Page 1

A

L

A

R

M

M

O

NIT

O

R

S

T

A

N

D

B

Y

CHANNEL

SELECT

MONITOR

CHANNEL

OFF

EtCO (mm Hg)

2

RR (breaths/min)

Technical Service Manual

Alaris®EtCO2Module, 8300 Series

Alaris®Products

Supports: Guardrails®Suite (v7 or later)

January 2006

Page 2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

This Technical Service Manual is subject to change without notification.

General Contact Information

Customer Advocacy - North America

Clinical and technical feedback.

Phone: 800.854.7128, Ext. 7812

E-Mail: CustomerFeedback@cardinal.com

Technical Support - North America

Maintenance and service information support; troubleshooting.

United States:

Phone:

858.458.6003

800.854.7128, Ext. 6003

Canada:

Phone:

Eastern: 800.908.9918

Western: 800.908.9919

Customer Care - North America

Instrument return, service assistance, and order placement.

United States:

Phone: 800.482.4822

Canada:

Phone: 800.387.8309

Cardinal Health

Alaris®Products

10221 Wateridge Circle

San Diego, California 92121

http://www.cardinal.com/alaris

Page 3

Chapter 1 - General Information

1.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Precaution Definitions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Operating Features, Controls and Indicators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1.5 Alarms, Errors, Messages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5.1 Silencing Alarms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2 - Checkout and Configuration

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 New Instrument Checkout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2.3 Configuration Options and Defaults

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 Configuration Setup - EtCO

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.1 Alarm Limits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 Limit Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.3 Waveform Height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.4 Waveform Time Scale

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Chapter 3 - Preventive Maintenance

3.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Regular and Preventive Maintenance Inspections, Calibrations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Chapter 4 - Principles of Operation

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 General Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

TABLE OF CONTENTS

i

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 4

Chapter 5 - Corrective Maintenance

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Disassembly/Reassembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Latch Assembly and Feet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 IUI Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.3 Rear Case

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.2.4 Frame Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2.5 Logic Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2.6 Power Board/Oridion Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.7 IUI Bracket

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.2.8 Gas Inlet/Outlet Door

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.9 Luer Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.10 Display Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.11 Status Indicator Lens

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Chapter 6 - Troubleshooting

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7 - Illustrated Part

s Breakdown

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Illustrations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.4 Ordering Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

ii

TABLE OF CONTENTS

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 5

TABLE OF CONTENTS

List of Tables

2-1 Record of Configured Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

5-1 Required Materials, Supplies and Tools

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 Torque Values

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5-3 Level of Testing Guidelines

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

6-1 Technical Troubleshooting Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Malfunction Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

7-1 Parts List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

List of Figures

7-1 Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7-2 Frame/Front Case Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7-3 IUI Bracket/Frame Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7-4 Oridion Module/Power Supply Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7-5 Front Case Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7-6 Rear Case Assembly/Latch Kit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7-7 EtCO

2

Cable Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

iii

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 6

iv

TABLE OF CONTENTS

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 7

1 GENERAL INFORMATION

Page 8

Page 9

Chapter 1 — GENERAL INFORMATION

1-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

1.1 INTRODUCTION

This manual describes how to service the

Alaris

®

EtCO2module 8300 Series (“EtCO

2

Module”). Use this manual in conjunction

with the following Alaris®System documents

and software:

• Alaris

®

PC point-of-care unit 8000 Series

(“PC Unit”) / Alaris®Pump module 8100

Series (“Pump Module”) Technical

Service Manual

• The PC Unit section of the Alaris

®

System

Directions for Use (

DFU)

• The EtCO

2

Module section of the Alaris

®

System DFU

• Maintenance Software User Manual

(version

7 or later)

This manual is intended for personnel

experienced in analysis, troubleshooting,

and repair of analog/digital microprocessorbased medical equipment.

The EtCO

2

Module is a capnograph

indicated for continuous, noninvasive

monitoring of end tidal carbon dioxide

(EtCO

2

), fractional inspired carbon dioxide

(FiCO

2

) and respiratory rate (

RR). The

EtCO

2

Module and disposables are

indicated for use with intubated and

nonintubated adult, pediatric, and neonatal

patients. It is not intended for direct

connection to ventilator or breathing

systems. Only one (

1) EtCO

2

Module can be

connected to the Alaris

®

System.

The EtCO

2

Module is used with Oridion’s

patented Microstream

®

Disposables/circuits

for sidestream capnography.

To avoid damaging the keypad, do not use sharp

objects (pens, pencils, etc.) to activate switches.

CAUTION

Any attempt to service this product by anyone

other than an authorized Cardinal Health Service

Representative while the product is under

warranty may invalidate the warranty.

CAUTION

Page 10

1.2 PRECAUTION DEFINITIONS

Refer to the Alaris

®

System DFU

.

1.3 SPECIFICATIONS

Refer to the product-specific (EtCO

2

Module) section of the Alaris®System

DFU.

1.4 OPERATING FEATURES, CONTROLS

AND INDICATORS

Refer to the product-specific section of the

Alaris

®

System DFU

.

1.5 ALARMS, ERRORS, MESSAGES

The scrolling Channel Message Display bar

shows alarms and other messages. Refer

to the product-specific (EtCO

2

Module)

section of the Alaris

®

System

DFU for

detailed information.

1.5.1 Silencing Alarms

All alarms can be temporarily silenced by

pressing the

SILENCE key on the PC Unit.

If an alarm condition on the EtCO2Module

occurs while the audio alarm is silenced, the

only alarm indications will be visual displays

and symbols related to the alarm condition.

WARNING

GENERAL INFORMATION

1-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 11

2 CHECKOUT & CONFIGURATION

Page 12

Page 13

Chapter 2 — CHECKOUT AND CONFIGURATION

2-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

2.1 INTRODUCTION

This chapter describes the initial setup and

configuration for the EtCO

2

Module.

2.2 NEW INSTRUMENT CHECKOUT

Refer to the EtCO

2

Module Directions for

Use (

DFU

) for instructions regarding

unpacking and setting up the instrument for

first time use.

When powering up the instrument, verify the

instrument beeps and all display

LED

segments flash. This confirms that the

instrument has performed its self test and is

operating correctly. During operation, the

instrument continually performs a self test,

and will alarm and display a message if it

detects an internal malfunction.

Contact Cardinal Health authorized service

personnel if the instrument has physical

damage, fails to satisfactorily pass the

startup sequence, fails a self test, or

continues to alarm.

For new instrument checkout, the minimum

checks (described in the Maintenance

Software User Manual) are:

• Regular Inspection

• Functional Tests

Should an instrument be jarred severely or

dropped, remove it from use immediately. It

should be thoroughly tested and inspected by

qualified service personnel to ensure proper

function prior to reuse.

CAUTION

Page 14

2.3 CONFIGURATION OPTIONS AND

DEFAULTS

NOTES:

• Changes to the factory default values are

retained after a power cycle.

• If Factory Default is Yes, then all the

configuration settings are set to their

factory default.

• If Factory Default is No, then one or

more of the configuration settings has

been changed. If desired, Factory

Default can be selected and set to Yes,

which will set all configuration settings to

their factory default.

• With the Profiles feature enabled, the

settings are configured independently for

each profile. A hospital-defined, bestpractice data set must be uploaded to

enable the Profiles feature. Date and

Time is a system setting and is the same

in all profiles.

System Settings: Refer to the PC Unit

section of the Alaris®System

DFU for

information on system settings (including

alarm audio profile, battery meter

enable/disable, clock setup, key click audio

enable, tamper resist enable/disable).

EtCO

2

Module Settings: Refer to the

product-specific (EtCO

2

Module) section of

the Alaris

®

System DFU for information on

EtCO

2

Module settings (including limit

mode, high and low respiratory rate alarm

limit, high and low EtCO

2

alarm limit, no

breath alarm setting, and high FiCO

2

alarm

limit).

NOTES:

• Pressing the

EXIT soft key while in a

System Config - Module screen

immediately powers the system down, with

no “Powering Down” display.

• Pressing the

EXIT soft key while in a

System Config - EtCO

2

screen returns the

display to the main System Config -

Module screen.

• Pressing the

CONFIRM soft key while in a

System Configuration option screen:

♦ accepts existing setting or setting

change

♦ displays next option setting screen (if

applicable) or returns display to System

Config - EtCO

2

screen

• Pressing the Point-of-Care Unit’s

CANCEL

key while in a System Configuration option

screen:

♦ leaves setting unchanged

♦ returns display to System Config -

EtCO

2

screen

CHECKOUT AND CONFIGURATION

2-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 15

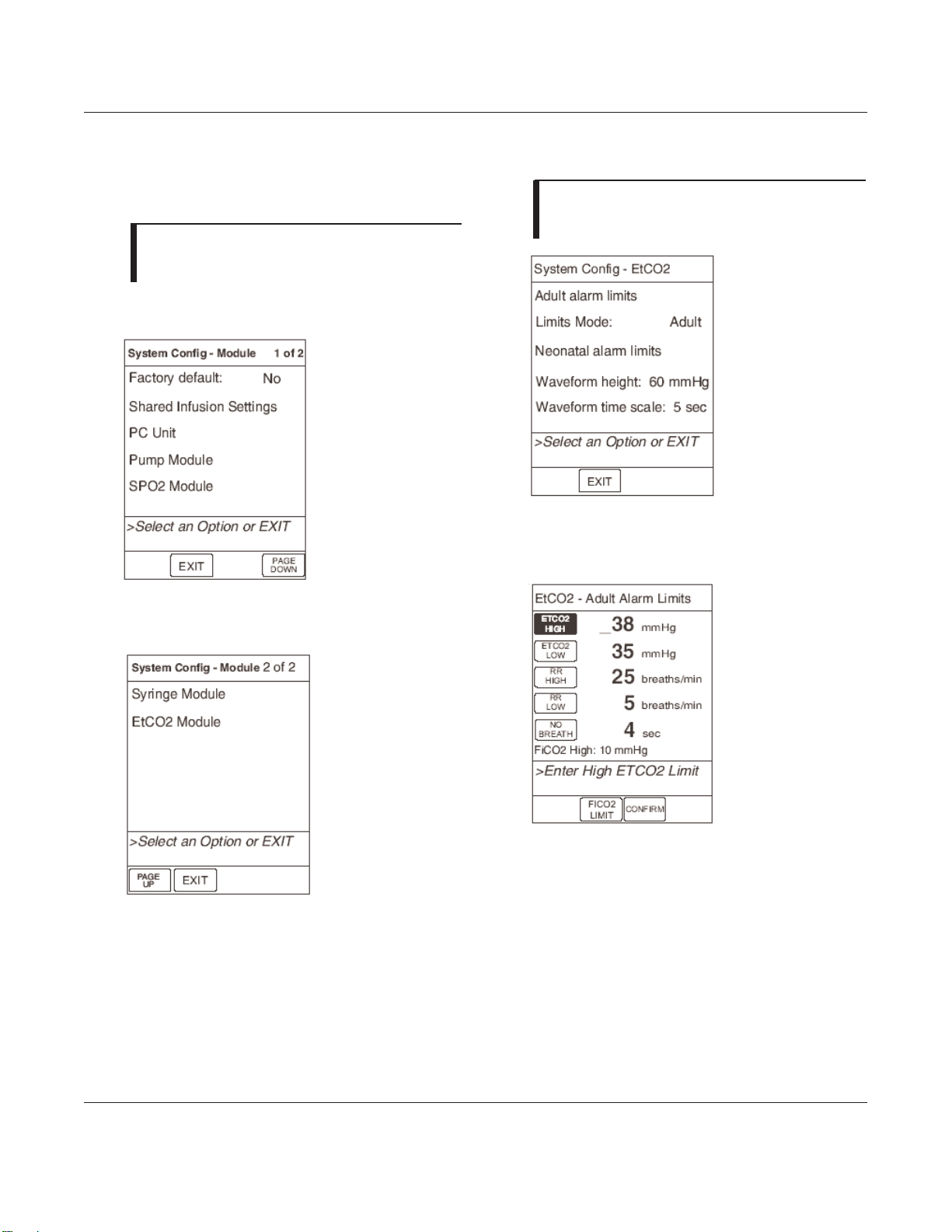

To access System Configuration options:

NOTE: Refer to EtCO2Module DFU for

alarm settings. If profiles are enabled, those

settings are set by the profile.

1. Hold OPTIONS key at power up.

2. Press

PAGE DOWN soft key.

3. Press EtCO

2

Module soft key.

2.4.1 Alarm Limits

NOTE: The following examples show adult

alarm limits for illustration. Follow the same

steps for neonatal alarm limits.

1. From the System Config - EtCO

2

display, press the Adult alarm limits or

Neonatal alarm limits soft key.

2. To change an alarm limit, press the soft

key next to that parameter. The selected

parameter is highlighted.

CHECKOUT AND CONFIGURATION

2-3

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP

Page 16

3. Enter a numeric value for the selected

alarm limit. Use the numeric keypad or

the up or down arrow keys to enter the

value. If a valid value appears in the

field for three seconds, the display

shows the prompt > Press CONFIRM to

Apply Changes.

4. Press ENTER on the Point-of-Care Unit

to confirm the value. Once you press

ENTER, the next limit is highlighted and

the display prompts for an entry.

5. To change another alarm limit, press the

soft key for that parameter and enter a

new value.

6. Once all changes are complete, press

the CONFIRM soft key.

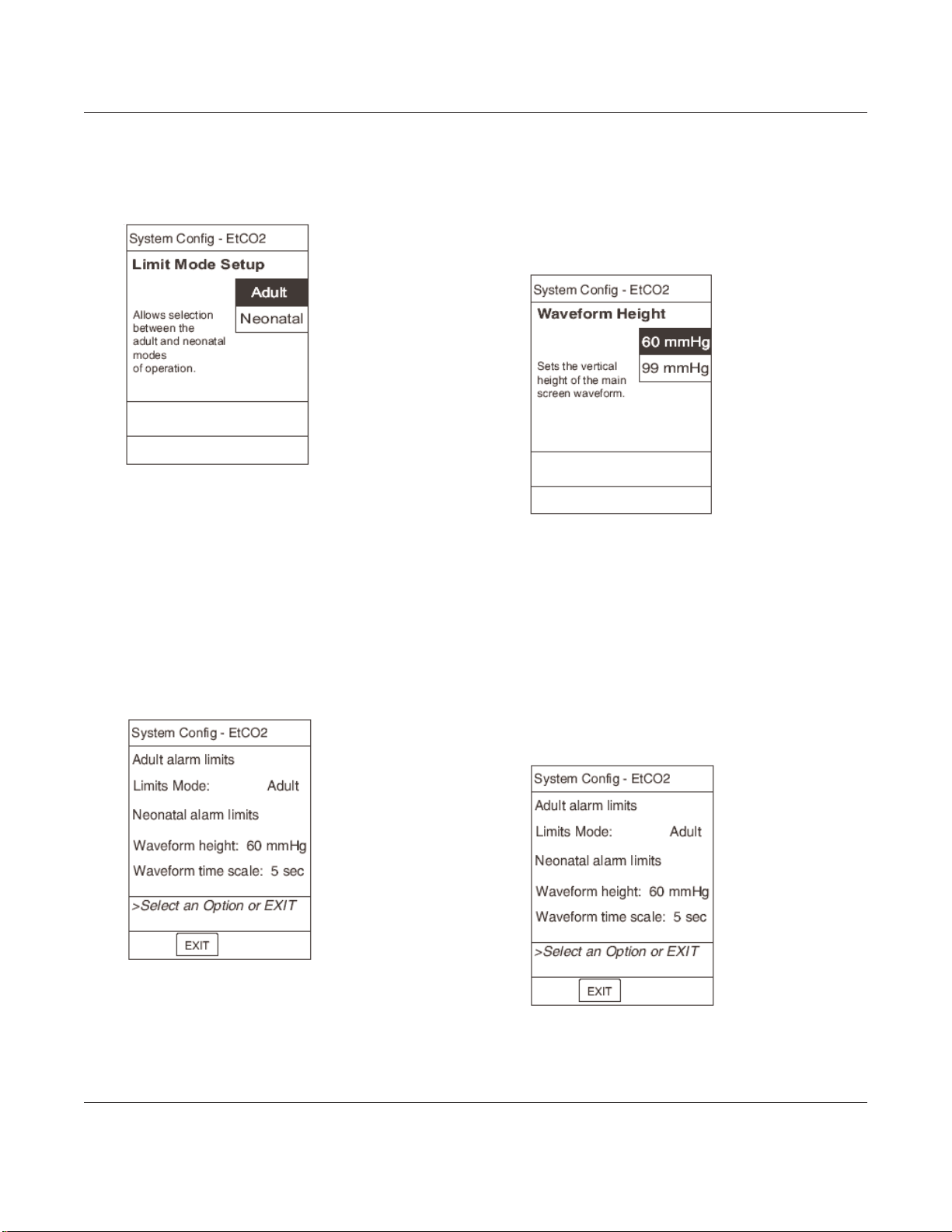

2.4.2 Limit Mode

NOTES:

• The following examples show adult alarm

limits for illustration. Follow the same

steps for neonatal alarm limits.

• If a profile is in use for programming, you

cannot change the Limit Mode.

1. To change the Limit Mode, toggle its

value from the System Config - EtCO

2

display, or use the Limits mode soft

key.

2. To toggle the value: From the System

Config - EtCO

2

display, press the soft

key for the Limit Mode selection. Every

key press toggles the value between

Adult and Neonatal.

3. To use the soft key: From the System

Config - EtCO

2

display, press the

Limits Mode soft key.

CHECKOUT AND CONFIGURATION

2-4

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP (Continued)

2.4.1 Alarm Limits (Continued)

Press the Limits

Mode soft key to

toggle between the

two acceptable

values

Page 17

4. Press the soft key to select the Limit

Mode Setup display, or press CANCEL

to exit the System Config - EtCO

2

display without changing the value.

2.4.3 Waveform Height

1. To change the waveform height, you can

toggle its value from the System Config

- EtCO

2

display, or you can use the

Waveform height soft key.

2. To toggle the value: From the System

Config - EtCO

2

display, press the soft

key for the waveform height value.

Every key press toggles the value

between 60 and 99 mmHg.

3. To use the soft key: From the System

Config - EtCO

2

display, press the

Waveform height soft key.

4. Press the soft key to select the

waveform height, or press CANCEL to

exit the Waveform Height display

without changing the value.

2.4.4 Waveform Time Scale

1. To change the waveform time scale, you

can toggle its value from the System

Config - EtCO

2

display, or you can use

the Waveform time scale soft key.

CHECKOUT AND CONFIGURATION

2-5

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

2.4 CONFIGURATION SETUP (Continued)

2.4.2 Limit Mode (Continued)

Press the

Waveform height

soft key to toggle

between the two

acceptable values

Press the

Waveform time

scale soft key to

toggle between the

two acceptable

values

Page 18

CHECKOUT AND CONFIGURATION

2-6

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

2. To toggle the value: From the System

Config - EtCO2display, press the soft

key for the Waveform Time Scale

value. Every key press toggles the value

between 5 and 10 sec.

3. To use the soft key: From the System

Config - EtCO

2

display, press the

Waveform time scale soft key.

4. Press the soft key to select the

waveform height, or press CANCEL to

exit the Waveform time scale display

without changing the value.

2.4 CONFIGURATION SETUP (Continued)

2.4.4 Waveform Time Scale (Continued)

Page 19

CHECKOUT AND CONFIGURATION

2-7

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

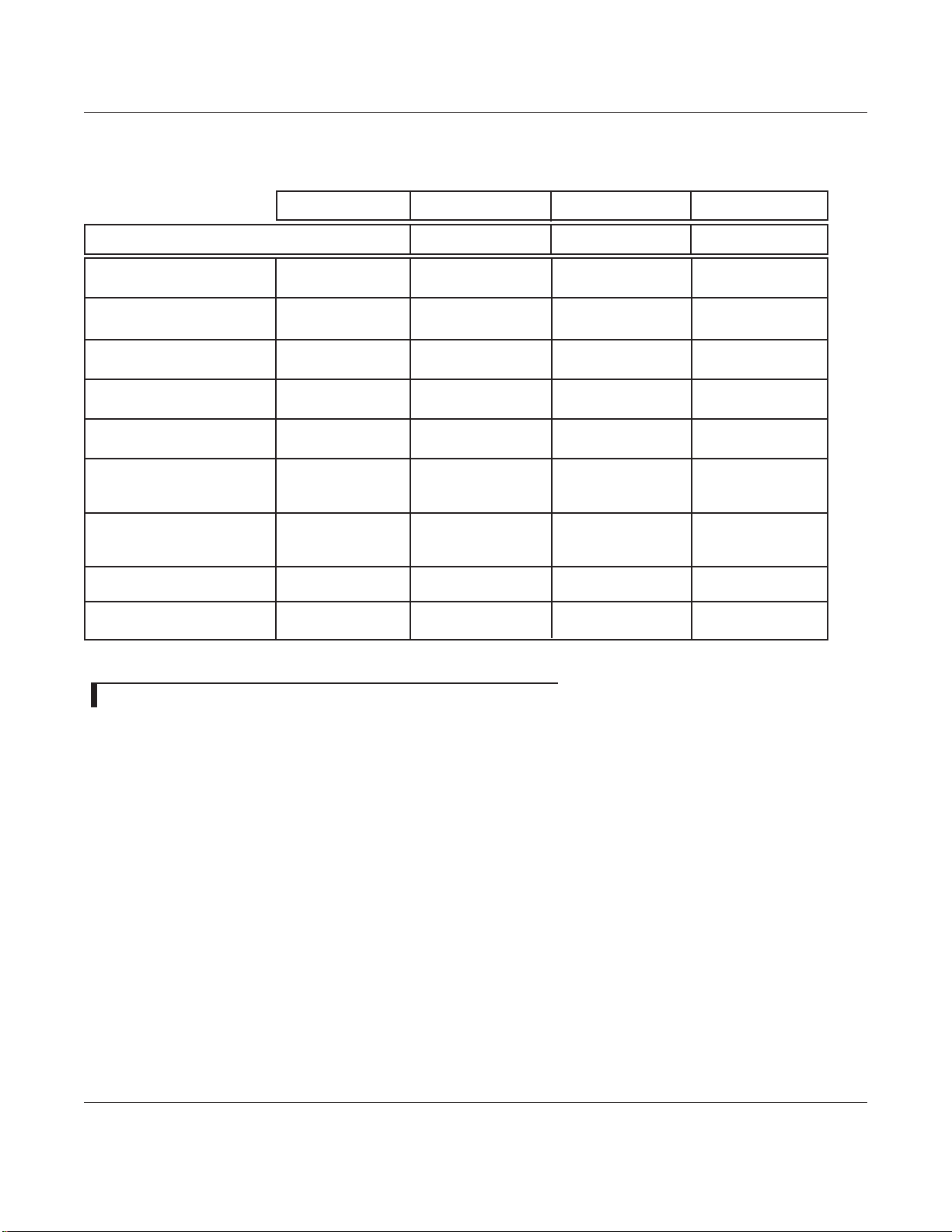

EtCO2Alarm Limit, High

EtCO

2

Alarm Limit, Low

FiCO

2

Alarm Limit, High

Limit Mode

No Breath Alarm

Respiratory Rate Alarm

Limit, High

Respiratory Rate Alarm

Limit, Low

Waveform Height

Waveform Time Scale

Table 2-1. Record of Configured Instruments

#1 #2 #3 #4

Instrument ID/Serial #

NOTE: If profiles are enabled, alarm limits are set by the profile.

Page 20

CHECKOUT AND CONFIGURATION

2-8

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 21

3 PREVENTIVE MAINTENANCE

Page 22

Page 23

Chapter 3 — PREVENTIVE MAINTENANCE

3-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

Failure to perform regular and preventive

maintenance inspections may result in improper

instrument operation.

WARNING

3.1 INTRODUCTION

Perform regular and preventive

maintenance inspections to ensure that the

EtCO

2

Module remains in good operating

condition:

• Perform regular inspections before each

use.

• Perform preventive maintenance

inspections annually.

These requirements and guidelines are

intended to complement the intent of Joint

Commission on Accreditation of Healthcare

Organizations (

JCAHO) requirements.

3.2 REGULAR AND PREVENTIVE

MAINTENANCE INSPECTIONS,

CALIBRA TION

Use the Maintenance Software (version 7 or

later) to perform calibration and preventive

maintenance.

Contact Cardinal Health Technical Support if

you need help obtaining or using the

Maintenance Software.

3.3 CLEANING

Refer to the PC Unit section of the Alaris

®

System DFU.

Page 24

PREVENTIVE MAINTENANCE

3-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 25

4 PRINCIPLES OF OPERATION

Page 26

Page 27

Chapter 4 — PRINCIPLES OF OPERATION

4-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

4.1 INTRODUCTION

This chapter describes the principles of

operation for the EtCO

2

Module and its

major subsystems.

Refer to the PC Unit/Pump Module

Technical Service Manual for Point-of-Care

Unit information.

4.2 GENERAL INFORMATION

The EtCO

2

Module uses Oridion’s patented

Microstream

®

non-dispersive infrared (NDIR)

spectroscopy to continuously measure the

amount of CO

2

during every breath, the

amount of CO

2

present at the end of

exhalation (EtCO

2

) and during inhalation

(FiCO

2

), and the Respiratory Rate. The

EtCO

2

Module is a side stream capnograph.

The Microstream

®

Disposables deliver a

sample of the inhaled and exhaled gases

from the ventilator disposable or directly

from the patient (via an oral/nasal cannula)

into the monitor for CO

2

measurement.

Moisture and patient secretions are

extracted from the sample by the

Microstream

®

inline filter while maintaining

the shape of the CO

2

waveform.

The 50 mL/min sampling flow rate reduces

liquid and secretion accumulation,

decreasing the risk of obstruction in the

sample pathway in humid ICU

environments. The small sample size

required by Microstream

®

eliminates the

need for water traps and prevents excess

fluid accumulation.

The EtCO

2

Module draws a gas sample

through a microsample cell (15 microliters).

This extremely small volume is quickly

flushed, allowing for a rise time of

Page 28

PRINCIPLES OF OPERATION

4-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

approximately 190 ms and accurate CO

2

readings, even at high respiration rates.

The Microbeam IR source illuminates the

microsample cell and the reference channel.

This proprietary IR light source generates

only the specific wavelengths characteristic

of the CO

2

absorption spectrum. The IR light

that passes through the microsample cell

and the IR light that passes through the

reference channel are measured by IR

detectors.

The microcomputer in the EtCO

2

Module

calculates the CO

2

concentration by

comparing the signals from both channels.

No operator intervention is required for

routine moisture or condensate.

All Microstream

®

Disposables contain an

inline hydrophobic filter to extract

condensate and/or patient secretions while

maintaining measurement and waveform

integrity. For humid conditions within the

operating parameters of the EtCO

2

Module

and Microstream

®

Disposables, humidity

has no quantitative effect on the CO

2

concentration, given the small 50 mL/min

sample size rate. In high humidity

environments or extended monitoring

periods (24-72 hours) only Microstream

®

Disposables designed for those instances

should be used. In the event of humidity or

condensate outside the EtCO

2

Module’s

operating specifications, the EtCO

2

Module

will present a “Remove Blocked Disposable”

message.

Due to the relatively small sampling size

needed for EtCO

2

readings, partial pressure

does not affect the ability of the EtCO

2

Module to measure EtCO2, as long as the

50 mL/min rate can be achieved.

Microstream

®

Disposables are single-use,

disposable devices which must be changed

with each use. The manufacturer’s sample

flow, 50 mL/minute, does not affect the

disposable’s life; however, humidity and

specific patient conditions may shorten the

effective life of the disposables.

Microstream

®

Disposables are rated for up

to 24 hour and 72 hour use, depending on

the specific Microstream

®

Disposable.

The EtCO

2

Module provides readings in

compliance with BTPS (body temperature,

pressure, saturation) standards. There is no

effect on accuracy due to cyclic pressure up

to 10 kPa.

NOTE: BTPS (body temperature, pressure,

saturation assumed 37°C, 47 mmHg)

calculations are made according to:

PCO2= FCO2X (Pb - 47)

Where:

FCO2is the fractional concentration of CO

2

in dry gas, and FCO2= % CO2/100.

Pb is the ambient pressure.

PCO2is the partial pressure of CO2at

BTPS.

4.2 GENERAL INFORMATION (Continued)

Page 29

5 CORRECTIVE MAINTENANCE

Page 30

Page 31

NOTE: Due to product changes over time,

components/ assemblies illustrated in this chapter

may differ from the instrument you disassemble. If

there are any questions, look for Service Bulletins

related to this chapter or contact Cardinal Health

Technical Support.

5.1 INTRODUCTION

This chapter describes how to disassemble

and reassemble the EtCO

2

Module.

For more efficient repair, read the “Principles

of Operation” chapter for information on the

mechanical and electrical functions of the

EtCO

2

Module.

The surface mount devices on the circuit

boards are not field repairable. Return

circuit boards to an authorized Cardinal

Health Service Center for repair. Attempting

circuit board repairs voids all warranties.

Whenever the EtCO2Module is repaired,

perform the minimum tests required for new

instrument checkout (use Maintenance

Software v

7 or later).

For information on replacement parts, see

the “Illustrated Parts Breakdown” chapter.

Following any level of maintenance, perform

the applicable tests (refer to “Level of

Testing Guidelines” table).

5-1

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Chapter 5 — CORRECTIVE MAINTENANCE

Disconnect the EtCO2Module from the Alaris

®

System before performing maintenance. qualified

personnel using proper grounding techniques

should open the instrument case.

WARNING

CMOS devices are sensitive to static electrical

charges and may be damaged during repair if the

repair activity is not performed in an electrostatic

discharge (

ESD) protected environment using

approved ESD protective procedures, including

personnel grounding.

CAUTION

Page 32

Follow these procedures in order for the

most efficient disassembly of EtCO

2

Module

subassemblies. To reassemble the EtCO

2

Module, reverse the disassembly steps.

NOTE: Perform all maintenance on an

antistatic surface, preferably a grounded

antistatic mat.

Before adhering gaskets and labels to the

instrument, clean the surface with a cotton

swab or soft cloth lightly dampened with

70% Isopropyl Alcohol.

5-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2 DISASSEMBLY/REASSEMBLY

Disconnect the EtCO2Module from the

Alaris

®

System Before attempting

disassembly.

CAUTION

To avoid the risk of electrical hazard or

damage to the instrument circuitry, do not

spray fluids directly onto the instrument or

allow fluids to enter the instrument.

CAUTION

Table 5-1. Required Materials, Supplies and Tools

NOTE: Contact/source information is subject to change.

• Loctite 242 (http://www.loctite.com)

• Silicone grease, Dow Corning Molykote

33, or equivalent (http://www.dowcorning.com)

•

#1 Phillips screwdriver

•

#2

Phillips screwdriver

• Small diagonal cutters

• Lint-free cloth (such as, Kimwipes or lint-free tissue)

Page 33

5.2.1 Latch Assembly and Feet

1. Remove two (

2) screws attaching Latch

Assembly to bottom of Rear Case and

remove Latch Assembly components.

2. Pull two (2) Feet from underside of

module.

NOTE: Pay close attention to Compression

Spring location and orientation to ensure

proper installation during reassembly.

During Reassembly:

When reinstalling the Latch Assembly, press

toward outer edge of the module and screw

into position.

Apply a thin layer of Dow Corning

Molykote

33 (or equivalent) silicone grease

to Feet.

NOTE: The Feet press-fit into the module.

5-3

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Feet

Rear Case

Latch Assembly

components

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Compression Spring

Page 34

5-4

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2 DISASSEMBLY/REASSEMBLY (Continued)

5.2.2 IUI Connectors

Remove two (

2) screws attaching each IUI

(left and right) to module.

During Reassembly:

• Ensure ground clips are still installed on

both IUI connectors.

• To install IUI Connector Gasket, remove

protective backing and adhere to IUI

Connector.

IUI Connector, Left

IUI Connector, Right

IUI Connector Seal, Right

IUI Connector Gasket, Right

Ground clip located at each mounting

hole on both IUI Connectors

Page 35

5.2.3 Rear Case

1. Remove two (

2) screws (and associated

washers) attaching Rear Case to

chassis assembly.

2. Pull Rear Case away from chassis

assembly.

During Reassembly:

Ensure that Silicone Tubing gasket in Rear

Case is in place and undamaged.

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Rear Case Assembly

Silicone Tubing

gasket

5-5

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Screws and

Washers (x2)

Page 36

5.2.4 Frame Assembly

1. Remove six (6) screws attaching Frame

Assembly to Front Case.

2. Use small diagonal cutters to remove

upper snap rivet attaching Power Board

to Frame Assembly.

2. Remove the IUI Bracket Strap from the

Display Board.

3. Carefully remove Frame Assembly from

Front Case Assembly, then place the

Frame Assembly to the left of the Front

Case, taking care not to damage hoses

and wires.

4. Disconnect electrical harness from

Oridion Module.

5. Disconnect the inlet and exhaust hoses

on the Oridion Module.

During Reassembly:

• Fit the top flange of the Frame Assembly

into the square slot on the Status

Indicator Lens.

• Fit the connectors on the Power Board

and Logic Board into the two (2)

connectors on the Display Board.

• Ensure that the harness and hoses are

fully connected, and route them so they

are not pinched during reinstallation.

• Slide the IUI Bracket Strap under the

keypad ground wire on the Display

Board.

5-6

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Frame

Assembly

Exhaust hose

IUI

Bracket

Strap

Snap

Rivet

Front Case

Assembly

Electrical

Harness

When using cutters to remove snap

rivet, take care not to cut the rivet.

CAUTION

Inlet hose

Screw

Keypad

ground wire

IUI

Bracket

Strap

Keypad

ground

wire

Page 37

5-7

5.2 DISASSEMBLY/REASSEMBLY (Continued)

5.2.5 Logic Board

1. Use small diagonal cutters to remove

snap rivet attaching Logic Board to

Frame Assembly .

2. Remove Logic Board from Frame

Assembly.

During Reassembly:

• Seat the holes in the Logic Board over

the standoffs on the IUI Bracket.

• Reinstall the snap rivet and its locking pin

to secure the Logic Board to the Frame

Assembly.

Snap

Rivet

Logic

Board

Standoff on

IUI Bracket

When using cutters to remove snap

rivet, take care not to cut the rivet.

CAUTION

Frame

Assembly

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Page 38

5-8

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2.6 Power Board/Oridion Module

1. Use small diagonal cutters to remove

upper (if installed) and lower snap

rivet(s) attaching Power Board to Frame

Assembly. If installed, remove IUI

Bracket Strap.

2. Remove screw holding PCB retainer to

Frame Assembly .

3. Remove Power Board from Frame

Assembly.

4. Disconnect electrical harness between

Power Board and Oridion Module.

5. Separate Power Board and Oridion

Module:

• Remove three (3) screws from

underside of Power Board.

• Remove screw and nut attaching

PCB retainer to Power Board.

During Reassembly:

• Ensure that Oridion Module and PCB

retainer are positioned correctly over the

Power Board before reinstalling.

• Reinstall the IUI Bracket Strap and snap

rivets to secure the Power Board to the

Frame Assembly .

5.2 DISASSEMBLY/REASSEMBLY (Continued)

PCB retainer

Power

Board

Oridion

Module

When using cutters to remove snap

rivet, take care not to cut the rivet.

CAUTION

Page 39

5-9

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2.7 IUI Bracket

Flex IUI Bracket away from key pins and

remove bracket and Ground Strap from

Frame Assembly .

During Reassembly:

Position IUI Bracket over key pins on Frame

Assembly

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Key pin

Frame

Assembly

IUI Bracket

Ground

Strap

Page 40

5-10

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2 DISASSEMBLY/REASSEMBLY (Continued)

5.2.8 Gas Inlet/Outlet Door

NOTE: To hold Torsion Spring in place

during removal, hold Spring Retainer firmly

when removing Cotter Pin.

1. From inside Front Case Assembly,

straighten Cotter Pin legs and from

Spring Retainer.

2. Slowly lift Spring Retainer to relieve

compression on Torsion Spring.

3. Remove Torsion Spring.

4. Remove Door from Front Case

Assembly.

During Reassembly:

1. Place Torsion Spring on Door shaft with

long end facing up.

2. Align Spring Retainer with shaft, push

Torsion Spring down, insert Cotter Pin

through Spring Retainer, then wind

Cotter Pin legs around Door shaft to

secure.

3. Wind Torsion Spring 1/4-turn and secure

long end of Spring under Spring

Retainer.

Door

Status

Indicator

Lens

Front

Case

Display

Board

Spring

Retainer

Cotter

Pin

Spring

Retainer

Cotter

Pin

Torsion

Spring

Torsion

Spring

Page 41

5-11

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2.9 Luer Assembly

1. Remove three (

3) screws attaching Luer

Retainer to Front Case.

2. Remove Luer Retainer from Front Case.

3. Separate Luer Assembly from Luer

Retainer.

During Reassembly:

• Ensure that O-ring is correctly positioned

on Luer Assembly, then apply a small

bead of water around the O-ring: this

helps O-ring to remain in place when

installing Luer Assembly into Front Case.

• Position Luer Retainer over screw holes

in Front Case, then install screws to

secure.

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Front Case

O-ring

Luer

Assembly

Luer

Retainer

Page 42

5-12

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2.10 Display Board

1. Remove screw attaching ground wire to

Display Board.

2. Cut cable tie, then disconnect Keypad

Harness and Backlight harnesses from

Display Board.

3. Remove three (3) screws attaching

Display Board to Front Case.

4. Remove Display Board from Front Case

During Reassembly:

• When reinstalling Display Board, slide

LEDs under Status Indicator Lens.

• Reinstall screws attaching Display Board

to Front Case.

• Reinstall Keypad and Backlight Harness,

then replace the cable tie.

• Reinstall the keypad ground wire.

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Display

Board

Front Case

Status

Indicator

Lens

Keypad

Ground

Wire

Keypad

Harness

Page 43

5-13

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

5.2.11 Status Indicator Lens

1. Remove two (2) screws attaching Status

Indicator Lens and Gasket to Front

Case.

2. Remove Status Indicator Lens.

5.2 DISASSEMBLY/REASSEMBLY (Continued)

Status

Indicator

Lens

Front

Case

Gasket

Screws (x2)

Page 44

Table 5-2. Torque Values

Functional Application Item Description Torque Value

FINAL ASSEMBLY

IUI Connectors 6-32 x

7

/16 12 in/lb

Latch Assembly 4-40 x

3

/8

Torx Security 6 in/lb

Rear Case - Internal Frame 6-32 x

7

/

16 12 in/lb

FRONT CASE ASSEMBLY

Display Board 4-40 x

5

/16

6 in/lb

Internal Frame - Front Case 4-40 x

3

/

4 6 in/lb

IUI Bracket Strap and Ground Wire 4-40 x

5

/16 6 in/lb

Status Indicator Lens 4-20 x

5

/16 6 in/lb

Luer Mount 4-20 x

5

/

16 6 in/lb

Power Board/Oridion Module 4-40 x

1

/8 6 in/lb

5-14

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Page 45

5-15

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Table 5-3. Level of Testing Guidelines

Display Board NNNN N N N

Frame Assembly NNNNNN N N

Front Case NNNNNN N N

Gas Inlet/Outlet Door NNNNNN N N

IUI Bracket NNX NNN N N

IUI Connectors NN N

Latch Assembly and Feet N

Logic Board NNNNNN N

Luer Assembly NNNNNN N N

Power Board/Oridion Module NNN NN

Rear Case NN

Status Indicator Lens NNNNNN N N

Miscellaneous: Ð

Instrument dropped NNX NNN N N

Instrument software flashed N

New instrument checkout NNX NNN N N

No fault found

N

(instrument not opened)

No fault found

NNNNNN N N

(instrument opened)

Channel ID/IUI Connector Test

CO

2

Sensor Calibration

Keypad Test

CO

2

Sensor Verification

Alarm Test

Tests to Perform

N

= Required

X = If verification fails.

Blank = Not Applicable

Repair/Replacement of: Ð

Simultaneous Display Test

Visual/Instrument Inspection

NOTES:

• Use the Maintenance Software to perform testing and calibration.

• After performing any calibration procedure, always perform the

associated verification test.

Leak Down Test

Page 46

THIS PAGE

INTENTIONALLY

LEFT BLANK

5-16

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

CORRECTIVE MAINTENANCE

Page 47

6 TROUBLESHOOTING

Page 48

Page 49

Chapter 6 — TROUBLESHOOTING

6-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

6.1 INTRODUCTION

This chapter describes possible technical

problems and operating errors that may

occur while using the EtCO

2

Module. Refer

to this chapter before attempting to service

the EtCO

2

Module.

Refer to the PC Unit / Pump Module

Technical Service Manual for information on

viewing the Malfunction Log.

Use extreme caution in servicing the

instrument when connected to AC power.

Hazardous voltages are present when AC

power is connected, regardless of the setting

of the power switch.

WARNING

Page 50

TROUBLESHOOTING

6-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Table 6-1. Technical Troubleshooting Guide

Follow the steps in the order they are listed until the problem/fault is corrected. Before making a final

diagnosis, visually inspect the instrument for damage and pay particular attention to the power cord

and plug. Following repair/replacement, use Maintenance Software to perform the required tests (see

Chapter

5). Perform the Ground Current Leakage and Ground Leakage tests described in the PC Unit /

Pump Module Technical Service Manual to verify that the system is electrically safe.

Problem Remedy

Display Problem 1. Check cable connections.

2. Replace Display.

3. Replace Logic Board.

4. Return to factory.

Key Stuck Alarm 1. Turn instrument off and back on to see if problem clears.

2. Replace Keypad Assembly.

3. Replace Logic Board.

4. Return to factory.

Instrument Malfunction 1. Turn instrument off and back on to see if problem clears.

2. Refer to alarm history, malfunction codes (Table 6-2), and subsystem codes (see

PC Unit / Pump Module (8000/8100 Series) Technical Service Manual).

Intermittent Operation 1. Check connections to Logic Board.

2. Replace Logic Board.

3. Return to factory.

Page 51

TROUBLESHOOTING

6-3

Table 6-2. Malfunction Codes

Refer to the PC Unit / Pump Module Technical Service Manual for information on viewing the

Malfunction Log.

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Malfunction

Code

Subsystem Explanation Remedy

500 Main Logic Board See NOTE See NOTE

510 Keypad Decoder See NOTE See NOTE

511 Keypad Decoder Comm Error See NOTE See NOTE

530 Keypad Error See NOTE See NOTE

550 IUI Error See NOTE See NOTE

560 Power Supply Board Error See NOTE See NOTE

570 EtCO2Board Error See NOTE See NOTE

571 EtCO2Board Comm Error See NOTE See NOTE

6200 EtCO2Board Error Failed continuous built-in

tests.

Cycle power. If error repeats,

replace EtCO

2

Board.

6210 EtCO2Board Error Communications error. Cycle power. If error repeats,

replace EtCO2Board.

6220 EtCO2Board Error Configuration error. Cycle power. If error repeats,

replace EtCO

2

Board.

6230 EtCO2Board Error Received value out of

range.

Replace Microstream

Disposable device. If error

repeats, replace EtCO

2

Board.

6240 EtCO2Board Error Missing sensor status. Replace Microstream

Disposable device. If error

repeats, replace EtCO

2

Board.

NOTE: Refer to Troubleshooting information in the PC Unit / Pump Module Technical Service Manual for more

detailed descriptions of codes.

Page 52

TROUBLESHOOTING

6-4

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 53

7 ILLUSTRATED PARTS

BREAKDOWN

Page 54

Page 55

Chapter 7 — ILLUSTRATED PARTS BREAKDOWN

7-1Alaris

®

EtCO2Module (8300 Series)

Technical Service Manual

7.1 INTRODUCTION

The illustrated parts breakdown for the

EtCO

2

Module is divided according to its

major assemblies.

7.2 ILLUSTRATIONS

Use the exploded views to identify the parts

of each assembly. Item numbers (the

numbers in bubbles) in the illustration

correspond to the item number in the parts

list. Apart that does not have an item

number is part of a higher assembly.

NOTE: Due to product changes over time,

illustrations in this chapter can differ from the

instrument under service. See applicable

Service Bulletins or contact Cardinal Health

Technical Support for more information.

7.3 PARTS LIST

The parts lists include the following

information for replaceable parts :

• Item: This number corresponds to the

item number in the illustration.

• Part Number: Use this number to order

the part. If a part number is not provided,

that part is not available for sale, is part

of a kit or higher assembly, or can only

be replaced/repaired by Cardinal Health

authorized service personnel.

• Description: Description of the part.

• QTY: Total number of each item used.

Page 56

Item Part Number Description QTY

15 146980-000 Gasket, Status Indicator 1

16 148140-000 Retainer, Luer 3

17 321245 O-Ring, 0.364 ID x 0.070 W 60 Duro 1

20 10013666

Front Case/Keypad Assembly

(Assembled parts: Front Case, Keypad, items

15, 25, 841 qty. 2)

1

21 148128-102 Door Assembly 1

22 148130-002 Spring, Torsion 1

23 148228-000 Retainer, Spring 1

24 3211246 Pin, Cotter, 1/32 OD x 3/8 L, extended prong 1

25 146978-001 Lens, Status Indicator 1

32 144424-100 LED, Keyboard Backlight 1

35 148112-103 Board Assembly, Display 1

36 321270 Standoff, F/F, 3/16

hex x

3

/8

4-40, AL

3

37 10011768 Module, Oridion 1

39 TC10003682 Board Assembly, Power Supply 1

40 142833-000 Bracket, IUI 1

45 148131-001 Frame 1

46 148227-002 Retainer, PCB 1

7.4 ORDERING PARTS

Parts can be ordered by writing or calling

Cardinal Health Customer Service (refer to

"General Contract Information" page at

beginning of this manual). When requesting

a part, provide the following information:

• Instrument name and model number; for

example, EtCO

2

Module, Model 8300.

• Instrument software version. Refer to

Alaris

®

System DFU

for directions on how

to view software version.

• Part number.

• Part description, as provided in parts list.

• For labels, specify required language.

ILLUSTRATED PARTS BREAKDOWN

7-2

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Table 7-1. Parts List

NOTE: An “assembly” is a preassembled group of parts. A “kit” is a group of unassembled parts.

Page 57

7-3

ILLUSTRATED PARTS BREAKDOWN

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Item Part Number Description QTY

47 148249-100

Assembly, EtCO2Cable

1

55 TC10003899 Board Assembly, Logic 1

60 146992-001 Strap, Ground, IUI Bracket 1

70

Silicone Grease, Molykote Medium or equivalent As required

75 142794-000 Foot, Rubber 2

80 320763 Tubing, Medium Silicone, 0.030 x 0.065 x 0.18 1

85 10013667 Assembly, Rear Case

(Assembled parts: Rear Case, Nameplate Label, items 75, 80, 603,

620

)

1

90 146456-000 Kit, Latch

(Includes: Latch, Compression Spring, Leaf Spring, Support)

1

120 147077-100 Kit, Right IUI Connector

(Includes: Right Seal, Right IUI Connector)

1

130 147078-100 Kit, Left IUI Connector

(Includes: Left Gasket, Left IUI Connector)

1

135 10013668 Kit, Luer

(Includes: Luer Assembly, item 17)

1

603 125569 Label, Serial Number, Replacement 1

620 148405-000 Label, Patent 1

630 148372-000 Label, Microstream 1

635 10010621 Label, Door 1

645 145820-000 Seal, Instrument 1

820 834031 Cable Tie, 4-in. L 1

825 300348 Screw, Machine, 4-40 x 3/4 PHH PHH 6

830 806112 Rivet, Snap, 0.125 dia., Nylon BLK 3

835 320855 Screw, 6-32 x 7/16 PHH PNH SS 6

840 320908 Washer, Flat, 0.146 ID x 0.270 OD x 0.03 THK, SS 10

841 300923 Screw, Machine, 4-40 x 5/

16 PHL PNH ZNC PLT STL

7

Table 7-1. Parts List (Continued)

Page 58

Table 7-1. Parts List (Continued)

ILLUSTRATED PARTS BREAKDOWN

7-4

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Item Part Number Description QTY

842 303822 Screw, 3LOB, 4-20 x 7/16

PNH PHH ZNC-STL

3

843 300347 Screw, Machine, 4-40 x 5/8

PNH PHH

1

844 300928 Nut, Hex, 4-40 STL PL 1

845 300345 Screw, Machine, 4-40 x 1/4 PHL PNH ZNC PLT STL 4

846 305121 Screw, Machine, PNH 6

10011281

Directions for Use, EtCO

2

1

Not sold by Cardinal Health.

Page 59

7-5

ILLUSTRATED PARTS BREAKDOWN

Figure 7-1. Housing Assembly

130

85

835

635

630

835

120

840

20

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

4 PL

2 PL

2 PL

Page 60

ILLUSTRATED PARTS BREAKDOWN

7-6

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-2. Frame/Front Case Assembly

841

825

830

3 PL

6 PL

39

32

55

Page 61

7-7

ILLUSTRATED PARTS BREAKDOWN

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-3. IUI Bracket/Frame Assembly

45

60

40

Page 62

3 PL

ILLUSTRATED PARTS BREAKDOWN

7-8

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-4. Oridion Module/Power Supply Board

46

39

36

37

8 PL

843

844

840

6 PL

846

Page 63

7-9

ILLUSTRATED PARTS BREAKDOWN

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-5. Front Case Assembly

15

25

21

35

16

17

23

24

135

842

3 PL

22

23

24

22

841

3 PL

841

2 PL

Page 64

ILLUSTRATED PARTS BREAKDOWN

7-10

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-6. Rear Case Assembly/Latch Kit

85

620

603

Nameplate label

75

90

2 PL

80

1

Labels (items

603 and 620) are provided as separate items and as part of Rear

Case Assembly Kit. Reference Table 7-1, item 85 for a list of parts included in

Rear Case Assembly Kit.

3

Before adhering Serial Number Label (item

603):

1. Print instrument model and serial number on label in permanent black ink.

2. Apply clear overlay to completely cover label.

2

Nameplate Label is available only as part of Rear Case Assembly Kit. This

label has a regulatory mark, and any level of service that requires its

replacement must be performed at the factory.

1

1

2

1

3

Page 65

7-11

ILLUSTRATED PARTS BREAKDOWN

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Figure 7-7. EtCO2Cable Assembly

47

Page 66

THIS PAGE

INTENTIONALLY

LEFT BLANK

ILLUSTRATED PARTS BREAKDOWN

7-12

Alaris®EtCO2Module (8300 Series)

Technical Service Manual

Page 67

Page 68

Alaris®and Guardrails®are registered trademarks of Cardinal Health, Inc. or one of its subsidiaries. Microstream®is a registered trademark of

Oridion Medical 1987 Ltd. All other trademarks belong to their respective owners.

Part Number 10011051 ©2005, 2006 Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.

Loading...

Loading...