Page 1

ASM 142

/

142

D

ASM

GRAPH

HELIUM LEAK DETECTOR

/

GRAPH

D

/

GRAPH D+

User’s

Manual

Page 2

Gb 02834

-

Edition

04

-

Feb

08

Alcatel Vacuum Technology,

Lucent

Group, has been supplying

helium and hydrogen leak detection

plasma sensors, vacuum measurement for severa

as

part of the Alcatel-

vacuum pumps,

systems

,

l

years.

Thanks

company

multiple

&

Alcatel Vacuum

Adixen, i

to its

complete range of products, the

has

become an essential player in

a

pplications : inst

D

eve

lopement, industry

rumentation, Research

and semic

Technology has

ts new brand name, in recognition o

onductors

launched

.

f

the company’s international standing in vacuum

sit

ion.

po

ISO

With both

Frenc

the

in

the high

h company

service

est

9001 and 14001 certifications,

is

an acknowlegded expert

and support, and

quality and

Adixen products have

environmental standards.

With 45

presence,

a whole host

and agents

The first step was

P

roducts

years

Fre

In Europe, AVTF-France hea

Alcatel

Technology

Benelux (Netherlands), Alcatel Vacuum Systems (Italy

and more recently Adixen Sensistor

2007)

etw

n

In Asia,

Vacuum Technology (Japan),

with Al

Vacuum

Technology Singapore, Alcatel Vacuum Technolog

Sha

This

epresensatives based

r

Thus,

produ

specialists in

years

of

experience, AVT

through its

of

experienced subsidiaries, dist

international network that includes

today

has a w

.

the founding of Alcatel Vacuum

(Hingham- MA)

ago,

mont

(CA)

reinforced

and

Tempe (AZ)

in the United States, t

today by 2 others

.

US subsidiaries

dquarters and its subs

Hochvakuumtechnik (Germany),

Alcatel Vacuum

UK (Scotland), Alcatel Vacuum Technolog

AB

in Sweden (in

form the foundation for the European partner

ork.

our

presence starte

d in 1993 with Alcatel

and has been strengthene

catel

Vacuum Technology Korea (in 1995),

Technology Taiwan (in 2001),

nghai

(China) (in

organization

2004).

is

rounded off by more than 40

in a variety

whatever the circumstances, the

cts

can

always

rely on quick support of our

of continents

Alcatel Vacuum

users

Vacuum Technology.

orldwid

ributor

hirty

in

idiaries

Alcatel

.

of Adixen

e

s

,

y

)

d

y

Page 3

A very wide range of helium leak

GB 00204 -

Edition

05 -

September

06

detectors

Dear customer,

You have just bought an

Adixen leak detector.

We would like to thank you

and we are proud to count

you among our customers.

This

product is a result of

the experience acquired

over 35 years by Alcatel

Vacuum

Technology France

in vacuum and leak

detection technology.

The applications of helium

leak testing are extremely

diversified ranging from

high-tech

installation

maintenance to highspeed testing of industrial

products.

Each product of the Adixen

detector range is designed

to meet the specific needs

of each application:

•

portability,

•

high sensitivity,

•

pumping capacity,

•

pumping type,

•

automation and

integration in an industrial

process.

1/2

Page 4

A very wide range of helium leak

GB 00204 -

Edition

05 -

September

06

detectors

This

product

complies

with the

requirements

of

European

Directives,

listed in the Declaration of Conformity contained in G100 of this

manual.

(E.C.

The

in German,

These Directives

Marking).

Declaration of Conformity and

Spanish,

are

Italian,

amended

by

Directive

Safety Instructions

Portuguese, Dutch

93/68/E.E.C

are available

and Danish

languages at the end of this manual.

Copyright/Intellectual property:

The use

property rights in force in any jurisdiction.

All rights

any part without prior written authorization from Alcatel Vacuum

T

echnology

of Adixen

reserved,

France.

products

are

subject

including copying this

to copyright and intellectual

document

in whole or

Specifications

by from Alcatel

2/2

and information are

Vacuum Technology

subject

France.

to

change

without notice

Page 5

M

anual reference

: 107817

ASM GRAPH D+: L0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

D

ASM GRAPH

D+

User’s

Manual

GB 00205 -

Edition

07 - March 09

e

dition

:

07 - March 2009

Software version:

ASM

142/ASM GRAPH

L

0088

v3.1 r

ASM

142 D/ASM GRAPH D/

Alcatel Vacuum Technology France - User’s

:

.02

Preliminary

remarks

Chapter

Chapter B

Chapter C

ASM GRAPH - ASM GRAPH

Throughout

“Summary of screen

User’s

A

Manual ASM

Manual.

A 100 - Introduction

A 200

A 201

A 202

A 300

A 400

A 401

A 500

A 600

A 700

A 800

A 801

A 900

A 901

B

100 - Safety instructions

B

110 - Unpacking - Storage - T

B

200 - Neutral gas purge and inlet vent connection

B

201 - Neutral gas purge installation (accessory)

B

210 - Connecting the

B

211 - Connecting the

B

300 - Controlling the

B

310 - Controlling the

B

320 - Connecting the

B

400 - Before

C

100 - Factory

C

110 - Operating principle of the control panel

C

120 - Setting

C

130 - Access

C

140 - Summary

C

200 - Starting up / Switching off the leak detector

C

210 - How to

C

211 - Operation of the leak detector

C

300 - Calibration of the leak detector

C

301 - Basic

C

302 - Advanced internal calibration of the leak detector

C

303 - External

C

304 - Correction factor

C

305 - Calibrated leak

C

306 - Adaptor for calibrated leak in sniffing mode

C

400 - Remote

C

410 - Headphone and loudspeaker

C

430 - 3

C

440 - Control panel with graphic interface

C

450 - Long

this

User’s

Please

-

ASM 142 - Detector

-

ASM 142 D - Detector

-

ASM 142 Graph D+ - Detector

-

Analyzer cell operating principle

-

Testing

methods

-

About Helium and Hydrogen

-

Operator interface: control panel

-

Options

-

Accessories

-

ASM 142 - T

-

ASM 142 D - ASM Graph D+ - T

-

Dimensions

-

Dimensions

starting up the leak detector

and

to level

internal calibration of the leak detector

masses

distance sniffer probe and Helium spray gun

142/142

D - ASM

Manual, you could find this type of message

C

140”: it

read it for further information.

to the ASM 142 series

operating principle

operating principle

operating principle

echnical

ASM Graph D+

configuration of the leak

maintenance

of screens

use

the leak detector: 2 methods

calibration of the leak detector

control

option

characteristics

echnical

ransportation

detector

detector

detector

detector

detector

to the installation

to the installation: ASM graph D+

with the I/O interface

with a

PC computer

directly to a printer or another device

detector

part

presentation

4

-

Password

values

programming

GRAPH/GRAPH D/GRAPH

refers

to a specific chapter of the

INTRODUCTION

characteristics

through the

parameters

of the control panel

D+

RS

232 interface

INSTALLA

OPERA

TION

TION

1/3

Page 6

M

anual reference

: 107817

ASM GRAPH D+: L0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

D

ASM GRAPH

D+

User’s

Manual

GB 00205 -

Edition

07 - March 09

e

dition

:

07 - March 2009

Software version:

ASM

142/ASM GRAPH

L

0088

v3.1 r

ASM

142 D/ASM GRAPH D/

2/3

:

.02

Chapter

Chapter E

Chapitre F

ASM GRAPH - ASM GRAPH

C

500 - Inlet vent

C

510 - Bargraph zoom

C

520 - Audio alarm/Digital voice

C

530 - Cycle end

C

540 - Zero function

C

550 - Memo function

C

560 - Helium pollution prevention

C

570 - Date - Time - Language - Unit

C

580 - Fault / information indicator and display

D

D 100 - T

D 200

D 300

D 300/D 400

D 400

able of

preventive maintenance

-

Maintenance message

-

General

-

Symptoms

troubleshooting

-

General

description

E

100 - Maintenance operations introduction

E

110 - ASM 142 / ASM 142

E

111 - ASM 142 D - ASM Graph D+ - Access

E

120 - Sending the leak detection for reparation to a

E

400 - Basic maintenance

E

530 - Valves

E

560 - Replacement

E

600 - Remote

E

610 - Long

E

710 - Primary

E

730 - Starting of the

E

740 - Greasing

E

750 - Primary

F

000 - Spare

F

001 - AVTF Customer Service

F

100 - T

F

200 - Monitoring and display

F

300 - Power and electrical supply

F

400 - Automatic control

F

500 - Measurement

F

600 - ASM 142 - Pumping

F

600 - ASM 142 D - Pumping

F

700 - Valves

F

800 - ASM 142 - Pipes - Connections - Seals

F

800 - ASM 142 D - Pipes - Connections - Seals

F

900 - Cover

F

1000 - Options - Accessories

F

1100 - Pictures

Alcatel Vacuum Technology France - User’s

installation and maintenance

of the internal calibrated leak

control

distance sniffer probe and Helium spray gun

pump

maintenance (AMD1)

molecular

molecular

pump maintenance

parts instructions

ools

of components

guide

troubleshooting

S -

Access

of the analyzer cell

and

turbomolecular

and

turbomolecular

of use

Offer

system

and

electronic

Manual ASM

MAINTENANCE - TROUBLESHOOTING

intervals

guide/Symptoms description

MAINTENANCE

to internal components

to the internal components

service

center

pumps

pumps

SHEETS

COMPONENTS

circuits

142/142

D - ASM

GRAPH/GRAPH D/GRAPH

D+

Page 7

M

anual reference

: 107817

ASM GRAPH D+: L0114

v3.1 r

.02

General

contents

ASM

142 -

ASM

142 D

D

ASM GRAPH

D+

User’s

Manual

GB 00205 -

Edition

07 - March 09

e

dition

:

07 - March 2009

Software version:

ASM

142/ASM GRAPH

L

0088

v3.1 r

ASM

142 D/ASM GRAPH D/

Alcatel Vacuum Technology France - User’s

:

.02

Chapter

ASM GRAPH - ASM GRAPH

G APPENDIX

G 100 - Declaration of

G 200

-

ASM 142 - Wiring

G 201

-

ASM 142 D - Wiring

G 300

-

Analog

G 400

-

Long

distance sniffer probe

G 500

-

Helium spray gun

G 600

-

Safety

G 800

- Tools

Indicates

confor

mity

output

questionnaire

diagrams

user manual

diagrams

user

manual

a potentially hazardous situation which, if not avoided,

could result in property damage.

CAUTION

CAUTION

Indicates

could result immoderate or minor injury. It may also be

against unsafe practices.

Indicates

could result in death or

a potentially hazardous situation which, if not avoided,

used

to alert

a potentially hazardous situation which, if not avoided,

severe

injury.

Indicated an imminently hazardous situation that, if not avoided,

W

ARNING

Manual ASM

will result in death or

142/142

D - ASM

GRAPH/GRAPH D/GRAPH

severe

injury

(extreme

D+

situations).

3/3

Page 8

Introduction

A

ASM

GRAPH

- ASM

GRAPH

D

GB 00206 -

Edition

03 -

June

08

Preliminary

remarks

ASM 142 - ASM 142 D

ASM

GRAPH

D+

Detailed contents

Throughout

“Summary of screen

User’s

this

Manual.

User’s

Please

Manual, you could find this type of message

read it for further information.

C

140”: it

User’s

refers

to a specific chapter of the

Manual

A 100

-

A 200 ASM 142 -

A 201 ASM 142 D -

A 202 ASM 142 Graph D+ -

A

300

A

400

A 401 About Helium and hydrogen

A 500 Operator interface : control panel

A new generation of Adixen helium leak detector

-

Vacuum

-

Stand-by

-

Roughing

-

Gross leak

-

Normal

-

Sniffing

-

Vacuum

-

Stand-by

-

Roughing

-

Gross leak

-

Normal

-

Sniffing

-

Vacuum

-

Stand-by

-

Roughing

-

Gross leak

-

Normal

-

Sniffing

-

Description

-

Design and manufacture

-

Overview

-

Helium

-

Spray method (inboard testing)

-

Sniffer method (outboard testing)

-

Bombing method

-

Helium

-

Helium and leak detection: which purity?

-

Hydrogen

circuit

mode

mode

test

mode

test

mode

test

mode

circuit

mode

mode

test

mode

test

mode

test

mode

circuit

mode

mode

test

mode

test

mode

test

mode

concentration

and signal displayed

Introduction

Detector

Detector

Detector

Analyzer cell

to the ASM 142 series

operating principle

operating principle

operating principle

operating

principle

T

esting methods

1/2

Page 9

Introduction

A

ASM

GRAPH

- ASM

GRAPH

D

GB 00206 -

Edition

03 -

June

08

ASM 142 - ASM 142 D

ASM

GRAPH

Detailed

D+

contents

User’s

Manual

A 600 Options

-

Which options for which model?

-

Metal

seals

-

Inlet port

-

Units

-

Languages

-

3 masses

-

Automatic

-

Roughing system

-

Interface

-

Remote

- Test

-

Stainless steel

-

Control panel with graphic interface

-

Control panel racks

-

Sniffing

-

Cables

test

chambers

board

control cable length

of gas

line

cover

lengths

(UCT)

A 700

-

Which

-

-

-

-

- Transport

-

-

-

-

-

-

-

-

-

- Test

-

-

-

-

-

-

-

-

-

accessories

Remote

control

Long Distance

10 m/30 feet

Headphone

cart

Foot pedal for cycle

Calibrated Helium leaks

Calibration

Spray probe

Inlet adaptor

Printer

Inlet filters

Short

distance sniffer probe (to be

Bombing chamber

chambers

Neutral gas vent line kit

4 swiveling

Covered sniffer probe and

Bottle

handle for cart

Built-in

mini-printer

2005 IS

Pressure measurement

Ventilation

Bottle

Pump

Kit

handle for cart

for which model?

Sniffer probe

LDS

extension

connector

command

accessory

wheels

kit (Ø125 mm)

kit

(1.5 m/5 feet)

connected

remote

control kit

to the inlet part of a leak detector)

Accessories

A 800 ASM 142 - Technical characteristics

2/2

A 801 ASM 142 D - ASM Graph D+ - Technical characteristics

A 900

A 901

Dimensions

Dimensions

- ASM Graph D+

Page 10

A

100

x

GB 00207

-

Edition 04

- June

08

A new generation

Adixen helium

Model photographed:

ASM

142

of

leak

detector

Introduction to the ASM 142 series

The

ASM

142/142 D/142

ASM

Graph D+ are

performance standards

These detectors

utilizing the

make them

high

performances, such

a roughing capacity of 7 CFM

(60 l/mn) with a usable helium

sensitivity

sec range.

high

a dry roughing capacity of 0.9

CFM

helium sensitivity

atm.cc/sec

a

in the

10

auto-zero

with two

for the operation of the unit,

the

parameters).

operator in his daily

(auto-calibration,

helium

...).

very rugged

field-proven components,

makes

environment.

reinforce

product (remote control,

probe).

totally dry leak detector.

specific to sniffing

applications.

graphic interface.

in the

performances, such

(1.5 m3/h) with a usable

range.

usable helium sensitivity

-7

atm.cc/sec

function).

comprehensive

distinct

other

for

evolved features

signal direct readout,

it ideal for any industrial

various accessories

the

We

your

are the

latest electronics technologies

a truly

-11

10

in the 10

range (with

control panel

areas (one

entering

to assist

operation

auto-zero,

design, based on

versatility

suggest

detector

complete

universal helium

universal

as,

atm.cc/

as,

-11

the

test

the

which

to

of the

sniffer

test mode

that you read this manual before you start to use

satisfaction.

S/ASM Graph/ASM Graph

leak

detectors

for

multi-purpose

end-result

of an

unit.

innovative engineering

and

unit:

ASM

142

x

x

x

x

x

to obtain optimum

ASM

Graph

ASM

142 D

x

x

x

x

x

x

levels

which

vacuum concepts,

ASM

Graph

x

x

x

x

x

x

of

performance

D/

set

new

approach

which

ASM

D

142 S

x

x

x

x

x

x

x

x

x

x

x

x

ASM

Graph

D+

x

x

x

x

x

x

x

and

1/1

Page 11

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

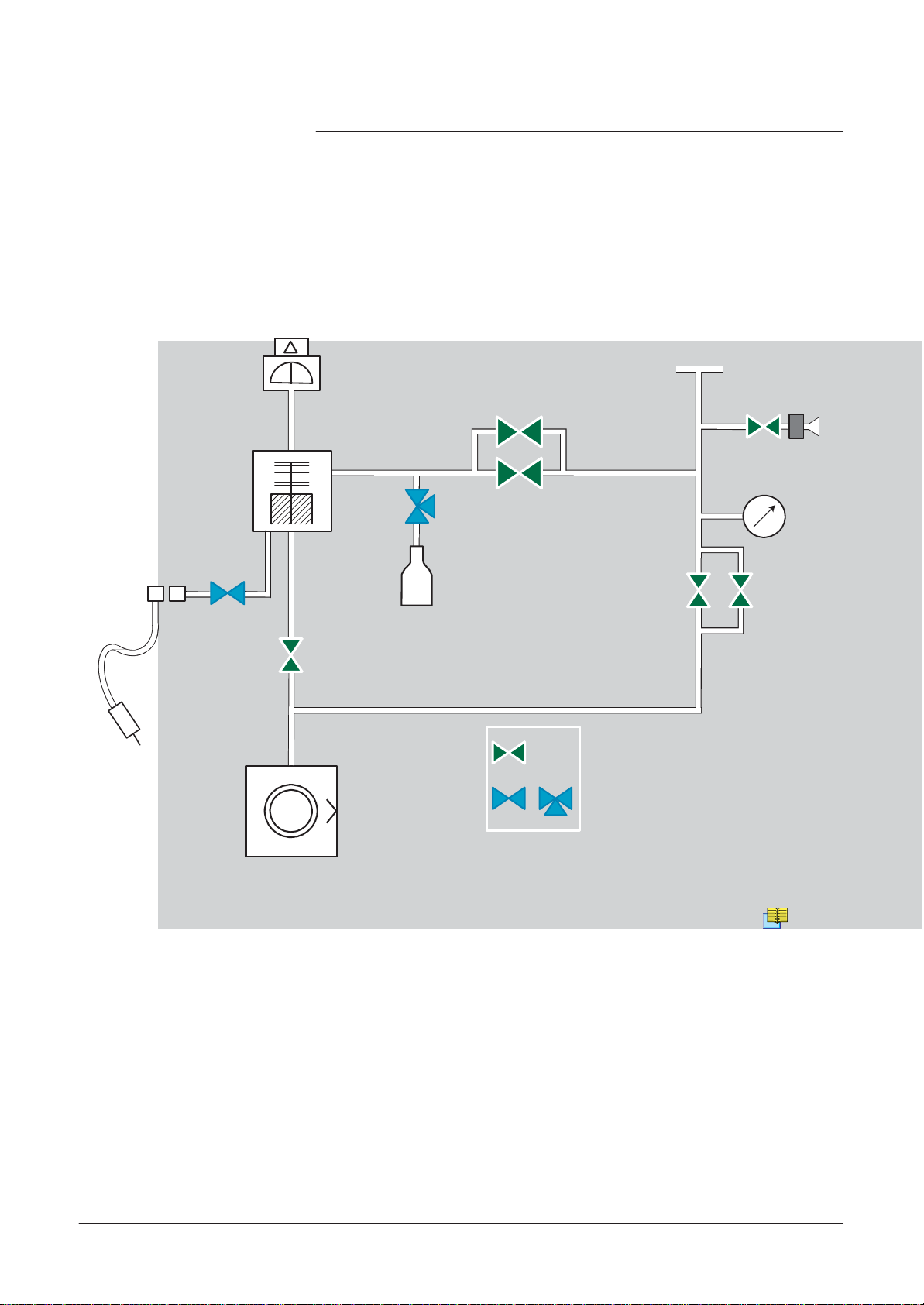

Vacuum

circuit

1

2

V

T3

18

V

C

V

T2

V

S

8

4

3

VA1 7

R1 VR2

V

5

15

VT1

Bacosol

Minisol valves

valve

Reference correspondence between valve/vacuum block marks

1 Preamplifier

2 Analyzer cell

3

Detector

inlet port

4 Internal calibrated leak

5 Inlet

pressure

gauge

7 Vent connector

Long

8

15

18

distance sniffer connector

Roughing

primary pump

Detection molecular

(RVP

20 0)

pump (AMP

007I)

A1 Inlet vent valve (6 points)

V

R1

V

R2

V

T1

V

T2

V

T3

V

V

S

Sniffing valve (9 points)

V

C

Calibration valve (7 points)

Roughing

Roughing

Exhaust

Detection

Detection

valve ( point)

valve (2 points)

valve (3 points)

valve (4 points)

valve (5 points)

E

530

/4

Page 12

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

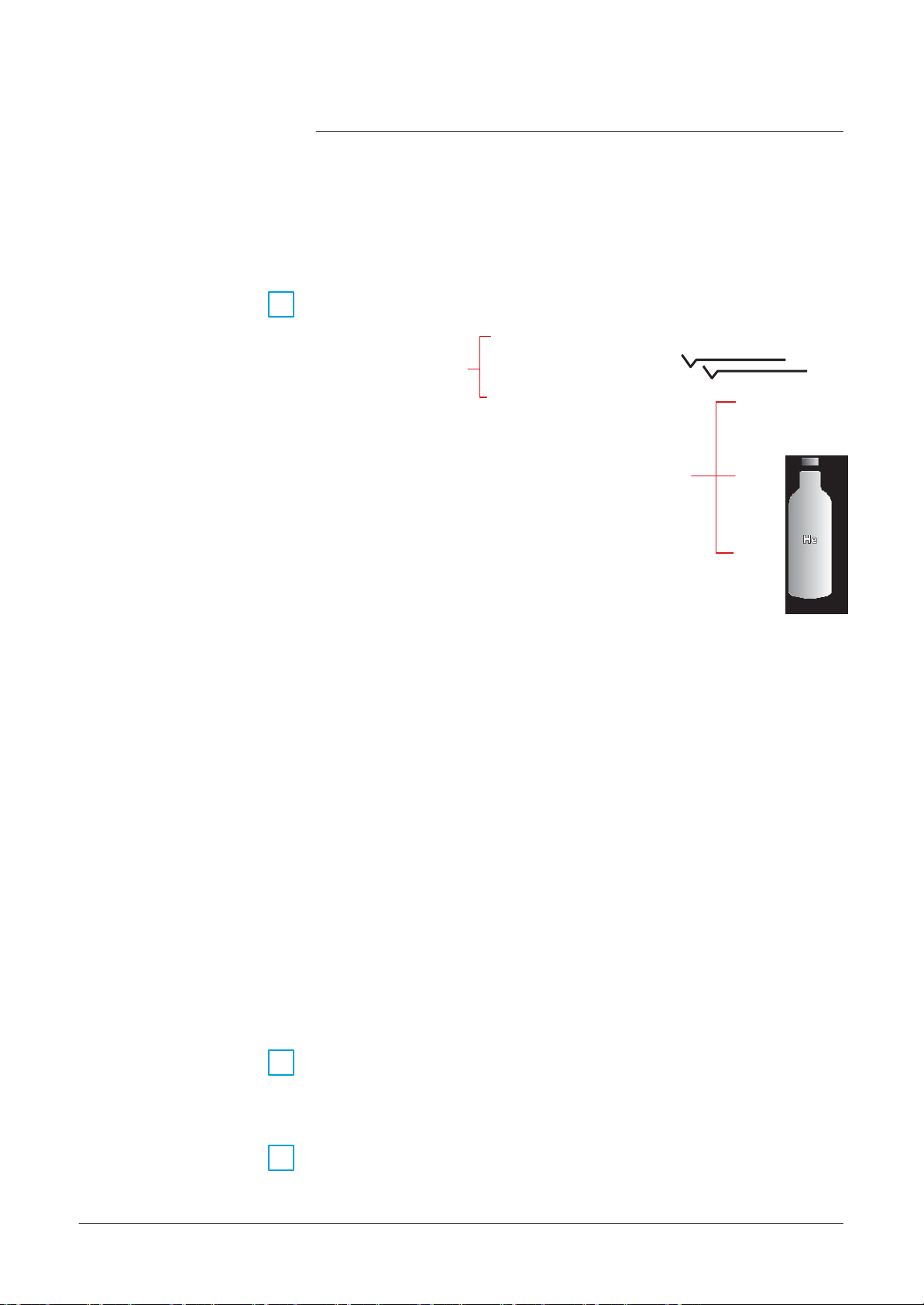

(Patm

Stand-by mode

Roughing

mode

to 10 mbar inlet

18

1

2

3

VA1 7

V

T1

15

3

pressure)

2/4

15

5

V

R1

VR2

Page 13

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Gross

leak

test

(10 mbar to

5x10

inlet

-1

pressure)

mode

mbar

1

2

18

3

VR1

VR2

5

VT1

15

V

3

T3

1

2

Normal

(lower than

5x10

test

-1

mode

mbar

18

VT1

VT2

5

inlet

pressure)

15

3/4

Page 14

A

200

ASM 142 detector operating principle

GB 00208

-

Edition 03

- June

08

Sniffing

test

mode

1

3

2

VA1

7

18

8 V

S

4/4

VT1

15

Page 15

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

2

Analyzer cell

V

Roughing

valve (1 point)

3

Detector

inlet port

V

Roughing

valve (2 points)

4

Internal calibrated leak

V

Exhaust

valve (3 points)

V

Detection

valve (4 points)

Vent connector

V

Detection

valve (5 points)

8

Long

distance sniffer connector

V

Sniffing valve (9 points)

10

Outlet pump connector

V

Calibration valve (7 points)

15

Roughing

pump (AMD1)

16

Roughing molecular

pump

18

Detection molecular pump (AMP

007I)

Vacuum

circuit

18

8

V

S

1

2

V

T3

V

C

4

V

T2

VT1

3

VA1 7

V

R1

5

VR2

15

10 12

16

Bacosol

valve

Minisol valves

Reference correspondence between valve/vacuum block marks

E

530

Preamplifier

1

Inlet

Purge

(MDP

pressure

filter

5006 HDS)

5

7

12

gauge

V

A1

R1

R2

T1

T2

T3

S

C

Inlet vent valve (6 points)

1/4

Page 16

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Stand-by mode

1

2

18

V

T1

3

VA1 7

(Patm

Roughing

mode

to 10 mbar inlet

16

pressure)

16

15

15

3

5

V

R1

VR2

2/4

Page 17

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

18

1

2

V

T1

VR1 VR2

3

5

Gross

leak

test

mode

(10 mbar to

5x10

-1

mbar

inlet pressure)

16

1

2

V

T2

15

3

18

test

Normal

mode

(lower than

-1

5x10

inlet

mbar

pressure)

16

V

T1

T3

V

15

5

3/4

Page 18

A

201

ASM 142 D detector operating principle

GB 01476

-

Edition 03

- June

08

Sniffing

4/4

test

mode

1

2

18

V

S

8

V

T1

16

15

3

VA1 7

Page 19

A

202

principle

GB 03710

-

Edition 01

- June

08

2

Analyzer cell

V

Roughing

valve (1 point)

Detector

inlet port

Roughing

valve (2 points)

4

Internal calibrated leak

V

Exhaust

valve (3 points)

5

Inlet

pressure

gauge

V

Detection

valve (4 points)

Sniffing valve (9 points)

10

Outlet pump connector

V

Calibration valve (7 points)

12

Purge

filter

15

Roughing

primary pump

(ACP 15)

Detection molecular pump (AMP

007I)

ASM 142 Graph D+ detector operating

Vacuum

circuit

18

8

10 12

V

S

1

2

V

T3

V

C

4

V

T2

VT1

15

16

Reference correspondence between valve/vacuum block marks

3

VA1 7

R1

V

5

VR2

Bacosol

valve

Minisol valves

E

530

Preamplifier

1

3

Vent connector

7

Long

8

16

18

distance sniffer connector

Roughing molecular

(MDP

5006 HDS)

pump

V

A1

R1

V

R2

T1

T2

V

T3

V

S

C

Inlet vent valve (6 points)

Detection

valve (5 points)

1/4

Page 20

A

202

principle

GB 03710

-

Edition 01

- June

08

ASM 142 Graph D+ detector operating

Stand-by mode

1

2

18

V

T1

Roughing

(Inlet pressure:

mode

Patm

16

15

to 10 mbar)

16

2/4

15

3

VA1 7

3

5

V

R1

VR2

Page 21

A

202

principle

GB 03710

-

Edition 01

- June

08

5

ASM 142 Graph D+ detector operating

18

16

18

16

1

1

2

V

T1

2

V

T1

3

VR1 VR2

15

3

V

T2

V

T3

15

5

3/4

Gross

leak

(Inlet

test

pressure:

10 mbar to

5x10

-1

mode

mbar)

Normal

(Inlet pressure:

than 5x10

test mode

lower

-1

mbar)

Page 22

A

202

principle

GB 03710

-

Edition 01

- June

08

ASM 142 Graph D+ detector operating

Sniffing

4/4

test

mode

1

2

18

V

S

8

V

T1

16

15

3

VA1 7

Page 23

A

300

Analyzer cell

operating principle

GB

00007

-

Edition 03

-

September

04

Description

The

analyzer

cell works on the principle of mass spectrometry and is

set to the mass of helium (m/e =

4).

m/e

= atomic mass of the

ionization

particle/number

of electrons lost

on

The principle of magnetic deflexion spectrometry is as follows. The

neutral molecules of the gas being

chamber

beam

(or source of ions) where they are

generated

by

a heated

molecules are transformed into

analyzed

tungsten filament. A

ions.

pass into an

bombarded

large

ionization

by an

electron

number of the

�

He

He

�

�

He

������

���

6

Leak Signal

��������������� ���

�

�

������������������

����������������������

��

���������

��

�����������������

��

������������������

�������������������

�������������������

��������������

������������

�����������

He

������������

Analyzer cell

-

functional

diagram

1/3

Page 24

A

300

Analyzer cell

operating principle

GB

00007

-

Edition 03

-

September

04

Description (continued)

These ionized particles are

accelerated

by an electrical

field.

The entire

property of deflecting the trajectories of the ions along different

according

to their

different masses, is divided into several

only ions with the same

separated

ions (N2+ or

analyzer

to the masses of those ions (to be more

m/e

ratios). Thus the ions

cell is subject to a magnetic field which has

precised, according

beam,

m/e

ratio. The helium ions (m/e = 4)

which

beams,

contained

each

from the lighter (H2+ or H1+, smaller beams) or

O2+,

small

beams).

ions with

containing

heavier

the

curves

are

Because there is a constant magnetic field

accelerator

= 4) follow

electrical field is adjusted so that the helium ions

a pre-determined

trajectory (passing through

and arrive on the target at the input to

(permanent

a

direct current

magnet),

(m/e

diaphragms)

amplifier.

the

The current of helium ions is

helium in the installation and by measuring it we can find the flow

rate of the leak that has been

proportional

detected.

to the partial pressure of

It

is essential that the total pressure in the

-4

10

mbar, so that the trajectories of the electrons and the ions are

disturbed by residual

Around

-3

10

mbar there is a risk of

molecules.

analyzer

damaging

cell is less

the

heated filament.

than

not

In order to

«stray ions», an electrode located in front of the target

the

secondary

«braking electrode».

separate

ions with low

the helium ions from «noise» caused by

eliminates

energies.

This electrode is called

the

There is an auxiliary electrode at the top of the cell,

a

plate, which collects the ions that are heavier than helium. This

electrode thus

measures

electrode serves as the plate for

«triode

2/3

electrode».

the total pressure in the

a

triode

gauge,

shaped like

analyzer.

This

hence its name of

Page 25

A

300

Analyzer cell

operating principle

GB

00007

-

Edition 03

-

September

04

Design

manufacture

and

Great care has been taken with the design and manufacture of

the cell in order to

and to achieve excellent stability:

– the metal parts are made of stainless

– the filament holder is made of

– there is an integral

repeatedly

amplifier.

obtain the same

steel,

machined aluminium,

characteristics

The cell assembly is

a

vacuum

–

– an optic holder

a permanent magnet,

–

amplifier.

– an

chamber

composed of:

or deflection

flange,

chamber,

•

The vacuum

The analysis cell vacuum

hollow with

(that are installed on the «optics holder» flange) are

chamber:

a rectangular opening

chamber

is made of light alloy.

into which the

electrodes,

placed.

It

is

•

The optics holder

The optics holder flange supports all the electrodes and

connections in the cell. They

– the sealed power supply socket, mounted on

– the amplifier, mounted on an elastomer

vthe supporting block which screens the target and on which

source of ions is

– the source of ions, which is made up of 2

• a

filament

•

an ionization

and a mass ion emitter.

holder,

flange:

mounted,

chamber

include:

with a stainless steel electron

gasket,

par

a

ts:

metal

electrical

gasket,

the

collector

The filament holder

with respect to the ionization

mechanically

chamber.

positions the tungsten filament

The electron collector and the filament have been

and positioned so that the

stabilizes at

filament. The cell is thus

the pieces being tested without the need of any special

system.

400°C

under

temperature

bombardment

rendered

of the electron

and

immune to

designed

collector

radiation

contamination

from

heating

the

from

3/3

Page 26

A

400

T

esting methods

GB

00008

-

Edition 05

-

February

02

Over

view

Leak detection is used to detect

micro-openings,

parts. The detection of these cracks involves the use of

gas, which is

capable

of infiltrating the smallest leak quickly: Helium.

porosities, etc. in test

a

light

tracer

The detector samples and measures the helium flow rate entering

test part via the

leak(s).

the

The testing method is selected

measurement accuracy required:

no

The part can be

connected to

The part is

sealed

an evacuation line

yes

Its

characteristics

allow it to

evacuated

be

yes

10

-1

mbar.

SPRAY

laeak rate

to

locating the

method

measurement

l/s

and possibility of

leak.

from

10

-10

no

Minimum

mbar.l/s

the

Its

characteristics

allow it to

pressurized

or

a

mixture

helium

SNIFFING

detectable

and possibility of

leak.

with helium

containing

yes

method

leak of

be

locating

according

-6

10

to the test part and

Its

characteristics

allow it to be

in

a vacuum

vessel

BOMBING

The sensitivity is limited by

internal dead

well as on the bombing time and

pressurization value.

Global test without possible

of the

leak.

volume of the part

the

placed

yes

method

the

location

as

the

1/4

Page 27

A

400

T

esting methods

GB

00008

-

Edition 05

-

February

02

Helium

and signal

(inboard testing)

2/4

concentration

displayed

Spray

method

Response time

In

leak

accordance

detection,

to the He

the signal

concentration

displayed

will

rate in the gas used for

change.

Example: signal

100

(with

% He in the gas

Signal

displayed

on the leak

This involves removing air from the test part,

analyzer

detector

and then

He

The part is

% He)

used

Global

part

placed

displayed

connected

1x10

spraying

test

under

with

a 1x10

to the detector inlet.

100 % 10 % 1 %

-7

mbar

.l/s

helium over the outer sur

detector

a

cover, into which helium is

injected.

The leak cannot be

located.

The detector measures the flow of helium

When

on the

there is

spraying

analyzer:

a response

starts, the leak signal is not

time which

depends

and the helium pumping speed S of the system at the

part,

according

T

= V/S

T

is the time required for the signal to reach 63 % of the final

to the following

(T

in

seconds,

relation:

V in litres, S in

-7

mbar.l/s calibrated leak

1x10

-8

mbar

.l/s

connecting

Spray

or

probe

spray

He

Potential leaking

sprayed

The leak can be

on the volume V being

with

penetrating

displayed instantaneously

l/s)

face.

test

part

helium.

located.

the

opening

the

-9

1x10

mbar

it to

the

detector

areas are

part.

tested

of

value.

.l/s

the

Page 28

A

400

T

esting methods

GB

00008

-

Edition 05

-

February

02

Sniffer

(outboard testing)

method

The test part is

Distance Sniffer)

pressurized

probe,

samples the helium

with helium. The detector, via an

escaping

from the

LDS

part.

(Long

Global test

or

He

The part is

part

LDS

placed

detector

under

a

cover containing a sniffer

probe.

The leak cannot be

The helium from the

accumulates over time inside

cover. The detector

the

concentration

located.

leak

measures

of

helium.

the

Local sniffing

He

part

LDS

test

detector

The sniffer probe is moved

areas

The leak can be

The signal supplied by

analyzer

measurement

The sniffer probe only

part of the helium

from the part. The

depends

separating

of the

likely to contain

located.

is not

a direct

of the

leak.

escaping

sample

on the

distance

the leak from the tip

probe.

leaks.

the

samples

over

3/4

Page 29

A

400

T

esting methods

GB

00008

-

Edition 05

-

February

02

Bombing method

This method is used for sealed objects that cannot be

directly to the detector

(semiconductors, waterproof watches, etc.).

connected

He

The part is

placed

part

Chamber 1

in

a chamber

part

Chamber

containing

2

pressurized helium.

He

detector

The helium

The part is then removed from the

vacuum

escapes

penetrates

the part if it has

a leak.

chamber

chamber

which is

connected

to the detector. The helium

from the part through the leak and

and

placed

in

another

produces a signal.

This signal is not a direct

pressure inside the part is difficult to

important part such as: the

pressure, the internal volume, the

4/4

measurement

determine.

pressurization

aeration

of the leak as the helium

Several parts play

time, the helium

bombing

time, the size of the

leak.

an

Page 30

A

401

About Helium and hydrogen

GB 02760

-

Edition 02

- June

08

Helium

Helium is the

representing

other

elements represent

second most common element

about 23 % of the total matter. 76 % is Hydrogen.

an insignificantly small fraction of the total.

in the universe,

All

Helium was

18, 1868.

element

common

very

is actually not abundant.

during the formation of earth escaped to space. Helium is created,

deep in the earth from the radioactive decay of Uranium and Thorium

which also

discovered

volcanic

spectrum

the

discovered

The

discovery in the

its name: “helios” in Greek

in the

generates

in 1881 by

gases emanated

as already known from the sun.

by

spectroscopy

sun’s chronosphere

universe most

Since

the earth its internal heat. On earth Helium was

spectroscopy

by the mountain showed the

of it is in the

it is so light all the Helium present

in a solar eclipse on August

gave the new

means

“sun”. While Helium is

stars:

of Mount

Vesuvio

on earth it

in Italy – the

same

lines in

Helium

of Krypton and 60

are isolated from air by liquefaction and rectification

as a contrary is “extracted” from natural gas and oil wells. Helium

comes

annual world wide production is ca. 3x10

4,500 tons.

concentration

up with the natural gas and is separated and stored. The

in the

times

atmosphere

higher than

is 5

times

Xenon. The

7 m3

bigger than the one

heavier noble gases

process.

or

Helium

Helium is

is so light that

other hand there is a

to earth.

world wide

constantly

This

gives a dynamic equilibrium and is the reason for the

constant concentration

seeping up from the ground all around us, but it

almost

all of it

constant

escapes

flow of Helium from space and the sun

into space fairly rapidly. On the

of ca. 5 ppm Helium in

air.

Helium is a very light

gases;

it is the

most

colorless element

difficult gas to liquefy.

and it is one of the six noble

Helium is a noble gas, which

all practical

protect things from oxidation – and of

gas.

intents

and

means

purposes. It’s used

it doesn’t react with anything for

course

as an inert shield gas to

as leak detection tracer

Helium is a 100 % green gas and has

impact on the atmosphere.

absolutely

no environmental

1/2

Page 31

A

401

About Helium and hydrogen

GB 02760

-

Edition 02

- June

08

Helium and

detection:

which purity ?

leak

Helium is available in many different purity

purity is

requested

from

some

laboratories for

very accurate analyses.

The use

doesn’t require

is enough

of the Helium as a tracer gas into a

such

attention. A purity in the range of 97 % to 99 %

.

levels,

the

fundamental

mass

spectrometer

highest

activities or

level of

There

is

absolutely

Hydrogen

cell analyzer by using standard purity level of Helium gas.

Hydrogen (H2) is the

of 0.0695 and a boiling point of -423 °F (-252.8 °C) at atmospheric

pressure.

It is a

concentrations

several methods,

of ammonia, and recovery from

manufacturing

transported

as a gas or a cryogenic

Hydrogen is flammable in the

air or oxygen and can detonate in the range 18 % to 60 % in air or

.

ygen

ox

2/2

no risk of accuracy lost or contamination for the

lightest element,

colorless, odorless, tasteless,

has a

gaseous

specific gravity

flammable gas found at

of about 0.0001 % in air. Hydrogen is produced by

including

and

petroleum

steam/methane

by-product streams

reforming, dissociation

from chemical

reforming. Hydrogen can be stored and

liquid.

concentration

range 4 % to 75 % in

Page 32

A

500

Operator

interface: control

panel

GB

00209

-

Edition 02

-

September

04

15

mbar.l/

s

Pa.m3/s

Torr.l/

14

-8

10

2

10

s

-7

-6

-5

-4

-3

-2

10

10

10

10

3

10

mba

hPa

Torr

ZERO

5

7

8

r

STDBY

EVAC

6

10

10

12

9

CYCLE

13

10

TEST

F1

F3

NEXT

-

+

SET POINTS SPECTRO MAINTENANCE OTHER

RESET

F2

F4

LEAK RATE

-12

-11

10

10

-10

10

10

-3

-2

-1

10

10

INLET

PRESSURE

AUTO CAL SNIFFER ZERO

Operation

COR

-9

-8

10

10

1

2

1 10

10

part

mbar.l/

s

Pa.m3/s

Torr.l /s

-7

-6

-5

-4

-3

10

10

10

10

3

10

mba

r

hP

a

STDBY

Torr

10

EVAC

CYCLE

-2

10

TEST

16

-11

10

-2

10

10

PRESSURE

10

-1

COR

-10

1 10

SNIFFER

-9

10

1

2

RESET

F2

F4

11

1

LEAK RATE

-12

10

-3

10

INLET

29

AUTO CAL

3 4

F1

18

F3

20 21 22

NEXT

19

24

SET POINTS SPECTRO

25 26 27

17

-

+

23

MAINTENANCE OTHER

28

1 Inlet port pressure

2 Control and menu selection indicators (ON when

3 Auto-calibration

4 Sniffing mode

5 Auto-zero

6 Cycle

ON/OFF

START/STOP

analog display

STAR

T/ABORT control key

ON/OFF

control key

control key

control key

activated)

Setting and

maintenance

part

(*)

*

Operator

access to setting and

maintenance

part

depends

on the user interface level.

User interface level C

120

7 Control keys (4 keys)

8 Standby

9 Evacuation

T

10

est

11 Helium signal

12 Helium signal

ON/OFF indicator

ON/OFF indicator

ON/OFF

indicatort

analogic display

analogic

13 Helium signal Zero scale

14 Correction factor COR indicator (applied to digital

15 Units

ON/OFF indicator

16 Helium signal digital

17 Alphanumeric display (4 lines x 20

18

Parameter function keys (1 key per display line)

19 Modification access keys (4 keys)

20

21/22

23

NEXT

: next

display/parameter

Plus or minus value adjustment,

RESET

of previously

displayed

scale

ON/OFF indicator

ON/OFF indicator

display

circular function

parameter

values (cancels temporary inputs)

characters)

selection, audio volume adjustment keys

display)

Parameter

function keys (1 key per display line)

F1

F3

F2

F4

NEXT

- +

SET POINTS

SPECTRO MAINTENANCE OTHER

RESET

LEAK RATE

-12

10

-3

10

INLET PRESSUR E

10

-2

10

AUTO CAL

-11

Helium signal

mbar.l/

-8

s

3

Pa.m

/s

Torr.l /s

-7

-6

10

10

3

10

mba

r

hPa

Torr

ZERO

COR

-10

-9

10

10

10

1

-1

10

2

1 10

10

SNIFFER

-5

10

STDBY

EVAC

display

-4

10

10

CYCLE

-3

-2

10

TEST

24 Menu selection access keys (4 keys)

25

26

SET

POINT menu selection key

SPECTRO

calibration

and

analyzer

cell configuration menu selection key

27 MAINTENANCE menu selection key

29 Remote control

28

OTHER

menus selection key (test mode selection, inlet

connection

VENT

selection,

date/time)

Modification access keys (4 keys) Control keys (4 keys)

Menu selection

access

keys (4 keys)

Remote control interface C

Control panel with graphic interface (option) C

control and menu selection

(ON when

400

440

and

indicators

activated)

1/2

Page 33

A

500

Operator

interface: control

panel

GB

00209

-

Edition 02

-

September

04

15

mbar.l/

s

Pa.m3/s

Torr.l/

14

-8

10

2

10

s

-7

-6

-5

-4

-3

-2

10

10

10

10

3

10

mba

hPa

Torr

ZERO

5

7

8

r

STDBY

EVAC

6

10

10

12

9

CYCLE

13

10

TEST

F1

F3

NEXT

-

+

SET POINTS SPECTRO MAINTENANCE OTHER

RESET

F2

F4

LEAK RATE

-12

-11

10

10

-10

10

10

-3

-2

-1

10

10

INLET

PRESSURE

AUTO CAL SNIFFER ZERO

Operation

COR

-9

-8

10

10

1

2

1 10

10

part

mbar.l/

s

Pa.m3/s

Torr.l /s

-7

-6

-5

-4

-3

10

10

10

10

3

10

mba

r

hP

a

STDBY

Torr

10

EVAC

CYCLE

-2

10

TEST

16

-11

10

-2

10

10

PRESSURE

10

-1

COR

-10

1 10

SNIFFER

-9

10

1

2

RESET

F2

F4

29

11

1

LEAK RATE

-12

10

-3

10

INLET

AUTO CAL

3 4

F1

18

F3

20 21 22

NEXT

19

24

SET POINTS SPECTRO

25 26 27

17

-

+

23

MAINTENANCE OTHER

28

1 Inlet port pressure

2 Control and menu selection indicators (ON when

3 Auto-calibration

4 Sniffing mode

5 Auto-zero

6 Cycle

ON/OFF

START/STOP

analog display

STAR

T/ABORT control key

ON/OFF

control key

control key

control key

activated)

Setting and

maintenance

part

(*)

*

Operator

access to setting and

maintenance

part

depends

on the user interface level.

User interface level C

120

7 Control keys (4 keys)

8 Standby

9 Evacuation

T

10

est

11 Helium signal

12 Helium signal

ON/OFF indicator

ON/OFF indicator

ON/OFF

indicatort

analogic display

analogic

13 Helium signal Zero scale

14 Correction factor COR indicator (applied to digital

15 Units

ON/OFF indicator

16 Helium signal digital

17 Alphanumeric display (4 lines x 20

18

Parameter function keys (1 key per display line)

19 Modification access keys (4 keys)

20

21/22

23

NEXT

: next

display/parameter

Plus or minus value adjustment,

RESET

of previously

displayed

scale

ON/OFF indicator

ON/OFF indicator

display

circular function

parameter

values (cancels temporary inputs)

characters)

selection, audio volume adjustment keys

display)

Parameter

function keys (1 key per display line)

F1

F3

F2

F4

NEXT

- +

SET POINTS

SPECTRO MAINTENANCE OTHER

RESET

LEAK RATE

-12

10

-3

10

INLET PRESSUR E

10

-2

10

AUTO CAL

-11

Helium signal

COR

-10

-9

10

10

-1

1 10

10

SNIFFER

mbar.l/

s

3

/s

Pa.m

Torr.l /s

-8

-7

10

1

10

-6

10

10

2

3

10

mba

r

hPa

Torr

ZERO

-5

10

STDBY

EVAC

display

-4

10

10

CYCLE

-3

-2

10

TEST

24 Menu selection access keys (4 keys)

25

26

SET

POINT menu selection key

SPECTRO

calibration

and

analyzer

cell configuration menu selection key

27 MAINTENANCE menu selection key

29 Remote control

28

OTHER

menus selection key (test mode selection, inlet

connection

VENT

selection,

date/time)

Modification access keys (4 keys) Control keys (4 keys)

Menu selection

access

keys (4 keys)

Remote control interface C

Control panel with graphic interface (option) C

control and menu selection

(ON when

400

440

and

indicators

activated)

2/2

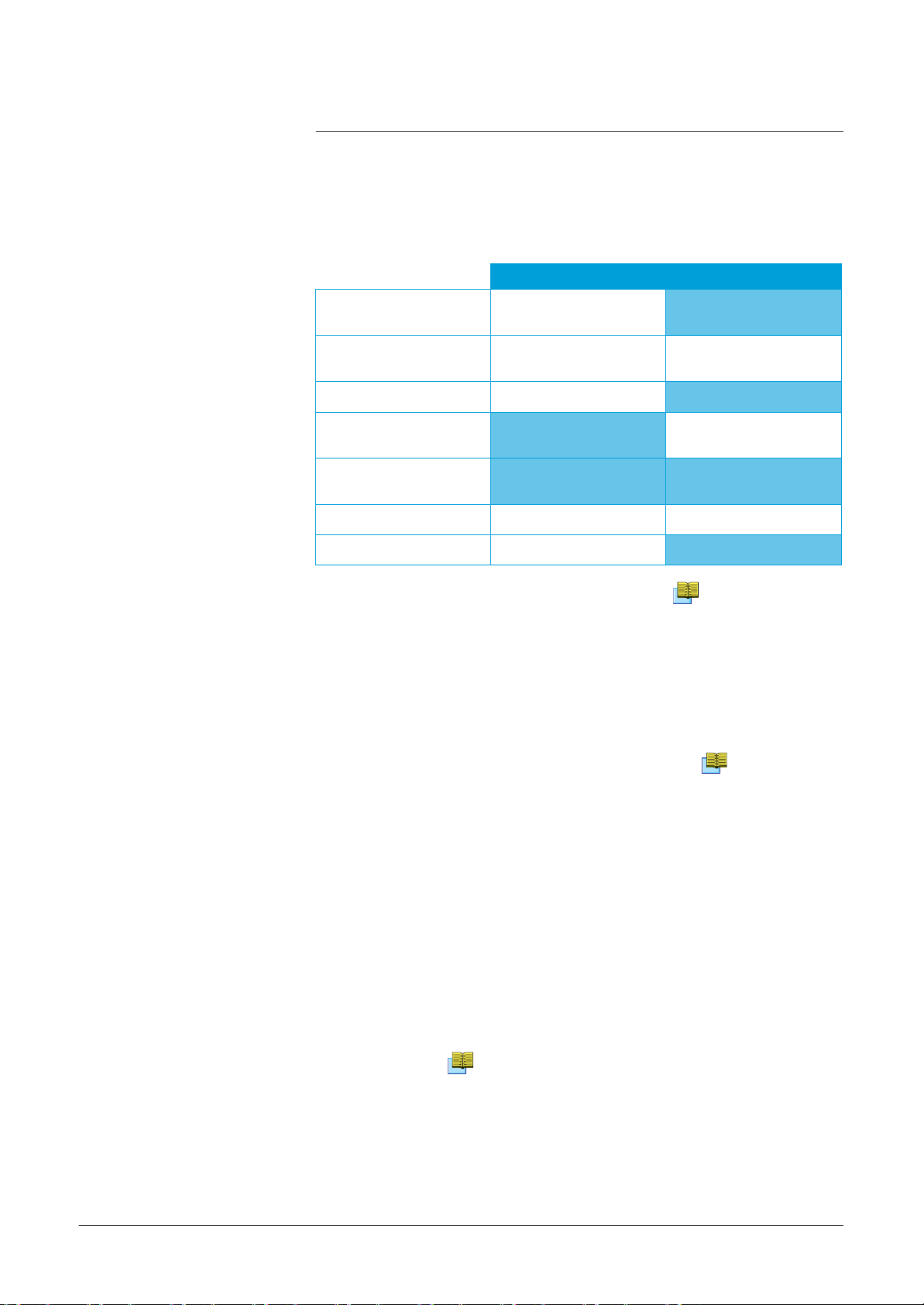

Page 34

A

600

Options

ASM

182

T

ASM

192 T2

ASM

192 TD+

ASI

22

A

700

GB 02446 -

Edition

04 -

June

08

Metal seals

Inlet

Units

Languages

3 masses

Automatic

Roughing

Interface

Remote

Test

Stainless steel

Control panel with graphic

Control panel racks

Sniffing*

Cables lengths

T

Voltage configuration

Power

Standard

*also available in accessories

Which options

which model?

port

test

chambers

system

board*

control cable length

of gas line

cover (UCT)

ransport

cart*

plug

remote

control*

for

inter

face*

S

102

122 D

ASM

ASM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A

700

-

-

• •

•

• • • • • • • • • • • • •

• • • • • • • • • • • • •

• • •

•

• • • • • • • • • • • • •

• • • • • • • • • • • • •

•

S

142

142

ASM

•

• • • •

•

142 D

ASM

ASM

• • • • • • • • •

• • • • • • • • •

• • •

T

Graph D+

ASM

192

ASM

• • • • • • •

• •

• •

182 TD+

ASM

•

•

•

•

• •

• • •

T2D+

192

1002

ASM

ASM

•

•

•

•

1/5

Page 35

A

600

Options

GB 02446 -

Edition

04 -

June

08

Inlet

port

Units

Metal seals

Inlet and high

with metal

1

detector

usefull

in case of high

contaminated

ASM 122 D:

DN 40 inlet port for convenience.

2

ASM 1002:

vacuum

seals

instead of

against contamination with helium.

sensitivity

environment”.

The

standard DN 25 inlet port can be replaced by a

The test

chamber can be replaced by a DN 25 inlet

port for convenience.

3

The user

T

orr

can choice the unit of the software: mbar.l/s, Pa.m3/s or

.l/s.

manifolds and the analyzer cell are equipped

elastomer seals

to protect the leak

This

option is particularly

helium leak detection in an ”helium

Localisation

of the metal seals

F

800

Languages

3

masses

The user

German or Japanese.

4

Note: ASM 142 S: English/French/German/Spanish.

can choice the language of the software:

ASM 1002: English/French.

For

use

of one of the 3 following tracer gases:

2.

Helium 4, Helium 3 or Hydrogen

5

English,

French,

Automatic test

chambers

2/5

This

is

used

for the automatic bombing

When the chamber cover is closed, the

contact.

6

aluminium

3

• a hemispheric

•

a cylindrical chamber,

maximum

•

a cylindrical chamber,

maximum

alloy

models

are available:

chamber, Ø 72 mm, depth 31 mm

maximum

depth 68 mm

(medium

maximum

depth 200 mm (large model).

Note: ASM 142: large model not available.

testing

test

cycle is initiated, via

Ø 85 mm and

model),

Ø 160 mm and

of small components.

a

(small

model),

Page 36

A

600

Options

GB 02446 -

Edition

04 -

June

08

Roughing

Remote

system

Interface

control cable

7

board

8

In order to reduce the roughing time when

second

•

•

Apart from the roughing capacity, the weight and the power

consumption,

remain the same.

The

which will offer a

•

•

auto-cal

•

•

maintenance

This RS

from a

monitor the

3

roughing pump can be added to the roughing system:

ASM 192 T /

ASM 192 TD+ / 192 T2D+ total capacity: 50

helium leak

3 operating modes: basic, advanced, printer;

possibility to

etc...);

possibility to obtain and adjust the settings;

possibility to obtain all the

232 is the

PC

lengths

are proposed: 5 m (16

192 T2

the

characteristics

detector

remote

purposes.

(data recording on an

detector

total capacity: 40

can be equipped with a software version

complete RS

control the

most effective

from a small PLC.

232 protocol:

maintenance

and the

detector

interface to

Excel sheet,

Ft),

testing

m3/h

use

(start/stop, autozero,

information for preventive

10 m (32

large

or 24 cfm.

m3/h

of the leak detector

supervise

for

instance)

Ft)

and 15 m (49 Ft).

volumes,

or 36 cfm.

your leak test

a

and/or to

length

Test

of gas

9

line

10

Used to perform spray

with a reduced

carrier gas injected in

In this case, the

connector

specific to this option.

testing

response

viscous

detector

on long lines (typical diameter 1/4’

time due to the

flow.

is equipped with an additionnal

transfer

of the helium by

1/4”

’),

a

VCR

Stainless steel

cover

(UCT)

11

Designed for

T

echnology”).

The

front and rear

use

of the unit in clean rooms (“Ultra Clean

covers

and frame are made of

stainless

steal.

3/5

Page 37

A

600

Options

F1

F2

F3

F4

GB 02446 -

Edition

04 -

June

08

The

Control panel

with

graphic

inter

face

control panel with graphic interface is equipped with a color

screen.

touch

control panel

It allows it to have, as a

functions,

a graphic interface.

supplement

to the standard

12

mbar.l/s

Pa.m3/s

LEAK RATE

-12

10

COR

-11

-10

-9

10

10

10

Torr.l/s

-8

-7

-6

-5

-4

-3

10

10

10

10

-2

10

10

10

SET

POIN TS SPECTRO MAINTENANCE OTHER

AUTO CAL SNIFFER ZERO

STDBY

EVAC TEST

CYCLE

Control panel

racks

13

The

leak

detector

is delivered with 5 m (16

Ft)

or 10 m (32

Ft)

cables.

Standard

The

setting,

standard control panel rack allows to manage the detector:

test,

calibration,

...

LEAK RATE

-12

10

COR

-11

-10

10

10

mbar

.l/s

Pa.m3/s

T

orr

.l/s

-9

10

-8

-7

-6

-5

-4

-3

10

10

10

10

-2

10

10

10

1

2

1 10

3

10

10

ZERO

mbar

hPa

T

orr

STDBY EVAC TEST

CYCLE

-3

-2

-1

10

10

10

INLET

NEXT

-

+

RESET

SET

POIN TS SPECTRO MAINTENANCE OTHER

PRESSURE

AUTO CAL

SNIFFER

T

ouchscreen

The

control panel with graphic interface is equipped with a color

touch

control panel

screen.

It allows it to have, as a

functions,

a graphic interface.

supplement

to the standard

LEAK RATE

-12

10

COR

-11

-10

10

10

mbar.l/s

Pa.m3/s

Torr.l/s

-9

-8

-7

-6

-5

-4

-3

10

10

10

10

10

STDBY

EVAC TEST

-2

10

10

10

SET

POIN TS SPECTRO MAINTENANCE OTHER

4/5

AUTO CAL SNIFFER ZERO

CYCLE

Page 38

A

600

Options

GB 02446 -

Edition

04 -

June

08

Snif

fing

This

14

option allows to work in sniffing mode.

The

ASI 22 can be fitted with a long distance sniffer probe kit

composed

n

a sniffing probe (to order separately A

n

a sniffing cell,

n

2 male and female connectors,

n

the connecting

(Installation

of the following:

accessories

B

250)

700)

and the hose.

Câbles lengths

2 cables

module are proposed: 2 m (6 ft) ou 5 m (16 ft).

15

lengths

connecting the

electronic

module and the detection

5/5

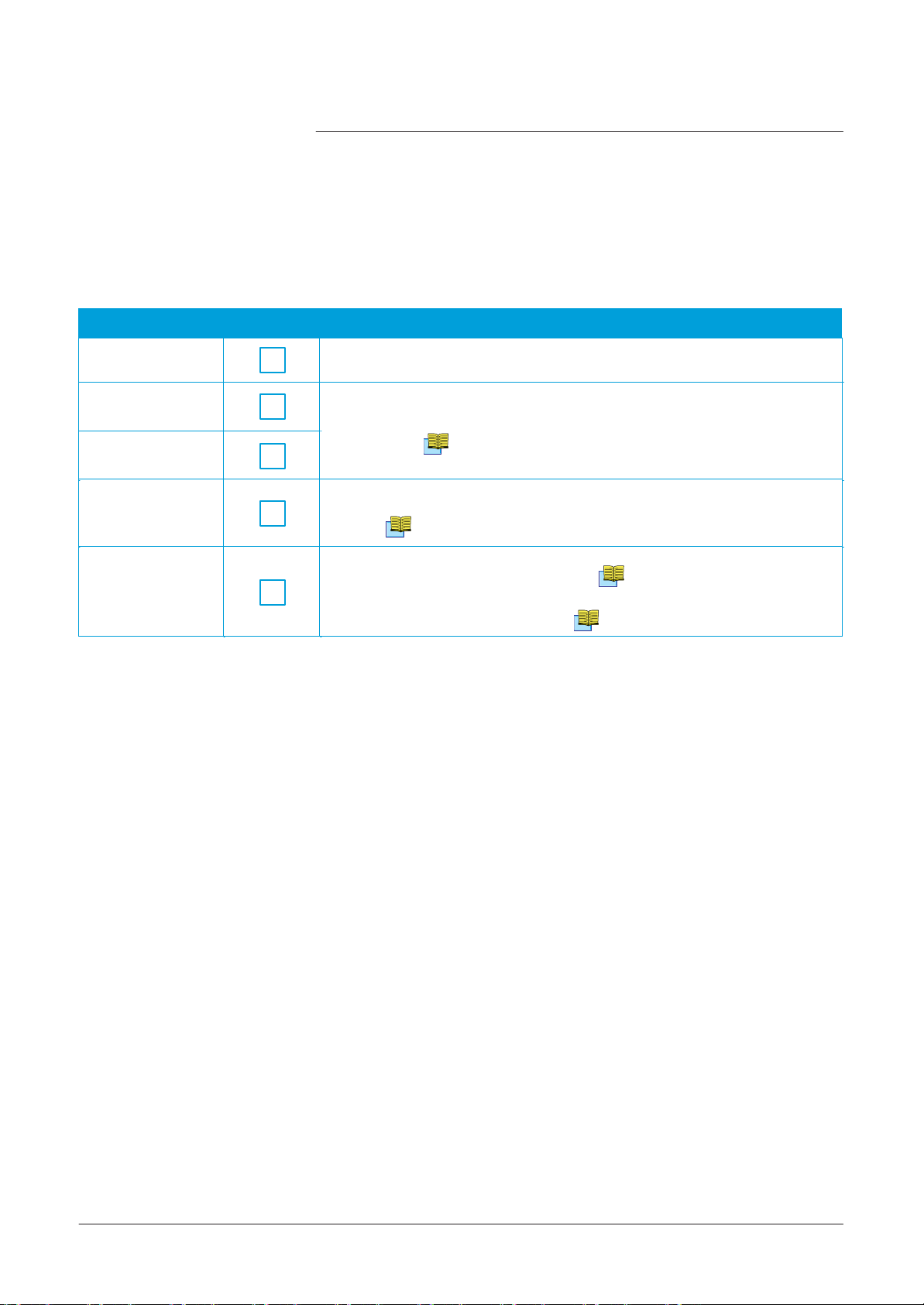

Page 39

A

700

Accessories

ASM

192 T2

ASM

192 TD+

ASM

1002

Headphone

connector

(required interface

board)

Foot pedal for cycle command

(1.5 m/ 5 feet)

A

600

Covered sniffer probe and

remote

control

kit

GB 02447 -

Edition

04 -

June

08

Which

accessories

which model?

Standard remote

Long distance

10 m/30 feet

T

ransport

Calibrated helium leaks

Calibration accessory

Spray probe

Interface

Inlet adaptor

Printer

Inlet filter

Short

*also available in options

distance sniffer probe

Bombing chamber

Test

chambers

Neutral gas vent line kit

4 swiveling

Bottle

handle for cart

Fitted

mini-printer

sniffer

LDS

cart*

board* (p/n 107657)

wheels

for

control and cable*

(LDS)

probe

extension

kit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

S

102

122 D

ASM

ASM

• • • • • • • • • • • • •

• • • • • • • • • • • • • •

• • • • • • • • • • • • • •

• • •

• • • • • • • • • • • • • •

• • • • • • • • • • • • • •

• •

• •

• •

• •

S

142

142

ASM

•

•

• • •

• • • •

•

142 D

ASM

ASM

•

•

• • • • • • • • • •

• • • • • • • • •

• • • •

• • • • • • • • •

• • • • • • • • •

•

Graph D+

ASM

•

T

T

182

192

ASM

ASM

•

•

•

•

•

•

• •

•

•

•

• •

•

182 TD+

ASM

•

•

•

•

• •

192 T2D+

ASM

•

•

•

•

•

•

•

1/14

22

ASI

Page 40

A

700

Accessories

ASM

192 T2

ASM

192 TD+

ASM

1002

Control panel rack *

cable: p/n

112776

A

600

GB 02447 -

Edition

04 -

June

08

Which

2005 IS pump

Pressure measurement

Ventilation kit

Control panel with graphic

(p/n:

n

Standard - 5 m (15 feet)

cable: p/n

n

Standard - 10 m (32 feet)

cable: p/n

n

Touchscreen - 5 m (15 feet)

cable: p/n

n

Touchscreen - 10 m (32 feet)

Long distance

Bootle

Remote control holder

*Also available in option

2/14

accessories

which model?

11171

6)

113134

112775

113133

sniffer kit * (p/n: 104757)

handfe for cart

for

21

kit

inter

face*

22

23

A

A

24

25

600

600

S

102

122 D

ASM

ASM

•

142

ASM

S

142

142 D

Graph D+

ASM

ASM

ASM

•

•

•

•

T

T

182

192

ASM

ASM

•

182 TD+

ASM

•

192 T2D+

ASM

22

ASI

•

•

•

•

•

Page 41

A

700

Accessories

Designation

Part No

Cable of 35 m/1

377˝

802

768

Cable of 40 m/1

575˝

802

769

GB 02447 -

Edition

04 -

June

08

Remote

control

1

The remote

to place it on a magnetized

signal and has

control is equipped with a magnet allowing the operator

surface. The

access

to control

autocalibration and auto-zero.

models

2

are available:

•

1 standard for all leak

detectors

operator can read the helium

keys such

as cycle command

except ASM 102 S /

ASM 142 S:

Remote

Designation Part No

Unit: mbar.l/s - Front

Unit: Torr

Unit: Pa.m3/s - Front

Unit: Pa.m3/s - Front

Note:

series

control with 5 m/15 feet cable length:

face in English

.l/s -

Front

face in English

face in English

face in Japanese

The remote

control is delivered in standard with the ASM

and ASM 122 D.

English

serigraphy

Japanese

106

688

108

881

108

880

106

690

192

serigraphy

mbar

.l/s

or

T

orr

.l/s

or

•

1 specific for sniffing leak

Remote

Designation Part No

Unit: mbar.l/s

control with 5 m/15 feet cable length:

Cable for

Cable of 10

Cable of 15

Cable of 20

Cable of 25

Cable of 30 m/1181˝

mbar

-

Front

remote

m/394˝

m/591˝

m/787˝

m/984˝

Pa.m3/s

-1

10

.l/s

face in English 112

control

detectors

(remote

(ASM 102 S /

control not provided):

ASM 142 S):

Pa.m3/s

only

-1

10

Pa.m3/s

110

110

802

802

802

747

881

882

494

339

767

Only Cable

Cable of 45 m/1771˝

Cable of 50 m/1

969˝

802

770

802

771

3/14

Page 42

A

700

Accessories

Designation

Part No

Tube

length 20

m/787˝

802

826

Tube

length 30 m/1181˝

802

827

802

828

Tube

length 50 m/1

969˝

Tube

length 60 m/2362˝

802

830

Tube

length 70 m/2

756˝

802

831

802

832

Tube

length 90

m/3543˝

Tube

length 100

m/3937˝

802

834

Tube

length 30 m/1181˝

802

836

Tube

length 40 m/1

575˝

802

837

802

838

Tube

length 60 m/2362˝

802

839

Tube

length 70 m/2

756˝

802

840

Tube

length 80

m/3150˝

802

841

Tube

length 100

m/3937˝

802

843

GB 02447 -

Edition

04 -

June

08

5 m/15

Ft

canalisation

10 m/32

Ft

canalisation

Rigid nipple

Flexible

nipple

Rigid nipple

Flexible

nipple

9 cm

30 cm

15 cm

45 cm

9 cm

30 cm

15 cm

45 cm

LDS

probe part number

Long Distance

Snif

Sniffer probe with a rigid nipple Sniffer probe with a flexible nipple

fer

probe

2

SNC1E1T1 SNC1E2T1 SNC1E3T1 SNC1E4T1 SNC2E1T1 SNC2E2T1 SNC2E3T1 SNC2E4T1

T

ube

Long

distance sniffer with

Tube

length 40 m/1

575˝

short

regid nozzle:

802

829

Nozzle length = 9

cm/3.5”

Tube

length 80

m/3150˝

802

833

T

ube

Nozzle length = 45

4/14

cm/18”

Long

distance sniffer with long flexible nozzle:

Designation Part No

Tube

length 20

Tube

length 50 m/1

Tube

length 90

m/787˝

969˝

m/3543˝

802

835

802

842

Page 43

A

700

Accessories

GB 02447 -

Edition

04 -

June

08

10 m/30 feet

extension

Headphone connector

LDS

3

4

Used to extend the

Part

No:

090216

With the headphone connector, the operator can

LDS

probe by 10 m/30 feet.

headphone to its detector.

Part

No:

A459818

The

headphone

detector

must be equipped with the interface board option.

connector

is an

accessory

connect

but to

a

use

it, the

T

ransport cart

ASM 182 range

Part

5

No:

111196

Which headphone

used?

C

410

5/14

Page 44

A

700

Accessories

610 mm/24.02 inch

335

mm

/

8

inch

1040

mm/

GB 02447 -

Edition

04 -

June

08

T

ransport

cart

(ctd)

ASM 142 range

It can be fixed to the detector.

Part

No:

108068

40.95 inch

13.1

ASM 142 range

In addition to the standard cart

(p/n 108068), a 4

steel

cart is proposed for 142 series.

Part

No:

No:

802862

100913

Foot

pedal for

cycle

Part

wheels

stainless

6/14

Part No:

command

(1.5 m/ 5

100913

feet)

6

Page 45

A

700

Accessories

Model

Part No

DN 16

110715

DN 25

110716

GB 02447 -

Edition

04 -

June

08

Calibrated Heli

Helium 3 and

external calibrated

Calibration

Hydrogen

calibrated

Principle

recalibration

accessory

um

leaks

7

leaks

leak

8

There

are

several

leaks, with or without reservoir, with

or without valve, covering

ranges.

The

types of calibrated

several

leak

choice of the appropriate

external calibrated leak depends on the

application requirements.

For further information on the Adixen

calibrated leaks, please refer to our

product catalog or

A.V.T.F. sales

engineer.

consult

your local

Most of the Adixen calibrated leaks are

delivered with a calibration certificate.

The manufacturer

and Hydrogen.

does not supply the calibrated leaks in Helium

All Adixen calibrated leaks are based on permeable membrane

technology.

Most calibrated leaks last many years even though the helium is

permanently

amount of helium contained in the reservoir: yearly

escaping (the leak rate is very small in comparison to the

loss

on the calibrated leak identification label).

However, it is

reservoir)

recalibrated on regular

recommended