet uplink module

• One slot for a Gigabit Ethernet uplink module as

described above or a stacking module

• Factory-installed power supply

• Connector for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

4 OmniSwitch 6600 Family March 2005

Page 11

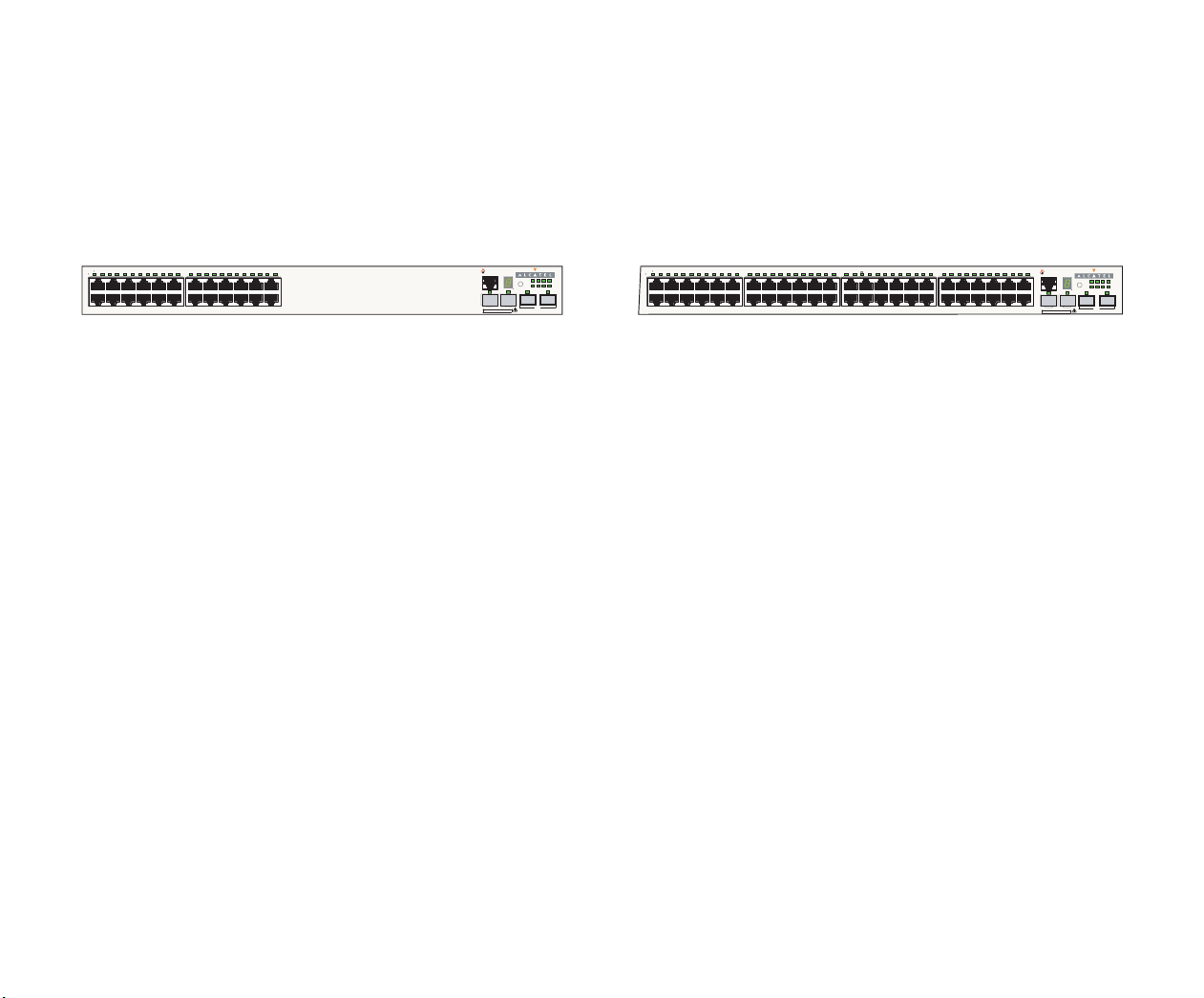

OmniSwitch 6602-24 (OS6602-24)

35698

10

1

1

1

20

2

SEC

28

CLASS

UCT

252

S

k

C

S1

OK1

S2

Sel

OK2

FAN

31569810

1311615191820

2

SEC

PR1

52

CLASS

9

50

S

k

1

PS1

O

PS

S

OK2

P

FAN

62829

303

36

353

8454

42

44

4

48

2

OmniSwitch 6602-48 (OS6602-48)

The OS6602-24 is a stackable edge/workgroup switch offering

24 10/100 Ethernet ports. The OS6602-24 can also be

equipped with up to two Gigabit Ethernet ports for connections to a high speed backbone or server.

3

7161514 211918

2 2324

OmniSwitch 6602-24

TM

1 LASER PROD

o

n

P

s

o

l

P

6

27

tac

The OS6602-24 chassis contains the following components:

• Console port (RJ-45)

• Stack indicator and status LEDs

• 24 10/100 Ethernet ports

• Two slots for MiniGBICs

• Two built-in stacking ports

• Factory-installed power supply

• Bay for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

The OS6602-48 is a stackable edge/workgroup switch offering

48 10/100 Ethernet ports. The OS6602-48 can also be

equipped with up to two Gigabit Ethernet ports for connections to a high speed backbone or server.

3 24

2

1 3332 34

74140393

3

5

647

OmniSwitch 6602-48

TM

C

o

el

n

K1

TM

s

o

l

2

4

5

tac

1 LASER PRODUCT

The OS6602-24 chassis contains the following components:

• Console port (RJ-45)

• Stack indicator and status LEDs

• 48 10/100 Ethernet ports

• Two slots for MiniGBICs

• Two built-in stacking ports

• Factory-installed power supply

• Bay for optional back up power supply

• Built-in fan tray with three fans

• Grounding block for type LCD8-10A-L grounding lug

March 2005 OmniSwitch 6600 Family 5

Page 12

Setting Up the Hardware

Items Required

In addition to the materials and components provided in the

OmniSwitch 6600 Family shipment, you must provide the

following items in order to complete this installation:

• Grounding wrist strap

• Phillips screwdriver

• Serial cable

• Rack mount screws, if applicable

Site Preparation

Environmental Requirements

OmniSwitch 6600 Family switches have the following environmental and airflow requirements:

• The installation site must maintain a temperature

between 0° and 45° Celsius (32° and 122° Fahrenheit)

and not exceed 95 percent maximum humidity (noncondensing) at any time.

• Be sure to allow adequate room for proper air ventila-

tion and access at the front, back, and sides of the

switch. No clearance is necessary at the top or bottom

of the chassis. Refer to “Airflow Considerations” on

page 9 for minimum clearance requirements.

Electrical Requirements

OmniSwitch 6600 Family switches have the following general

electrical requirements:

• Each switch requires one grounded AC power source

for each power supply installed in the chassis .

• Grounded AC power source must be 110V for North

American installations (220V international).

• Each supplied AC power cord is 2 meters (approxi-

mately 6.5 feet) long. Do not use extension cords.

Redundant Circuit Recommendation. If possible, it is

recommended that the primary and back up power

supplies are plugged into AC sources on separate circuits.

With redundant AC, if a single circuit fails, the switch’s

back up power supply (on a separate circuit) will likely be

unaffected and can therefore continue operating.

6 Setting Up the Hardware March 2005

Page 13

Weight Considerations

OS6624

With a back up power supply installed, a single OS6624

weighs approximately 13.5 lbs (6.1 Kgs).

A stack of eight OS6624 switches—fully populated with

uplink and stacking modules and back up power supplies—

weighs approximately 108 lbs (49.1 Kgs).

A stack of eight OS6600-P24 switches—without back up

power supplies— weighs approximately 96 lbs (36 Kgs).

OS6602-24

Without a back up power supply installed, a single OS6602-24

weighs approximately 12 lbs (4.5 Kgs).

A stack of eight OS6602-24 switches—without back up power

supplies— weighs approximately 96 lbs (36 Kgs).

OS6648

With a back up power supply installed, a single OS6648

weighs approximately 15.5 lbs (6.8 Kgs).

A stack of eight OS6648 switches—fully populated with

uplink and stacking modules and back up power supplies—

weighs approximately 124 lbs (56.4 Kgs).

OS6600-U24

With a back up power supply installed, a single OS6600-U24

weighs approximately 13.06 lbs (5.92 Kgs).

A stack of eight OS6600-U24 switches—with back up power

supplies— weighs approximately 104.48 lbs (47.36 Kgs).

OS6600-P24

Without a back up power supply installed, a single OS6600P24 weighs approximately 12 lbs (4.5 Kgs).

OS6602-48

Without a back up power supply installed, a single OS6602-48

weighs approximately 12 lbs (4.5 Kgs).

A stack of eight OS6602-48 switches—without back up power

supplies— weighs approximately 96 lbs (36 Kgs).

Items Included

Your OmniSwitch 6600 Family switch order includes the

following items:

• OmniSwitch chassis

• Blank cover panels for empty uplink module and

backup power supply bays

• Rack mount flanges with attachment screws

• Grounding wrist strap

• Power cord (country-specific)

March 2005 Setting Up the Hardware 7

Page 14

• Hardcopy OmniSwitch 6600 Family Getting Started

Guide (OS6624, OS6648, OS6600-U24, OS6600-P24

only)

• Documentation CD containing the following

OmniSwitch 6600 Family-specific manuals:

OmniSwitch 6600 Family Getting Started Guide

• SFP-100-LC-MM, SFP-100-LC-SM, or SFP-100-MTRJ

100 Mbps SFPs (OS6600-U24 only)

• Stacking kit (includes one stacking module and

30 centimeter cable)

• Redundant stacking kit (includes one stacking module

and one-meter cable)

OmniSwitch 6600 Family Hardware Users Guide

OmniSwitch CLI Reference Guide

OmniSwitch 6600 Family Switch Management Guide

OmniSwitch 6600 Family Network Configuration

Guide

OmniSwitch 6600 Family Advanced Routing Configuration Guide

Optional Items

Depending on your order, the OmniSwitch shipment may also

include one or more of the following optional items:

• Back up power supply

• OS6600-GNI-U2 or OS6600-GNI-C2 Gigabit Ethernet

uplink modules

• MiniGBIC-SX, MiniGBIC-LX, or MiniGBIC-LH-70

Mini Gigabit Ethernet Interface Converters (for switches

using OS6600-GNI-U2 uplink modules only)

Unpacking and Initial Setup

Unpacking the Chassis

To protect your OmniSwitch chassis and hardware components from electrostatic discharge (ESD) and physical damage,

read all unpacking recommendations and instructions carefully before beginning.

Recommendations

• Unpack your OmniSwitch chassis as close as possible

to the location where it will be installed.

• Depending on your order, uplink modules,

MiniGBICs, stacking modules, and SFPs may be packaged separately. In order to greatly reduce exposure to

electrostatic discharge (ESD) and physical damage, do

not unpack these items until they are ready to be

installed.

8 Setting Up the Hardware March 2005

Page 15

Instructions

Setting Up the Switch

1 Carefully cut the tape along the seam at the top of the

box containing the chassis.

2 Lift the box’s top flaps. Remove any smaller boxes or

pouches that are enclosed and set them aside.

3 Lift the chassis out of the packaging.

4 Carefully remove the foam pads and protective plastic

from the switch chassis.

Note. Alcatel provides factory-installed blank cover plates

for empty module slots. Because they play an important

role in chassis ventilation, do not remove these cover

plates unless a module or back up power supply is to be

installed immediately at the corresponding slot.

5 If you are installing multiple switches in a stacked

configuration, repeat steps 1 through 4 for the remaining

switches that will make up the stack.

6 Once all OmniSwitch 6600 Family switches have been

removed from their packaging, continue to “Setting Up

the Switch” on page 9.

Note. Due to their airflow and access requirements,

OmniSwitch 6600 Family switches cannot be wallmounted.

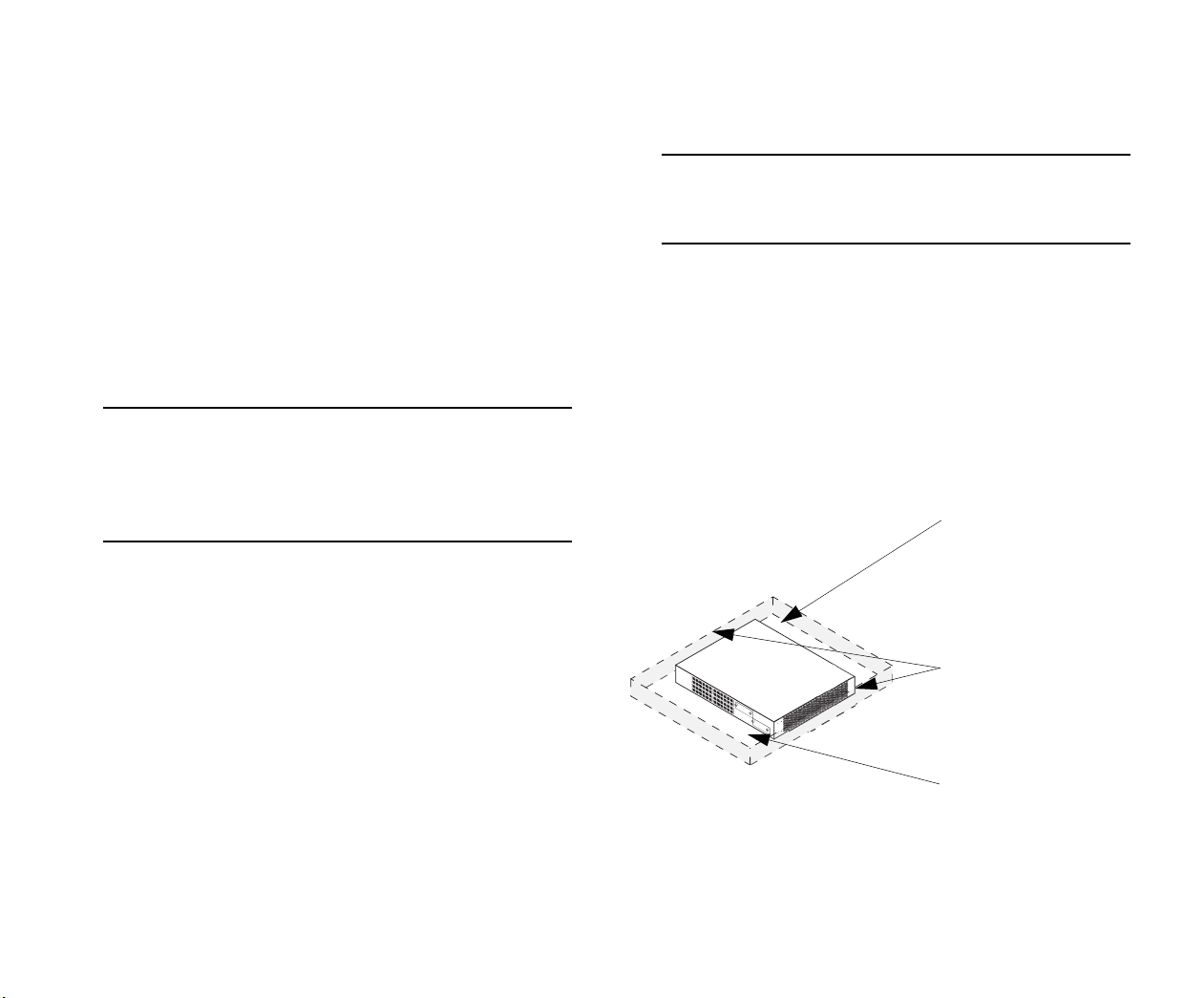

Airflow Considerations

Be sure that your switch is placed in a well-ventilated, staticfree environment. Always allow adequate clearance at the

front, rear, and sides of the switch.

The following diagram shows recommended minimum clearances for adequate chassis airflow and access to components at

the rear of the chassis—e.g., back up power supply and power

switch(es).

Rear. 5 inches minimum

at rear of chassis for

installation and removal

of optional back up

power supply.

Sides. 2 inches minimum

at left and right sides for

chassis airflow.

Front. 6 inches minimum

at front of chassis for

cable access and LED

visibility.

Chassis Top View

March 2005 Setting Up the Hardware 9

Page 16

Never obstruct the air vents located at the left and right sides

of the chassis.

Note. Clearance is not required at the top and bottom of

the chassis. For detailed chassis airflow diagrams, refer to

the Hardware Users Guide.

There are two ways in which the OmniSwitch 6600 Family

can be installed:

Installing the Switch on a Tabletop or Bench

OmniSwitch 6600 Family switches can be installed freestanding as tabletop units. Locate your switch in a stable, flat, staticfree surface.

Note. OmniSwitch 6600 Family switches must be placed

“right side up.” Never attempt to operate a switch positioned on its side.

• Tabletop installation

• Rack-mount installation

For information on setting up a switch as a tabletop unit, refer

to “Installing the Switch on a Tabletop or Bench” on page 10.

For information on rack-mounting the switch, refer to

“Rack-Mounting the Switch” on page 11.

To install the switch as a tabletop unit, follow the steps below:

1 Position the chassis on the table or bench where it is to

be installed. Refer to page 7 for chassis weight consider-

ations.

2 Be sure that adequate clearance has been provided for

chassis airflow and access to the front, back, and sides of

the switch. For recommended clearances, refer to page 9.

Also, be sure that you have placed the chassis within reach

of all required AC power sources. For environmental and

electrical requirements, refer to page 6.

3 If you are placing multiple switches in a stacked

configuration, carefully stack the remaining switches, one

on top of the other. Up to eight switches may be stacked to

form a single virtual chassis. Be sure to maintain adequate

clearance at the front, rear, left, and right side of all

switches.

4 Verify that the on/off switch for each OmniSwitch

6600 Family is in the off ( O ) position.

10 Setting Up the Hardware March 2005

Page 17

5 Plug the power cord (supplied) into the power socket

located on the switch’s rear panel; next, plug the cord into

an easily-accessible grounded AC power source. See

“Electrical Requirements” on page 6 for more informa-

tion.

Note. If you are installing the switch in a 23-inch wide

rack, Alcatel offers optional 23-inch rack-mounting hardware. For more information, contact your Alcatel representative.

Note. Do not turn on the power supplies at this time. You

will power on all switches later in the setup process.

6 Continue to “Installing a Back Up Power Supply

(OS6624, OS6648, OS6600-U24)” on page 14.

Rack-Mounting the Switch

Refer to the important guidelines below before installing the

OmniSwitch chassis in a rack.

• It is recommended that two people install the switch in

the rack—one person to hold the chassis and position it

in the rack, and a second person to secure the chassis to

the rack using attachment screws (not supplied).

• Alcatel provides two rack-mount flanges with each

OmniSwitch 6600 Family switch. These flanges

support standard 19-inch rack mount installations.

These flanges must be attached to the chassis before

the switch can be rack mounted.

• Alcatel does not provide rack-mount screws. Use the

screws supplied by the rack vendor.

• To prevent a rack from becoming top heavy, it is

recommended that you install heavier equipment at the

bottom of the rack whenever possible.

• If you are installing the switch in a relay rack, be sure

to install and secure the rack per the rack manufacturer’s specifications.

• Review page 9 for important chassis airflow and access

recommendations before installing.

To rack-mount the switch, follow the steps below.

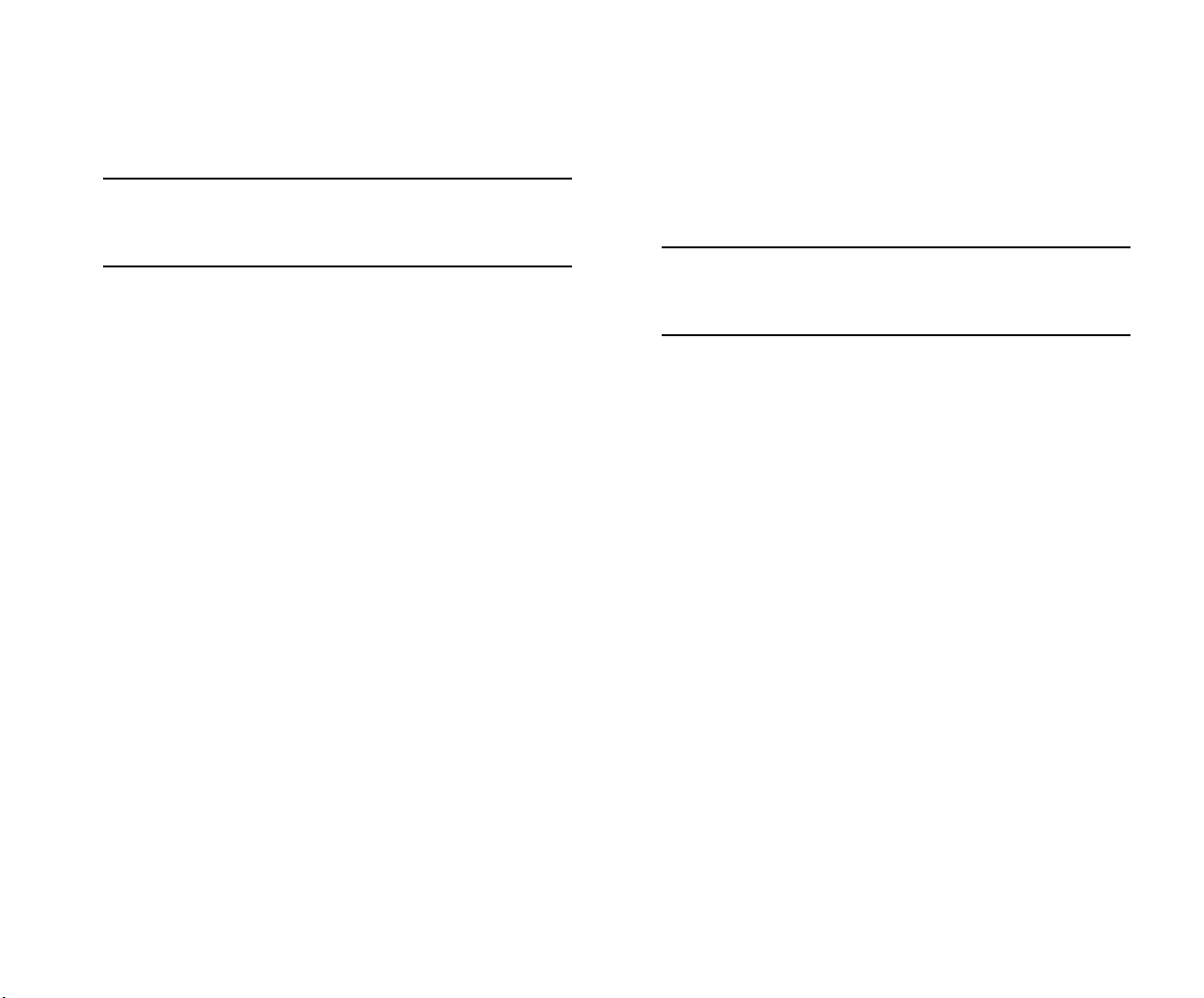

1 Align the holes in the provided rack-mount flanges

with the four threaded holes in the OmniSwitch chassis.

These threaded holes are located in the left and right sides

of the chassis, near the front panel.

March 2005 Setting Up the Hardware 11

Page 18

2 Attach the flanges to the chassis using the provided

3

4

8

Phillips-head screws. Be sure to tighten each of the screws

firmly using a Phillips screwdriver.

4

OmniSwitch 662

M

T

CONSOLE

MP

TE

SEL

I

PR

PS1

K1

FAN

O

SEC

PS2

2

OK

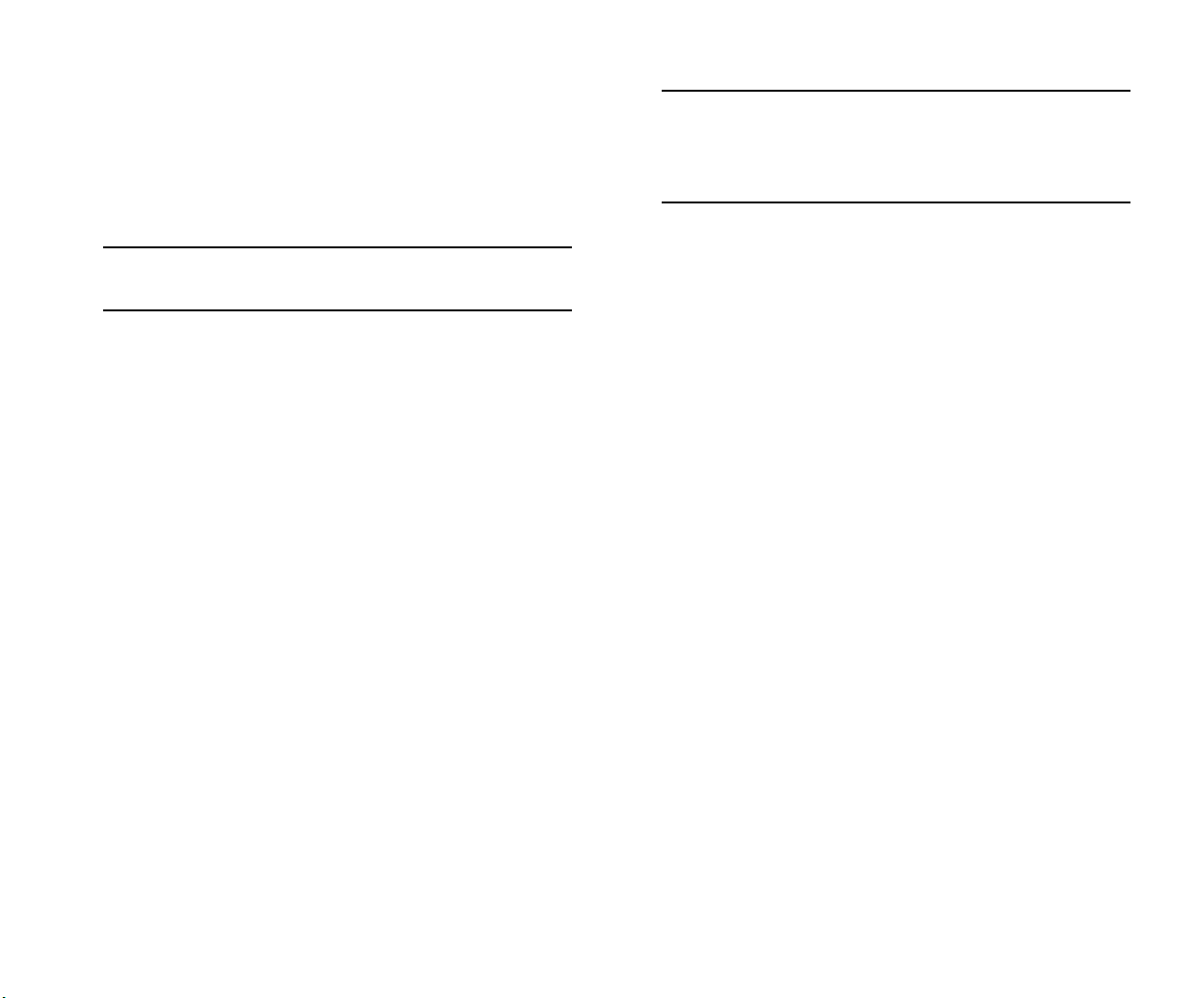

6 Once the holes are aligned, insert a rack mount screw

(not provided) through the bottom hole of each flange.

Tighten both screws until they are secure.

ACKING

52

EXPANSION/ST

051

4

9

5

EXPANSION

7

3 After the rack-mount flanges are secured to the chas-

sis, mark the holes on the rack where the switch is to be

installed.

Note. Be sure to install the screws in the bottom hole of

each flange, as shown, before proceeding.

4 Lift and position the switch until the rack-mount

flanges are flush with the rack post.

7 Once the screws at the bottom of each flange are

secure, install the remaining two rack mount screws. Be

5 Align the holes in the flanges with the rack holes that

sure that all screws are securely tightened.

were marked in step 3.

8 On OS6624, OS6648, OS660-U24, and OS6600-P24

switches verify that the on/off switch for the OmniSwitch

6600 Family switch is in the off ( O ) position. The on/off

switch is located on the switch’s rear panel.

12 Setting Up the Hardware March 2005

Page 19

9 Plug the power cord (supplied) into the power socket

located on the switch’s rear panel; next, plug the cord into

an easily-accessible grounded AC power source. See

“Electrical Requirements” on page 6 for more informa-

tion.

Note. Do not turn on the power supply at this time. You

will power on the switch later in the setup process.

10 If you wish to install a supplemental ground for the

switch, you may attach a type LCD8-10A-L grounding lug

to the grounding lug, located on the switch’s rear panel.

Install the type LCD8-10A-L grounding lug per manufacturer’s specifications.

Rack Mounting Stacked Configurations

If you are rack mounting multiple switches in a stacked

configuration, be sure to place all switches in verticallyadjacent rack positions. This will ensure that all required

stacking cables will have adequate length for the installation.

For additional instructions on rack mounting a stacked configuration, follow the steps below:

1 Install the rack mount flanges for all switches that are

to be included in the stacked configuration, as described

on page 11. Up to eight switches may be stacked to form a

single virtual chassis.

2 Place the next switch in the stack directly on top of the

previously installed switch.

11 If you are installing multiple switches in a rack to

form a stacked configuration, refer to “Rack Mounting

3 Align the holes in the flanges with the holes in the

rack’s vertical posts.

Stacked Configurations” on page 13. If you are not install-

ing a stacked configuration, continue to “Installing a Back

Up Power Supply (OS6624, OS6648, OS6600-U24)” on

page 14.

4 Once the holes are aligned, insert a rack mount screw

through the bottom hole of each flange. Tighten both

screws until they are secure. Once the screws at the

bottom of each flange are secure, install the remaining two

rack mount screws. Be sure that all screws are securely

tightened.

5 Repeat steps 1 through 4 above for all remaining

switches.

6 On OS6624, OS6648, OS660-U24, and OS6600-P24

switches verify that the on/off switch for each

OmniSwitch 6600 Family switch is in the off ( O ) posi-

tion.

March 2005 Setting Up the Hardware 13

Page 20

7 Plug a power cord (supplied) into the power socket of

each switch; next, plug each cord into an easily-accessible

grounded AC power source.

Note. Do not turn on the power supplies at this time. You

will power on all switches later in the setup process.

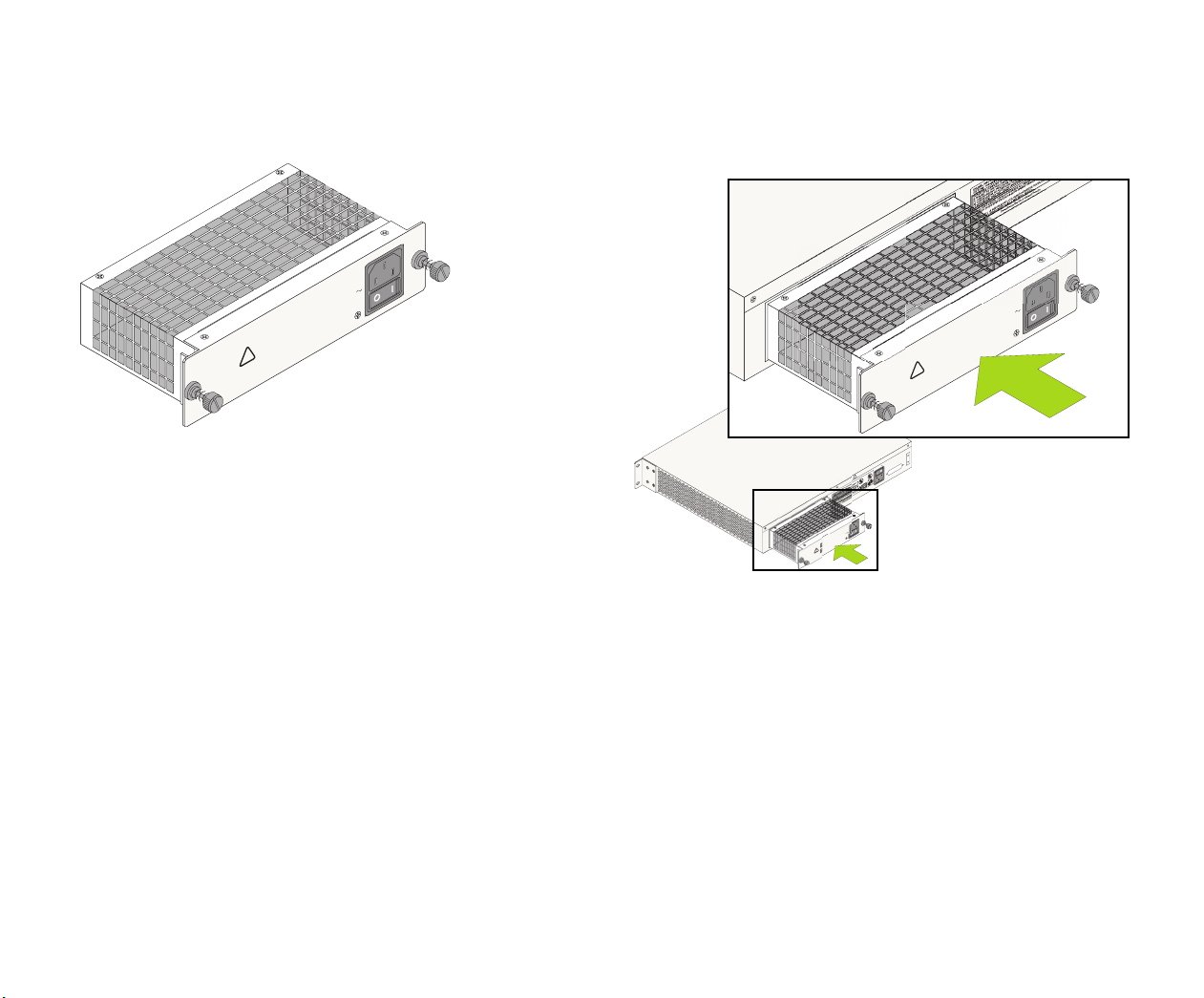

Installing a Back Up Power Supply (OS6624, OS6648, OS6600-U24)

If the optional back up power supply was included with your

order, install the power supply now by following the steps

below. The back up power supply bay is located at the

switch’s rear panel.

8 If you wish to install a supplemental ground for each

switch, you may attach a type LCD8-10A-L grounding lug

to the grounding lug. Install the type LCD8-10A-L

grounding lug per manufacturer’s specifications.

9 After you have rack-mounted your switches, continue

to “Installing a Back Up Power Supply (OS6624, OS6648,

OS6600-U24)” on page 14.

Anti-Static Warning. Before handling any components,

free yourself of static by wearing a grounding strap, or by

grounding yourself properly. Static discharge can damage

the switch and the back up power supply.

1 If there is a blank cover panel installed at the back up

power supply bay, uninstall it by removing the two Phil-

lips attachment screws. After the attachment screws have

been removed, carefully pry the blank cover panel out and

away from the chassis. Set the cover panel and attach-

ment screws aside.

14 Setting Up the Hardware March 2005

Page 21

2 To avoid attempting to install the power supply upside

AD

A

down, orient the unit as shown in the diagram below.

Top

V

0

A

3

/1

/2

/2

5

1

, 2

/1

z

0

H

0

E

0

1

PED

/6

UC

T

IP

0

C

U

ED

5

Q

NE

R

N

E

O

O

BE

NS. T

AY

M

TIO

IT

RE

CK, DISC

EC

O

N

N

IS UN

SH

BEFO

O

S

AL

TH

C

ER

RIC

TE

W

HE

R

CT

DE

C

ECTION

PO

N

PO

LE

N

A

E

FIN

O

N

M

F E

D

. A

EBR

O

CAUTION:

R CO

.

ION

E

ITH TW

ISK

ANTE

W

V

NIT

W

ES, D

R

TAT

A

U

U

N

PO

PPAREIL CO

EN

G

THE

A

RIQ

IN

TH

TIO

T

IC

E

TA

'ALIM

BO

V

C

N

E

N D

SER

O

S ELECT

C

'ALIM

RD

O

S D

N

.

S CHO

O

'UN C

LE

ION

ATTENTION:

S D

ORD

NIR

C

E

PLU

EUX

PREV

D

!

LES

FAIRE LA REPARAT

Orient the back up power

supply with the vent side

up, as shown.

3 Grasp the front portion of the power supply and care-

fully insert the rear of the casing into the power supply

bay. Slide the power supply back until the unit meets the

connector in the chassis power supply bay.

s

U CAN

R D

omponent

LEU

IL

OU

on-US C

R

B

d N

IEL

an

R

É

of US

US

bled in the

Assem

V

100/115/230

50/60 Hz, 2/2/1 A

CONNECT

BE EQUIPPED

CTIONS. TO REDUCE

S BEFORE

THIS UNIT MAY

:

N

DE

POWER CONNE

TIO

AU

C

ON. AFIN

.

VANTE DE

WITH TWO

AREIL COMPORTE

THE RISK OF ELECTRICAL SHOCK, DIS

ON A

ATI

BOTH POWER CONNECTION

CET APP

:

N

SERVICING UNIT

IO

T

N

E

S CHOCS ELECTRIQUES, DEBRANCHE

TT

A

ARATION.

PLUS D'UN CORDON D'ALIMENTATI

PREVENIR LE

!

LES DEUX CORDONS D'ALIMENT

FAIRE LA REP

E

TE

E

H

R

D

C

O

N

N

P

FI

M

RA

A

O

DE

E

N.

C

T

DEB

O

I

,

T

AN

S

REIL

A

A

AV

UE

NT

Q

E

ON

APP

I

M

RI

I

T

T

A

CT

T

CE

E

L

:

D'AL

E

N

N

IMEN

O

L

DO

CS

I

A

'

T

OR

HO

D

N

C

C

S

E

N

.

S

T

O

N

UN

T

'

LE

D

T

O

D

I

R

R

A

R

T

I

O

A

N

O

US

E

P

PL

PAR

UX C

EV

E

V

R

A

R

D

DE

PR

E

E

1

30

/

W

P

LA

ES

2

2

P

/

L

I

P

/

DUC

RE

5

I

ECT

1

RE

A

, 2

N

F

EQU

1

z

NN

O

/

A

T

H

0

.

BE

CO

L

0

S

0

Y

IS

1

6

A

/

D

ION

,

M

0

E

K

5

IT

R

CT

C

O

E

F

UN

HO

NN

IS

BE

L S

CO

A

TH

NS

2

:

IC

0

O

ER

I

N

,4

W

4

O

CTR

O

I

9

ECT

E

P

T

L

,3

5

E

O

NN

U

.

O

F

A

O

C

TW

O

C

N

R

H

K

T

IT

IS

IT.

N

N

W

E

OWE

E R

T

P

A

TH

H

P

NG U

T

.

CI

O

S

.

B

VI

U

ER

S

D

R

E

!

T

IS

L

.

E

.

T

.

I

1

C

7

3

Z

1

5

6

V

4

d

U

n

T

y

a

6

l

t

n

e

i

f

1

e

a

h

S

t

E

R

c

u

d

o

r

P

e

t

R

f

u

r

t

p

i

e

e

g

h

r

e

h

c

i

S

.

A

D

A

N

s

A

t

C

n

e

U

n

o

D

p

R

m

U

o

E

C

L

L

S

I

U

U

n

O

o

R

N

B

d

L

n

a

IE

R

S

É

U

f

o

S

U

e

th

in

d

le

b

m

e

ss

A

V

A

0

3

1

/

2

/

2

/

5

2

1

,

1

/

z

0

H

0

D

E

0

1

E

C

6

P

/

U

T

P

I

0

D

C

U

E

5

E

R

Q

N

E

N

O

E

T

O

.

B

C

S

S

Y

I

N

A

D

O

I

M

,

E

T

K

T

I

R

C

C

N

O

E

O

F

U

N

H

E

N

S

S

I

B

O

L

H

S

C

A

T

N

C

R

:

I

O

E

E

I

R

N

E

T

T

T

E

W

H

R

C

O

C

D

O

I

C

E

O

E

P

N

N

T

P

L

N

I

A

E

E

F

O

N

M

U

R

A

D

O

F

O

W

A

.

B

C

T

C

E

O

N

E

C

T

L

R

H

K

D

O

I

.

I

N

,

T

E

S

T

E

I

I

T

I

A

S

R

A

W

V

R

N

W

E

T

A

A

O

U

E

U

P

N

P

N

H

Q

P

E

G

I

T

O

H

A

N

I

M

R

I

I

T

T

T

T

L

C

O

A

I

E

C

A

T

'

B

V

C

E

N

D

R

L

:

E

E

E

N

N

M

S

I

O

S

L

O

D

C

I

A

'

R

O

T

D

O

H

N

C

C

S

E

N

.

N

S

T

O

N

E

U

'

L

D

T

O

D

I

R

A

R

T

I

S

O

A

N

U

C

R

L

E

A

X

P

V

P

U

E

E

E

R

R

D

P

A

!

S

L

E

E

L

R

I

A

F

4 Continue sliding the power supply back until the front

panel is flush with the rear panel of the chassis. Do not

force the power supply into the bay. Otherwise you can

damage the connectors.

March 2005 Setting Up the Hardware 15

Page 22

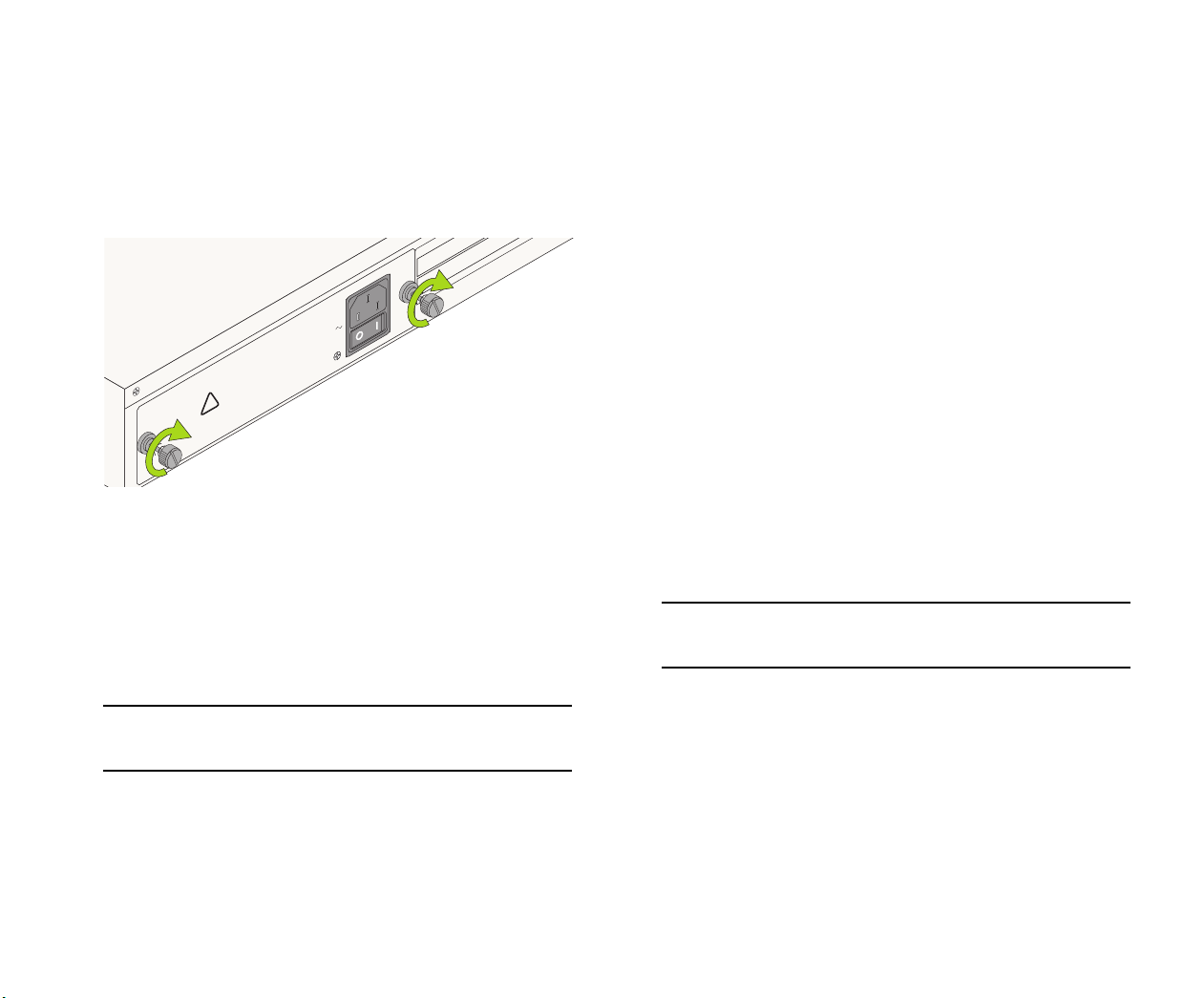

5 Tighten the two captive screws, located at the left and

OS

0V

ITH

G

T

AR

ER

RED

IRE

LAT

ES

ADA

right sides of the power supply’s front panel. Be sure not

to overtighten the captive screws. If you use a screwdriver, the torque used to tighten the screws must not

exceed 2.3 inch pounds.

!

L SHOCK, DISCO

THIS UNIT MA

ELECTRICA

CONNECTION

CAUTION:

WITH TWO POWER CONNECTIONS.

THE RISK OF

BOTH POWER

VICING UNIT.

CET APPAREIL

N D'ALIMENT

SER

RDO

NS D'ALIMENT

S CHOCS EL

RDO

ATTENTION:

ARATION.

PLUS D'UN CO

REP

PREVENIR LE

LES DEUX CO

FAIRE LA

Y

S BEFORE

ECTRIQUES,

BE EQUIPPED

COMPOR

ATION. AFIN DE

ATION AVANTE DE

T

O REDUCE

NNECT

TE

DEBRANCHE

100/115/230

50/60 Hz, 2/2/1 A

ANY INT

100-24

NOT CAUSE H

MODEL NO:

ACCEPT

TO THE FOLLOWIN

AY CAUSE UNDESI

RATING:

ATUS MEETS

THIS DEVICE COMPLIES W

DEVICE MAY

PAR

IS SUBJECT

DEVICE MUST

(1) THIS

ENCE-CAUSING EQUIPMENT

IGITAL AP

(2) THIS

A D

INTERFERENCE THAT M

RIQUE DE LA CLA

Assembled in the US of US and Non-US Component

THIS CLASS

REGLEMENT SUR LE MATÉRIEL BROUILLEUR DU CAN

CANADIAN INTERFER

CET APPAREIL NUMÉ

EXIGENCES DU

V

s

TS L

REQU

REGU

ALL

RESPECTE TOU

SSE A

6 On OS6624, OS6648, OS660-U24, and OS6600-P24

switches verify that the power supply’s on/off switch is in

the off ( O ) position.

8 If you are installing back up power supplies in a multi-

chassis, stacked configuration, install all remaining power

supply units now by repeating steps 1 through 7 for each

chassis.

9 Continue to “Installing Uplink and Stacking Modules”

on page 16.

Installing Uplink and Stacking Modules

OmniSwitch 6600 Family switches support the following

modules:

• OS6600-GNI-C2 Copper Gigabit Ethernet Uplink

Module

• OS6600-GNI-U2 Fiber Gigabit Ethernet Uplink

Module

• Stacking Module

7 Plug a power cord (supplied) into the unit’s power

socket; next, plug the cord into an easily-accessible,

Note. This section does not apply to OS6602-24 and

OS6602-48 switches.

grounded power source.

Note. Do not turn on the power supply at this time. You

will power on all supplies later in the setup process.

16 Setting Up the Hardware March 2005

Page 23

If uplink modules and/or stacking kits were specified with

your order, install them now by following the steps below:

screws have been removed, carefully pry the blank cover

panel out and away from the chassis. Set the cover panel

and attachment screws aside.

Important. Stacking modules can only be installed in the

far-right module slot. This slot is labeled EXPANSION/

STACKING and contains port positions 27 and 28

(OS6624 and OS6600-U24) or 51 and 52 (OS6648).

Do not attempt to install stacking modules at the

EXPANSION slot at port positions 25 and 26 (OS6624

and OS6600-U24) or 49 and 50 (OS6648).

OS6600-GNI-U2 and OS6600-GNI-C2 uplink modules

can be installed in either slot location. However, if you

install a Gigabit Ethernet uplink module in the

EXPANSION/STACKING slot, the switch must be used

as a stand-alone unit.

Port numbers are clearly marked on the OmniSwitch 6600

Family chassis front panels.

Anti-Static Warning. Before handling any components,

free yourself of static by wearing a grounding strap, or by

grounding yourself properly. Static discharge can damage

the switch and the uplink or stacking module.

1 If there is a blank cover panel installed over the uplink

or stacking module slot position, uninstall it by removing

the two Phillips attachment screws. After the attachment

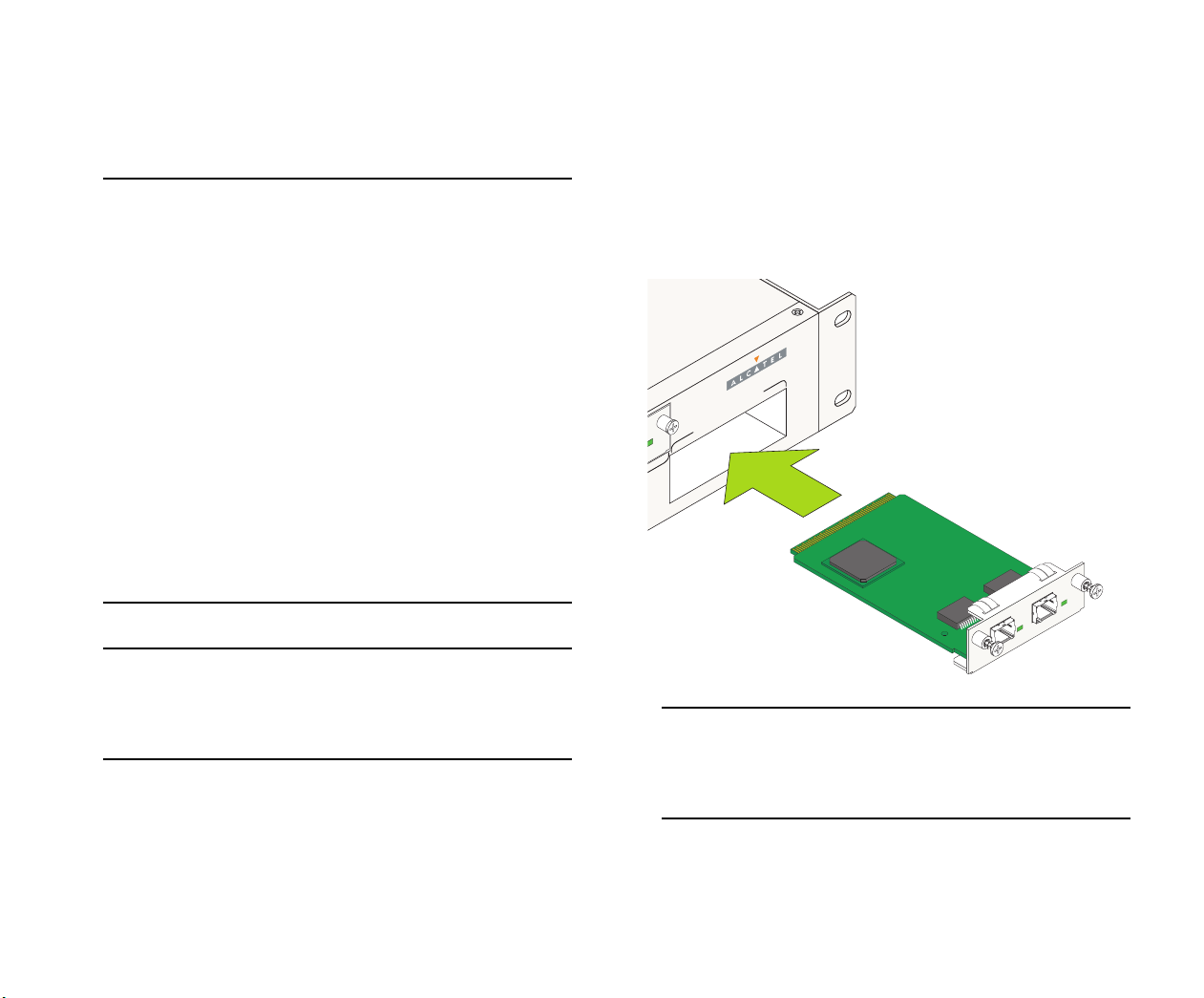

2 Holding the uplink or stacking module by the front

panel, carefully slide the circuit board into the card guide

located in the chassis slot.

EXPANSION/STACKING

51 52

LINK/ACT

LINK/ACT

Note. The module should slide in easily. Do not force the

module into the slot. If any resistance is encountered,

ensure that the module is aligned properly in the card

guide and try again.

March 2005 Setting Up the Hardware 17

Page 24

3 Slide the module back until the backplane connector is

TX

RX

inserted in the chassis backplane; the module’s front panel

should be flush with the front of the chassis. Do not force

the module into the slot. Otherwise you can damage the

connectors.

4 Once the module is firmly seated and flush with the

chassis front panel, secure the module by tightening the

two captive screws. Be sure not to overtighten the captive

screws. If you use a screwdriver, the torque used to

tighten the screws must not exceed 2.3 inch pounds.

52

EXPANSION/STACKING

51

LINK/ACT

LINK/ACT

Installing MiniGBIC Connectors

Each OS6600-GNI-U2 uplink module supports up to two Mini

Gigabit Interface Converters (MiniGBICs). These MiniGBICs

are packaged separately and therefore are not factory-installed.

Mini Gigabit Interface Converter (MiniGBIC)

If you are using one or more OS6600-GNI-U2 modules to

uplink to the backbone or server, you must install the MiniGBIC(s) by following the steps below.

Anti-Static Warning. Before handling any components,

free yourself of static by wearing a grounding strap, or by

grounding yourself properly. Static discharge can damage

the MiniGBIC, as well as the switch and uplink module.

18 Setting Up the Hardware March 2005

Page 25

1 Holding the MiniGBIC by its sides, carefully slide it

into the desired MiniGBIC slot in the OS6600-GNI-U2

module, as shown.

52

EXPANSION/STACKING

51

G

IN

K

C

A

2

ST

5

/

N

IO

NS

A

XP

E

1

5

0

5

N

7

4

SIO

AN

P

9

X

4

5

E

4

3

4

1

4

8

4

9

3

3

2

6

4

7

1

3

2

4

4

9

1

5

3

2

4

7

1

3

3

0

4

4

2

5

1

1

3

8

2

3

2

3

1

9

2

0

2

6

3

7

1

2

1

8

1

4

3

5

9

2

6

1

2

3

7

4

1

0

3

5

8

2

2

1

6624

3

6

2

0

1

1

8

OmniSwitch

M

T

E

6

L

O

S

N

O

C

4

2

P

M

E

EL

T

S

I

R

P

1

S

P

N

1

A

K

F

O

C

E

S

2

S

P

2

K

O

Note. The MiniGBIC should slide in easily. Do not force

the MiniGBIC into the slot. Otherwise you can damage the

connectors. If any resistance is encountered, ensure the

MiniGBIC is aligned and oriented properly, as shown in

the diagram above.

2 Push the MiniGBIC into the slot until it is completely

inserted and securely seated in the OS6600-GNI-U2

module, as shown.

52

EXPANSION/STACKING

51

March 2005 Setting Up the Hardware 19

Page 26

Installing SFP Connectors (OS6600-U24 Only)

The OS6600-U24 supports up to twenty-four 924) 100 Mbps

Small Form-factor Pluggable (SFPs). These SFPs are packaged separately and therefore are not factory-installed.

100 Mbps SFP

1 Holding the SFP by its sides, carefully slide it into the

desired SFP slot (ports 1–24) on the OS6600-U24 module,

as shown.

Follow the steps below to install an SFP.

Anti-Static Warning. Before handling any components,

free yourself of static by wearing a grounding strap, or by

grounding yourself properly. Static discharge can damage

the MiniGBIC, as well as the switch and uplink module.

20 Setting Up the Hardware March 2005

Note. The SFP should slide in easily. Do not force the

SFP into the slot. Otherwise you can damage the connectors. If any resistance is encountered, ensure the SFP is

aligned and oriented properly, as shown in the diagram

above.

2 Push the SFP into the slot until it is completely inserted

and securely seated in the OS6600-U24 SFP slot, as

shown.

Page 27

Blank Cover Plates

Blank cover plates are factory-installed in the chassis and are

used to cover empty uplink and stacking module slots, as well

as empty back up power supply bays.

These cover plates play an important role in chassis airflow

and temperature management. They also protect the switch’s

processor board and other sensitive internal switch components from physical damage by closing off a chassis that is not

fully populated.

Because they regulate airflow and help protect internal chassis

components, blank cover plates should remain installed over

empty module slots and power supply bays at all times.

For detailed diagrams showing chassis airflow and the effects

of missing blank cover plates on chassis airflow, refer to the

Hardware Users Guide.

March 2005 Setting Up the Hardware 21

Page 28

Connections and Cabling

Once your switch is properly set up and all required hardware

components are installed, you should connect all network and

management cables required for your network applications.

Connections may include:

• Serial cable (OS6624 and OS6648) or RJ-45 (OS6600-

U24, OS6600-P24, OS6602-24, OS6602-48) to the

console port

• Gigabit Ethernet cables to MiniGBICs, as required by

your network

• Ethernet cables to 10/100 Ethernet ports, as required

by your network

• Single mode or multimode fiber cables to SFPs

(OS6600-U24), as required by your network

Important. If you are installing switches in a stacked

configuration, do not install the stacking cables at this

time, as this will adversely affect the slot assignments.

You will be prompted to install the stacking cables later in

the setup process.

Connecting the Serial Cable to the Console Port

The console port, located on the chassis front panel, provides a

serial connection to the switch and is required when logging

into the switch for the first time. By default, this connector (a

male DB-9 on OS6624 and OS6648 and an RJ-45 on OS6600U24, OS6600-P24, OS6602-24, OS6602-48) provides a DCE

console connection.

Serial Connection Default Settings

The default settings for the serial connection are as follows:

baud rate 9600

parity none

data bits (word size) 8

stop bits 1

For information on modifying these settings, refer to

“Modifying the Serial Connection Settings” on page 38.

Stacked Configurations. To modify the default serial

settings for switches in a stack, you must configure these

settings when each switch is operating as a stand-alone

unit.

22 Connections and Cabling March 2005

Page 29

The Next Step

If you are setting up a stand-alone OmniSwitch 6600 Family

switch (i.e., a switch that is not a part of a stacked configuration), skip to “Booting Stand-Alone Switches” on page 29.

March 2005 Connections and Cabling 23

Page 30

Completing a Stacked Configuration

All switches in the stacked configuration should now be

placed in their proper location (e.g., tabletop to rack). In order

to complete the stacked configuration process, you must

complete the following steps:

1 Individually assign slot numbers to all switches

2 Attach all required stacking cables

3 Boot the newly-configured stack

For OmniSwitch 6600 Family switches, the term “slot” refers

to the priority status of the switch within the stacked configuration. Slot numbers may range from 1 to 8.

Slot Assignment Guidelines

Before assigning slot numbers to switches in a stacked configuration, note the following guidelines.

• Slot numbers do not need to be sequential. However,

each switch in a stack must have a unique slot number.

If duplicate slot numbers are encountered, an error will

occur and the stack will be disabled.

• By default, the primary—or management—role will be

given to the switch with the lowest chassis MAC

address. All other switches in the stack will be in nonoperational status until slot numbers are assigned by

the user and the stack is manually rebooted.

• After manually assigning the slot assignments for all

switches and rebooting the stack, the primary role will

be given to the switch with the lowest slot number. The

secondary role will be given to the switch with the

next-lowest number. All additional switches with

higher numbers will be given idle status. For more

information on primary, secondary, and idle roles, refer

to the “Managing OmniSwitch 6600 Family Stacks”

chapter in the OmniSwitch 6600 Family Hardware

Users Guide.

• Changing the slot number of a chassis does not imme-

diately change its management role (i.e., primary,

secondary, or idle). You must reboot all the switches in

the stack before these changes will take effect.

Refer to the illustration on page 26 for one of many valid

slot numbering possibilities.

• The top switch in the stack does not have to be desig-

nated as slot 1.

24 Completing a Stacked Configuration March 2005

Follow the steps beginning on page 25 to assign slot numbers

for OmniSwitch 6600 Family switches.

Page 31

Assigning Slot Numbers

4

EM

EL

1 Power on a single switch in the stack. Do not power on

any additional switches in the stack at this time.

The slot number is displayed by the slot indicator LED

located on the left side of the chassis front panel (refer to

“OmniSwitch 6600 Status LEDs” on page 67 for more

information). Because the switch’s default slot number is

8, the slot indicator LED displays “8” when the switch is

first booted.

2 To change the slot number, gently insert a pointed

item, such as the open, pointed end of a paper clip, into

the small hole (labeled SEL) below the slot number LED

on the switch’s front panel. The LED display will begin to

flash. You can manually change the slot number as long as

the LED continues to flash.

Note. The LED may also advance by one number when

the SEL button is initially pressed.

3 Change the slot number by gently pressing the pointed

item into the SEL hole again. Each time the SEL button is

pressed, the LED display increases or decreases in increments of one.

T

PRI

PS1

FAN

OK1

SEC

PS2

OK2

OmniSwitch 6624

TM

CONSOLE

TEMP

PRI

PS1

FAN

OK1

SEC

PS2

OK2

S

25

28

3

26

1

4

2

SEL

3

9

32

7

30

5

10

8

6

14 16

12

SEL Button Location

4 Continue pressing the SEL button until you reach the

number that is one increment higher than the desired slot

number, then hold in the SEL button until the LED

decreases one increment (to your desired number) and

stops flashing.

5 Power off the switch.

6 Repeat steps 1 through 5 for all switches in the stack.

7 Continue to “Connecting Cables to Stacking Modules”

on page 27. For a diagram showing one of many valid slot

numbering examples, refer to page 26.

March 2005 Completing a Stacked Configuration 25

Page 32

Slot Numbering Example

31

OmniSwitch 6624

TM

E

L

O

S

N

O

C

TEMP

PRI

PS1

FAN

OK1

SEC

PS2

OK2

OmniSwitch 6624

TM

E

L

O

S

N

O

C

TEMP

PRI

PS1

FAN

OK1

SEC

PS2

OK2

OmniSwitch 6624

TM

E

L

O

S

N

O

C

TEMP

PRI

PS1

FAN

OK1

SEC

PS2

OK2

OmniSwitch 6624

TM

E

L

O

S

N

O

C

TEMP

PRI

PS1

FAN

OK1

SEC

PS2

OK2

29

27

25

30

5

28

3

26

1

6

4

29

2

L

E

S

L

E

S

L

E

S

L

E

S

27

25

30

5

28

3

26

1

6

4

29

2

27

25

30

5

28

3

26

1

6

4

29

2

27

25

30

5

28

3

26

1

6

4

2

9

32 34 36

7

10

8

33

31

34

9

32

7

10

8

33

31

34

9

32

7

10

8

33

31

34

9

32

7

10

8

11

12

35

36

11

Valid Slot Assignments

The illustration at left (showing a stacked

configuration with four switches) shows one

of many valid slot numbering possibilities.

• Although the slot numbers are not

sequential (4, 5, 6, and 3), all switches

in the stack have a unique slot number.

12

35

• The top switch in the stack does not

have to be designated as slot 1; for this

example, the top switch has been

36

11

designated slot number 4.

• Because it has the lowest user-assigned

12

35

36

11

12

slot number, switch number 3 will be

given the stack’s primary management

role in this example. Switch number 4

will be given the secondary role.

Switches 5 and 6 will be given idle

status. Refer to the Hardware Users

Guide for more information.

Stack of Four Switches with Unique Slot Numbers

26 Completing a Stacked Configuration March 2005

Page 33

Connecting Cables to Stacking Modules

Guidelines

• If you have not already individually assigned slot

numbers and powered off each switch, do not connect

stacking cables to the stacking modules. Instead, refer to

“Assigning Slot Numbers” on page 25 and follow the

instructions for assigning slot numbers to each switch.

• Before attempting to connect OmniSwitch 6600 Family

switches in a stacked configuration, be sure that stacking

modules are installed in the EXPANSION/STACKING

slots of all switches. The stacking module provides two

dedicated High Speed Serial Data Connectors (HSSDCs) at

ports 27 and 28 (OS6624, OS6600-U24, OS6600-P24,

OS6602-24) or 51 and 52 (OS6648 and OS6602-48). For

detailed information on installing stacking modules, refer

to “Installing Uplink and Stacking Modules” on page 16.

• Stacking modules can only be installed in the far-right

module slot. This slot is labeled EXPANSION/STACKING and contains port positions 27 and 28 (OS6624 and

6600-U24) or 51 and 52 (OS6648).

• Do not attempt to install the stacking module at the

EXPANSION slot at port positions 25 and 26 (OS6624,

OS6600-U24, OS6600-P24, OS6602-24) or 49 and 50

(OS6648 and OS6602-48).

• Port numbers are clearly marked on the chassis front

panel.

1 Starting from the top of the stack, attach one end of a

30 cm stacking cable to a High Speed Serial Data

Connector (HSSDC) located on the switch’s stacking

module, as shown.

52

EXPANSION/STACKING

51

LINK/ACT

LINK/ACT

Attaching the Stacking Cable to a Stacking Module

March 2005 Completing a Stacked Configuration 27

Page 34

2 Attach the other end of the cable to a HSSDC connec-

tor on the switch immediately below. Repeat this procedure until all switches in the stack are connected (see

illustrations a, b, and c below).

3 To provide added resiliency and redundancy, it is

strongly recommended that you install the optional onemeter stacking cable to connect the top switch in the stack

to the bottom switch. Connect the unused HSSDC stacking connectors located at ports 27 and 28 (OS6624,

OS6600-U24, OS6600-P24, OS6602-24) or 51 and 52

(OS6648 and OS6602-28) of each switch, as shown.

PA

X

E

51

PA

X

E

51

PA

X

E

51

PA

X

E

51 52

a

G

IN

K

C

A

T

52

/S

N

IO

S

N

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

52

/S

N

IO

S

N

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

S

52

/

N

IO

S

N

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

S

/

N

IO

S

N

LINK/ACT

LINK/ACT

N

A

P

X

E

51

LINK/ACT

N

A

P

X

E

51

LINK/ACT

N

A

P

X

E

51

LINK/ACT

N

A

P

X

E

51 52

LINK/ACT

G

IN

K

C

A

T

S

52

/

N

IO

S

LINK/ACT

G

N

I

K

C

A

T

S

52

/

N

IO

S

LINK/ACT

G

IN

K

C

A

T

S

52

/

N

IO

S

LINK/ACT

G

IN

K

C

A

T

S

/

N

IO

S

LINK/ACT

b

N

A

P

X

E

51

N

A

P

X

E

51

N

A

P

X

E

51

N

A

P

X

E

51 52

c

G

IN

K

C

A

T

S

52

/

N

IO

S

LINK/ACT

LINK/ACT

G

N

I

K

C

A

T

S

52

/

N

IO

S

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

S

52

/

N

O

I

S

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

S

/

N

O

I

S

LINK/ACT

LINK/ACT

Connecting the Switches in the Stack

Note. There are no restrictions on which HSSDC stacking

ports must be connected. For example, a stacking cable

connected to port 51 on an OS6648 may be connected to

either port 51 or port 52 on the OS6648 immediately

below. However, for easier management, it is recommended that you keep a consistent pattern for all switches

in the stack.

Note. The one-meter stacking cable is available with

Alcatel’s optional Redundant Stacking Kit.

G

IN

K

C

A

T

2

5

/S

N

IO

S

N

PA

X

E

1

5

LINK/ACT

LINK/ACT

G

IN

K

C

A

T

2

5

/S

N

IO

S

N

XPA

E

CT

51

LINK/A

LINK/ACT

G

IN

K

C

A

T

2

S

5

/

N

IO

S

N

PA

EX

51

K/ACT

LIN

LINK/ACT

G

IN

K

C

A

T

2

/S

N

IO

S

N

XPA

E

51 5

LINK/ACT

LINK/ACT

d

Recommended Redundant Connection Between Switches

28 Completing a Stacked Configuration March 2005

Page 35

4 Now that all switches in the stack are connected,

continue to “Booting the Stack” on page 29.

Booting the Stack

In order for the switches in the stack to operate using their

newly-assigned slot numbers, all switches in the stack must be

manually booted. To manually boot the stack, follow the steps

below.

1 Power on all switches by moving the on/off switch for

each switch to the on ( | ) position.

3 After you have booted the stack and powered on all

back up power supplies (if applicable), continue to

“Verifying LED Status” on page 30.

Booting Stand-Alone Switches

1 To boot a single, stand-alone switch, simply move the

on/off switch for each switch to the on ( | ) position. This

switch is located on the rear panel of the switch, next to

the power cord socket.

Important. Be sure to power on all switches in the stack

in rapid succession. If you do not power up all switches

within approximately three seconds, switches may take

unintended stack management roles.

After the stack is completely booted, all switches in the

stack will operate with the user-assigned slot numbers.

Automatic Software Synchronization. In order to ensure

effective redundancy within a stacked configuration, the

primary switch will automatically distribute its system and

configuration software to all switches in the stack as the

virtual chassis boots.

2 If back up power supplies are installed in one or more

switches in the stack, power on all back up power supplies

at this time.

March 2005 Completing a Stacked Configuration 29

Note. Because the switch’s default slot number is 8, the

slot indicator LED displays “8” when the switch is first

booted.

2 If the stand-alone switch has a back up power supply

installed, you may power on this unit as well. Move the

on/off switch for the back up power supply to the on ( | )

position.

3 After you have booted the stand-alone switch and

powered on the back up power supply (if applicable),

continue to “Verifying LED Status” on page 30. This

section provides information on LED states and switch

status both during and after the boot process.

Page 36

Verifying LED Status

Component LEDs

The boot process takes a few moments to complete. During

this process, the LEDs on the switch’s front panel may flash

and change color, indicating different stages of the boot.

Following a successful boot, the LEDs should display as

follows:

OK1 Solid Green

OK2 Blinking Green

PS1 Solid Green

PS2 Solid Green (if back up power supply is

installed). Amber if no back up power supply is installed or if a back up power supply

error has occurred.

PRI Solid Green (if the switch is either a stand-

alone switch or the primary switch in a

stack; otherwise, if the switch status is secondary or idle, this LED is off)

SEC Solid Green (if the switch is the secondary

switch in a stack; otherwise, this LED is

off)

TEMP Solid Green

FAN Solid Green

If the LEDs do not display as indicated, make sure the boot