Page 1

Software User Manual

Field Maintenance Software Version 5.0

MedSystem III® Infusion Pump

Model 286X

Alaris® Products

June 2006

Page 2

GENERAL CONTACT INFORMATION

Cardinal Health

Alaris® Products

10221 Wateridge Circle

San Diego, California 92121

http://www.cardinalhealth.com/alaris

Customer Advocacy

Clinical and technical feedback.

North America:

Phone: 800.854.7128, Ext. 7812

E-Mail: CustomerFeedback@cardinal.com

Technical Support - North America

Maintenance, service information support, and troubleshooting.

United States - Phone:

858.458.6003

800.854.7128, Ext. 6003

Within Canada: 800.387.8309

From United States: 800.908.9918

Canada - Phone:

Customer Care - North America

Instrument return, service assistance, and order placement.

United States - Phone: 800.482.4822 Canada - Phone: 800.387.8309

Page 3

Table of Contents

INTRODUCTION

ABOUT FMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

WARNINGS AND CAUTIONS

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings

Cautions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SOFTWARE REVISION HIGHLIGHTS

ABBREVIATIONS/ACRONYMS

COMMANDS/DEFINITIONS

INSTRUMENT PROGRAMMING AND FMS FUNCTIONS

Instrument Programming

Calibration Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Event, Alarm, and Status Log Functions

Other FMS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION AND SETUP

SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Software

SOFTWARE INSTALLATION

Unpacking FMS Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cable Hookup

Uninstalling Software

Checking Installed Software Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

STARTING FMS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Running FMS

Main Menu Options

Serial Port Setup

General Page Layout

On-line Help

Automatic Maintenance Mode Recognition

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FIELD MAINTENANCE SOFTWARE

CUSTOMIZING PARAMETERS: INSTRUMENT CONFIGURATION MODE . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Custom Instrument Configurations

Reset Faults (Selection 00)

Clear Instrument Logs (Selection 01)

Reset Rate, VR, and Time to Default Values (Selection 02)

Set Instrument Serial Number (Selection 03)

Set User Information Line (Selection 04)

Special Note Message / Enable / Set Date (Selection 05, 06, 07)

Clear Battery Installation Dates and Clear Battery Log (Selection 08, 09)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . 25

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Table of Contents i

Page 4

FIELD MAINTENANCE SOFTWARE (CONTINUED)

CUSTOMIZING PARAMETERS: INSTRUMENT CONFIGURATION MODE (CONTINUED)

Reset Device Specific Parameters (Selection 10)

Enable/Disable ClrAir Softkey (Selection 11)

Change Rate Breakpoint for ClrAir Softkey (Selection 12)

Lock/Unlock Dose Rate Calculator (Selection 13)

Set Keep Vein Open Rate (Selection 14)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set Maximum Primary Rate (Selection 15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set Maximum Primary Volume Remaining (Selection 16)

Set Maximum Secondary Rate (Selection 17)

Set Maximum Secondary Volume Remaining (Selection 18)

Enable/Disable Audio Volume Ramping (Selection 19)

Set OFF Delay (Selection 20)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Set Main Battery Installation Date (Selection 21)

Set Memory-Backup Battery Installation Date (Selection 22)

Set Fractional Scrolling Breakpoint (General Purpose II and Operating Room II only) 3

(Selection 23)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lock/Unlock Device Type Change (Selection 24)

Lock/Unlock IVPB (Selection 25)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Enable/Disable ALL Settings for VR (Selection 26)

Set Air-in-Line Alarm Sensitivity (Selection 27) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Set Incremental Pressure (Selection 28)

Set Maximum Pressure (Selection 29)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Lock/Unlock Dose Parameters (Selection 30)

Reset Configuration Data (Selection 31)

INSTRUMENT PROGRAMMING

Dose Calculator

Batch Programming

CALIBRATION

Calibration Options

Calibration Prerequisites

Starting Calibration

Full Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cassette/Latch Sensor/OPSI Calibration

Patient-side Occlusion Calibration

Fluid-side Occlusion Calibration

Calibration Data Menu

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Full Calibration Information Menu

Exiting Calibration Menu

LOGS MENU

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Storing a Log to File

Displaying a Log

Printing a Log

Exiting Logs Menu

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

EXITING FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ii Table of Contents

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 5

APPENDIX

PARAMETER VERIFICATION PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Verification Procedure A

Verification Procedure B

Verification Procedure C

Verification Procedure D

SERVICE INFORMATION

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Software Return

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

TRADEMARKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Table of Contents iii

Page 6

THIS PAGE

INTENTIONALLY

LEFT BLANK

iv Table of Contents

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 7

Introduction

Product Notification:

• Documentation provided with this product may reference product(s) not present in

your facility or not yet available for sale in your area.

• Field Maintenance Software (FMS) User Manual is designed to assist Biomedical

personnel in customizing the MedSystem III

®

infusion pump (instrument) to meet

special needs of their institutions.

• Main text discusses different features of FMS and how to initiate them. Appendices

provide additional information for instrument Configuration, Calibration, and Log

Menu pages.

• All KEY NAMES are written in regular type as they appear on instrument or computer

keyboard. All SCREEN MESSAGES are as they appear on screen, except they are

in italic type, and Menu Titles are in regular type with only first letters capitalized.

• For more information on other MedSystem III

®

infusion pump features, refer to

instrument Directions for Use (DFU).

About FMS

This software is provided under and subject to a license from Cardinal Health.

Presented herein is a detailed description of FMS, a program that runs on a personal

computer (PC) running Windows 2000 or Windows XP. This program assists

organizations in servicing and customizing configuration of instrument. This manual is to

be used only with instrument software versions 4.0 or higher.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Introduction 1

Page 8

Warnings and Cautions

WARNING

A

is an alert to a potential hazard which could result in serious personal

injury and/or product damage if proper procedures are not followed.

CAUTION

A

is an alert to a potential hazard which could result in minor personal

injury and/or product damage if proper procedures are not followed.

WARNINGS

• At no time should FMS be used to configure instrument while it is connected to a

patient.

• Ensure instrument is in operational status before returning it to patient use.

• FMS version 5.0 is not compatible with instrument software versions 3.0 and 3.5

CAUTIONS

Hospital policies and procedures should be consulted when determining appropriate

air-in-line thresholds. As a general guideline, set lowest thresholds appropriate when

patient susceptibility to infused air is an important consideration.

2 Introduction

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 9

Software Revision Highlights

Below are examples of differences between FMS Dos version 2.24 and FMS Windows

version 5.0. User interface changes have also occurred due to differences in systems.

DOS Windows

If more than one configuration function is

executed, FMS prompts user to save a

configuration file. If only one function is

executed FMS will NOT prompt user to

save a configuration file.

User can not change directory when

saving a file.

An option is selected either by using up or

down arrow keys on computer keyboard to

highlight desired option, or by typing fi rst

character of desired option (such as L to

select Logs Menu).

A selected option is executed by pressing

enter key.

No delay in establishing and ending

communications between instrument and

computer.

If one or more configuration function is

exectued, FMS prompts user to save

configuration file.

User can choose which directory to save

fi le in.

An option is selected by clicking it with

mouse.

A selected option is executed by clicking

ok button on screen with mouse.

A slight delay in establishing and ending

communications between instrument

and computer due to a more robust

communication method.

Navigating menu items can only be

accomplished when establishing

communication with instrument.

2 COM port options available, COM1 and

COM2.

Reports are navigated using only up or

down arrows.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Navigating menu items can be

accomplished with or without establishing

communication with instrument.

8 COM port options available, COM1

through COM8.

Reports are navigated using horizontal

and vertical scroll bars.

Introduction 3

Page 10

Abbreviations / Acronyms

CIDLIP Cassette Indentifi cation/Latch in Place

ClrAir Clear Air

COM Communications

CP Controller Pressure

DRC Dose Rate Calculator

FMS Field Maintenance Software

GP General Purpose

GP2 General Purpose II

GPII General Purpose II

IBM International Business Machines

ID Identifi cation

KVO Keep Vein Open

LCD Liquid Crystal Display

NN Neonatal

NiCd Nickel Cadmium

OR Operating Room

OR2 Operating Room II

ORII Operating Room II

PC Personal Computer

PSOD Patient Side Occlusion Detection

vol Volume

VR Volume Remaining

4 Introduction

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 11

Commands / Definitions

With FMS, user can customize configuration of instrument from a menu of parameters.

User highlights a selected Configuration Command on Instrument Configuration

Command Menu, and then places instrument in Maintenance Mode by following

directions on screen.

This list of commands will be displayed as follows:

00 Reset Faults - Allows pump channel to be reset from Service to an operational

status.

01 Clear Log - Allows user to clear all entries in internal Event, Status, or Alarm Log.

02 Reset Rate, Volume Remaining, Time Remaining - Resets rate, VR, and time

remaining to factory default settings. This should be used in event of a Watchdog

(30,x) Range Error.

03 Set Instrument Serial Number - Allows user to enter instrument serial number

for display on User Information and Instrument Settings pages.

04 Set User Information Line - Allows an institution to enter their ID number, code,

or name for display on User Information page. Limited to 25 characters including

spaces.

05 Enable/Disable Special Notes - Allows user to enable/disable Special Note

page feature.

06 Set Date To Display Special Note - Allows user to set date for Special Notes page.

Page displays every time instrument is turned on.

07 Set Special Note Messages - Allows user to enter up to five lines of text, 27

characters per line including spaces on Special Notes page.

08 Clear Main Battery Date - Allows main battery installation date and Battery

Log to be cleared.

09 Clear Backup Battery Date - Allows only backup battery installation date to be

cleared.

10 Reset Device Specific Parameters - Automatically resets all device type specific

parameters in instrument to factory default values.

11 Enable/Disable ClrAir Softkey - Allows user to enable/disable ClrAir

softkey for a specific device type.

12 Change Rate Breakpoint for ClrAir - Allows user to set a specific device type and

specific Clear Air rate breakpoint, below which ClrAir softkey is not available.

13 Lock/Unlock Dose Rate Calculator - Allows user to lock out Dose Rate

Calculator feature.

14 Set KVO Rate for Device Type - Set Keep Vein Open (KVO) Rate for a specific

device type, which occurs following an Infusion Complete Advisory.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Introduction 5

Page 12

Commands / Definitions (Continued)

15 Set Maximum Rate for Device Type - Set maximum limit for Primary infusion rates

for a specific device type.

16 Set Maximum VR for Device Type - Set maximum limit for Primary VR for a

specific device type.

17 Set Max Secondary Rate for Device - Set maximum limit for Secondary infusion

rates for a specific device type.

18 Set Max Secondary VR for Device - Set maximum limit for Secondary VR for a

specific device type.

19 Enable/Disable Audio Ramping - Allows automatic ramping of alarm audio

volume to be enabled or disabled when alarms are ignored.

20 Set Instrument Off Delay (1, 3, 5, 10 seconds) - Allows user to set period of

time that OFF key must be pressed and held to turn off instrument.

21 Set Main Battery Install Date - Allows instrument’s memory to maintain date NiCd

battery pack was last changed.

22 Set Backup Battery Install Date - Allows instrument’s memory to maintain date

memory-backup battery was last changed.

23 Set Fractional Scrolling Breakpt - Allows user to set breakpoint at which

VR and Rate change from increments of tenths of a milliliter (0.1) to increments of 1

milliliter (1.0) (for General Purpose II and Operating Room II device types only).

24 Lock/Unlock Device Type Change - Allows instrument to be locked in current

device type.

25 Lock/Unlock IVPB - Allows all three channels to be locked in current channel

mode (such as, Basic, Dual Rate).

26 Enable/Disable ALL Setting for VR - Allows a channel to infuse until container is

empty, rather than infusing a set volume remaining (VR) (applicable for Operating

Room and Operating Room II device types only).

27 Set Air-in-Line Alarm Sensitivity - Set threshold at which an Air-in-Line alarm occurs

for a specific device type.

28 Set Pressure Increment - Set incremental pressure over baseline at which a

Patient-side Occlusion alarm occurs for a specific device type.

29 Set Maximum Pressure - Sets maximum pressure at which a Patient-side

Occlusion alarm occurs.

30 Lock/Unlock Dose Parameters - Allows user to access and change drug

concentration and dose rate units for all drugs.

31 Reset Instrument Configuration Data - Automatically resets non-device type specific

instrument configuration parameters to factory default settings, including rate, VR

and time.

6 Introduction

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 13

Instrument Programming and FMS Functions

Instrument Programming

Programming Menu is available from Main Menu by highlighting Instrument

Programming. The following selections are displayed:

• Dose Rate Calculator - Allows user to select and program a Dose Rate Calculator

Drug Table confi guration to an instrument.

• Batch Programming - Allows user to execute a set of confi guration commands by

selecting a Batch Programming fi le, then reviewing and executing sequential

commands in fi le.

• Quit Programming - Returns user to Main Menu.

Calibration Functions

Calibration data can be stored, displayed, or printed by using appropriate FMS

commands.

Calibration operations provided by FMS:

• Full Calibration (all channels)

• Cassette/Latch Sensor Calibration (all channels)

• Patient-Side Occlusion Calibration (all channels)

• Fluid-Side Occlusion Calibration (all channels)

• Single Calibration Menu (single channel)

• Calibration Data Menu

• Full Calibration Information

• Quit Calibration

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Introduction 7

Page 14

Instrument Programming and FMS Functions (Continued)

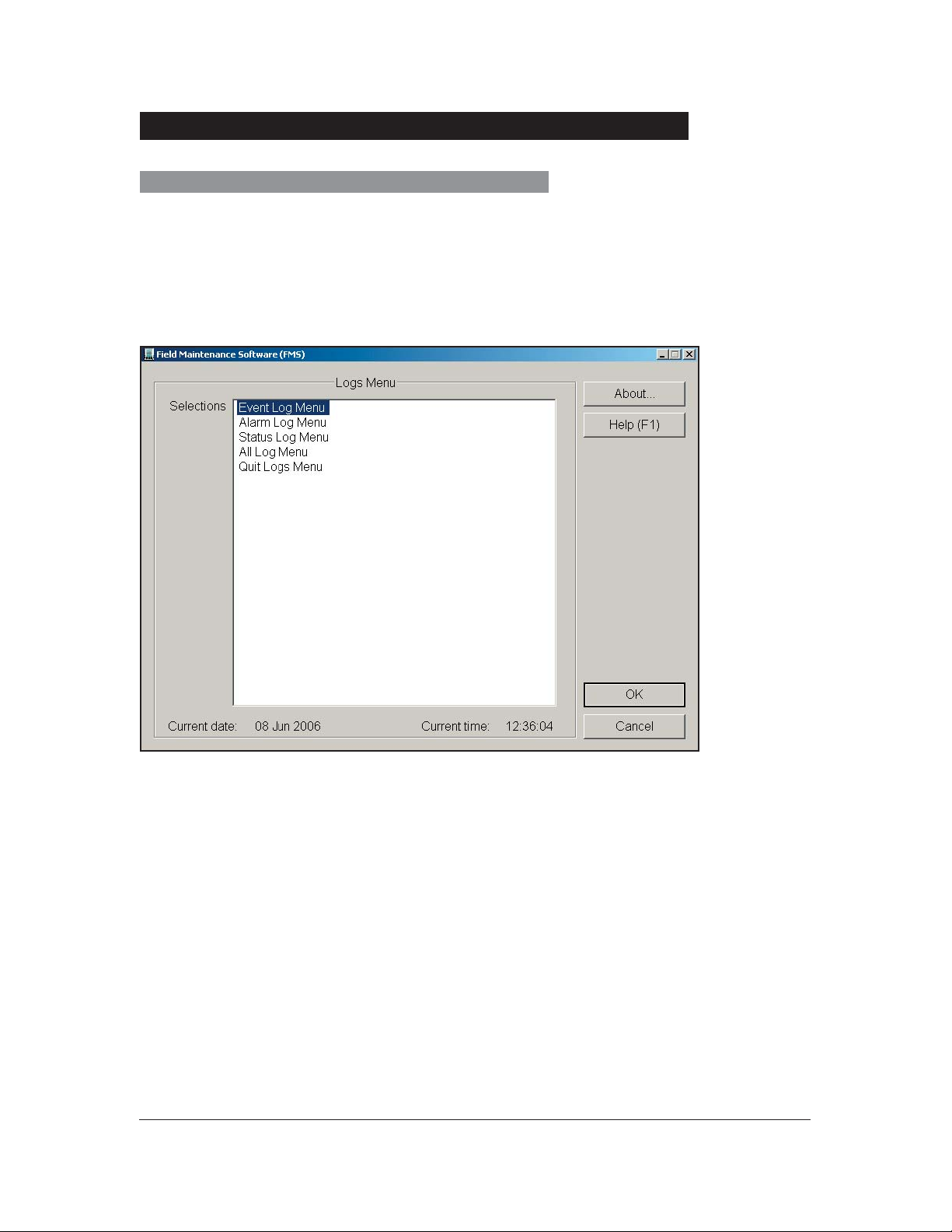

Event, Alarm, and Status Log Function

Logs Menu functions provided by FMS:

• Retrieves Event, Status, Alarm, or All Logs from instrument and stores it to a fi le

• Displays Event, Status, Alarm, or All Logs from either instrument or a fi le

• Prints Event, Status, Alarm, or All Logs from a fi le

Other FMS Functions

• Obtains on-line help information at any time by pressing F1 key

• Displays available commands when F3 key is pressed (under Instrument

Confi guration)

• Displays parameter ranges and units when F4 key is pressed (under Instrument

Confi guration)

• Selects desired communication port (COM1 through COM8)

• Recognizes critical errors and issues prompts to process them

• Recognizes disk full errors and prompts user accordingly. An empty disk can be

inserted and operation repeated

• Recognizes old instrument communications protocol (version 3.5 and earlier)

NOTE: During FMS operation, Control C input from keyboard is ignored.

8 Introduction

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 15

Installation and Setup

System Requirements

FMS uses a PC serial communications (COM) port to communicate with an instrument.

Hardware

• IBM-PC or compatible with a minimum of 512K memory

• CD ROM Drive

• Serial port (COM1 through COM8)

• EGA, CGA, or VGA display

• 9- to 25-pin (female to male) adapter (as needed)

• Serial to USB adapter (as needed) (See note below)

• Printer (optional)

NOTE: If using a serial to USB adapter, because no serial port is available, Windows

will assign a COM port number. If assigned number is higher than 8, consult the adapter

documentation to reassign the port number.

Software

• Microsoft Windows 2000 or Windows XP Operating System. Use of one of these

operating systems is required to provide necessary support.

• Field Maintenance Software (FMS) version 5.0

Software Installation

Unpacking FMS Kit

FMS kit should contain following items:

• RS-232 cable with 7-pin connector (optional)

• Field Maintenance Software CD ROM

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Installation and Setup 9

Page 16

Software Installation (Continued)

Installing Software

This CD contains the following:

Adobe Acrobat Reader 6.0.1

FMS Application Software

FMS Directions for Use

Accessing the Directions for Use*

The DFU can be opened directly from the CD or from within Adobe Acrobat Reader.

Access from the CD

1. On the CD locate the DFU PDF file in the FMS folder.

2. Double click on the file to open it.

3. If desired, save file to directory of choice.

Access from Adobe Acrobat Reader

1. Select [File] from the menu, then select [Open].

2. Navigate to the FMS folder on the CD using the [Open] dialog [Look in] option.

3. Select the DFU file, then [Open].

4. If desired, save file to directory of choice.

Accessing the FMS Application

The FMS application can be run from the CD. It is, however, recommended that the

application be run from the Hard Drive.

1. On the CD locate the FMS folder. The following files are in the folder:

• DRUGDEFT.SET

• FMS.EXE

• X40DA.RL

• X40DE.RL

• X40DS.RL

2. Copy the FMS folder to directory of choice on Hard Drive.

*If Adobe Acrobat 6.0.1 is needed, see text file in “Adobe Acrobat 6.0.1” folder.

NOTE: Icon associated with FMS.EXE will be displayed in directory where FMS is located,

in task bar when FMS is in use, and as the shortcut icon.

10 Installation and Setup

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 17

Software Installation (Continued)

Cable Hookup

Connect special 7-pin connector on serial cable to COM port on side of instrument.

Connect 25-pin connector end to selected COM port of PC. If PC uses a 9-pin

connector, use a 9- to 25-pin (female to male) adapter.

Turn instrument on in Maintenance Mode by simultaneously pressing ON/OFF and

MORE OPTIONS keys. LCD should now read Maintenance and indicate current device

type. Instrument is now ready for FMS.

Uninstalling Software

CAUTION

Software uninstall program automatically and permanently deletes unsaved data.

To avoid this, save any unsaved data before uninstall procedure is performed.

1. Select Start Settings Control Panel.

• Control Panel window opens.

2. Double-click Add or Remove Programs.

3. Select FMS.

4. Click Remove.

5. Follow prompts to complete uninstall procedure.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Installation and Setup 11

Page 18

Software Installation (Continued)

Checking Installed Software Version

Select About Button from main menu.

• About box opens.

• To close about box press enter or click OK.

NOTE: 5.0 in illustrated display represents

current software version.

About FMS Software Version

12 Installation and Setup

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 19

Starting FMS

General Information

Running FMS

To open FMS, select FMS shortcut on desktop.

OR

Select Start ► Programs ► Alaris Products ► FMS v5.0 ► Title Page opens.

Title page

Verify software, version appearing on Title Page is correct, press enter or click OK to

bring up FMS Main Menu functions. Serial port information will also be displayed on title

page.

NOTE: Date and time set on the computer are used by FMS when storing instrument Logs

and Calibration Data, so it is important that these values are correct.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Starting FMS 13

Page 20

Main Menu

Software Installation (Continued)

Main Menu Options

Verify date, time on Main Menu are correct. If date or time are incorrect, exit by

executing Quit Program option on FMS Main Menu. Then set correct date/time on

computer.

An option is selected either by using up and down arrow keys on computer keyboard to

highlight desired option, by typing fi rst character of desired option (such as, L to select

Logs Menu), double clicking on menu item or highlighting item and clicking OK.

To execute selected option, press Enter key. If there are two options having same fi rst

character, they will be alternately selected when key is pressed (such as, fi rst C will

select Confi guration command; second C will select Calibration menu).

For an overall program fl ow of FMS, refer to “Overall Program Flow of FMS” fi gure.

14 Starting FMS

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 21

Software Installation (Continued)

Overall Program Flow of FMS

F1

Help

Context Sensitive

<ESC>

Execute FMS program

<ESC>

Q

<ESC>

F

L

Program

Quit FMS

FMS Setup

Configuration

<ESC>

Logs Menu

Exit to Windows

Menu

Event Log

E

1st A

Menu

Alarm Log

Menu

Status Log

S

All Logs

2nd A

Menu

Menu

Quit Log

Q

FMS Icon

Title Page

NOTE: and indicates commands

Main Menu

2nd C

<ESC>

I

<ESC>

1st C

<ESC>

<ESC>

Calibration Menu

<ESC>

Instrument

Programming

<ESC>

Instrument

Configuration

Full Calibration

1st F

DRC

D

Menu

Help

Commands

F3, F4

All Channels

P,

C,

Menu

Batch

Configuration

Pages

All Channels

Single Calibration

F

B

Menu

Programming

Quit Instrument

Single Calibration

S

Q

All Channels

Menu

Programming

Information

Full Calibration

3rd F

Data Menu

Calibration

2nd C

Menu

Quit Calibration

Q

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Starting FMS 15

Page 22

General Information (Continued)

Serial Port Setup

• FMS is provided with COM1 as default communications port.

• FMS remembers last port used.

• FMS attempts to establish communication with last port used. If instrument

is not connected to that port, FMS Setup option on Main Menu must be used

to select new port.

• To switch between communication ports, use FMS Setup option on Main Menu.

Serial communications ports are chosen randomly, if computer has more than 8

ports use Windows setup options to set one port as COM port to communicate with

instrument.

NOTE: To establish communication, port to which instrument communication cable is

connected must match port selected through FMS.

• When starting FMS, Title page will indicate last port used.

Select FMS Setup Screen from Main Menu.

Current communication port confi guration will be displayed. Select port and then confi rm

selection.

FMS Setup Screen

During an FMS session, if software cannot make connection with a COM port, user will

be prompted with message, Instrument is off or cable is not connected to right port.

16 Starting FMS

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 23

General Information (Continued)

General Page Layout

After an item is selected from Main Menu the display will switch screens for selected

item. Screen for each item is divided into the following four sections:

SELECTION - Indicates currently highlighted function.

MESSAGES FOR OPERATOR - Guides operator through use of given function, and

provides instructions in case of errors.

OPERATOR INPUT - Shows what user entered via computer keyboard.

INSTRUMENT RESPONSE - Shows response of instrument to a certain command by

operator. A “successful” response indicates that command was accepted. If command is

not accepted, appropriate error message will be displayed.

Instrument Confi guration Screen

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Starting FMS 17

Page 24

General Information (Continued)

On-line Help

• On-line HELP is available in FMS by using F1 key or by clicking help button

on right side of screen, as depicted in “Context Sensitive Help Example” fi gure. Help box

will pop up in center of screen and outlines what command will do. This help option is

only available at menu levels.

• Use F3 key for User Summary information regarding available commands in

Instrument Confi guration mode. Use F4 key to display a table of allowable

parameter ranges. For a complete display of Summary Information screens, see

“Usng Summary Information in Instrument Confi guration Commands Using F3 key”,

“Parameter Ranges and Units Using F4 Key ” fi gures .

Context Sensitive Help Example

18 Starting FMS

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 25

General Information (Continued)

Using Summary Information in Instrument Confi guration Commands Using F3 Key

Parameter Ranges and Units Using F4 Key

Automatic Maintenance Mode Recognition

At start of an operation that requires communication with instrument, FMS automatically

checks to see if instrument is in Maintenance Mode. If not, FMS display prompts user to

put instrument in Maintenance Mode.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Starting FMS 19

Page 26

THIS PAGE

INTENTIONALLY

LEFT BLANK

20 Starting FMS

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 27

Field Maintenance Software

Customizing Parameters: Instrument Configuration Mode

Instrument parameters can be customized using Instrument Confi guration Mode. For

FMS to set instrument parameters described in this section, instrument must be in

Maintenance Mode.

To place instrument in Maintenance Mode, turn instrument on by simultaneously

pressing ON/OFF and MORE OPTIONS keys on instrument. On fi rst line of

Maintenance screen, instrument LCD should now read Maintenance (Device Type),

Current device type will be refl ected in parentheses.

NOTE: After certain Instrument Confi guration changes, confi guration parameters (such

as, Device Type Change Lockout) should be verifi ed by exercising function that was

changed, or by viewing parameter value on instrument. Appendix contains procedures

for verifying parameter values and is referenced throughout this chapter.

Custom Instrument Configuration

When making changes to specifi c parameters of a device type, changes are only valid

for selected device types. Changes must be repeated for each device type, as required.

Some parameter changes will affect entire instrument and are specifi cally noted. When

making changes to parameters that will affect entire instrument, the instrument can be

set in any device type.

Reset Faults (Selection 00)

RESET faults clears the fault from memory. It does not repair anything. If the condition

that triggered the fault has not been addressed, the fault will re-occur.

When a channel is in SERVICE status, it may be made operational again by using Reset

Faults command from Instrument Confi guration Commands Menu. Command resets

faults on all channels. The fault will re-occur if a hardware problem exists (See Technical

Service Manual).

This command can be verifi ed by turning instrument off and on again. Status of all

channels should be operational.

CAUTION

Do not return instrument to clinical use after resetting faults without fi rst referring to instrument’s

Technical Service Manual. Additional testing or servicing may be required for specifi c faults.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 21

Page 28

Customizing Parameters: Instrument Configuration Mode

(Continued)

Clear Instrument Logs (Selection 01)

Event, Alarm, and Status Logs (which are stored in instrument memory) can be cleared

using Clear Log command from Instrument Confi guration Commands Menu.

After Clear Log command is issued, user has a choice of which log to clear:

Event Log

Alarm Log

Status Log

After Clear Log command is issued, press Esc key to return to Main Menu. To verify

cleared log, select Logs Menu, then retrieve and display appropriate log from instrument.

Reset Rate, VR, and Time to Default Values

(Selection 02)

Software errors and out-of-range values may cause a persistent Watchdog 30,x

condition (parameter out of range). This condition may be corrected by issuing Reset

Rate, VR, and Time command from Instrument Confi guration Commands Menu.

Reset Rate, VR, and Time - Resets Rate, VR, and Time Remaining to default values.

This command can be verifi ed by turning instrument off and on again. Rate, VR, and

Time Remaining of all channels should be reset to default values.

NOTE: The Watchdog 30,x message appears when instrument is powered up and will

be listed in Event Log. Refer to Technical Service Manual for more detailed watchdog

information.

22 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 29

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Instrument Serial Number (Selection 03)

Instrument displays Title page and Instrument Settings pages (see instrument DFU).

This information is kept in the instrument memory, and it may be lost if power is

disrupted or instrument is exposed to high levels of static electricity.

User can enter serial number into instrument using Set Instrument Serial Number

command from Instrument Confi guration Commands Menu. Serial number must be 3 - 9

digits long. Use serial number found on back label of instrument.

This number is used for identifi cation in every log.

Always verify that correct serial number was entered by turning instrument off, then on,

keeping ON/OFF key depressed to observe serial number on Title page.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Set User Information Line (Selection 04)

Instrument is capable of displaying an ID line of up to 25 characters, including spaces,

on Title page. Text for User Information line can be set using Set User Information Line

command from Instrument Confi guration Commands Menu.

Always verify that correct User Information line was entered by turning instrument off,

then on, keeping ON/OFF key depressed and observing Title page.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 23

Page 30

Customizing Parameters: Instrument Configuration Mode

(Continued)

Special Note Message / Enable / Set Date

(Selections 05, 06, 07)

A provision is made for a Special Note page on which you can enter up to fi ve lines

of text. This page appears when instrument is turned on and after Title page clears,

provided Special Note date is same as or earlier than current date shown on Instrument

Settings page.

Special Note page is enabled or disabled with Enable/Disable Special Note command

from Instrument Confi guration Commands Menu. Date to display Special Note page is

entered by Set Date To Display Special Note command from Instrument Confi guration

Commands Menu. Each line of text (up to a maximum of fi ve lines and 27 characters

including spaces) is entered separately after appropriate line number by using Set

Special Note Messages command from Instrument Confi guration.

NOTE: Digits will not be accepted as fi rst character of a line on Special Note page. To have

a digit as fi rst character, precede it with a space.

Commands menu

The Following input enters a Special Note Message:

Message Line 1: This instrument should be

Message Line 2: Returned to Biomed for

Message Line 3: Annual maintenance

Message Line 4: (blank)

Message Line 5: (blank)

Special Note Message reads:

This instrument should be

Returned to Biomed for

Annual maintenance.

After a special note is entered, enabled, and display date is set correctly, the message

can be verifi ed by exiting Maintenance Mode by turning instrument off, then on.

After Title page clears, Special Note page appears. Press CLEAR softkey to bypass

message.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

24 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 31

Customizing Parameters: Instrument Configuration Mode

(Continued)

Clear Battery Installation Dates and

Clear Battery Log (Selection 08, 09)

Instrument will display main and backup installation dates on Battery History Log,

accessible by using BATLOG softkey. Installation dates can be cleared using the

following commands.

Clear Main Battery Date - Clears Main Battery Installation Date and Battery Log

contents. This command will reset all fi elds in the log, other than the backup battery

date, to 0 or ----.

NOTE: This should always be executed anytime the backup battery has been

disconnected.

Clear Backup Battery Date - Clears only Backup Battery Installation Date.

This command can be verifi ed by using Verifi cation Procedure D located in appendix

section..

Reset Device Specific Parameters (Selection 10)

This feature is used to reset device specifi c parameters such as Air-in-line thresholds,

Patient-side-occlusion thresholds, Clear Air parameters, and Rate/Volume boundaries

back to manufacturer settings.

This command can be verifi ed by using Verifi cation Procedure B located in appendix

section.

Enable/Disable ClrAir Softkey (Selection 11)

ClrAir softkey is activated after accessing air-related alarm information for affected

channel. This feature can be enabled/disabled for selected Device Type from Instrument

Confi guration Commands Menu.

This command can be verifi ed by using Verifi cation Procedure B located in appendix

section.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 25

Page 32

Customizing Parameters: Instrument Configuration Mode

(Continued)

Change Rate Breakpoint for ClrAir Softkey

(Selection 12)

ClrAir softkey is normally activated for current device type after a predetermined rate

breakpoint. If a different rate breakpoint is desired, it can be changed by using Change

Rate Breakpoint for ClrAir command from Instrument Confi guration Commands Menu.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

Lock/Unlock Dose Rate Calculate (Selection 13)

This feature allows user to lock out Dose Rate Calculator function of instrument by

using Lock/Unlock Dose Rate Calculator command from Instrument Confi guration

Commands menu. When command is set to Locked Out, Dose Rate Calculator feature

is not accessible. When command is set to Unlocked, Dose Rate Calculator feature is

available.

NOTE: This feature is not device type specific.

This command can be verifi ed by using Verifi cation Procedure C located in appendix

section.

Set Keep Vein Open Rate (Selection 14)

After an infusion is complete on a channel (VR=0), instrument will generate an Infusion

Complete Advisory. If a channel is infusing at a rate higher than Keep Vein Open (KVO)

rate, it will automatically change to KVO rate. KVO rate can be customized for different

device types. For range of available KVO rates see table below.

Device Type KVO Rates Increments

General Purpose

1.0 to 20 ml/h 1.0 ml/h

Operating Room

Controller Pressure

General Purpose II

1.0 to 20 ml/h 1.0 ml/h

Operating Room II

Neonatal 0.1 to 5 ml/h 0.1 ml/h

26 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 33

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Keep Vein Open Rate (Selection 14)

(Continued)

Changing KVO rate is done by selecting Set KVO Rate for Device Type from Instrument

Confi guration Commands Menu. After user selects desired device type, allowable range

will be displayed for user to select their chosen value.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Set Maximum Primary Rate (Selection 15)

For Maximum rate range allowable by user when instrument is operating in Primary

regimen refer to the table below. Also see instrument DFU.

Device Type Maximum Rates

General Purpose

1-999 ml/h

Operating Room

General Purpose II

1-999 ml/h

Operating Room II

Controller Pressure 1-299 ml/h

Neonatal 0.1-99.9 ml/h

Changing maximum primary rate is done by selecting Set Maximum Rate for Device

Type from Instrument Confi guration Commands Menu. After user selects desired device

type, allowable range will be displayed when selecting new value.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 27

Page 34

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Maximum Primary Volume Remaining

(Selection 16)

Maximum VR range allowable by user when instrument is operating in Primary regimen

of Dual Rate mode is 1-9999 ml for all device types. (see instrument DFU).

To change maximum primary volume remaining select Set Maximum VR for Device

Type from Instrument Confi guration Commands Menu. After user selects desired device

type, allowable range will be displayed for user to select a new value.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

NOTE:

entered for user verifi cation.

If this command is executed, the instrument will return the value that was

Set Maximum Secondary Rate (Selection 17)

For maximum rate range allowable by user for Secondary regimen for a device see

table below. Also refer to instrument DFU.

Device Type Maximum Rates

General Purpose

1-999 ml/h

Operating Room

General Purpose II

1-999 ml/h

Operating Room II

Controller Pressure 1-299 ml/h

Neonatal 0.1-99.9 ml/h

To change maximum secondary rate select Set Max Secondary Rate for Device from

Instrument Confi guration Commands Menu. After user selects desired device type,

allowable range will be displayed for user to select a new value.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

28 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 35

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Maximum Secondary Volume Remaining

(Selection 18)

Maximum Secondary VR range allowable by user in Dual Rate mode is 1-9999 ml for all

device types. Also refer to instrument DFU.

To change maximum secondary VR select Set Max Secondary VR for Device from

Instrument Confi guration Commands Menu. After user selects desired device type,

allowable range will be displayed for user to select a new value.

This command can be verifi ed by using Verifi cation Procedure A located in appendix.

NOTE:

entered for user verifi cation.

If this command is executed, the instrument will return the value that was

Enable/Disable Audio Volume Ramping

(Selection 19)

Once activated, alarm volume on instrument automatically begins increasing to loudest

level after 1 minute if alarm is not addressed. This feature can be enabled/disabled

using Enable/Disable Audio Ramping command from Instrument Confi guration

Commands Menu.

NOTE: This feature is not device type specific, and it changes alarm ramping for all

device types.

This command can be verifi ed by using Verifi cation Procedure B located in appendix.

Set OFF Delay (Selection 20)

Turning off instrument normally requires pressing OFF key for 1 second. Using FMS,

this time period can be changed to 3, 5, or 10 seconds by using Set Instrument Off

Delay command from Instrument Confi guration Commands Menu.

NOTE: This feature is not device type specifi c.

This command can be verifi ed by using Verifi cation Procedure B located in appendix.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 29

Page 36

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Main Battery Installation Date (Selection 21)

Date main NiCd battery pack was last replaced can be entered into memory, using Set

Main Battery Install Date command from Instrument Confi guration Commands Menu.

NOTE: This feature is not device type specifi c.

This command can be verifi ed by using Verifi cation Procedure D located in appendix.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Set Memory-Backup Battery Installation Date

(Selection 22)

Date internal memory-backup lithium battery was last replaced can be entered

into memory by using Set Backup Battery Install Date command from Instrument

Confi guration Commands Menu.

NOTE: This feature is not device type specifi c.

This command can be verifi ed by using Verifi cation Procedure D located in appendix.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

30 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 37

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Fractional Scrolling Breakpoint (General

Purpose II and Operation Room II only)

(Selection 23)

Breakpoint at which Rate and VR change from 0.1 to 1.0 increments can be set using

Set Fractional Scrolling Breakpoint command from Instrument Confi guration Commands

Menu.

This command is verifi ed by actually scrolling rate and VR on a selected channel and

observing that as value scrolls below breakpoint, it does so in 0.1 increments. When

breakpoint is reached, value then scrolls in increments of 1.0.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Lock/Unlock Device Type Change (Selection 24)

Current device type can be locked so that instrument users will not be able to

change device type once it leaves the Biomedical Engineering Department. This is

accomplished by using Lock/Unlock Device Type Change command from Instrument

Confi guration Commands Menu.

Setting command to Locked Out will lock device type in its current confi guration. Setting

command to Unlocked will allow device type to be changed.

This command can be verifi ed by exiting Maintenance Mode by turning off instrument,

then on. Press MORE OPTIONS key until DEVICE softkey appears. Press DEVICE

softkey to verify that Device Type Change command is in effect.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 31

Page 38

Customizing Parameters: Instrument Configuration Mode

(Continued)

Lock/Unlock IVPB (Selection 25)

Instrument channels are capable of operating in Primary or Secondary/IVPB mode.

Instrument can be confi gured to prevent changing channel modes once they have been

set for all three channels. This is accomplished by using Lock/Unlock IVPB command

from Instrument Confi guration Commands Menu.

Setting command to Locked Out will lock out Secondary/IVPB mode for all channels.

Setting command to Unlocked will allow Secondary/IVPB mode on all channels.

NOTE: This change will affect all device types.

This command can be verifi ed by using Verifi cation Procedure B located in appendix.

Enable/Disable ALL Settings for VR (Selection 26)

As a general rule, when specifying Volume Remaining (VR) on instrument, a value is

entered showing number of milliliters of solution to be delivered. A feature that allows

VR to be set to ALL is available only for Operating Room and Operating Room II Device

Types.

When VR is set to ALL, instrument will continue infusing until solution container is empty

and air is detected by Air-in-Line detector of instrument channel. ALL mode availability

can be enabled for Operating Room and Operating Room II Device Types by using

Enable/Disable ALL Setting for VR command from Instrument Confi guration Commands

Menu.

Setting ALL mode availability to Disable (meaning No) prevents setting VR to ALL.

Setting ALL mode availability to Enable (meaning Yes) enables ALL mode in VR.

NOTE: This command alters ALL mode availability for Operating Room and Operating

Room II Device Types only.

This command can be verifi ed by using Verifi cation Procedure A located in appendix.

32 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 39

Customizing Parameters: Instrument Configuration Mode

(Continued)

CAUTION

Hospital policies and procedures should be consulted when determining appropriate Air-in-line

thresholds. As a general guideline, set lowest thresholds appropriate when patient susceptibility

to infused air is an important clinical consideration.

Set Air-in-Line Alarm Sensitivity (Selection 27)

Air-in-line parameters can be customized according to the standards of an institution.

Air-in-line algorithm generates an alarm when it detects a certain volume of air

(threshold) in a specifi c volume of fl uid (window).

Alarm threshold and level can be altered using Set Air-in-line Alarm Sensitivity command

from Instrument Confi guration Commands Menu. Thresholds are defi ned in “Air-in-line

Confi guration” fi gure shown below. Entry of any Air-in-line threshold values other than

those shown in “Air-in-line Confi guration” fi gure are not allowed.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

NOTE:

entered for user verifi cation.

If this command is executed, the instrument will return the value that was

AIR-IN-LINE CONFIGURATION

Window Threshold Available ?

1 ml 10 μl * All device types

1 ml 25 μl * All device types

1 ml

@@@ 50 μl@@@ All device types

1 ml 75 μl All device types

1 ml 100 μl All except Neonatal

1 ml 150 μl All except Neonatal

1 ml 250 μl Not available

1 ml 500 μl Not available

2 ml 10 μl * All device types

2 ml 25 μl * All device types

2 ml 50 μl All device types

2 ml 75 μl All device types

2 ml 100 μl All device types

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 33

Page 40

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Air-in-Line Alarm Sensitivity (Selection 27)

(Continued)

AIR-IN-LINE CONFIGURATION (continued)

Window Threshold Available ?

2 ml 150 μl * All except Neonatal

2 ml 250 μl * All except Neonatal

2 ml 500 μl Not available

3 ml 10 μl All device types

3 ml 25 μl All device types

3 ml 50 μl All device types

3 ml 75 μl All device types

3 ml 100 μl All device types

3 ml 150 μl * All except Neonatal

3 ml 250 μl * All except Neonatal

3 ml

@@ 500 μl@@ All except Neonatal

*10 and 25-microliter thresholds are approximate due to inherent diffi culties in creating and

measuring air bubbles of such small size during testing. On the confi guration display 25 will be

indicated by <50, 10 will be indicated by <<50.

@@ Factory setting

@@@ Neonatal default setting

Set Incremental Pressure (Selection 28)

Incremental pressure above baseline value, at which a Patient-side Occlusion alarm is

generated, can be customized using Set Increment Pressure command from Instrument

Confi guration Commands Menu. Range for incremental pressure is from 1 to 15 psi (in

1-psi increments) for General Purpose, General Purpose II, Operating Room, Operating

Room II, and Neonatal Device Types. Incremental pressure is not applicable when

instrument is operating in Controller Pressure Device Type.

This command can be verifi ed by using Verifi cation Procedure A located in appendix.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

34 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 41

Customizing Parameters: Instrument Configuration Mode

(Continued)

Set Maximum Pressure (Selection 29)

Maximum pressure at which a patient-side occlusion alarm is generated can be set

using Set Maximum Pressure command from Instrument Confi guration Commands

Menu. Range for maximum pressure is 4 to 15 psi (in 1-psi increments) for General

Purpose, General Purpose II, Operating Room, Operating Room II, and Neonatal

Device Types, and 1 to 6 ft H

0 (in 1-ft H20 increments) in Controller Pressure Device

2

Type.

The pressure at which a Patient-side Occlusion alarm is generated will be either

incremental pressure over baseline, or maximum pressure setting, whichever is lower.

This command can be verifi ed by using Verifi cation Procedure A located in appendix

section.

NOTE: If this command is executed, the instrument will return the value that was

entered for user verifi cation.

Lock/Unlock Dose Parameters (Selection 30)

This feature allows user to access and change drug concentration parameters and dose

rate parameters for all drugs in Dose Rate Calculator. This is accomplished by using

Lock/Unlock Dose Parameters command from Instrument Confi guration Commands

Menu.

Setting command to Locked Out will not allow user to change drug concentration units

and dose rate units for any drugs (except DRUG?). Setting command to Unlocked will

allow drug concentration units and dose rate units for all drugs to be changed.

This command can be verifi ed by using Verifi cation Procedure B located in appendix.

Reset Configuration Data (Selection 31)

This feature allows instrument to be reconfi gured with factory settings. This feature

includes confi guration command Reset Rate, Volume Remaining, and Time to Default

Values. User can access this feature by using Reset Confi guration Data command from

Instrument Confi guration Commands Menu.

This command can be verifi ed by using Verifi cation Procedure B located in appendix.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 35

Page 42

Instrument Programming

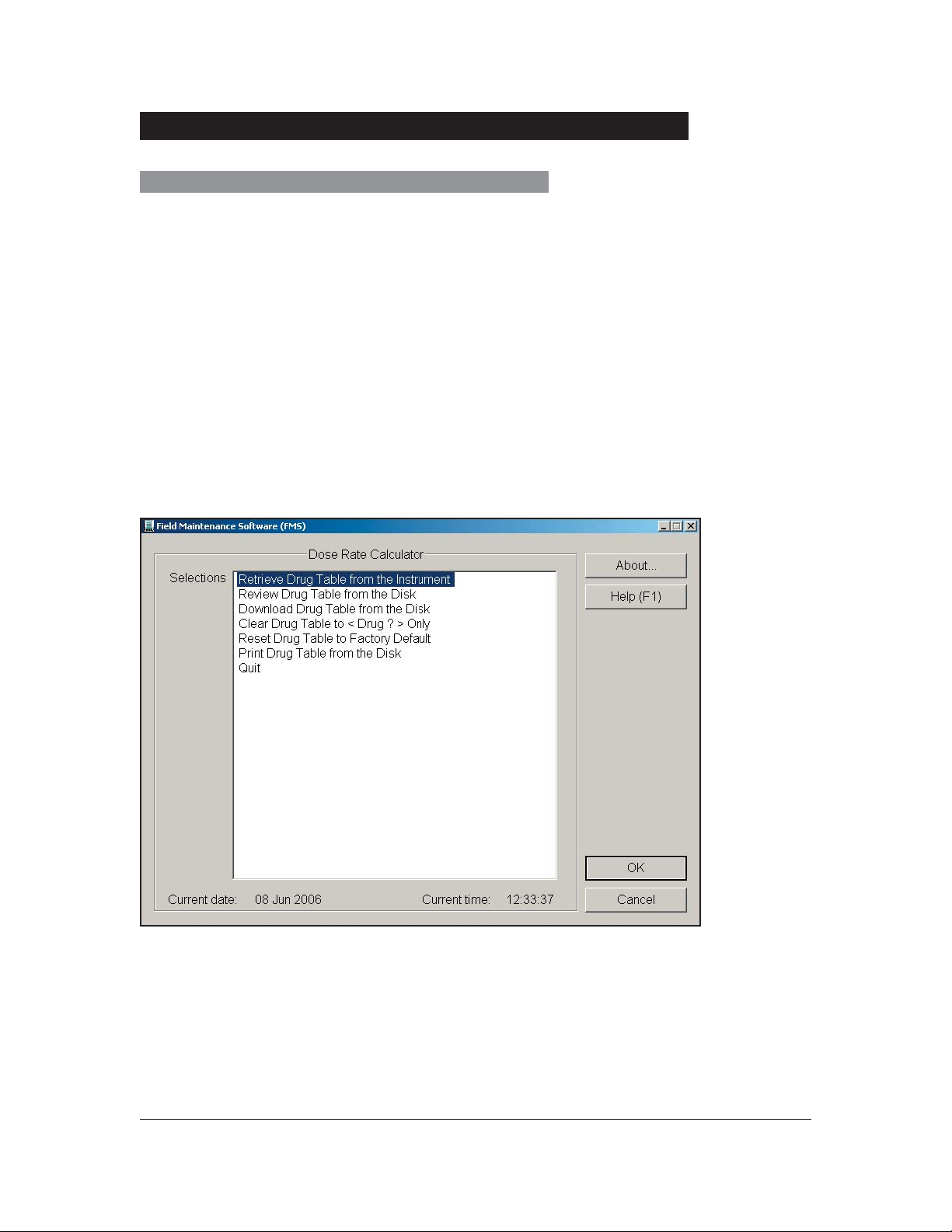

Dose Rate Calculator

This feature allows user to confi gure, review, and print Dose Rate Calculator Drug Table

fi le. User selects desired option by using keyboard arrows or by typing fi rst character,

then pressing ENTER key. See “Dose Rate Calculator Menu” fi gure below. The following

options are also included:

• Retrieve drug table from instrument.

• Review a drug table from disk in computer.

• Download a drug table from disk in computer.

• Clear drug table to (DRUG?) only.

• Reset drug table in instrument to factory default.

• Print drug table from disk in computer.

• Quit Dose Rate Calculator (and return to Instrument Programming Menu).

Dose Rate Calculator Menu

Drug table has a convention extension, .drc. drug table will contain information on Drug

Number, Drug Name, Drug Dosage, Diluent Volume, Dose Regimen, Weight, Time, Fast

Next, and Fast Previous.

36 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 43

Instrument Programming (Continued)

Batch Programming

This feature allows user to manipulate instrument confi guration script fi les, and execute

a fi le to an instrument. See “Batch Programming Menu” fi gure shown below. The

following options are also included:

• Review a script fi le from disk in computer. Script fi les have convention

extension .ics.

• Execute one script fi le to an instrument (such as, change instrument to settings

specifi ed in script fi le).

• Review result of an execution of a script fi le to an instrument. Script fi les use

script fi le name plus convention extension .inf. See “Sample and Explanation of a

Batch Execution Script File” fi gure.

• Print a script fi le from disk in computer.

• Quit Batch Programming (and return to Instrument Programming Menu).

Batch Programming Menu

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 37

Page 44

Instrument Programming (Continued)

Sample and Explanation of a Batch Execution Script File

Calibration

Differences among instrument components (such as, transducers, mechanical

components, circuit gains and offsets) necessitate calibration of certain systems. These

systems detect cassette installation, latch closure, patient-side occlusions, and fl uid-side

occlusions.

Software functions are used to perform instrument calibrations. Calibration is required

after replacing certain components as a part of preventive maintenance, or if memory

contents are corrupted. Refer to Technical Service Manual for help in troubleshooting

calibration failures.

Every calibration step will display a series of numbers and a pass or fail message.

These numbers are A/D results from a calibration step. In the event of a failure the

numerical results aid in diagnosis.

38 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 45

Calibration (Continued)

Calibration Options

There are six basic options from which to choose when calibrating instrument. See

“Calibration Menu” fi gure shown below.

Calibration Menu

Full Calibration - All channels

This guides user through calibration procedures for all sensor systems on all channels.

This is used most often for annual maintenance. It is suggested as a best practice to run

a full calibration whenever calibration is done to calibrate an entire system.

Single Sensor Calibration - Options:

Cassette/Latch Sensor Calibration - All channels

Patient-side Occlusion Calibration - All channels

Fluid-side Occlusion Calibration - All channels

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 39

Page 46

Calibration (Continued)

Calibration Options (Continued)

These options allow user to simultaneously calibrate individual sensor systems for all

channels. This is used most often when troubleshooting.

Single Calibration Menu - Single Channels

This guides user through steps necessary to calibrate an individual channel (such

as, cassette sensors for Channel A), as shown below. A single calibration is useful for

troubleshooting a single aspect of an individual channel.

Single Calibration Menu - Single Channels

40 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 47

Calibration (Continued)

Calibration Data Menu

This menu provides user ability to retrieve calibration data from instrument and store it

to a fi le on disk.

Calibration fi le naming convention is 3 - 9 digit serial number of instrument plus:

!C for current instrument calibration log fi le (12345678.9!C);

#C for backup instrument calibration log fi le (12345678.9#C).

This menu also provides user with ability to review data fi les from disk in computer and

to print data.

Full Calibration Information

This menu provides user with ability to review full calibration conversation fi les from disk

in computer.

Calibration fi le naming convention is 3 - 9 digit serial number of instrument plus:

!F for current full calibration information fi le (12345678.9!F);

#F for backup full calibration information fi le (12345678.9#F).

This menu also provides user ability to print full calibration conversation fi les from disk in

computer.

Quit Calibration returns user to Main Menu.

Calibration Prerequisites

• Cassette/Latch Sensor Calibration with no cassettes installed must be completed

before Cassette/Latch Sensor Calibration with cassettes installed.

• 0 psi Calibration must be performed before 12 psi Calibration can be performed.

• Cassette/Latch Sensor Calibration must be performed before Fluid-side Occlusion

Calibration can be performed.

• Fluid-side Occlusion Calibration with no load must be performed before Fluid-side

Occlusion Calibration with a load can be performed.

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Field Maintenance Software 41

Page 48

Calibration (Continued)

Starting Calibration

Select Calibration Menu from FMS Main Menu. Select desired calibration option. For

FMS to access calibration functions described in this section, instrument must be placed

in Maintenance Mode.

To place instrument in Maintenance Mode, turn on instrument by simultaneously

pressing ON/OFF and MORE OPTIONS keys. Instrument LCD should now read

Maintenance, followed by current device type.

NOTE: Always perform calibration procedures with instrument connected to AC power.

Instrument battery alarms are not active in Maintenance Mode.

NOTE: Ensure all channels have required equipment, as described in following

procedures. Otherwise, calibration parameters will be out of range.

Whether calibration is full or single channel, set up process of each step is the same

and the following details in full calibration for brevity.

If a failure is determined, follow prompts to repeat calibration procedures.

Every calibration step will display a series of numbers and a pass or fail message.

These numbers are A/D results from a calibration step. In the event of a failure the

numerical results aid in diagnosis.

Always perform a functional test after calibration is completed to ensure proper

operation of equipment.

Full Calibration

Full calibration performs calibration with following the criteria:

• No cassette installed and pressure zero calibration

• Cassette installed and 12-psi pressurized cassette calibration

• 12-psi pressure verifi cation

• 6-psi pressure verifi cation

• 0-psi pressure verifi cation

• Fluid-side Occlusion calibration with no load

• Fluid-side Occlusion calibration with load

42 Field Maintenance Software

Field Maintenance Software

Model 286X, v5.0

Software User Manual

Page 49

Calibration (Continued)

Cassette/Latch Sensor/OPSI Calibration

To begin Cassette/Latch Sensor Calibration, you will need one to three administration

sets that have been modifi ed for Cassette/Latch Sensor Calibration by cutting inlet