Page 1

..

MedSystem

III™

For

most

Troubleshooting

common

errors.

Tip

Sheet

Error

Codes

(6,3):

(16,X):

fere

SO

人

(31,3):

1.

Check

disconnected.

2.

Use a known

to

Air-in-line

Air-in-line

1.

Clean

2.

Replace

1.

Reseat

2.

Check

3.

Check

4.

Replace

5.

Replace

Opto

Top

Fuse.

Battery.

Troubleshooting

see

if

any

Air-in-Line

good

Air-in-Line

sensors

sensors*.

Module

Opto

are

defective.

and

Module*.

Board.

Power

MEA*.

Supply*.

do

CID/LIP

Steps

Sensors

Sensor

Replace

have

become

to

find

out

which

defective

calibration.

Xz

(33,3)

(40,X):

(95,X):

Chana

O-A

3

る

(259):

(263):

A

1.

Reseat

2.

Replace

1.

Reseat

2.

Replace

1.

Check

Top

Top

to

disconnected.

2,

Replace

causes

1.

Clean

2.

Switch

with

the

channel

drive

Drive

channel

4.

Do

Pressure

Giso

Check

Board

MEA*.

Board.

Power

see

the

Supply",

if

any

Air-in-Line

pump

and

module

Module

replace

MEA*.

calibration.

Lihumim

and

EPOM.

Air-in-Line

Sensor*

to

go

into

do

FSOD

with

another

replace

Drive

bet

Sensors

on

whichever

alarm

when

calibration.

channel.

Module”.

have

become

channel

started.

if

error

If

error

moves

stays

with

in

same

Page 2

(272):

1.

Do

CID/LIP

calibration.

(278):

(276);

(289)/(290)

(292)

uN

1.

2.

1.

1.

2.

1.

(293)

ON

Clean

Switch

with

channel

Do

FSOD

Clean

Do

FSOD

Switch

with

channel

Reset

1.

Reset

and

drive

Drive

replace

Encoder

drive

Drive

replace

faults.

faults.

.

Lubricate

module

Module

channel,

with

replace

MEA*.

calibration.

Disk.

Make

calibration.

module

Module

with

replace

MEA*.

do

another

Drive

sure

another

Drive

FSOD

channel.

calibration.

Module.

dust

cover

channel.

Module”.

0000

If

error

If

error

is

properly

If

error

If

error

moves

stays

in

installed.

moves

stays

with

in

same

with

same

(301)/(24)

(302)/(47)

1.

.

>

.

.

.

BOND

(305)/(88)

(303)/(67)

1.

2.

一

(311)

Replace

Reseat

Check

Check

Replace

Replace

Replace

.

Reseat

.

Check

.

Check

.

Replace

AWN

.

Reseat

.

Check

.

Check

.

Replace

BONS

MEA*.

Top

Board.

Fuse.

Battery.

Power

Power

MEA*.

Top

Board.

Fuse.

Battery.

MEA*.

Top

Board.

Fuse.

Battery.

Power

Supply

Supply

Supply

Board”,

Board".

Board".

Page 3

(313)

1.

Replace

Air-in-Line

Sensor

*.

(314)

(315)

(326)

sofico

5,0

*

Follow

MK

1.

1.

2.

level

Replace

Replace

1.

Do

FSOD.

Replace

of

testing

Air-in-Line

Air-in-Line

MEA*.

Guide

Sensor*.

Sensor”.

Lines

in

Service

Bulletin

404A.

Page 4

il

¡IVAC

#TO*CAL

\

SYSTEMS

Inquiries

fluid

the

1.

.

.

have

been

made

side

occlusion

subject,

but

SOLUTION

Viscous

algorithm

but

instead

solutions

written

certain

factors

of a 20

Suggestions:

alarms.

intended

VISCOSITY

obviously

into

can

and

knowledge

If

this

MOTOR

It is

possible

become

would

A

occupied.

this

observe

and B are

channel

Suggestions:

of

999

for a period

that

stiff

as

selected.

The

that

This

over

in

any

that

result

is

associated

issue

of 4 to 5 hours - this

DISPOSABLE

The

pumping

inserted.

will

have

lubricant

will

also

Suggestions:

for

whatever

manufacturing

CALIBRATION

Annual

systems. A variety

failing

to

Suggestions:

chamber

The

amount

an

impact

was

applied

degrade

the

Once

reason, I recommend

problem

calibration

perform

the

Calibrate

Medsystem

as

to

the

The

quick

a

as

requires

the

FSOD

complicate

regarding

appears

to

be

extended

mechanical

typically,

is

for a single

On

the

that

ch.

average - ch. C is

with

is

easily

is

sealed

of

energy

on

FSOD.

in

the

piston

you

have

take

is

recommended

of

symptoms

An

manufacturing

mobility.

determined

action

calibration.

the

instrument.

UM

possible

following

reference

system

the

flow.

the

cause,

periods

assembly.

C has

nuisance

overcome

by a silicone

required

example

FSOD

causes

information

guide.

more

effort

is

designed

These

the

use

suggest a 20dpm

of

infusion,

longer

FSOD

by

is

normally

piston

by

the

of

of

the

that

you

install a new

to

return

to

including

the set

account

nuisances

and

suggested

is

in

moving

to

factors

of

the

confirm

non-use,

If

we

ch. A is

chosen

periods

simply

motor

this

the

of

alarms.

running

done

sleeve

to

would

cassette.

piston

cassette,

for

for

any

FSOD

remedies

not

an

all

inclusive

through

compensate

include

set

the

motor

analyze

selected,

only

non-use

by

biomed.

in

which

drive

be

in

for

using a 60

key.

be

used.

and

channel

for

after

chs. A and B are

and

the

instrument

the

the

piston

cases

where

Contamination,

portion

of

//

the

it

analysis.

wear

or

drift

alarms

could

May

8,

for

nuisance

study

the

set.

fluid

viscosity

drop

drive

belt

utilization

two

lines

quite

often

at a rate

plastic

piston

up

and

insufficient

spills,

cassette

appears

in

to

the

result

1996

on

The

set

may

we

chs.

it

is

is

down

etc...,

is

stiff

be

a

sensor

from

NOTE - In

Box

Gites

Office

85335

hit

Corporate

Р.О.

Web.

CONTAMINATION

Spills,

the

moving

Suggestions:

the

important

danny

leaking

FSOD

parts.

recommended

any

Wateridge

10221

a

Diego.

San

ae

com

system.

Encourage

case

that

California

nef

sets

and

The

increased

cleaning

where

the

set

San

a

Circle

92186-5335

other

As

the

the

procedure

the

be

returned

Diego.

(619)

m

forms

solution

load

institution

of

contamination

begins

on

the

motor

to

for

MSIL,

administration

to

IVAC-Creedmoor

California

92124-1579

458-7000

will

have a negative

to

dry,

friction

triggers

FSOD

maintain a cleaning

hospitals

set

is

found

for

develops

alarms.

regimen

that

do,

to

be

analysis.

between

as

benefit

leaking,

Lee

Sr.

greatly.

it

Wengronowitz

Support

Tech.

impact

outlined

is

on

the

in

vitally

Spec.

om

ire

©

Page 5

ALARIS

MEDICAL

MEMO

Date

11-19-98

To:

Technical

Cc:

Rob

SYSTEMS

Support

Pecsar,

Tam

Tran

From:

Subject:

1.

At

password.

can

The

file.

installed

2.

Hiep

Background

the

first

not

be

only

The dle.pwi

(default

Resetting

Exit

DLE

Launch

Open

Click

Click

Click

Record

Click on

.

Uncheck

OBNOASWH>

410.

Click

11.

Click

12.

On

the

13.

Hit

the

14.

Click

15.

Verify

16.

Click

Dinh

Resetting

time

of

running

This

password

changed.

way

to

change

file

at

cAmsiiidle)

program.

Windows

‘Msiiidle’

or

‘View’.

‘Options’.

‘View’

‘Apply’

‘OK’

‘Yes’

tab.

the

settings

‘Show

‘Hide

button.

button.

right

hand

‘Delete’

button

that

there

ail

file

key

‘View’.

the

DLE

(Version

DLE,

will

be

the

DLE

is

located

Password

NT

Explorer

‘msiiidie’

on

files’

extensions

side

on

on

is

no

folder,

this

button.

window,

the

keyboard.

the

‘Confirm

dle.pw

the

program

saved

password

in

the

directory

(Start,

or

window.

for

known

click

File

file

in

2.00)

Password

asks

in

the

is

for

Program,

the

folder

file

the

dle.pwl

Delete’

the

right

the

users

hidden

to

where

reset

the

file,

it

Windows

Windows

where

types’

hand

box.

icon

popup

side

Instruction

to

set

named

by

deleting

DLE

DLE

to

highlight

die.pwi,

application

NT

Explorer).

was

window.

window.

the

DLE

and

the

dle.pwl

was

NT

installed.

it.

Memo:

Resetting

the

DLE

(Version

2.00)

Password

Instruction

Page 1 of

3

Page 6

ALARIS

MEDICAL

SYSTEMS

17.Click

18.

Click

19.

Reset

20.

Click

21.Click

22.

Close

23.

Start

3.

Resetting

+

Exit

DLE

Launch

Open

Click

AN

Click

Glick

Record

Uncheck

OND

Folders.

9.

Click

10.

Click

11.

Click

12.

On

the

413.

Hit

the

14.

Click

15.

Verify

16.

Click

17.

Click

18.

Click

24.

Reset

19.

Click

20.

Click

21.Close

22.

Start

‘Options’.

‘View’

‘Apply’

‘OK’

the

the

settings

button.

the

‘Windows

DLE

tab.

button.

program.

program.

'Windows

‘Msilidle’

‘View’.

‘Folder

‘View’

on

‘Apply’

‘OK’

Options...’

tab.

the

settings

‘Hide

‘Show

button.

button.

right

hand

‘Delete’

‘Yes’

button

that

there

‘View’.

‘Folder

‘View’

the

‘Apply’

‘OK’

the

the

Options...’.

tab.

settings

button.

button.

‘Windows

DLE

on

this

NT

Password

Explorer’

or

‘msilidie’

on

this

file

extensions

all

files’

side

window,

key

on

the

on

the

is

no

dle.pwi

on

this

Explorer’

program.

window

Explorer’

Enter

and

(Start,

folder,

window.

for

button

under

click

keyboard.

‘Confirm

file

window

window.

Enter and

as

recorded

window.

confirm a new

for

Program,

or

the

known

Hidden

the

File

Delete’

in

the

as

recorded

confirm a new

Windows

folder

file

types’

files.

dle.pwi

right

hand

earlier.

password.

Windows

Explorer).

where DLE

box

icon

popup

side

earlier.

password.

was

under

to

highlight

window.

window.

95

installed.

Files

and

it.

4.

Exit

Launch

Open

Click

DONT

Memo:

Resetting

DLE

program.

‘File

Manager’.

‘msilidle’

‘View’.

Resetting

the

folder,

DLE

(Version

Password

or

the

folder

2.00)

where

Password

for

Instruction

Windows

DLE

was

installed.

3.1X

Page 2 of

3

Page 7

ALARIS

の

Click

Record

Check

の

Click

On

oo

10.

Hit

the

11.

Click

12.

Click

13.

Verify

14,

Click

15.

Click

16.

Reset

17.

Click

18.

Close

19.

Start

[end]

MEDICAL

‘By

File

the

‘Show

‘OK’

the

right

‘Delete’

‘OK’

‘Yes’

that

View.

'By

the

‘OK

the

the

SYSTEMS

Type...’.

settings

Hidden/System

button.

hand

side

key

button

button

there

File

settings

on

on

is

no

Type...”.

on

button.

‘File

Manager’

DLE

program.

on

this

window,

on

the

the

the

die.pwl

this

window.

Files’.

click

keyboard.

‘Delete’

popup

‘Confirm

file

window

window.

Enter

and

the

die.pwt

window.

File

Delete’

in

the

right

as

recorded

confirm a new

icon

papup

hand

earlier.

password.

ta

window.

side

window.

highlight

it.

Memo:

Resetting

the

DLE

(Version

2.00)

Password

Instruction

Page 3 of

3

Page 8

Ни.

al

IVAC

MEDICAL

SYSTEMS

NOTIFICATION

‘

OF

PRACTICES

TO

REDUCE

THE

OCCURRENCE

THE

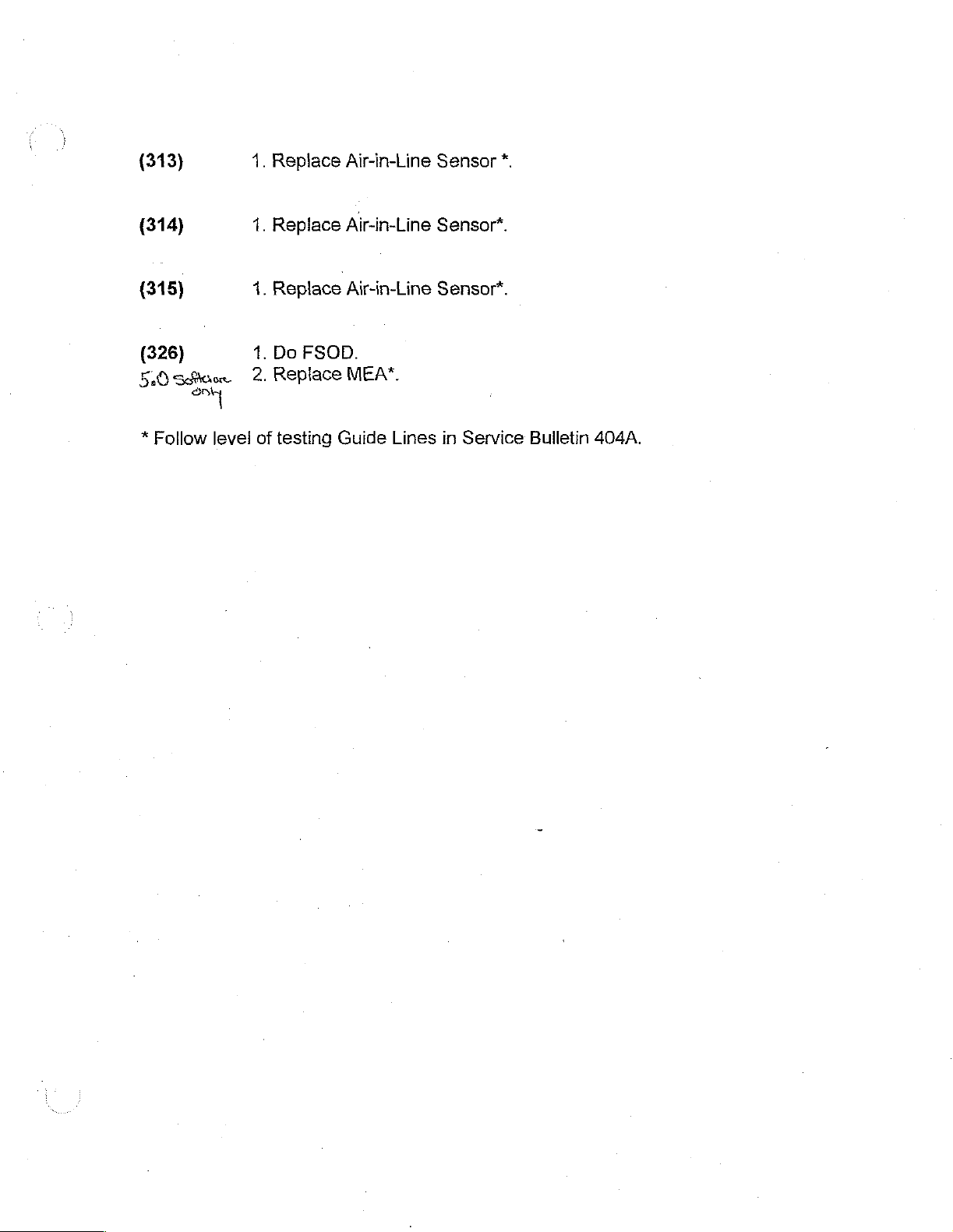

Attention:

IVAC

alarms

e

9

s

Medical

can

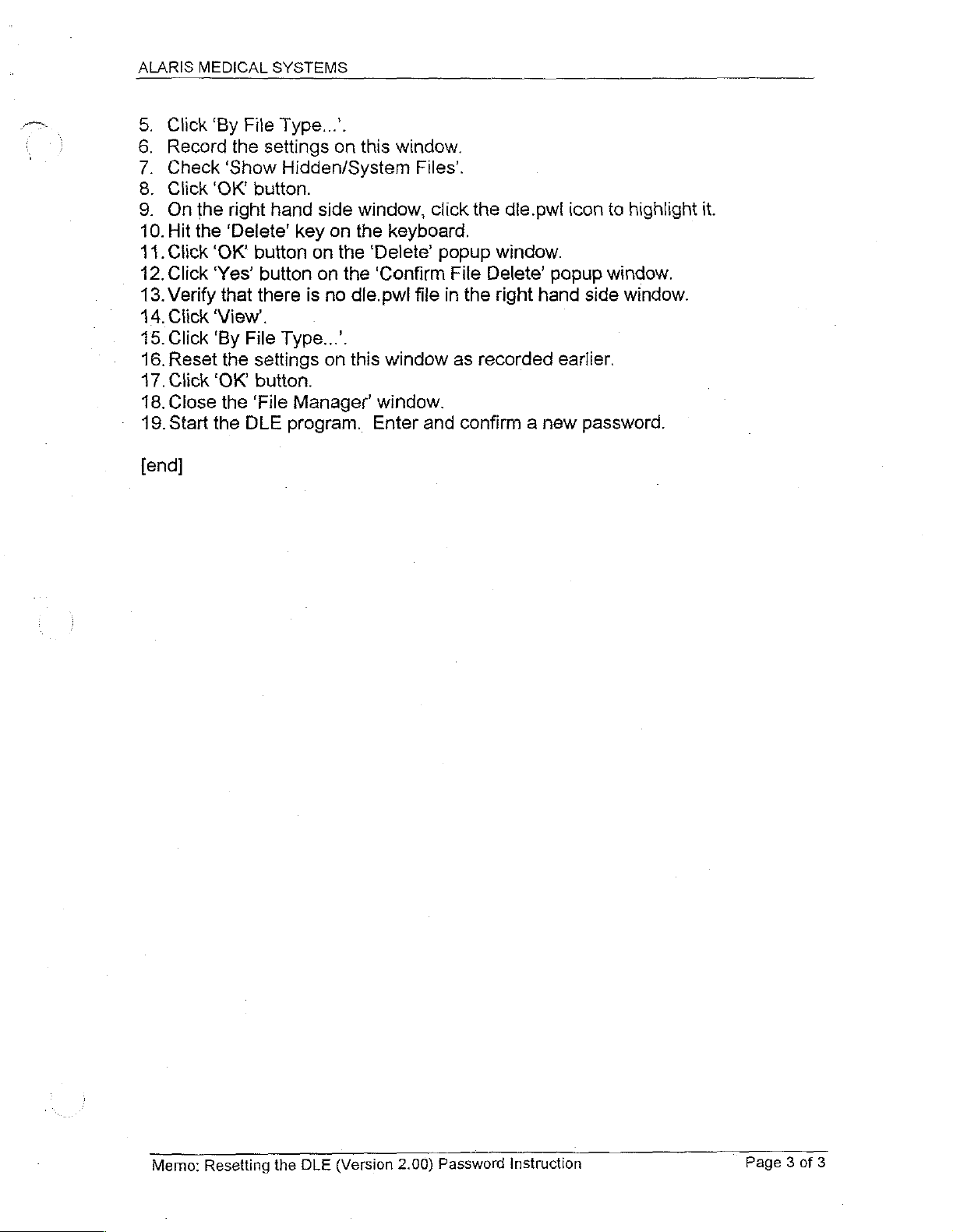

Fully

extending

as

illustrated

Turing

Stopping

Removing

IVAC®

Sales

be

reduced

the

the

the

OF

MEDSYSTEM

Force

Systems,

in

Figure 1 below.

pump

channel

cassette

with

the

cassette

on

Inc.

the

before

before

from

PUMP

has

determined

following

slide

clamp

inserting

removing

the

pump

INCORRECT

LATCH

III™

that

practices:

when

the

cassette

the

cassette

before

CASSETTE

SLIDE

CLOSED

INFUSION

the

occurrence

removing

into

from

turning

the

<>

Em

the

the

pump

of

the

cassette

pump.

pump.

off.

ALARMS

PUMP

pump

latch

from

the

FOR

closed

pump

7

To

address a pump

+

Using

as

illustrated

e

{f

the

pumping

qualified

If

you

require

Corporate

only

service

STAT

latch

closed

your

finger,

in

Figure 2 below.

latch

jaw

personnel.

further

line

information

using

alarm,

push

is

visibly

our

down

toll

free

Figure

the

procedure

the

closed

broken,

PUMPING

press

LATCH

Figure

regarding

number

1

pumping

JAW

2

this

(800)

below

the

should

latch

“SERVICE”

notification,

547-7828.

be

followed:

jaw

until

softkey

please

it

snaps

and

call

open

contact

IVAC's

Corporate

PO. Box

35335

Web

Site:

Office @ 10221

dl

San

http:/

/www.ivac.com/

Wateridge

Di

Circle 8 San

California

92186-5335 @ 1819)

-wac/

Diego.

California

92121-1579

453-7000

Page 9

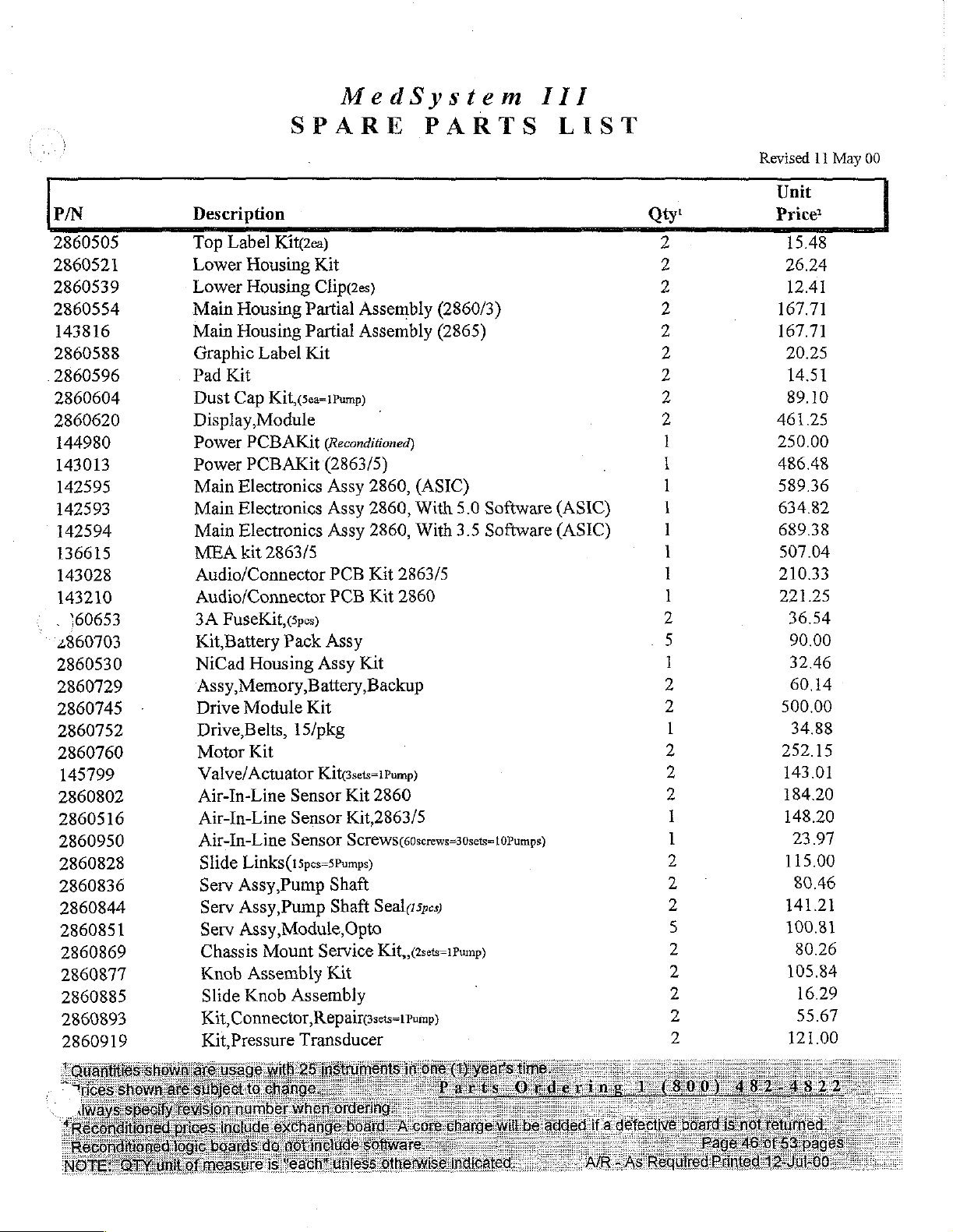

MedSystem

III

P/N

2860505

2860521

2860539

2860554

143816

2860588

2860596

2860604

2860620

144980

143013

142595

142593

142594

136615

143028

143210

.

160653

2860703

2860530

2860729

2860745

2860752

2860760

145799

2860802

2860516

2860950

2860828

2860836

2860844

2860851

2860869

2860877

2860885

2860893

2860919

Description

Top

Lower

Lower

Main

Main

Graphic

Pad

Dust

Display,

Power

Power

Main

Main

Main

MEA

Audio/Connector

Audio/Connector

3A

Kit,Battery

NiCad

‘Assy,Memory,

-

Drive

Kit,

SPARE PARTS

Label

Kit

FuseKit,(5pcs)

Drive

Motor

Valve/Actuator

Air-In-Line

Air-In-Line

Air-In-Line

Slide

Serv

Serv

Serv

Chassis

Knob

Slide

Kit,Pressure

Kit(2ea)

Housing

Housing

Housing

Housing

Label

Cap

Kitf,(5ea=1Pump)

Module

PCBAKit

PCBAKit

Electronics

Electronics

Electronics

kit

2863/5

Pack

Housing

Module

Belts,

15/pkg

Kit

Sensor

Sensor

Sensor

Links(15pes=5Pumps)

Pump

Assy,

Pump

Assy,

Assy,Module,Opto

Mount

Assembly

Assembly

Knob

Connector,

Transducer

Kit

Clip(2es)

Partial

Partial

Kit

Assembly

Assembly

(2860/3)

(2865)

|

(Reconditioned)

(2863/5)

Assy

Assy

Assy

PCB

PCB

2860,

2860,

Kit

Kit

2860,

2863/5

2860

(ASIC)

With

5.0

With

3.5

Software

Software

Assy

Assy

Kit

Battery,

Backup

Kit

Kit@sets=1Pump)

Kit

2860

Kit,2863/5

Screws(soscrews=30sets=10Pumps)

Shaft

Seal(15pes)

Shaft

(2sets-1Pump)

Service

Kit,

Kit

RepairGsets=1Pump)

LIST

(ASIC)

(ASIC)

Qty!

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

1

2

„5

1

2

2

1

2

2

2

1

1

2

2

2

5

2

2

2

2

2

Revised

Unit

Price

15.48

26.24

12.41

167.71

167.71

20.25

14.51

89.10

46125

250.00

486.48

589.36

634.82

689.38

507.04

210.33

221.25

36.54

90.00

32.46

60.14

500.00

34.88

252.15

143.01

184.20

148.20

23.97

115.00

80.46

141.21

100.81

80.26

105.84

16.29

55.67

121.00

11

May

00

Page 10

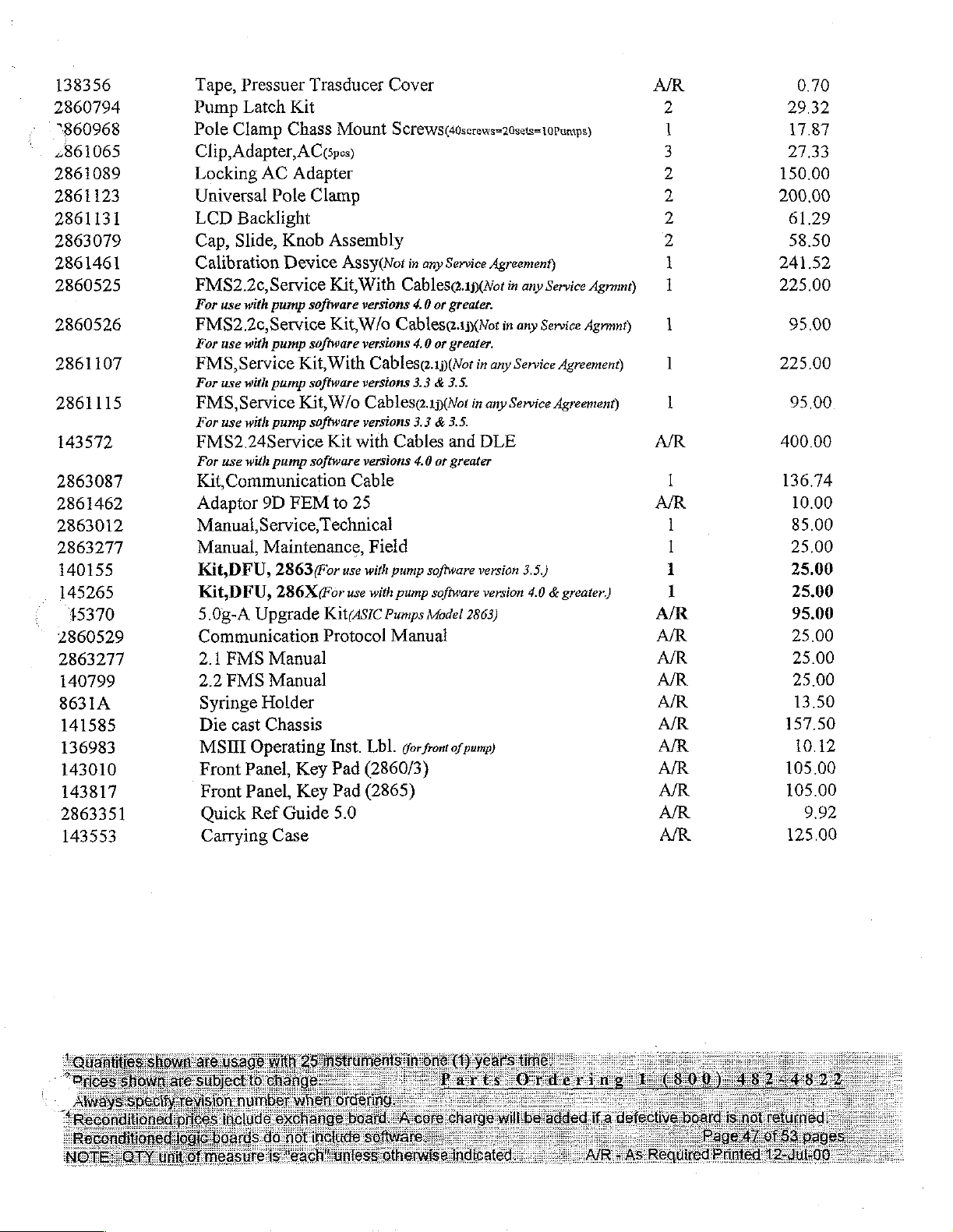

138356

2860794

"860968

2861065

2861089

2861123

2861131

2863079

2861461

2860525

2860526

2861107

2861115

143572

2863087

2861462

2863012

2863277

140155

145265

15370

2860529

2863277

140799

8631A

141585

136983

143010

143817

2863351

143553

Tape,

Pressuer

Pump

Pole

Clip,

Locking

Universal

LCD

Cap,

Calibration

FMS2.2c,

For

Latch

Clamp

Adapter,

AC

Pole

Backlight

Slide,

Service

use

with

pump

Kit

Chass

AC

Adapter

Knob

Device

FMS2.2c,Service

For

use

with

pump

FMS,

For

FMS,

For

Service

use

with

Service

use

with

Kit,

pump

Kit,

pump

FMS2.24Service

For

use

with

pump

Kit

Communication

Adaptor

Manual

Manual,

Kit,

Kit,

5.08-A

Communication

2.1

2.2

Syringe

Die

MSIII

Front

Front

Quick

Carrying

9D

Service,

Maintenance,

DFU,

2863

DFU,

286X

Upgrade

FMS

Manual

FMS

Manual

Holder

cast

Chassis

Operating

Panel,

Panel,

Ref

Case

FEM

Key

Key

Guide

Trasducer

Mount

Gpes)

Clamp

Assembly

Assy(Not

Kit,

With

software

software

software

software

software

versions

Kit,

W/o

versions

With

Cablesq.1p(Not

versions

W/o

Cables.1p(Wot

versions

Kit

with

versions

Cable

to

25

Technical

Field

For

use

with

(For

use

with

Kit(ASIC

Protocol

Inst.

Lbl.

Pad

(2860/3)

Pad

(2865)

5.0

Cover

Screws(4osccows=20sets=10Pumps)

in

any Service

Cables@.1p(Wot

4.0

or

Cables¢.1j(Not

4.0

or

3.3 & 3.5.

3.3 & 3.5.

Cables

4.0

or

pump

software

pump

software

Pumps

Model

Agreement)

greater.

greater.

in

any Service

in

any

and

DLE

greater

version

version

2863)

in

any

Service

in

any

Service

Agreement)

Service

Agreement)

3.5.)

4.0 & greater.)

Agrmnt)

Agrmní)

Manual

gor

front

of

pump)

0.70

29.32

17.87

27.33

150.00

200.00

61.29

58.50

241.52

225.00

95.00

225.00

95.00

400.00

136.74

10.00

85.00

25.00

25.00

25.00

95.00

25.00

25.00

25.00

13.50

157.50

10.12

105.00

105.00

9.92

125.00

Page 11

Page 12

MEDICAL

SYSTEMS

Technical

IVAC®

MedSystem

Service

Manual

III“

Infusion

System

Page 13

This

of

the

device

is

following

protected

U.S.

Patents:

under

one

or

more

4,814,685

4,818,190

4,832,299

4,850,817

_

4,856,340

4,863,425

4,872,813

D

309,188

D

309,662

Other

U.S.

and/or

Copyright O 1999

All

Rights

Reserved.

Reproduction

English

or

in

in

prior

reviews

or

written

other

scientific

permission

ALARIS

in

any

languages,

4,878,896

4,884,065

4,919,596

4,940,399

4,950,235

5,000,663

5,006,110

5,009,641

5,041,086

foreign

manner,

Medical

papers,

of

ALARIS

patents

in

except

is

may

Systems,

whole

or

for

prohibited

Medical

be

Inc.

in

part,

brief

excerpts

without

Systems.

5,053,747

5,064,412

5,126,616

5,149,603

5,176,343

5,176,631

pending.

in

Certification

has

(DE

been

granted

by

the

following

p

©

Standard

Risk

agencies:

C22.2

Class

2G

No.

125

Page 14

ALARIS”

Medical

Systems,

Inc.

IVAC®

Models

MedSystem

2860

Multi-Channel

Technical

Service

III"

and

Infusion

2863

Manual

Pump

MedSystem

Ill?

is

the

trademark

of

ALARIS

Medical

Systems,

Inc.

formerly

known

as

IVAC

Corporation.

Page 15

MedSystem

111%

Technical

Service

Manual

Copyright O 1999

This

document

possession

described.

authorization

.

This

Product

Diego,

Printed

Manual

does

Reproduction,

service

Support

CA

92126-5335,

in

the

part

from

manual

U.S.A.

number

ALARIS

contains

not

convey

ALARIS

is

subject

at

(800)

139981B

Medical

proprietary

any

rights

disclosure,

Medical

to

change

854-7128

attention

Product

Systems,

information

Systems,

ext.

to

or

use

without

6003,

Support.

Inc.

reproduce

other

Inc.

of

ALARIS

its

than

for

is

strictly

notification.

or

write

ALARIS

All

Medical

contents,

the

intended

forbidden.

For

Medical

Rights

Systems,

or

to

manufacture

purpose

current

Systems,

Reserved.

Inc.,

and

without

technical

Inc.,

its

receipt

or

sell

any

specific

information

P.O.

Box

or

product

written

please

85335,

call

San

Page 16

WARRANTY

ALARIS

“ALARIS

A.

Each

use

Medical

Medical

new

and

Medical

B.

Each

new

use

and

Medical

If

any

product

should

'

Diego,

this

expense.

packaged

repair

in

consequential

Systems

warranty

Furthermore,

responsible

any.

(a)

communicate

CA)

warranty,

The

and

facility

no

event

product.

shall

ALARIS

repaired

representative;

Systems™,

Systems”)

instrument

service

Systems.

for a period

to

accessory

service

Systems

to

shall

shall

this

for,

Medical

by

for a period

requires

determine

repair

product

postage

be

ALARIS

damages

This

not

warranty

any

anyone

Inc.

warranis

is

free

the

original

is

free

to

the

original

service

directly

the

appropriate

or

replacement

requiring

prepaid

at

purchaser's

Medical

in

connection

warranty

apply

loss

Systems

to

shall

or

damage

other

formerly

that:

from

defects

of

one

purchaser.

from

defects

of

ninety

purchaser.

during

with

the

service

by

purchaser.

risk.

Systems

shall

any

not

apply

product

than

IVAC®

in

material

(1)

year

in

material

(90)

days

the

applicable

ALARIS

repair

will

with the

apply

subsequent

arising

which

an

authorized

be

carried

should

to,

and

in

has

be

facility.

purchase

solely

connection

Corporation

and

from

the

and

from

the

warranty

Medical

Loss

liable

owner

ALARIS

been;

Systems

Except

out

at

be

returned

or

damage

for

or

to

the

Medical

ALARIS

or

(hereinafter

workmanship

date

of

delivery

workmanship

date

of

delivery

as

ALARIS

any

use

original

holder

with

the

Medical

period,

provided

in

incidental,

of

Systems

the

headquarters

Medical

promptly,

return

any

ALARIS

purchaser.

of

purchase

Systems

referred

under

under

normal

by

ALARIS

normal

by

ALARIS

purchaser

otherwise

Systems

properiy

shipment

indirect

Medical

the

product.

shall

not

or

use

service

to

as

(San

This

be

in

to

or

of

(b)

altered

product's

(c)

subjected

serial

(d)

improperly

written

This

warranty

obligations

not

give

person

with

the

ALARIS

in

stability

or

lot

instructions

or

or

grant,

to

assume

sale

or

MEDICAL

OR IMPLIED,

FITNESS

See

FOR A PARTICULAR

packing

inserts

anyway

to

number

maintained

is

liabilities

use

so

or

misuse

altered,

furnished

in

lieu

of

directly

on

behalf

of

ALARIS

reliability;

or

ALARIS

SYSTEMS

INCLUDING

for

international

as

to

affect,

negligence

effaced

or

used

by

of

all

other

Medical,

or

indirectly,

of

ALARIS

Medical

DISCLAIMS

ANY

PURPOSE

in

ALARIS

or

accident,

or

removed;

or

in

any

manner

ALARIS

Medical

warranties,

Systems

the

Medical

Systems

WARRANTY

OR

warranty,

Medical

or

which

other

Systems.

express

and

ALARIS

authority

Systems

products.

ALL

to

any

OTHER

OF

MERCHANTABILITY

APPLICATION.

if

applicable.

Systems

-

has

had

than

in

accordance

or

implied,

Medical

any

representative

other

liability

WARRANTIES,

judgement,

the

product's

with

and

all

other

Systems

in

connection

or

does

other

EXPRESS

OR

the

the

OF

iii

Page 17

The

purpose

trained

troubleshoot,

All

KEY

instrument.

This

manual

Summary,

the

instrument.

in

the

NAMES

Screen

Appendix

of

analysis

contains

this

and

are

Technical

and

repair

the

written

messages

guidelines

H,

for

MedSystem

Servcie

servicing

MedSystem

in

regular type

are

written

for

general

precautions

III?

Technical

Service

Foreword

Manual

of

microprocessor-controlled

user

M1?

Infusion

as

they

in

italics.

and

patient

is

to

appear

before

enable

System.

safety.

beginning

personnel

on

Manual

who

instrumentation

the

computer

We

suggest

any

maintenance

are

experienced

to

keyboard

you consult

or

and

maintain,

or

the

Safety

repair

on

Specific

applicable.

If

local

If

If

you

you

you

advisory

need

ALARIS

need

need

and

cautionary

Contacting

assistance

Medical

technical

Customer

Systems

assistance,

ALARIS

with the

Service

information

Medical

installation

Account

call

or

Parts,

Manager.

toll

free

call

is

contained

or

operation

(800)

toll

free

」

Systems

of

854-7128

(800)

throughout

Technical

MedSystem

extension

482-4822.

the

manual

Support

Ill

equipment,

6003.

where

contact

your

Page 18

:

Chapter

1:

INTRODUCTION

MAIN

TABLE

OF

CONTENTS

Chapter

contents.

Chapter

Chapter

for

the

Chapter

Chapter Three

after

Chapter

Chapter

operating

Chapter

Chapter

optimum

Chapter

One

contains

2:

PRINCIPLES

Two

MedSystem

3:

SYSTEM

repair

or

4:

MAINTENANCE

Four

efficiently

5:

CALIBRATION

Five

performance.

6:

TROUBLESHOOTING

general

provides

III.

an

overview

FUNCTIONAL

describes

calibration,

provides

contains

the

and

procedures

and

to

references

information

OF

OPERATION

functional

annually

detect

the

for

about

of

the

system

TESTS

tests

recommended

as

part

of

for

properly

need

for

calibrating

the

MedSystem

and

details

preventive

maintaining

repair

or

adjustment.

and

adjusting

Ill

the

principles

`

prior

to

maintenance.

the

the

and about

of

using

the

instrument

instrument

the

manual

operation

instrument,

to

keep

it

to

maintain

Chapter

possible

procedures

Chapter

Chapter

reassembling

and

Six

contains

malfunctions.

in

the

event

7:

REPAIR

Seven

contains

the

instrument,

subassemblies.

troubleshooting

References

of a malfunction.

detailed

and

are

for

step-by-step

procedures

included

removing

to

to

help

guide

procedures

and

installing

isolate

service

replaceable

and

identify

personnel

for

disassembling

causes

to

the

proper

and

components

of

Page 19

MedSystem

ili

Technical

Service

Manual

Appendix

This

appendix

instrument.

Appendix

This

appendix

depicting

Appendix

This

appendix

Appendix

This

appendix

useful

troubleshooting.

Appendix

in

MAIN

A:

TECHNICAL

contains

B:

REQUIRED

is a general

special

C:

RECOMMENDED

lists

D:

BATTERY

provides

performing

E:

ILLUSTRATED

TABLE

the

EQUIPMENT

listing

tooling

and

recommended

HISTORY

details

battery

OF

CONTENTS

SPECIFICATIONS

physical,

electrical,

AND SUPPLIES

of

required

equipment.

SPARE PARTS

spare

parts,

LOG

about

the

Battery

operating

PARTS

time

functional

LIST

and

equipment

as

well

as

History

checks,

(Continued)

mechanical

and

the

order

Log,

specifications

supplies,

numbers

which

contains

annual

of

as

well

as

figures

for

each.

information

maintenance,

the

and

This

appendix

each.

Appendix

This

appendix

Appendix

This

appendix

Appendix

This

appendix

the

manual.

Appendix

This

appendix

assembly

is

an

illustrated

F:

LIST

OF

provides a list

G:

GLOSSARY

defines

H:

SAFETY

provides

I:

SCHEMATICS

provides

and

the

power

listing

ABBREVIATIONS

of

the

abbreviations

OF.

TERMS

some

words

SUMMARY

general

supply,

board

safety

assemblies

along

of

instrument

and

terms

precautions

with

parts,

AND

an

ACRONYMS

and

which

may

that

and

schematics

interconnect

as

well

acronyms

not

be

are

not

diagram.

as

the

order

used

in

the

well-known

included

for

the

within

main

numbers

manual.

to

the

user.

the

electronics

for

text

of

Page 20

TABLE

INTRODUCTION

1.0

Systeminiroducton........................

1.1

Objeciives................

1.2

UsinghisManual..........................

1.3

Newinstrument

1.3.1

1.3.2

1.4

Customizing

15

PointsofContaci.........................

oPhysicalinspection

Functionallesis.........................

Checkout.

.................

............................

Parameters...................

OF

CONTENTS

cee

00mm

444

00...

eserse

eee

0.0.

eee

ων

een

κών

eee

enes

ence

eens

нина

κενο ν 1-4

ώ

ον

ké

Page

1-3

1-3

14

1-4

14

1-5

1-5

MedSystem

III

Technical

Service

Manual

1-1

Page 21

Introduction

1-2

MedSystem

III

Technical

Service

Manual

Page 22

Chapter

1

Introduction

1.0

System

The

MedSystem

*

based

venous,

the

bottles

operates

and

The

fluid

equivalent

or

programmed

air

in a line,

tored

using

design

following

・

Upgradeable

»

Low

e

Calibration

*

CMOS

*

Modular

Easy

Maintenance,

of

MedSystem

user

to

communicate

port,

using

Introduction

II ™ Infusion

delivery

intra-arterial,

bags

via a disposable

and

built-in

and

features:

maintenance,

surface-mount

design

disassembly/reassembly

an

device

or

subcutaneous

of

an

independent

located

above

infusion

for

infusion

low

power.

self-tests

construction

software

no

through

calibration,

TI

software

Field

Maintenance

with

IBM-PC

compatible

capable

or

tasks.

The

to

of

lubrication

circuitry

and

customization

the

infusion

System

is a small,

of

controlled

routes.

infusion

below

the

cassette.

Infusions

electronic

help

ensure

the

MedSystem

Software

system through

computer.

and

Each

device

level

of

able

Channels

are

and

software

safe

operation.

III

features

(FMS).

three-channel,

monitored

of

the

three

to

pump

the

instrument.

are

individually

monitored

functions

Infusion

are

available

This

its

RS-232

microprocessor-

infusion

channels

fluid

to

detect

System

software

communications

via

provides

from

syringes,

Each

channel

controlled

occlusions,

are

also

moni-

provides

through

the

allows

intra-

the

use

the

1.1

Objectives

The

purpose

troubleshoot,

prepared

analysis

mended

or

repair

In

light of

and

specialized

it

is

recommended

ule

or

replaceable

minimal

It is

suggested

procedures

tions

For

tions

for

of

and

under

and

servicing

that a factory

of

the

the

or

no

be

Use

Use,

this

manual

repair

the

presumption

is

to

enable

the

MedSystem

that

of

microprocessor-controlled

authorized

training

instrument.

state-of-the-art

equipment

that

troubleshooting

part

level.

unsoldering

that a complete

obtained.

(DFU)

in

and

addition

technology

required

Replaceable

of

circuit

overview

This

can

the

MedSystem

to

this

Technical

qualified

HI

Infusion

the

user

program

used,

in

the

replacement

and

parts

components.

of

be

done

by

If

Service

service

System.

is

experienced

instrumentation.

precede

proprietary

repair

all

be

are

items

features,

consulting

Field

Maintenance

Manual.

personnel

This

and

any

actual

nature

of

individual

performed

that

can

functions,

the

MedSystem

to

maintain,

manual

trained

of

has

in

It

is

disassembly

the

software,

components,

only

to

the

be

replaced

and

operating

II

Software

been

the

recom-

mod-

with

Direc-

Direc-

MedSystem

HI

Technica!

Service

Manual

1-3

Page 23

Introduction

1.2

Using

This

Throughout

to

both

called

The

Each

principles

them.

ter 5 describes

bleshooting,

troubleshooting

This

manual

models.

Manual

includes

the

manual,

Where

out.

Technical

chapter

Service

is

clearly

of

operation.

Chapter 4 provides

procedures

and

includes a number

process.

ment.

The

appendices

A-

Technical

B - Required

C - Recommended

D - Battery

E-

Illustrated

E-

List

of

G - Glossary

H-

Safety

I-

Schematics

All

instructions,

each

chapter

tion.

It

is

suggested

ning any

type

included

Specifications

Equipment

History

Parts

Abbreviations

of

Terms

Summary

special

to

minimize

that

of

service

information

if

no

information

Manual

defined

on

the

model

number

is

specific

is

specifically

in

the

table

Chapter 3 discusses

both

routine

for

calibrating

of

Chapter 7 is a detailed

are:

and

Supplies

Spare

the

Log

List

Safety

Parts

and

notes,

the

need

on

the

Acronyms

and

illustrations

to

refer

Summary,

instrument.

Model

is

of

functional

and

annual

the

tables

to

Appendix

2860

and

Model

specified,

to

one

structured

contents.

the

model,

to

Chapter 2 discusses

tests

maintenance

instrument.

to

be

used

Chapter.6

as

procedure

are

integrated

multiple

H,

pages

be

reviewed

2863

pumps.

information

that

model

facilitate

and

how

number

ease

to

complete

procedures.

discusses

guides during

for

repairing

within

during a single

the

before

pertains

is

of

use.

the

Chap-

trou-

the

the

instru-

text

of

opera-

begin-

1.3

1.3.1

1.3.2

_

New

Physical

*..

*

+

Instrument

Inspection

Before

affected

Check

Check

found,

unpacking,

contents.

to

for

report

Functional

Refer

and

to

your

testing

of

Recommended

MedSystem

1H

Technical

Checkout

check

Report

ensure

any

Tests

institution's

that

all

physical

it

to

Customer

incoming

equipment

functional

Service

Manual

accessories

damage

policies

tests

the

shipping

any

shipping

Service.

for

are

container

are

to

the

instrument

specific

before

given

in

for

damage

included

to

in

or

requirements

use.

Chapter 3 of

damage

Customer

the

that

Service.

package.

accessories.

regarding

this

manual.

may

have

If

any

is

inspection

Page 24

Introduction

1.4

1.5

Customizing

Certain

customizing

Directions

Points

For

Customer

1-800-482-4822

For

Product

1-800-854-7128

MedSystem

For

of

parts,

disposables,

Service

technical

Support

is

desired,

Use.

Contact

information,

Parameters

II

operating

refer

or

repair

Department

assistance

Department

extension

6003

to

the

service,

parameters

MedSystem

telephone:

with

repair,

can

be

I

Directions

or

technical

customized

For

Use

training,

using

telephone:

and

FMS.

the

if

FMS

MedSystem

III

Technical

Service

Manual!

1-5

Page 25

Page 26

Page 27

Page 28

Chapter

2

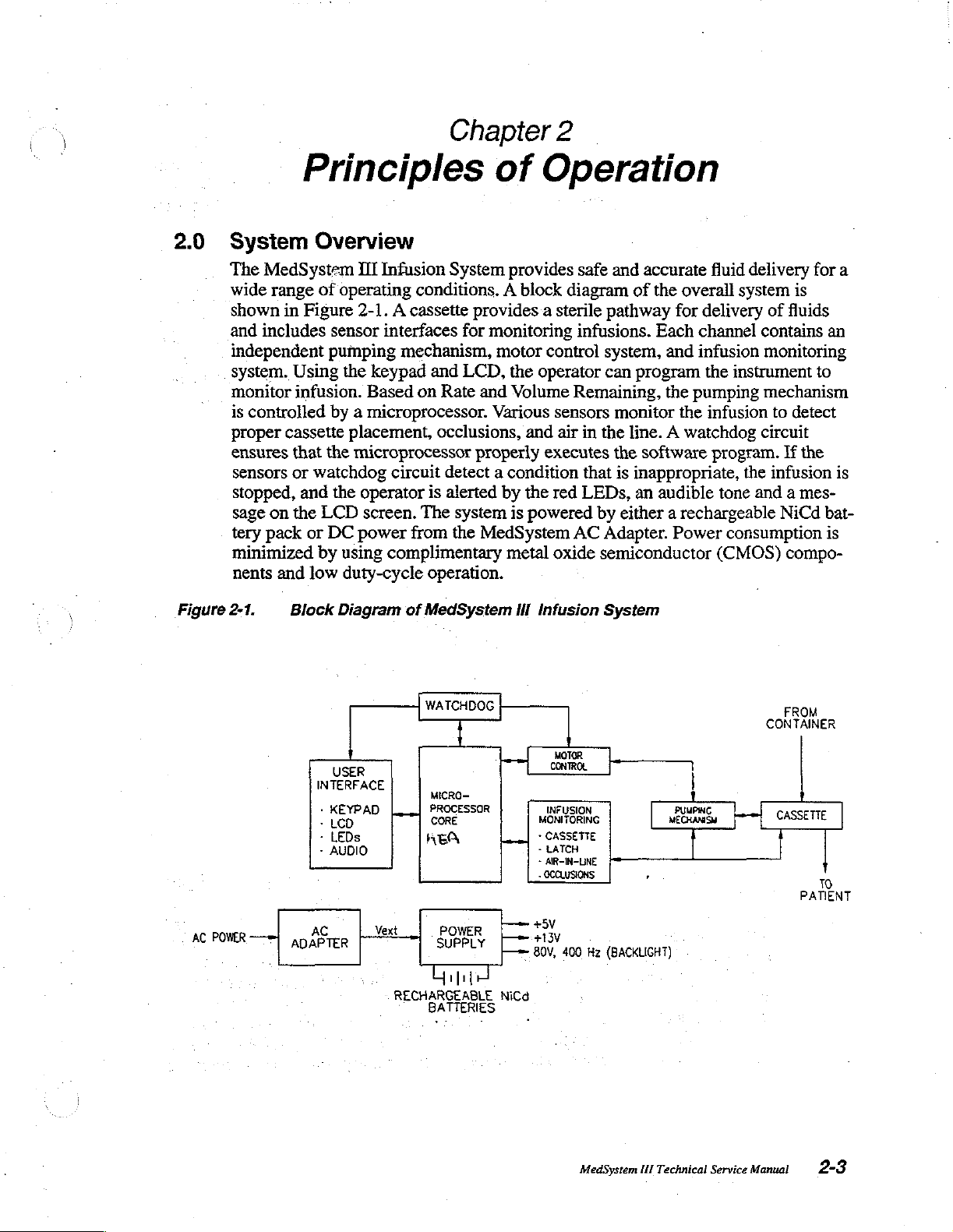

2.0

Figure

Principles

System

The

MedSystem

wide

shown

and

includes

independent

system.

monitor

is

controlled

proper

ensures

sensors

stopped,

sage

on

tery

pack

minimized

nents

2-1.

Overview

range

of

in

Figure

Using

infusion.

cassette

that

or

watchdog

and

the

LCD

or

by

and

low

Block

of

III

Infusion

operating

2-1. A cassette

sensor

pumping

the

Based

keypad

interfaces

mechanism,

by a microprocessor.

placement,

the

microprocessor

circuit

the

operator

screen.

DC

power

using

complimentary

duty-cycle

Diagram

System

conditions. A block

provides a sterile

for

monitoring

motor

and

LCD,

on

Rate

and

Various

occlusions,

properly

detect a condition

is

alerted

The

system

from

the

MedSystem

operation.

of

MedSystem

Operation

provides

the

Volume

and

by

the

is

powered

metal oxide

Ill

safe

diagram

pathway

infusions.

control

operator

system,

can

Remaining,

sensors

air

in

the

executes

that

red

LEDs,

by either a rechargeable

AC

Adapter.

semiconductor

Infusion

System

and

of

monitor

line. A watchdog

the

is

accurate

the

Each

fluid

overall

for

delivery

channel

delivery

system

contains

and infusion

program

software

inappropriate,

an

audible

the

pumping

the

Power

the

instrument

infusion

circuit

program.

the

tone

and a mes-

consumption

(CMOS)

for

a

is

of

fluids

an

monitoring

to

mechanism

to

detect

If

the

infusion

NiCd

is

bat-

is

compo-

POWER

AC

一

USER

INTERFACE

・

Ker

AD

:

-

LEDs

-

AUDIO

AC

ADAPTER

WATCHDOG

MICRO—

PROCESSOR

CORE

AEA

Vext

POWER

SUPPLY

Grup

RECHARGEABLE

BATTERIES

MONITORING

>

-

-

»

OCCLUSIONS

+5V

Lee

+13V

|

Bov.

NICO

MOTOR

CONTROL

CASSETTE

LATCH

АВ-М-ВМЕ

Hz

400

MEGHAN

(BACKLIGHT)

FROM

CONTAINER

CASSETTE

το

PATIENT

MedSystem

HI

Technical

Service

Manual

2-3

Page 29

Principles

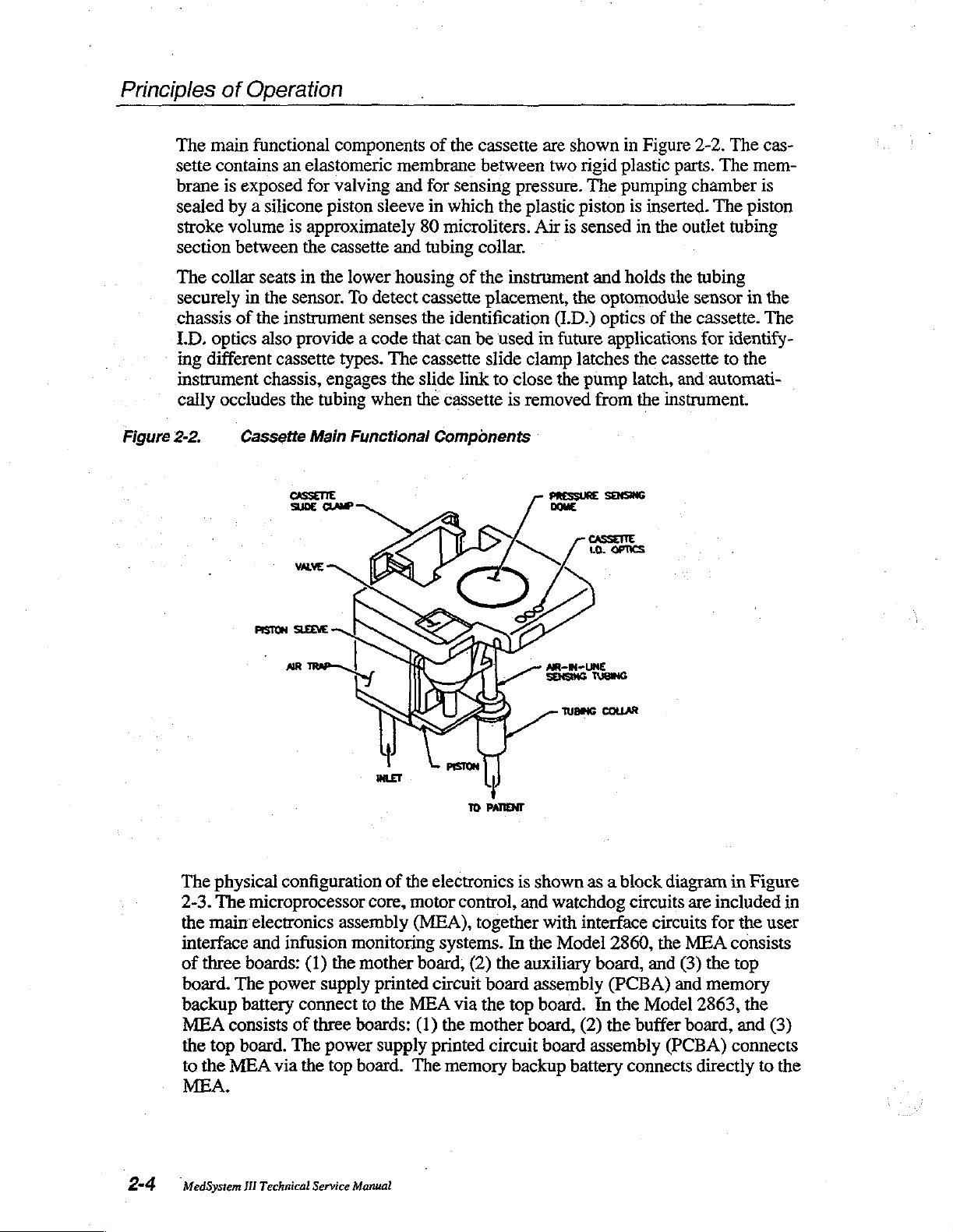

The

main

sette

contains

brane

sealed

stroke

section

The

collar

securely

chassis

LD.

optics

ing

different

instrument

cally

of

Operation

functional

an

elastomeric

is

exposed

for

by a silicone

volume

between

of the

is

seats

in

the

instrument

also

approximately

the

in

sensor.

provide a code

cassette

chassis,

occludes

the

tubing

components

valving

piston

the

engages

sleeve

cassette

and

lower

To

detect

senses

types.

The

the

when

of

the

membrane

and

for

sensing

in

which

80

microliters.

tubing

housing

of

cassette

the

identification

that.can

cassette

slide

link

the

cassette

cassette

between

are

two

pressure.

the

plastic

Air

collar.

the

instrument

placement,

(I.D.)

be

used

in

slide

clamp

to

close

is

removed

shown

rigid

The

piston

is

sensed

and

the

optomodule

optics

future

applications

latches

the

pump

from

in

Figure

plastic

pumping

holds

parts.

is

inserted.

in

the

outlet

the

of

the

the

cassette

latch,

and

the

instrument.

2-2.

The

The

mem-

chamber

The

piston

tubing

tubing

sensor

cassette.

in

for

identify-

to

the

automati-

cas-

is

the

The

Figure

2-2.

The

2-3.

the

Cassette

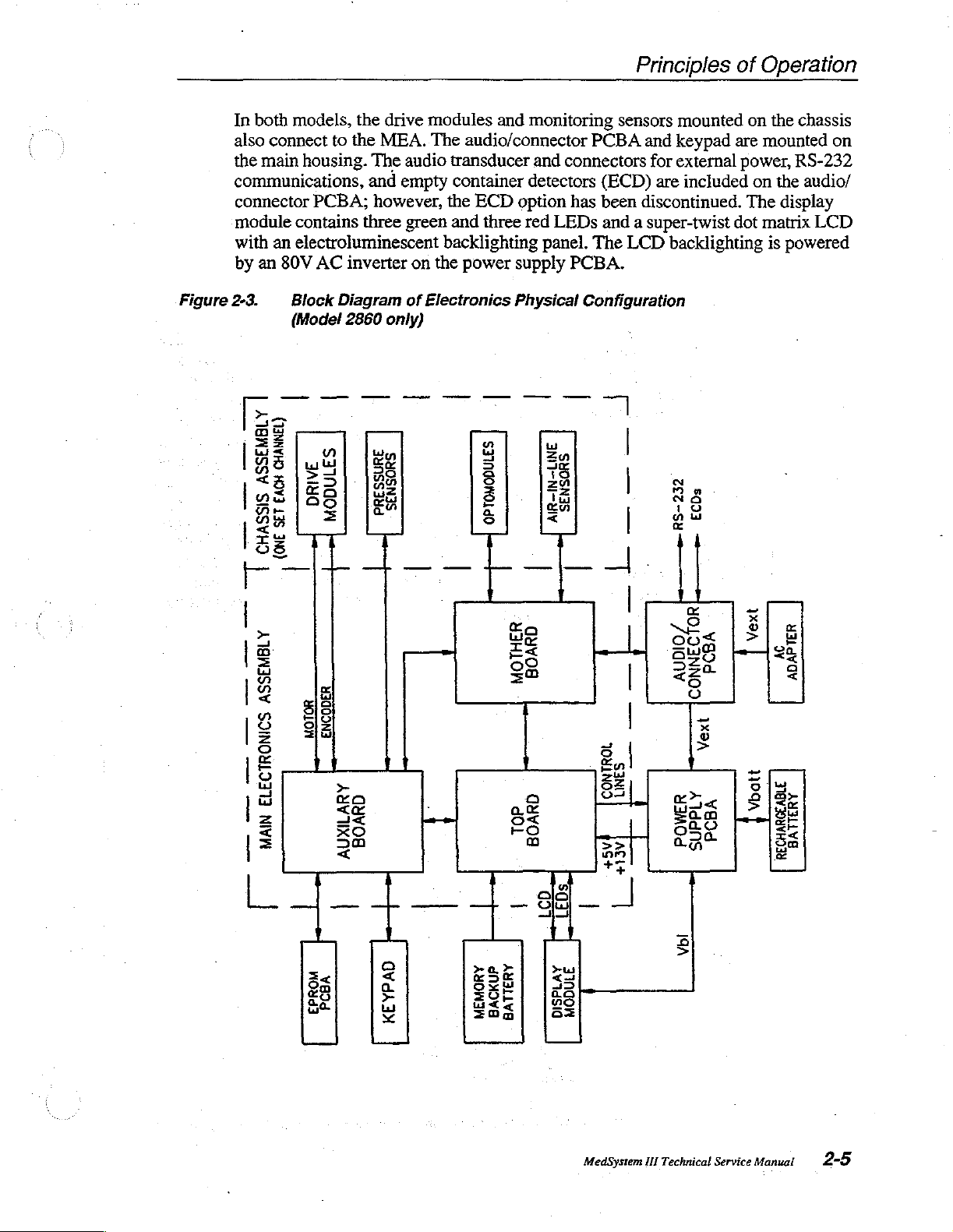

physical

The

maim

interface

of

three

boards:

board.

backup

MEA

the

to

The

consists

top

board.

the

MEA

battery

MEA.

Main

Functional

configuration

microprocessor

electronics

and

infusion

(1)

power

supply

connect

of

three

The

via

the

core,

assembly

monitoring

the

mother

printed

to

boards:

power

top

board.

of

the

motor

(MEA),

board,

the

MEA

(1)

supply

The

Components

electronics

is

control,

together

systems.

circuit

via the

the

printed

memory

In

(2)

the

board

top

mother

circuit

backup

shown

and

the

auxiliary

as a block

watchdog

with

interface

Model

assembly

board.

board,

(2)

board

assembly

battery

circuits

2860,

board,

(PCBA)

In

the

the

buffer

connects

diagram

are

circuits

the

MEA

and

(3)

and

Model

board, and

(PCBA)

in

Figure

included

for the

user

consists

the

top

memory

2863,

the

connects

directly

to

in

(3)

the

2-4

MedSystem Ш Technical

Service

Manual

Page 30

In

both

models,

also

connect

the

main

housing.

communications,

connector

module

with

by

contains

an

electroluminescent

an

80V

to

PCBA;

AC

inverter

the

the

drive

MEA.

The

audio

and

empty

however,

three

green

on

modules

The

transducer

the

backlighting

the

and

audio/connector

container

ECD

option

and

three

red

power

supply

monitoring

PCBA

and

connectors

detectors

LEDs

panel.

(ECD)

has

been

and a super-twist

The

PCBA.

Principles

sensors

LCD

mounted

and

keypad

for

external

are

included

discontinued.

backlighting

of

Operation

on

the

chassis

are

mounted

power,

The

dot

RS-232

on

the

display

matrix

is

powered

on

audio/

LCD

Figure

2-3.

lag

dE

|

|

WS

lw

«δις

jus

Be

пы

|

ー

|

>

그

E

č

a

<

[2

8

=

o

|

E

o

之

£

=

|

Block

(Model

|

(BS)

oo]

=

ge

Js

O)

as

二

|

Diagram

2860

only)

lu

še

Da

a

|

jeg

ce

SE

=5

38

<

of

Electronics

Physical

a y

5

8

8 | [15

と

5

5%

i |

za

ah

<

ge

τας

55

og

=

e

at

은

E

1

C

Configuration

|

|

|

|

|

4

3

|

En

5

|

35

|

22|

++

EDs

N

38

19

yu

| |

gs

ち < |

205

SHE

250

そら

8

я

2

|

Ex

Sam

Lo

a

Vbl

S|

っ

(E

고

|

LIRE

Bui

ЕН

ES

回

G

と

a

<

a

EPROM

PCBA

KEYPAD

MEMORY

BACKUP

BATTERY

MODULE

DISPLAY

MedSystem

Ill

Technical

Service

Manual

2-5

Page 31

Principles

of

Operation

Fluid

Delivery

|

~

è

Proper

correct

after

ponents

personnel.

Fluid

is

delivered

module.

The

elastomeric

moved

„system

by a cam

the

connected

a

track

rocate

rotates

shaft

power

Each

valves

back

is

shown

in

cam

face

in

the

when

the

bearings

is

removed

of

to

cam

information

|

pump

operation

replacing

or

the

to

the

channel

the

pump

membrane

and

forth by

in

Figure

the

drive

module.

properly.

the

pump

side

of

the

the

cam

is

via

an

for

support,

from

for

controlling

WARNING

latch

and

valve

of

the

instrument.

certain

pump

patient

has

are

in

The

shaft.

cam,

rotated: A direct

elastomeric

the

drive

components.

latch

should

by a reciprocating

an

independent

formed

the

valve

the

pumping

2-4.

cassette

Follower

by

area

The

valve

Return

piston

springs

causing

belt.

and a one-way

motor.

fluid

An

delivery.

actuator

actuators

of

mechanism. A functional

actuators

bearings

the

current

The

encoder

heights

Heights

only

be

drive

module

in

the

cassette.

ensure

is

captured

attached

pump

latch

(DC)

drive

clutch

on

are

must

Removal

performed

piston

the

chassis

The

and

cassette

that

by

and

motor

module

to

prevent

the

cam

necessary

be

adjusted

of

drive

by

pump

mounted

powered

compressing

cassette

diagram

piston

the

valve

the

pump

to

the

pump

cassette

in

the

housing

backdriving

shaft

provides

for

com-

trained

by a drive

to

the

chassis.

piston

of

are

operated

actuators

latch

which

shaft

engage

piston

drive

to

module

includes

when

position

the

is

this

follow

is

recip-

cam

Figure

2-4..

Functional

DRIVE

MODULE

DRIVE

BELT

we

am

Diagram

MOTOR

」

4

o

|

of

.

Peston

Pumping

çimli

DNCODER

É

CASSETTE

Mechanism

m

CSS

nus

ONE-mAY

САМ

CAM

FOLLOWER

VALVE

PUMP

cusica | Tee

Encuees

BEARNGS

ACTUATOR

LATCH

in

tre

housing.

NOTE:

MedSystem

Arrangement

HI

Technical

and

Service

scaling

Manual

of

components

may

be

different

than

actual

configuration.

This

is

for

clarity.

Page 32

Principles

of

Operation

Cassette

turned

at

the

nal

During

slot

the

is

pushed

the

the

against

closing

sis

patient.

Sensors

together

fluid

Pumping

valve

by

closes

overlapped

closed.

chamber

installation

on

beginning

from

the

installation

in

the

side

that

in,

pump

slide

clamp

the

off

also

unclamps

The

in

with

delivery.

begins

is

closed

retracting

the inlet

Fluid

(see

prepares

and a cassette

of

the

fill

encoder,

allows

(see

front

of

the

slide

engages a slot

the

tab

pushes

latch.

The

cassette

also

engage

chassis.

the

tubing

the

to

This

fluid

pathway.

the

patient-side

collar

optomodule

the

air

sensor's

by

positioning

and

the

the

piston

valve

and

ensure

is

Figure

then

the

delivered

2-6B).

the

is

not

installed,

stroke.

the

Figure

2-5), a tab

link.

in

the

the

slide

piston

holders

forces

the

Pushing

is

then

detect

detection

inlet

valve

(see

Figure 2-6A).

opens

fiuid

pathway

by

system

The

home

pump

The

back

latch

movable

of the

link,

is

now

in

the

valve

the

tubing,

secured

cassette

of

the

valves

is

opened.

the

outlet

between

advancing

for

fluid

delivery.

the

cam

is

position,

to

easily

on

the

cassette

jaw

slide

which,

held

in

firmly

chassis

actuators

cassette

allowing

in

the

air-in-line

placement

fluid,

signals

to

fill

the

The

pumping

Once

the

valve.

the

Opening

the

piston

When

rotated

which

capture

slide

of

the

pump

link.

As

the

turn,

closes

by

the

to

hold

the

against

slide

clamp

fluid.to

sensor

and

pump

that

pumping

chamber

and closing

container

toward

the

to

the

"home"

is

indicated

the

cassette

clamp

latch

cassette

the

pump

cassette

the

cassette

in

toward

be

delivered

by

latch

the

channel

chamber.

chamber

is

filled,

and

patient

the

instrument

position

by a sig-

piston.

engages

has a post

slide

movable

latch.

Tabs

body

valve

the

to

the

the

operator.

closure.

is

ready

The

is

then

the

cam

of

valves

is

always

bottom

of

is

a

on

clamp

jaw

of

on

firmly

area,

chas-

This,

for

outlet

filled

is

the

Delivery

back

ing:

stroke,

ing

results

counter

grammed

and

mines

turned

The

pulse

voltage

13V

controlled

stroke.

tains

rate

from

the

(1)

sensing

(2)

sensing

the

home

in a volume

that

by

measured

the

appropriate

on.

controller

width

circuit. A drive

is

used

by

This

fluid

delivery

experienced

is

regulated

encoder.

whether

the

incremental

position.

resolution

accumulates

the

user,

is

encoder

motor

performs

is

loaded

for

logic

signal

during

into a programmable

rates

greater

circuits;

is

referred

rate

infusions.

by

varying

An

encoder

the

pump

The

delivery

of

encoder

converted

counts, a feedback

pulse

these

calculations

voltage

than

using

to

at

the

programmed

the

on

the

channel

motion

stroke

0.5

microliters.

counts

to

required

width

of

5V

is

275

ml/h.

an

optical

as

DEL.

used

duty

cycle

cam

shaft

is

in

the

during

is

divided

The

for

each

encoder

control

which

is

every

interval

for a rate

Valving

encoder

This

closed-loop

value

of

the

motor,

has

several

fill

stroke

fluid

delivery,

into

160

microprocessor

channel.

algorithm

the

three

timer

and

signal

The

counts.

duration

seconds.

that

of

275

pump

that

system

despite

the

based

functions,

or

in

the

delivery

and

(3)

increments,

reads

infusion

From

the

in

the

software

that

the

motor

The

calculated

controls

ml/h

filling

marks

the

or

less,

phases

the

accurately

varying

loads

on

feed-

includ-

determin-

which

a

rate,

pro-

required

deter-

is

drive

and

are

delivery

main-

that

are

MedSystem I Technical

Service

Manual

2-7

Page 33

Principles

of

Operation

Figure

2-5.

PUMP

STATIONARY.

PUMP

MOVING

SUDE

Cassette

SHAFT

LINK

AW

LATCH

JAW

Installation

A.

CHASSIS

INSERT

:

.

CASSETTE.

CASSETTE

CASSETTE

SLIDE

PISTON

CLAMP

2-8

MedSystem

Il

Technical

C.

Service

Manual

CASSETTE

ENGAGED.

2

~

Z

Page 34

Principles

of

Operation

Figure

2-6.

Pumping

CHASSIS

RIGID

PLASTIC

OF

CASSETTE

Chamber

OUTLET

ACTUATOR

ZA

SILICONE

DIAPHRAGM

PISTON

BY

VALVE

RETRACTED

PUMP

LATCH

L

TI

VALVE

CLOSED

Th

U

クノ

¡EOS

ELİA

—_

7

AN

クン ン シン

クン

ンジ

:

MOTUATOR

DSS

Li

[piston

Gee

N

BO-p!

SLEEVE

PISTON

VALVE

FLUID

N

CHAMBER

ACTUATOR

FLUID OUT

RIGID

PISTON

BY

PUMP

me

A)

PLASTIC

ADVANCED

LATCH

A.

FILL

À

K

STROKE.

Tan

LAA

ACTUATOR

E

.

3

CLOSED

nů

B.

DELIVERY

STROKE.

MedSystem

III

Technical

Service

Manual

2-9

Page 35

Principles

of

Operation

2.2

Microprocessor

Figures

nents

unless

A.

A

tions.

tions,

trollers,

ates

Моде]

24.576

B.

The

trol

the

PLD

devices

address

address

maps

2-7

and

2-7a

connected

otherwise

to

noted.

Microprocessor

Z180

8-bit

microprocessor

On-chip

two

and

the

6.144

2863,

MHz

Address

functions

16-bit

programmable

an

interrupt

MHz

an

on-chip

external

Decoding

microprocessor

lines.

In

the

Model

Z180

via

logic

is

connected

on

the

microprocessor

decode

bus and

generate

circuits