Page 1

MedSystemIII

®

Multi-Channel Infusion Pump with

Advanced Dose Rate Calculation

DIRECTIONS FOR USE

Page 2

INTRODUCTION

BASIC OPERATION

ADVANCED OPERATION

TROUBLESHOOTINGMAINTENANCE

TABLE OF CONTENTS

INTRODUCTION

ABOUT THE PUMP....................................................................... 1

FEATURES.................................................................................... 2

SYSTEM COMPONENTS ............................................................... 4

OPERATIONAL PRECAUTIONS ...................................................... 6

BASIC OPERATION

PREPARING THE INFUSION .......................................................... 9

PREPARING THE ADMINISTRATION SET ........................................ 9

LOADING THE SET ....................................................................... 9

FRONT PANEL OVERVIEW ............................................................ 10

PROGRAMMING PRIMARY INFUSION........................................... 14

MAKING CHANGES WHILE INFUSING .......................................... 15

KVO STATUS................................................................................ 17

ADVANCED OPERATION

SECONDARY MODE .................................................................... 19

PREPARING THE ADMINISTRATION SET ........................................ 19

PROGRAMMING SECONDARY INFUSION...................................... 20

DOSE RATE CALCULATOR (DRC) USING A SPECIFIC DRUG NAME............... 22

DOSE RATE CALCULATOR PROGRAMMING WITH DRUG? ........................... 24

DEVICE........................................................................................ 26

CONFIG....................................................................................... 28

NOTE .......................................................................................... 29

BATLOG....................................................................................... 29

TROUBLESHOOTING

RESPONDING TO AN ADVISORY, ALARM OR FAULT ...................... 31

ALARM RESPONSE KEYS .............................................................. 31

ADVISORIES ................................................................................ 32

ALARMS...................................................................................... 33

FAULT.......................................................................................... 36

WATCHDOG ................................................................................ 36

OTHER CONDITIONS.................................................................... 36

MAINTENANCE

SPECIFICATIONS .......................................................................... 37

CLEANING................................................................................... 38

INSPECTION REQUIREMENTS ....................................................... 41

SERVICE INFORMATION............................................................... 42

WARRANTY................................................................................. 43

GLOSSARY................................................................................... 44

Alaris MedSystem III Directions For Use v

Page 3

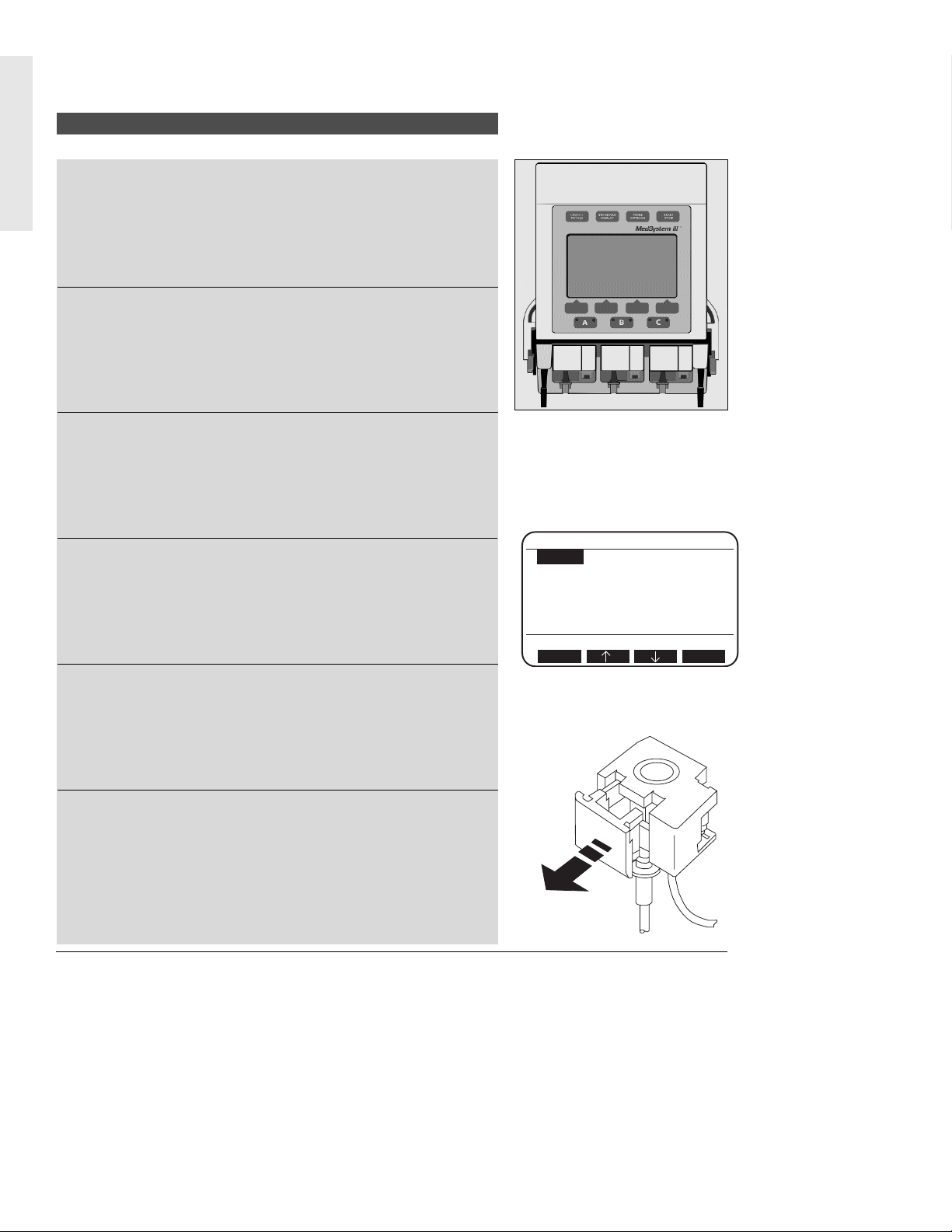

INTRODUCTION

CHAPTER 1 — INTRODUCTION

The MedSystem III®Multi-Channel Infusion Pump —

• three independent fluid delivery systems in the space of one.

• compact size:

- reduces bedside clutter

- simplifies patient transport

• easy to setup and use, yet provides advanced features.

• accurate delivery of a variety of fluids.

• accommodates assorted container types.

• multiple delivery methods:

Intravenous/Intra-arterial/Subcutaneous/Epidural

• Uses administration sets that provide free flow protection.

• Six available Device Types with configurable parameters

(maximum and minimum rates, maximum volumes, baseline

and maximum pressures, and air-in-line thresholds) to

achieve specific clinical applications:

General Purpose

Neonatal

Controller Pressure

Operating Room

General Purpose II

Operating Room II

• Displays infusion status for rate, volume remaining and

volume infused.

• Infusions can be programmed to deliver at a specified rate or

over a specified period of time.

• Secondary mode allows fluids and medications to be

delivered at two different rates, sequentially.

• Dose Rate Calculator (DRC) feature performs the volumetric

rate and/or dose rate calculations.

• With DRC activated, displays infusion status for rate, dosing

regimen and drug name.

• Communications Protocol allows clinical monitoring,

instrument configuration and maintenance.

• Field Maintenance software (FMS) available for Biomed to

configure, service and troubleshoot the pump.

About the Pump

1

CAUTION: With any

multiple or parallel infusions (i.e.,

connection of additional infusion

systems to the MedSystem III pump

and connection to the patient venous

system), air infusion, reverse flow,

and flow interruption are possible.

Please consult the “Overall

Problem/Solution Matrix” contained

in DIN/VDE Standard 0753 in such

cases.

WARNING: The use of

positive displacement infusion devices

ported together with gravity flow

infusion systems into a common IV

site may impede the flow of common

“gravity only” systems affecting their

performance (hospital personnel

must ensure the performance of the

common IV site is satisfactory under

these circumstances).

WARNING: The pump is

designed to stop fluid flow under

alarm conditions other than the Low

Battery and KVO. Periodic patient

monitoring must be performed to

ensure infusion is proceeding as

expected.

WARNING: The

MedSystem III is a positive pressure

delivery system capable of developing

positive fluid pressures to overcome

widely varying resistances to flow. It

is neither designed nor intended to

detect infiltrations and will not alarm

under infiltration conditions.

WARNING: Hospital

personnel must ensure the

compatibility of the drugs as well as

the performance of each pump as

part of the overall infusion. Potential

hazards include drug interactions,

inaccurate delivery rates, inaccurate

pressure alarms, and nuisance alarms.

CAUTION: Only systems

that have been qualified to

International Standard IEC 60601-1

should be connected to the

Communications Receptacle, and the

connection should ONLY be

performed by qualified personnel.

The selection, testing, and use of host

computer hardware and software, in

conjunction with the MedSystem III

pump is strictly the responsibility of

the purchaser.

Page 4

INTRODUCTION

Multi-channel Fluid Delivery System

The instrument combines three independent infusion channels

in an unparalleled small size.

Lightweight/portable

The pump with pole clamp weighs just over 5 pounds and is

easy to transport.

Unique, rotating pole clamp

The Pump may be attached to a variety of surfaces.

Dose Rate Calculator (DRC)

The pump calculates a volumetric or dose rate based on values

entered for patient weight, drug concentration (drug amount

and diluent volume) and dosing parameters.

Six Device Types available

General Purpose, Neonatal, Controller Pressure, Operating

Room, General Purpose II, and Operating Room II.

Free-flow Protection

The IVAC 28 and 25 Series Administration Sets contain a

cassette that provides protection from free-flow conditions. To

remove the cassette from the pump, the cassette’s slide clamp

is pulled to full extension, occluding the tubing and preventing

fluid from flowing.

Features

2

A: Stopped

DRUG? Wt ---- KG= 0.0 LB

A:Conc ------- mg/---- ml

A:Dose ------- mcg/kg/min

A:Rate ------- ml/h

A:VR 1 ml (Vol Rem)

A:VI 0 ml DI 0.0 mg

Press Select to choose line

Select

Clear

Page 5

INTRODUCTION

Monitoring System

The instrument continuously monitors pump conditions and

alerts with adjustable audio tones and visual messages.

Data Monitoring

The pump can be configured to communicate with a remote

computer, such as a centralized patient monitoring nurses

station. The COMM receptacle is compatible with RS-232

cabling. A communications manual that describes the

programming and hardware involved is available.

Field Maintenance Software (FMS)

The pump can be modified to accommodate specialized clinical

applications. The Device Type parameters, occlusion limit, and

air-in-line threshold can be reconfigured with the optional FMS

software.

Secondary Mode

Allows the user to program two different rates of infusion to

run sequentially.

Full Range of Delivery Rates

Rates from 0.1 to 999 milliliters an hour.

Battery Capacity

A fully-charged battery provides 6 to 8 hours of operating time

with rates at 125 ml/h per channel.

3

A: Infusing Secondary

A: Secondary Rate 100 ml/h

A: Sec VolRem (VR) 100 ml

A: Sec Time(TR) 1 hr

A: Sec VolInf(VI) 1 ml

since 12:37p 01 Feb 02

Stop Affects Secondary

Select

Fast

Page 6

INTRODUCTION

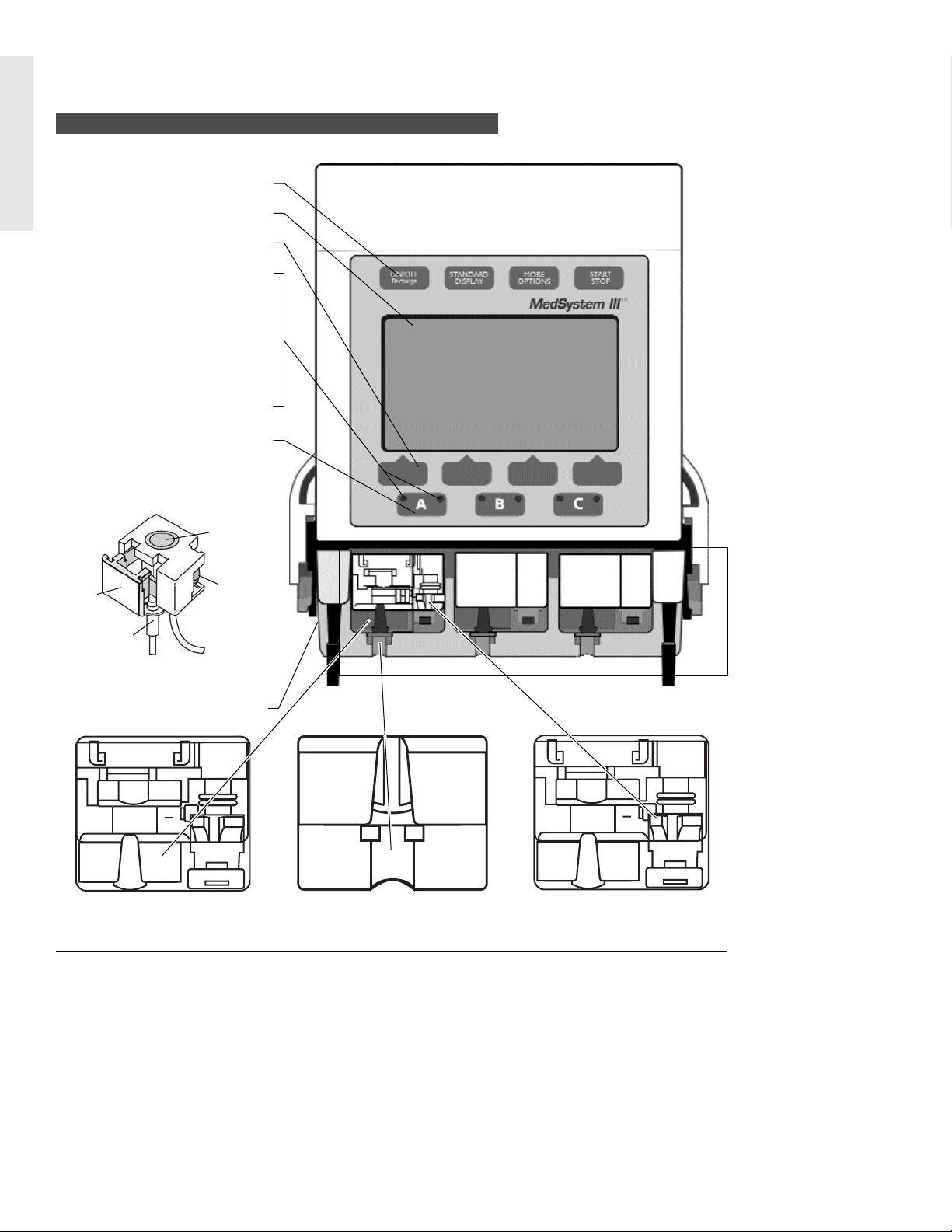

System Components

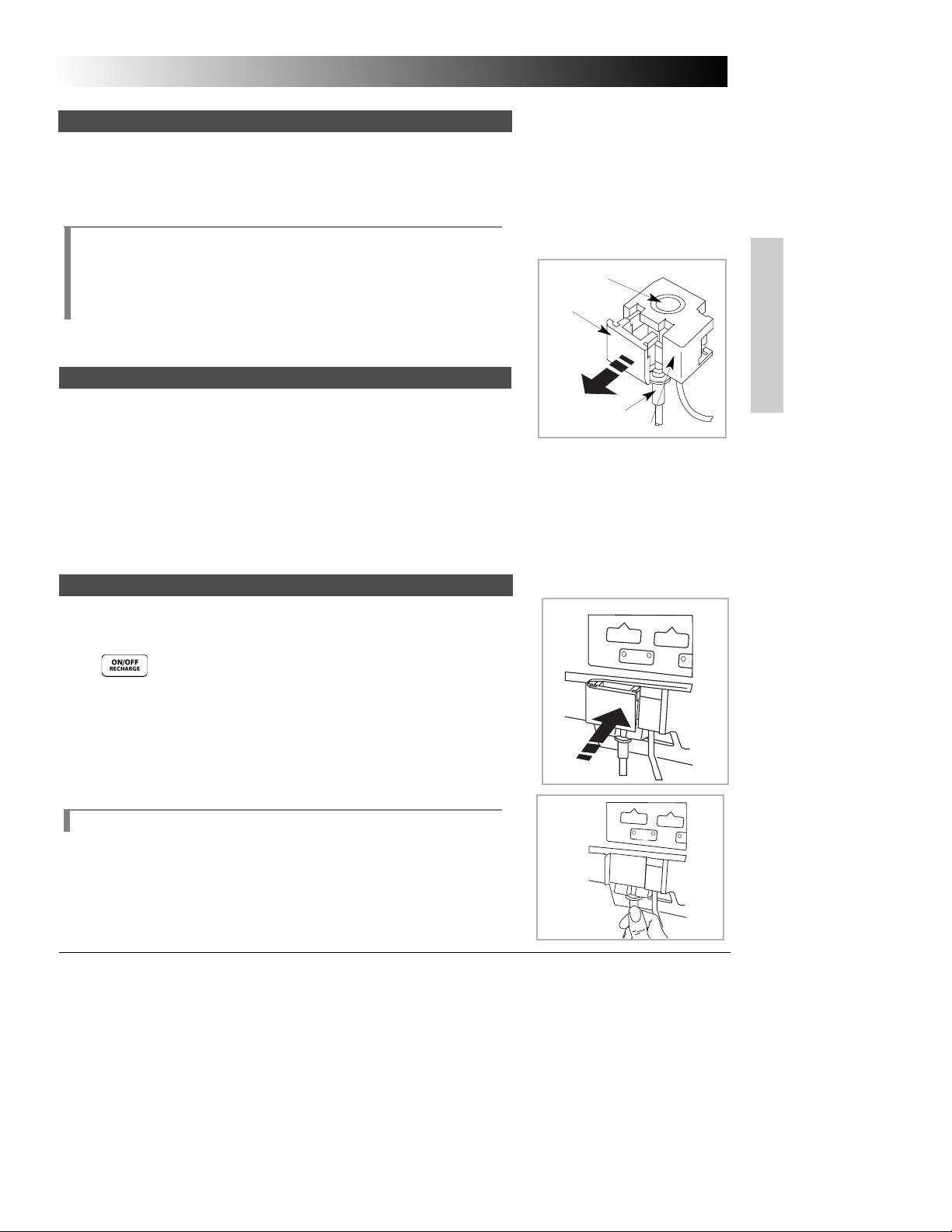

Slide

Clamp

Pressure

Dome

Piston

Tubing

Collar

Lower Assembly

3 Cassette Holders

Pump Latch Mechanism

Drives the cassette piston to move

fluid through the tubing.

Air-in-Line Sensor

Detects bubbles of air during

infusion.

Tubing Collar Recess

Holds tubing collar in place.

Front Panel

Instrument Keys

Display Screen

Softkey Pads

Channel Indicator Lights

Green:

• Steady - infusing on AC

power

• Flashing - infusing on

battery power

Red:

• Slow flashing - Advisory

• Rapid flashing - Alert

Channel Select Keys

Cassette

Portion of administration set,

inserts into cassette holder.

4

Page 7

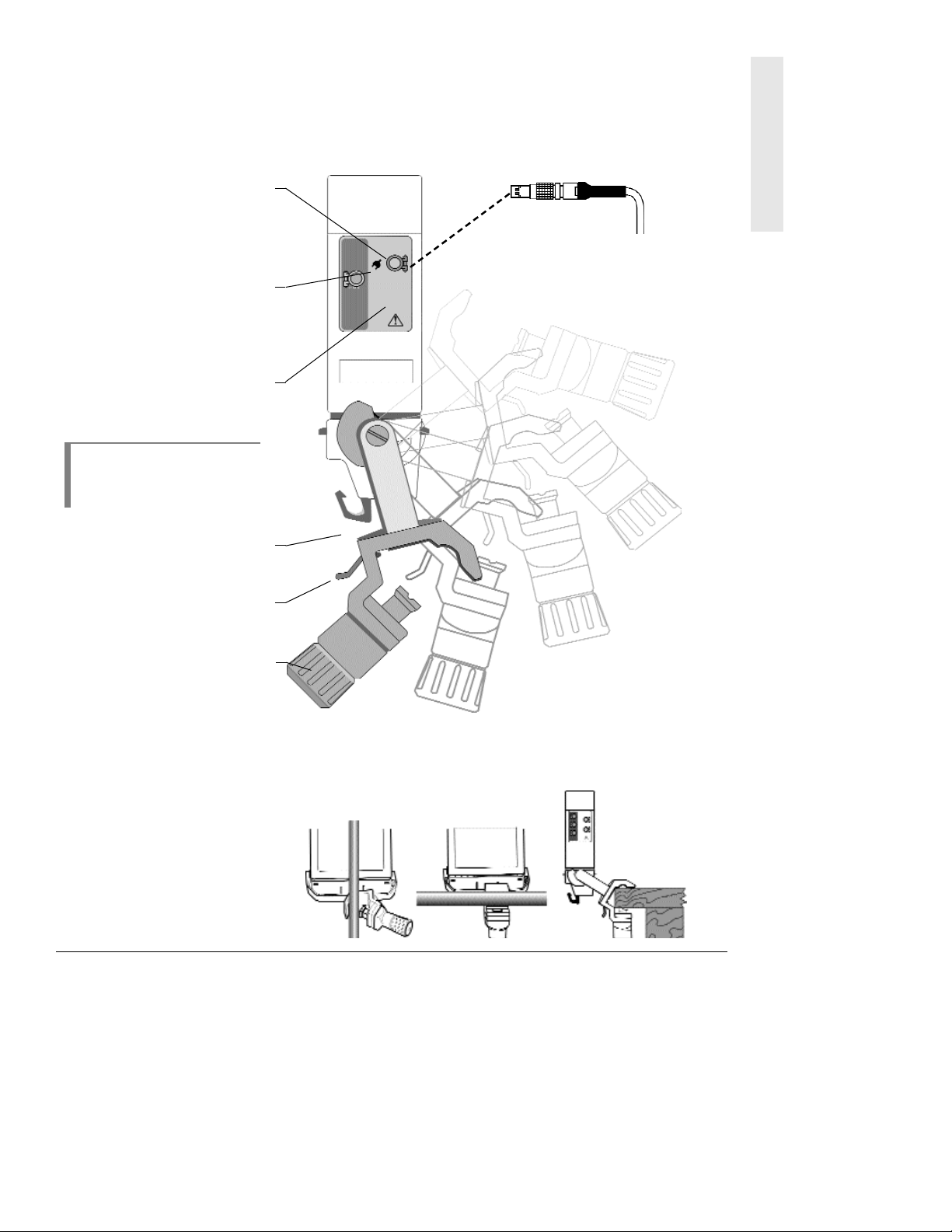

INTRODUCTION

AC Adapter Power Cord

120V/60 Hz three-pronged

grounded adapter with 4 pin

locking connector, standard on

Model 2863.

Connector Panel

External Power

External power receptacle connects with power cord.

Plug Symbol

Green light on indicates AC

power is connected; batteries are

charging.

COMM

Communications line receptacle

connects with RS-232.

NOT E:

When inserting or

removing connectors to the

receptacles, avoid excessive

force or twisting.

Container Hook

One hook on each side of the

instrument.

Rotating Latch

Allows clamp to spin 360° and

position at every 90°.

Adjustable Pole Clamp

Jaw with clutch feature, mounts

pump to a pole or bedside.

Attaching Pole Clamp

To attach the pole clamp,

position the clamp jaw over the

mounting surface and turn the

knob until the clamp is tightened

and the pump feels secure.

When the knob is as tight as

possible, continued turning will

make it click and spin freely

without over-tightening.

5

Page 8

INTRODUCTION

To avoid possible injury to the patient, observe the following

precautions:

Epidural Administration

The MedSystem III pump can be used for epidural administration of

anesthetic and analgesic drugs. This application is only appropriate

when using anesthetic and analgesic drugs labeled for continuous

epidural administration and catheters intended specifically for

epidural use. Use only an IVAC 28 or 25 series set

wwiitthhoouutt

a ‘Y’

connector or injection port, for epidural infusions. The pump‘s

secondary mode must

nnoott

be used when the pump is being used for

epidural administration of anesthetic and analgesic drugs.

- Epidural administration of anesthetic drugs — Use indwelling

catheters specifically indicated for short-term (96 hours or less)

anesthetic epidural drug delivery.

- Epidural administration of analgesic drugs — Use indwelling

catheters specifically indicated for either short-term or long-term

analgesic epidural drug delivery.

Administration Sets

• Use only IVAC 28 and 25 Series Administration Sets. The use

of other sets will cause improper pump operation.

• Do not use the set if damaged.

• Do not insert a cassette into a channel with a Service status.

• Remove any cassettes from channel(s) requiring service.

• Ensure the cassette is properly installed before starting

infusions.

Electromagnetic and Radio Frequencies

Operating the pump near equipment which radiates high-energy

electromagnetic and radio frequencies (electrosurgical/cauterizing

equipment, portable radios, cellular telephones, etc.) may cause false

alarm conditions. If this happens, reposition the pump away from the

source of interference; or turn off the pump and manually regulate

the flow with the administration set regulating clamp.

Operational Precautions

Patient Precautions

WARNING:Epidural

administration of drugs other than

those indicated for epidural use

could result in serious injury to the

patient.

WARNING: It is strongly

recommended that the infusion

pump source container and

administration set used for epidural

drug delivery be clearly

differentiated from those used for

other types of administration.

6

Page 9

INTRODUCTION

Artifacts

It is normal for intravenous infusion devices to produce nonhazardous currents when infusing electrolytes. These currents vary at

a rate proportional to the infusion device flow rate. When the ECG

monitoring system is not functioning under optimal conditions, these

currents may appear as artifacts, simulating actual ECG readings. To

determine if ECG abnormalities are caused by patient condition or the

ECG equipment, place the infusion device on hold. If the ECG

readings become normal, the ECG equipment requires attention.

Proper setup of the ECG equipment should eliminate these artifacts.

Reference the appropriate ECG monitoring system documentation for

instructions on setup and maintenance.

Dropping/Jarring

If a pump is dropped or severely jarred, it should be immediately

taken out of service and inspected by qualified service personnel to

ensure proper function prior to reuse.

To ensure proper performance of the pump and to reduce potential

injury to the operator, observe the following precautions:

• The power cord must be connected to a properly grounded,

3-wire receptacle (“Hospital Use” or “Hospital Grade”)

• Avoid excessive force or twisting of detachable power cords,

when inserting or removing connector terminals.

• Use power cord indoors only.

• Disconnect AC and battery power when performing

maintenance.

• Do not use the pump in the presence of flammable

anesthetics.

• Do not open the instrument case. The case should only be

opened by qualified service personnel using proper

grounding techniques.

• Do not stack instruments on top of each other.

User Precautions

WARNING: When the

case is opened, an electrical shock

hazard exists which can result in

serious injury to persons and

instrument component damage.

7

Page 10

THERE IS

NO

PRINTING

ON THIS

PAGE

Page 11

BASIC OPERATION

9

BASIC OPERATION

Prepare solution container in accordance with the manufacturers’

instructions.

• A syringe can be used as the container for the IV fluid to be

infused. Syringe sizes from 20cc to 60cc of the B-D and Monoject

®

brands can be used.

NOTE:

The IVAC Model 8631A Syringe Holder is available as an

accessory that provides a convenient place to hold syringes while they

are being used as containers for IV fluid. The Syringe Holder is designed

to be easily installed and removed from the top of the pump and to

support up to three syringes. Do not use the Syringe Holder as a handle

to carry the pump.

Connect the container to the IV set.

Prime the IVAC 28 or 25 Series administration set in accordance with

Administration Set Directions for Use.

It is important to prime the set properly to eliminate air bubbles.

Ensure the cassette slide clamp is pushed in completely so tubing is not

occluded.

Invert the cassette so tubing is up. Slowly open the regulating clamp

and establish fluid flow to fully prime the set. Gently tap the cassette

and ‘Y’ sites as necessary to remove all air. Gently massage the pressure

dome to ensure no air bubbles are trapped.

Close regulating clamp before inserting and removing the cassette to

reduce the risk of free flow.

Press to turn pump on.

With tubing down, use a 45 degree, upward motion to insert cassette

into channel.

Push on clear portion of cassette until completely seated. Then push in

slide clamp flush with entire cassette.

Pull down gently on tubing collar. Press with thumb to seat tubing

collar in recess beneath cassette.

NOTE: Three beeps sound when inserted properly.

Preparing the Infusion

Loading the Set

Preparing the Administration Set

WARNING: An open

regulating clamp and slide

clamp can cause a freeflow condition and may

result in serious injury to

the patient.

Pressure Dome

Slide

Clamp

Tubing Collar

Clear portion of cassette

A

A

A

Page 12

10

BASIC OPERATION

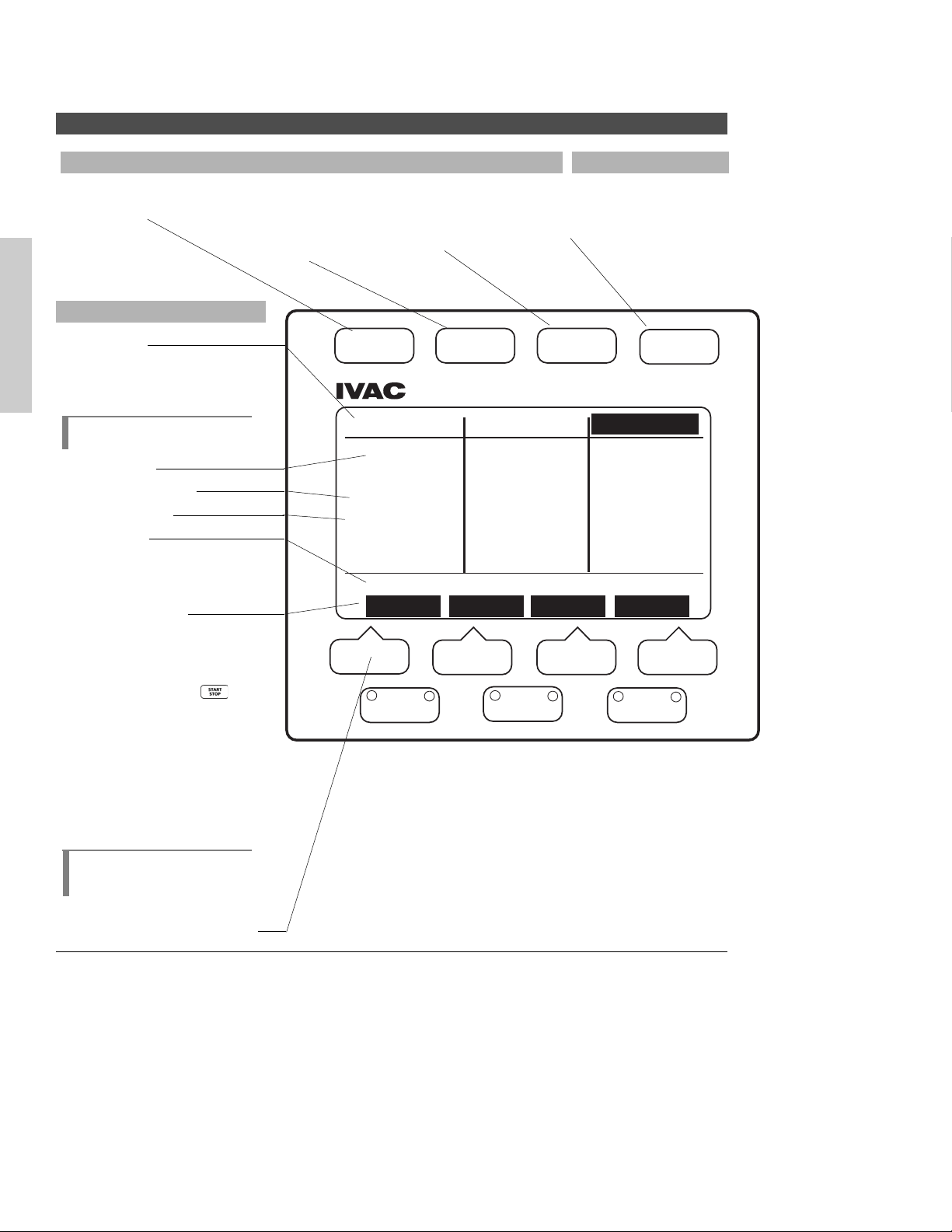

Status Line

Displays infusion status

(Infusing; Stopped; Standby;

KVO; ALARM; FAULT; SERVICE)

for each channel.

NOTE:

S

tatus line in selected

channel is highlighted.

Infusion Rate

Volume Remaining

Volume Infused

Prompt Line

Displays messages that prompt

the user to make programming

choices and/or take appropriate

actions.

Softkeys Prompts

Displays function of specific

softkey.

STNDBY – Appears in softkey

information line

when

is

pressed during

infusion.

Cntrst – (Contrast) Brightens

or dims display.

GP II – When pressed, indi-

cates full name of

selected Device

Type on the

prompt line.

NOT E:

Additional softkey

prompts are displayed by

pressing More Options.

Softkey Pads (4)

Front Panel Overview

Instrument Control Keys

ON/OFF Recharge Key

Turns the pump on and

off.

STANDARD DISPLAY Key

Allows the user to

display Standard Display

page to view infusion

settings for all channels.

MORE OPTIONS Key

Allows the user to

display additional softkey

functions.

START/STOP Key

Starts or stops infusion

on selected channel.

Channel Control Key

Standard Display Page

ON/OFF

STANDARD

DISPLAY

MORE

OPTIONS

START

STOP

Stopped

125

VR: 996.2

VI: 12.8

Start affects channel C

STNDBY Cntrst GP

®

ml/h

MedSystem III® DLE

Standby

25

ml/h

VR: 138.8

VI: 26.9

A

B

Standby

95

ml/h

VR: 93.2

VI: 16.8

C

Page 13

BASIC OPERATION

11

Selected channel is indicated by

the letter displayed at the

beginning of the first five lines.

Status Line

Displays infusion status for selected channel.

Infusion Rate

Volume Remaining

Time Remaining

Volume Infused

Date/Time

Displays when volume infused

was last cleared and infusion

began.

Prompt Line

Displays messages that prompt

the user to make programming

choices and/or take appropriate

action.

Soft Key Prompts

Displays function of specific

softkey.

Select – Moves highlight bar

through the

programmable

infusion

parameters.

↑↑

– Increases highlighted value.

↓↓

– Decreases highlighted value.

Fast

↑↑

– Increases highlighted

value at greater

increments.

Fast

↓↓

– Decreases highlighted

value at greater

increments.

Programming Page

ON/OFF

®

STANDARD

DISPLAY

MORE

OPTIONS

MedSystem III® DLE

A: Stopped

A: Primary Rate 25 ml/h

A: Pri VolRem (VR) 250 ml

A: Pri Time(TR) 10h 00m

A: Pri VolInf (VI) 10 ml

since 12:37p 01 Feb 02

Press Select to choose line

Select Fast

A

B

C

START

STOP

Page 14

12

BASIC OPERATION

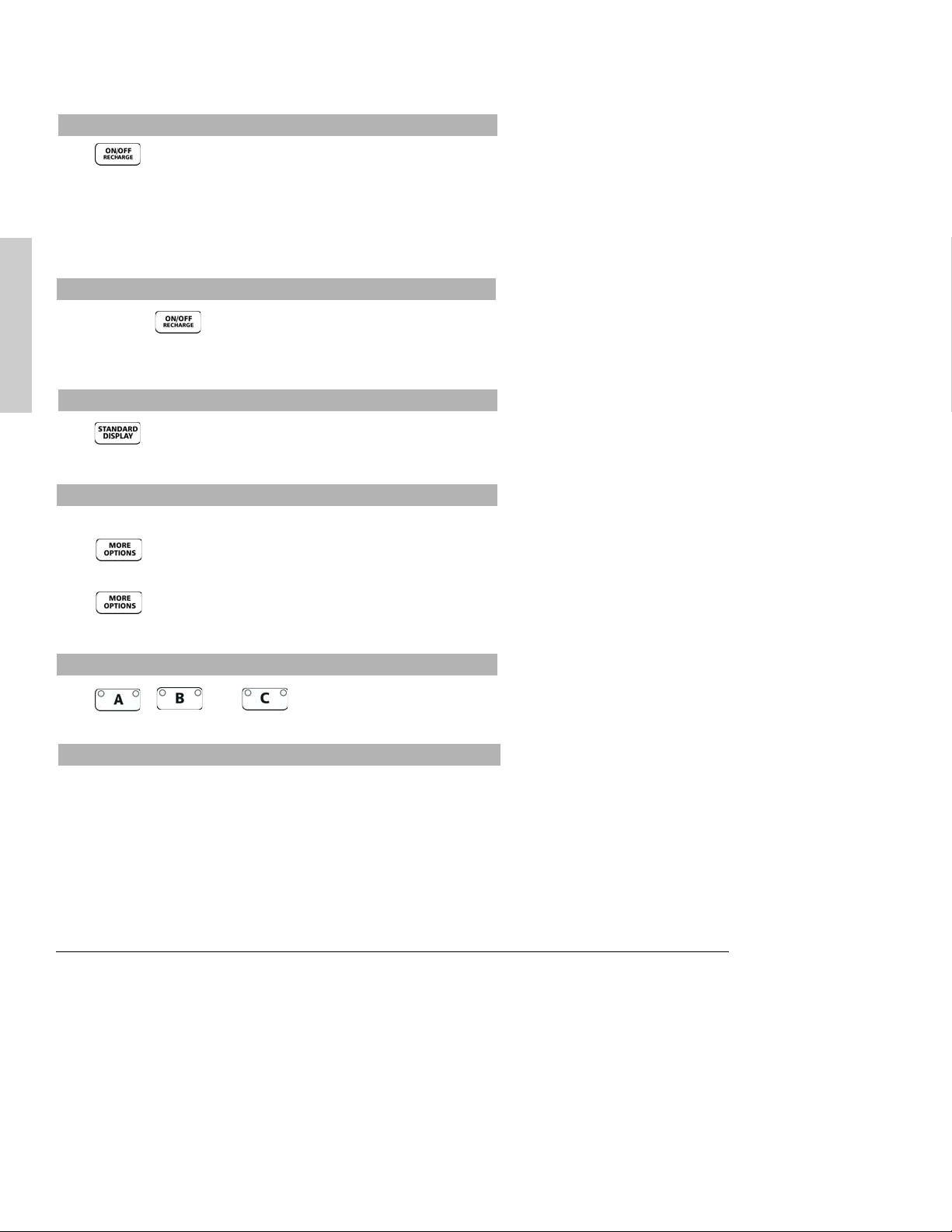

Press .

• Instrument information page is momentarily displayed.

• Continuing to hold down ON/OFF key will keep the information

on the display.

• When the ON/OFF key is released, the Standard Display page is

displayed.

Press and hold .

• Display disappears.

• Pump is turned off.

Press .

• Standard Display page is displayed.

With the Standard Display page displayed:

Press

,

once.

•

TotVol, Device, Config, and Note softkeys appear.

Press again.

•

Batlog and DemoWd softkeys appear.

Press , , or .

• Selected channel programming page is displayed.

With programming page displayed:

Press

Select to choose value to change.

• Value is highlighted.

Scroll through values using

↑↑

, ↓↓, FAST↑↑, or FAST↓↓.

•

↑↑

and FAST↑↑increases highlighted values in single or multiple

increments.

To turn pump on

To activate additional Standard Display softkey prompts

To turn pump off

To view infusion settings for all active channels

To select channel and display Programming Pages

To program infusion

Page 15

BASIC OPERATION

13

• ↓↓and FAST↓↓decreases highlighted values in single or multiple

increments.

• Pressing

↑↑

or ↓↓changes direction of the FAST↑↑or FAST

↓↓

• Highlight remains flashing until Enter is pressed. If Enter is not

pressed, the entry incomplete advisory will sound.

Press

Enter to accept new value.

• Highlight moves to next programmable value if channel status is

Stopped or Standby.

• If status is

Infusing, highlight remains on selected value.

To recall a previous value after a new value is introduced but not

entered, press .

• Recall soft key appears.

Press

Recall.

• Number returns to previous value.

Press .

• Infusion starts or stops immediately, unless the channel’s

programming is incomplete, or if an advisory, alarm, or fault

condition exists on selected channel.

•

ALARM is displayed in affected channel status line.

• Alarm condition is displayed on the Standard Display of the

affected channel.

Press affected channel , , or .

• Alarm Information page is displayed for that channel.

With the programming page displayed:

Press .

Press

2°Sec to access Secondary page.

Press

CalcOn to access Dose Rate Calculation page.

Press .

Press

CalcOff to discontinue use of the Dose Rate Calculator.

To access alarm information

To activate additional Programming Page softkeys

See the TROUBLESHOOTING section

of this manual for more alarm

information.

See the ADVANCED OPERATION

section of this manual for

information on the use of the Dose

Rate Calculator function.

Page 16

14

BASIC OPERATION

Press , , or .

• Programming Page is displayed.

• Rate is highlighted.

Press

Select if current rate is desired

OR

Press

↑↑

, ↓↓, FAST↑↑, or FAST

↓↓

to change Rate.

• Value flashes.

Press

Enterto confirm.

• Highlight moves to volume remaining (VR)

Press

Select if current VR is desired

OR

Press

↑↑

, ↓↓, FAST↑↑, or FAST

↓↓

to change VR.

• Value flashes.

Press

Enter to confirm.

• Primary time remaining (TR) is calculated automatically, based on

VR and Rate.

• Highlight moves to volume infused (VI).

Press

Select if current VI is desired

OR

Press

Clear to reset volume infused to zero.

• Date and time are cleared.

•

Clear softkey switches to Recall.

Pressing

Recall softkey recalls previous VI value.

Press

Enter to confirm.

THEN

Open regulating clamp on administration set.

Press to begin infusion.

• Channel starts infusing.

• Current date and time are entered.

• Green infusion light on channel key stays lit.

• Display reverts to Standard Display page after one minute.

Verify solution flow.

Press .

Verify settings.

Programming Primary Infusion

To set primary rate

To set primary volume remaining (VR)

To clear primary volume infused (VI)

A: Stopped

A: Stopped

A: Primary Rate 100 ml/h

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 1 ml

A: Pri VolInf(VI) 1 ml

since 12:37p 01 Feb 02

Press Select to choose line

Select

A: Stopped

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 1 ml

Press Select to choose line

Select

A: Stopped

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 800 ml

Press Select to choose line

Select

A: Stopped

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 0 ml

Press Enter or Recall

Enter

since 12:37p 01 Feb 02

Press Select to choose line

Select

since 12:37p 01 Feb 02

since 12:37p 01 Feb 02

since -----

Fast

Fast

Clear

Recall

Fast

Page 17

BASIC OPERATION

15

Press , , or .

• Programming Page is displayed.

• Rate is highlighted.

Press

↑↑

, ↓↓, FAST↑↑, or FAST

↓↓

to change Rate

• Value flashes.

Press

Enter to confirm.

• New rate begins infusing immediately.

Press , , or .

• Programming Page is displayed.

• Rate is highlighted.

Press

Select to highlight VR.

Press

↑↑

, ↓↓, FAST↑↑, or FAST

↓↓

to change VR.

• Value flashes.

Press

Enter to confirm.

• Infusion continues with new volume remaining.

Press , , or .

• Programming Page is displayed.

• Rate is highlighted.

Press

Select to highlight VI.

Press

Clear then Enter to reset volume infused to zero.

• Date and time are cleared.

•

Clear softkey switches to Recall.

Pressing

Recall softkey recalls previous VI value.

OR

Press

Enter to confirm.

• Infusion continues with volume infused reset to zero.

• Current date and time are entered.

Making Changes While Infusing

To titrate or change primary rate during infusion

To change volume remaining during infusion

To clear volume infused during infusion

NOTE: When the channel VI is

cleared, that volume is not

subtracted from the volume on

the TotVol page.

Page 18

16

BASIC OPERATION

Press .

• Standard Display page is displayed.

Press .

•

TotVol, Device, Config and Note softkeys appear.

Press

TotVol softkey.

• Total Volume page is displayed

• VI for each channel and total pump VI values are highlighted.

Press

ClrTotto reset volume infused to zero.

• Date and time are cleared.

Press

Enter to accept clearing of all values.

OR

Press

RECALL to return the previous Total VI .

Press appropriate channel , , or .

Press to stop infusion.

Press .

• Standard Display page is displayed.

Press

Stndby.

Press appropriate channel , , or .

Press to start infusion.

Press if Standard Display page not already displayed.

Press .

•

TotVol, Device, Config and Note softkeys appear.

Press

Config softkey.

• The first of five Instrument Settings pages is displayed.

Press

Select to move the highlight to Setup Line Option.

Press

↑↑

or ↓↓to choose Yes.

•

↑↑

and ↓↓will not be displayed if pump is infusing.

Press

Enter to enable programming option.

Press channel , , or .

To start an infusion from Standby status

To set up an infusion by Rate/Volume or Volume/Time

To place a channel on Standby during infusion

NOTE: When a channel is

Stopped for two minutes with a

cassette in place, a Channel Not

In Use advisory sounds. When a

channel is on Standby, the

advisory does not sound.

NOTE: Infusing channel should

always be stopped prior to

removing cassette.

Programming Option

To simultaneously clear Total Volume Infused for all channels

Stopped Stopped Stopped

TotVI A TotVI B TotVI C

Pri 20 Pri 20 Pri 20

Sec 0 Sec 0 Sec 0

= 20 = 20 = 20

Total VI = 60 ml

since 03:25p 10 Feb 02

Press ClrTot to clear TotVI

Stopped Stopped Stopped

TotVI A TotVI B TotVI C

Pri 0 Pri 0 Pri 0

Sec 0 Sec 0 Sec 0

= 0 = 0 = 0

Total VI = 0 ml

since -----

Press Enter or Recall

Enter

Stopped

100

ml/h

VR: 450

VI: 50

Start affects channel A

STNDBY Cntrst GP II

ClrTot

Recall

Instrument Settings (1 of 5)

* Audio Volume: highest

Sec Complete Advisory: No

Setup Line Option No

Time: am/pm 02:16p 01 Jul 02

Press Stnd Display to Exit

Select

NextPg

Page 19

BASIC OPERATION

17

With a channel infusing at KVO rate:

• Green light on channel key remains on.

• Red light on channel key flashes .

• Two toned advisory sounds.

Press appropriate channel , , or twice.

• VR is highlighted.

Press

REPEAT to recall previous VR.

OR

Press

↑↑

, ↓↓, FAST↑↑, and FAST↓↓to change VR.

• Value flashes.

Press

Enterto confirm.

Press to resume infusion and stop KVO rate.

NOTE: If current infusion rate is set below KVO rate, channel

will infuse at the lower rate.

To resume infusion when VR=0 (KVO)

KVO Status

Press if channel is infusing.

Press

Select to move highlight to

Setup:Select VR and Time.

OORR

Setup: Select VR and Rate

If highlighted choice is not desired, use arrow softkeys to change

setup choice.

• Choice flashes.

Press

Enter to accept .

• Highight moves to top of page.

NOTE: Rate will highlight but

cannot be changed if

Volume/Time option is active.

Time remaining selection will

highlight but cannot be changed

if Rate/Volume option active.

A: Stopped

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 1 ml

since 02:16p 01 Jul 02

Setup: Select VR and Time

Press Select to choose line

Select

A: Stopped

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 500 ml

A: Pri Time(TR) 05h 00m

A: Pri VolInf(VI) 1 ml

since 02:16p 01 Jul 02

Setup: Select VR and Rate

Press Enter or Recall

Enter

Recall

KVO

100

Infusion

Complete

VR = 0

Alarm Info: Press A

Cntrst GP II

A: KVO 3.0 ml/h

A: Primary Rate 100 ml/h

A: Pri VolRem (VR) 0 ml

A: Pri Time (TR) ---A: Pri VolInf (VI) 100 ml

since 12:37p 01 Feb 02

Press Select to choose line

Select

REPEAT

Page 20

THERE IS

NO

PRINTING

ON THIS

PAGE

Page 21

ADVANCED OPERATION

19

ADVANCED OPERATION

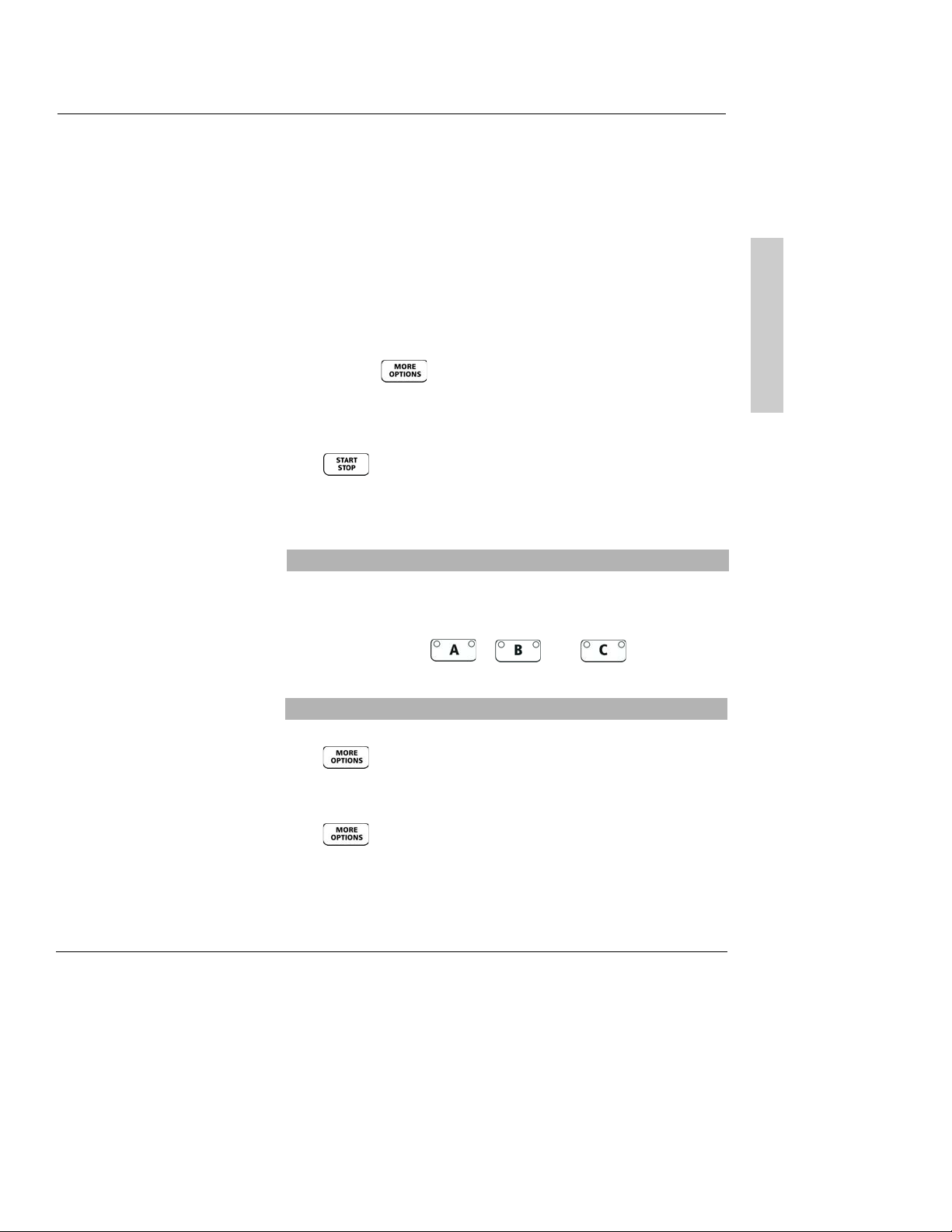

This option allows two different rates of infusion to be administered

sequentially. When secondary volume remaining reaches zero, primary

infusion resumes automatically.

To avoid the possibility of sympathetic flow during secondary delivery

of intermittent medications, set up the administration set as

recommended below.

• Use a 16 gauge needle to attach secondary

set to primary upper ‘Y’ site, below a check

valve.

• Prepare the secondary IV container

according to your institution’s policy.

• Suspend secondary solution container at

least 8 inches above primary solution

container.

• Press , , or to

select channel.

WARNING: Setting a secondary rate over 275

ml/h may result in sympathetic flow with the primary

container.

Secondary Mode

Preparing the Administration Set and Container

8"

®

MORE

START

STANDARD

ON/OFF

OPTIONS

STOP

DISPLAY

®

®

DLE

BCA

Page 22

20

ADVANCED OPERATION

Press , , or .

• Primary programming page is displayed.

Press .

Press 2º Sec softkey.

• Secondary programming page is displayed.

Press Select to highlight secondary VR, if necessary.

Press REPEAT to enter the last VR selected.

OR

Press ↑↑,

↓↓

, Fast ↑↑or Fast

↓↓

to change VR.

• Value flashes.

Press Enter to confirm.

• Secondary time remaining (TR) is calculated automatically, based

on VR and Rate.

• Highlight moves to secondary volume infused (VI).

Press Select if current VI is desired

OR

Press Clear to reset volume infused to zero.

• Date and time are cleared.

• Clear softkey switches to Recall.

Pressing Recall softkey recalls previous VI value.

Press Enter to confirm.

Press Select if current rate is desired

OR

Press ↑↑,

↓↓

, Fast ↑↑or Fast

↓↓

to change Rate.

• Value flashes.

Press Enter to confirm.

THEN

Open regulating clamp on secondary administration set.

Press to begin infusion.

• Four tones sound if primary infusion is in progress.

• Pump starts infusing at secondary rate.

• Current date and time are entered.

Programming Secondary Infusion

To set secondary rate

To set secondary volume remaining(VR)

To clear secondary volume infused(VI)

NOTE: Secondary programming page

is reverse highlighted.

A: Infusing

A: Primary Rate 50 ml/h

A: Pri VolRem (VR) 450 ml

A: Pri Time(TR) 09h 00m

A: Pri VolInf(VI) 50 ml

since 12:37p 01 Feb 02

Press Select to choose line

2° Sec

A: Infusing

A: Secondary Rate 100 ml/h

A: Sec VolRem (VR) 0 ml

A: Sec Time(TR) -----

A: Sec VolInf(VI) 200 ml

since 12:37p 01 Feb 98

Stop Affects Secondary

Select

CalcOn

Repeat

Page 23

ADVANCED OPERATION

21

• Display reverts to Standard Display page after one minute.

Press .

Verify settings.

Verify solution flow from secondary container.

Press , , or .

• Secondary programming page is displayed.

• Rate is highlighted.

Press ↑↑,

↓↓

, Fast ↑↑or Fast

↓↓

to change rate.

• Value flashes.

Press Enter to confirm.

• New rate begins infusing immediately.

Press , , or .

• Secondary programming page is displayed.

Press .

• 1ººPri and CalcOn softkeys appear.

Press 1ººPri softkey.

• Primary programming page is displayed.

Press Select to highlight value(s) to change.

Press ↑↑,

↓↓

, Fast ↑↑or Fast

↓↓

to change value(s).

Press Enter to confirm.

Close regulating clamp on secondary infusion set.

Press , , or .

• Secondary programming page is displayed.

Press .

• 1ººPri and CalcOn softkeys appear.

Press 1ººPri softkey.

• Primary programming page is displayed.

Press to begin primary infusion and stop secondary infusion.

• Four tones will sound.

• Infusion starts at primary rate.

To titrate or change secondary rate during infusion

To review or change primary value(s) during secondary infusion

To start primary infusion before secondary completes

WARNING: Pressing

would result in the remaining

secondary medication being delivered

at the primary rate.

NOTE: Channel display on the

Standard Display is reverse

highlighted.

Infusing

Secondary

100

ml/h

VR = 91

VI = 9

Stop affects channel A

Cntrst GP II

Page 24

Press , , or .

• Primary programming page is displayed.

If infusing, press to stop infusion.

Press .

• 2

ºº

Sec and CalcOn softkeys appear.

Press CalcOn.

• Dose Rate Calculator programming page is displayed.

• Drug? is highlighted.

Scroll using arrow softkeys to display alphabetized, abbreviated,

generic drug names.

• ↓↓moves A to Z.

• ↑↑moves Z to A.

e.g. Dopamine___ mg/___ml and ___mcg/kg/min

Lidocaine___ Gm/ml and ___ mg/min

Press Enter when desired drug name is highlighted.

• Highlight moves to Wt.

Choose patient’s kilogram weight using the arrow softkeys.

Press Enter when desired weight is displayed.

• Highlight moves to Conc.

Choose

concentration

using the

arrow softkeys.

Press Enter when desired concentration is displayed.

• Highlight moves to value for diluent volume.

Choose

diluent volume

using the

arrow softkeys.

Press Enter when desired volume is displayed.

• VR is automatically set when the diluent volume value is

enteredbut can be changed if desired.

• Highlight moves to Dose.

22

ADVANCED OPERATION

With this feature, the instrument calculates a volumetric or dose rate

based on values entered for patient weight, drug concentration (drug

amount and diluent volume) and dosing parameters. If a dose is

entered, the volumetric rate is calculated. If a volumetric rate is

entered, the dose is calculated.

Dose Rate Calculator (DRC) Programming using a specific drug name

WARNING:

Ensure correct

entry of all drug calculation infusion

parameters. Consult the drug

manufacturer’s labeling for information

concerning appropriate administration

guidelines and

dosages.

Programming Drug

Programming Weight

Programming Concentration

NOTE

:

Pressing , ,or

at any time during DRC set-up,

returns the highlight to the top of

the page.

NOTE:

Dose Rate programming

page will not display if channel is

infusing. If infusing in secondary

mode, switch to primary mode

and stop infusion before

proceeding.

NOTE

: Changing drug name clears

previous values and changes drug

concentration and dose rate

parameters to parameters

appropriate for the selected drug.

A: Stopped

DRUG? Wt ---- KG= 0.0 LB

A:Conc ------- mg/---- ml

A:Dose ------- mcg/kg/min

A:Rate ------- ml/h

A:VR 1 ml (Vol Rem)

A:VI 0 ml DI 0.0 mg

Press Select to choose line

Select

Clear

A: Stopped

DOPAMINE Wt 70.0 KG=154.3LB

A:Conc 400 mg/ 250 ml

A:Dose 5.0 mcg/kg/min

A:Rate 13.1 ml/h

A:VR 250 ml (Vol Rem)

A:VI 0 ml DI 0.0 mg

Press Select to choose line

Select

Fast

Page 25

ADVANCED OPERATION

23

Programming Dose

NOTE: Calculated rates for infusion

are fractional and will be displayed

as a fraction on the Standard

Display even if Device Type is set

for whole numbers.

Choose

dose

using the

arrow softkeys.

Press Enter when desired dose is displayed.

• Volumetric rate is automatically calculated.

• Highlight moves to Rate.

Choose

rate value

using the

arrow softkeys if dose rate is not desired.

Press Enter when desired volumetric rate is displayed.

• When rate is changed, dose value is automatically calculated.

• Highlight moves to VR.

Change

VR value using the arrow softkeys.

Press Enter when desired VR is displayed.

• Highlight moves to VI.

Press Clear then Enter to reset volume infused to zero.

• Highlight moves to DI.

Press Clear then Enter to reset dose infused to zero.

Open regulating clamp.

Press to begin infusing.

• Channel starts infusion.

• Display switches to Standard Display page after 1 minute. DRC

parameters are displayed.

Verify fluid flow.

Press .

Verify settings.

Press , , or .

• Dose Rate Calculator programming page is displayed.

• Dose value is highlighted.

Press Select to scroll through values that can be changed.

When highlight is on value to be changed (Dose, Rate, VR, VI, DI), use

arrow softkeys until desired value is displayed

.

• When dose is changed, rate is automatically recalculated.

• When rate is changed, dose is automatically recalculated.

When highlight is on value for VI or DI, Clear softkey becomes active.

Pressing the Clear softkey changes the value to 0.0.

Press Enter after each value change to accept the new value.

• New rate begins infusing immediately.

Press .

• Verify settings.

Changing DRC values while infusing

Changing Volumetric Rate

Changing Volume Remaining

Clearing the Volume Infused(VI) and Dose Infused(DI)

NOTE: Stop infusion to make

changes to the drug name, weight,

or concentration.

Infusing

1

13

ml/h

5.0

mcg/k/mn

DOPAMINE

Stop affects channel A

Cntrst GP II

Page 26

24

ADVANCED OPERATION

Dose Rate Calculator Programming with DRUG?

NOTE:

Dose Rate programming

page will not display if channel is

infusing. If infusing in secondary

mode, switch to primary mode and

stop infusion before proceeding.

Programming Weight

Programming Concentration

Programming Dose

D

rug concentration

parameters

G

m, mg, mcg, mMol, mEq, mUn, and Un

Dose parameters

measure —

Gm, mg, mcg, Ng,

mMol, mEq, mUn, or Un

weight —

kg

time —

min, hr, or day

The Drug? selection can be used to calculate a drug not listed in the

pump or for an alternative dosing regimen.

Press , , or .

• Primary programming page is displayed.

Press if channel is infusing.

Press .

• 2º Sec and CalcOn softkeys appear.

Press CalcOn.

• Dose Rate Calculator programming page is displayed.

• Drug? is highlighted.

Press Select.

• Highlight moves to Wt.

Choose

patient’s KG weight using arrow softkeys.

Press Enter when desired weight is displayed.

• Highlight moves to Conc.

Choose

concentration using arrow softkeys.

Press Enter when desired concentration is displayed.

• Highlight moves to concentration parameters.

Choose

desired concentration parameters using arrow softkeys.

Press Enter when desired parameter is displayed.

• Highlight moves to value for diluent volume.

Choose

diluent volume value using arrow softkeys.

Press Enter when desired volume is displayed.

• VR is automatically set when the diluent volume is entered, but

can be changed if desired.

• Highlight moves to Dose parameters.

Choose dose parameters (measure/weight/time) using arrow softkeys.

Press Enter when each desired dose parameter is displayed.

• Highlight moves to next parameter each time Enter is pressed.

• Highlight moves to Dosewhen Enter is pressed to accept time

value.

Choose

dose using arrow softkeys.

Press Enter.

• Highlight moves to Rate parameters.

A: Stopped

DRUG? Wt ---- KG= 0.0 LB

A:Conc ------- mg/---- ml

A:Dose ------- mcg/kg/min

A:Rate ------- ml/h

A:VR 1 ml (Vol Rem)

A:VI 0 ml DI 0.0 mg

Press Select to choose line

Select

Clear

Page 27

ADVANCED OPERATION

25

Choose

volumetric rate using arrow softkeys if dose calculation is not desired.

Press Enter when desired rate is displayed.

• When rate is changed, dose is automatically calculated.

• Highlight moves to VR.

Choose

VR value using the arrow softkeys.

Press Enter when desired VR is displayed.

• Highlight moves to VI.

Press Clearthen Enter to change VI value to 0.

• Highlight moves to DI.

Press Clear then Enter to change DI value to 0.

Open regulating clamp.

Press to begin infusion.

• Channel starts infusing.

• Display switches to Standard Display page after 1 minute. DRC

parameters are displayed.

Verify fluid flow.

Press .

Verify settings.

Press , , or .

• Dose Rate Calculator programming page is displayed.

Press to stop if infusing.

Press .

Press CalcOff.

• Display reverts to primary programming page.

• Volumetric rate, volume remaining and volume infused from DRC

is carried over to the primary programming page.

Discontinuing DRC option

Changing Volume Remaining

Clearing Volume Infused (VI) or Dose Infused (DI)

Facts about DRC

Changing Volumetric Rate

• Drug name, patient weight, or drug concentration

cannot be changed while infusing. Changes to patient

weight or concentration will recalculate volumetric rate

but maintain dose rate.

• All drug names are generic and abbreviated if the name

contains more than eight letters.

• Weight can only be entered in Kg’s but is displayed in

Kg’s

and

Lbs. Weight units can be switched to grams

by pressing

↓↓

to value of 1Kg then repress

↓↓

. A two

tone advisory sounds.

• If dose measurement parameters and concentration

measurement parameters are unrelated, a volumetric

rate will not calculate. Attempts to start will display a

prompt message:

Verify all dose settings.

• When a drug amount is 10,000 or greater, a Kis used

to replace 000th (i.e. 10,000=10K; 12,000 = 12K).

• If a recalculated dose results in a rate outside the rate

ranges, a prompt message is displayed:

Rate too

High,reenter value or Rate too Low,reenter value.

• If a recalculated rate results in a dose outside the dose

range, the channel will infuse at the entered rate but

the dose will display the minimum or maximum

allowable limit: (i.e. <0.1 or >999k).

• Secondary option cannot be used when the Dose Rate

Calculator is enabled.

• If instrument is off for more than five minutes, the DRC

mode will revert to the primary mode.

A: Stopped

DOPAMINE Wt 70.0 KG=154.3LB

A:Conc 400 mg/ 250 ml

A:Dose 5.0 mcg/kg/min

A:Rate 13.1 ml/h

A:VR 250 ml (Vol Rem)

A:VI 0 ml DI 0.0 mg

Press Select to choose line

CalcOff

Page 28

26

ADVANCED OPERATION

There are six Device Types with preset parameters that accommodate

specific clinical applications. They are:

General Purpose

Neonatal

Controller Pressure

When setting up the pump, select the device type that best suits your

clinical needs.

The abbreviated name of the Device Type appears as a

softkey on the Standard Display page. Pressing the softkey displays

the device type on the prompt line.

Maximum rate, maximum volume, pressure and air-in-line threshold

are configured at the factory. See Table 1 for a complete listing of

preset parameters. Refer to the config softkey section following Table 1

for programmable and configurable parameters. These parameters can

be modified to meet the institution’s specific requirements using the

optional FMS software.

Press .

Press .

• TotVol, Device, Config and Note softkeys appear.

Press Device softkey.

• The currently selected Device Type has an asterisk and is highlighted.

Press Select to move the highlight through the list.

Press Enter when the desired device is highlighted.

If preset values are compatible with the newly selected device type,

• An asterisk appears next to the device name.

If channel is not infusing when device type is changed and preset

values are not compatible with the newly selected device type,

• The display switches to a notification screen.

• Incompatible Channel(s) indicated.

• Choice is given to continue.

If Yes,

• Incompatible values are cleared.

• Display reverts to Standard Display Page.

• New Device Type becomes active.

If No,

• Display reverts to Change Device Type page.

Device

NOTE: The Device Type

programming selection affects all

three channels. It is not possible to

program different Device Types for

a channel independently.

To change Device Type

Operating Room

General Purpose II

Operating Room II

Stopped

100

ml/h

VR: 450

VI: 50

Device: General Purpose II

STNDBY

Cntrst

GP II

Infusing

100

ml/h

VR: 450

VI: 50

Stop affects channel A

TotVol Device Config Note

Change Device Type

General Purpose

Neonatal

Controller Pressure

Operating Room

* General Purpose II

Operating Room II

Press Stnd Display to Exit

Select

Enter

Page 29

ADVANCED OPERATION

27

If channel is infusing when device type is changed and preset values

are not compatible with the newly selected device type,

• The display switches to the notification screen.

• Incompatible Channel(s) is indicated.

• Choice is given to continue.

If No,

• Display reverts to Change Device Type page for user to select

another device type.

If Yes,

• The pump will alarm.

• Infusion will stop on affected channel.

• Display reverts to Standard Display with Alarm indicated in

affected channel.

Press affected channel , , or

.

Follow instructions displayed.

Table 1

Occlusion

Detection

Method

Occlusion Alarm

Setting

Maximum

Pressure

Air-in-line Alarm

Threshold

KVO Rate*

Rate Range

Maximum VR

Setting

Pump Not In

Use Advisory

ALL Setting

for VR

Baseline

Baseline 5 psi

15 psi

500 µl

3 ml/h

1 —999 ml/h

9999 ml

Yes

N/A

Baseline

Baseline+3 psi

15 psi

50 µl

1.0 ml/h

0.1—99.9 ml/h

9999 ml

Yes

N/A

Absolute

Threshold

Absolute

3 ft H2O

3 ft H2O

500 µl

3 ml/h

1 — 299 ml/h

9999 ml

Yes

N/A

Baseline

Baseline+5 psi

15 psi

500 µl

3 ml/h

1 —999 ml/h

9999 ml

No

Option

Baseline

Baseline+5 psi

15 psi

500 µl

3.0 ml/h

0.1—999 ml/h

9999 ml

Yes

N/A

Baseline

Baseline+5 psi

15 psi

500 µl

3.0 ml/h

0.1—999 ml/h

9999 ml

No

Option

Default General

Neonatal

Controller Operating General Operating

Parameter Purpose Pressure Room Purpose II Room II

* Channel will infuse at the KVO rate shown in table or at the current infusion rate,

whichever is lower.

NOTE: Values shown in table can

be modified to meet the

institution’s requirements using

optional FMS software. To review

actual default parameters on a

MedSystem III pump, select a

Device Type and refer to

Instrument Settings pages 2

through 5. An asterisk appears

beside settings which are not

factory default.

ALARM

-----

Rate/Vol

Settings

Cleared

Alarm Info: Press channel A

CANCEL QUIET

Page 30

28

ADVANCED OPERATION

Config

(Configuration)

The Config option allows the user to view and/or change some

instrument settings. There are five pages in this option. Items shown

on page 1 can be changed by user (see Table 2). Pages 2 - 5 can only

be changed by qualified personnel using the optional FMS software .

Press .

Press .

• TotVol, Device, Config and Note softkeys appear.

Press Config softkey.

• The first of five Instrument Settings pages is displayed.

• An asterisk indicates options that have been changed from

factory settings.

Pressing Select moves the highlight through the list .

Press ↑↑and ↓↓to change a highlighted setting.

• Select softkey changes to Enter and NextPg softkey changes

to Recall when a setting is changed.

Press Enter to accept new setting

OR

Press Recall to recall previous setting.

Press to exit Instrument Settings page.

T

able 2

Option Choices Description

Audio Volume: low

medium

high

highest

Sec Complete Advisory: Yes

No

Setup Line Option: No

Yes

Time: 24 hr

am/pm

Hour/minutes

00:00-23:59

Day 1-31

Month Jan-Dec

Years

00-99

To access Instrument Settings information

A tone accompanies each level to aid in

determining volume choice. If an alarm is

ignored, the volume will ramp to the

highest audio unless disabled by FMS.

Pump sounds two tones and displays

advisory when secondary VR = 0.

Enables infusion to be set up as

rate/volume or volume/time. Stop infusion

before modifying this line option.

Allows pump to be set with a 12 or 24

hour clock.

}

Each item can be adjusted when

highlighted

Infusing

100

ml/h

VR: 450

VI: 50

Stop affects channel A

TotVol Device Config Note

Instrument Settings ( 1 of 5 )

*Audio Volume: low

*Sec Complete Advisory: Yes

Setup Line Option: No

Time: am/pm 9:56a 01 Feb 02

Press Stnd Display to Exit

Select

NextPg

Page 31

ADVANCED OPERATION

29

The Note soft key accesses the Special Note Message page. When

note is programmed, it appears when the pump is turned on.

Press .

Press .

• TotVol, Device, Config and Note softkeys appear.

Press Note softkey.

• Note information is displayed.

• If no information has been programmed on the note page, there

will be a two tone advisory and the message There is no Special

Note will display on the prompt line.

The BatLog softkey accesses the Battery History Log page. This page is

provided for the Biomedical Engineering staff to review and record

battery history data.

Press .

Press twice.

• BatLog and DemoWD softkeys appear.

Press BatLog softkey.

• The Battery History page is displayed.

Display switches to Standard Display page after 1 minute

OR

Press to exit Battery History page.

NNoottee

BBaattLLoogg

(Battery History Log)

To access Note(s)

To access Battery History Log

Infusing

100

ml/h

VR: 450

VI: 50

Stop affects channel A

TotVol Device Config Note

Infusing

100

ml/h

VR: 450

VI: 50

There is no Special Note

TotVol Device Config Note

Infusing

100

ml/h

VR: 450

VI: 50

Stop affects channel A

BatLog DemoWD

Page 32

THERE IS

NO

PRINTING

ON THIS

PAGE

Page 33

NOTE: Channel’s VR and VI calculations are updated with each press

of ClrAir softkey.

NOTE: A appears on S tandard Display page to indicate CONFIRM has

been pressed.

TROUBLESHOOTING

31

Use this troubleshooting information in conjunction with appropriate

hospital procedures.

Press

QUIET.

• Audio tone stops.

• Red light flashes on affected channel.

Press affected channel , , or

• Alarm Information page is displayed.

Take appropriate action(s) indicated on the display.

Press to resume infusion.

silences Advisories, Alarms, and Faults for two

minutes. Softkey is accessible during alarm status.

clears alarm and advisory messages and stops

tone. Use when alarm or advisory condition cannot

be corrected or user chooses not to correct.

moves air bubbles past air-in-line sensor. Each

press of the ClrAir softkey displaces 0.2 ml of air

and fluid. Three beeps indicate when air bubble is

no longer in front of the air-in-line sensor.

is present during Check Fluid Side alarms. Allows

infusion tocontinue if no upstream occlusion is

found and fluid is flowing in drip chamber.

resets resumable fault conditions. Used when

attempting to re-establish normal operation of a

channel.

disables use of affected channel. Servicing of the

pump is required before channel can be used.

SERVICE

RETRY

CONFIRM

ClrAir

CANCEL

QUIET

To respond to an advisory, alarm, or fault message

Alarm Response Keys

TROUBLESHOOTING

Page 34

32

TROUBLESHOOTING

Check Air Sensor

At installation of cassette:

a) air is detected in tubing;

b) tubing collar is not prop-

erly seated;

OR

c) air sensor is dirty or

damaged.

• Verify tubing collar is fully seated in air sensor recess.

• Verify tubing in air sensor recess is not damaged, twisted or dirty.

• Press ClrAir on channel's Alarm Information page. Three beeps

indicate air bubble is no longer in front of air sensor.

• If air is still present, remove cassette and manually clear air

according to hospital policy.

• If no air is present, clean air sensor recess as directed in cleaning

instructions.

Infusion Complete VR=0

VR has counted down to

zero. Channel is infusing at

KVO rate.

• Enter new VR or, if same volume is desired, press REPEAT.

• Press Enter.

• Press to resume primary infusion rate.

Low Battery

30 minutes or less battery

power remaining.

• Connect AC adapter power cord to pump.

• Plug into wall outlet.

Channel Not In Use

Two minutes have elapsed

since cassette was

installed or infusion was

stopped.

• Remove cassette,

OR

• Press to start infusion,

OR

• Press

STNDBY to place channel on Standby.

T wo beeps, slow flashing red light

on infusing channel’s channel key;

infusion continues.

CORRECTIVE ACTION

Advisories

Page 35

TROUBLESHOOTING

33

Air In Line

Air detected in fluid pathway during infusion, or air

sensor is dirty.

• Verify tubing collar is fully seated in air sensor recess.

• Verify tubing in air sensor recess is not damaged, twisted or dirty.

• Press ClrAir softkey on channel's Alarm Information page. Three

beeps indicate air bubble is no longer in front of air sensor.

NOTE: Each press of the ClrAir softkey displaces 0.2 ml of air and

fluid and updates channel’s VR and VI calculations.

• If air is still present, remove cassette and manually clear air

according to hospital policy.

• If no significant air is present, clean air sensor recess as directed

in cleaning instructions.

• Set up pump at, or slightly below, IV site to minimize formation

of micro bubbles.

• Press to resume infusion.

Air In Lower Tubing

Air bubbles detected in fluid

pathway with a total volume

exceeding the air in line

threshold setting.

Possible outgassing and/or

leaks in administration set.

• Check administration set for leaks.

• Check lower tubing for multiple small air bubbles.

• Press ClrAir softkey on channel's Alarm Information page. Three

beeps indicate air bubble is no longer in front of air sensor.

NOTE: Each press of the ClrAir softkey displaces 0.2 ml of air and

fluid and updates channel’s VR and VI calculations.

• If air is present, clear air according to hospital policy.

• Set up pump at or slightly below, IV site to minimize formation

of micro bubbles.

• If no significant air is present, press to resume infusion.

Battery Depleted

Insufficient battery power.

The pump will shut down in

5 minutes.

• Connect AC adapter power cord to pump and plug into wall outlet.

• Press to resume infusion(s).

CORRECTIVE ACTION

Four rapid-beeps, infusion stops,

rapidly flashing red light on

channel key .

Alarms

Page 36

• Check tubing between container and pump for a closed regulating

clamp, closed vent (with unvented container), kinked tubing,

empty syringe, or any restriction to flow.

• If NO occlusion is present, press CONFIRM.

• Press to resume infusion.

• Verify fluid is flowing in drip chamber.

• A appears on standard display to indicate Confirm has been

pressed.

34

TROUBLESHOOTING

Cassette Not Latched

Cassette is partially

disengaged or latching

mechanism is dirty.

ALARMS (continued)

Four rapid-beeps audio,

rapid-flashing red light and

infusion stops.

• Push cassette completely in. Ensure slide clamp is flush with

entire cassette. Press to resume infusion.

• If condition continues, try cassette in a different channel. Replace

administration set if alarm recurs.

• Clean lower assembly according to Cleaning Instruction described

in MAINTENANCE section of this document.

Cassette Removed

Cassette is removed from

holder while channel is

infusing.

• Reinstall cassette, and press to resume infusion.

OR

• Press CANCEL.

Check Fluid Side

Possible upstream restrictions to flow.

Cassette Jammed

Cassette piston is difficult

to move or piston sleeve is

loose.

• Remove cassette, check placement of soft, plastic piston sleeve

and reposition, if necessary.

• If condition continues, try cassette in a different channel.

• Replace administration set if alarm recurs or if piston does not

move freely.

• If Alarm recurs with several cassettes, channel may need service.

CORRECTIVE ACTION

INCORRECT

CORRECT

Page 37

TROUBLESHOOTING

35

Faulty Cassette

Cassette may be damaged

or inoperable.

Possible disfunction of

cassette sensor located in

holder.

• Reinsert cassette in another channel.

• If alarm recurs in second channel, replace administration set.

• If alarm recurs with two cassettes in the same channel, press

SERVICE and contact qualified service personnel.

Fluid-Side Occluded

Upstream restriction to

flow.

• Check tubing between container and pump for a closed regulating

clamp, closed vent (with unvented container), kinked tubing,

empty syringe, or any restriction to flow.

• Clear occlusion.

• Press to resume infusion.

Patient-Side Occluded

Downstream restriction to

flow.

• Check tubing between pump and patient for kinks, closed clamps,

closed stopcocks, clogged filters, site problems, etc.

• Clear occlusion or change infusion site.

• Press to resume infusion.

Pumping Latch Closed

Pumping latch jaw located

to right of air sensor is

closed or broken.

ALARMS (continued)

Four rapid-beeps audio,

rapid-flashing red light and

infusion stops.

INCORRECT

Rate/V ol Settings Cleared

Rates and/or volumes are

incompatible with newly

selected Device Type.

• Re-enter settings as required.

• Press to resume infusion.

CORRECTIVE ACTION

CORRECT

CORRECTIVE ACTION

CORRECT

Air Sensor

Pumping

Latch Jaw

• Using only your finger, push down pumping latch jaw until it snaps

open.

• If pumping latch jaw is visibly broken, press SERVICE and contact qualified service personnel.

CAUTION:

Never use a blunt instrument to open a closed pumping latch.

INCORRECT

Page 38

36

TROUBLESHOOTING

Screen is too light or dark

to read, with pump on.

• Press

• Press Cntrst softkey to change screen contrast.

Pump Shut Off: Low Power

Pump had shut down after

a Battery Depleted alarm

had not been corrected.

• If power cord has been detached from pump, reconnect terminal

end to pump’s EXTERNAL POWER receptacle.

• Plug AC adapter power cord into electrical outlet.

• next to EXTERNAL POWER receptacle is lit green when

power cord is properly attached.

Channel Out of Order

Safety checks built into

software have detected a

faulty channel.

Fault Number

Safety checks built into

software have detected a

fault condition.

Numeric message, Europeansiren, rapid-flashing red light, infusion stops.

CORRECTIVE ACTION for resumable faults, only.

• Press affected channel , , or

• Follow instructions on channel's Alarm Information page.

• Press RETRY to clear Fault.

• If Fault recurs, press SERVICE and contact qualified service

personnel.

Blank screen, continuous-tone red

and green lights continuous, all

infusions stop.

Blank Screen

Safety checks built into

software have detected an

instrument error condition.

Attempt to reset pump:

• Turn pump off, then on again.

• Press to resume each channel that had been infusing.

• If Watchdog alarm recurs or pump cannot be turned on, replace

pump and notify qualified service personnel.

CORRECTIVE ACTION

CORRECTIVE ACTION

CORRECTIVE ACTION

Fault

Watchdog

Other Conditions

Page 39

MAINTENANCE

Specifications

STANDARDS UL 544

CSA C22.2, No. 125

CASE MATERIAL Impact resistant polycarbonate/ABS alloy

DIMENSIONS Height 7.875 inches (20.00 centimeters)

Width 6 inches (15.24 centimeters)

Depth 2.10 inches (5.33 centimeters)

WEIGHT Approximately 5.1 pounds (2.32 kilograms) includes Pole Clamp.

AIR-IN-LINE (

OCCLUSION PRESSURE (

DEFAULT) 500 µl except for Neonatal which is 50µl

DEFAULT) 15 psi except for Controller pressure device which is 3 ft H

OPERATING TEMPERATURE 50-104° Fahrenheit (10° - 40° Celsius)

STORAGE TEMPERATURE <95° Fahrenheit (<35° Celsius) for optimum battery life.

MAXIMUM STORAGE 131° Fahrenheit (55° Celsius)

TEMPERATURE

RATE RANGE 0.1 - 999 milliliter per hour (each channel)

VOLUME RANGE 0.1 - 9999 milliliter (each channel)

KVO RATE RANGE 0.1 - 20.0 milliliter per hour

* NOTE:

60601-2-24, under the following conditions: Head

Height: 30”; Test Solution: Distilled Water;

Environmental: Ambient temperature; Back

Pressure: 18 gauge needle; IV Set: Model 28034.

SYSTEM ACCURACY 1.0 - 999 ml/hr ±5% with a standard deviation of 1.96 under

Long-term accuracy specified, per IEC

specified conditions. *

0.1 - 0.9 ml/hr ±10% with a standard deviation of 1.96.

ADMINISTRATION SETS Use only IVAC MedSystem III Administration Sets.

POWER CONSUMPTION 6 watts AC power. Use only IVAC MedSystem III AC Adapter, Model 1555 or

1550.

BATTERIES Main – Rechargeable NiCd Battery Pack

NOTE:

Use only approved ALARIS Medical Systems

Battery Packs.

Memory Back-up – Nonrechargeable Lithium

0

2

NOTE:

Replacement of both the main and memory

backup batteries must be performed by qualified

service technicians.

all channels running at 125 milliliter per hour and backlighting usage

of 2 minutes per hour.

The main battery retains 80% of its capacity after 500 charging cycles,

and retains 90% of its capacity after 3 months of

continuous AC charging.

AC ADAPTER & CORD LENGTH Model 1555, 7.5 VDC @ 1A with 10ft. (3.05 meter) cord.

Model 1550, 8.5 VDC @ 750mA with 8.5ft. (2.59 meter) cord.

AC ADAPTER CONNECTOR 4 pin locking connector is standard on Model 2863. Detachable

connector is standard on Model 2860.

FUSES 3 amp fast-blow internal

GROUND CONTINUITY Maximum 0.1 ohm

LEAKAGE CURRENT Maximum 100 microamps

BATTERY CHARGE A fully charged battery has a minimum of 6 hours running time with

MAINTENANCE

37

Page 40

MAINTENANCE

Clean the pump regularly to maintain proper working order and

optimum performance.

WARNING: To avoid electrical hazard, always disconnect AC

adapter power cord from the wall outlet before cleaning the instrument.

CAUTIONS:

• DO NOT SPRAY cleaning solutions onto instrument

housing or immerse the instrument. Fluid leakage into the

instrument can cause damage. Apply cleaning solutions to

a cloth then apply to instrument for cleaning.

• Do not clean the instrument before inspecting the

condition of the housing for damage that could allow fluid

to enter the case interior.

• Do not invert the instrument when cleaning or rinsing, to

prevent fluids from possibly leaking into the instrument.

• Do not steam, autoclave, or EtO gas sterilize the

instrument.

• Do not use pressurized air to dry the mechanisms after

cleaning. Pressurized air force could move fluid past

moisture seals and fluid leakage into the instrument can

cause damage.

• Do not use organic solvents, ammonia, ammonium- based

agents, isopropyl alcohol, and/or abrasive cleansers for

cleaning.

• Do not use sharp or metallic tools to remove residue.

Instrument exterior and pumping mechanism area

, use:

• Mild, non-abrasive, non-staining solution (e.g.,

commercially available, alcohol-free, dish washing liquid,

well diluted with warm water.)

Instrument exterior

, use:

• Mild, non-abrasive, non-staining, standard hospital

disinfectant (e.g., warm water with 10% bleach.)

NOTE:

After cleaning with a bleach solution, rinse thoroughly with

water.

Instrument Exterior

• Routinely clean the exterior surfaces of the instrument,

using a cloth dampened with the appropriate cleaning

Cleaning

Before Cleaning

38

Page 41

MAINTENANCE

To Clean

solution, as specified in the “Cleaning Solutions” section.

• Rinse with a cloth dampened with water.

• Wipe dry with a clean cloth or allow to air dry.

Lower Housing Removal to Access Pumping Mechanisms

• To access the pumping mechanisms, remove the lower

housing by simultaneously depressing the four black

release tabs and pulling straight down.

Slide Link and Pumping Mechanism

• Place the instrument in the upright position.

• Clean the slide link and pump latch mechanism using small

soft-bristled brush (or lint-free swab), dampened with the

appropriate cleaning solution, as specified in the “Cleaning

Solutions” section. If dried residue is difficult to remove, or

the slide link or pump latch sticks, spray the cleaning

solution on the residue and allow it to soak until it can be

more easily removed.

• After removing residue, rinse with a lint-free swab

dampened with water. Water may be sprayed on the

cleaned surfaces to rinse areas that are difficult to reach

with a swab.

• Dry with a lint-free swab or cloth, or allow to air dry.

A

ir-in-line Sensor

NOTE

: Air-in-line alarms may occur when dried residue builds up in the

air-in-line sensor tubing recess.

• Inspect the air-in-line sensor module to ensure that there is

no separation or breakage of the glued seams.

NOTE:

Defective air-in-line sensor modules must be replaced before

using the instrument.

• Place the instrument in the upright position.

• Clean the tubing recess (using a downward motion) with a

lint-free swab dampened with the appropriate cleaning

solution, as specified in the “Cleaning Solutions” section.

CAUTION: Use of abrasives or abrasive cleaners on the air-in-

line sensor recess may cause false Air-in-line or Check Air Sensor

alarms.

• Rinse with a lint-free swab dampened with water.

• Dry with a lint-free swab or allow to air dry.

SLIDE

LINK ASSY

PUMP

LATCH

39

AIR SENSOR

A

Page 42

40

MAINTENANCE

Optomodule

WARNING: When cleaning the optomodule, use EXTREME

CARE to avoid damage to valve actuators. Damage or breakage of the

actuator tips could cause an uncontrolled flow condition.

CAUTION: Do not use isopropyl alcohol or chlorine water on

the optomodule.

• Place the instrument in the upright position.

• Gently clean the optomodule using a lint-free swab

dampened with the appropriate cleaning solution, as

specified in the “Cleaning Solutions” section. The cleaning

solution may be sprayed on difficult to remove residue to

help wet and soften the residue for easier removal.

• After removing residue, gently rinse with a lint-free swab

dampened with water. Water may be sprayed on the

cleaned surfaces to rinse areas that are difficult to reach

with a swab.

• Gently dry with a lint-free swab or allow to air dry.

V

alve Actuator

WARNING: Care must be taken when cleaning the vicinity of

the valve actuators to avoid damage and breakage of the actuator tips.

Damage or breakage of the actuator tips could cause an uncontrolled

flow condition.

CAUTION: Do not use isopropyl alcohol to clean the valve

actuators.

• Gently clean the valve actuator and actuator seal area using a

lint-free swab dampened with the appropriate cleaning

solution, as specified in the “Cleaning Solutions” section. The

cleaning solution may be sprayed on difficult to remove

residue to help wet and soften the residue for easier removal.

• After removing the residue, gently rinse using a lint-free swab

dampened with water. Water may be sprayed on the cleaned

surfaces to rinse areas that are difficult to reach with a swab.

• Gently dry with a lint-free swab or allow to air dry.

• After cleaning, inspect the exposed tips of the valve actuators.

A broken tip may be supported by the actuator seal and not

appear defective. Lightly attempt to push the tips of the valve

actuators from side to side with a dry lint-free swab. If a tip

is not rigid, then it is broken and must be replaced before

using the instrument.

OPTOMODULE

NOTE

: Use extra-diluted, non-

alcohol cleaning solution.

NOTE

: A broken valve actuator